A Novel Magnetic Nano-Adsorbent Functionalized with Green Tea Extract and Magnesium Oxide to Remove Methylene Blue from Aqueous Solutions: Synthesis, Characterization, and Adsorption Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Adsorbent Preparation

2.3. Characterizations

2.4. Batch Adsorption Experiments

3. Results

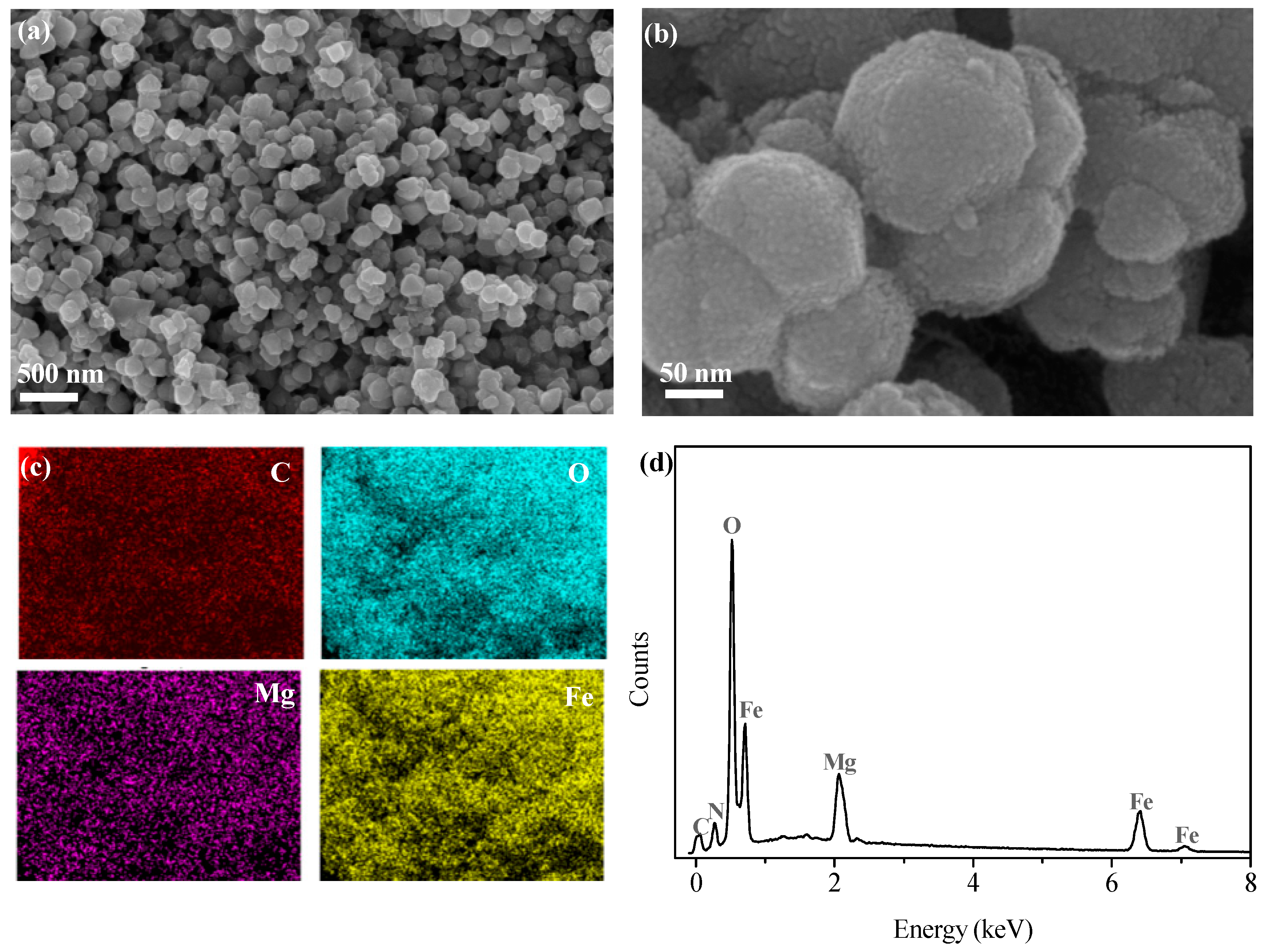

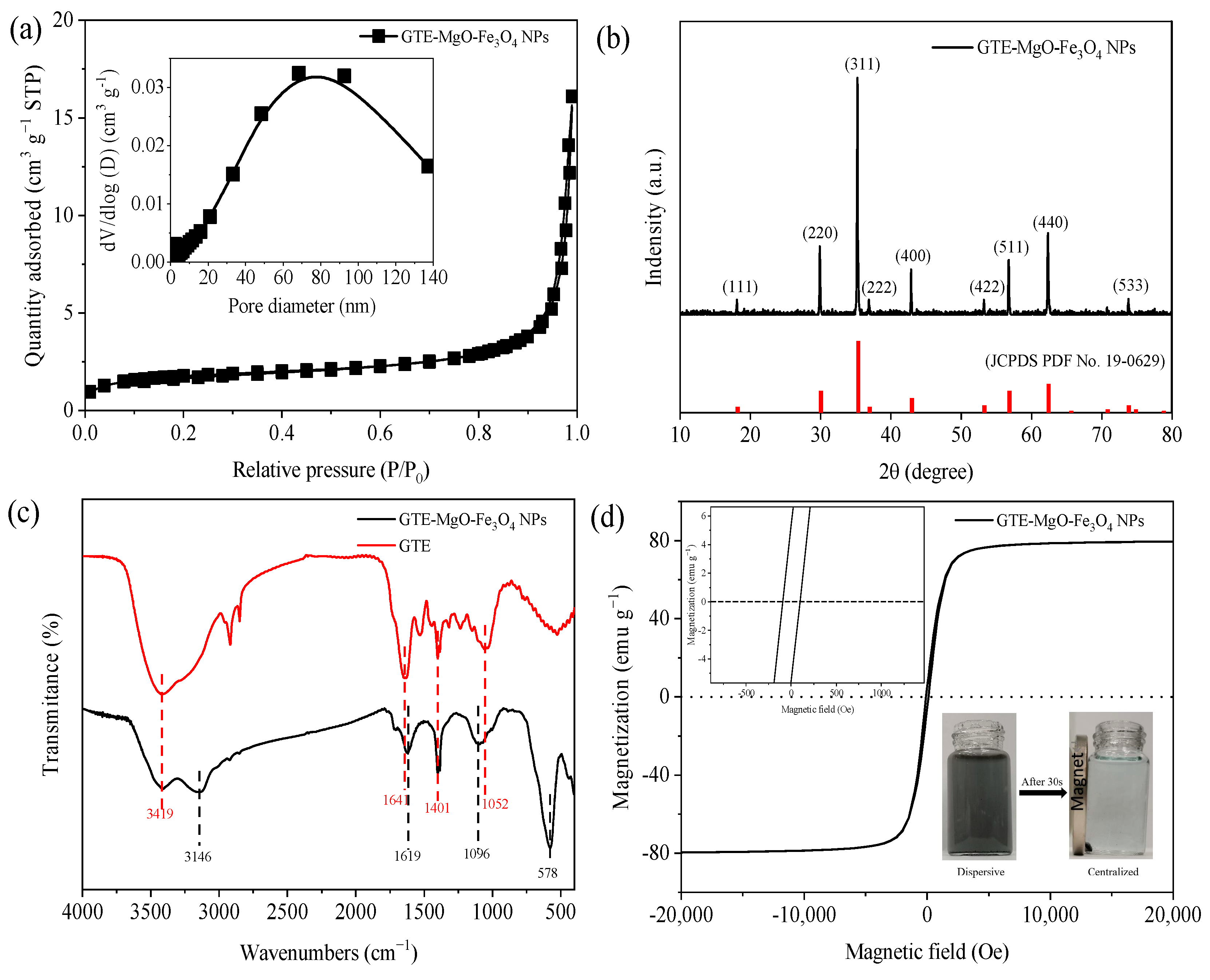

3.1. Characterization of GTE-MgO-Fe3O4 NPs

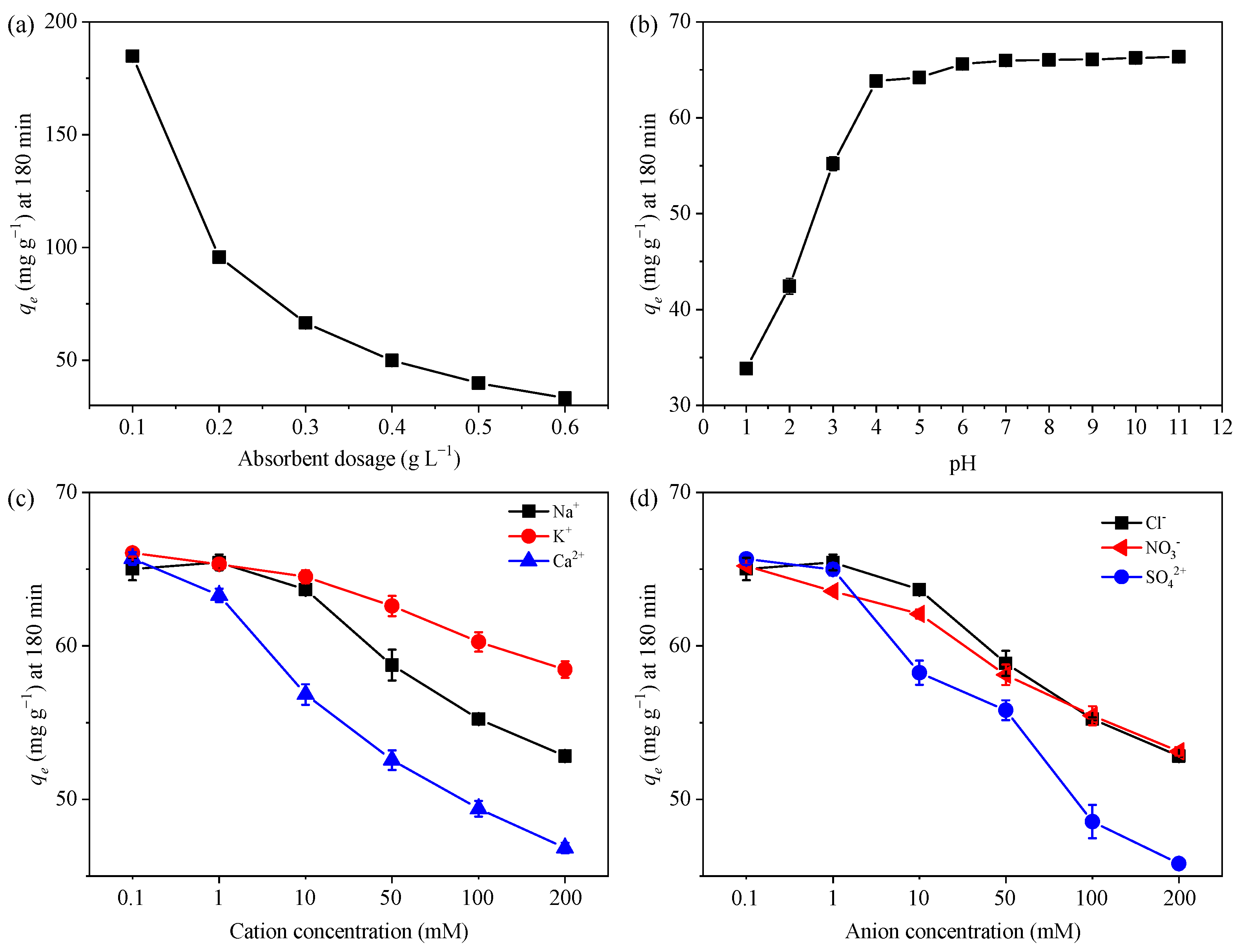

3.2. Influencing Factors

3.2.1. Effect of Adsorbent Dosage

3.2.2. Effect of pH

3.2.3. Effect of Coexisting Ions

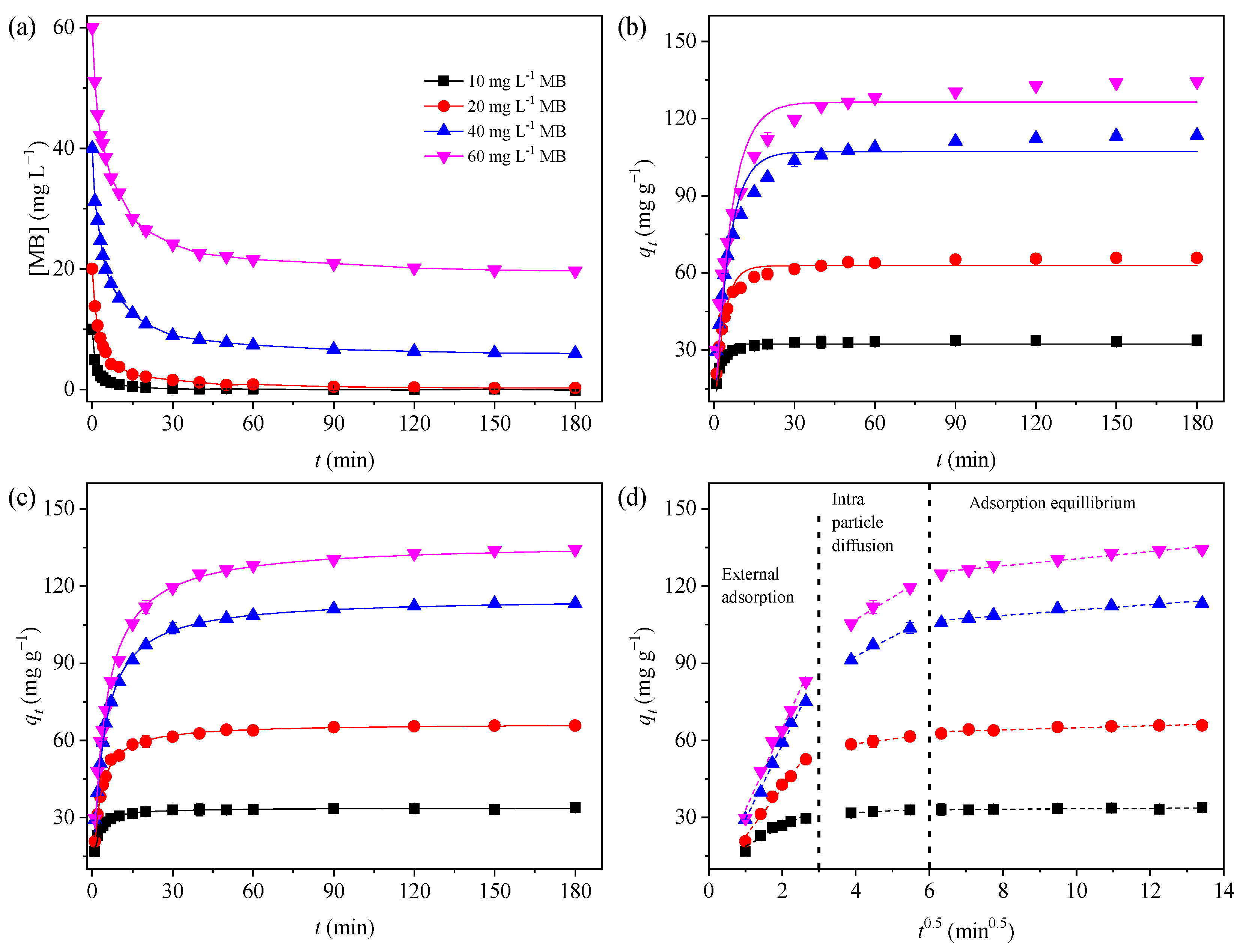

3.3. Effect of Contact Time and Initial MB Concentration: Adsorption Kinetics

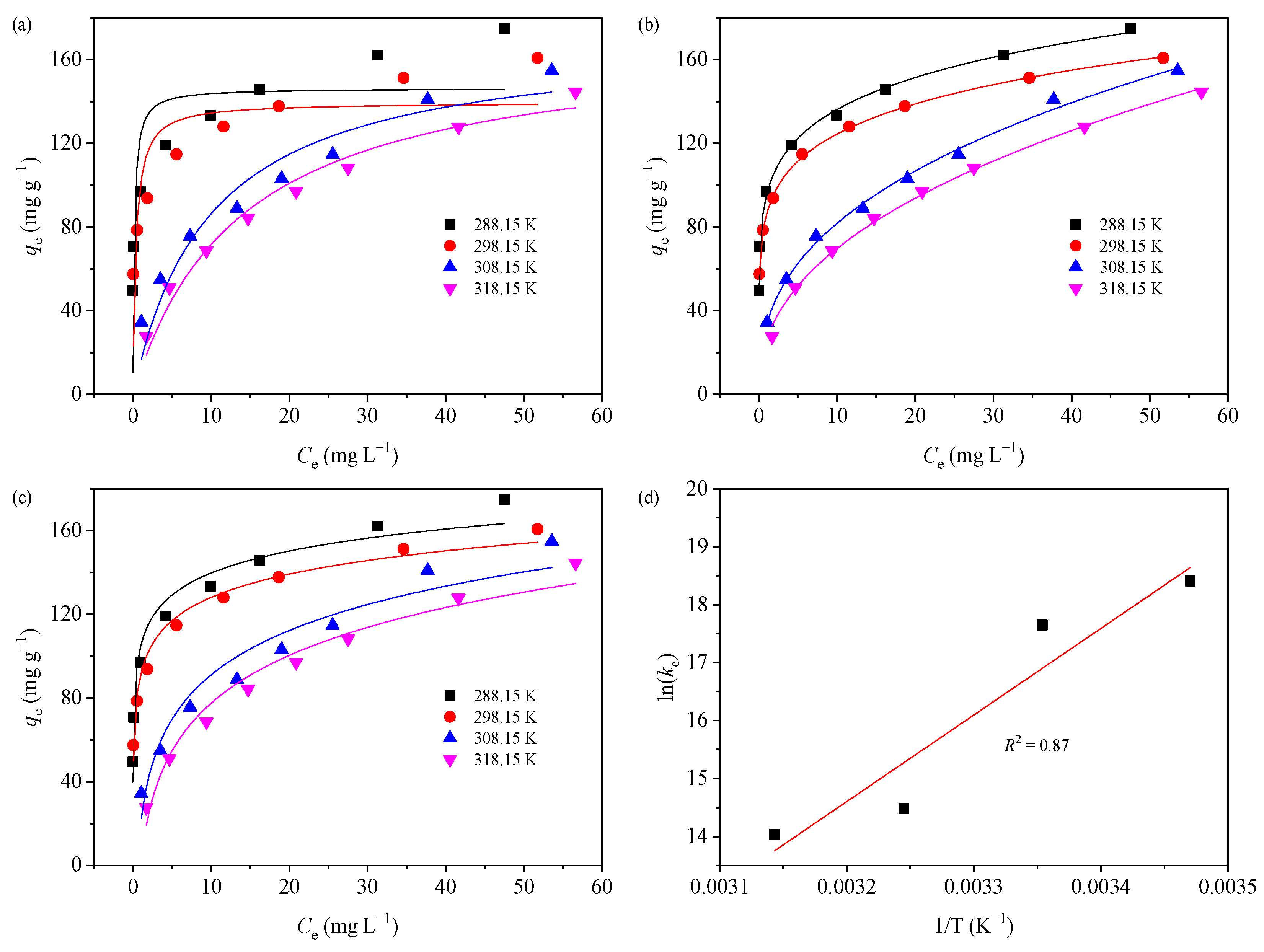

3.4. Effect of Initial MB Concentration and Temperature: Adsorption Isotherms

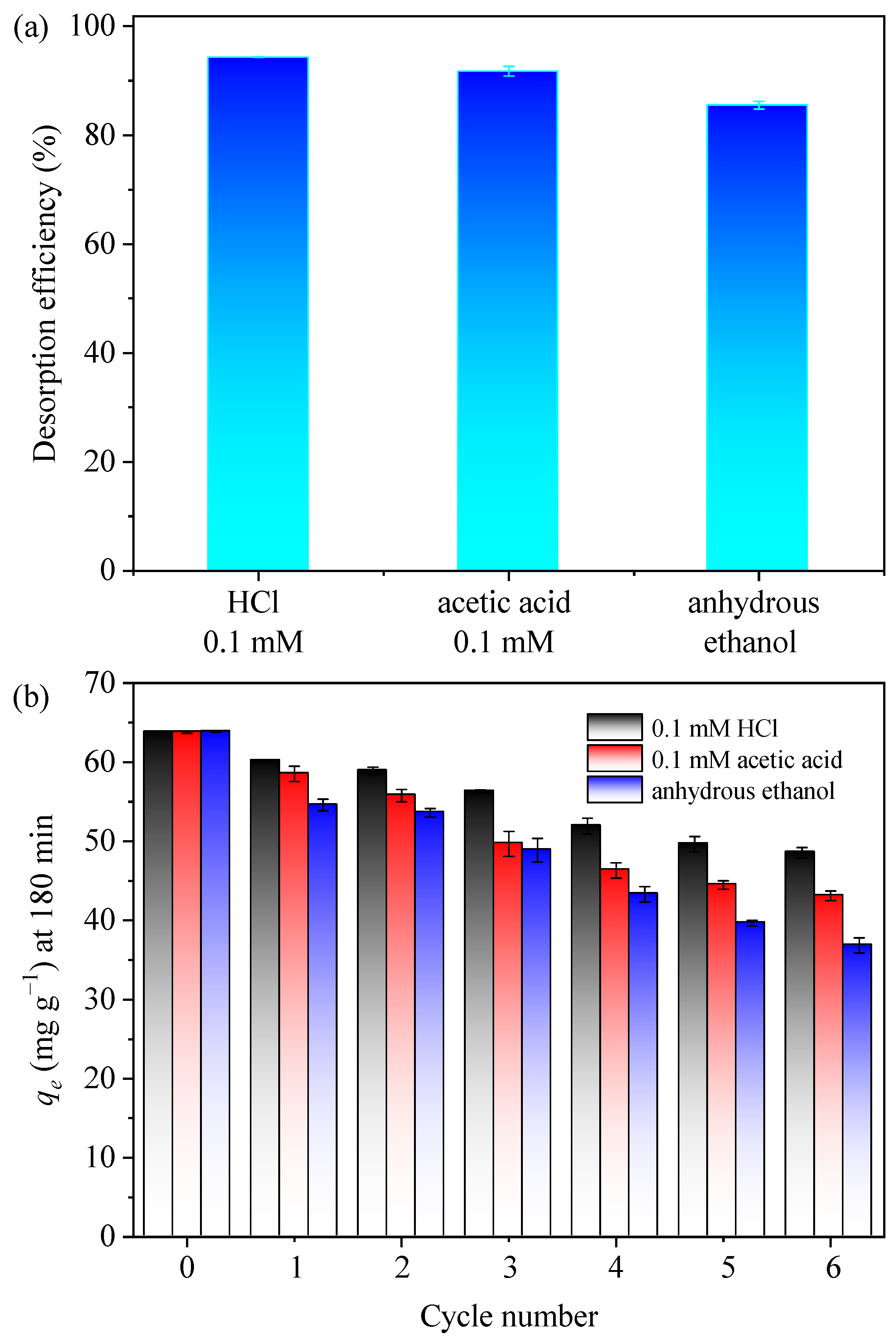

3.5. Desorption of MB and Recyclability of GTE-MgO-Fe3O4 NPs

3.6. Comparison with the Literature

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forgacs, E.; Cserhati, E.; Oros, G. Removal of synthetic dyes from wastewaters: A review. Environ. Int. 2004, 30, 953–971. [Google Scholar] [CrossRef] [PubMed]

- Moharrami, P.; Motamedi, E. Application of cellulose nanocrystals prepared from agricultural wastes for synthesis of starch-based hydrogel nanoNPs: Efficient and selective nanoadsorbent for removal of cationic dyes from water. Bioresour. Technol. 2020, 313, 123661. [Google Scholar] [CrossRef] [PubMed]

- Eren, M.A.; Arslanoğlu, H.; Çiftçi, H. Production of microporous Cu-doped BTC (Cu-BTC) metal-organic framework composite materials, superior adsorbents for the removal of methylene blue (basic blue 9). J. Environ. Chem. Eng. 2020, 8, 104247. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Ashiq, M.N. Adsorption of dyes from aqueous solutions on activated charcoal. J. Hazard. Mater. 2007, 139, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Cazetta, A.L.; Vargas, A.M.M.; Nogami, E.M.; Kunita, M.H.; Guilherme, M.R.; Martins, A.C.; Silva, T.L.; Moraes, J.C.G.; Almeida, V.C. NaOH-activated carbon of high surface area produced from coconut shell: Kinetics and equilibrium studies from the methylene blue adsorption. Chem. Eng. J. 2011, 174, 117–125. [Google Scholar] [CrossRef]

- Li, H.; Budarin, V.L.; Clark, J.H.; North, M.; Wu, X. Rapid and efficient adsorption of methylene blue dye from aqueous solution by hierarchically porous, activated starbons®: Mechanism and porosity dependence. J. Hazard. Mater. 2022, 436, 129174. [Google Scholar] [CrossRef] [PubMed]

- Yagub, M.T.; Sen, T.K.; Afroze, S.; Ang, H.M. Dye and its removal from aqueous solution by adsorption: A review. Adv. Colloid Interface Sci. 2014, 209, 172–184. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Tan, X.; Liu, Y.; Gu, Y.; Zeng, G.; Hu, X.; Wang, H.; Zhou, L.; Jiang, L.; Zhao, B. Production of biochars from ca impregnated ramie biomass (Boehmeria nivea (L.) Gaud.) and their phosphate removal potential. RSC Adv. 2016, 6, 5871–5880. [Google Scholar] [CrossRef]

- Yang, J.; Wei, Q.; Tian, C.; Li, D.; Li, H.; Qin, G.; Hu, K.; Zhang, Q. Preparation of biomass carbon NPs MgO@ZnO@BC and its adsorption and removal of Cu(II) and Pb(II) in wastewater. Molecules 2023, 28, 6982. [Google Scholar] [CrossRef]

- Jung, K.; Lee, S.; Lee, Y.J. Synthesis of novel magnesium ferrite (MgFe2O4)/biochar magnetic NPs and its adsorption behavior for phosphate in aqueous solutions. Bioresour. Technol. 2017, 245, 751–759. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, J.; Zhang, Y.; Zhou, J.; Shi, B. Conversion of tannery solid waste to an adsorbent for high-efficiency dye removal from tannery wastewater: A road to circular utilization. Chemosphere 2021, 263, 127987. [Google Scholar] [CrossRef]

- Thines, K.R.; Abdullah, E.C.; Mubarak, N.M.; Ruthiraan, M. Synthesis of magnetic biochar from agricultural waste biomass to enhancing route for waste water and polymer application: A review. Renew. Sustain. Energy Rev. 2017, 67, 257–276. [Google Scholar] [CrossRef]

- Zheng, X.; Zheng, H.; Zhao, R.; Sun, Y.; Sun, Q.; Zhang, S.; Liu, Y. Polymer-functionalized magnetic nanoparticles: Synthesis, characterization, and methylene blue adsorption. Materials 2018, 11, 1312. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.S.; Zhang, L.; Wei, J.; Hou, Y.R.; Wei, Y.; Zhou, S.L.; Jia, Z.F.; Su, X.D. Ultra-efficient and selective adsorption of cationic dyes by Ti-doped SiO2 functionalized hydrophilic Fe3O4 nanoparticles with superior structural stability. J. Water Process. Eng. 2024, 57, 104729. [Google Scholar] [CrossRef]

- Hinsene, H.; Bhawawet, N.; Imyim, A. Rice husk biochar doped with deep eutectic solvent and Fe3O4/ZnO nanoparticles for heavy metal and diclofenac removal from water. Sep. Purif. Technol. 2024, 339, 126638. [Google Scholar] [CrossRef]

- Ifthikar, J.; Wang, J.; Wang, Q.; Wang, T.; Wang, H.; Khan, A.; Jawad, A.; Sun, T.; Jiao, X.; Chen, Z. Highly efficient lead distribution by magnetic sewage sludge biochar: Sorption mechanisms and bench applications. Bioresour. Technol. 2017, 238, 399–406. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; He, C.; Lyu, W.; Zhang, W.; Yan, W.; Yang, L. Development of rare earth element doped magnetic biochars with enhanced phosphate adsorption performance. Colloid Surf. A 2019, 561, 236–243. [Google Scholar] [CrossRef]

- Yan, Q.; Wan, C.; Liu, J.; Gao, J.; Yu, F.; Zhang, J.; Cai, Z. Iron nanoparticles in situ encapsulated in biochar-based carbon as an effective catalyst for the conversion of biomass-derived syngas to liquid hydrocarbons. Green Chem. 2013, 15, 1631–1640. [Google Scholar] [CrossRef]

- Zhu, S.; Ho, S.; Huang, X.; Wang, D.; Yang, F.; Wang, L.; Wang, C.; Cao, X.; Ma, F. Magnetic nanoscale zerovalent iron assisted biochar: Interfacial chemical behaviors and heavy metals remediation performance. ACS Sustain. Chem. Eng. 2017, 5, 9673–9682. [Google Scholar] [CrossRef]

- Kumar, K.M.; Mandal, B.K.; Kumar, K.S.; Reddy, P.S.; Sreedhar, B. Biobased Green method to synthesise palladium and iron nanoparticles using terminalia chebula aqueous extract. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2013, 102, 128–133. [Google Scholar] [CrossRef] [PubMed]

- Cazetta, A.L.; Pezoti, O.; Bedin, K.C.; Silva, T.L.; Junior, A.P.; Asefa, T.; Almeida, V.C. Magnetic activated carbon derived from biomass waste by concurrent synthesis: Efficient adsorbent for toxic dyes. Acs Sustain. Chem. Eng. 2016, 4, 1058–1068. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, W.; Feng, L.; Wu, L.; Lv, J.; Du, W. Characteristics and mechanisms of phosphorous adsorption by peanut shell-derived biochar modified with magnesium chloride by ultrasonic-assisted impregnation. ACS Omega 2022, 7, 43102–43110. [Google Scholar] [CrossRef] [PubMed]

- Asilturk, M.; Sayilkan, F.; Arpac, E. Effect of Fe3+ ion doping to TiO2 on the photocatalytic degradation of malachite green dye under UV and Vis-irradiation. J. Photochem. Photobiol. A-Chem. 2009, 203, 64–71. [Google Scholar] [CrossRef]

- Shin, H.; Tiwari, D.; Kim, D. Phosphate adsorption/desorption kinetics and P bioavailability of Mg-biochar from ground coffee waste. J. Water Process. Eng. 2020, 37, 101484. [Google Scholar] [CrossRef]

- Cirtiu, C.M.; Raychoudhury, T.; Ghoshal, S.; Moores, A. Systematic comparison of the size, surface characteristics and colloidal stability of zero valent iron nanoparticles pre- and post-grafted with common polymers. Colloids Surf. A 2011, 390, 95–104. [Google Scholar] [CrossRef]

- Wang, X.; Du, Y.; Ma, J. Novel synthesis of carbon spheres supported nanoscale zero-valent iron for removal of metronidazole. Appl. Surf. Sci. 2016, 390, 50–59. [Google Scholar] [CrossRef]

- Prasannamedha, G.; Kumar, P.S.; Mehala, R.; Sharumitha, T.J.; Surendhar, D. Enhanced adsorptive removal of sulfamethoxazole from water using biochar derived from hydrothermal carbonization of sugarcane bagasse. J. Hazard. Mater. 2021, 407, 124825. [Google Scholar] [CrossRef] [PubMed]

- Ding, W.; Zheng, H.; Sun, Y.; Zhao, Z.; Zheng, X.; Wu, Y.; Xiao, W. Activation of MnFe2O4 by sulfite for fast and efficient removal of arsenic (III) at circumneutral ph: Involvement of Mn (III). J. Hazard. Mater. 2021, 403, 123623. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Liu, X.; Dong, W.; Zhang, L.; Kong, Q.; Wang, W. Efficient adsorption of sulfamethazine onto modified activated carbon: A plausible adsorption mechanism. Sci. Rep. 2017, 7, 12437. [Google Scholar] [CrossRef]

- Sarker, P.; Lei, X.; Taylor, K.; Holmes, W.; Yan, H.; Cao, D.; Zappi, M.E.; Gang, D.D. Evaluation of the adsorption of sulfamethoxazole (SMX) within aqueous influents onto customized ordered mesoporous carbon (OMC) adsorbents: Performance and elucidation of key adsorption mechanisms. Chem. Eng. J. 2023, 454, 140082. [Google Scholar] [CrossRef]

- Peng, X.; Hu, X.; Fu, D.; Lam, F.L.Y. Adsorption removal of Acid Black 1 from aqueous solution using ordered mesoporous carbon. Appl. Surf. Sci. 2014, 294, 71–80. [Google Scholar] [CrossRef]

- Mohammadi, N.; Khani, H.; Gupta, V.K.; Amereh, E.; Agarwal, S. Adsorption process of methyl orange dye onto mesoporous carbon material-kinetic and thermodynamic studies. J. Colloid Interface Sci. 2011, 362, 457–462. [Google Scholar] [CrossRef]

- Dos Santos, H.H.; Demarchi, C.A.; Rodrigues, C.A.; Greneche, J.M.; Nedelko, N.; Ślawska-Waniewska, A. Adsorption of As (III) on chitosan-Fe-crosslinked complex (Ch-Fe). Chemosphere 2011, 82, 278283. [Google Scholar] [CrossRef]

- Kumari, H.J.; Krishnamoorthy, P.; Arumugam, T.K.; Radhakrishnan, S.; Vasudevan, D. An efficient removal of crystal violet dye from waste water by adsorption onto tlac/chitosan composite: A novel low cost adsorbent. Int. J. Biol. Macromol. 2017, 96, 324–333. [Google Scholar] [CrossRef]

- Sun, F.; Liu, M.; Yuan, B.; He, J.; Wu, P.; Liu, C.; Jiang, W. Separation of vanadium and chromium by selective adsorption by titanium-based microspheres. Chem. Eng. J. 2022, 450, 138039. [Google Scholar] [CrossRef]

- Hu, Q.; Lan, R.; He, L.; Liu, H.; Pei, X. A critical review of adsorption isotherm models for aqueous contaminants: Curve characteristics, site energy distribution and common controversies. J. Environ. Manag. 2023, 329, 117104. [Google Scholar] [CrossRef]

- Singh, K.K.; Senapati, K.K.; Sarma, K.C. Synthesis of superparamagnetic Fe3O4 nanoparticles coated with green tea polyphenols and their use for removal of dye pollutant from aqueous solution. J. Environ. Chem. Eng. 2017, 5, 2214–2221. [Google Scholar] [CrossRef]

- Abdulla, N.K.; Siddiqui, S.I.; Tara, N.; Hashmi, A.A.; Chaudhry, S.A. Psidium guajava leave-based magnetic nanocomposite γ-FeO@GL: A green technology for methylene blue removal from water. J. Environ. Chem. Eng. 2019, 7, 103423. [Google Scholar] [CrossRef]

- Prabakaran, E.; Pillay, K.; Brink, H. Hydrothermal synthesis of magnetic-biochar nanocomposite derived from avocado peel and its performance as an adsorbent for the removal of methylene blue from wastewater. Mater. Today Sustain. 2022, 18, 100123. [Google Scholar] [CrossRef]

- Bayantong, A.R.B.; Shih, Y.J.; Ong, D.C.; Abarca, R.R.M.; Dong, C.D.; de Luna, M.D.G. Adsorptive removal of dye in wastewater by metal ferrite-enabled graphene oxide nanocomposites. Chemosphere 2021, 274, 129518. [Google Scholar] [CrossRef]

- Zirak, M.; Abdollahiyan, A.; Eftekhari-Sis, B.; Saraei, M. Carboxymethyl cellulose coated Fe3O4@SiO2 core-shell magnetic nanoparticles for methylene blue removal: Equilibrium, kinetic, and thermodynamic studies. Cellulose 2017, 25, 503–515. [Google Scholar] [CrossRef]

- Harimu, L.; Wahyuni, S.; Nasrudin, N. Fabrication of chitosan/Fe3O4 nanocomposite as adsorbent for reduction methylene blue contents. Ind. J. Chem. 2022, 22, 878–886. [Google Scholar]

- Saini, J.; Garg, V.K.; Gupta, R.K. Removal of Methylene Blue from aqueous solution by Fe3O4@Ag/SiO2 nanospheres: Synthesis, characterization and adsorption performance. J. Mol. Liq. 2018, 250, 413–422. [Google Scholar] [CrossRef]

- El-Azazy, M.; El-Shafie, A.S.; Yousef, B.A. Green Tea waste as an efficient adsorbent for Methylene Blue: Structuring of a novel adsorbent using full factorial design. Molecules 2021, 26, 6138. [Google Scholar] [CrossRef] [PubMed]

| Models | Expression |

|---|---|

| PFO | |

| PSO | |

| Intra-Particle Diffusion | |

| Langmuir | |

| Freundlich | |

| Temkin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, W.; Huang, Y.; Liu, S.; Ding, W.; Li, H.; Zheng, H. A Novel Magnetic Nano-Adsorbent Functionalized with Green Tea Extract and Magnesium Oxide to Remove Methylene Blue from Aqueous Solutions: Synthesis, Characterization, and Adsorption Behavior. Magnetochemistry 2024, 10, 31. https://doi.org/10.3390/magnetochemistry10050031

Lin W, Huang Y, Liu S, Ding W, Li H, Zheng H. A Novel Magnetic Nano-Adsorbent Functionalized with Green Tea Extract and Magnesium Oxide to Remove Methylene Blue from Aqueous Solutions: Synthesis, Characterization, and Adsorption Behavior. Magnetochemistry. 2024; 10(5):31. https://doi.org/10.3390/magnetochemistry10050031

Chicago/Turabian StyleLin, Wenchao, Yaoyao Huang, Shuang Liu, Wei Ding, Hong Li, and Huaili Zheng. 2024. "A Novel Magnetic Nano-Adsorbent Functionalized with Green Tea Extract and Magnesium Oxide to Remove Methylene Blue from Aqueous Solutions: Synthesis, Characterization, and Adsorption Behavior" Magnetochemistry 10, no. 5: 31. https://doi.org/10.3390/magnetochemistry10050031