Abstract

Although distributed additive manufacturing can provide high returns on investment, the current markup on commercial filament over base polymers limits deployment. These cost barriers can be surmounted by eliminating the entire process of fusing filament by three-dimensional (3-D) printing products directly from polymer granules. Fused granular fabrication (FGF) (or fused particle fabrication (FPF)) is being held back in part by the accessibility of low-cost pelletizers and choppers. An open-source 3-D printable invention disclosed here allows for precisely controlled pelletizing of both single thermopolymers as well as composites for 3-D printing. The system is designed, built, and tested for its ability to provide high-tolerance thermopolymer pellets with a number of sizes capable of being used in an FGF printer. In addition, the chopping pelletizer is tested for its ability to chop multi-materials simultaneously for color mixing and composite fabrication as well as precise fractional measuring back to filament. The US$185 open-source 3-D printable pelletizer chopper system was successfully fabricated and has a 0.5 kg/h throughput with one motor, and 1.0 kg/h throughput with two motors using only 0.24 kWh/kg during the chopping process. Pellets were successfully printed directly via FGF as well as indirectly after being converted into high-tolerance filament in a recyclebot.

1. Introduction

Adopting an open-source model of technological development by the founding members of the self-replicating rapid prototyper (RepRap) three-dimensional (3-D) printer [1,2,3] community radically reduced the costs of additive manufacturing (AM). With the costs of prosumer (producing consumer) desktop 3-D printers dropping low enough, the phenomenon of distributed manufacturing with AM emerged [4,5,6]. Using commercial polymer filament 3-D printing enables prosumers significant savings as compared to purchasing mass-manufactured products such as glasses [7], alternative energy mechanical parts [8], flexible products [9], toys and games [10], and a wide range of other consumer products [11,12]. The business community recognizes the potential shift in manufacturing with AM [13,14,15] because of millions of freely shared digital design files for 3-D printable products [12]. A high return on investment (ROI) is found for prosumer distributed manufacturing with commercial polymer 3-D printing filament based on downloaded substitution values [16,17]. These savings are somewhat muted by the markup on commercial filament over base commercial polymers, which is currently about five to 10 times the cost of the raw plastic pellets. This reduces the deployment of distributed manufacturing to accelerate the adoption of AM at the prosumer level [18], in addition to limiting the vast majority of 3-D printed articles to small objects.

One method of overcoming these cost barriers is to skip the entire process of fusing filament into a 3-D printed object by printing directly from polymer granules. Fused granular fabrication (FGF) or the more generic fused particle fabrication (FPF) (indicating any size or shape of polymer feedstock) have been developed and designs are flourishing in maker communities [19,20,21] as well as in industry with commercialized printers [21,22,23,24,25,26]. Academia has also taken a keen interest in the technology [27,28] for virgin [29] and recycled materials [30,31] including multi-head [32], industrial robot adaptations [33], electronics printing [34], flexible materials printing [35], and biopolymer printing [36]. To date, however, only a small subset of the thermoplastic materials capable of being printed by such systems have been investigated. Moreover, there has been almost no research on printing with the nearly unlimited variety of obvious composited 3-D printing materials [37].

Potential applications available from coupling materials science with FGF are being held back in part by the accessibility of low-cost pelletizers and choppers. In general, these are large industrial machines not conducive for research or prosumer use because of their high throughputs and capital costs. There have been some attempts at making such systems on the small scale by the maker community [38,39,40,41]. These systems have several deficiencies. First, with current solutions, the feed rate is fixed at a constant speed, meaning the size of the granules cannot be changed. The current solutions also only allow one inlet for filaments, meaning you can only chop one type of filament at a time. The throughput of material can be slower as well, because of the single input on the currently available machines.

In order to provide a low-cost tool for making precise chopped pellets of both single thermopolymers as well as composites, this study follows the open-source hardware design paradigm [42,43]. It thus provides open-source designs of a 3-D printable polymer pelletizer chopper for FGF-based AM. The system is designed, built, and tested for its ability to provide high-tolerance thermopolymer pellets with a number of sizes capable of being used in an FGF printer. In addition, the chopping pelletizer is tested for its ability to chop multi-materials simultaneously for color mixing and composite fabrication as well as precise fractional measuring. The results are presented and discussed.

2. Materials and Methods

2.1. Designs

The bill of materials (BOM) summary can be seen in Table 1 and the tools and consumables are shown in Table 2. As Table 1 shows, a single motor version of the system can be fabricated for US$185. A more detailed BOM along with the STP (STandard for the Exchange of Product files for redesign in FreeCAD) and STL files (Standard Triangle Language file for direct 3-D printing on any RepRap-class fused filament fabrication (FFF) 3-D printer) are available in the Open Science Framework [44]. All STL parts, unless specifically labeled to be printed with NinjaFlex, can be printed with polylactic acid (PLA) or any other hard FFF thermoplastic.

Table 1.

Bill of materials (BOM) for a one-motor setup.

Table 2.

Tools and consumables.

2.1.1. Mechanical

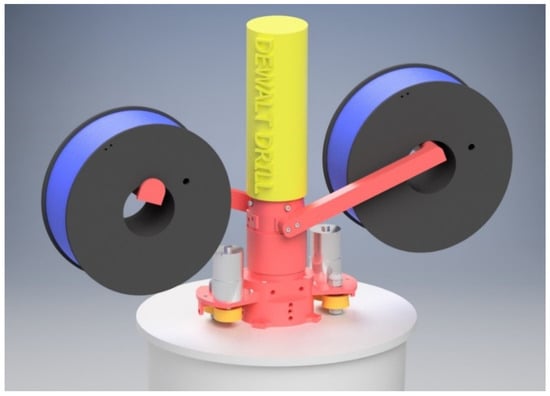

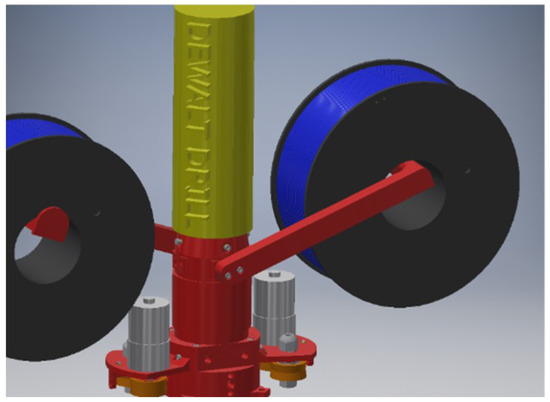

3-D printable parts were manufactured on a Lulzbot Taz 6 (Aleph Objects, Loveland, CO, USA) with 50% fill for PLA and 100% Ninjaflex (Ninjatek, St. Manheim, PA, USA). After 3-D printing all of the STLs reported in Reference [44] with a RepRap class 3-D printer from NinjaFlex (for gripping wheels) and PLA (all other parts), and purchasing the components in Table 1, assembly can begin. In order to comply with open-source hardware design guidelines, detailed assembly instructions are provided in this section. The mechanical assembly can be guided by a rendering of the major components shown in Figure 1.

Figure 1.

Rendering of major components of the 2× version of the open-source 3-D printable pelletizer chopper.

Filament is fed through Ninjaflex gripper wheels into the main assembly, where it is chopped by the Forstner bit driven by the drill motor. The size of the pellets is controlled with the speed controller governing the NinjaFlex wheels and the motor.

The basic mechanical assembly instructions:

- Subassembly preparation for grabbing wheels.

- Glue Ninjaflex wheels to double stack of bearings

- Glue Ninjaflex wheels to printed motor wheel

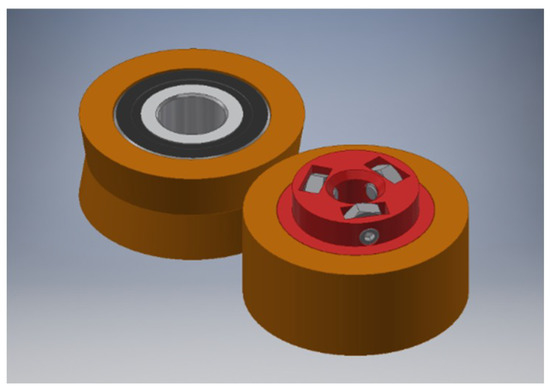

- Place M3 nuts and M3 grub screws into printed motor wheel as shown in Figure 2.

Figure 2. Rendering of Ninjaflex grabber wheels with nut traps and bearings.

Figure 2. Rendering of Ninjaflex grabber wheels with nut traps and bearings.

- Base Layer

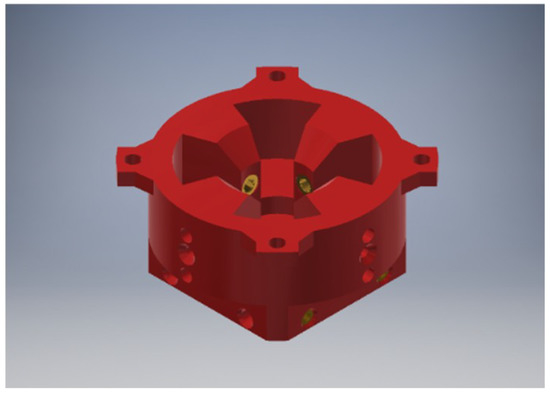

- Start with the base part facing down (Figure 3), insert an M5 heat insert into the holes you plan on using.

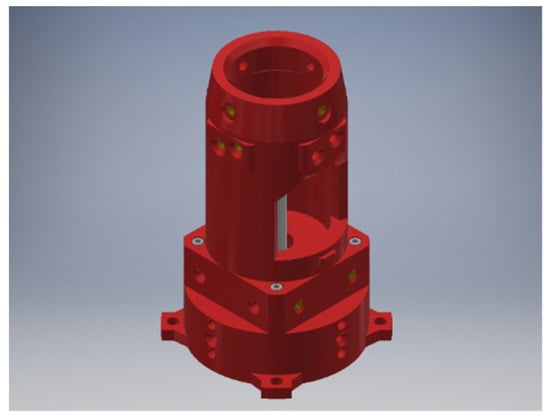

Figure 3. Rendering of base of the open-source 3-D printable pelletizer chopper.

Figure 3. Rendering of base of the open-source 3-D printable pelletizer chopper. - Flip the base over and insert M3 heat inserts into the sides and top. Only insert where needed (e.g., one motor only needs one side, four motors need all sides).

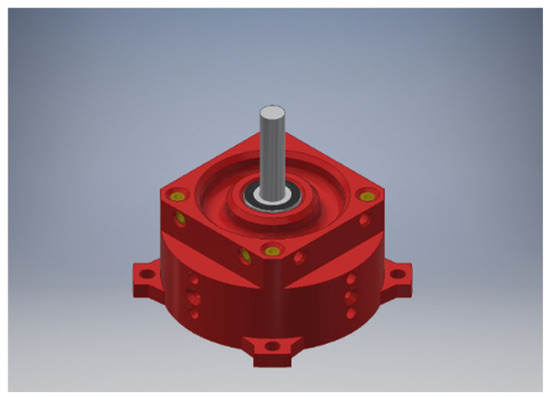

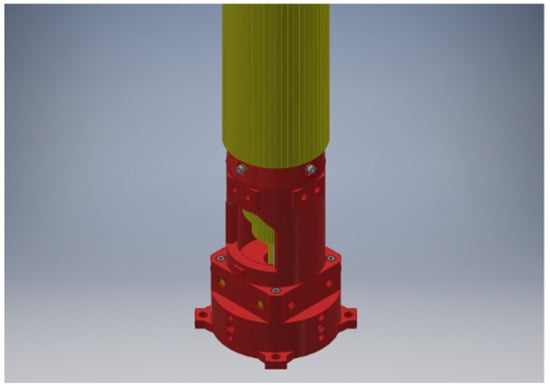

- Once complete (Figure 4), insert bearing into the top as shown, then insert Forstner bit through the bottom.

Figure 4. Rendering of assembled base of the open-source 3-D printable pelletizer chopper.

Figure 4. Rendering of assembled base of the open-source 3-D printable pelletizer chopper.

- Middle Layer

- Place the middle section on top of base, secure using M3 × 10 mm screws.

- Insert the M3 heat set inserts into the top four holes as well as the angled holes for the spool holders (only need to insert into sides being used).

- Make sure the Forstner bit goes through both the middle and the base, as in Figure 5.

Figure 5. Rendering of middle section of the open-source 3-D printable pelletizer chopper.

Figure 5. Rendering of middle section of the open-source 3-D printable pelletizer chopper. - Put drill motor in through the top and use the included chuck key to tighten it onto Forstner bit (Figure 6).

Figure 6. Rendering of assembled middle section of the open-source 3-D printable pelletizer chopper.

Figure 6. Rendering of assembled middle section of the open-source 3-D printable pelletizer chopper.

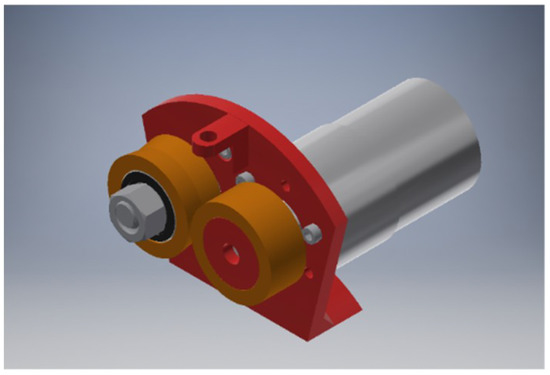

- Filament Drivers

- Screw the motor into the bracket using M3 × 10 mm screws, then place the printed motor wheel onto the shaft.

- Screw in the filament guide using an M3 × 10 mm screw and heat set insert, as shown in Figure 7.

Figure 7. Rendering of filament driver of the open-source 3-D printable pelletizer chopper.

Figure 7. Rendering of filament driver of the open-source 3-D printable pelletizer chopper. - Assemble the idler wheel with the following sequence: bolt head, bracket, printed spacer, NinjaFlex wheel, and nut.

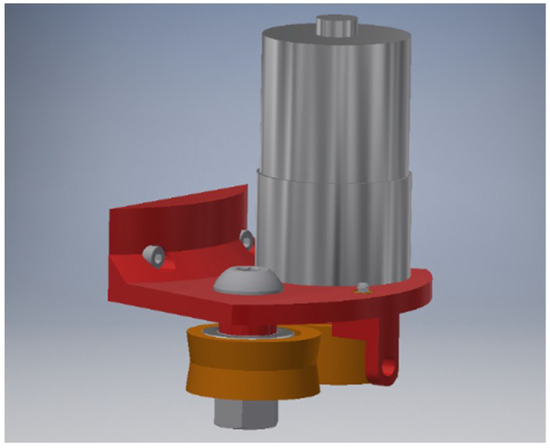

- Secure filament driver assembly onto the rest of the main assembly, as shown in Figure 8.

Figure 8. Rendering of the assembled filament driver with motor of the open-source 3-D printable pelletizer chopper.

Figure 8. Rendering of the assembled filament driver with motor of the open-source 3-D printable pelletizer chopper.

- Spool Holder

- Use the M3 × 10 mm bolts to attach the spool holder arms (Figure 9).

Figure 9. Rendering of the details of the spool arms of the open-source 3-D printable pelletizer chopper.

Figure 9. Rendering of the details of the spool arms of the open-source 3-D printable pelletizer chopper.

2.1.2. Electrical

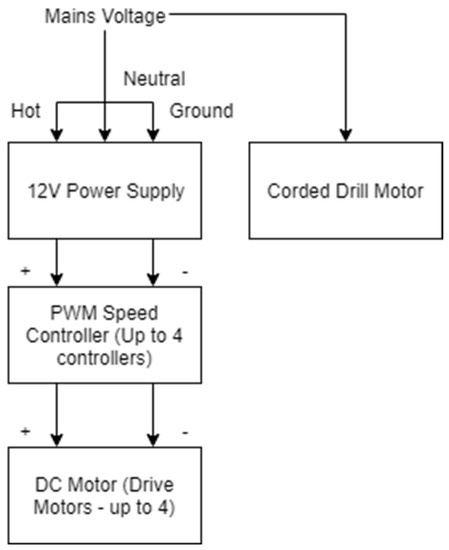

Figure 10 shows the wiring schematic for the open-source 3-D printable pelletizer chopper.

Figure 10.

Pelletizer wiring schematic.

2.2. Materials

For testing, the two most popular 3-D printing materials and diameters were used: 1.75 mm polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) from Matterhackers, as well as 2.85 mm PLA and ABS from Ultimachine. In addition, coffee-filled PLA filament made using waste byproducts from coffee developed by 3DFuel, polypropylene (PP) from Ultimaker, and glycol-modified polyethylene terephthalate (PETg) from E-Sun were tested. Lastly, NinjaFlex developed by NinjaTek was attempted; but it was found to be too flexible to be used in the machine in its current design.

2.3. System Performance Quantification

The size characteristics of the particles for each starting material as a function of drive speed from 200 to 100 to 50 rpm were quantified using digital imaging and the open-source Fiji/ImageJ [45]. The rate of pellet production (kg/h) was timed with a digital watch and determined with an electronic scale (±0.05). Electricity consumption was monitored with a multimeter (±0.005 kW·h) for each material during processing.

2.4. FPF 3-D Printing

A prototype Gigabot X [46,47] was used to print the materials. 3-D models were sliced with Slic3r [48] and the printer was controlled with Marlin Firmware [49].

2.5. Pellets as Recyclebot Feedstock

A RepRapable recyclebot [50] (an open-source waste plastic extruder [51,52]) was used to make PLA filament from pellets. The extrusion temperature was set at 170 °C with cooling enabled at 100% and a fixed puller rate.

3. Results

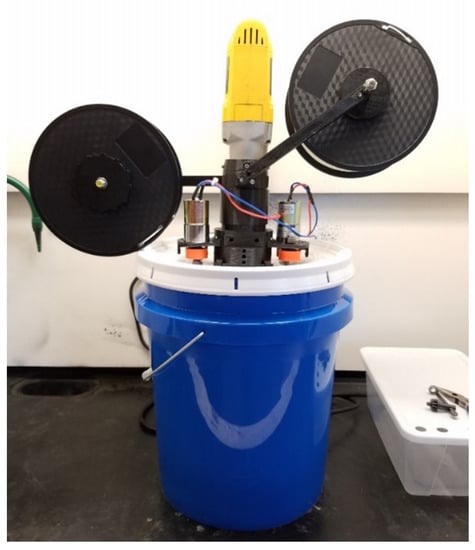

The open-source 3-D printable pelletizer chopper system was successfully fabricated, as shown in Figure 11, and operated as demonstrated in Video S1. It has a 0.5 kg/h throughput with one motor and a 1.0 kg/h throughput with two motors. The electricity consumption was found to be 0.24 kWh/kg during the chopping process with two motors. It should be noted that the power draw from the feeder motors did not have an impact on the energy utilization of the entire device.

Figure 11.

Fully assembled open-source 3-D printable pelletizer chopper system.

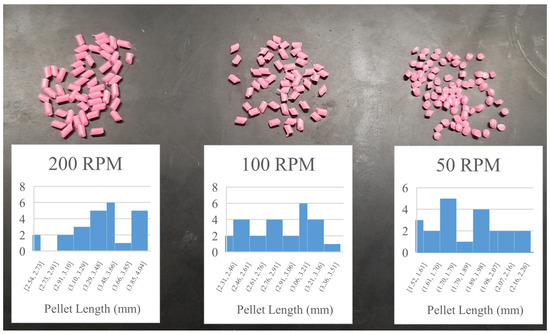

3.1. Pellet Manufacturing

The system could control the particle size by changing the speed. The particle size distributions are shown in Figure 12.

Figure 12.

Photograph of particle sizes for 200, 100, and 50 rpm with the particle size distributions shown in the inset.

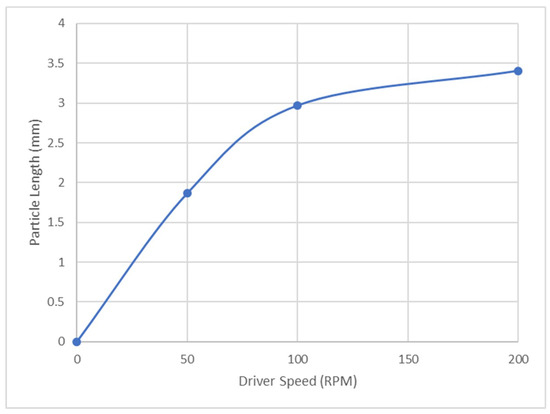

A graph of the mean particle size and the speed of the system is shown in Figure 13.

Figure 13.

Mean particle size as a function of the speed of the filament driver.

The pellet production rate in kg/h is a function of speed of the motor and is linear: 0.5 kg/h at full speed with one motor, 0.25 at 100 rpm, and 0.125 at 50 rpm.

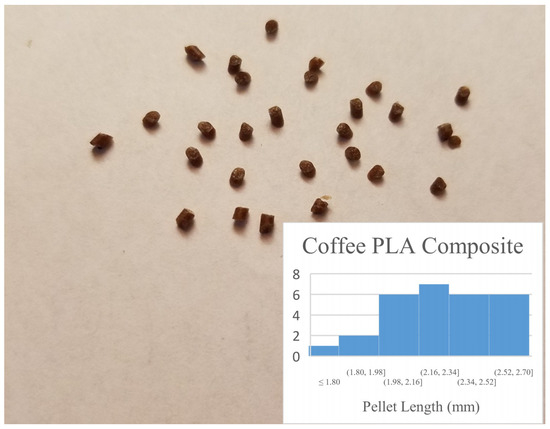

Pellets can also be made of specialty materials, as demonstrated in Figure 14 for a coffee-waste-infused PLA composite. These results provide the potential for fabricating more waste byproduct 3-D printable composites following the multistep process detailed by Pringle et al. [53]. In this process, a waste material is mixed with a thermopolymer and rough extruded once from a recyclebot, chopped, and then re-extruded to obtain a high-quality filament [53].

Figure 14.

Photograph of particle sizes with the particle size distributions determined from ImageJ shown for a coffee-PLA composite.

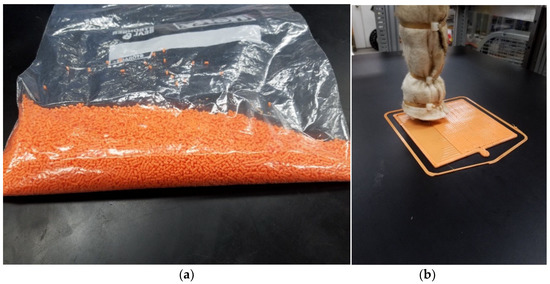

3.1.1. Pellets for FGF

PLA pellets (Figure 15a) were fed into the prototype Gigabot X and no issues were detected during the printing process (Figure 15b). The small size and cylindrical shape of the uniform pellets allowed them to flow very easily through the hopper and down into the extrusion screw.

Figure 15.

(a) PLA pellets made with the pelletizer; (b) printing with ease on the Gigabot X.

3.1.2. Pellets for Recyclebot

The results from making filament from the pelletized PLA are shown in Figure 16. Feeding into the hopper was consistent and no issues occurred during the filament extrusion process. The filament came out with a diameter of 1.75 mm ± 0.10 mm, which is the same as the result achieved when using virgin PLA pellets from NatureWorks LLC.

Figure 16.

Example filament with a diameter of 1.75 mm ± 0.10 mm made from RepRapable recyclebot, using the pelletized filament shown in the bag.

3.2. Fractional Control of Color and Composite Mixing

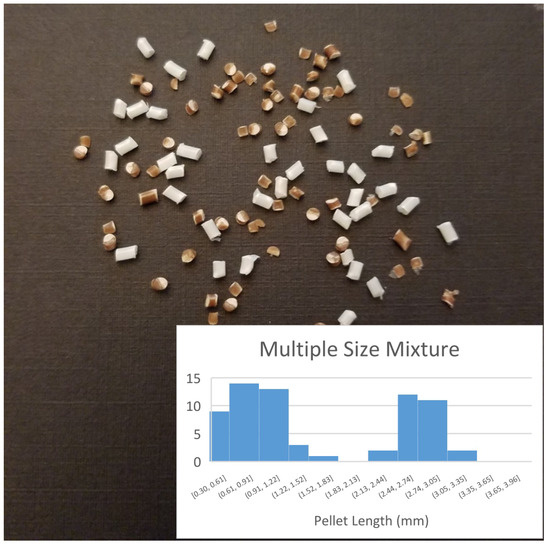

Multi-materials can be chopped simultaneously, as shown in Video S2.

In addition, the system can perform multi-material size chops, as shown in different size distributions in Figure 17, to change color or other properties using mixing in the composition.

Figure 17.

Image analysis of multiple size pelletization demonstrated with large (white) and small (brown) filament.

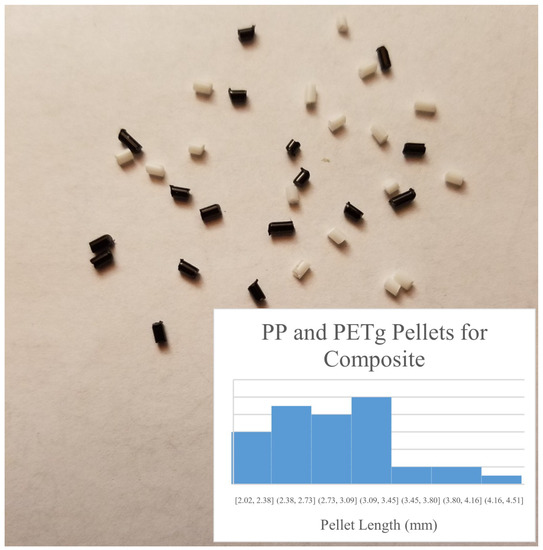

Another useful application of the device is to achieve material blends to make consumer-grade plastics such as polyethylene terephthalate (PET) and polypropylene (PP) that are acceptable as low-cost and sustainable feedstock for FFF additive manufacturing [54]. Using post-consumer waste plastic can improved the loop tightness for the circular economy [55]. This is demonstrated in Figure 18, which shows a PP and PETg dual pelletized blend ready to be formed into a composite.

Figure 18.

Image analysis of multiple sizes of pellets of different materials to make a composite demonstrated with polypropylene (PP) and PETg filament.

4. Discussion

4.1. Pellet Manufacturing

4.1.1. Pellets for Fused Granular Fabrication

There were no issues with feeding the pellets into the hopper or having the auger push the pellets into the barrel of the Gigabot X. This process could be used when trying to extrude ground-up plastic flakes or chunks to convert them into more a uniform shape for better feeding into the auger, as was conducted by Pringle et al. for waste wood–PLA composites [53]. Each time a polymer is heated and extruded (whether in the recyclebot filament-making process or during conventional fused filament fabrication (FFF)/fused deposition modeling (FDM) 3-D printing), the mechanical properties of the thermopolymer are degraded [56,57,58,59] by as much as 10% after the first cycle [60]. FGF reduces the number of melt-solidify cycles a polymer must go through to obtain to a finished product. Thus, FGF printing has advantages of better economics and a smaller environmental footprint than conventional FFF 3-D printing [30,31].

4.1.2. Pellets for Recyclebot Filament Manufacturing

3-D printing with filament is still by far the most widespread method of AM [18]. Thus, this is a form of downcycling [61] that is acceptable for about five cycles [56,57]. To maintain acceptable mechanical properties, the recycled filament must be blended with virgin materials or reinforced with more robust materials. Despite these drawbacks, a life cycle analysis of materials processed with a recyclebot found a 90% decrease in the embodied energy of the filament compared to traditional filament manufacturing [62,63,64]. Thermopolymers already demonstrated to be acceptable for the recyclebot process include successfully recycled as single component thermoplastic filaments such as polylactic acid (PLA) [50,56,57,60,65], high-density polyethylene (HDPE) [52,66,67], acrylonitrile butadiene styrene (ABS) [54,67,68], and elastomers [9], as well as composites such as waste wood biopolymers [55] and carbon fiber-reinforced plastics [69]. With commercial versions of recyclebots becoming more prevalent [51], there is an opportunity to drive a tighter loop for the circular economy [54]. The system here was shown to be able to produce pellets for the recyclebot, which could be used to make composites and alter the properties of filament (e.g., change color).

4.2. Fractional Control of Color and Composite Mixing

However, producing pellets from these systems for complex composites, such as waste wood biopolymer composites [55], provides an even larger ecologically beneficial opportunity. The device disclosed and characterized in this study supports this aim. For example, in an industrial or quasi-industrial granulator [70] used to make flakes or chips, the produced material can be converted to low-quality filament, which can then be subsequently chopped by the invention discussed here and then converted to high-quality 3-D printing filament. This filament can be tuned for specific properties such as those needed for scientific hardware [71,72,73,74]. This becomes important as manufacturers begin to disclose the materials from which they are made [75] in order to facilitate recycling and/or market opportunities from consumers understanding the material ingredients that make up their products. Some countries such as China already aid more aggressive recycling by having a detail-rich recycling code system, and this has already been adapted to the 3-D printing community [76]. The invention of the open-source 3-D printable pelletizer chopper system can speed research and development in these areas. Also, in large-scale niche 3-D printing markets, the need for more material in the printer is essential for the elimination of human intervention, in changing out empty spools. When changing over to pellet-fed systems, huge hoppers full of pellets can be stored next to the printer, with simple vacuum systems used to feed the printer as needed. This solution removes the need for large, 8–10 kg spools, which cause strain on the extruder motors for large 3-D printers and can almost provide an endless source of feedstock [77]. These features generally enable the technical and economic potential of large-scale polymer 3-D printing.

4.3. Applications

The open-source 3-D printable pelletizer chopper system is appropriate for both a home manufacturing setting, such as use by prosumers in a garage or basement, as well as for a shared public manufacturing setting such as a school, machine shop, library, fablab, or makerspace. It uses standard AC electricity and does not need any lab-grade infrastructure. In general, if the polymer filaments being chopped are non-toxic, there is no health and safety concerns with emissions from the system. As can be heard in the Supplementary Videos (Video S1: Open-source 3-D printable pelletizer chopper system during production; Video S2: Multi-materials chopped simultaneously by the open-source 3-D printable pelletizer chopper system), the system does create some noise. Thus, it would need to be in a sound-separated room if used in a library or office setting. Also as shown in Video S2, when the device is removed from the collection bucket the noise from the system is amplified by the bucket. Therefore, if noise is a problem for a specific application, pellets could be collected over a sheet instead of in a bucket.

4.4. Future Work

This study investigated both single- and double-line use of the open-source 3-D printable pelletizer chopper system. This system is adequate for matching the majority this generation of polymer 3-D printers available on the market (e.g., colorants or simple composites such as glitter or glow-in-the-dark filaments). The current design can hold up to four incoming lines, which can be used to make more complex composites such as those designed to be used for sintering metal or other higher-temperature materials. In addition, the open-source 3-D printable pelletizer chopper system can be easily expanded to even increase upon that using the STP file (STandard for the Exchange of Product). Future designs should also look into replacing the expensive and proprietary drill motor with a cheaper DC gear motor or other alternatives, including the distributed manufacturing of the motor itself. Lastly, the current design is inadequate for chopping extremely flexible filament such as NinjaFlex; future work could focus on geometric improvements that would allow for such filaments to be used.

5. Conclusions

This study disclosed a low-cost open-source 3-D printable invention of a pelletizer chopper for precisely controlled pelletizing of both single thermopolymers as well as composites for 3-D printing applications. The system was successfully developed using open-source design strategies and fabricated using low-cost open-source 3-D printers. The invention provided high-tolerance thermopolymer pellets with a number of sizes capable of being used in an FGF printer as well as for recyclebot reformulation of 3-D printing filament. It has a 0.5 kg/h throughput with one motor, and a 1.0 kg/h throughput with two motors using only 0.24 kWh/kg during the chopping process. Pellets were successfully 3-D printed directly via FGF, as well as indirectly after being converted into high-tolerance filament in a recyclebot.

Supplementary Materials

The following are available online at http://www.mdpi.com/2411-5134/3/4/78/s1.

Author Contributions

Conceptualization, J.M.P.; Data curation, A.L.W.; Formal analysis, A.L.W. and J.M.P.; Funding acquisition, J.M.P.; Methodology, A.L.W. and J.M.P.; Writing—original draft, J.M.P.; Writing—review and editing, A.L.W. and J.M.P.

Funding

This research was funded by the National Science Foundation SBIR Phase I grant number: 1746480, re:3D, Aleph Objects, and the Richard Witte Endowment.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The replicating rapid prototyper-maximizing customizability by breeding the means of production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2007. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap-the replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D printing and humanity’s first imperfect replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Scan, B. How to Make (almost) Anything. The Economist, 2005. Available online: http://www.economist.com/node/4031304 (accessed on 2 November 2018).

- Gershenfeld, N. How to Make Almost Anything: The Digital Fabrication Revolution. 2012. Available online: http://cba.mit.edu/docs/papers/12.09.FA.pdf (accessed on 2 November 2018).

- Markillie, P. A Third Industrial Revolution. The Economist, 2012. Available online: http://www.economist.com/node/21552901 (accessed on 2 November 2018).

- Gwamuri, J.; Wittbrodt, B.; Anzalone, N.; Pearce, J. Reversing the trend of large scale and centralization in manufacturing: The case of distributed manufacturing of customizable 3-D-printable self-adjustable glasses. Challeng. Sustain. 2014, 2, 30–40. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Laureto, J.; Tymrak, B.; Pearce, J. Distributed manufacturing with 3-D printing: A case study of recreational vehicle solar photovoltaic mounting systems. J. Frugal Innov. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. Distributed manufacturing of flexible products: Technical feasibility and economic viability. Technologies 2017, 5, 71. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY home manufacturing with 3D printing on the toy and game market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of home manufacturing in the developed world: Return on investment for Open-Source 3-D printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Anderson, P.; Sherman, C.A. A discussion of new business models for 3D printing. Int. J. Technol. Market. 2007, 2, 280–294. [Google Scholar] [CrossRef]

- Laplume, A.; Anzalone, G.; Pearce, J. Open-source, self-replicating 3-D printer factory for small-business manufacturing. Int. J. Adv. Manuf. Technol. 2015, 85, 633–642. [Google Scholar] [CrossRef]

- Laplume, A.; Petersen, B.; Pearce, J. Global value chains from a 3D printing perspective. J. Int. Bus. Stud. 2016, 47, 595–609. [Google Scholar] [CrossRef]

- Pearce, J. Quantifying the value of open source hardware development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Babak, K. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Reports; Wohlers Associates Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Horne, R. RepRap Development and Further Adventures in DIY 3D Printing: No More Filament?—Quest for a Universal Pellet Extruder for 3D Printing. Reprap Development and Further Adventures in DIY 3D Printing 2014. Available online: https://richrap.blogspot.com/2014/12/no-more-filament-quest-for-universal.html (accessed on 2 November 2018).

- Universal Pellet Extruder. Available online: http://upe3d.blogspot.com/ (accessed on 2 November 2018).

- Braanker, G.B.; Duwel, J.E.P.; Flohil, J.J.; Tokaya, G.E. Developing a Plastics Recycling Add-on for the RepRap 3D-Printer; Delft University of Technology: Delft, The Netherlands, 2010. [Google Scholar]

- The PartDaddy—Large Format Delta 3D Printer—Custom. Available online: https://www.seemecnc.com/products/partdaddy-large-format-delta-3d-printer (accessed on 9 July 2018).

- Cheetah Pro Large Format 3D Printer by Hans Fouche. Available online: http://www.fouche3dprinting.com (accessed on 9 July 2018).

- Introducing David. Available online: http://sculptify.com/david (accessed on 9 July 2018).

- Erecto-Struder 24v, ErectorBot Store. Available online: http://www.erectorbot.com/store/product_info.php?cPath=23&products_id=65 (accessed on 9 July 2018).

- Gigabot X: Large-Scale, Recycled Plastic Pellet 3D Printer. Available online: https://www.kickstarter.com/projects/re3d/gigabot-x-your-direct-pellet-extrusion-3d-printer (accessed on 9 July 2018).

- Giberti, H.; Sbaglia, L.; Silvestri, M. Mechatronic design for an extrusion-based additive manufacturing machine. Machines 2017, 5, 29. [Google Scholar] [CrossRef]

- Liu, X.; Chi, B.; Jiao, Z.; Tan, J.; Liu, F.; Yang, W. A large-scale double-stage-screw 3D printer for fused deposition of plastic pellets. J. Appl. Polym. Sci. 2017, 134, 45147. [Google Scholar] [CrossRef]

- Volpato, N.; Kretschek, D.; Foggiatto, J.A.; da Silva Cruz, C.G. Experimental analysis of an extrusion system for additive manufacturing based on polymer pellets. Int. J. Adv. Manuf. Technol. 2015, 81, 1519–1531. [Google Scholar] [CrossRef]

- Woern, A.; Byard, D.; Oakley, R.; Fiedler, M.; Snabes, S.; Pearce, J.; Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; et al. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing. Unpublished work. 2018. [Google Scholar]

- Beaudoin, A. JMS-1704: Multihead 3D Printer. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2016. [Google Scholar]

- Wang, Z.; Liu, R.; Sparks, T.; Liou, F. Large-scale deposition system by an industrial robot (I): Design of fused pellet modeling system and extrusion process analysis. 3D Print. Addit. Manuf. 2016, 3, 39–47. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Extrusion-based additive manufacturing process for producing flexible parts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 143. [Google Scholar] [CrossRef]

- Whyman, S.; Arif, K.M.; Potgieter, J. Design and development of an extrusion system for 3D printing biopolymer pellets. Int. J. Adv. Manuf. Technol. 2018, 96, 3417–3428. [Google Scholar] [CrossRef]

- Pearce, J.M. A novel approach to obviousness: An algorithm for identifying prior art concerning 3-D printing materials. World Patent Inf. 2015, 42, 13–18. [Google Scholar] [CrossRef]

- Barbosa, F. Thingiverse.com High Speed Filament Pelletizer by Fred_barbosa. Available online: https://www.thingiverse.com/thing:397524 (accessed on 1 November 2018).

- Hada, W. Thingiverse.com 3D Filament Pelletizer Powered by Drill by Wahada. Available online: https://www.thingiverse.com/thing:288465 (accessed on 1 November 2018).

- Scott, C. Shred-Buddy 3D Recycler Turns Your Old Filament, Bottles, and Even Fishing Line into Brand New 3D Printing Material. Available online: https://3dprint.com/144236/shred-buddy-3d-recycler/ (accessed on 20 November 2018).

- Filament Pelletizer (Page 1)—Filastruder—SoliForum—3D Printing Community. Available online: http://www.soliforum.com/topic/5159/filament-pelletizer/ (accessed on 1 November 2018).

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014; ISBN 978-0-321-90604-5. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General design procedure for free and open-source hardware for scientific equipment. Designs 2017, 2, 2. [Google Scholar] [CrossRef]

- 3-D Printable Polymer Pelletizer Chopper. Open Science Framework, 2018. Available online: https://osf.io/6t4dn/ (accessed on 2 November 2018).

- FIJI Is Just ImageJ. Available online: https://fiji.sc/ (accessed on 9 July 2018).

- Re:3D. Available online: https://github.com/Gigabot-Labs/Pellet-Extruder (accessed on 21 July 2018).

- re:3D | Life-Sized Affordable 3D Printing. Available online: https://re3d.org/ (accessed on 9 July 2018).

- Slic3r-G-Code Generator for 3D Printers. Available online: http://slic3r.org (accessed on 10 July 2018).

- Marlin Firmware. Available online: http://marlinfw.org (accessed on 10 July 2018).

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Recyclebot. Appropedia. Available online: http://www.appropedia.org/Recyclebot (accessed on 19 December 2017).

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Protot. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J. Wood furniture waste-based recycled 3-D printing filament. For. Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2018. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Proceedings of the 2015 Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, Austin, TX, USA, 10–12 August 2015; pp. 10–12. [Google Scholar]

- Cruz Sanchez, F.A.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stabil. 2015, 114. [Google Scholar] [CrossRef]

- Hyung Lee, J.; Sub Lim, K.; Gyu Hahm, W.; Hun Kim, S. Properties of recycled and virgin poly(ethylene terephthalate) blend fibers. Appl. Polym. Sci. 2012, 128, 2. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical properties of specimens 3D printed with virgin and recycled polylactic acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; Farrar, Straus and Giroux: New York, NY, USA, 2010; ISBN 978-1-4299-7384-7. [Google Scholar]

- Kreiger, M.; Anzalone, G.C.; Mulder, M.L.; Glover, A.; Pearce, J.M. Distributed recycling of post-consumer plastic waste in rural areas. MRS Online Proc. 2013, 1492, 91–96. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Zhong, S.; Rakhe, P.; Pearce, J.M. Energy payback time of a solar photovoltaic powered waste plastic recyclebot system. Recycling 2017, 2, 10. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the Use of Recycled or Biodegradable Filaments for Sustainability of 3D Printing. In Sustainable Design and Manufacturing; Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical characterization and pre-assessment of recycled high-density polyethylene as 3D printing material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Mohan, M.; Das, A.; Johnson, M.D.; Badwal, P.S.; McLean, D.; Gibson, I. A low carbon footprint approach to the reconstitution of plastics into 3D-printer filament for enhanced waste reduction. KnE Eng. 2017, 2, 234–241. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Das, A.; Gomez-Kervin, E.; Wilson, D.; Gibson, I. EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. Solid Freeform Fabrication 2017. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- OSHE Granulator MKII, Open Science Framework. Available online: https://osf.io/auswp/ (accessed on 10 July 2018).

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open labware: 3-D printing your own lab equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef] [PubMed]

- Winters, B.J.; Shepler, D. 3D printable optomechanical cage system with enclosure. HardwareX 2018, 3, 62–81. [Google Scholar] [CrossRef]

- Hietanen, I.; Heikkinen, I.T.S.; Savin, H.; Pearce, J.M. Approaches to open source 3-D printable probe positioners and micromanipulators for probe stations. HardwareX 2018, 4, e00042. [Google Scholar] [CrossRef]

- Bellon, J.A.; Pino, M.J.; Wilke, N. Low-cost equipment for electroformation of Giant Unilamellar Vesicles. HardwareX 2018, 4, e00037. [Google Scholar] [CrossRef]

- Pearce, J.M. Expanding the Consumer Bill of Rights for material ingredients. Mater. Today 2018, 21, 197–198. [Google Scholar] [CrossRef]

- Hunt, E.J.; Zhang, C.; Anzalone, N.; Pearce, J.M. Polymer recycling codes for distributed manufacturing with 3-D printers. Resour. Conserv. Recycl. 2015, 97, 24–30. [Google Scholar] [CrossRef]

- Stevenson, K. The Other Reason for 3D Printing Pellets. Fabbaloo. Available online: http://www.fabbaloo.com/blog/2018/5/10/the-other-reason-for-3d-printing-pellets (accessed on 9 July 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).