Recent Trends of Recycling and Upcycling of Polymers and Composites: A Comprehensive Review

Abstract

:1. Introduction

2. Recycling Technologies of Thermoset Polymers and Their Composites

2.1. Thermal Processes

2.1.1. Fluidised Bed

2.1.2. Pyrolysis

- Pyrolysis chamber; the material is inserted to be pyrolysed;

- Gas inlet, located at beginning of the chamber; it is connected with the inert gas to ensure proper conditions;

- Gas outlet located at the end of the chamber to ensure the proper removal of gas and liquid by-products;

- Condenser chamber for condensable gases;

- Scrubber unit;

- Gas filtration system.

2.2. Chemical Processes—Solvolysis

2.2.1. Low Temperature and Pressure Solvolysis

2.2.2. Solvolysis at Near- or Super-Critical Condition

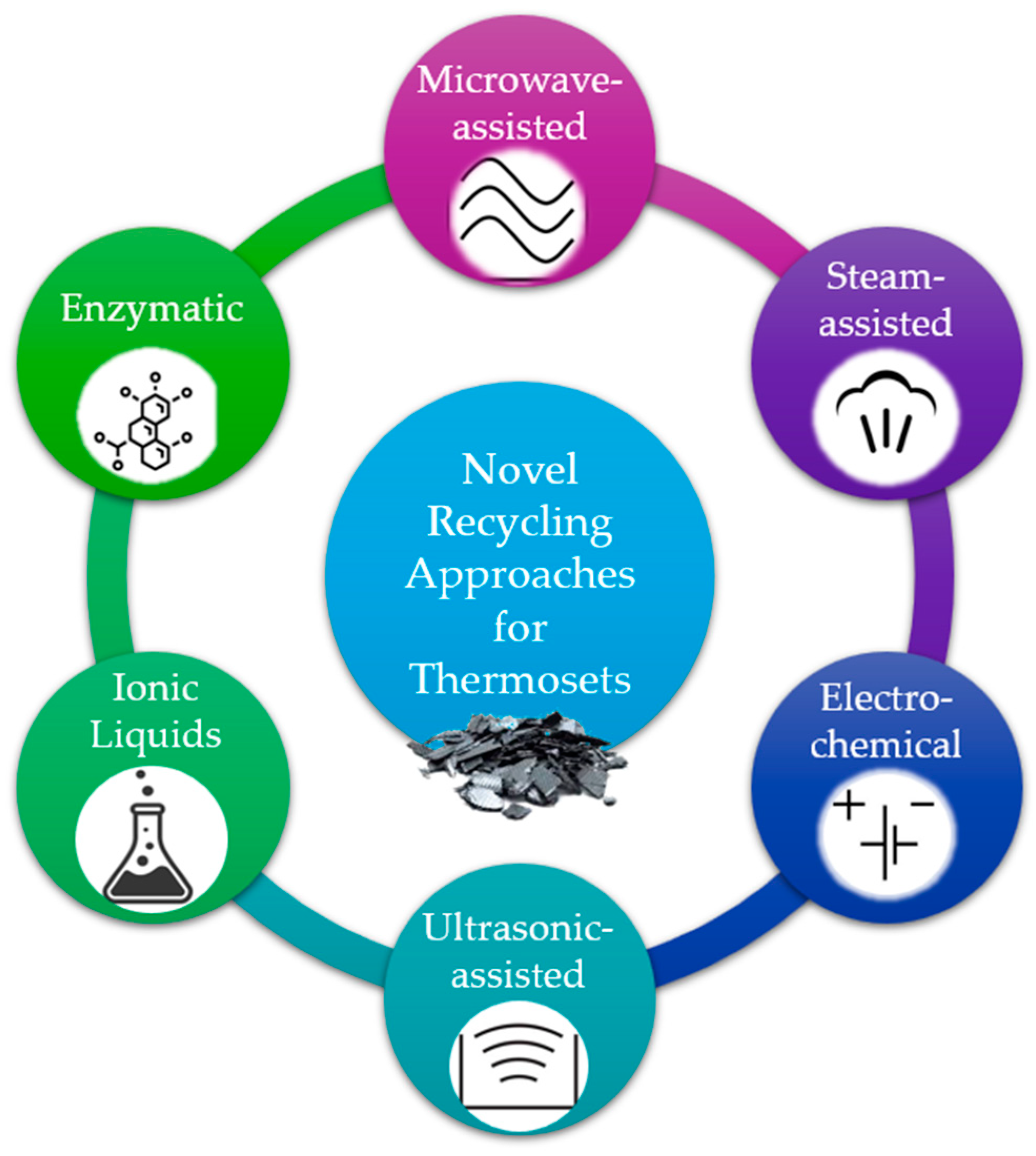

2.3. Extraordinary and Combined Recycling Processes

2.3.1. Microwave-Assisted Recycling

2.3.2. Superheated Steam Recycling

2.3.3. Electrochemical Recycling

2.3.4. Ultrasonic Recycling

2.3.5. Recycling with Ionic Liquids

2.3.6. Biological Recycling

2.4. Upcycling of Thermoset Composites to Vitrimers

2.5. Upcycling of Thermoset Composites

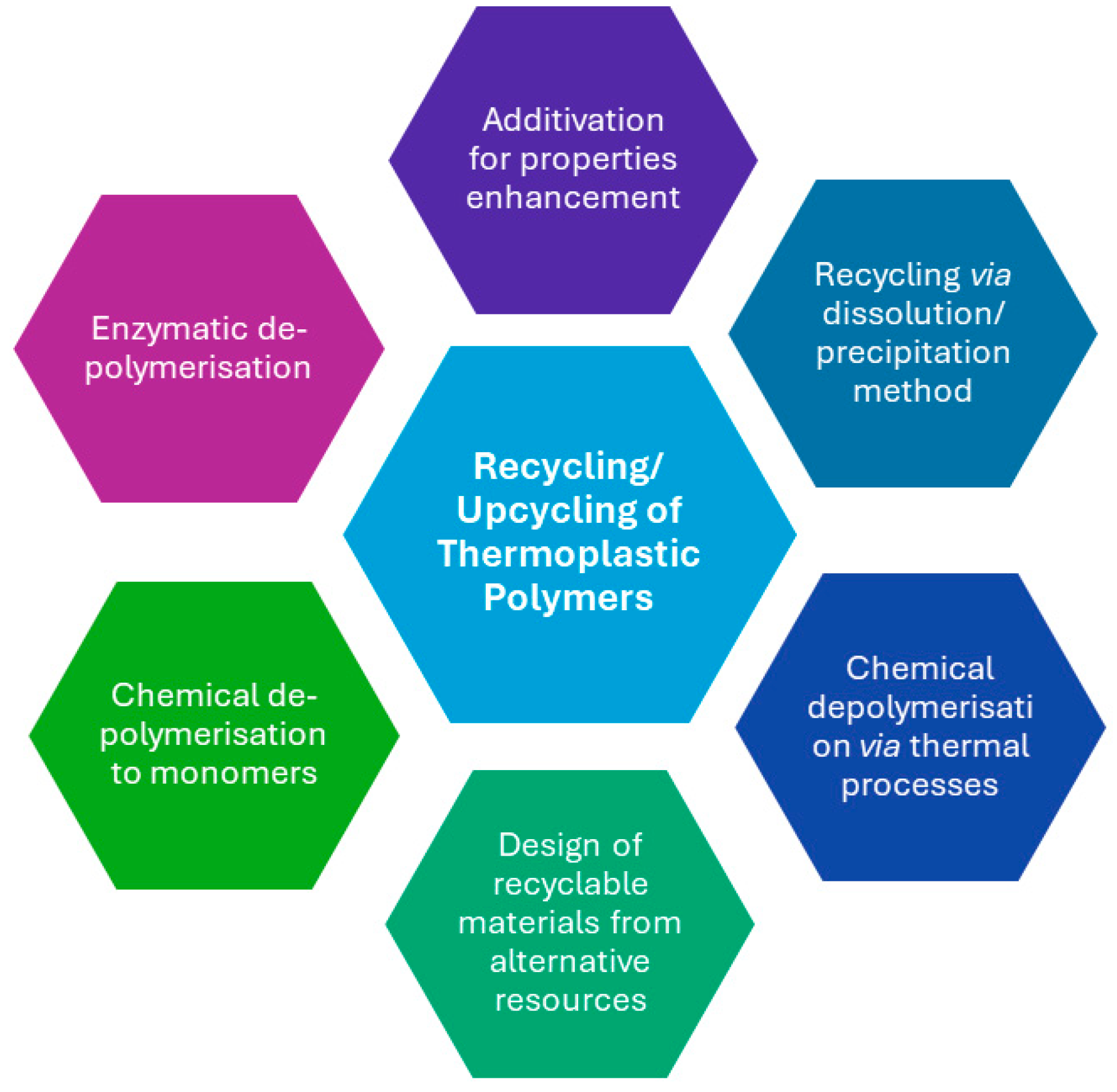

3. Recycling Technologies of Thermoplastic Polymers

3.1. Overview

3.2. Mechanical Recycling and Upcycling

| Sorting Method | Main Principle | Ref. |

|---|---|---|

| Magnetic density separation | A magnetic mixture is used to separate plastics by their differences in densities. | [129] |

| Electrostatic separation | Electrostatic field is used to separate different plastics according due to their differences in electrical properties. Usually, friction is used to electrostatically charge the different plastics and then the fractions are separated due to their negative or positive charges. | [129] |

| Froth flotation separation | In this method, different plastics are separated by hydrophobic and hydrophilic properties. | [130] |

| NIR separation | Separation based in the different spectrums of different polymers. | [131] |

| LIBS separation | Based on the different atomic emission spectrums of different polymers. | [132] |

3.2.1. Compatibilizers

3.2.2. Impact Modifiers

3.2.3. Plasticizers

3.2.4. Antioxidants and UV Stabilizers

3.3. Recycling of Multilayer Plastic Materials

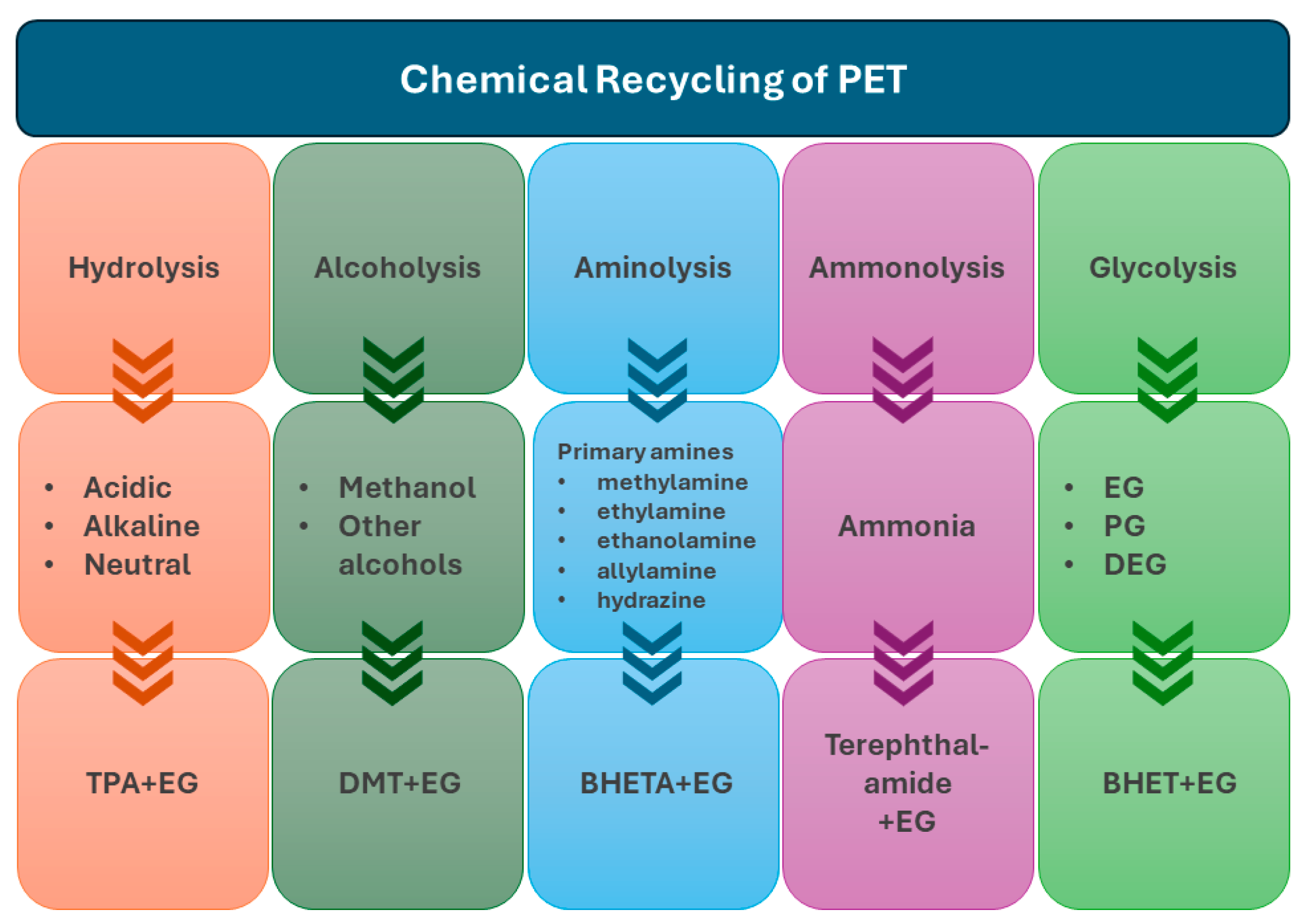

3.4. Chemical Recycling and Upcycling

- Polyolefins (such as PE, PP) that can be chemically recycled via thermal degradation;

3.4.1. Pyrolysis

- Initiation: scission of the initial bonds in the chain to produce two radicals (may arise at either random or end-chain positions);

- Hydrogen transfer reactions: intermolecular or intramolecular reactions that result in the formation of olefinic species and polymeric fragments and also the generation of secondary radicals through hydrogen abstraction between a primary radical and a polymeric fragment;

- Β-cleavage of secondary radicals: resulting in an end-chain olefinic group and a primary radical;

- Termination: coupling of two primary radicals or the disproportionation of primary macroradicals.

3.4.2. Depolymerisation to Monomers

3.4.3. Other Upcycling Approaches for Thermoplastics

3.5. Enzymatic Recycling and Upcycling

3.6. Recycling Technologies for Thermoplastic Composites

4. Conclusions and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Walker-Franklin, I.; Jambeck, J. Plastics; Essential Knowledge series, eBook; The MIT Press: Cambridge, MA, USA, 2023; pp. 11–20. [Google Scholar]

- Recycling of Thermoset Materials: The Potential Impact on Reducing Fossil-Based Plastic Waste. Available online: https://www.prescouter.com/inquiry/recycling-of-thermoset-materials/ (accessed on 14 March 2024).

- Johst, P.; Kucher, M.; Bühl, M.; Schulz, P.; Kupfer, R.; Schilling, L.; Santos, R.M.; Carneiro, C.; Voigt, P.; Modler, N.; et al. Identification and Environmental Assessments for Different Scenarios of Repurposed Decommissioned Wind Turbine Blades. Mater. Circ. Econ. 2023, 5, 13. [Google Scholar] [CrossRef]

- Johst, P.; Chatzipanagiotou, K.-R.; Kucher, M.; Zschiebsch, W.; Voigt, P.; Breinl, D.; Koumoulos, E.P.; Böhm, R. Concept and Life Cycle Assessment of a Tiny House Made from Root Section Structures of a Decommissioned Large-Scale Wind Turbine Blade as a Repurposed Application. Mater. Circ. Econ. 2024, 6, 5. [Google Scholar] [CrossRef]

- Carbon Fibre Composites Market—By End-Use (Aerospace, Automotive, Wind Turbines, Sport & Leisure, Civil Engineering, Marine), By Matrix Material (Polymer [Thermosetting, Thermoplastics], Carbon, Ceramic, Metal, Hybrid) & Forecast, 2022–2030; For Insights Consultancy: New York, NY, USA, 2023.

- Composites Germany—Results of the 20th Composites Market Survey Now Available, PRESS RELEASE February 2023, No. 1/2023. Available online: https://www.composites-germany.org/index.php/en/news-en/market-information/737-20th-composites-market-survey (accessed on 14 March 2024).

- University of Sydney. The Looming 840,000 ton Waste Problem that Isn’t Single-Use Plastics. ScienceDaily. ScienceDaily, 3 July 2023. Available online: https://www.sydney.edu.au/news-opinion/news/2023/07/03/-the-looming-840-000-tonne-waste-problem-that-isn-t-single-use-p.html (accessed on 14 March 2024).

- Schmid, M.; Gonzalez Ramon, N.; Dierckx, A.; Wegman, T. Accelerating Wind Turbine Blade Circularity; WindEurope; Cefic; EuCIA: Brussels, Belgium, 2020; Available online: https://windeurope.org/intelligence-platform/product/accelerating-wind-turbine-blade-circularity/ (accessed on 14 March 2024).

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-waste Monitor—2017, United Nations University (UNU), International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Vienna. Available online: https://www.itu.int/en/ITU-D/Environment/Pages/Toolbox/Global-E-waste-Monitor-2017.aspx (accessed on 14 March 2024).

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential. United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)—Co-Hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Rotterdam. Available online: https://collections.unu.edu/eserv/UNU:7737/GEM_2020_def_july1.pdf (accessed on 14 March 2024).

- UNEP (2014) Valuing Plastics: The Business Case for Measuring, Managing and Disclosing Plastic Use in the Consumer Goods Industry. Available online: https://wedocs.unep.org/handle/20.500.11822/9238;jsessionid=5FE97F45C8AC6A7514ACBF870A6D35F6 (accessed on 14 March 2024).

- Ellen MacArthur Foundation. The Global Commitment 2021; Ellen MacArthur Foundation: Isle of Wight, UK, 2021. [Google Scholar]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future; Ellen MacArthur Foundation: Isle of Wight, UK, 2017. [Google Scholar]

- Teresa Haukkala, K.N.; Turunen, L.L.M. Fashion in Turmoil: Impact of the COVID-19 Pandemic on Finland’s Textile and Fashion Industry. Sustain. Sci. Pract. Policy 2023, 19, 2173424. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, P.; Schartup, A.T.; Zhang, Y. Plastic Waste Release Caused by COVID-19 and Its Fate in the Global Ocean. Proc. Natl. Acad. Sci. USA 2021, 118, e2111530118. [Google Scholar] [CrossRef]

- Shams, M.; Alam, I.; Mahbub, M.S. Plastic Pollution during COVID-19: Plastic Waste Directives and Its Long-Term Impact on the Environment. Environ. Adv. 2021, 5, 100119. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Policy. 2020. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 14 March 2024).

- Directive (EU). 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment (Text with EEA Relevance). Off. J. Eur. Union 2019, L155/I, 1–19. [Google Scholar]

- Directorate-General for Environment Proposal for a Regulation on Circularity Requirements for Vehicle Design and on Management of End-of-Life Vehicles, 13 July 2023. Available online: https://environment.ec.europa.eu/publications/proposal-regulation-circularity-requirements-vehicle-design-and-management-end-life-vehicles_en (accessed on 14 March 2024).

- Stapleton, M.J.; Ansari, A.J.; Ahmed, A.; Hai, F.I. Evaluating the Generation of Microplastics from an Unlikely Source: The Unintentional Consequence of the Current Plastic Recycling Process. Sci. Total Environ. 2023, 902, 166090. [Google Scholar] [CrossRef]

- Guo, Y.; Xia, X.; Ruan, J.; Wang, Y.; Zhang, J.; LeBlanc, G.A.; An, L. Ignored Microplastic Sources from Plastic Bottle Recycling. Sci. Total Environ. 2022, 838, 156038. [Google Scholar] [CrossRef]

- Suzuki, G.; Uchida, N.; Tanaka, K.; Higashi, O.; Takahashi, Y.; Kuramochi, H.; Yamaguchi, N.; Osako, M. Global Discharge of Microplastics from Mechanical Recycling of Plastic Waste. Environ. Pollut. 2024, 348, 123855. [Google Scholar] [CrossRef]

- Jacob, J.; Linson, N.; Binoj, J.S.; Mansingh, B.B.; Kuriakose, S.; Thomas, S. Chapter 2—Polymers and Fillers Used in the Packaging Industry. In Nanostructured Materials for Food Packaging Applications; Jacob, J., Cacciotti, I., Thomas, S., Eds.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2024; pp. 31–48. ISBN 978-0-323-99525-2. [Google Scholar]

- Eriksen, M.K.; Pivnenko, K.; Olsson, M.E.; Astrup, T.F. Contamination in Plastic Recycling: Influence of Metals on the Quality of Reprocessed Plastic. Waste Manag. 2018, 79, 595–606. [Google Scholar] [CrossRef] [PubMed]

- Pöhlein, M.; Llopis, A.S.; Wolf, M.; van Eldik, R. Rapid Identification of RoHS-Relevant Flame Retardants from Polymer Housings by Ultrasonic Extraction and RP-HPLC/UV. J. Chromatogr. A 2005, 1066, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Gripon, L.; Belyamani, I.; Legros, B.; Seaudeau-Pirouley, K.; Lafranche, E.; Cauret, L. Brominated Flame Retardants Extraction from Waste Electrical and Electronic Equipment-Derived ABS Using Supercritical Carbon Dioxide. Waste Manag. 2021, 131, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Preetam, A.; Jadhao, P.R.; Naik, S.N.; Pant, K.K.; Kumar, V. Supercritical Fluid Technology—An Eco-Friendly Approach for Resource Recovery from e-Waste and Plastic Waste: A Review. Sep. Purif. Technol. 2023, 304, 122314. [Google Scholar] [CrossRef]

- Strobl, L.; Diefenhardt, T.; Schlummer, M.; Leege, T.; Wagner, S. Recycling Potential for Non-Valorized Plastic Fractions from Electrical and Electronic Waste. Recycling 2021, 6, 33. [Google Scholar] [CrossRef]

- Devic, A.C.; Ierides, M.; Fernandez, V.; Verbenkov, M.; Bax, L. Polymer Composites Circularity, Suschem Material Working Group. 2018. Available online: https://suschem.org/publications/ (accessed on 14 March 2024).

- Ratna, D. Recent Advances and Applications of Thermoset Resins. Chapter 2—Properties and Processing of Thermoset Resin, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Guo, Q. (Ed.) Thermosets: Structure, Properties, and Applications; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780081010211. [Google Scholar]

- Morici, E.; Dintcheva, N.T. Recycling of Thermoset Materials and Thermoset-Based Composites: Challenge and Opportunity. Polymers 2022, 14, 4153. [Google Scholar] [CrossRef] [PubMed]

- Torres, A.; de Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Legarreta, J.A.; Cabrero, M.A.; González, A.; Chomón, M.J.; Gondra, K. Recycling by Pyrolysis of Thermoset Composites: Characteristics of the Liquid and Gaseous Fuels Obtained. Fuel 2000, 79, 897–902. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials-Current Status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Kennerley, J.R.; Kelly, R.M.; Fenwick, N.J.; Pickering, S.J.; Rudd, C.D. The Characterisation and Reuse of Glass Fibres Recycled from Scrap Composites by the Action of a Fluidised Bed Process. Compos. Part A Appl. Sci. Manuf. 1998, 29, 839–845. [Google Scholar] [CrossRef]

- Pickering, S.J.; Kelly, R.M.; Kennerley, J.R.; Rudd, C.D.; Fenwick, N.J. A Fluidised-Bed Process for the Recovery of Glass Fibres from Scrap Thermoset Composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

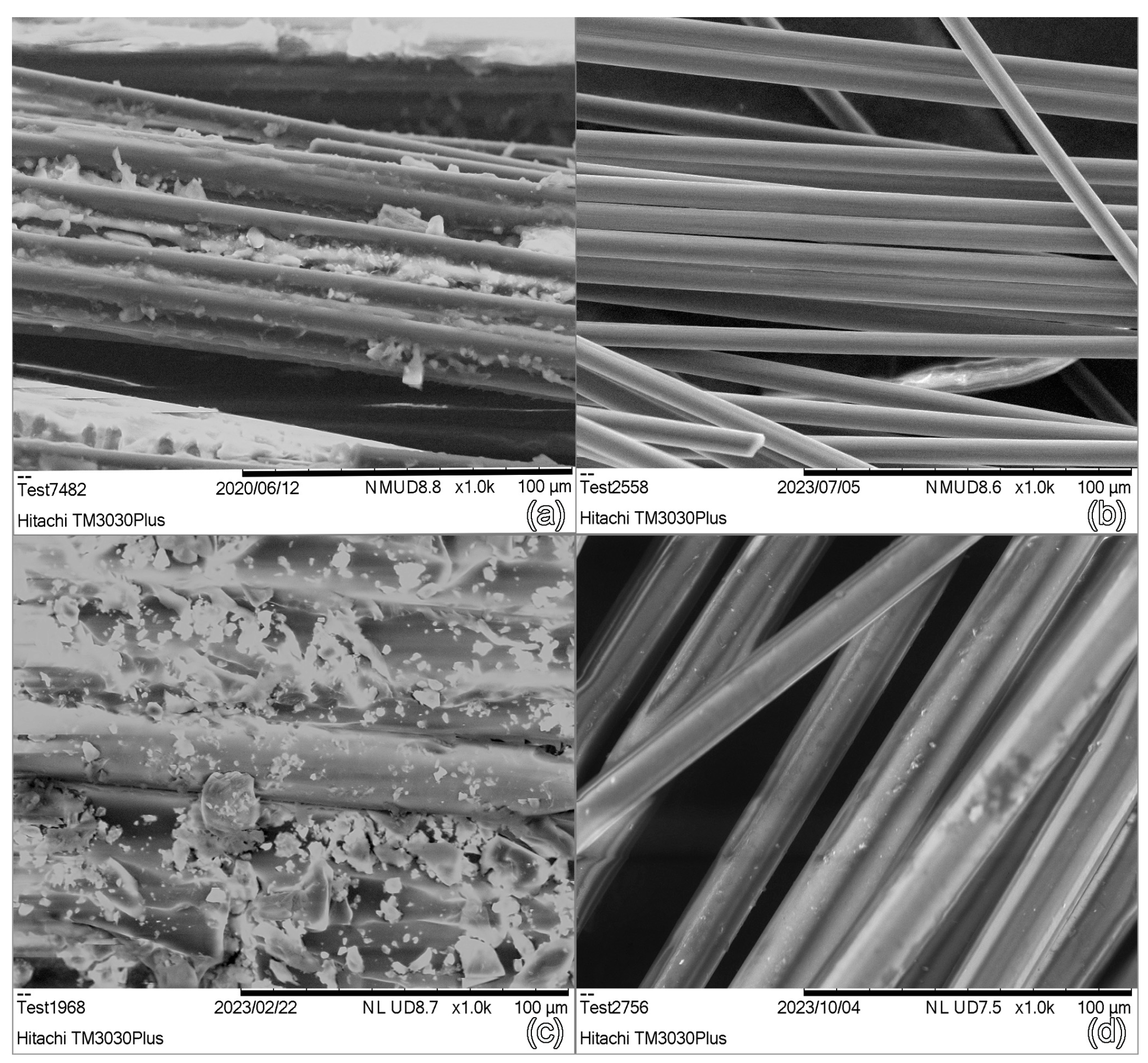

- Jiang, G.; Pickering, S.J.; Walker, G.S.; Wong, K.H.; Rudd, C.D. Surface Characterisation of Carbon Fibre Recycled Using Fluidised Bed. Appl. Surf. Sci. 2008, 254, 2588–2593. [Google Scholar] [CrossRef]

- Lopez-Urionabarrenechea, A.; Gastelu, N.; Acha, E.; Caballero, B.M.; Orue, A.; Jiménez-Suárez, A.; Prolongo, S.G.; de Marco, I. Reclamation of Carbon Fibers and Added-Value Gases in a Pyrolysis-Based Composites Recycling Process. J. Clean. Prod. 2020, 273, 123173. [Google Scholar] [CrossRef]

- Pielichowski, K.; Njuguna, J.; Majka, T.M. 1—Introduction to Thermal Degradation of Polymeric Materials. In Thermal Degradation of Polymeric Materials, 2nd ed.; Pielichowski, K., Njuguna, J., Majka, T.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–8. ISBN 978-0-12-823023-7. [Google Scholar]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling Following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Bradna, P.; Zima, J. Compositional Analysis of Epoxy Matrices of Carbon-Fibre Composites by Pyrolysis—Gas Chromatography/Mass Spectrometry. J. Anal. Appl. Pyrolysis 1992, 24, 75–85. [Google Scholar] [CrossRef]

- Evans, S.J.; Haines, P.J.; Skinner, G.A. Pyrolysis–Gas-Chromatographic Study of a Series of Polyester Thermosets. J. Anal. Appl. Pyrolysis 2000, 55, 13–28. [Google Scholar] [CrossRef]

- Termine, S.; Naxaki, V.; Semitekolos, D.; Trompeta, A.-F.; Rovere, M.; Tagliaferro, A.; Charitidis, C. Investigation of Carbon Fibres Reclamation by Pyrolysis Process for Their Reuse Potential. Polymers 2023, 15, 768. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Jones, N.; Williams, P.T. Recycling of Fibre-Reinforced Polymeric Waste by Pyrolysis: Thermo-Gravimetric and Bench-Scale Investigations. J. Anal. Appl. Pyrolysis 2003, 70, 315–338. [Google Scholar] [CrossRef]

- Blazsó, M. Composition of Liquid Fuels Derived from the Pyrolysis of Plastics. In Feedstock Recycling and Pyrolysis of Waste Plastics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; pp. 315–344. ISBN 9780470021545. [Google Scholar]

- Xu, M.; Di, J.; Wu, Y.; Meng, X.; Ji, H.; Jiang, H.; Li, J.; Lu, Q. Insights into the Pyrolysis Mechanisms of Epoxy Resin Polymers Based on the Combination of Experiments and ReaxFF-MD Simulation. Chem. Eng. J. 2023, 473, 145404. [Google Scholar] [CrossRef]

- Ge, L.; Li, X.; Feng, H.; Xu, C.; Lu, Y.; Chen, B.; Li, D.; Xu, C. Analysis of the Pyrolysis Process, Kinetics and Products of the Base Components of Waste Wind Turbine Blades (Epoxy Resin and Carbon Fiber). J. Anal. Appl. Pyrolysis 2023, 170, 105919. [Google Scholar] [CrossRef]

- Adler, S.E.; Güttler, B.E.; Bendler, L.; Friedrich, K. Evaluation of Recycled Carbon Fibre/Epoxy Composites: Thermal Degradation Behaviour of Pyrolysed and Virgin Carbon Fibres Using Thermogravimetric Analysis. Adv. Ind. Eng. Polym. Res. 2021, 4, 82–92. [Google Scholar] [CrossRef]

- Nahil, M.A.; Williams, P.T. Recycling of Carbon Fibre Reinforced Polymeric Waste for the Production of Activated Carbon Fibres. J. Anal. Appl. Pyrolysis 2011, 91, 67–75. [Google Scholar] [CrossRef]

- Greco, A.; Maffezzoli, A.; Buccoliero, G.; Caretto, F.; Cornacchia, G. Thermal and Chemical Treatments of Recycled Carbon Fibres for Improved Adhesion to Polymeric Matrix. J. Compos. Mater. 2012, 47, 369–377. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Mazzocchetti, L.; Leonardi, C.; Zattini, G.; Minak, G.; Dolcini, E.; Cavazzoni, M.; Montanari, I.; Tosi, C. Recovery of Carbon Fibers from Cured and Uncured Carbon Fiber Reinforced Composites Wastes and Their Use as Feedstock for a New Composite Production. Polym. Compos. 2015, 36, 1084–1095. [Google Scholar] [CrossRef]

- Hadigheh, S.A.; Wei, Y.; Kashi, S. Optimisation of CFRP Composite Recycling Process Based on Energy Consumption, Kinetic Behaviour and Thermal Degradation Mechanism of Recycled Carbon Fibre. J. Clean. Prod. 2021, 292, 125994. [Google Scholar] [CrossRef]

- Yang, P.; Zhou, Q.; Li, X.-Y.; Yang, K.-K.; Wang, Y.-Z. Chemical Recycling of Fiber-Reinforced Epoxy Resin Using a Polyethylene Glycol/NaOH System. J. Reinf. Plast. Compos. 2014, 33, 2106–2114. [Google Scholar] [CrossRef]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; DeOto, L.; Masini, A. Recyclability and Reutilization of Carbon Fiber Fabric/Epoxy Composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, L.; Huang, Y.; Du, J. Recycling of Carbon/Epoxy Composites. J. Appl. Polym. Sci. 2004, 94, 1912–1916. [Google Scholar] [CrossRef]

- Ballout, W.; Sallem-Idrissi, N.; Sclavons, M.; Doneux, C.; Bailly, C.; Pardoen, T.; Van Velthem, P. High Performance Recycled CFRP Composites Based on Reused Carbon Fabrics through Sustainable Mild Solvolysis Route. Sci. Rep. 2022, 12, 5928. [Google Scholar] [CrossRef] [PubMed]

- Dang, W.; Kubouchi, M.; Sembokuya, H.; Tsuda, K. Chemical Recycling of Glass Fiber Reinforced Epoxy Resin Cured with Amine Using Nitric Acid. Polymer 2005, 46, 1905–1912. [Google Scholar] [CrossRef]

- Okajima, I.; Sako, T. Recycling Fiber-Reinforced Plastic Using Supercritical Acetone. Polym. Degrad. Stab 2019, 163, 1–6. [Google Scholar] [CrossRef]

- Keith, M.J.; Román-Ramírez, L.A.; Leeke, G.; Ingram, A. Recycling a Carbon Fibre Reinforced Polymer with a Supercritical Acetone/Water Solvent Mixture: Comprehensive Analysis of Reaction Kinetics. Polym. Degrad. Stab. 2019, 161, 225–234. [Google Scholar] [CrossRef]

- Henry, L.; Schneller, A.; Doerfler, J.; Mueller, W.M.; Aymonier, C.; Horn, S. Semi-Continuous Flow Recycling Method for Carbon Fibre Reinforced Thermoset Polymers by near- and Supercritical Solvolysis. Polym. Degrad. Stab. 2016, 133, 264–274. [Google Scholar] [CrossRef]

- Knight, C.C.; Zeng, C.; Zhang, C.; Wang, B. Recycling of Woven Carbon-Fibre-Reinforced Polymer Composites Using Supercritical Water. Environ. Technol. 2012, 33, 639–644. [Google Scholar] [CrossRef] [PubMed]

- Yildirir, E.; Onwudili, J.A.; Williams, P.T. Recovery of Carbon Fibres and Production of High Quality Fuel Gas from the Chemical Recycling of Carbon Fibre Reinforced Plastic Wastes. J. Supercrit. Fluids 2014, 92, 107–114. [Google Scholar] [CrossRef]

- Oliveux, G.; Bailleul, J.-L.; Salle, E.L.G. La Chemical Recycling of Glass Fibre Reinforced Composites Using Subcritical Water. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1809–1818. [Google Scholar] [CrossRef]

- Obunai, K.; Fukuta, T.; Ozaki, K. Carbon Fiber Extraction from Waste CFRP by Microwave Irradiation. Compos. Part A Appl. Sci. Manuf. 2015, 78, 160–165. [Google Scholar] [CrossRef]

- Jiang, L.; Ulven, C.A.; Gutschmidt, D.; Anderson, M.; Balo, S.; Lee, M.; Vigness, J. Recycling Carbon Fiber Composites Using Microwave Irradiation: Reinforcement Study of the Recycled Fiber in New Composites. J. Appl. Polym. Sci. 2015, 132, 42658. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Liu, C.; Mahmoodi, R.; Li, Q.; Naebe, M. Development of a Low Cost and Green Microwave Assisted Approach towards the Circular Carbon Fibre Composites. Compos. B Eng. 2020, 184, 107750. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. Development of Sustainable Microwave-Based Approach to Recover Glass Fibers for Wind Turbine Blades Composite Waste. Resour. Conserv. Recycl. 2022, 179, 106107. [Google Scholar] [CrossRef]

- Åkesson, D.; Skrifvars, M. Recycling of Thermoset Composites by Microwave Pyrolysis. In Proceedings of the ICCM International Conferences on Composite Materials (ICCM 18), Jeju Island, Republic of Korea, 21–26 August 2011. [Google Scholar]

- Cai, G.; Wada, M.; Ohsawa, I.; Kitaoka, S.; Takahashi, J. Influence of Treatment with Superheated Steam on Tensile Properties of Carbon Fiber. Compos. Part A Appl. Sci. Manuf. 2018, 107, 555–560. [Google Scholar] [CrossRef]

- Cai, G.; Wada, M.; Ohsawa, I.; Kitaoka, S.; Takahashi, J. Interfacial Adhesion of Recycled Carbon Fibers to Polypropylene Resin: Effect of Superheated Steam on the Surface Chemical State of Carbon Fiber. Compos. Part A Appl. Sci. Manuf. 2019, 120, 33–40. [Google Scholar] [CrossRef]

- Wada, M.; Kawai, K.; Suzuki, T.; Hira, H.; Kitaoka, S. Effect of Superheated Steam Treatment of Carbon Fiber on Interfacial Adhesion to Epoxy Resin. Compos. Part A Appl. Sci. Manuf. 2016, 85, 156–162. [Google Scholar] [CrossRef]

- Jeong, J.-S.; Kim, K.-W.; An, K.-H.; Kim, B.-J. Fast Recovery Process of Carbon Fibers from Waste Carbon Fibers-Reinforced Thermoset Plastics. J. Environ. Manag. 2019, 247, 816–821. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.H.; Wakisaka, M.; Nishida, H. Specific Oligomer Recovery Behavior from Cured Unsaturated Polyester by Superheated Steam Degradation. Polym. Degrad. Stab. 2019, 161, 1–6. [Google Scholar] [CrossRef]

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.-H.; Xing, F. Recycling of Carbon Fibers from Carbon Fiber Reinforced Polymer Using Electrochemical Method. Compos. Part A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Oshima, K.; Matsuda, S.; Hosaka, M.; Satokawa, S. Rapid Removal of Resin from a Unidirectional Carbon Fiber Reinforced Plastic Laminate by a High-Voltage Electrical Treatment. Sep. Purif. Technol. 2020, 231, 115885. [Google Scholar] [CrossRef]

- Mativenga, P.T.; Shuaib, N.A.; Howarth, J.; Pestalozzi, F.; Woidasky, J. High Voltage Fragmentation and Mechanical Recycling of Glass Fibre Thermoset Composite. CIRP Ann. 2016, 65, 45–48. [Google Scholar] [CrossRef]

- Sarmah, A.; Sarikaya, S.; Thiem, J.; Upama, S.T.; Khalfaoui, A.N.; Dasari, S.S.; Arole, K.; Hawkins, S.A.; Naraghi, M.; Vashisth, A.; et al. Recycle and Reuse of Continuous Carbon Fibers from Thermoset Composites Using Joule Heating. ChemSusChem 2022, 15, e202200989. [Google Scholar] [CrossRef]

- Marinis, D.; Farsari, E.; Alexandridou, C.; Amanatides, E.; Mataras, D. Chemical Recovery of Carbon Fibers from Composites via Plasma Assisted Solvolysis. J. Phys. Conf. Ser. 2024, 2692, 012017. [Google Scholar] [CrossRef]

- Das, M.; Varughese, S. A Novel Sonochemical Approach for Enhanced Recovery of Carbon Fiber from CFRP Waste Using Mild Acid–Peroxide Mixture. ACS Sustain. Chem. Eng. 2016, 4, 2080–2087. [Google Scholar] [CrossRef]

- Ragupathi, B.; Bacher, M.F.; Balle, F. First Efforts on Recovery of Thermoplastic Composites at Low Temperatures by Power Ultrasonics. Clean. Mater. 2023, 8, 100186. [Google Scholar] [CrossRef]

- Nie, W.; Liu, J.; Liu, W.; Wang, J.; Tang, T. Decomposition of Waste Carbon Fiber Reinforced Epoxy Resin Composites in Molten Potassium Hydroxide. Polym. Degrad. Stab. 2015, 111, 247–256. [Google Scholar] [CrossRef]

- Pérez, R.L.; Ayala, C.E.; Opiri, M.M.; Ezzir, A.; Li, G.; Warner, I.M. Recycling Thermoset Epoxy Resin Using Alkyl-Methyl-Imidazolium Ionic Liquids as Green Solvents. ACS Appl. Polym. Mater. 2021, 3, 5588–5595. [Google Scholar] [CrossRef] [PubMed]

- Perli, G.; Okada, C.Y.; Michelin, C.; El Omari, Y.; Gérard, J.-F.; Duchet-Rumeau, J.; Livi, S. Design for Disassembly of Composites and Thermoset by Using Cleavable Ionic Liquid Monomers as Molecular Building Blocks. Compos. B Eng. 2023, 264, 110899. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, P.; Yue, J.; Huan, H.; Bi, G.; Zhang, L. Recycling Glass Fibers from Thermoset Epoxy Composites by in Situ Oxonium-Type Polyionic Liquid Formation and Naphthalene-Containing Superplasticizer Synthesis with the Degradation Solution of the Epoxy Resin. Compos. B Eng. 2023, 254, 110435. [Google Scholar] [CrossRef]

- Dolz, M.; Mateljak, I.; Méndez-Sánchez, D.; Sánchez-Moreno, I.; de Santos, P.; Viña-Gonzalez, J.; Alcalde, M. Colorimetric High-Throughput Screening Assay to Engineer Fungal Peroxygenases for the Degradation of Thermoset Composite Epoxy Resins. Front. Catal. 2022, 2, 883263. [Google Scholar] [CrossRef]

- Pathak, G.S.; Hinge, M.; Otzen, D.E. Transdisciplinary pragmatic melioration for the plastic life cycle: Why the social, natural, and technical sciences should prioritize reducing harm. Sci. Total Environ. 2023, 895, 165154. [Google Scholar] [CrossRef] [PubMed]

- Nehls, G. European R&D Project Bizente Researches Enzymatic Technologies to Recover Thermosets, CompositesWorld, Published 19 December 2022. Available online: https://www.compositesworld.com/news/european-rd-project-bizente-researches-enzymatic-technologies-to-recover-thermoset-resins (accessed on 14 March 2024).

- You, Y.; Fu, M.R.; Rong, M.Z.; Zhang, M.Q. Improving Creep Resistance While Maintaining Reversibility of Covalent Adaptive Networks via Constructing Reversibly Interlocked Polymer Networks. Mater. Today Chem. 2022, 23, 100687. [Google Scholar] [CrossRef]

- Bowman, C.; Du Prez, F.; Kalow, J. Introduction to Chemistry for Covalent Adaptable Networks. Polym. Chem. 2020, 11, 5295–5296. [Google Scholar] [CrossRef]

- Guggari, S. Recyclability Purpose-Vitrimers Strategy Covalent Adaptable Networks; Specific Polymers: Castries, France, 2022. [Google Scholar]

- Scheutz, G.M.; Lessard, J.J.; Sims, M.B.; Sumerlin, B.S. Adaptable Crosslinks in Polymeric Materials: Resolving the Intersection of Thermoplastics and Thermosets. J. Am. Chem. Soc. 2019, 141, 16181–16196. [Google Scholar] [CrossRef]

- Kloxin, C.J.; Bowman, C.N. Covalent Adaptable Networks: Smart, Reconfigurable and Responsive Network Systems. Chem. Soc. Rev. 2013, 42, 7161–7173. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Long, Y.; Xu, S.; Liu, X.; Chen, L.; Wang, Y.-Z. Recovery of Epoxy Thermosets and Their Composites. Mater. Today 2023, 64, 72–97. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y.; Du, S.; Zhu, J.; Ma, S. Upcycling of Thermosetting Polymers into High-Value Materials. Mater. Horiz. 2022, 10, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Odriozola, I.; De Luzuriaga, A.R.; Rekondo, A.; Martín, R.; Markaide, N.; Cabañero, G.; Grande, H.-J. Thermomechanically Reprocessable Epoxy Composites and Processes for Their Manufacturing. WO2015181054A1, 21 May 2015. [Google Scholar]

- Ruiz De Luzuriaga, A.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodríguez, J.; Odriozola, I. Epoxy Resin with Exchangeable Disulfide Crosslinks to Obtain Reprocessable, Repairable and Recyclable Fiber-Reinforced Thermoset Composites. Mater. Horiz. 2016, 3, 241–247. [Google Scholar] [CrossRef]

- Hubbard, A.M.; Ren, Y.; Sarvestani, A.; Konkolewicz, D.; Picu, C.R.; Roy, A.K.; Varshney, V.; Nepal, D. Recyclability of Vitrimer Materials: Impact of Catalyst and Processing Conditions. ACS Omega 2022, 7, 29125–29134. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yu, Z.; Wang, B.; Xu, X.; Feng, H.; Li, P.; Zhu, J.; Ma, S. High-Performance Epoxy Covalent Adaptable Networks Enabled by Alicyclic Anhydride Monoesters. Eur. Polym. J. 2022, 173, 111272. [Google Scholar] [CrossRef]

- Zhang, B.; Yuan, C.; Zhang, W.; Dunn, M.L.; Qi, H.J.; Liu, Z.; Yu, K.; Ge, Q. Recycling of Vitrimer Blends with Tunable Thermomechanical Properties. RSC Adv. 2019, 9, 5431–5437. [Google Scholar] [CrossRef] [PubMed]

- Memon, H.; Liu, H.; Rashid, M.A.; Chen, L.; Jiang, Q.; Zhang, L.; Wei, Y.; Liu, W.; Qiu, Y. Vanillin-Based Epoxy Vitrimer with High Performance and Closed-Loop Recyclability. Macromolecules 2020, 53, 621–630. [Google Scholar] [CrossRef]

- Ma, Y.; Jiang, X.; Shi, Z.; Berrocal, J.A.; Weder, C. Closed-Loop Recycling of Vinylogous Urethane Vitrimers. Angew. Chem. Int. Ed. 2023, 62, e202306188. [Google Scholar] [CrossRef]

- Zhou, Z.; Kim, S.; Bowland, C.C.; Li, B.; Ghezawi, N.; Lara-Curzio, E.; Hassen, A.; Naskar, A.K.; Rahman, M.A.; Saito, T. Unraveling a Path for Multi-Cycle Recycling of Tailored Fiber-Reinforced Vitrimer Composites. Cell Rep. Phys. Sci. 2022, 3, 101036. [Google Scholar] [CrossRef]

- Tran, T.N.; Mai, B.T.; Setti, C.; Athanassiou, A. Transparent Bioplastic Derived from CO2-Based Polymer Functionalized with Oregano Waste Extract toward Active Food Packaging. ACS Appl. Mater. Interfaces 2020, 12, 46667–46677. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhang, K.; Zhang, K.; Jiang, B.; Huang, Y. Facile Preparation of Reprocessable and Degradable Phenolic Resin Based on Dynamic Acetal Motifs. Polym. Degrad. Stab. 2022, 196, 109818. [Google Scholar] [CrossRef]

- Fukuda, K.; Shimoda, M.; Sukegawa, M.; Nobori, T.; Lehn, J.M. Doubly Degradable Dynamers: Dynamic Covalent Polymers Based on Reversible Imine Connections and Biodegradable Polyester Units. Green Chem. 2012, 14, 2907–2911. [Google Scholar] [CrossRef]

- Yue, L.; Bonab, V.S.; Yuan, D.; Patel, A.; Karimkhani, V.; Manas-Zloczowe, I. Vitrimerization: A Novel Concept to Reprocess and Recycle Thermoset Waste via Dynamic Chemistry. Glob. Chall. 2019, 3, 1800076. [Google Scholar] [CrossRef] [PubMed]

- Bandegi, A.; Gray, T.G.; Mitchell, S.; Jamei Oskouei, A.; Sing, M.K.; Kennedy, J.; Miller McLoughlin, K.; Manas-Zloczower, I. Vitrimerization of Crosslinked Elastomers: A Mechanochemical Approach for Recycling Thermoset Polymers. Mater. Adv. 2023, 4, 2648–2658. [Google Scholar] [CrossRef]

- Lorero, I.; Mujica, A.; Campo, M.; Prolongo, S.G. Mechanical Recycling and Electro-Thermal Welding of Epoxy Vitrimer Nanocomposites. Polym. Compos. 2024, 45, 6041–6058. [Google Scholar] [CrossRef]

- Lei, Z.; Chen, H.; Luo, C.; Rong, Y.; Hu, Y.; Jin, Y.; Long, R.; Yu, K.; Zhang, W. Recyclable and Malleable Thermosets Enabled by Activating Dormant Dynamic Linkages. Nat. Chem. 2022, 14, 1399–1404. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, H.; Wang, H.; Huang, X.; Huang, G.; Wu, J. Weldable, Malleable and Programmable Epoxy Vitrimers with High Mechanical Properties and Water Insensitivity. Chem. Eng. J. 2019, 368, 61–70. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.; Jiang, H.; Zhang, X.; Shang, Y.; Jiang, C.; Wang, X.; Qi, G.; Li, B.; Xu, P.; et al. Upcycling of Carbon Fiber-Reinforced Polymer Composites. Compos. Sci. Technol. 2023, 231, 109824. [Google Scholar] [CrossRef]

- Martin, S.; Milickovic, T.K.; Charitidis, C.A.; Moisan, S. Ready-to-Use Recycled Carbon Fibres Decorated with Magnetic Nanoparticles: Functionalization after Recycling Process Using Supercritical Fluid Chemistry. J. Compos. Sci. 2023, 7, 236. [Google Scholar] [CrossRef]

- Semitekolos, D.; Papadopoulos, I.; Anagnou, S.; Dashtbozorg, B.; Li, X.; Dong, H.; Charitidis, C.A. Nanomaterial-Enhanced Sizings: Design and Optimisation of a Pilot-Scale Fibre Sizing Line. Fibers 2024, 12, 16. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, X.; An, W.; Zhou, X.; Zhang, S.; Xu, S.; Wang, Y.-Z. Upcycling of Waste Thermosets into Multiple-Responsive Supramolecular Materials via Acid-Catalyzed Oxidation. Polymer 2023, 270, 125774. [Google Scholar] [CrossRef]

- Shao, L.; Chang, Y.-C.; Zhao, B.; Yan, X.; Bliss, B.J.; Fei, M.; Yu, C.; Zhang, J. Bona Fide Upcycling Strategy of Anhydride Cured Epoxy and Reutilization of Decomposed Dual Monomers into Multipurpose Applications. Chem. Eng. J. 2023, 464, 142735. [Google Scholar] [CrossRef]

- Reis, J.P.; de Moura, M.; Samborski, S. Thermoplastic Composites and Their Promising Applications in Joining and Repair Composites Structures: A Review. Materials 2020, 13, 5832. [Google Scholar] [CrossRef] [PubMed]

- da Silva, D.J.; Wiebeck, H. Current Options for Characterizing, Sorting, and Recycling Polymeric Waste. Prog. Rubber Plast. Recycl. Technol. 2020, 36, 284–303. [Google Scholar] [CrossRef]

- Ayre, D. Technology Advancing Polymers and Polymer Composites towards Sustainability: A Review. Curr. Opin. Green Sustain. Chem. 2018, 13, 108–112. [Google Scholar] [CrossRef]

- Valerio, O.; Muthuraj, R.; Codou, A. Strategies for Polymer to Polymer Recycling from Waste: Current Trends and Opportunities for Improving the Circular Economy of Polymers in South America. Curr. Opin. Green Sustain. Chem. 2020, 25, 100381. [Google Scholar] [CrossRef]

- Sohn, Y.J.; Kim, H.T.; Baritugo, K.A.; Jo, S.Y.; Song, H.M.; Park, S.Y.; Park, S.K.; Pyo, J.; Cha, H.G.; Kim, H.; et al. Recent Advances in Sustainable Plastic Upcycling and Biopolymers. Biotechnol. J. 2020, 15, 1900489. [Google Scholar] [CrossRef] [PubMed]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; van Harmelen, T.; de Wild, P.; van der Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond Mechanical Recycling: Giving New Life to Plastic Waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Morici, E.; Carroccio, S.C.; Bruno, E.; Scarfato, P.; Filippone, G.; Dintcheva, N.T. Recycled (Bio)Plastics and (Bio)Plastic Composites: A Trade Opportunity in a Green Future. Polymers 2022, 14, 2038. [Google Scholar] [CrossRef] [PubMed]

- Abu-Thabit, N.Y.; Pérez-Rivero, C.; Uwaezuoke, O.J.; Ngwuluka, N.C. From Waste to Wealth: Upcycling of Plastic and Lignocellulosic Wastes to PHAs. J. Chem. Technol. Biotechnol. 2021, 97, 3217–3240. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Di Benedetto, G. Physical Properties of Virgin-Recycled ABS Blends: Effect of Post-Consumer Content and of Reprocessing Cycles. Eur. Polym. J. 2012, 48, 637–648. [Google Scholar] [CrossRef]

- Rahimi, M.; Esfahanian, M.; Moradi, M. Effect of Reprocessing on Shrinkage and Mechanical Properties of ABS and Investigating the Proper Blend of Virgin and Recycled ABS in Injection Molding. J. Mater. Process. Technol. 2014, 214, 2359–2365. [Google Scholar] [CrossRef]

- Chiu, H.-T.; Huang, J.-K.; Kuo, M.-T.; Huang, J.-H. Characterisation of PC/ABS Blend during 20 Reprocessing Cycles and Subsequent Functionality Recovery by Virgin Additives. J. Polym. Res. 2018, 25, 124. [Google Scholar] [CrossRef]

- Serranti, S.; Bonifazi, G. 2—Techniques for Separation of Plastic Wastes. In Use of Recycled Plastics in Eco-Efficient Concrete; Pacheco-Torgal, F., Khatib, J., Colangelo, F., Tuladhar, R., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2019; pp. 9–37. ISBN 978-0-08-102676-2. [Google Scholar]

- Fraunholcz, N. Separation of Waste Plastics by Froth Flotation—A Review, Part I. Miner. Eng. 2004, 17, 261–268. [Google Scholar] [CrossRef]

- Near Infrared (NIR) Sorting in the Plastics Recycling Process; Document number Res-Sort-2. Association of Plastic Recyclers: Washington, DC, USA, 2018; Available online: https://plasticsrecycling.org/images/Design-Guidance-Tests/APR-RES-SORT-2-NIR-sorting-resource.pdf (accessed on 14 March 2024).

- Gondal, M.A.; Siddiqui, M.N. Identification of Different Kinds of Plastics Using Laser-Induced Breakdown Spectroscopy for Waste Management. J. Environ. Sci. Health Part A 2007, 42, 1989–1997. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Militky, J. LCA (Life Cycle Assessment) on Recycled Polyester. In Environmental Footprints of Recycled Polyester; Textile Science and Clothing Technology; Springer Nature Singapore Pte Ltd.: Singapore, 2020; ISBN 978-981-13-9578-9. [Google Scholar] [CrossRef]

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Expanding Plastics Recycling Technologies: Chemical Aspects, Technology Status and Challenges. Green Chem. 2022, 24, 8899–9002. [Google Scholar] [CrossRef]

- Curtzwiler, G.; Williams, E.; Hurban, E.; Greene, J.; Vorst, K. Certification Markers for Empirical Quantification of Post-Consumer Recycled Content in Extruded Polyethylene Film. Polym. Test. 2018, 65, 103–110. [Google Scholar] [CrossRef]

- Curtzwiler, G.; Schweitzer, M.; Li, Y.; Jiang, S.; Vorst, K. Mixed Post-Consumer Recycled Polyolefins as a Property Tuning Material for Virgin Polypropylene. J. Clean. Prod. 2019, 239, 117978. [Google Scholar] [CrossRef]

- Luzuriaga, S.; Kovářová, J.; Fortelný, I. Degradation of Pre-Aged Polymers Exposed to Simulated Recycling: Properties and Thermal Stability. Polym. Degrad. Stab. 2006, 91, 1226–1232. [Google Scholar] [CrossRef]

- Sato, T.; Shishido, M. Mechanical and Structural Properties for Recycled Thermoplastics from Waste Fishing Ropes. J. Mater. Cycles Waste Manag. 2020, 22, 1682–1689. [Google Scholar] [CrossRef]

- Ghosh, A. Performance Modifying Techniques for Recycled Thermoplastics. Resour. Conserv. Recycl. 2021, 175, 105887. [Google Scholar] [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; Van Geem, K.M.; Ragaert, K.; De Meester, S. Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef]

- Sankar, V.; Kumar, S. Common Additives Used in Recycling of Polymers: Methods, Characterization and Applications; Wiley Online Library: Hoboken, NJ, USA, 2016; pp. 11–53. ISBN 9783527338481. [Google Scholar]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical Recycling: Compatibilization of Mixed Thermoplastic Wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Ojijo, V.; Sinha Ray, S.; Sadiku, R. Toughening of Biodegradable Polylactide/Poly(Butylene Succinate-Co-Adipate) Blends via in Situ Reactive Compatibilization. ACS Appl. Mater. Interfaces 2013, 5, 4266–4276. [Google Scholar] [CrossRef]

- Pionteck, J.; Sadhu, V.; Jakisch, L.; Pötschke, P.; Häuβler, L.; Janke, A. Crosslinkable Coupling Agents: Synthesis and Use for Modification of Interfaces in Polymer Blends. Polymer 2005, 46, 6563–6574. [Google Scholar] [CrossRef]

- Soundararajan, S.R.; Palanivelu, K. Studies on Mechanical, Thermal & Electrical Properties and Insitu Compatibilization of Recycled Nylon 6-Poly Propylene Blends. IOSR J. Appl. Chem. 2012, 2, 48–51. [Google Scholar]

- Demir, T.; Tinçer, T. Preparation and Characterization of Poly(Ethylene Terephthalate) Powder-Filled High-Density Polyethylene in the Presence of Silane Coupling Agents. J. Appl. Polym. Sci. 2001, 79, 827–835. [Google Scholar] [CrossRef]

- Vuillaume, P.Y.; Vachon, A.; Grey, W.; Pépin, K.; Zhang, C.J. Compatibilisation of Various PLA/Thermoplastic Elastomer Blends with Diisocyanate Coupling Agent. Plast. Rubber Compos. 2018, 47, 95–105. [Google Scholar] [CrossRef]

- Chiou, K.-C.; Chang, F.-C. Reactive Compatibilization of Polyamide-6 (PA 6)/Polybutylene Terephthalate (PBT) Blends by a Multifunctional Epoxy Resin. J. Polym. Sci. B Polym. Phys. 2000, 38, 23–33. [Google Scholar] [CrossRef]

- Oner, B.; Gokkurt, T.; AYTAC, A. Studies On Compatibilization Of Recycled Polyethylene/Thermoplastic Starch Blends By Using Different Compatibilizer. Open Chem. 2019, 17, 557–563. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Zhou, J.; Min, B.G. Compatibilizing Effect of Epoxy Resin on the Phase Separation and Properties of Polyamide 6/Poly(Ethylene Terephthalate) Blends. IEEE Trans. Softw. Eng. 2014, 51, 21–26. [Google Scholar]

- Raffaella, A.; Antonio, A. Liquid Crystalline Polymers Compatibilization and Adhesion Enhancement by Reactive Blending in Post-Consumers PET’s. Am. J. Eng. Appl. Sci. 2016, 9, 530–539. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, Q.; Clemons, C.; Guo, W. Phase Structure and Properties of Poly(Ethylene Terephthalate)/High-Density Polyethylene Based on Recycled Materials. J. Appl. Polym. Sci. 2009, 113, 1710–1719. [Google Scholar] [CrossRef]

- Ha, C.-S.; Park, H.; Cho, W. Compatibilizers for Recycling of the Plastic Mixture Wastes. II. the Effect of a Compatibilizer for Binary Blends on the Properties of Ternary Blends. J. Appl. Polym. Sci. 2000, 76, 1048–1053. [Google Scholar] [CrossRef]

- Araujo, L.; Morales, A. Compatibilization of Recycled Polypropylene and Recycled Poly (Ethylene Terephthalate) Blends with SEBS-g-MA. Polímeros 2018, 28, 84–91. [Google Scholar] [CrossRef]

- Mahanta, D.; Dayanidhi, S.; Mohanty, S.; Nayak, S. Mechanical, Thermal, and Morphological Properties of Recycled Polycarbonate/Recycled Poly(Acrylonitrile-Butadiene-Styrene) Blend Nanocomposites. Polym. Compos. 2012, 33, 2114. [Google Scholar] [CrossRef]

- Wang, K.; Addiego, F.; Bahlouli, N.; Ahzi, S.; Rémond, Y.; Toniazzo, V. Impact Response of Recycled Polypropylene-Based Composites under a Wide Range of Temperature: Effect of Filler Content and Recycling. Compos. Sci. Technol. 2014, 95, 89–99. [Google Scholar] [CrossRef]

- Jouenne, S.; Chakibi, H.; Levitt, D. Polymer Stability After Successive Mechanical-Degradation Events. SPE J. 2017, 23, 18–33. [Google Scholar] [CrossRef]

- Ambrogi, V.; Carfagna, C.; Cerruti, P.; Marturano, V. Additives in Polymers; Elsevier: Amsterdam, The Netherlands, 2016; pp. 87–108. ISBN 9780323443531. [Google Scholar]

- Tseng, W.; Lee, J.-S. Functional MBS Impact Modifiers for PC/PBT Alloy. J. Appl. Polym. Sci. 2000, 76, 1280–1284. [Google Scholar] [CrossRef]

- Titow, W.V. PVC PLASTICS Properties, Processing, and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1990. [Google Scholar]

- Kazemi, Y.; Ramezani Kakroodi, A.; Rodrigue, D. Compatibilization Efficiency in Post-Consumer Recycled Polyethylene/Polypropylene Blends: Effect of Contamination. Polym. Eng. Sci. 2015, 55, 2368–2376. [Google Scholar] [CrossRef]

- Inoya, H.; Wei Leong, Y.; Klinklai, W.; Takai, Y.; Hamada, H. Compatibilization of Recycled Poly(Ethylene Terephthalate) and Polypropylene Blends: Effect of Compatibilization on Blend Toughness, Dispersion of Minor Phase, and Thermal Stability. J. Appl. Polym. Sci. 2012, 124, 5260–5269. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Liu, G.; Pu, S. Core/Shell Morphologies in Recycled Poly(Ethylene Terephthalate)/Linear Low-Density Polyethylene/Poly(Styrene-b-(Ethylene-Co-Butylene)-b-Styrene) Ternary Blends. Polym. Bull. 2017, 74, 4223–4233. [Google Scholar] [CrossRef]

- Santana, R.; Manrich, S. Studies on Morphology and Mechanical Properties of PP/HIPS Blends from Postconsumer Plastic Waste. J. Appl. Polym. Sci. 2003, 87, 747–751. [Google Scholar] [CrossRef]

- Tostar, S.; Stenvall, E.; Foreman, M.R.S.J.; Boldizar, A. The Influence of Compatibilizer Addition and Gamma Irradiation on Mechanical and Rheological Properties of a Recycled WEEE Plastics Blend. Recycling 2016, 1, 101–110. [Google Scholar] [CrossRef]

- Vazquez, Y.V.; Barbosa, S.E. Recycling of Mixed Plastic Waste from Electrical and Electronic Equipment. Added Value by Compatibilization. Waste Manag. 2016, 53, 196–203. [Google Scholar] [CrossRef]

- Tanrattanakul, V.; Bunkaew, P. Effect of Different Plasticizers on the Properties of Bio-Based Thermoplastic Elastomer Containing Poly(Lactic Acid) and Natural Rubber. Express Polym. Lett. 2014, 8, 387–396. [Google Scholar] [CrossRef]

- Wu, D.; Hakkarainen, M. Recycling PLA to Multifunctional Oligomeric Compatibilizers for PLA/Starch Composites. Eur. Polym. J. 2015, 64, 126–137. [Google Scholar] [CrossRef]

- Kaewtatip, K.; Thongmee, J. The Effects of Cross-Linked Starch on the Properties of Thermoplastic Starch. Mater. Des. 2013, 45, 586–589. [Google Scholar] [CrossRef]

- Müller, K.; Zollfrank, C.; Schmid, M. Natural Polymers from Biomass Resources as Feedstocks for Thermoplastic Materials. Macromol. Mater. Eng. 2019, 304, 1800760. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Tawakkal, I.S.M.A.; Ilyas, R.A. Water Barrier and Mechanical Properties of Sugar Palm Crystalline Nanocellulose Reinforced Thermoplastic Sugar Palm Starch (TPS)/Poly(Lactic Acid) (PLA) Blend Bionanocomposites. Nanotechnol. Rev. 2021, 10, 431–442. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and Photostabilization of Polymers, Especially Polystyrene: Review. Springerplus 2013, 2, 398. [Google Scholar] [CrossRef]

- Kockott, D. Natural and Artificial Weathering of Polymers. Polym. Degrad. Stab. 1989, 25, 181–208. [Google Scholar] [CrossRef]

- Rabek, J.F. Photostabilization of Polymers: Principles and Applications; Elsevier Applied Science: London, UK, 1990. [Google Scholar]

- Silva Freitas, F.L.; Chinellato, A.C.; Pereira Filho, E.R.; Cruz, S.A. Evaluation of the Effect of Additives on Thermo-Oxidative and Hydrolytic Stabilization of Recycled Post-Consumer Poly (Ethylene Terephthalate) Using Design of Experiments. Polym. Test. 2020, 81, 106275. [Google Scholar] [CrossRef]

- Liu, L.-C.; Liang, W.-C.; Chen, C.-M. Manufacture of Recyclable Thermoplastic Polyurethane (TPU)/Silicone Blends and Their Mechanical Properties. Manuf. Lett. 2022, 31, 1–5. [Google Scholar] [CrossRef]

- Yang, H.; He, P.; Cheng, H.; Shentu, B. Preparation of Nano-TiO2 Loaded Antioxidant and Its Anti-Aging Performance against UV/O3 in Thermoplastic Vulcanizates. Ind. Eng. Chem. Res. 2019, 58, 12516–12524. [Google Scholar] [CrossRef]

- Utracki, L.A. Compatibilization of Polymer Blends. Can. J. Chem. Eng. 2002, 80, 1008–1016. [Google Scholar] [CrossRef]

- Azevedo, V.; Carvalho, R.; Borges, S.; Claro, P.; Hasegawa, F.; Yoshida, M.; Marconcini, J.M. Thermoplastic Starch/Whey Protein Isolate/Rosemary Essential Oil Nanocomposites Obtained by Extrusion Process: Antioxidant Polymers. J. Appl. Polym. Sci. 2019, 136, 47619. [Google Scholar] [CrossRef]

- Kuczenski, B.; Geyer, R. Material Flow Analysis of Polyethylene Terephthalate in the US, 1996–2007. Resour. Conserv. Recycl. 2010, 54, 1161–1169. [Google Scholar] [CrossRef]

- Piringer, O.G.; Baner, A.L. (Eds.) Plastic Packaging: Interactions with Food and Pharmaceuticals, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Moreno, D.D.P.; Saron, C. Influence of Compatibilizer on the Properties of Low-Density Polyethylene/Polyamide 6 Blends Obtained by Mechanical Recycling of Multilayer Film Waste. Waste Manag. Res. 2018, 36, 729–736. [Google Scholar] [CrossRef]

- Antón, N.; González-Fernández, Á.; Villarino, A. Reliability and Mechanical Properties of Materials Recycled from Multilayer Flexible Packages. Materials 2020, 13, 3992. [Google Scholar] [CrossRef] [PubMed]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic Flexible Films Waste Management—A State of Art Review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef] [PubMed]

- Pappa, G.; Boukouvalas, C.; Giannaris, C.; Ntaras, N.; Zografos, V.V.; Magoulas, K.; Lygeros, A.I.; Tassios, D.P. The Selective Dissolution/Precipitation Technique for Polymer Recycling: A Pilot Unit Application. Resour. Conserv. Recycl. 2001, 34, 33–44. [Google Scholar] [CrossRef]

- Achilias, D.S.; Roupakias, C.; Megalokonomos, P.; Lappas, A.A.; Antonakou, Ε. V Chemical Recycling of Plastic Wastes Made from Polyethylene (LDPE and HDPE) and Polypropylene (PP). J. Hazard. Mater. 2007, 149, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Georgiopoulou, I.; Pappa, G.D.; Vouyiouka, S.N.; Magoulas, K. Recycling of Post-Consumer Multilayer Tetra Pak® Packaging with the Selective Dissolution-Precipitation Process. Resour. Conserv. Recycl. 2021, 165, 105268. [Google Scholar] [CrossRef]

- Walker, T.W.; Frelka, N.; Shen, Z.; Chew, A.K.; Banick, J.; Grey, S.; Kim, M.S.; Dumesic, J.A.; Van Lehn, R.C.; Huber, G.W. Recycling of Multilayer Plastic Packaging Materials by Solvent-Targeted Recovery and Precipitation. Sci. Adv. 2020, 6, eaba7599. [Google Scholar] [CrossRef]

- Mulakkal, M.C.; Castillo Castillo, A.; Taylor, A.C.; Blackman, B.R.K.; Balint, D.S.; Pimenta, S.; Charalambides, M.N. Advancing Mechanical Recycling of Multilayer Plastics through Finite Element Modelling and Environmental Policy. Resour. Conserv. Recycl. 2021, 166, 105371. [Google Scholar] [CrossRef]

- Payne, J.; Jones, M.D. The Chemical Recycling of Polyesters for a Circular Plastics Economy: Challenges and Emerging Opportunities. ChemSusChem 2021, 14, 4041–4070. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Liew, M.S. Tertiary Recycling of Plastics Waste: An Analysis of Feedstock, Chemical and Biological Degradation Methods. J. Mater. Cycles Waste Manag. 2021, 23, 32–43. [Google Scholar] [CrossRef]

- Kosloski-Oh, S.C.; Wood, Z.A.; Manjarrez, Y.; de Los Rios, J.P.; Fieser, M.E. Catalytic Methods for Chemical Recycling or Upcycling of Commercial Polymers. Mater. Horiz. 2021, 8, 1084–1129. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Narro, G.; Hassan, S.; Phan, A.N. Chemical Recycling of Plastic Waste for Sustainable Polymer Manufacturing—A Critical Review. J. Environ. Chem. Eng. 2024, 12, 112323. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Rashid, U.; Khalina, A.; Ilyas, R.A. Pyrolysis of Polypropylene Plastic Waste into Carbonaceous Char: Priority of Plastic Waste Management amidst COVID-19 Pandemic. Sci. Total Environ. 2022, 803, 149911. [Google Scholar] [CrossRef] [PubMed]

- Eze, W.U.; Umunakwe, R.; Obasi, H.C.; Ugbaja, M.I.; Uche, C.C.; Madufor, I.C. Plastics Waste Management: A Review of Pyrolysis Technology. Clean Technol. Recycl. 2021, 1, 50–69. [Google Scholar] [CrossRef]

- Mishra, R.; Kumar, A.; Singh, E.; Kumar, S. Recent Research Advancements in Catalytic Pyrolysis of Plastic Waste. ACS Sustain. Chem. Eng. 2023, 11, 2033–2049. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Impact of Fast and Slow Pyrolysis on the Degradation of Mixed Plastic Waste: Product Yield Analysis and Their Characterization. J. Energy Inst. 2019, 92, 1647–1657. [Google Scholar] [CrossRef]

- Honus, S.; Kumagai, S.; Fedorko, G.; Molnár, V.; Yoshioka, T. Pyrolysis Gases Produced from Individual and Mixed PE, PP, PS, PVC, and PET—Part I: Production and Physical Properties. Fuel 2018, 221, 346–360. [Google Scholar] [CrossRef]

- Bow, Y.; Rusdianasari, R.; Pujiastuti, L.S. Pyrolysis of Polypropylene Plastic Waste into Liquid Fuel. IOP Conf. Ser. Earth Environ. Sci. 2019, 347, 012128. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Ureel, Y.; Eschenbacher, A.; Vermeire, F.H.; Varghese, R.J.; Oenema, J.; Stefanidis, G.D.; Van Geem, K.M. Challenges and Opportunities of Light Olefin Production via Thermal and Catalytic Pyrolysis of End-of-Life Polyolefins: Towards Full Recyclability. Prog. Energy Combust. Sci. 2023, 96, 101046. [Google Scholar] [CrossRef]

- Lee, H.W.; Park, Y.K. Catalytic Pyrolysis of Polyethylene and Polypropylene over Desilicated Beta and AL-MSU-F. Catalysts 2018, 8, 501. [Google Scholar] [CrossRef]

- Oh, D.; Lee, H.W.; Kim, Y.M.; Park, Y.K. Catalytic Pyrolysis of Polystyrene and Polyethylene Terephthalate over Al-MSU-F. Energy Procedia 2018, 144, 111–117. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: Moving toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef]

- Khan, S.R.; Zeeshan, M.; Ahmed, A.; Saeed, S. Comparison of Synthetic and Low-Cost Natural Zeolite for Bio-Oil Focused Pyrolysis of Raw and Pretreated Biomass. J. Clean. Prod. 2021, 313, 127760. [Google Scholar] [CrossRef]

- Khazaal, R.M.; Abdulaaima, D.A. Valuable Oil Recovery from Plastic Wastes via Pressurized Thermal and Catalytic Pyrolysis. Energy Convers. Manag. X 2023, 20, 100430. [Google Scholar] [CrossRef]

- Wang, P.; Qiao, L.; Wang, W.; Yu, J. Catalytic Pyrolysis of Waste Composite Plastics with Waste FCC Catalyst. J. Energy Inst. 2023, 110, 101338. [Google Scholar] [CrossRef]

- Bhatt, K.P.; Patel, S.; Upadhyay, D.S.; Patel, R.N. A Critical Review on Solid Waste Treatment Using Plasma Pyrolysis Technology. Chem. Eng. Process. Process Intensif. 2022, 177, 108989. [Google Scholar] [CrossRef]

- Wang, J.; Shen, J.; Ye, D.; Yan, X.; Zhang, Y.; Yang, W.; Li, X.; Wang, J.; Zhang, L.; Pan, L. Disinfection Technology of Hospital Wastes and Wastewater: Suggestions for Disinfection Strategy during Coronavirus Disease 2019 (COVID-19) Pandemic in China. Environ. Pollut. 2020, 262, 114665. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Yansaneh, O.Y.; Zein, S.H. Recent Advances on Waste Plastic Thermal Pyrolysis: A Critical Overview. Processes 2022, 10, 332. [Google Scholar] [CrossRef]

- Ma, C.; Kumagai, S.; Saito, Y.; Yoshioka, T.; Huang, X.; Shao, Y.; Ran, J.; Sun, L. Recent Advancements in Pyrolysis of Halogen-Containing Plastics for Resource Recovery and Halogen Upcycling: A State-of-the-Art Review. Environ. Sci. Technol. 2024, 58, 1423–1440. [Google Scholar] [CrossRef]

- Xu, S.; Han, Z.; Yuan, K.; Qin, P.; Zhao, W.; Lin, T.; Zhou, T.; Huang, F. Upcycling Chlorinated Waste Plastics. Nat. Rev. Methods Primers 2023, 3, 44. [Google Scholar] [CrossRef]

- Chen, S.; Liu, Z.; Jiang, S.; Hou, H. Carbonization: A Feasible Route for Reutilization of Plastic Wastes. Sci. Total Environ. 2020, 710, 136250. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, L.; Noor, T.; Iqbal, N. Conversion of Plastic Waste to Carbon-Based Compounds and Application in Energy Storage Devices. ACS Omega 2022, 7, 13403–13435. [Google Scholar] [CrossRef] [PubMed]

- Sharifian, S.; Asasian-Kolur, N. Polyethylene Terephthalate (PET) Waste to Carbon Materials: Theory, Methods and Applications. J. Anal. Appl. Pyrolysis 2022, 163, 105496. [Google Scholar] [CrossRef]

- Rahimi, A.R.; Garciá, J.M. Chemical Recycling of Waste Plastics for New Materials Production. Nat. Rev. Chem. 2017, 1, 0046. [Google Scholar] [CrossRef]

- Shojaei, B.; Abtahi, M.; Najafi, M. Chemical Recycling of PET: A Stepping-Stone toward Sustainability. Polym. Adv. Technol. 2020, 31, 2912–2938. [Google Scholar] [CrossRef]

- del Mar Castro López, M.; Ares Pernas, A.I.; Abad López, M.J.; Latorre, A.L.; López Vilariño, J.M.; González Rodríguez, M.V. Assessing Changes on Poly(Ethylene Terephthalate) Properties after Recycling: Mechanical Recycling in Laboratory versus Postconsumer Recycled Material. Mater. Chem. Phys. 2014, 147, 884–894. [Google Scholar] [CrossRef]

- Raheem, A.B.; Noor, Z.Z.; Hassan, A.; Abd Hamid, M.K.; Samsudin, S.A.; Sabeen, A.H. Current Developments in Chemical Recycling of Post-Consumer Polyethylene Terephthalate Wastes for New Materials Production: A Review. J. Clean. Prod. 2019, 225, 1052–1064. [Google Scholar] [CrossRef]

- Thiounn, T.; Smith, R.C. Advances and Approaches for Chemical Recycling of Plastic Waste. J. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Martín, A.J.; Mondelli, C.; Jaydev, S.D.; Pérez-Ramírez, J. Catalytic Processing of Plastic Waste on the Rise. Chem 2021, 7, 1487–1533. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Chen, H.; Liu, H. Towards Recycling Purpose: Converting PET Plastic Waste Back to Terephthalic Acid Using PH-Responsive Phase Transfer Catalyst. Chin. J. Chem. Eng. 2022, 51, 53–60. [Google Scholar] [CrossRef]

- Hu, H.; Wu, Y.; Zhu, Z. Optimization of Microwave-Assisted Preparation of TPA from Waste PET Using Response Surface Methodology. J. Polym. Environ. 2018, 26, 375–382. [Google Scholar] [CrossRef]

- Ügdüler, S.; van Geem, K.M.; Denolf, R.; Roosen, M.; Mys, N.; Ragaert, K.; de Meester, S. Towards Closed-Loop Recycling of Multilayer and Coloured PET Plastic Waste by Alkaline Hydrolysis. Green Chem. 2020, 22, 5376–5394. [Google Scholar] [CrossRef]

- Bengtsson, J.; Peterson, A.; Idström, A.; de la Motte, H.; Jedvert, K. Chemical Recycling of a Textile Blend from Polyester and Viscose, Part II: Mechanism and Reactivity during Alkaline Hydrolysis of Textile Polyester. Sustainability 2022, 14, 6911. [Google Scholar] [CrossRef]

- Güçlü, G.; Yalçinyuva, T.; Özgümüş, S.; Orbay, M. Hydrolysis of Waste Polyethylene Terephthalate and Characterization of Products by Differential Scanning Calorimetry. Thermochim. Acta 2003, 404, 193–205. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.; Pan, Z. Catalytic Depolymerization of Polyethylene Terephthalate in Hot Compressed Water. J. Supercrit. Fluids 2012, 62, 226–231. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Y.; Zhang, D. Effects of Temperature on Catalytic Hydrolysis of PET by Zinc Sulfate under Microwave Irradiation. Adv. Mater. Res. 2011, 233–235, 1628–1631. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Song, H.; Wang, Y.; Deng, T.; Hou, X. Zinc-Catalyzed Ester Bond Cleavage: Chemical Degradation of Polyethylene Terephthalate. J. Clean. Prod. 2019, 208, 1469–1475. [Google Scholar] [CrossRef]

- Liu, F.; Cui, X.; Yu, S.; Li, Z.; Ge, X. Hydrolysis Reaction of Poly(Ethylene Terephthalate) Using Ionic Liquids as Solvent and Catalyst. J. Appl. Polym. Sci. 2009, 114, 3561–3565. [Google Scholar] [CrossRef]

- Kang, M.J.; Yu, H.J.; Jegal, J.; Kim, H.S.; Cha, H.G. Depolymerization of PET into Terephthalic Acid in Neutral Media Catalyzed by the ZSM-5 Acidic Catalyst. Chem. Eng. J. 2020, 398, 125655. [Google Scholar] [CrossRef]

- Islam, M.S.; Islam, Z.; Hasan, R.; Jamal, A.H.M.S.I.M. Acidic Hydrolysis of Recycled Polyethylene Terephthalate Plastic for the Production of Its Monomer Terephthalic Acid. Prog. Rubber Plast. Recycl. Technol. 2023, 39, 12–25. [Google Scholar] [CrossRef]

- Barredo, A.; Asueta, A.; Amundarain, I.; Leivar, J.; Miguel-Fernández, R.; Arnaiz, S.; Epelde, E.; López-Fonseca, R.; Gutiérrez-Ortiz, J.I. Chemical Recycling of Monolayer PET Tray Waste by Alkaline Hydrolysis. J. Environ. Chem. Eng. 2023, 11, 109823. [Google Scholar] [CrossRef]

- Onwucha, C.N.; Ehi-Eromosele, C.O.; Ajayi, S.O.; Schaefer, M.; Indris, S.; Ehrenberg, H. Uncatalyzed Neutral Hydrolysis of Waste PET Bottles into Pure Terephthalic Acid. Ind. Eng. Chem. Res. 2023, 62, 6378–6385. [Google Scholar] [CrossRef]

- Chen, J.; Lv, J.; Ji, Y.; Ding, J.; Yang, X.; Zou, M.; Xing, L. Alcoholysis of PET to Produce Dioctyl Terephthalate by Isooctyl Alcohol with Ionic Liquid as Cosolvent. Polym. Degrad. Stab. 2014, 107, 178–183. [Google Scholar] [CrossRef]

- Laldinpuii, Z.T.; Khiangte, V.; Lalhmangaihzuala, S.; Lalmuanpuia, C.; Pachuau, Z.; Lalhriatpuia, C.; Vanlaldinpuia, K. Methanolysis of PET Waste Using Heterogeneous Catalyst of Bio-Waste Origin. J. Polym. Environ. 2022, 30, 1600–1614. [Google Scholar] [CrossRef]

- Samuilov, A.Y.; Korshunov, M.V.; Samuilov, Y.D. Methanolysis of Polycarbonate Waste as a Method of Regenerating Monomers for Polycarbonate Synthesis. Polym. Sci. Ser. B 2020, 62, 411–415. [Google Scholar] [CrossRef]

- Gupta, P.; Bhandari, S. Chemical Depolymerization of PET Bottles via Ammonolysis and Aminolysis. In Recycling of Polyethylene Terephthalate Bottles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 109–134. [Google Scholar]

- Shirazimoghaddam, S.; Amin, I.; Faria Albanese, J.A.; Shiju, N.R. Chemical Recycling of Used PET by Glycolysis Using Niobia-Based Catalysts. ACS Eng. Au 2023, 3, 37–44. [Google Scholar] [CrossRef]

- Mo, S.; Guo, Y.; Liu, X.; Wang, Y. Efficient Depolymerization of PET over Ti-Doped SBA-15 with Abundant Lewis Acid Sites via Glycolysis. Catal. Sci. Technol. 2023, 13, 6561–6569. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Chen, C.; Li, H. Chemical Degradation of Thermoplastic Polyurethane for Recycling Polyether Polyol. Fibers Polym. 2011, 12, 857–863. [Google Scholar] [CrossRef]

- Ronkvist, Å.M.; Xie, W.; Lu, W.; Gross, R.A. Cutinase-Catalyzed Hydrolysis of Poly(Ethylene Terephthalate). Macromolecules 2009, 42, 5128–5138. [Google Scholar] [CrossRef]

- Pan, Y.; Qi, Z.; You, S.; Gao, Y.; Zhou, Y.; Jiang, N.; Wang, M.; Su, R.; Qi, W. Integrating Glycolysis and Enzymatic Catalyst to Convert Waste Poly(Ethylene Terephthalate) into Terephthalic Acid. Biochem. Eng. J. 2024, 207, 109328. [Google Scholar] [CrossRef]

- Tang, H.; Li, N.; Li, G.; Wang, A.; Cong, Y.; Xu, G.; Wang, X.; Zhang, T. Synthesis of Gasoline and Jet Fuel Range Cycloalkanes and Aromatics from Poly(Ethylene Terephthalate) Waste. Green Chem. 2019, 21, 2709–2719. [Google Scholar] [CrossRef]

- Du, J.T.; Sun, Q.; Zeng, X.F.; Wang, D.; Wang, J.X.; Chen, J.F. ZnO Nanodispersion as Pseudohomogeneous Catalyst for Alcoholysis of Polyethylene Terephthalate. Chem. Eng. Sci. 2020, 220, 115642. [Google Scholar] [CrossRef]

- Scremin, D.M.; Miyazaki, D.Y.; Lunelli, C.E.; Silva, S.A.; Zawadzki, S.F. PET Recycling by Alcoholysis Using a New Heterogeneous Catalyst: Study and Its Use in Polyurethane Adhesives Preparation. Macromol. Symp. 2019, 383, 1800027. [Google Scholar] [CrossRef]

- Zhou, L.; Lu, X.; Ju, Z.; Liu, B.; Yao, H.; Xu, J.; Zhou, Q.; Hu, Y.; Zhang, S. Alcoholysis of Polyethylene Terephthalate to Produce Dioctyl Terephthalate Using Choline Chloride-Based Deep Eutectic Solvents as Efficient Catalysts. Green Chem. 2019, 21, 897–906. [Google Scholar] [CrossRef]

- Fang, P.; Lu, X.; Zhou, Q.; Yan, D.; Xin, J.; Xu, J.; Shi, C.; Zhou, Y.; Xia, S. Controlled Alcoholysis of PET to Obtain Oligomers for the Preparation of PET-PLA Copolymer. Chem. Eng. J. 2023, 451, 138988. [Google Scholar] [CrossRef]

- Fang, P.; Xia, S.; Lu, X. Rapid Alcoholysis of PET Enhanced by Its Swelling under High Temperature. J. Environ. Chem. Eng. 2022, 10, 107823. [Google Scholar] [CrossRef]

- Dębowski, M.; Iuliano, A.; Plichta, A.; Kowalczyk, S.; Florjańczyk, Z. Chemical Recycling of Polyesters. Polimery 2021, 64, 764–776. [Google Scholar] [CrossRef]

- Verma, A.; Soni, R.K.; Teotia, M. Prevention of Poly(Vinyl Chloride) Degradation through Organic Terephthalamides Generated from Poly(Ethylene Terephthalate) Waste. J. Appl. Polym. Sci. 2019, 136, 48022. [Google Scholar] [CrossRef]

- Teotia, M.; Chauhan, M.; Khan, A.; Soni, R.K. Facile Synthesis, Characterization, and Ab-Initio DFT Simulations of Energy Efficient NN′ Dialkyl 1,4 Benzene Dicarboxamide Monomers Recovered from PET Bottle Waste. J. Appl. Polym. Sci. 2020, 137, 49321. [Google Scholar] [CrossRef]

- Jamdar, V.; Kathalewar, M.; Sabnis, A. Depolymerization Study of PET Waste Using Aminoethylethanolamine and Recycled Product Application as Polyesteramide Synthesis. J. Polym. Environ. 2018, 26, 2601–2618. [Google Scholar] [CrossRef]

- More, A.P.; Kute, R.A.; Mhaske, S.T. Chemical Conversion of PET Waste Using Ethanolamine to Bis(2-Hydroxyethyl) Terephthalamide (BHETA) through Aminolysis and a Novel Plasticizer for PVC. Iran. Polym. J. (Engl. Ed.) 2014, 23, 59–67. [Google Scholar] [CrossRef]

- Kárpáti, L.; Fejér, M.; Kalocsai, D.; Molnár, J.; Vargha, V. Synthesis and Characterization of Isophorondiamine Based Epoxy Hardeners from Aminolysis of PET. Express Polym. Lett. 2019, 13, 618–631. [Google Scholar] [CrossRef]

- Parab, Y.S.; Shukla, S.R. Microwave Synthesis and Antibacterial Activity of 1,4-Bis (5-Aryl-1,3,4-Oxadiazole-2-Yl) Benzene Derivatives from Terephthalic Dihydrazide Obtained through Aminolysis of PET Bottle Waste. Waste Biomass Valorization 2013, 4, 23–27. [Google Scholar] [CrossRef]

- Zhang, Y.; Tian, F.; Wu, Z.; Li, X.; Liu, X.; He, Y. Chemical Conversion of Waste PET to Valued-Added Bis(2-Hydroxyethyl) Terephthalamide through Aminolysis. Mater. Today Commun. 2022, 32, 104045. [Google Scholar] [CrossRef]

- Dutt, K.; Soni, R.K. Synthesis and Characterization of Bis-Amino Ethyl Terephthalamide from PET Waste and Its Applications as Hardener in DGEBA. Int. J. Plast. Technol. 2014, 18, 16–26. [Google Scholar] [CrossRef]

- Kim, D.H.; Han, D.O.; In Shim, K.; Kim, J.K.; Pelton, J.G.; Ryu, M.H.; Joo, J.C.; Han, J.W.; Kim, H.T.; Kim, K.H. One-Pot Chemo-Bioprocess of PET Depolymerization and Recycling Enabled by a Biocompatible Catalyst, Betaine. ACS Catal. 2021, 11, 3996–4008. [Google Scholar] [CrossRef]

- Alikin, M.B.; Alekseeva, K.D.; Panfilov, D.A.; Dvorko, I.M.; Lavrov, N.A. The properties of epoxy compositions cured by aminolytic splitting products of a secondary polyethylene terephthalate and polycarbonate. Mech. Compos. Mater. 2022, 58, 999–1010. [Google Scholar] [CrossRef]

- Chan, K.; Zinchenko, A. Conversion of Waste Bottles’ PET to a Hydrogel Adsorbent via PET Aminolysis. J. Environ. Chem. Eng. 2021, 9, 106129. [Google Scholar] [CrossRef]

- Chan, K.; Zinchenko, A. Aminolysis-Assisted Hydrothermal Conversion of Waste PET Plastic to N-Doped Carbon Dots with Markedly Enhanced Fluorescence. J. Environ. Chem. Eng. 2022, 10, 107749. [Google Scholar] [CrossRef]

- Suhaimi, N.A.S.; Muhamad, F.; Abd Razak, N.A.; Zeimaran, E. Recycling of Polyethylene Terephthalate Wastes: A Review of Technologies, Routes, and Applications. Polym. Eng. Sci. 2022, 62, 2355–2375. [Google Scholar] [CrossRef]

- Jeya, G.; Dhanalakshmi, R.; Anbarasu, M.; Vinitha, V.; Sivamurugan, V. A Short Review on Latest Developments in Catalytic Depolymerization of Poly (Ethylene Terephathalate) Wastes. J. Indian Chem. Soc. 2022, 99, 100291. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, Q.; Huang, J.; Huang, R.; Jaffery, Q.Z.; Yan, D.; Zhou, Q.; Xu, J.; Lu, X. Progress in the Catalytic Glycolysis of Polyethylene Terephthalate. J. Environ. Manag. 2021, 296, 113267. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Zhou, W.; Shen, Y.; Li, Z. Chemically Recyclable Polyurethanes Based on Bio-Renewable γ-Butyrolactone: From Thermoplastics to Elastomers. Polym. Degrad. Stab. 2022, 204, 110116. [Google Scholar] [CrossRef]

- Tu, Y.M.; Wang, X.M.; Yang, X.; Fan, H.Z.; Gong, F.L.; Cai, Z.; Zhu, J.B. Biobased High-Performance Aromatic-Aliphatic Polyesters with Complete Recyclability. J. Am. Chem. Soc. 2021, 143, 20591–20597. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, F.; Liu, Y.; Shen, Y.; Li, Z. Functionalizable and Chemically Recyclable Thermoplastics from Chemoselective Ring-Opening Polymerization of Bio-Renewable Bifunctional α-Methylene-δ-Valerolactone. Angew. Chem. Int. Ed. 2022, 61, e202207105. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Shen, Y.; Li, Z. Chemical Upcycling of Poly(3-Hydroxybutyrate) into Bicyclic Ether Ester Monomer toward Value-Added, Degradable and Recyclable Poly(Ether-Ester). ACS Sustain. Chem. Eng. 2022, 10, 8228–8238. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, D.; Shen, Y.; Li, Z. Ring-Opening Polymerization of Enantiopure Bicyclic Ether-Ester Monomers toward Closed-Loop Recyclable and Crystalline Stereoregular Polyesters via Chemical Upcycling of Bioplastic. Angew. Chem. Int. Ed. Engl. 2023, 62, e202302101. [Google Scholar] [CrossRef]

- Shi, C.; Clarke, R.W.; McGraw, M.L.; Chen, E.Y.X. Closing the “One Monomer-Two Polymers-One Monomer” Loop via Orthogonal (De)Polymerization of a Lactone/Olefin Hybrid. J. Am. Chem. Soc. 2022, 144, 2264–2275. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Rettner, E.M.; Harry, K.L.; Hu, Z.; Miscall, J.; Rorrer, N.A.; Miyake, G.M. Chemically Recyclable Polyolefin-like Multiblock Polymers. Science 2023, 382, 310–314. [Google Scholar] [CrossRef] [PubMed]

- Guselnikova, O.; Semyonov, O.; Sviridova, E.; Gulyaev, R.; Gorbunova, A.; Kogolev, D.; Trelin, A.; Yamauchi, Y.; Boukherroub, R.; Postnikov, P. “Functional Upcycling” of Polymer Waste towards the Design of New Materials. Chem. Soc. Rev. 2023, 52, 4755–4832. [Google Scholar] [CrossRef]

- Saxon, D.J.; Gormong, E.A.; Shah, V.M.; Reineke, T.M. Rapid Synthesis of Chemically Recyclable Polycarbonates S1 of S36 Supporting Information Rapid Synthesis of Chemically Recyclable Polycarbonates from Renewable Feedstocks. ACS Macro Lett. 2021, 10, 98–103. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Dai, J.; Wu, Y.-C.; Chen, J.-X.; Shan, S.-Y.; Cai, Z.; Zhu, J.-B. Highly Reactive Cyclic Carbonates with Fused-Ring towards Functionalizable and Recyclable Polycarbonates. ACS Macro Lett. 2022, 11, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.S.K.; Chen, Y.-C.; Jeng, R.-J.; Abu-Omar, M.M.; Lin, C.-H. Upcycling Waste Polycarbonate to Poly(Carbonate Imine) Vitrimers with High Thermal Properties and Unprecedented Hydrolytic Stability. ACS Sustain. Chem. Eng. 2023, 11, 8580–8591. [Google Scholar] [CrossRef]

- Cywar, R.M.; Rorrer, N.A.; Mayes, H.B.; Maurya, A.K.; Tassone, C.J.; Beckham, G.T.; Chen, E.Y.X. Redesigned Hybrid Nylons with Optical Clarity and Chemical Recyclability. J. Am. Chem. Soc. 2022, 144, 5366–5376. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.S.; Truong, N.P.; Pei, Z.; Coote, M.L.; Anastasaki, A. Reversing RAFT Polymerization: Near-Quantitative Monomer Generation Via a Catalyst-Free Depolymerization Approach. J. Am. Chem. Soc. 2022, 144, 4678–4684. [Google Scholar] [CrossRef]

- Jacobsen, A.J. A Future Vision for More Sustainable Plastics. Nature Portfolio. 2023, Amazon. Available online: https://www.nature.com/articles/d42473-022-00488-1 (accessed on 14 March 2024).

- Yang, R.; Xu, G.; Dong, B.; Guo, X.; Wang, Q. Selective, Sequential, and “One-Pot” Depolymerization Strategies for Chemical Recycling of Commercial Plastics and Mixed Plastics. ACS Sustain. Chem. Eng. 2022, 10, 9860–9871. [Google Scholar] [CrossRef]

- García, J.L. Enzymatic Recycling of Polyethylene Terephthalate through the Lens of Proprietary Processes. Microb. Biotechnol. 2022, 15, 2699–2704. [Google Scholar] [CrossRef]

- Singh, A.; Rorrer, N.A.; Nicholson, S.R.; Erickson, E.; DesVeaux, J.S.; Avelino, A.F.T.; Lamers, P.; Bhatt, A.; Zhang, Y.; Avery, G.; et al. Techno-Economic, Life-Cycle, and Socioeconomic Impact Analysis of Enzymatic Recycling of Poly(Ethylene Terephthalate). Joule 2021, 5, 2479–2503. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Mavinkere Rangappa, S.; Siengchin, S.; Puttegowda, M.; Thiagamani, S.M.K.; Hemath Kumar, M.; Oladijo, O.P.; Fiore, V.; Moure Cuadrado, M.M. Sustainable Recycling Technologies for Thermoplastic Polymers and Their Composites: A Review of the State of the Art. Polym. Compos. 2022, 43, 5831–5862. [Google Scholar] [CrossRef]

- Then, J.; Wei, R.; Oeser, T.; Barth, M.; Belisário-Ferrari, M.R.; Schmidt, J.; Zimmermann, W. Ca2+ and Mg2+ Binding Site Engineering Increases the Degradation of Polyethylene Terephthalate Films by Polyester Hydrolases from Thermobifida Fusca. Biotechnol. J. 2015, 10, 592–598. [Google Scholar] [CrossRef]

- Sadler, J.C.; Wallace, S. Microbial Synthesis of Vanillin from Waste Poly(Ethylene Terephthalate). Green Chem. 2021, 23, 4665–4672. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, T.A.; Barbosa, R.; Mesquita, A.B.S.; Ferreira, J.H.L.; de Carvalho, L.H.; Alves, T.S. Fungal Degradation of Reprocessed PP/PBAT/Thermoplastic Starch Blends. J. Mater. Res. Technol. 2020, 9, 2338–2349. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A Review on Degradation Mechanisms of Polylactic Acid: Hydrolytic, Photodegradative, Microbial, and Enzymatic Degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Almushaikeh, A.M.; Alaswad, S.O.; Alsuhybani, M.S.; AlOtaibi, B.M.; Alarifi, I.M.; Alqahtani, N.B.; Aldosari, S.M.; Alsaleh, S.S.; Haidyrah, A.S.; Alolyan, A.A.; et al. Manufacturing of Carbon Fiber Reinforced Thermoplastics and Its Recovery of Carbon Fiber: A Review. Polym. Test. 2023, 122, 108029. [Google Scholar] [CrossRef]

- Roux, M.; Eguémann, N.; Dransfeld, C.; Thiébaud, F.; Perreux, D. Thermoplastic Carbon Fibre-Reinforced Polymer Recycling with Electrodynamical Fragmentation: From Cradle to Cradle. J. Thermoplast. Compos. Mater. 2017, 30, 381–403. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling Glass Fiber Thermoplastic Composites from Wind Turbine Blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Kiss, P.; Stadlbauer, W.; Burgstaller, C.; Stadler, H.; Fehringer, S.; Haeuserer, F.; Archodoulaki, V.-M. In-House Recycling of Carbon- and Glass Fibre-Reinforced Thermoplastic Composite Laminate Waste into High-Performance Sheet Materials. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106110. [Google Scholar] [CrossRef]

| No. | FRP Type | Pyrolysis Conditions | Post- Pyrolysis | Pyrolysis By-Products | Fibres Evaluation | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temp. Ranges (°C) | Duration (min) | Gas | Gases | Liquids | Solids | |||||

| 1 | GF/calcium carbonate and aluminium trihydrate fillers/ Polyester-styrene resin | 10 °C/min heating rate, 350–800 °C | 60 | N2 (preheated at 180 °C) | - | 2.6–14.4 wt.% | 14.5–47.4 wt.% | 38.2–82.9 wt.% | - | [45] |

| 2 | GF polyester-styrene resin | 0.6–4.6 wt.% | 5.1–11.9 wt.% | 83.4–94.3 wt.% | ||||||

| 3 | CF/Phenolic resin | 0.2–3.0 wt.% | 19.0–31.7 wt.% | 65.3–81.7 wt.% | ||||||

| 4 | GF/CF/epoxy resin | 1.1–4.6 wt.% | 15.0–64.1 wt.% | 32.6–83.4 wt.% | ||||||

| 5 | Woven CF/Polybenzoxazine resin | 5 °C/min heating rate, 350–700 °C | 60 | Nitrogen | 500 °C for 120 min and 700 °C for 15 min | (vol %) CH4 (7.8–31.7) C2 gas (1.7–1) C3 gas (7.8–7.1) C4 gas (4.7–2.7) H2 (11.2–26.5) CO (7.7–10.1) CO2 (59.1–20.9) | Toluene, Benzene, 1,3-dimethyl Ethylbenzene, Aniline, Benzene, 1-methyl-3-(-methylethyl)-Phenol, 2-methyl, Aniline, N-methyl-Phenol, 2-ethyl-Benzeneamine, N,4-dimethyl-Phenol, 3-(1-methylethyl)-Thymol, Phenylalanine, 4-amino-N-BOC-, t-butyl ester | Yield 83–70% | Optimum quality of fibres obtained at 500 °C for both pyrolysis and post-pyrolysis. | [50] |

| 6 | Woven Prepreg Hexply 913C/HTA CF-125 °C 913 epoxy | 10 °C/min 400–600 | 30–120 | Air, N2 | - | - | - | - | Clean fibres achieved between 500–600 °C in 2 h treatment | [41] |

| 7 | T800SCF/epoxy composite | 550 | 20 | N2 | 90 min at 550 °C | - | - | - | [51] | |

| 8 | Isotropic GF/ polyester mat | 500–600 | 150 | N2 | 500–600 °C at 10–60 min | (vol %) CO2 (32.6–20.4) H2 (5.8–11.5) CH4 (10.6–20.7) C2H4 (4.8–5.2) C2H6 (2.8–5.2) | (g/L) Benzene (3.4–6.8) Toluene (15.0–27.3) Ethylbenzene (16.7–21.5) Styrene (7.9–13.6) | 44.3–38.7 wt.% | Complete removal of char at 500 °C for 60 min | [52] |

| 9 | Woven CF/epoxy | 550 | 330 | N2 | 400 °C at 10–50 min 500 °C at 10–50 min | - | - | 78–93.68 * | Complete removal of char at 500 °C for 60 min | [44] |

| Recycling Approach | Procedure | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|

| Primary Recycling | Closed-loop Includes the mechanical reprocessing of high purity industrial polymeric residues from the production processes (scrap) | Industries can maximize their energy savings, easy identification of the polymeric streams industrially, highly clean, uncontaminated, single polymer type waste streams | Very small percentage of material recycled by primary recycling | [118,119] |

| Secondary or Mechanical recycling | Open-loop Includes the mechanical reprocessing of post-consumer polymeric waste streams | High industrial expertise and infrastructure | Highly contaminated waste streams, great heterogeneity in terms of composition due to the variety of polymer qualities and grades | [120] |

| Tertiary or Chemical recycling | Closed- or open-loop Includes the chemical transformation (hydrolysis, pyrolysis, or other decomposition mechanism) that can lead either to monomer recovery (closed-loop), or feedstock (open-loop) | Added value output materials | In some cases, hazardous materials are required (e.g., catalysts, solvents) with scalability of processes and economic viability | [121] |

| Quaternary or Energy recovery | Open-loop Includes the incineration of the waste polymers for energy generation | Can be applied when no other value-added routes can be performed, incinerator steam can be used to generate electricity via turbine generators | Partial recovery of energy, does not generate economic value or moderate the materials resource depletion in the long term, generates emissions of CO2 and other hazardous gases, toxic residues with high environmental impact | [121] |

| Recycling Method | Material | Reagent/ Catalyst | Temperature (°C)/Pressure (atm) | Yield | Reaction Time | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|---|---|---|---|

| Hydrolysis (acidic) | PET | Sulfuric acid | 100 | 85–99% TPA | 30 min | Low reaction times, High purity of TPA product | Low pH creates safety concerns | [234] |

| Hydrolysis (alkaline) | PET | NaOH/TBHDPB | 80–100 | 93.5% TPA | 4 h | High purity of TPA product | Higher temperatures and longer reaction times/needs catalysis | [235] |

| Hydrolysis (neutral) Hydrolysis (neutral) | PET PET | H2O | 200/autoclave | 86% TPA | 6 h | Environmentally friendly process | High temperatures/pressure, High reaction times/Low purity of products | [236] |

| 98% TPA | 24 h | |||||||

| H2O/ ZnCl2/microwave assisted | 180 | 100% TPA | 8 h | Low purity of products | [233] | |||

| Alcoholysis | PET | 2-EH/[Bmim]Cl/ZA | 190–200 | 93.1% DOTP | 5 h | The imidazole IL [Bmim]Cl is low-cost and also can be recycled, high yields, low reaction times | - | [237] |

| Methanolysis | PET | MeOH/BLA | 200/ 20–40 | 78% DMT 76% EG | 2 h | Low-cost reagents | Lower yields, separation of EG from DMT and catalyst residues | [238] |

| PC | MeOH/NaOH/THF | 40 | 80% Bisphenol A | 10 min | Mild conditions | - | [239] | |

| Aminolysis | PET | Ethanolamine/1,5,7-Triazabicyclo[4.4.0]dec-5-ene | 120 | 93% BHETA | 2 h | Milder conditions (temperature, pressure), high yield and purity | - | [240] |

| Glycolysis | PET | EG/niobia-based catalyst | 195 | 85% BHET | 220 min | Nontoxic and inexpensive catalyst, lower reaction times | - | [241] |

| PET | EG/M/SBA-15 | 190 | 87.2% BHET | 45 min | Lower reaction times | [242] | ||