Classification via an Embedded Approach

Abstract

:1. Introduction

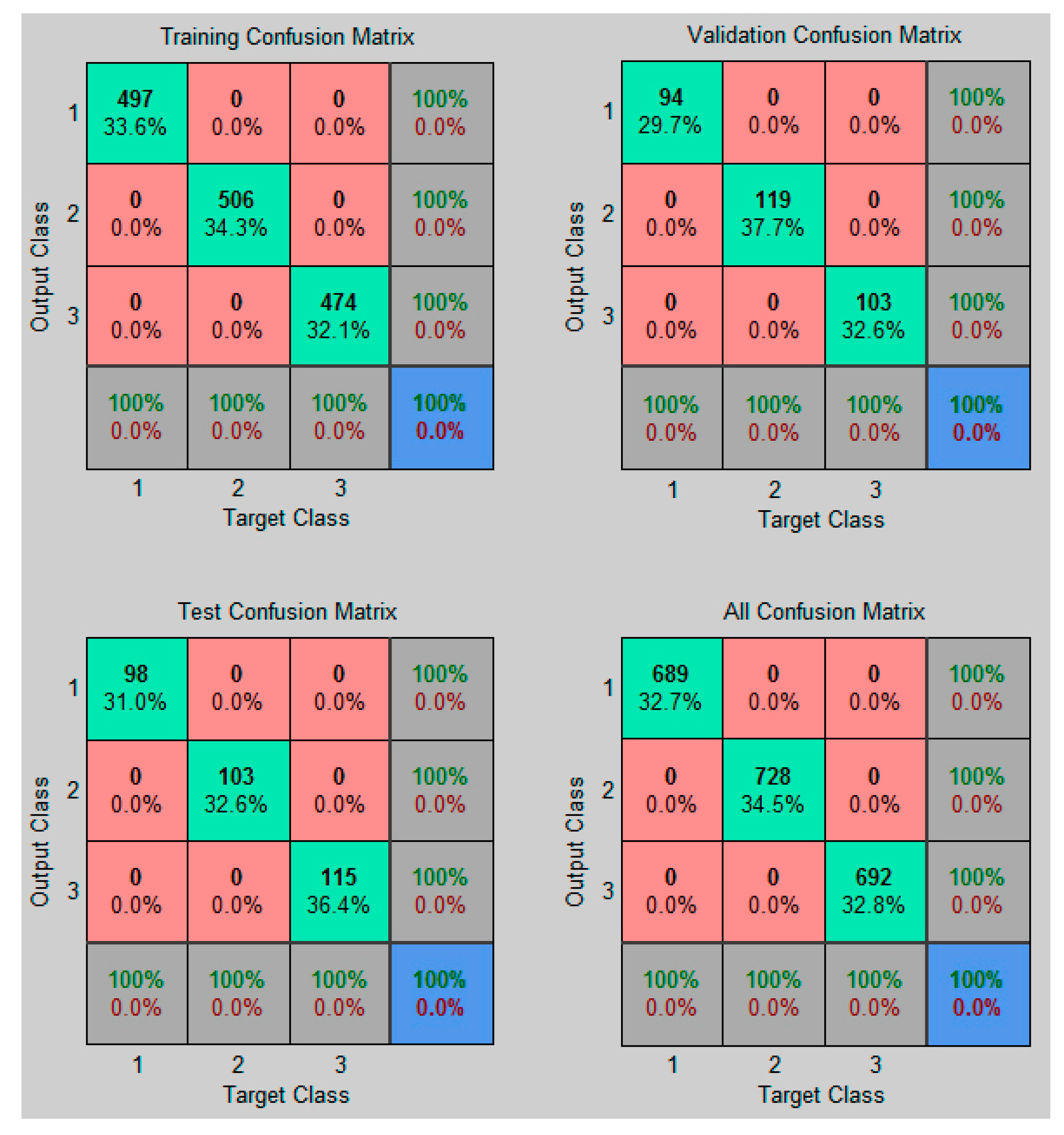

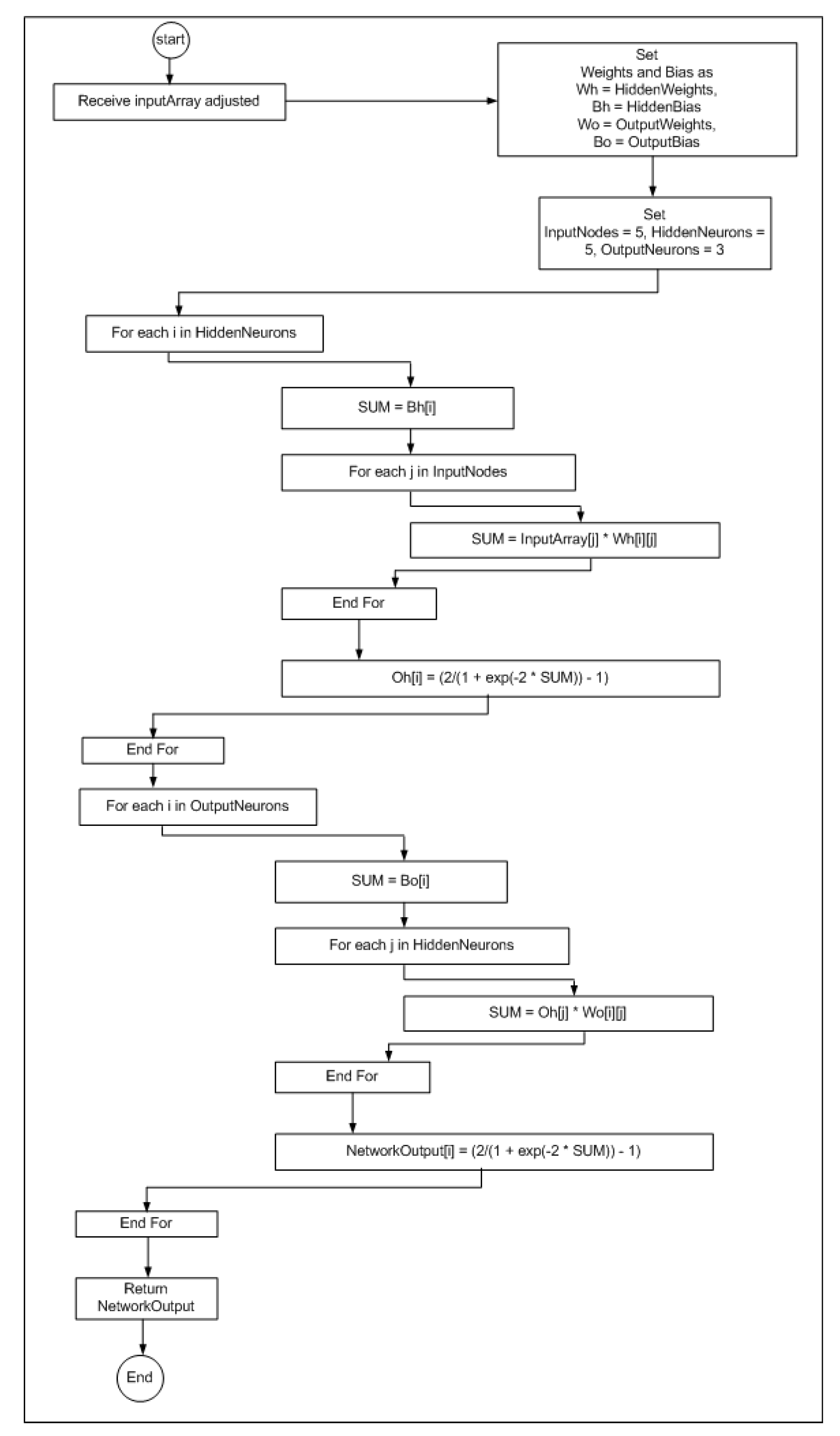

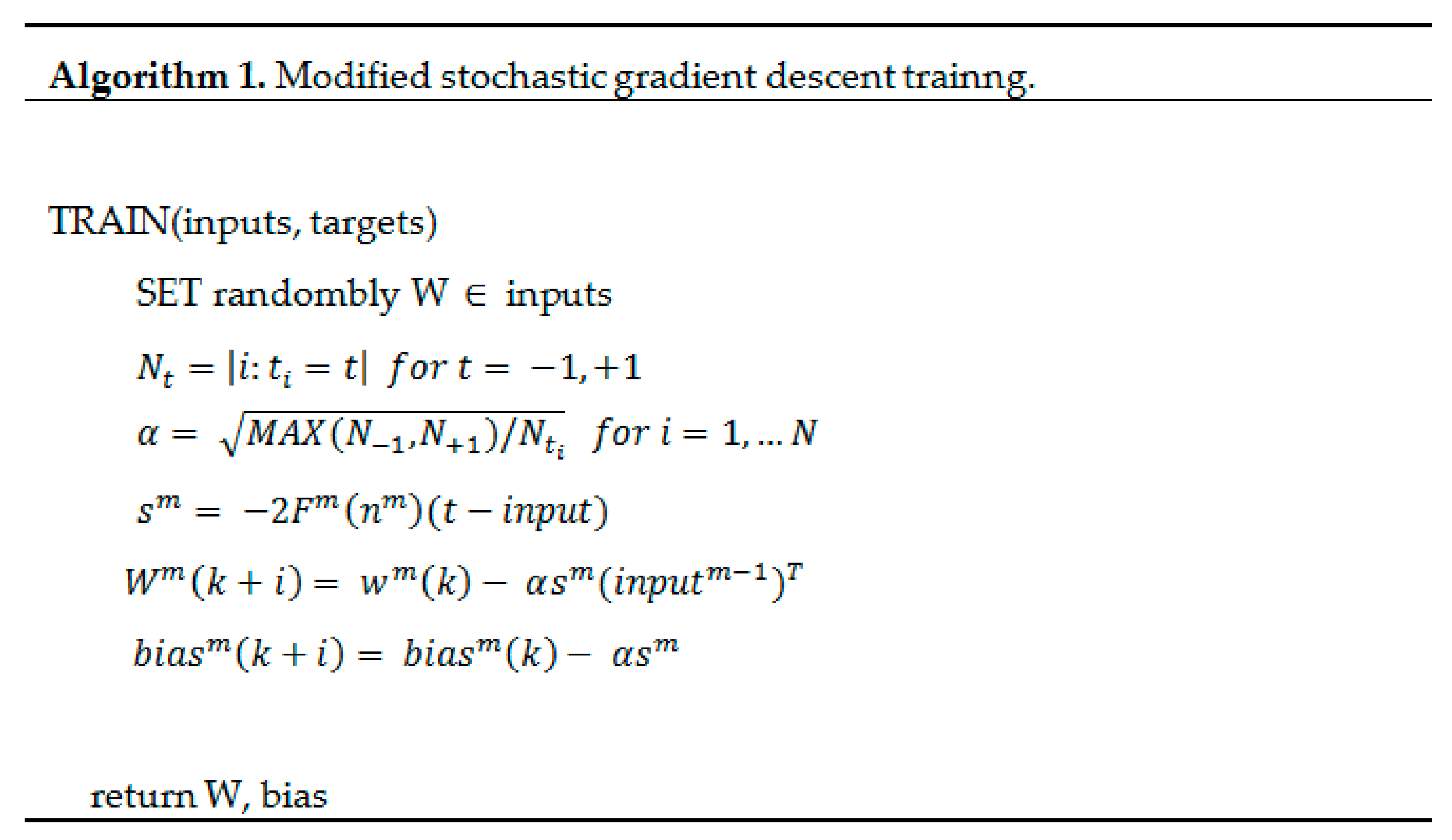

2. Approach and Method

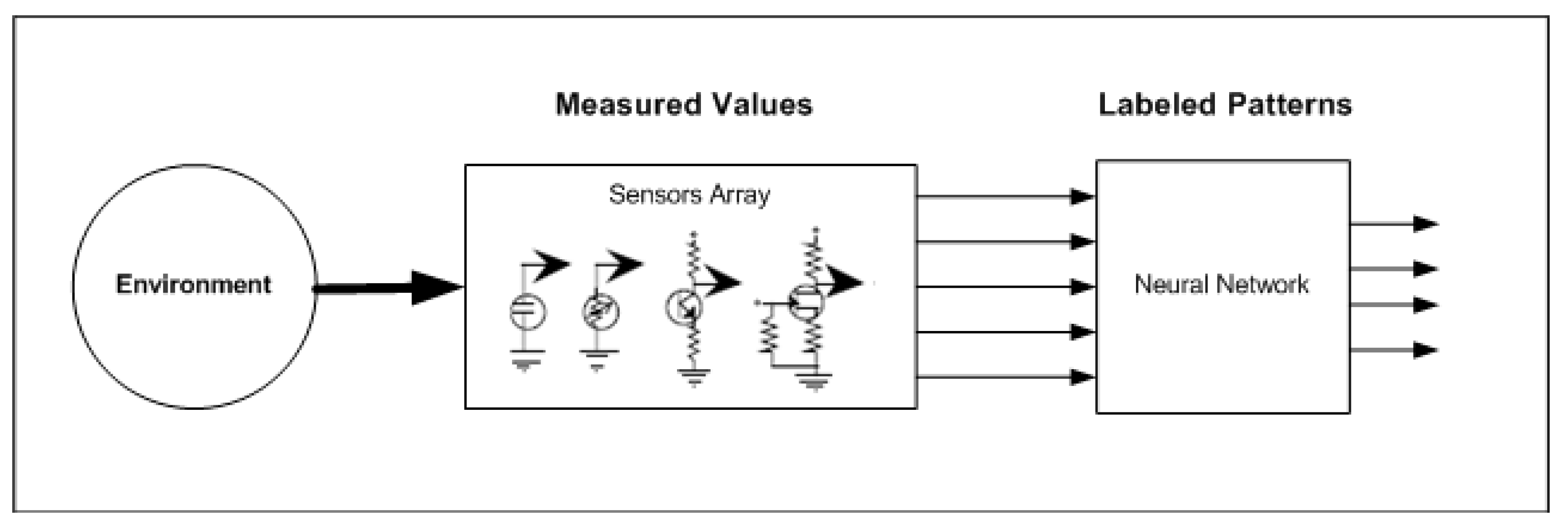

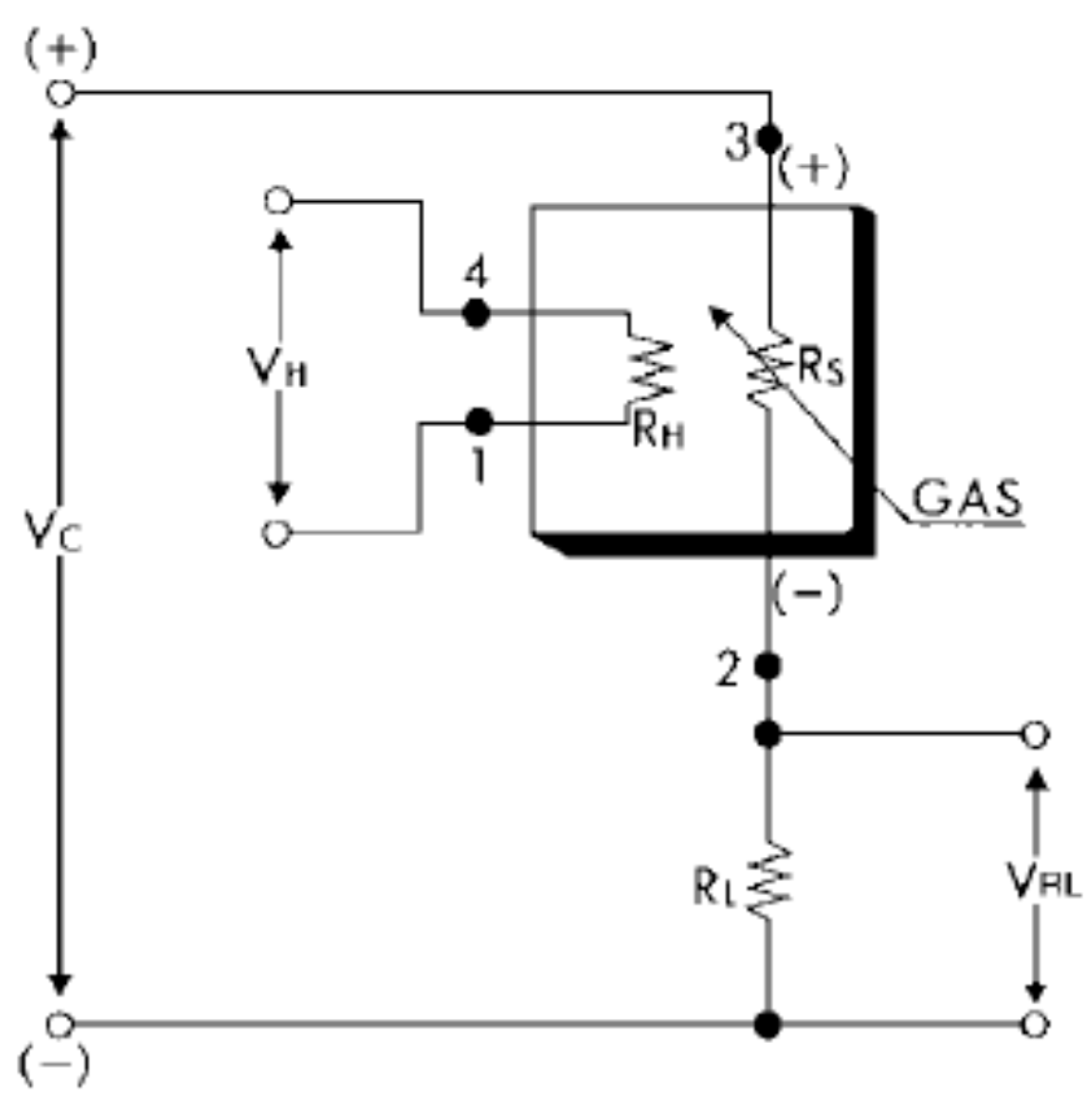

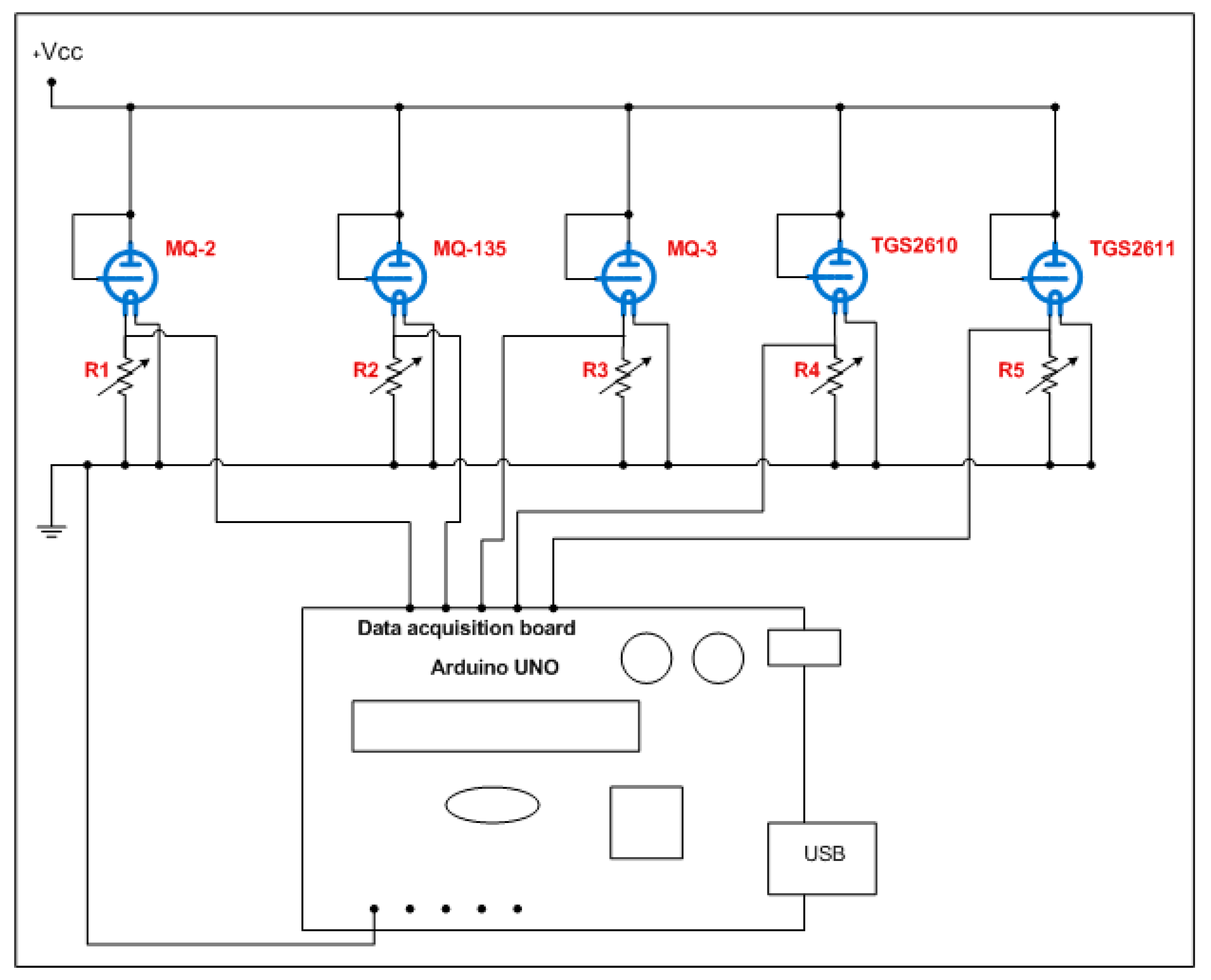

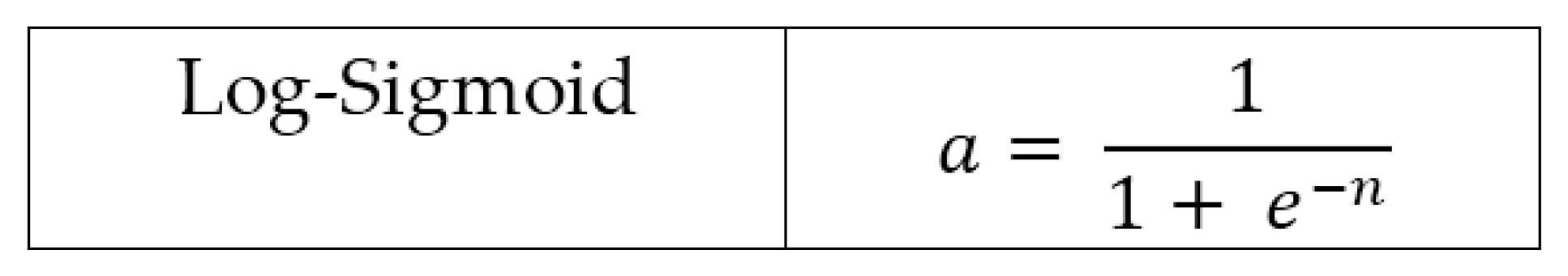

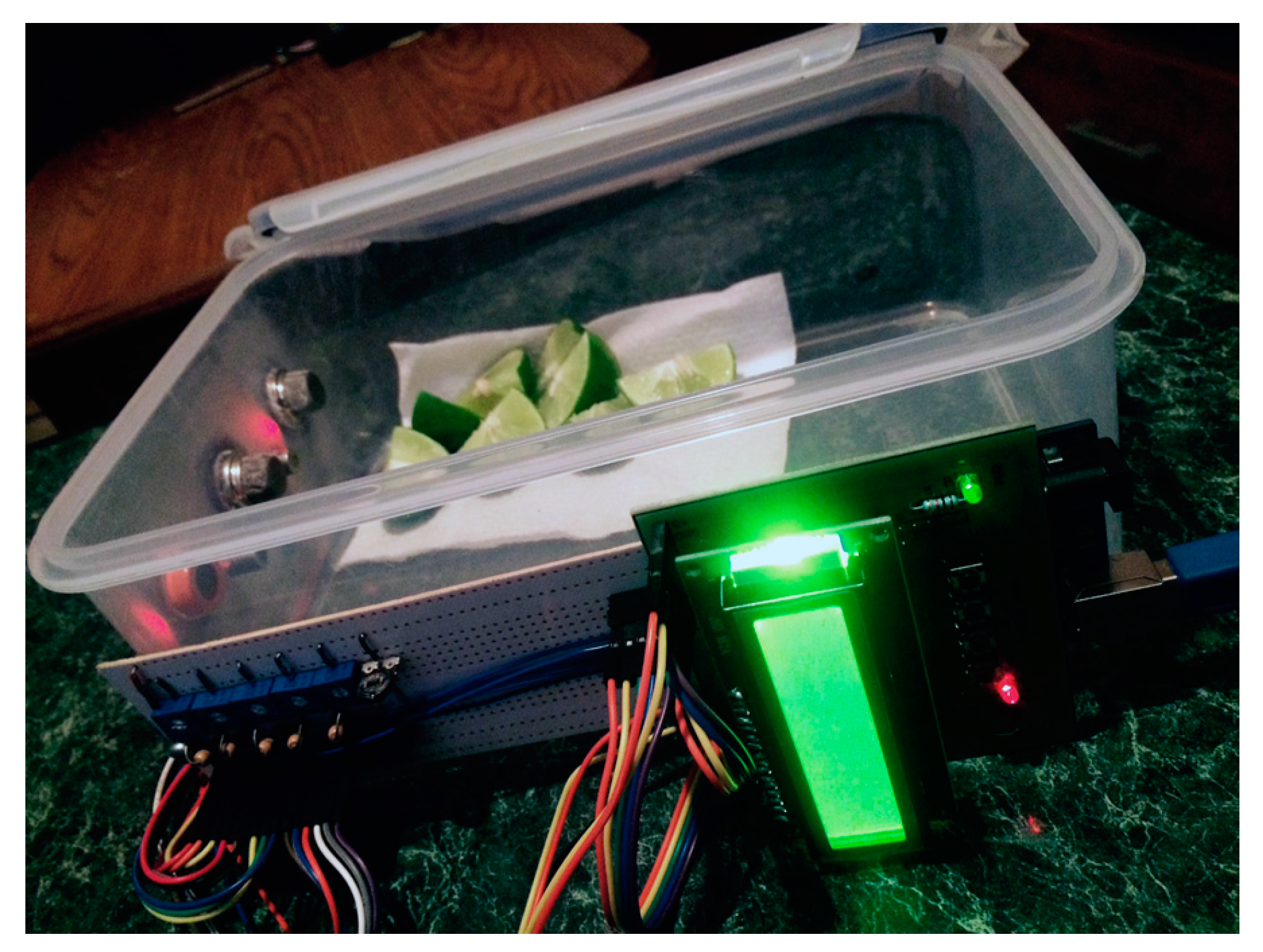

2.1. Electronic Nose

2.2. Arduino Uno

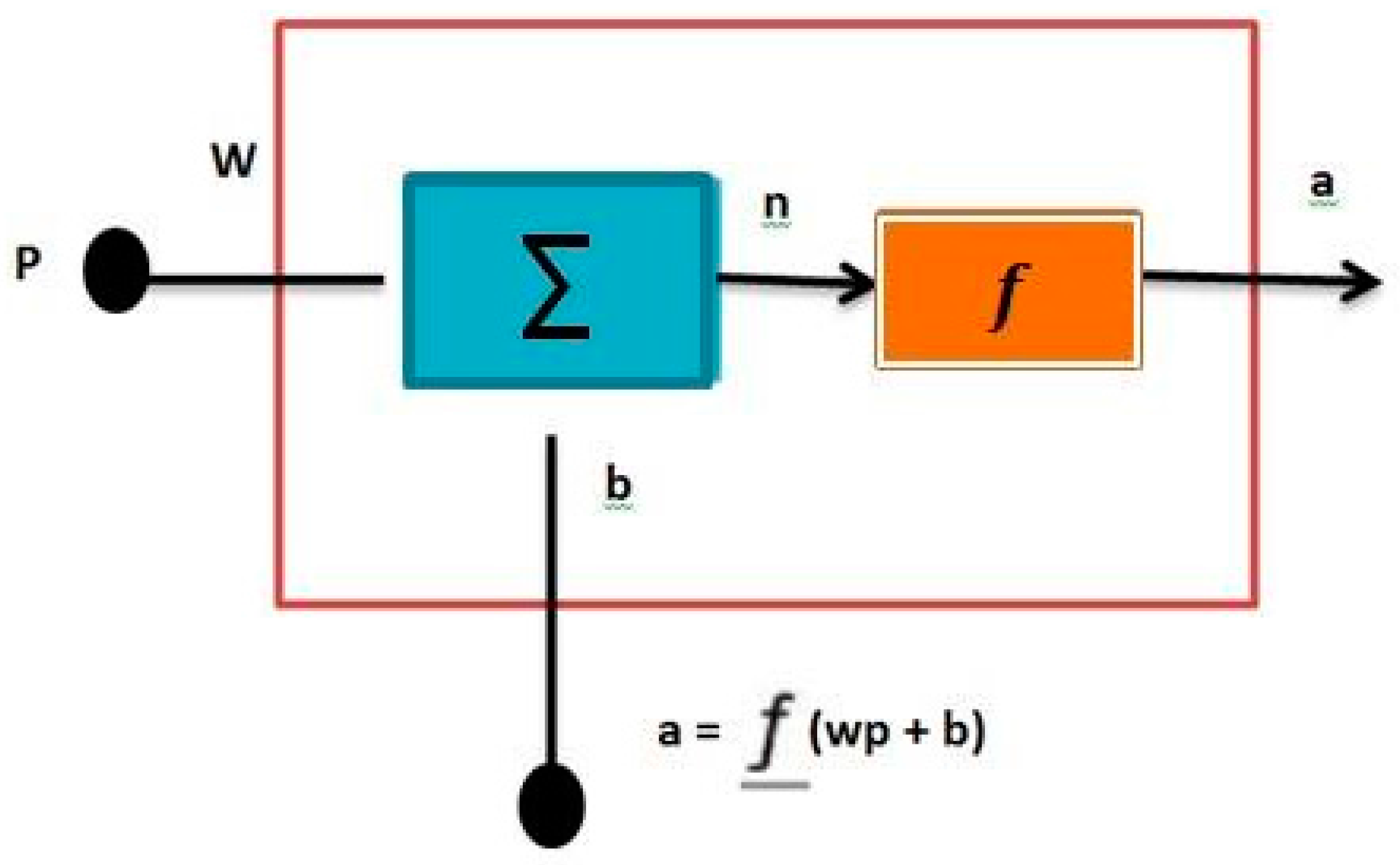

2.3. Approach

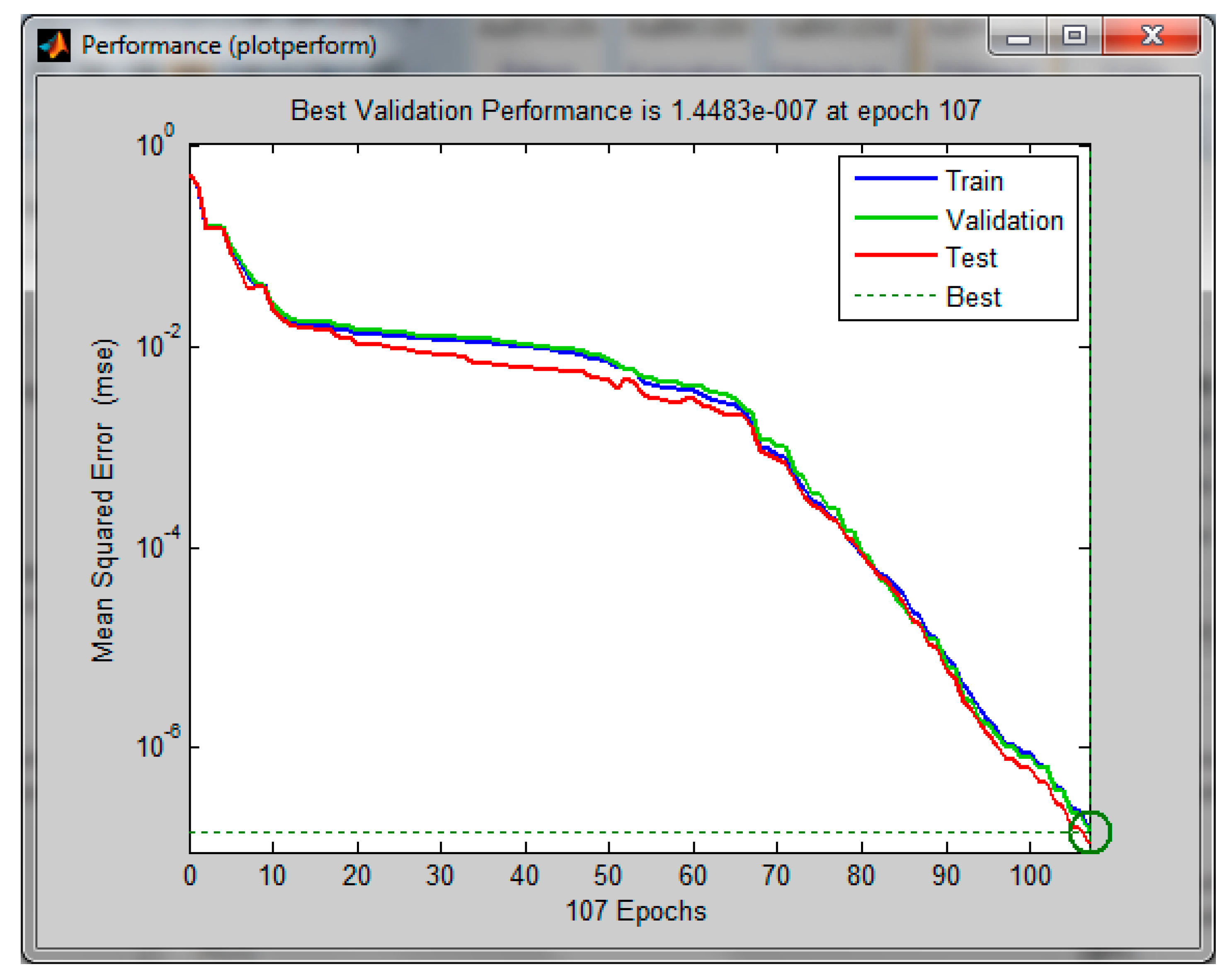

2.4. Implementation and Experiments

2.5. Advised Approach

3. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gomez, A.; Hu, G.; Wang, J.; Pereira, A. Evaluation of tomato maturity by electronic nose. Comput. Electron. Agric. 2006, 54, 44–52. [Google Scholar] [CrossRef]

- Pearce, T.C.; Schiffman, S.S.; Nagle, H.T.; Gardner, J.W. Handbook of Machine Olfaction: Electronic Nose Technology; WILEY-VCH Verlag GmbH & Co., KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Wang, J.; Tang, K.; Chen, H. An embedded probabilistic neural network with on-chip learning capability. In Proceedings of the 2013 Biometrical Circuits and Systems Conference (BioCAS), Rotterdam, The Netherlands, 31 October–2 November 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 29–32. [Google Scholar]

- Sysoev, V.V.; Musatov, V.Y.; Silaev, A.V.; Zalyalov, T.R. The optimization of number of sensors in one-chip electronic nose microarrays with the help of 3-layered neural network. In Proceedings of the 2007 Siberian Conference on Control and Communications, Tomsk, Russia, 20–21 April 2007; pp. 185–191. [Google Scholar]

- Carreno, E.; Leguizamon, G.; Wagner, N. Evolution of classification rules for comprehensible knowledge discovery. In Proceedings of the 2007 IEEE Congress on Evolutionary Computation, Singapore, 25–28 September 2007; Volume 1, pp. 1261–1268. [Google Scholar]

- Domınguez-Isidro, S.; Mezura-Montes, E.; Leguizamon, G. Performance comparison of local search operators in differential evolution for constrained numerical optimization problems. In Proceedings of the 2014 IEEE Symposium on Differential Evolution (SDE), Orlando, FL, USA, 9–12 December 2014; Volume 1, pp. 1–8. [Google Scholar]

- Maschenko, A.A.; Musatov, V.Y.; Varezhnikov, A.S.; Kiselev, I.; Sommer, M.; Sysoev, V.V. On the feasibility to apply a neural network processor for analyzing a gas response of a multisensor microarray. Sens. Actuators A Phys. 2013, 190, 61–65. [Google Scholar] [CrossRef]

- Yu, W.; Moreno-Armendariz, M.A.; Rodriguez, F.O. Stable adaptive compensation with fuzzy CMAC for an overhead crane. Inf. Sci. 2011, 181, 4895–4907. [Google Scholar] [CrossRef]

- Noorsal, E.; Sidek, O.; Mohamad, J. Automated odour measurement in electronic nose system using microcontroller. In Proceedings of the 2006 International Conference on Man-Machine Systems, Langwaki, Malaysia, 15–16 September 2006. [Google Scholar]

- Haddi, Z.; El Barbri, N.; Tahri, K.; Bougrini, M.; El Bari, N.; Llobet, E.; Bouchikhi, B. Instrumental assessment of red meat origins and their storage time using electronic sensing systems. Anal. Methods 2015, 7, 5193–5203. [Google Scholar] [CrossRef]

- Pazienza, G.E.; Bellana-Camanes, J.; Riera-Babures, J.; Vilasis-Cardona, X.; Moreno-Armendariz, M.A.; Balsi, M. Optimized cellular neural network universal machine emulation on FPGA. In Proceedings of the 2007 18th European Conference on Circuit Theory and Design, Seville, Spain, 27–30 August 2007; pp. 815–818. [Google Scholar]

- Arduino. Arduino Board Uno. 2015. Available online: https://www.arduino.cc/en/Main/ArduinoBoardUno (accessed on 10 August 2015).

- De Rubio, J.J.; Ortigoza, R.S.; Avila, F.J.; Melendez, A.; Stein, J.M. A fuzzy inference system for the identification. IEEE Lat. Am. Trans. 2015, 13, 2823–2829. [Google Scholar] [CrossRef]

- Agatonovic-Kustrin, S.; Beresford, R. Basic concepts of artificial neural network (ANN) modeling and its application in pharmaceutical research. J. Pharm. Biomed. Anal. 2000, 22, 717–727. [Google Scholar] [CrossRef]

- Hagan, M.T.; Demuth, H.B.; Beale, M.H. Neural Network Design; PWS Pub: Boston, MA, USA, 2002. [Google Scholar]

- Arbib, M.; Ballard, D.; Bower, J.; Orban, G. Neural Networks Algorithms, Applications; Addison-Wesley Pub (Sd): Boston, MA, USA, 1994; Volume 7. [Google Scholar]

- Keller, P.E.; Kouzes, R.T.; Kangas, L.J.; Box, P.O. Three neural network based sensor systems for environmental monitoring. In Proceedings of the 1994 Electro/94 International Conference Proceedings—Combined Volumes, Boston, MA, USA, 10–12 May 1994; pp. 378–382. [Google Scholar]

- Zhang, G.P. Neural Networks For Data Mining. Artif. Intell. 2010, 157, 1–8. [Google Scholar]

- Choi, I.H.; Pak, J.M.; Ahn, C.K.; Mo, Y.H.; Lim, M.T.; Song, M.K. New preceding vehicle tracking algorithm based on optimal unbiased finite memory filter. Measurement 2015, 73, 262–274. [Google Scholar] [CrossRef]

- Samidurai, R.; Manivannan, R.; Ahn, C.K.; Karimi, H.R. New criteria for stability of generalized neural networks including Markov jump parameters and additive time delays. IEEE Trans. Syst. Man Cybern. Syst. 2016. [Google Scholar] [CrossRef]

- Pak, J.M.; Ahn, C.K.; Shmaliy, Y.S.; Lim, M.T. Improving reliability of particle filter-based localization in wireless sensor networks via hybrid particle/FIR filtering. IEEE Trans. Ind. Inform. 2015, 11, 1089–1098. [Google Scholar] [CrossRef]

- Czarnecki, W.M. Weighted tanimoto extreme learning machine with case study in drug discovery. IEEE Comput. Intell. 2015, 10, 19–29. [Google Scholar] [CrossRef]

- Giungato, P.; de Gennaro, G.; Barbieri, P.; Briguglio, S.; Amodio, M.; de Gennaro, L.; Lasigna, F. Improving recognition of odors in a waste management plant by using electronic noses with different technologies, gas chromatography-mass spectrometry/olfactometry and dynamic olfactometry. J. Clean. Prod. 2016, 133, 1395–1402. [Google Scholar] [CrossRef]

- Soares, E.R.; Cabete, S.; Ferreira, N.M.F.; Ferreira, F.J.T.E. Electronic nose. In ControlO’2014—Proceedings of the 11th Protuguese Conference on Automatic Control; Springer: Cham, Switzerland, 2015; Volume 321, pp. 689–695. [Google Scholar]

- Gomes, M.T.S.R. Electronic nose in dairy products. In Electronic Noses and Tongues in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 21–30. [Google Scholar]

- Zou, Y.; Wan, H.; Zhang, X.; Da, H.; Wang, P. Electronic Nose and Electronic Tongue; Wang, P., Liu, Q., Wu, C., Hsia, K., Eds.; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar]

- Vorobioff, J.; Boggio, N.; Lamagna, A.; Salomon, O.; Rinaldi, C. Improvement of the electronic nose response to detect presence of transmitters of Chagas disease. In Proceedings of the ISOEN 2017—ISOCS/IEEE International Symposium on Olfaction and Electronic Nose, Montreal, QC, Canada, 28–31 May 2017. [Google Scholar]

- Gong, G.; Zhu, H. A portable embedded explosion gas detection and identification device based on intelligent electronic nose system. Sens. Rev. 2016, 36, 57–63. [Google Scholar] [CrossRef]

- Bona, E.; Da Silva, R.S.D.S.F. Coffee and the electronic nose. In Electronic Noses and Tongues in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Urbina, L.; Duchanoy, C.A.; Faustino-Gonzalez, G.; Moreno-Armendariz, M.A.; Cruz-Villar, C.A.; Calvo, H. A novel tire contact patch soft sensor via Neural Networks. In Proceedings of the 2015 12th International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 28–30 October 2015; Volume 1, pp. 1–6. [Google Scholar]

| Gas Sensors for the Sensors Array | |||

|---|---|---|---|

| Model | Manufacturer | Material | Chemical Sensitivity (Collected from Data Sheets) |

| MQ-2 | Hanwei | SnO2—Tin dioxide | Combustible gas and smoke, Liquid Petroleum Gas (LPG), isobutane, propane, methane, alcohol, hydrogen |

| MQ-3 | Hanwei | SnO2—Tin dioxide | Alcohol and Benzene |

| MQ-135 | Hanwei | SnO2—Tin dioxide | Air quality, NH3 Ammonia, NOx—nitrogen oxide, CO2, alcohol and benzene |

| TGS2610 | Figaro | Semiconductor type D1 | Gas Liquid Petroleum (LP), Propane and Butane |

| TGS2611 | Figaro | Semiconductor type D1 | Methane and Methane |

| /* Procedure for data acquisition */ |

| OrganicCompounds = [Lemon, Banana, Grape] |

| Open TopCover from SensingChamber |

| Turn on electronic nose |

| Wait 10 min |

| For each element in OrganicCompounds |

| Place element in SensingChamber |

| Close TopCover of SensingChamber |

| While time <= 5 min |

| Capture data from 5 sensors |

| End while |

| Open TopCover from SensingChamber |

| Remove element |

| Wait 5 min |

| End For |

| MQ-2 | MQ-135 | TGS2610 | TGS2611 | MQ-3 |

|---|---|---|---|---|

| 138 | 64 | 68 | 90 | 111 |

| 139 | 64 | 69 | 90 | 111 |

| 167 | 79 | 93 | 95 | 123 |

| 167 | 77 | 91 | 95 | 124 |

| 168 | 78 | 91 | 96 | 129 |

| 208 | 84 | 112 | 90 | 249 |

| 210 | 85 | 114 | 90 | 252 |

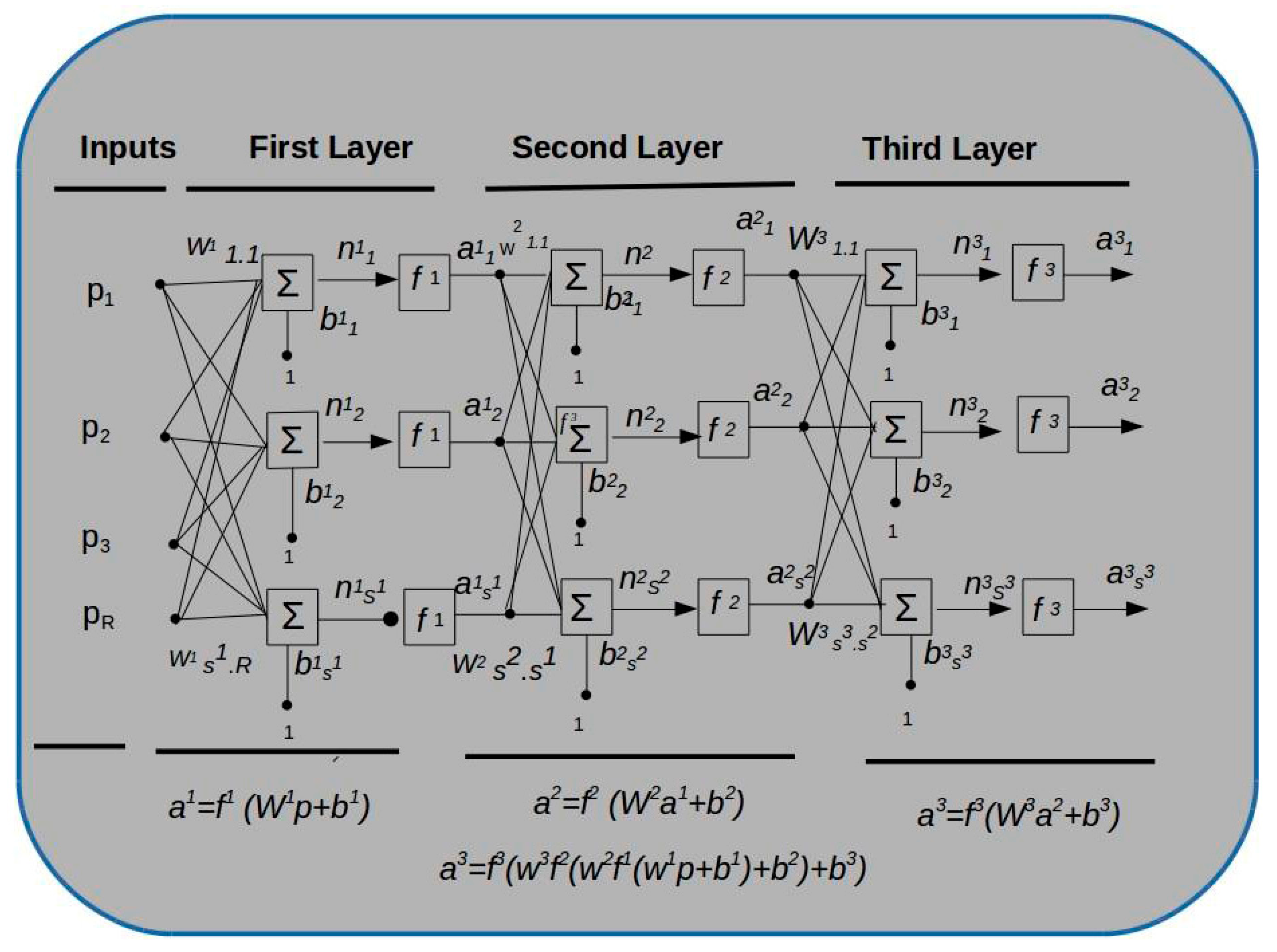

| Approach | |

|---|---|

| Approach type | Feed Forward |

| Inputs | 5 |

| Phases | 2 |

| Hidden phases units | 5 |

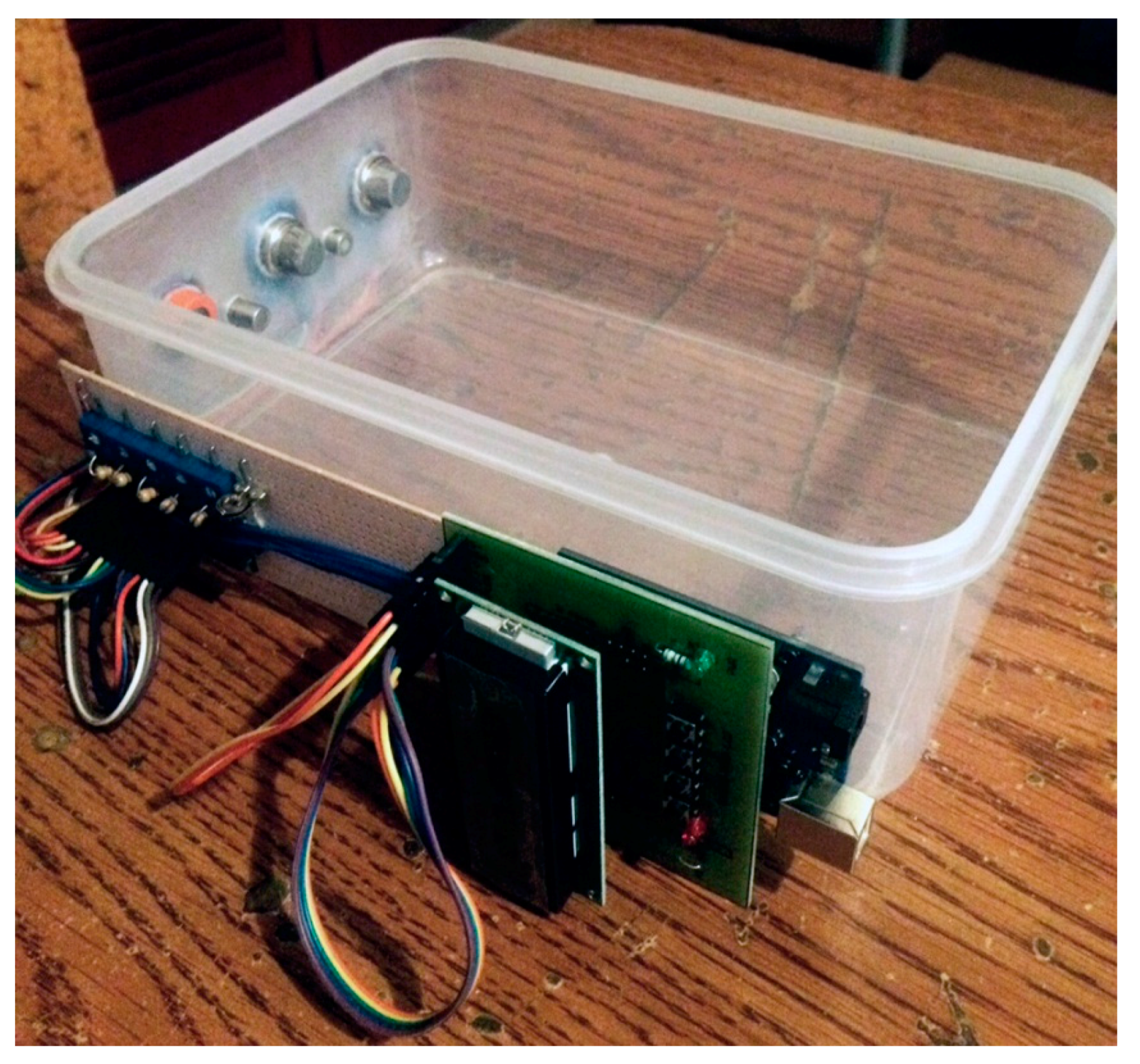

| Transfer function in hidden phase | Log-Sigmoid |

| Output phase units | 3 |

| Transfer function in output phase | Log-Sigmoid |

| Training algorithm | Stochastic gradient descent |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubio, J.D.J.; Avila, F.J.; Meléndez, A.; Stein, J.M.; Meda, J.A.; Aguilar, C. Classification via an Embedded Approach. Designs 2017, 1, 7. https://doi.org/10.3390/designs1010007

Rubio JDJ, Avila FJ, Meléndez A, Stein JM, Meda JA, Aguilar C. Classification via an Embedded Approach. Designs. 2017; 1(1):7. https://doi.org/10.3390/designs1010007

Chicago/Turabian StyleRubio, José De Jesús, Francisco Jacob Avila, Adolfo Meléndez, Juan Manuel Stein, Jesús Alberto Meda, and Carlos Aguilar. 2017. "Classification via an Embedded Approach" Designs 1, no. 1: 7. https://doi.org/10.3390/designs1010007