Development and Validation of a Novel Setup for LEDs Lifetime Estimation on Molded Interconnect Devices

Abstract

:1. Introduction

2. System Design and Methods

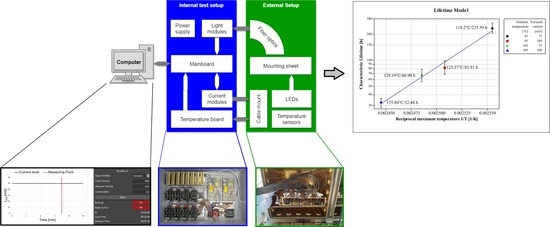

2.1. LED Lifetime Analyzer

2.1.1. The Test Setup

- Housing the microcontroller and its peripherals, as well as logic;

- Hardware power supply with +5 V, −5 V, and +3.3 V;

- Serial communication with the control software via a USB cable;

- Switching the digital and analog multiplexers;

- Reading the values coming from the light sensors via the I2C bus;

- Analog-to-digital conversion for the voltage and temperature measurement;

- Control of the constant current levels by providing the appropriate analog control voltages.

2.1.2. The Software

2.2. Experimental Procedure

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- EIAJ ED-4701/100 Standard of Japan Electronics and Information Technology Industries Association. Environmental and Endurance Test Methods for Semiconductor Devices. Japan. 2001. Available online: https://home.jeita.or.jp/tsc/std-pdf/ED-4701_400-1.pdf (accessed on 4 December 2018).

- STEADY-STATE TEMPERATURE-HUMIDITY BIAS LIFE TEST | JEDEC. Available online: https://www.jedec.org/standards-documents/docs/jesd-22-a101c (accessed on 1 July 2018).

- JEDEC Solid State Technology Association. JEDEC Standard No. 22-A108D: Temperature, Bias, and Operating Life; JEDEC: Arlington, VA, USA, 2010. [Google Scholar]

- DIN EN IEC 62663-2—Non-ballasted LED lamps—Performance requirements (IEC 34A/1601/CD:2012); Deutsches Institut für Normung—German Institute for Standardization: Berlin, Germany, 2012.

- DIN EN IEC 62717:2014 + AMD1:2015 CSV—LED modules for general lighting—Performance requirements; Deutsches Institut für Normung—German Institute for Standardization: Berlin, Germany, 2015.

- Chen, C.H.; Tsai, W.L.; Tsai, M.Y. Thermal resistance and reliability of low-cost high-power LED packages under WHTOL test. In Proceedings of the 2008 International Conference on Electronic Materials and Packaging, Taibei, Taiwan, 22–24 October 2008; pp. 271–276. [Google Scholar]

- Solid State Lighting Reliability: Components to Systems; Van Driel, W.D.; Fan, X. (Eds.) Solid State Lighting Technology and Application Series; Springer: New York, NY, USA, 2012; ISBN 978-1-4614-3066-7. [Google Scholar]

- Van Driel, W.D.; Fan, X.; Zhang, G.Q. Solid State Lighting Reliability Part 2: Components to Systems; Springer: Cham, Switzerland, 2018; ISBN 978-3-319-58175-0. [Google Scholar]

- Thermal Management for LED Applications; Lasance, C.J.M.; Poppe, A. (Eds.) Solid State Lighting Technology and Application Series; Springer: New York, NY, USA, 2014; Volume 2, ISBN 978-1-4614-5091-7. [Google Scholar]

- Lu, G.; Yang, S.; Huang, Y. Analysis on failure modes and mechanisms of LED. In Proceedings of the 2009 8th International Conference on Reliability, Maintainability and Safety, Chengdu, China, 20–24 July 2009; pp. 1237–1241. [Google Scholar]

- Guoguang, L.; Yun, H.; Yunfei, E.; Shaohua, Y.; Zhifeng, L. The relationship between LED package and reliability. In Proceedings of the 2009 16th IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits, Suzhou, China, 6–10 July 2009; pp. 323–326. [Google Scholar]

- Albertini, A.; Masi, M.G.; Mazzanti, G.; Peretto, L.; Tinarelli, R. A test set for LEDs life model estimation. In Proceedings of the 2010 IEEE Instrumentation & Measurement Technology Conference, Austin, TX, USA, 3–6 May 2010; pp. 426–431. [Google Scholar]

- Albertini, A.; Masi, M.G.; Mazzanti, G.; Peretto, L.; Tinarelli, R. Experimental Analysis of LEDs’ Reliability Under Combined Stress Conditions. In Proceedings of the 2011 IEEE International Instrumentation and Measurement Technology Conference, Binjiang, China, 10–12 May 2011. [Google Scholar]

- Nogueira, E.; Orlando, V.; Ochoa, J.; Fernandez, A.; Vazquez, M. Accelerated Life Test of high luminosity blue LEDs. Microelectron. Reliabil. 2016, 64, 631–634. [Google Scholar] [CrossRef]

- Albertini, A.; Mazzanti, G.; Peretto, L.; Tinarelli, R. Development of a Life Model for Light Emitting Diodes Stressed by Forward Current. IEEE Trans. Reliabil. 2014, 63, 523–533. [Google Scholar] [CrossRef]

- Soltani, M.; Kulkarni, R.; Liu, Y.; Barth, M.; Groezinger, T.; Zimmermann, A. Experimental and computational study of array effects on LED thermal management on molded interconnect devices MID. In Proceedings of the 2018 13th International Congress Molded Interconnect Devices (MID), Wurzburg, Germany, 25–26 September 2018; p. 6. [Google Scholar]

- Barth, M.; Kulkarni, R.; Soltani, M.; Eberhardt, W.; Meißner, T.; Zimmermann, A. Heat dissipation for MID applications in lighting technology. In Proceedings of the 2016 12th International Congress Molded Interconnect Devices (MID), Wurzburg, Germany, 28–29 September 2016; pp. 1–4. [Google Scholar]

- Leneke, T.; Schmidt, B. Entwärmungskonzepte durch funktionale Strukturen in spritzgegossenen dreidimensionalen Schaltungsträgern; Berichte aus der Elektrotechnik; 1. Aufl.; Shaker: Aachen, Germany, 2013; ISBN 978-3-8440-1688-8. [Google Scholar]

- Heinle, C. Simulationsgestützte Entwicklung von Bauteilen aus wärmeleitenden Kunststoffen; Universität Erlangen-Nürnberg: Erlangen, Germany, 2012. [Google Scholar]

- Heinle, C. Development and Production of highly integrated LED-Systems with Thermal Conductive Polymers by (Assembly-) Molding. In Proceedings of the Workshop three-dimensional arrangement of LEDs, Bregenz, Austria, 25 September 2013. [Google Scholar]

- Groezinger, T. Untersuchungen zu Zuverlässigkeit und Lebensdauermodellen für gelötete SMD auf spritzgegossenen Schaltungsträgen. Ph.D. Thesis, Institute for Micro Integration, University of Stuttgart, Stuttgart, Germany, 2015. [Google Scholar]

- Wild, P.; Groezinger, T.; Lorenz, D.; Zimmermann, A. Void Formation and Their Effect on Reliability of Lead-Free Solder Joints on MID and PCB Substrates. IEEE Trans. Reliabil. 2017, 66, 1229–1237. [Google Scholar] [CrossRef]

- Wild, P.; Lorenz, D.; Groezinger, T.; Zimmermann, A. Effect of voids on thermo-mechanical reliability of chip resistor solder joints: Experiment, modelling and simulation. Microelectron. Reliabil. 2018, 85, 163–175. [Google Scholar] [CrossRef]

- Soltani, M.; Freyburger, M.; Kulkarni, R.; Mohr, R.; Groezinger, T.; Zimmermann, A. Reliability study and thermal performance of LEDs on molded interconnect devices (MID) and PCB. Multidiscip. Open Access J. IEEE Access 2018, 11, 51669–51679. [Google Scholar] [CrossRef]

- Chang, M.-H.; Das, D.; Varde, P.V.; Pecht, M. Light emitting diodes reliability review. Microelectron. Reliabil. 2012, 52, 762–782. [Google Scholar] [CrossRef]

- Svasta, P.; Simion-Zanescu, D.; Ionescu, R. Components’ emissivity in reflow soldering process. In Proceedings of the 2004 54th Electronic Components and Technology Conference (IEEE Cat. No. 04CH37546), Las Vegas, NV, USA, 4 June 2004; Volume 2, pp. 1921–1924. [Google Scholar]

- Bertsche, B.; Lechner, G. Zuverlässigkeit im Fahrzeug- und Maschinenbau: Ermittlung von Bauteil- und System-Zuverlässigkeiten; VDI; 3. überarb. und erw. Aufl.; Springer: Berlin, Germany, 2004; ISBN 978-3-540-20871-6. [Google Scholar]

- Bertsche, B.; Göhner, P.; Jensen, U.; Schinköthe, W.; Wunderlich, H.-J. Zuverlässigkeit mechatronischer Systeme: Grundlagen und Bewertung in frühen Entwicklungsphasen; VDI; Springer: Berlin, Germany, 2009; ISBN 978-3-540-85089-2. [Google Scholar]

- Hartzell, A.L.; da Silva, M.G.; Shea, H.R. Lifetime Prediction. In MEMS Reliability; Springer: Boston, MA, USA, 2011; pp. 9–42. ISBN 978-1-4419-6017-7. [Google Scholar]

| Factor | Stage Low | Stage High |

|---|---|---|

| Forward current | 75 mA | 100 mA |

| Ambient Temperature | 85 °C | 105 °C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltani, M.; Freyburger, M.; Kulkarni, R.; Mohr, R.; Groezinger, T.; Zimmermann, A. Development and Validation of a Novel Setup for LEDs Lifetime Estimation on Molded Interconnect Devices. Instruments 2018, 2, 28. https://doi.org/10.3390/instruments2040028

Soltani M, Freyburger M, Kulkarni R, Mohr R, Groezinger T, Zimmermann A. Development and Validation of a Novel Setup for LEDs Lifetime Estimation on Molded Interconnect Devices. Instruments. 2018; 2(4):28. https://doi.org/10.3390/instruments2040028

Chicago/Turabian StyleSoltani, Mahdi, Moritz Freyburger, Romit Kulkarni, Rainer Mohr, Tobias Groezinger, and André Zimmermann. 2018. "Development and Validation of a Novel Setup for LEDs Lifetime Estimation on Molded Interconnect Devices" Instruments 2, no. 4: 28. https://doi.org/10.3390/instruments2040028