Recent Advances in Thermal Management Strategies for Lithium-Ion Batteries: A Comprehensive Review

Abstract

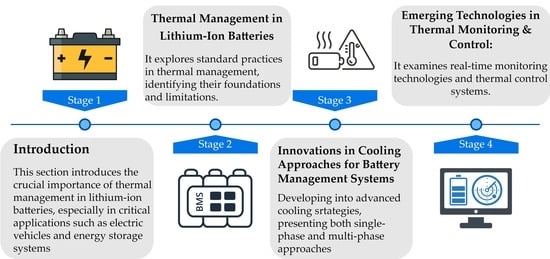

:1. Introduction

- The primary contribution of this work lies in its comprehensive approach, addressing not only thermal efficiency to enhance battery performance but also placing significant emphasis on safety. This is achieved through innovative strategies in the design of BTMSs that tackle both overheating and temperature variations, thereby mitigating risks of accelerated aging and potential fire hazards.

- We contribute to the scientific literature by highlighting the essential role of advanced materials and innovative designs in BTMSs. This work provides a thorough review of recent advancements in this regard, emphasizing how these innovations can be crucial for effective thermal management during charging and discharging processes, especially in high-demand applications such as electric vehicles.

- A significant novelty of this review is the emphasis on researching internal heat generation in lithium-ion batteries. Through a detailed analysis of thermo-electrochemical processes and the impact of variable battery properties on heat generation, this work contributes to a better understanding of the fundamentals underlying battery efficiency and safety.

- This paper highlights a comprehensive evaluation of various thermal management strategies used in EVs. From pulsed operations to hybrid systems combining liquid cooling with PCMs, we provide a complete overview of the advantages and disadvantages of each approach, identifying best practices to optimize thermal efficiency and minimize pressure loss.

- We present specific results from a recent hybrid system that combines liquid cooling channels with PCMs. This work not only highlights the theory behind this innovation but also demonstrates its practical application, optimizing thermal efficiency and addressing pressure loss, which is crucial for successful implementation in EVs.

2. Thermal Management in Lithium-Ion Batteries

3. Innovations in Cooling Approaches for Battery Management Systems

4. Emerging Technologies in Thermal Monitoring and Control

4.1. Advanced Sensors

4.2. Application of Intelligent Technologies and Machine Learning

5. Challenges and Solutions in Extreme Conditions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yue, Q.L.; He, C.X.; Wu, M.C.; Zhao, T.S. Advances in Thermal Management Systems for Next-Generation Power Batteries. Int. J. Heat. Mass. Transf. 2021, 181, 121853. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1–R25. [Google Scholar] [CrossRef]

- Cai, S.; Zhang, X.; Ji, J. Recent Advances in Phase Change Materials-Based Battery Thermal Management Systems for Electric Vehicles. J. Energy Storage 2023, 72, 108750. [Google Scholar] [CrossRef]

- Olabi, A.G.; Maghrabie, H.M.; Hameed, O.; Adhari, K.; Sayed, T.; Youse, B.A.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery Thermal Management Systems: Recent Progress and Challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Akkurt, N.; Aghakhani, S.; Mahmoud, M.Z.; El Din, E.M.T. The influence of battery distance on a hybrid air-cooled cylindrical lithium-ion battery phase change material thermal management system for storing solar energy. J. Energy Storage 2022, 52, 1048730. [Google Scholar] [CrossRef]

- Richardson, G.; Korotkin, I. Heat Generation and a Conservation Law for Chemical Energy in Li-Ion Batteries. Electrochim. Acta 2021, 392, 138909. [Google Scholar] [CrossRef]

- Wu, W.; Xiao, X.; Huang, X. The Effect of Battery Design Parameters on Heat Generation and Utilization in a Li-Ion Cell. Electrochim. Acta 2012, 83, 227–240. [Google Scholar] [CrossRef]

- Garud, K.S.; Tai, L.D.; Hwang, S.G.; Nguyen, N.H.; Lee, M.Y. A Review of Advanced Cooling Strategies for Battery Thermal Management Systems in Electric Vehicles. Symmetry 2023, 15, 1322. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, Z.; Xiao, S.; Gao, M.; Bai, J.; Liebig, D.; Lu, L.; Han, X.; Li, Y.; Du, J.; et al. Temperature Consistency—Oriented Rapid Heating Strategy Combining Pulsed Operation and External Thermal Management for Lithium-Ion Batteries. Appl. Energy 2023, 335, 120659. [Google Scholar] [CrossRef]

- Chavan, S.; Venkateswarlu, B.; Prabakaran, R.; Salman, M.; Joo, S.W.; Choi, G.S.; Kim, S.C. Thermal Runaway and Mitigation Strategies for Electric Vehicle Lithium-Ion Batteries Using Battery Cooling Approach: A Review of the Current Status and Challenges. J. Energy Storage 2023, 72, 108569. [Google Scholar] [CrossRef]

- Yao, F.; Guan, X.; Chen, Q.; Lin, L. Research on Thermal Management System of Lithium-Ion Battery with a New Type of Spider Web Liquid Cooling Channel and Phase Change Materials. J. Energy Storage 2024, 81, 110447. [Google Scholar] [CrossRef]

- Liu, J.; Yadav, S.; Salman, M.; Chavan, S.; Kim, S.C. Review on Thermal Coupled Battery Models and Parameter Identication or Lithium-Ion Battery Heat Generation in EV Battery Thermal Management System. Int. J. Heat. Mass. Transf. 2024, 218, 124748. [Google Scholar] [CrossRef]

- Khan, N.; Sable, M.J. A Review on Lithium-Ion Battery Thermal Management Systems. Int. Res. J. Modern. Eng. Technol. Sci. 2023, 5, 2550–2559. [Google Scholar]

- Khan, A.; Yaqub, S.; Ali, M.; Ahmad, A.W.; Nazir, H.; Khalid, H.A.; Iqbal, N.; Said, Z.; Sopian, K. A State-of-the-Art Review on Heating and Cooling of Lithium-Ion Batteries for Electric Vehicles. J. Energy Storage 2024, 76, 109852. [Google Scholar] [CrossRef]

- Mahmud, M.; Rahman, K.S.; Rokonuzzaman, M.; Habib, A.K.M.A.; Islam, M.R.; Motakabber, S.M.A.; Channumsin, S.; Chowdhury, S. Lithium-Ion Battery Thermal Management for Electric Vehicles Using Phase Change Material: A Review. Results Eng. 2023, 20, 101424. [Google Scholar] [CrossRef]

- Kumar, R.; Goel, V. A Study on Thermal Management System of Lithium-Ion Batteries for Electrical Vehicles: A Critical Review. J. Energy Storage 2023, 71, 108025. [Google Scholar] [CrossRef]

- Jiang, W.; Feng, G.; Wang, H.; Chang, Z.; Tan, X.; Ji, J.; Zhang, Y.; Zhou, J. Analysis of Hybrid Active-Passive Prismatic Li-Ion Battery Thermal Management System Using Phase Change Materials with Porous-Filled Mini-Channels. J. Energy Storage 2024, 80, 110144. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.; Wang, Y.; Wang, S.; Huang, L. Battery Thermal Management Systems (BTMs) Based on Phase Change Material (PCM): A Comprehensive Review. Chem. Eng. J. 2022, 430, 132741. [Google Scholar] [CrossRef]

- Moaveni, A.; Siavashi, M.; Mousavi, S. Passive and Hybrid Battery Thermal Management System by Cooling Flow Control, Employing Nano-PCM, Fins, and Metal Foam. Energy 2024, 288, 129809. [Google Scholar] [CrossRef]

- Alaoui, C. Passive/Active BTMS for EV Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2018, 67, 3709–3719. [Google Scholar] [CrossRef]

- Patel, J.R.; Rathod, M.K. Recent Developments in the Passive and Hybrid Thermal Management Techniques of Lithium-Ion Batteries. J. Power Sources 2020, 480, 228820. [Google Scholar] [CrossRef]

- Ranjbaran, Y.S.; Shojaeefard, M.H.; Molaeimanesh, G.R. Thermal Performance Enhancement of a Passive Battery Thermal Management System Based on Phase Change Material Using Cold Air Passageways for Lithium Batteries. J. Energy Storage 2023, 68, 107744. [Google Scholar] [CrossRef]

- Osmani, K.; Alkhedher, M.; Ramadan, M.; Choi, D.S.; Li, L.K.B.; Doranehgard, M.H.; Olabi, A.G. Recent Progress in the Thermal Management of Lithium-Ion Batteries. J. Clean. Prod. 2023, 389, 136024. [Google Scholar] [CrossRef]

- Chen, J.; Kang, S.; Jiaqiang, E.; Huang, Z.; Wei, K.; Zhang, B.; Zhu, H.; Deng, Y.; Zhang, F.; Liao, G. Effects of Different Phase Change Material Thermal Management Strategies on the Cooling Performance of the Power Lithium Ion Batteries: A Review. J. Power Sources 2019, 442, 227228. [Google Scholar] [CrossRef]

- Li, K.; Yan, J.; Chen, H.; Wang, Q. Water Cooling Based Strategy for Lithium Ion Battery Pack Dynamic Cycling for Thermal Management System. Appl. Therm. Eng. 2018, 132, 575–585. [Google Scholar] [CrossRef]

- Fini, A.S.; Gharehghani, A. Experimental Investigation of Pressure Effect on the PCM Performance in Li-Ion Battery Thermal Management System. J. Energy Storage 2024, 79, 110273. [Google Scholar] [CrossRef]

- Mei, J.; Shi, G.; Liu, H.; Wang, Z.; Chen, M. Investigation on the Optimization Strategy of Phase Change Material Thermal Management System for Lithium-Ion Battery. J. Energy Storage 2022, 55, 105365. [Google Scholar] [CrossRef]

- Son, Y.W.; Kang, D.; Kim, J. Passive Battery Thermal Management System for an Unmanned Aerial Vehicle Using a Tetrahedral Lattice Porous Plate. Appl. Therm. Eng. 2023, 225, 120186. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Zhang, S.; Tang, B. Phase Change Materials for Lithium-Ion Battery Thermal Management Systems: A Review. J. Energy Storage 2024, 80, 110259. [Google Scholar] [CrossRef]

- Liu, X.; Yao, L.C.; Su, C.Q.; Xiong, X.; Wang, Y.P. A Hybrid Battery Thermal Management System Coupling with PCM and Optimized Thermoelectric Cooling for High-Rate Discharge Condition. Case Stud. Therm. Eng. 2023, 49, 103269. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, Y.; Zhang, C.; Xu, H.; Zhou, Q.; Wang, C. A Novel Hybrid Battery Thermal Management System for Prevention of Thermal Runaway Propagation. IEEE Trans. Transp. Electrif. 2022, 207, 3215691. [Google Scholar] [CrossRef]

- Kharabati, S.; Saedodin, S. A Systematic Review of Thermal Management Techniques for Electric Vehicle Batteries. J. Energy Storage 2024, 75, 109586. [Google Scholar] [CrossRef]

- Khan, M.M.; Alkhedher, M.; Ramadan, M.; Ghazal, M. Hybrid PCM-Based Thermal Management for Lithium-Ion Batteries: Trends and Challenges. J. Energy Storage 2023, 73, 108775. [Google Scholar] [CrossRef]

- Wang, H.; Guo, Y.; Ren, Y.; Yeboah, S.; Wang, J.; Long, F.; Zhang, Z.; Jiang, R. Investigation of the Thermal Management Potential of Phase Change Material for Lithium-Ion Battery. Appl. Therm. Eng. 2024, 236, 121590. [Google Scholar] [CrossRef]

- Napa, N.; Agrawal, M.K.; Tamma, B. Design of Novel Thermal Management System for Li-Ion Battery Module Using Metal Matrix Based Passive Cooling Method. J. Energy Storage 2023, 73, 109119. [Google Scholar] [CrossRef]

- Afraz, M.V.; Ali Mohammadi, Z.; Karimi, G. A Novel Compact Thermal Management Model for Performance Evaluation of Tesla-like Lithium-Ion Battery Packs. Energy Convers. Manag. 2024, 300, 117927. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of Battery Thermal Management Systems in Electric Vehicles. Renew. Sustain. Energy Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Rana, J.; Dikshit, M.K. Recent Advancements in Materials for Battery Thermal Management Systems in Li-Ion Battery: A Mini Review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Choi, H.; Lee, H.; Kim, J.; Lee, H. Hybrid Single-Phase Immersion Cooling Structure for Battery Thermal Management under Fast-Charging Conditions. Energy Convers. Manag. 2023, 287, 117053. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Li, C.; Yu, Y.; Zhou, G.; Wang, C.Y.; Zhao, W. Temperature Prediction of Lithium-Ion Battery Based on Artificial Neural Network Model. Appl. Therm. Eng. 2023, 228, 120482. [Google Scholar] [CrossRef]

- Kurucan, M.; Özbaltan, M.; Yetgin, Z.; Alkaya, A. Applications of Artificial Neural Network Based Battery Management Systems: A Literature Review. Renew. Sustain. Energy Rev. 2024, 192, 114262. [Google Scholar] [CrossRef]

- Xiong, R.; Li, X.; Li, H.; Zhu, B.; Avelin, A. Neural Network and Physical Enable One Sensor to Estimate the Temperature for All Cells in the Battery Pack. J. Energy Storage 2024, 80, 110387. [Google Scholar] [CrossRef]

- Alsuwian, T.; Ansari, S.; Ammirrul Atiqi Mohd Zainuri, M.; Ayob, A.; Hussain, A.; Hossain Lipu, M.S.; Alhawari, A.R.H.; Almawgani, A.H.M.; Almasabi, S.; Taher Hindi, A. A Review of Expert Hybrid and Co-Estimation Techniques for SOH and RUL Estimation in Battery Management System with Electric Vehicle Application. Expert. Syst. Appl. 2024, 246, 123123. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Chen, Q. Kalman Filtering State of Charge Estimation for Battery Management System Based on a Stochastic Fuzzy Neural Network Battery Model. Energy Convers. Manag. 2012, 53, 33–39. [Google Scholar] [CrossRef]

- Rimsha; Murawwat, S.; Gulzar, M.M.; Alzahrani, A.; Hafeez, G.; Khan, F.A.; Abed, A.M. State of Charge Estimation and Error Analysis of Lithium-Ion Batteries for Electric Vehicles Using Kalman Filter and Deep Neural Network. J. Energy Storage 2023, 72, 108039. [Google Scholar] [CrossRef]

- Lee, D.; Lee, P.Y.; Baek, I.; Kwon, S.; Kim, J. Deriving the Optimized Battery Model for Battery Pack and Anomaly Detection Based on the Cloud Battery Management System. J. Energy Storage 2023, 74, 109338. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, S.; Gao, Z.; Wang, G.; Zong, L.; Liu, J.; Feng, Z.; Ming, H.; Zheng, Y.; Chen, F.; et al. A Statistical Distribution-Based Pack-Integrated Model towards State Estimation for Lithium-Ion Batteries. eTransportation 2023, 19, 100302. [Google Scholar] [CrossRef]

- Kim, M.; So, J. VLSI Design and FPGA Implementation of State-of-Charge and State-of-Health Estimation for Electric Vehicle Battery Management Systems. J. Energy Storage 2023, 73, 108876. [Google Scholar] [CrossRef]

- Jiang, K.; Liao, G.; Jiaqiang, E.; Zhang, F.; Chen, J.; Leng, E. Thermal Management Technology of Power Lithium-Ion Batteries Based on the Phase Transition of Materials: A Review. J. Energy Storage 2020, 32, 101816. [Google Scholar] [CrossRef]

- Fayaz, H.; Afzal, A.; Samee, A.D.M.; Soudagar, M.E.M.; Akram, N.; Mujtaba, M.A.; Jilte, R.D.; Islam, M.T.; Ağbulut, Ü.; Saleel, C.A. Optimization of Thermal and Structural Design in Lithium-Ion Batteries to Obtain Energy Efficient Battery Thermal Management System (BTMS): A Critical Review. Arch. Comput. Methods Eng. 2022, 29, 129–194. [Google Scholar] [CrossRef] [PubMed]

- Deng, T.; Zhang, G.; Ran, Y.; Liu, P. Thermal Performance of Lithium Ion Battery Pack by Using Cold Plate. Appl. Therm. Eng. 2019, 160, 114088. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, Q.; Zhao, S.; Zhai, S.; Zhao, T.; Ni, M. A New Battery Thermal Management System Employing the Mini-Channel Cold Plate with Pin Fins. Sustain. Energy Technol. Assess. 2022, 51, 101993. [Google Scholar] [CrossRef]

- Selvaraj, V.; Vairavasundaram, I. Flyback Converter Employed Non-Dissipative Cell Equalization in Electric Vehicle Lithium-Ion Batteries. e-Prime Adv. Electr. Eng. Electron. Energy 2023, 5, 100278. [Google Scholar] [CrossRef]

- Sharma, D.K.; Prabhakar, A. A Review on Air Cooled and Air Centric Hybrid Thermal Management Techniques for Li-Ion Battery Packs in Electric Vehicles. J. Energy Storage 2021, 41, 102885. [Google Scholar] [CrossRef]

- Murugan, M.; Saravanan, A.; Elumalai, P.V.; Murali, G.; Dhineshbabu, N.R.; Kumar, P.; Afzal, A. Thermal Management System of Lithium-Ion Battery Packs for Electric Vehicles: An Insight Based on Bibliometric Study. J. Energy Storage 2022, 52, 104723. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, W.; Jiaqiang, E.; Li, J.; Li, Q.; Sun, K.; Zhou, K.; Zhang, G. Performance Comparison between Straight Channel Cold Plate and Inclined Channel Cold Plate for Thermal Management of a Prismatic LiFePO4 Battery. Energy 2022, 248, 123637. [Google Scholar] [CrossRef]

- Hao, M.; Li, J.; Park, S.; Moura, S.; Dames, C. Efficient Thermal Management of Li-Ion Batteries with a Passive Interfacial Thermal Regulator Based on a Shape Memory Alloy. Nat. Energy 2018, 3, 899–906. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, X.; Wang, C.; Lu, R.; Zhang, T.; Chen, H.; Zheng, X. Progress in Thermal Rectification Due to Heat Conduction in Micro/Nano Solids. Mater. Today Phys. 2023, 30, 100941. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Jaguemont, J.; Gandoman, F.H.; Kalogiannis, T.; Berecibar, M.; Van Mierlo, J. Novel Thermal Management Methods to Improve the Performance of the Li-Ion Batteries in High Discharge Current Applications. Energy 2021, 224, 120165. [Google Scholar] [CrossRef]

- Wang, H.; Tao, T.; Xu, J.; Mei, X.; Liu, X.; Gou, P. Cooling Capacity of a Novel Modular Liquid-Cooled Battery Thermal Management System for Cylindrical Lithium Ion Batteries. Appl. Therm. Eng. 2020, 178, 115591. [Google Scholar] [CrossRef]

- Yang, T.; Su, S.; Xin, Q.; Zeng, J.; Zhang, H.; Zeng, X.; Xiao, J. Thermal Management of Lithium-Ion Batteries Based on Honeycomb-Structured Liquid Cooling and Phase Change Materials. Batteries 2023, 9, 287. [Google Scholar] [CrossRef]

- Yu, Y.; Vincent, T.; Sansom, J.; Greenwood, D.; Marco, J. Distributed Internal Thermal Monitoring of Lithium Ion Batteries with Fibre Sensors. J. Energy Storage 2022, 50, 104291. [Google Scholar] [CrossRef]

- McKerracher, R.D.; Guzman-Guemez, J.; Wills, R.G.A.; Sharkh, S.M.; Kramer, D. Advances in Prevention of Thermal Runaway in Lithium-Ion Batteries. Adv. Energy Sustain. Res. 2021, 2, 20000059. [Google Scholar] [CrossRef]

- Ghalkhani, M.; Habibi, S. Review of the Li-Ion Battery, Thermal Management, and AI-Based Battery Management System for EV Application. Energies 2023, 16, 185. [Google Scholar] [CrossRef]

- Boujelbene, M.; Goodarzi, M.; Ali, M.A.; Shigidi, I.M.T.A.; Pashameah, R.A.; Homod, R.Z.; Alzahrani, E.; Safaei, M.R. Machine-Learning Optimization of an Innovative Design of a Li-Ion Battery Arrangement Cooling System. J. Energy Storage 2023, 58, 106331. [Google Scholar] [CrossRef]

- Ghaeminezhad, N.; Wang, Z.; Ouyang, Q. A Review on Lithium-Ion Battery Thermal Management System Techniques: A Control-Oriented Analysis. Appl. Therm. Eng. 2023, 219, 119497. [Google Scholar] [CrossRef]

- Zheng, Y.; Che, Y.; Hu, X.; Sui, X.; Stroe, D.I.; Teodorescu, R. Thermal State Monitoring of Lithium-Ion Batteries: Progress, Challenges, and Opportunities. Prog. Energy Combust. Sci. 2024, 100, 101120. [Google Scholar] [CrossRef]

- Ling, X.; Zhang, Q.; Xiang, Y.; Chen, J.S.; Peng, X.; Hu, X. A Cu/Ni Alloy Thin-Film Sensor Integrated with Current Collector for in-Situ Monitoring of Lithium-Ion Battery Internal Temperature by High-Throughput Selecting Method. Int. J. Heat. Mass. Transf. 2023, 214, 124383. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, Q.; Guo, H.; Zhang, X.; Wang, K.; Zhang, Q.; Xu, H.; Xu, J.; Tashiro, Y.; Li, Z.; et al. Contactless Sensor for Real-Time Monitoring of Lithium Battery External Short Circuit Based on Magnetoelectric Elastomer Composites. J. Power Sources 2024, 589, 233776. [Google Scholar] [CrossRef]

- Guo, Z.; Briggs, C.; Vincent, T.A.; Gulsoy, B.; Sansom, J.E.H.; Marco, J. Global Thermal Image of Cylindrical 21700 Li-Ion Batteries with Distributed Optical Fibre Sensor. J. Power Sources 2024, 592, 233980. [Google Scholar] [CrossRef]

- Mao, S.; Han, X.; Lu, Y.; Wang, D.; Su, A.; Lu, L.; Feng, X.; Ouyang, M. Multi Sensor Fusion Methods for State of Charge Estimation of Smart Lithium-Ion Batteries. J. Energy Storage 2023, 72, 108736. [Google Scholar] [CrossRef]

- Chen, D.; Zhao, Q.; Zheng, Y.; Xu, Y.; Chen, Y.; Ni, J.; Zhao, Y. Recent Progress in Lithium-Ion Battery Safety Monitoring Based on Fiber Bragg Grating Sensors. Sensors 2023, 23, 5609. [Google Scholar] [CrossRef]

- Liu, S.; Li, K.; Chong, B.; Chen, Y. State-of-Charge Estimation of Li-Ion Battery Packs Based on Optic Fibre Sensor Measurements. Transp. Res. Procedia 2023, 70, 388–397. [Google Scholar] [CrossRef]

- El Ouazzani, H.; El Hassani, I.; Barka, N.; Masrour, T. MSCC-DRL: Multi-Stage Constant Current Based on Deep Reinforcement Learning for Fast Charging of Lithium Ion Battery. J. Energy Storage 2024, 75, 109695. [Google Scholar] [CrossRef]

- Matijašević, T.; Antić, T.; Capuder, T. A Systematic Review of Machine Learning Applications in the Operation of Smart Distribution Systems. Energy Rep. 2022, 8, 12379–12407. [Google Scholar] [CrossRef]

- Waseem, M.; Ahmad, M.; Parveen, A.; Suhaib, M. Battery Technologies and Functionality of Battery Management System for EVs: Current Status, Key Challenges, and Future Prospectives. J. Power Sources 2023, 580, 233349. [Google Scholar] [CrossRef]

- Zou, Y.; Lin, Z.; Li, D.; Liu, Z.C. Advancements in Artificial Neural Networks for Health Management of Energy Storage Lithium-Ion Batteries: A Comprehensive Review. J. Energy Storage 2023, 73, 109069. [Google Scholar] [CrossRef]

- Wei, Z.; Li, P.; Cao, W.; Chen, H.; Wang, W.; Yu, Y.; He, H. Machine Learning-Based Hybrid Thermal Modeling and Diagnostic for Lithium-Ion Battery Enabled by Embedded Sensing. Appl. Therm. Eng. 2022, 216, 119059. [Google Scholar] [CrossRef]

- Hossain Lipu, M.S.; Ansari, S.; Miah, M.S.; Meraj, S.T.; Hasan, K.; Shihavuddin, A.S.M.; Hannan, M.A.; Muttaqi, K.M.; Hussain, A. Deep Learning Enabled State of Charge, State of Health and Remaining Useful Life Estimation for Smart Battery Management System: Methods, Implementations, Issues and Prospects. J. Energy Storage 2022, 55, 105752. [Google Scholar] [CrossRef]

- Bai, G.; Su, Y.; Rahman, M.M.; Wang, Z. Prognostics of Lithium-Ion Batteries Using Knowledge-Constrained Machine Learning and Kalman Filtering. Reliab. Eng. Syst. Saf. 2023, 231, 108944. [Google Scholar] [CrossRef]

- Samanta, A.; Williamson, S.S. A Comprehensive Review of Lithium-Ion Cell Temperature Estimation Techniques Applicable to Health-Conscious Fast Charging and Smart Battery Management Systems. Energies 2021, 14, 5960. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Pang, Q.; Wang, J.; Lian, Y.; Ouyang, M.; Burke, A.F. Battery Prognostics and Health Management from a Machine Learning Perspective. J. Power Sources 2023, 581, 233474. [Google Scholar] [CrossRef]

- Jiao, M.; Wang, D.; Qiu, J. A GRU-RNN Based Momentum Optimized Algorithm for SOC Estimation. J. Power Sources 2020, 459, 228051. [Google Scholar] [CrossRef]

- Khawaja, Y.; Shankar, N.; Qiqieh, I.; Alzubi, J.; Alzubi, O.; Nallakaruppan, M.K.; Padmanaban, S. Battery Management Solutions for Li-Ion Batteries Based on Artificial Intelligence. Ain Shams Eng. J. 2023, 14, 102213. [Google Scholar] [CrossRef]

- Mamo, T.; Wang, F.K. Long Short-Term Memory with Attention Mechanism for State of Charge Estimation of Lithium-Ion Batteries. IEEE Access 2020, 8, 94140–94151. [Google Scholar] [CrossRef]

- Surya, S.; Rao, V.; Williamson, S.S. Comprehensive Review on Smart Techniques for Estimation of State of Health for Battery Management System Application. Energies 2021, 14, 4617. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Pang, Q.; Fowler, M.; Lian, Y.; Ouyang, M.; Burke, A.F. Battery Safety: Machine Learning-Based Prognostics. Prog. Energy Combust. Sci. 2024, 102, 101142. [Google Scholar] [CrossRef]

- Yang, Q.; Xu, J.; Li, X.; Xu, D.; Cao, B. State-of-Health Estimation of Lithium-Ion Battery Based on Fractional Impedance Model and Interval Capacity. Int. J. Electr. Power Energy Syst. 2020, 119, 105883. [Google Scholar] [CrossRef]

- Nawaz, M.; Ahmed, J.; Abbas, G. Energy-Efficient Battery Management System for Healthcare Devices. J. Energy Storage 2022, 51, 104358. [Google Scholar] [CrossRef]

- Park, K.; Choi, Y.; Choi, W.J.; Ryu, H.Y.; Kim, H. LSTM-Based Battery Remaining Useful Life Prediction with Multi-Channel Charging Profiles. IEEE Access 2020, 8, 20786–20798. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Saad, M.H.; Ayob, A. Neural Network Approach for Estimating State of Charge of Lithium-Ion Battery Using Backtracking Search Algorithm. IEEE Access 2018, 6, 10069–10079. [Google Scholar] [CrossRef]

- Zhang, F.; Zhai, L.; Zhang, L.; Yi, M.; Du, B.; Li, S. A Novel Hybrid Battery Thermal Management System with Fins Added on and between Liquid Cooling Channels in Composite Phase Change Materials. Appl. Therm. Eng. 2022, 207, 118198. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, F.; Yang, W.; Gui, Y.; Zhang, Y. A Hybrid Thermal Management System with Liquid Cooling and Composite Phase Change Materials Containing Various Expanded Graphite Contents for Cylindrical Lithium-Ion Batteries. Appl. Therm. Eng. 2022, 200, 117702. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z.; Liu, X.; Zhao, J. Investigation of Power Battery Thermal Management by Using Mini-Channel Cold Plate. Energy Convers. Manag. 2015, 89, 387–395. [Google Scholar] [CrossRef]

- Hasan, M.K.; Mahmud, M.; Ahasan Habib, A.K.M.; Motakabber, S.M.A.; Islam, S. Review of Electric Vehicle Energy Storage and Management System: Standards, Issues, and Challenges. J. Energy Storage 2021, 41, 102940. [Google Scholar] [CrossRef]

- ISO 12405-4:2018; Electrically Propelled Road Vehicles—Test Specification for Lithium-Ion Traction Battery Packs and Systems—Part 4: Performance Testing. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://bit.ly/3wxWXrL (accessed on 19 January 2024).

- UN38.3 Certification for Lithium Batteries. Electrically Propelled Road Vehicles-Test Specification for Lithium-Ion Traction Battery Packs and Systems. Available online: https://bit.ly/3TgkNRD (accessed on 19 January 2024).

- Wang, Y.; Zhang, X.; Li, K.; Zhao, G.; Chen, Z. Perspectives and Challenges for Future Lithium-Ion Battery Control and Management. eTransportation 2023, 18, 100260. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Jaguemont, J.; Kalogiannis, T.; Karimi, D.; He, J.; Jin, L.; Xie, P.; Van Mierlo, J.; Berecibar, M. A Novel Liquid Cooling Plate Concept for Thermal Management of Lithium-Ion Batteries in Electric Vehicles. Energy Convers. Manag. 2021, 231, 113862. [Google Scholar] [CrossRef]

- Yue, Q.L.; He, C.X.; Sun, J.; Xu, J.B.; Zhao, T.S. A Passive Thermal Management System with Thermally Enhanced Water Adsorbents for Lithium-Ion Batteries Powering Electric Vehicles. Appl. Therm. Eng. 2022, 207, 118156. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, Z.; Song, G. Thermal Management of a Li-Ion Battery Pack Employing Water Evaporation. J. Power Sources 2017, 360, 166–171. [Google Scholar] [CrossRef]

- Shahjalal, M.; Shams, T.; Islam, M.E.; Alam, W.; Modak, M.; Hossain, S.B.; Ramadesigan, V.; Ahmed, M.R.; Ahmed, H.; Iqbal, A. A Review of Thermal Management for Li-Ion Batteries: Prospects, Challenges, and Issues. J. Energy Storage 2021, 39, 102518. [Google Scholar] [CrossRef]

- Shen, Z.G.; Chen, S.; Liu, X.; Chen, B. A Review on Thermal Management Performance Enhancement of Phase Change Materials for Vehicle Lithium-Ion Batteries. Renew. Sustain. Energy Rev. 2021, 148, 111301. [Google Scholar] [CrossRef]

- Samimi, F.; Babapoor, A.; Azizi, M.; Karimi, G. Thermal Management Analysis of a Li-Ion Battery Cell Using Phase Change Material Loaded with Carbon Fibers. Energy 2016, 96, 355–371. [Google Scholar] [CrossRef]

- Hossain Lipu, M.S.; Hannan, M.A.; Karim, T.F.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Miah, M.S.; Indra Mahlia, T.M. Intelligent Algorithms and Control Strategies for Battery Management System in Electric Vehicles: Progress, Challenges and Future Outlook. J. Clean. Prod. 2021, 292, 126044. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Y.; Xing, G.; Chou, S.L.; Tang, Y. Electrochemical Energy Storage Devices Working in Extreme Conditions. Energy Environ. Sci. 2021, 14, 3323–3351. [Google Scholar] [CrossRef]

- Li, Y.; Yu, L.; Hu, W.; Hu, X. Thermotolerant Separators for Safe Lithium-Ion Batteries under Extreme Conditions. J. Mater. Chem. A Mater. 2020, 8, 20294–20317. [Google Scholar] [CrossRef]

| Ref. | BTMS Method | Operating Principle | Key Findings | Advantages | Disadvantages |

|---|---|---|---|---|---|

| [24] | Active | Uses forced air flow to cool the batteries in a rectangular container. | Modifications to outlet size and shape significantly decrease system temperature, improves cooling uniformity. | Requires no moving parts, improves temperature uniformity. | Limited heat transfer capacity, less effective for high thermal loads. |

| [25] | Active | Circulates water around the battery pack to dissipate heat. | More effective for thermal management at low cycling rates. | Effective for thermal management at low cycling rates, improves thermal performance. | Not as effective at high cycling rates, may require combination with other systems. |

| [26] | Passive | Uses PCMs with applied pressure to enhance heat dissipation. | PCMs show the most promising performance compared to traditional active air/liquid cooling methods. | Maintains stable temperatures without energy consumption, improved performance with pressure. | Increased mechanical complexity and costs due to pressure application. |

| [27] | Passive | Uses PCMs, such as paraffin, to absorb and release heat during phase change. | Provides more uniform temperature distribution compared to air-cooling and liquid cooling. | Effective thermal management, uniform temperature distribution, paraffin is resistant and safe. | Low thermal conductivity of paraffin, slow thermal response. |

| [28] | Passive | Proposes a passive BTMS using a tetrahedral lattice porous plate for drone batteries. | Significant reduction in maximum temperature and thermal deviation on the battery surface. | Lightweight, requires no additional equipment, mechanically protects the battery. | Minimal weight increase, challenges in heat management across different operation modes. |

| [29] | Passive | Based on using PCMs to control temperature through heat absorption and release. | PCM-based BTMSs stand out for their cost-effectiveness and ability to maintain temperature uniformity. | Cost-effective, simple installation, minimal space required, excellent temperature uniformity. | Challenges in PCM application, such as low thermal conductivity and rigidity. |

| [30] | Hybrid | It combines the high heat absorption of PCMs with the active and localized cooling of thermoelectric coolers (TECs). | Delayed TEC current after PCM reaches 80% melting improves temperature uniformity and energy efficiency. | Improved temperature control, utilizes latent heat of PCMs, active cooling of TEC. | More complex than passive systems, higher cost, TEC requires energy, potential temperature variation. |

| [31] | Hybrid | Uses active liquid cooling combined with passive cooling materials like PCMs. | Effectively prevents TR propagation; maintains uniform temperature during normal operation. | Effective against TR propagation, maintains thermal uniformity, combines active and passive. | Increased complexity and potential additional costs compared to single systems. |

| [32] | Hybrid | Integrates liquid cooling systems with passive systems for optimal thermal management. | Considered more viable for future thermal management; effectively cools high-energy/power battery packs. | Combines the advantages of active and passive systems, enhancing overall thermal management. | More complex and expensive than single cooling systems. |

| [33] | Hybrid | Combination of PCMs with active cooling methods for effective thermal management. | Highlights benefits of integrated solutions, needs further research for higher conductivity PCMs. | Improves thermal uniformity and performance, optimizes temperature. | Challenges in integration, need for high conductivity PCMs, environmental impact of larger PCM volume. |

| [34] | Hybrid | Uses different techniques like air, liquid, and PCMs to cool batteries. | PCM-RT35 showed the best temperature control ability at ambient temperatures of 20 °C or 30 °C. | PCMs offer a passive approach with high efficiency, good temperature management. | PCMs have limited heat absorption capacity, complexity in managing multiple systems. |

| Ref. | Innovations in Thermal Efficiency | Advantages | Disadvantages | Challenges |

|---|---|---|---|---|

| [35] | Use of PCMs | They absorb latent heat during phase transition, keeping the battery temperature within a safe range. | Low thermal conductivity, which limits the ability to dissipate heat evenly. | Development of materials with higher thermal conductivity and life cycle. |

| [51] | Use of miniature channel cooling plates | Increased contact area between the coolant and the cells, which improves heat transfer. | Higher complexity and manufacturing cost. | Optimize channel distribution to reduce pressure loss. |

| [49] | Phase change composite materials | They combine the advantages of PCMs with those of conductive materials, improving thermal conductivity. | Higher production cost. | Develop composite materials with higher energy density. |

| [55] | Hybrid system combining heat pipes with evaporative cooling | Improves thermal efficiency in high-current applications. | Increased complexity and manufacturing cost. | Optimize system design to reduce pressure losses. |

| [58] | Graphene composite structures | Excellent thermal conductivity, which improves heat distribution within the battery. | High production cost. | Develop more efficient production methods. |

| [56] | Miniature channel design with tilt angles | Reduces pressure losses, improving heat transfer. | Excessively high tilt angles can cause leakage problems. | Optimize the tilt angle for maximum thermal efficiency. |

| [50] | Passive interfacial thermal regulator based on shape memory alloy | It changes its thermal conductance reversibly, improving battery performance in hot and cold climates. | Challenges related to the development of shape memory alloys with increased thermal cycling and long-term stability. | Optimize device design to facilitate integration into modules and battery packs. |

| [59] | Hybrid system combining heat pipes with evaporative cooling | Improves thermal efficiency in high-current applications. | Increased complexity and manufacturing cost. | Optimize system design to reduce pressure losses. |

| [53] | Modular cooling plate design | Greater versatility and adaptability to variable configurations. | Modular designs require joints and connections that can increase the overall thermal resistance. | Achieve large-scale manufacturing of these modular systems in a cost-effective manner. |

| [57] | System based on liquid cooling of honeycomb structure and phase-change materials | Significantly reduces the maximum temperature and temperature difference in the batteries. | Structural and cooling complexity leads to higher manufacturing costs. | Evaluation under extreme conditions such as actual loading and unloading cycles or thermal packaging situations. |

| [60] | Modular liquid cooling system | Greater versatility and adaptability to variable configurations. | Modular designs require joints and connections that can increase the overall thermal resistance. | Achieve large-scale manufacturing of these modular systems in a cost-effective manner. |

| [61] | System based on liquid cooling of honeycomb structure and phase-change materials | Significantly reduces the maximum temperature and temperature difference in the batteries. | Compact structure and uniform heat dissipation. | Evaluate its performance under extreme conditions such as real loading and unloading cycles or thermal packaging situations. |

| [54] | Phase change composite materials | Improve thermal uniformity within the battery modules. | Composite materials tend to be more expensive to produce. | Develop composite materials with higher effective thermal conductivity. |

| [52] | Mini-channel cooling plates with spine-shaped fins | They improve heat transfer performance and reduce thermal gradients. | Horizontal fins cause a significantly higher pressure loss. | Optimize the geometry and arrangement of the fins to achieve the optimum balance between heat transfer and pressure loss. |

| Thermal Management Technology | Detailed Description | Relation to Thermal Leakage | Specific Benefits | Limitations and Challenges |

|---|---|---|---|---|

| Hybrid Systems Refs. [95,99] | The authors combine the efficiency of liquid cooling with the heat storage capacity of PCMs. They offer a dynamic and adaptive response to temperature variations. | They provide balanced thermal management, absorbing excess heat and releasing it when needed, which is crucial in fast-load or high-demand situations. | They significantly improve battery life and safety by adapting to different operating conditions. | They require a complex design and may have a higher cost. |

| Liquid Cooling Refs. [94,98,100,101] | It uses a fluid, usually water or a mixture of water and glycol, to efficiently transfer heat from the batteries to a heat exchanger. This technique is especially effective in fast charging or high-power density situations. | Essential to prevent overheating at high temperatures and maintain a stable thermal environment, reducing the risk of TR and battery degradation. | It provides fast and uniform heat dissipation, is scalable, and can be adjusted to different battery sizes and designs. | It can be susceptible to leaks and requires regular maintenance, in addition to an efficient pumping system. |

| PCM Refs. [49,102,103,104] | PCMs absorb and release heat during their phase transitions (solid to liquid and vice versa), allowing them to maintain a constant temperature in the battery. They are particularly useful in variable charge and discharge conditions. | They offer passive thermal response, stabilizing the internal temperature of the battery and reducing TR in extreme climates. | They provide high thermal storage capacity with minimal change in temperature, which is ideal for space-constrained applications. | They may have limitations in thermal conductivity and cycle life, as well as challenges in integration with other battery components. |

| Active Heating Systems Refs. [1,98,105] | These systems use heating elements or strategies such as battery preheating to maintain the optimum temperature in cold environments, thus improving battery response and efficiency. | They are essential to mitigate TR at low temperatures, ensuring that the battery operates efficiently and avoiding problems such as electrolyte crystallization. | Improve performance and safety in cold climates, extending battery life and preventing damage to internal components. | They increase energy consumption and may require additional time before use to reach optimum temperature. |

| Phase Shift Cooling Ref. [106] | It uses the evaporation and condensation of a refrigerant fluid to effectively absorb and dissipate heat. This method is based on the latent heat of phase change of the refrigerant, offering high heat dissipation capacity. | Efficiently controls temperature under peak load and unload, preventing overheating and excessive thermal runaway. | It offers precise thermal control and is capable of handling high thermal loads, making it suitable for energy-intensive applications. | It requires careful design to ensure the efficiency of the phase change system and can present challenges in refrigerant replenishment. |

| Thermal Management with AI Refs. [95,105] | It implements AI algorithms to monitor and adjust thermal management in real time, based on usage patterns and environmental conditions. | It enables fast and accurate response to temperature variations, optimizing thermal management to reduce TR and improve efficiency. | Maximizes battery life and performance by continuously adapting to changing conditions, improving safety and efficiency. | It depends on the accuracy of algorithms and data collection and may require constant updates and maintenance. |

| Thermotolerant Separators Ref. [107] | Advanced separators designed to withstand high temperatures without losing functionality, improving battery stability and safety in extreme heat conditions. | They prevent overheating and reduce TR by maintaining structural and functional integrity at high temperatures, avoiding internal short circuits. | They significantly increase safety in extreme conditions, resisting high temperatures without degrading. | They can increase the cost of battery manufacturing and present challenges in integration with other components. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz, Y.; Arévalo, P.; Peña, D.; Jurado, F. Recent Advances in Thermal Management Strategies for Lithium-Ion Batteries: A Comprehensive Review. Batteries 2024, 10, 83. https://doi.org/10.3390/batteries10030083

Ortiz Y, Arévalo P, Peña D, Jurado F. Recent Advances in Thermal Management Strategies for Lithium-Ion Batteries: A Comprehensive Review. Batteries. 2024; 10(3):83. https://doi.org/10.3390/batteries10030083

Chicago/Turabian StyleOrtiz, Yadyra, Paul Arévalo, Diego Peña, and Francisco Jurado. 2024. "Recent Advances in Thermal Management Strategies for Lithium-Ion Batteries: A Comprehensive Review" Batteries 10, no. 3: 83. https://doi.org/10.3390/batteries10030083

APA StyleOrtiz, Y., Arévalo, P., Peña, D., & Jurado, F. (2024). Recent Advances in Thermal Management Strategies for Lithium-Ion Batteries: A Comprehensive Review. Batteries, 10(3), 83. https://doi.org/10.3390/batteries10030083