Numerical Study on the Flow and Heat Transfer Coupled in a Rectangular Mini-Channel by Finite Element Method for Industrial Micro-Cooling Technologies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Governing Equations

2.1.1. Laminar Flow

2.1.2. Law of Friction, Number of Theoretical Poiseuille

2.2. Numerical Method

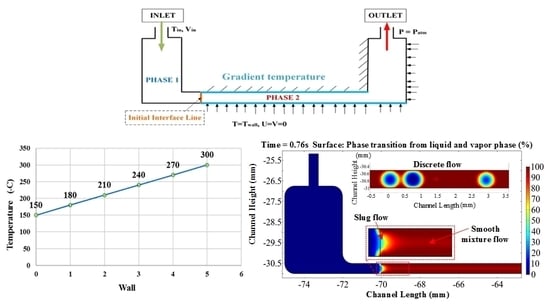

2.2.1. Simulation Parameters

2.2.2. Boundary Conditions

- -

- The flow regime is laminar and the fluid generated in the channel is water

- -

- At the inlet of the channel, (x = 0)

- -

- At the outlet of the channel, (x = L)—the gradients of the velocity and temperature parameters are zero, only the pressure is equal to the atmospheric pressure

- -

- At the bottom wall (y = 0) and the top wall (y = Dh) of the mini-channel

2.2.3. Mesh

3. Results and Discussions

3.1. Velocities Profiles

3.2. Drop Pressure

3.3. Friction Factor

3.4. Heat Transfer of Fluids

3.4.1. Two-Phase Flow Heat Transfer at Constant Wall Temperature in the Approximative Model

3.4.2. Determination of the Dissipated Heat Flux for Different Application Areas, the Convective Heat Transfer Coefficient and the Fin Efficiency of the Rectangular Mini-Channel Based on the Approximate Model of Two-Phase Flow

3.4.3. Dynamic Heat Transfer with the Variation of Temperature (Temperature Gradient) along the Walls Considering the Phase Change inside the Channel.

3.4.4. The Pressure, Velocity and Temperature Distribution in the Microflow with Increasing and Decreasing Temperature along the Top and Bottom Walls Considering Phase Change inside the Channel in the Phase-Field

3.4.5. Flow Boiling Phenomenon in the Rectangular Mini-Channel at Constant Wall Temperature Considering the Phase Change inside the Channel and Flow Patterns

3.4.6. Flow Boiling Phenomenon in the Rectangular Mini-Channel with Increasing Temperature along the Top and Bottom Walls and Flow Patterns.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368. [Google Scholar] [CrossRef]

- Giri, B. Laboratory Methods in Microfluidics; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Fabbri, M.; Dhir, V.K. Optimized heat transfer for high power electronic cooling using arrays of microjets. J. Heat Transf. 2005, 127, 760–769. [Google Scholar] [CrossRef]

- Hamami, A. Simulation de l’écoulement Dans un Minicanal. Ph.D. Thesis, Université de Batna 2, Fesdis, Algeria, 2005. [Google Scholar]

- King, M.R. Biomedical applications of microchannel flows. In Heat Transf. Fluid Flow Minichannels Microchannels; Elsevier: New York, NY, USA, 2005; pp. 409–442. [Google Scholar]

- Brand, O.; Fedder, G.K.; Hierold, C.; Korvink, J.G.; Tabata, O. Micro Process Engineering: Fundamentals, Devices, Fabrication and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Schmidt, R. Challenges in electronic cooling—Opportunities for enhanced thermal management techniques—Microprocessor liquid cooled minichannel heat sink. Heat Transf. Eng. 2004, 25, 3–12. [Google Scholar] [CrossRef]

- Ohadi, M.; Choo, K.; Dessiatoun, S.; Cetegen, E. Next Generation Microchannel Heat Exchangers; Springer: New York, NY, USA, 2013. [Google Scholar]

- Kandlikar, S.G.; Bapat, A.V. Evaluation of jet impingement, spray and microchannel chip cooling options for high heat flux removal. Heat Transf. Eng. 2007, 28, 911–923. [Google Scholar] [CrossRef]

- Jahan, S.A.; El-Mounayri, H. A thermomechanical analysis of conformal cooling channels in 3D printed plastic injection molds. Appl. Sci. 2018, 8, 2567. [Google Scholar] [CrossRef] [Green Version]

- Torres-Alba, A.; Mercado-Colmenero, J.M.; Diaz-Perete, D.; Martin-Doñate, C. A New Conformal Cooling Design Procedure for Injection Molding Based on Temperature Clusters and Multidimensional Discrete Models. Polymers 2020, 12, 154. [Google Scholar] [CrossRef] [Green Version]

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Peiyi, W.; Little, W.A. Measurement of friction factors for the flow of gases in very fine channels used for microminiature Joule-Thomson refrigerators. Cryogenics 1983, 23, 273–277. [Google Scholar] [CrossRef]

- Papautsky, I.; Brazzle, J.; Ameel, T.; Frazier, A.B. Laminar fluid behavior in microchannels using micropolar fluid theory. Sens. Actuators A Phys. 1999, 73, 101–108. [Google Scholar] [CrossRef]

- Pfund, D.; Rector, D.; Shekarriz, A.; Popescu, A.; Welty, J. Pressure drop measurements in a microchannel. AIChE J. 2000, 46, 1496–1507. [Google Scholar] [CrossRef]

- Wilding, P.; Pfahler, J.; Bau, H.H.; Zemel, J.N.; Kricka, L.J. Manipulation and flow of biological fluids in straight channels micromachined in silicon. Clin. Chem. 1994, 40, 43–47. [Google Scholar] [CrossRef]

- Yang, C.Y.; Webb, R.L. Friction pressure drop of R-12 in small hydraulic diameter extruded aluminum tubes with and without micro-fins. Int. J. Heat Mass Transf. 1996, 39, 801–809. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Fundamental issues related to flow boiling in minichannels and microchannels. Exp. Therm. Fluid Sci. 2002, 26, 389–407. [Google Scholar] [CrossRef]

- Debray, F.; Franc, J.P.; Maitre, T.; Reynaud, S. Measurement of Forced Convection Heat Transfer Coefficients in Mini-Channels; Mesure des Coefficients de Transfert Thermique par Convection Forcee en Mini-Canaux. Mec. Ind. 2001, 2, 443–454. [Google Scholar]

- Peng, X.F.; Peterson, G.P. Convective heat transfer and flow friction for water flow in microchannel structures. Int. J. Heat Mass Transf. 1996, 39, 2599–2608. [Google Scholar] [CrossRef]

- Peng, X.F.; Peterson, G.P.; Wang, B.X. Frictional flow characteristics of water flowing through rectangular microchannels. Exp. Heat Transf. Int. J. 1994, 7, 249–264. [Google Scholar] [CrossRef]

- Li, J.; Peterson, G.P. Boiling nucleation and two-phase flow patterns in forced liquid flow in microchannels. Int. J. Heat Mass Transf. 2005, 48, 4797–4810. [Google Scholar] [CrossRef]

- Jing, D.; Song, J.; Sui, Y. Hydraulic and thermal performances of laminar flow in fractal treelike branching microchannel network with wall velocity slip. Fractals 2020, 28, 2050022. [Google Scholar] [CrossRef]

- Jing, D.; Yi, S. Electroosmotic flow in tree-like branching microchannel network. Fractals 2019, 27, 1950095. [Google Scholar] [CrossRef]

- Chafaa, N.; Benramdane, H. Simulation Numérique de la Convection Forcée Dans un Canal Horizontal Muni des Sources de Chaleur (Application: Refroidissements des Composants Électroniques). Master’s Thesis, Université de Tlemcen, Chetouane, Algeria, 2015. [Google Scholar]

- Özdemir, M.R.; Mahmoud, M.M.; Karayiannis, T.G. Flow Boiling of Water in a Rectangular Metallic Microchannel. Heat Transf. Eng. 2020, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Kandlikar, S.G.; Balasubramanian, P. An Experimental Study on the Effect of Gravitational Orientation on Flow Boiling of Water in 1054 × 197 μm Parallel Minichannels. J. Heat Transf. 2005, 127, 820–829. [Google Scholar] [CrossRef] [Green Version]

- Kandlikar, S.G. Heat Transfer Mechanisms During Flow Boiling in Microchannels. J. Heat Transf. 2004, 126, 8–16. [Google Scholar] [CrossRef]

- Lee, P.-S.; Garimella, S.V. Saturated flow boiling heat transfer and pressure drop in silicon microchannel arrays. Int. J. Heat Mass Transf. 2008, 51, 789–806. [Google Scholar] [CrossRef] [Green Version]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977. [Google Scholar] [CrossRef] [Green Version]

- Wen, J.; Gu, X.; Liu, Y.; Wang, S.; Li, Y. Effect of surface tension, gravity and turbulence on condensation patterns of R1234ze(E) in horizontal mini/macro-channels. Int. J. Heat Mass Transf. 2018, 125, 153–170. [Google Scholar] [CrossRef]

- Cahn, J.W.; Hilliard, J.E. Free Energy of a Nonuniform System. I. Interfacial Free Energy. J. Chem. Phys. 1958, 28, 258–267. [Google Scholar] [CrossRef]

- Belhadje, A.; Rachid, S.; Bouchnafa, R. Etude Thermo-Énergétique de la Convection Forcée dans les Microcanaux avec un Changement Périodique de la Section Transversale. In Proceedings of the Abou Bekr Belkaid University of Tlemcen Faculty of Technology 3rd Seminar on Advanced Mechanical Technologies, University Abu Bekr Belkaid, Chetouane, Algeria, 8–9 November 2014. [Google Scholar]

- Hu, J.; Xiong, X.; Xiao, H.; Wan, K. Effects of Contact Angle on the Dynamics of Water Droplet Impingement. In Proceedings of the COMSOL Conference, Boston, MA, USA, 8 October 2015. [Google Scholar]

- Cengel, Y.A.; Cimbala, J.M.; Turner, R.H.; Kanoglu, M. Fundamentals of Thermal-Fluid Sciences; McGraw-Hill Higher Education Boston: New York, NY, USA, 2012; Volume 3. [Google Scholar]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical Data; Academic Press: New York, NY, USA, 1978; Suppl. 1. [Google Scholar]

- Chen, N.H. An Explicit Equation for Friction Factor in Pipe. Ind. Eng. Chem. Fund. 1979, 18, 296–297. [Google Scholar] [CrossRef]

- Chen, X.; Hu, Z.; Zhang, L.; Yao, Z.; Chen, X.; Zheng, Y.; Liu, Y.; Wang, Q.; Liu, Y.; Cui, X. Numerical and Experimental Study on a Microfluidic Concentration Gradient Generator for Arbitrary Approximate Linear and Quadratic Concentration Curve Output. Int. J. Chem. React. Eng. 2018, 16. [Google Scholar] [CrossRef]

- Hassinet, L. Etude De L’ecoulement Laminaire Dans Un Minicanal Par La Methode Des Volumes Finis. Ph.D. Thesis, Université de Batna 2, Fesdis, Algeria, 2008. [Google Scholar]

- Sahar, A.M.; Wissink, J.; Mahmoud, M.M.; Karayiannis, T.G.; Ashrul Ishak, M.S. Effect of hydraulic diameter and aspect ratio on single phase flow and heat transfer in a rectangular microchannel. Appl. Therm. Eng. 2017, 115, 793–814. [Google Scholar] [CrossRef]

- Harley, J.C.; Huang, Y.; Bau, H.H.; Zemel, J.N. Gas flow in micro-channels. J. Fluid Mech. 1995, 284, 257–274. [Google Scholar] [CrossRef]

- Sarkar, D. Thermal Power Plant: Design and Operation; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- At what Temperature Do Conventional Electronics Packages Fail? Available online: https://www.twi-global.com/technical-knowledge/faqs/faq-at-what-temperature-do-conventional-electronics-packages-fail.aspx (accessed on 1 September 2020).

- Karayiannis, T.G.; Mahmoud, M.M. Flow boiling in microchannels: Fundamentals and applications. Appl. Therm. Eng. 2017, 115, 1372–1397. [Google Scholar] [CrossRef]

- Oyinlola, M.A.; Shire, G.S.F. Heat Transfer in Low Reynolds Number Flows Through Miniaturized Channels. In Proceedings of the 12th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics; De Montfort University (DMU): Leicester, UK, 2016. [Google Scholar]

- Turek, L.J.; Rini, D.P.; Saarloos, B.A.; Chow, L.C. Evaporative spray cooling of power electronics using high temperature coolant. In Proceedings of the 2008 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Orlando, FL, USA, 28–31 May 2008; IEEE: Orlando, FL, USA, 2008; pp. 346–351. [Google Scholar]

- Bostanci, H.; Van Ee, D.; Saarloos, B.A.; Rini, D.P.; Chow, L.C. Thermal Management of Power Inverter Modules at High Fluxes via Two-Phase Spray Cooling. IEEE Trans. Compon. Packag. Manufact. Technol. 2012, 2, 1480–1485. [Google Scholar] [CrossRef]

- Kreith, F.; Black, W.Z. Basic Heat Transfer; Harper & Row: New York, NY, USA, 1980. [Google Scholar]

- Incropera, F.P.; Lavine, A.S.; Bergman, T.L.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Advanced Piping Design (Process Piping Design Handbook) (v. II)—PDF Free Download. Available online: https://epdf.pub/advanced-piping-design-process-piping-design-handbook-v-ii.html (accessed on 6 May 2020).

- Buongiorno, J. Notes on two-phase flow, boiling heat transfer and boiling crises in PWRs and BWRs. In Engineering of Nuclear Systems; MIT Department of Nuclear Science & Engineering (NSE): Cambridge, MA, USA, OpenCourseWare. License: Creative Commons BY-NC-SA; 2010; pp. 1–34. Available online: https://ocw.mit.edu (accessed on 1 September 2020).

- Guo, Z.Y.; Li, D.Y.; Wang, B.X. A novel concept for convective heat transfer enhancement. Int. J. Heat Mass Transf. 1998, 41, 2221–2225. [Google Scholar] [CrossRef]

- Kim, S.-M.; Kim, J.; Mudawar, I. Flow condensation in parallel micro-channels–Part 1: Experimental results and assessment of pressure drop correlations. Int. J. Heat Mass Transf. 2012, 55, 971–983. [Google Scholar] [CrossRef]

- Wu, H.Y.; Cheng, P. Condensation flow patterns in silicon microchannels. Int. J. Heat Mass Transf. 2005, 48, 2186–2197. [Google Scholar] [CrossRef]

- Cheng, P.; Quan, X.; Gong, S.; Liu, X.; Yang, L. Recent analytical and numerical studies on phase-change heat transfer. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 2014; Volume 46, pp. 187–248. [Google Scholar]

- Tullius, J.F.; Vajtai, R.; Bayazitoglu, Y. A Review of Cooling in Microchannels. Heat Transf. Eng. 2011, 32, 527–541. [Google Scholar] [CrossRef]

- Zhuan, R.; Wang, W. Flow pattern of boiling in micro-channel by numerical simulation. Int. J. Heat Mass Transf. 2011, S0017931011006661. [Google Scholar] [CrossRef]

| Sections (Parts) | Materials |

|---|---|

| Walls | (1) No specific material, (2) Copper |

| Phase 1 | Water, liquid |

| Phase 2 | Water, gas |

| Parameters | Value | Symbol |

|---|---|---|

| Inlet velocity | 0.25 m/s | V1 |

| Channel length | 144 mm | L |

| Fluid density | 1000 kg/m3 | |

| Viscosity dynamic | 0.001 kg/m.s | |

| Hydraulic diameters | 0.5–0.98–1 mm | Dh |

| Reynolds number | 125 | Re |

| Inlet temperature | 20 °C | Tin |

| Wall temperature | 150 °C | Twall |

| Processing time | 30 s | t |

| Range time | (0;0.05;30) s | |

| Transition interval between phase 1 and phase 2 | 80 K | |

| Latent heat of vaporization | 2256 KJ/kg | |

| Phase change temperature between phase 1 and phase 2 | 373.15 K |

| Application Areas | Operating Temperature |

|---|---|

| Engine cooling | Between 80 °C and 90 °C [42] |

| Electronic components for industrial applications | 85 °C [43] |

| Electronic components for military applications | 125 °C [43] |

| Aerospace engineering | 225 °C [43] |

| Automotive on-board electronics | 150 °C [43] |

| Applications Areas | Tinlet | TWall | Tavg |

|---|---|---|---|

| Engine cooling | 20 °C | 80 °C | 50 °C = 323 K |

| Electronics components | 125 °C | 72.5 °C = 345.5 K | |

| Aerospace engineering | 225 °C | 122.5 °C = 395.5 K | |

| Automotive on-board electronics | 150 °C | 85 °C = 358 K |

| Applications Areas | Tinlet | TWall | Tavg (Dynamic) | High Heat Flux |

|---|---|---|---|---|

| Engine cooling | 20 °C | 80 °C | 327 K | 2.11 × 105 W/m2 (Single phase flow) |

| Electronics components | 125 °C | 348.48 K | 1 × 106 W/m2 | |

| Aerospace engineering | 225 °C | 394.88 K | 1.18 × 106 W/m2 | |

| Automotive on-board electronics | 150 °C | 359.9 K | 1.02 × 106 W/m2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamdem Kamdem, C.A.; Zhu, X. Numerical Study on the Flow and Heat Transfer Coupled in a Rectangular Mini-Channel by Finite Element Method for Industrial Micro-Cooling Technologies. Fluids 2020, 5, 151. https://doi.org/10.3390/fluids5030151

Kamdem Kamdem CA, Zhu X. Numerical Study on the Flow and Heat Transfer Coupled in a Rectangular Mini-Channel by Finite Element Method for Industrial Micro-Cooling Technologies. Fluids. 2020; 5(3):151. https://doi.org/10.3390/fluids5030151

Chicago/Turabian StyleKamdem Kamdem, Claude Aurélien, and Xiaolu Zhu. 2020. "Numerical Study on the Flow and Heat Transfer Coupled in a Rectangular Mini-Channel by Finite Element Method for Industrial Micro-Cooling Technologies" Fluids 5, no. 3: 151. https://doi.org/10.3390/fluids5030151