Mechanistic Analysis of Asphalt Pavements in Support of Pavement Preservation Decision-Making

Abstract

:1. Introduction

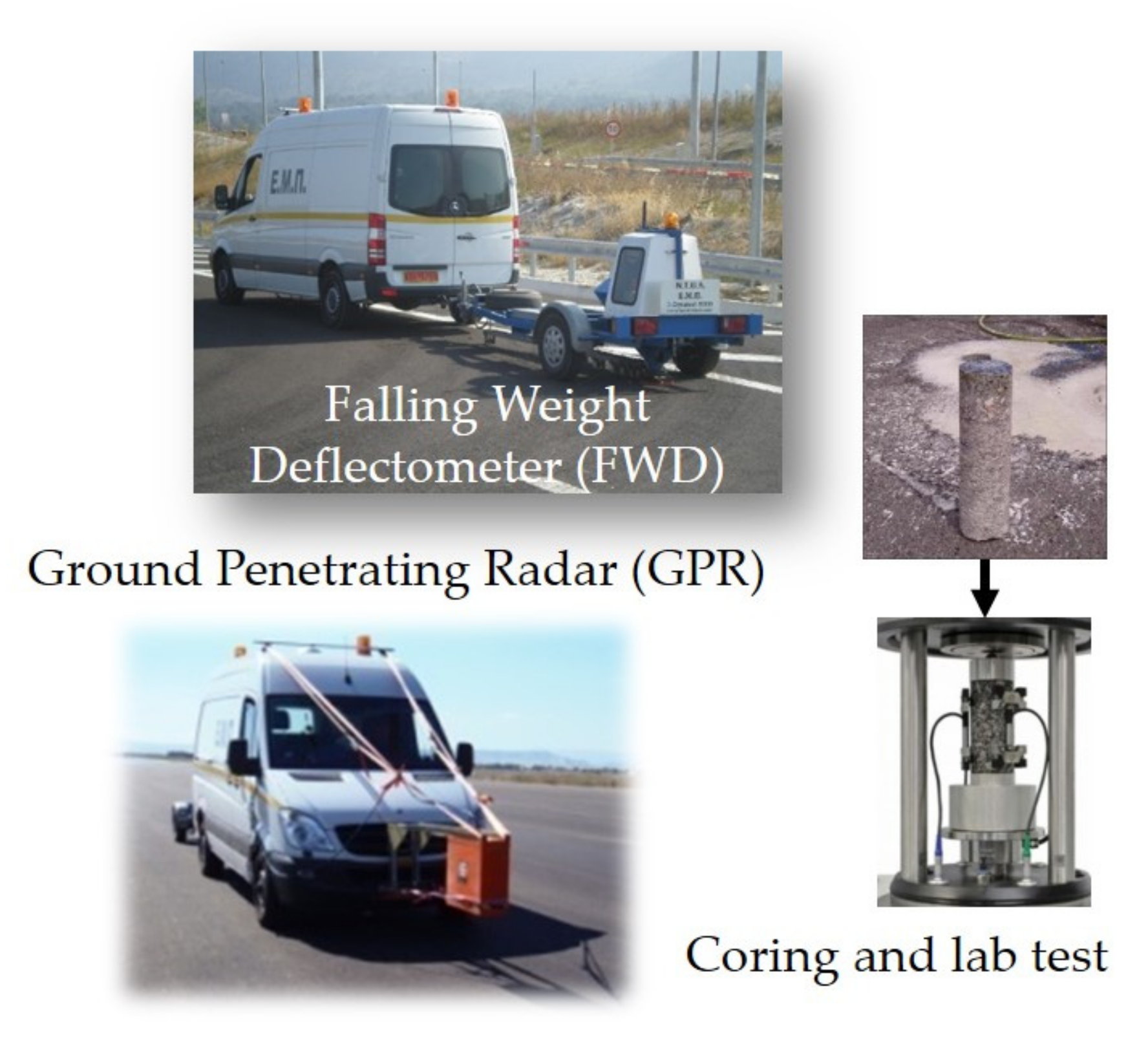

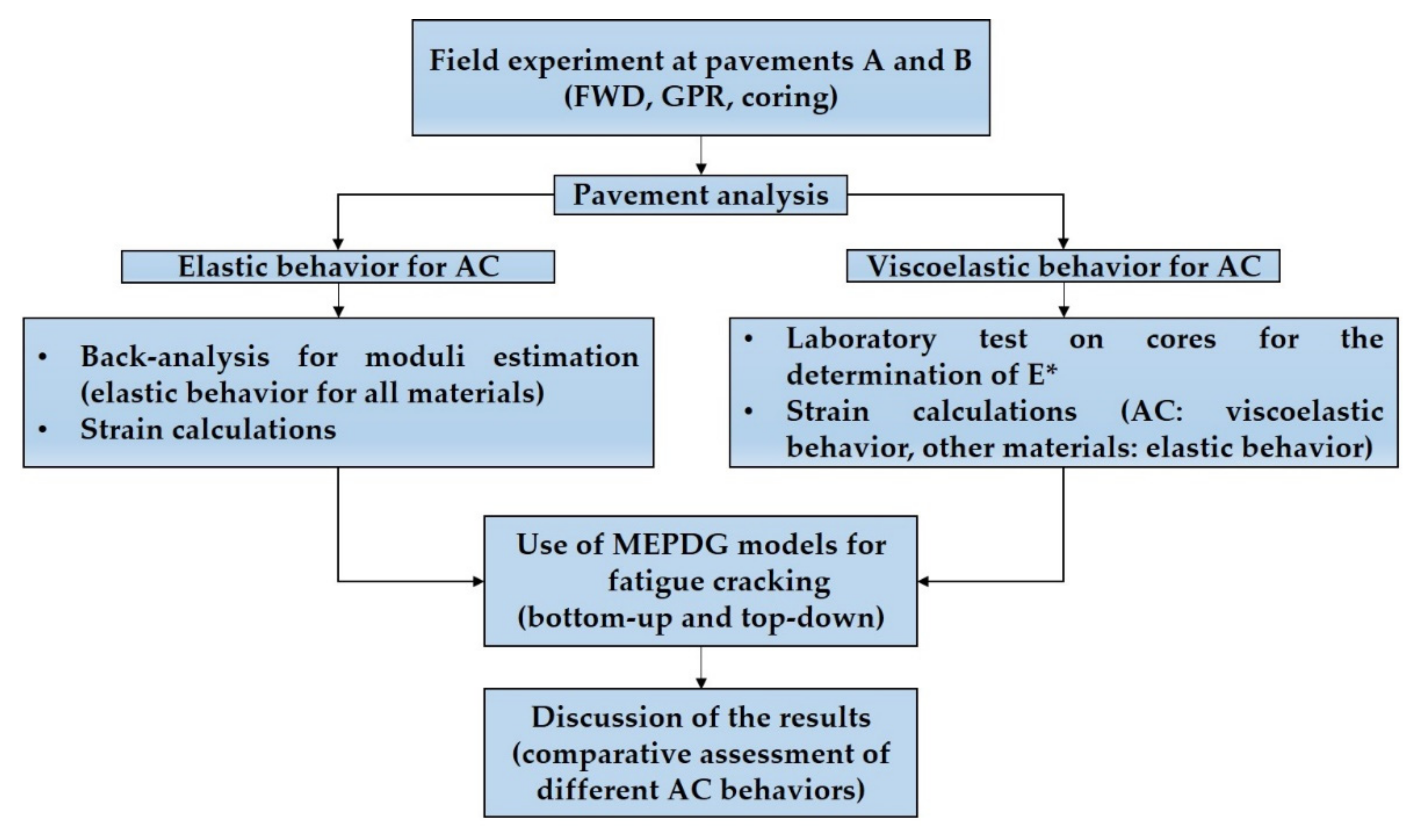

2. Materials and Methods

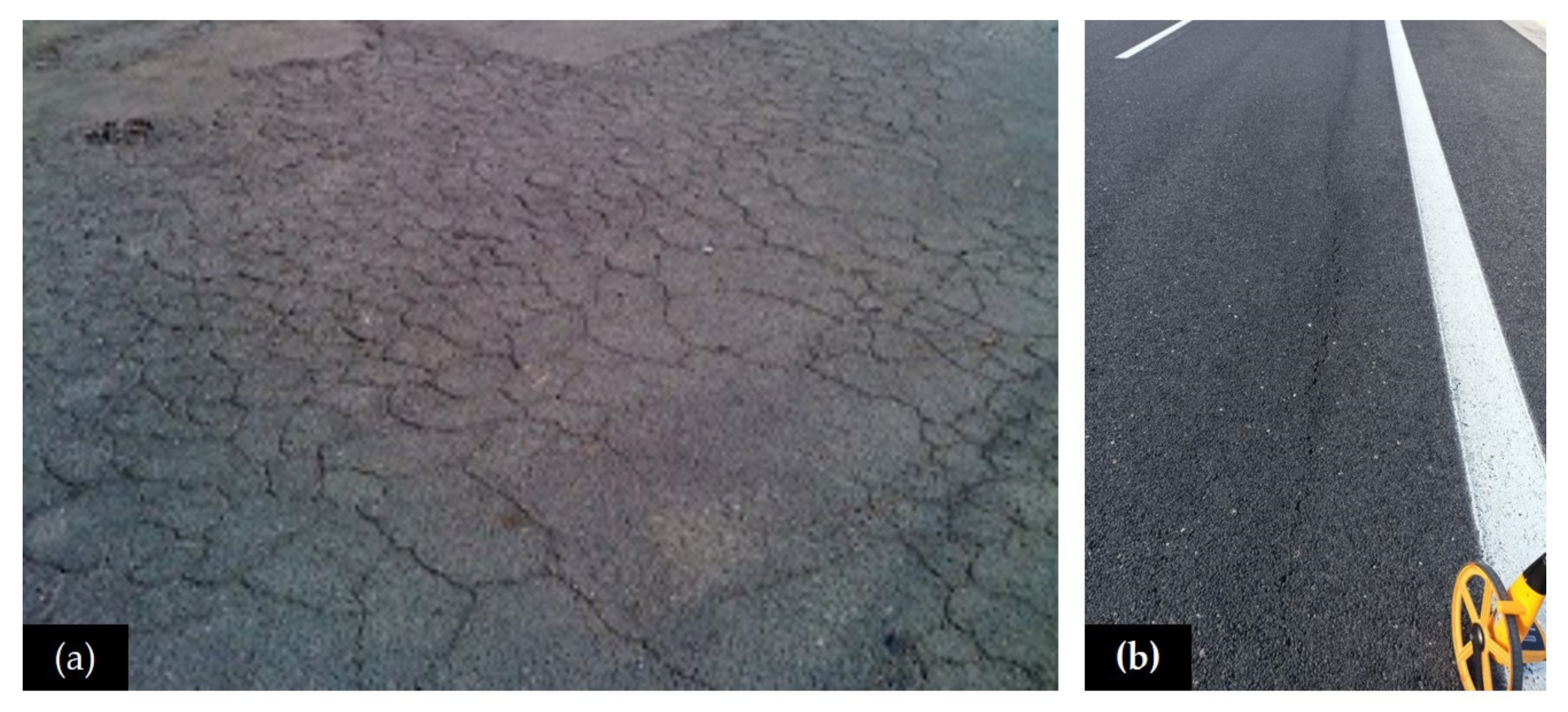

2.1. Test Sites and Materials

2.2. Experimental Framework

- Response calculations considering elastic and viscoelastic behavior for the AC materials and elastic behavior for the other pavement layers, i.e., base and subgrade.

- Performance prediction for alligator and longitudinal cracking potential (fatigue analysis for bottom-up and top-down cracking, respectively) considering different inputs from the response calculations.

2.3. Analysis Overview

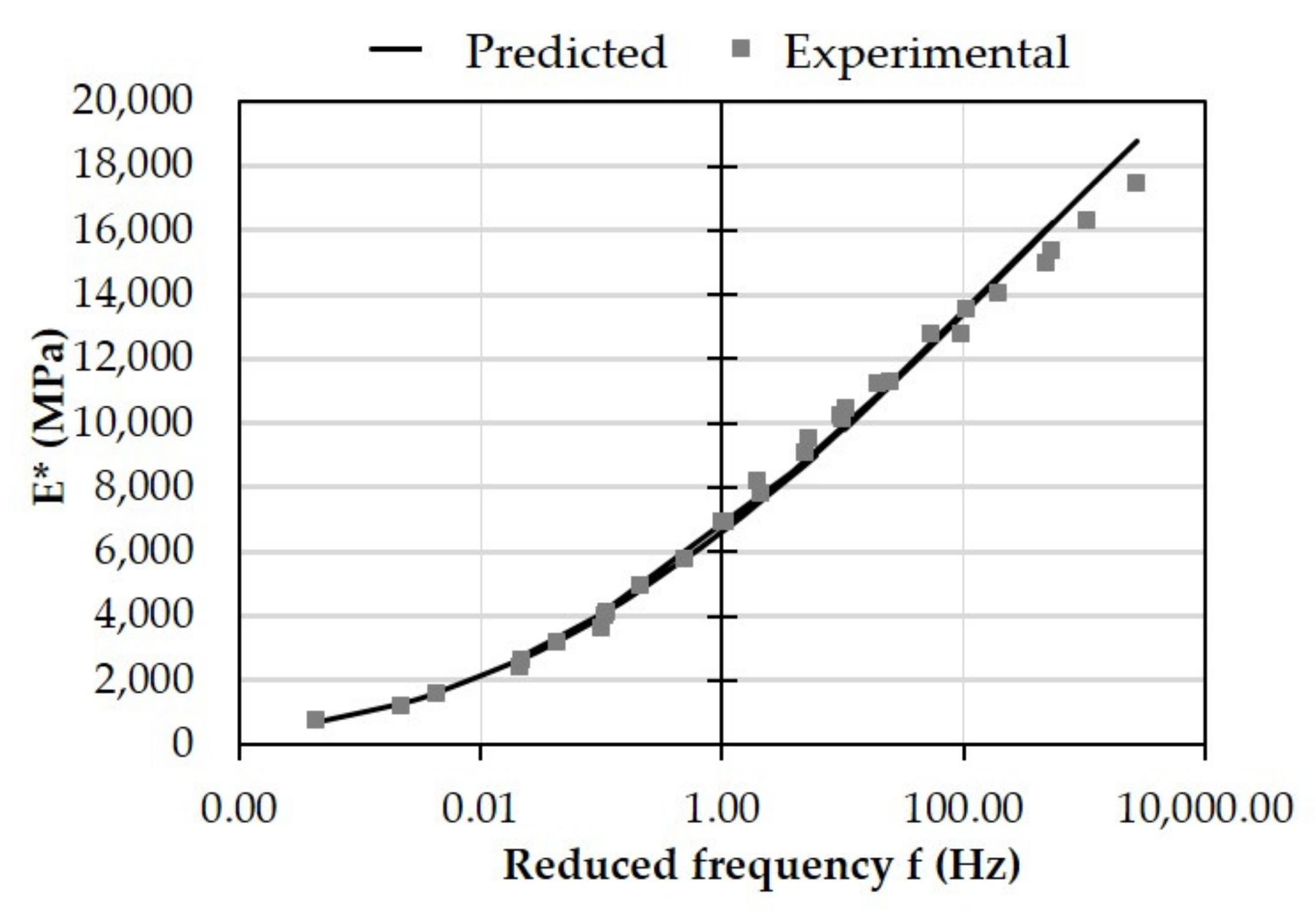

2.3.1. Response Calculations

2.3.2. Performance Prediction

- , and , Vb and Va: binder and air-void contents (by mixture volume),

- Ch is a factor dependent on the AC thickness (hAC in inches) and its use is expected to increase the predicted pavement fatigue life (transfer function). Ch is defined in Equation (5) (a, b, c, and d are parameters that vary depending on the failure mode—see Table 2):

- : local or mixture-specific field calibration constants; for the global calibration effort, these constants were set to 1.0.

- : global field calibration constants. NCHRP 1-37A proposes the values of 1, 3.9492, and 1.281 for bottom-up cracking prediction and the values of 1, 3.291, and 0.854 for top-down cracking prediction [27].

- , : tensile strain (m/m) and AC dynamic modulus (expressed in psi) at depths for bottom-up cracking prediction and for top-down cracking prediction.

- , with in inches.

- . This conforms to the failure criterion according to which, a totally damaged pavement () is perceived by alligator cracking at a percentage of considering a reference lane area with dimensions 3.6 × 150 m [27].

3. Results

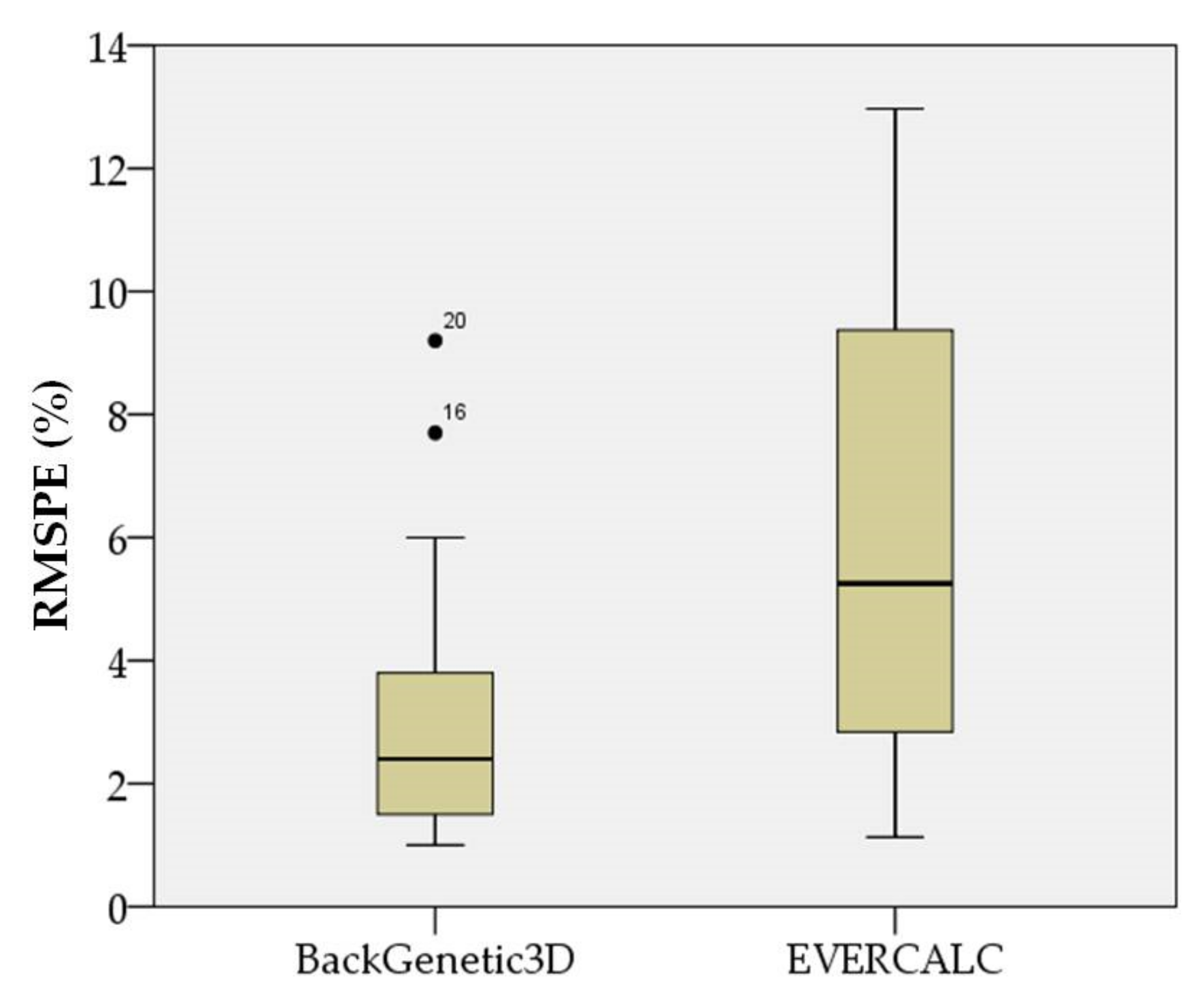

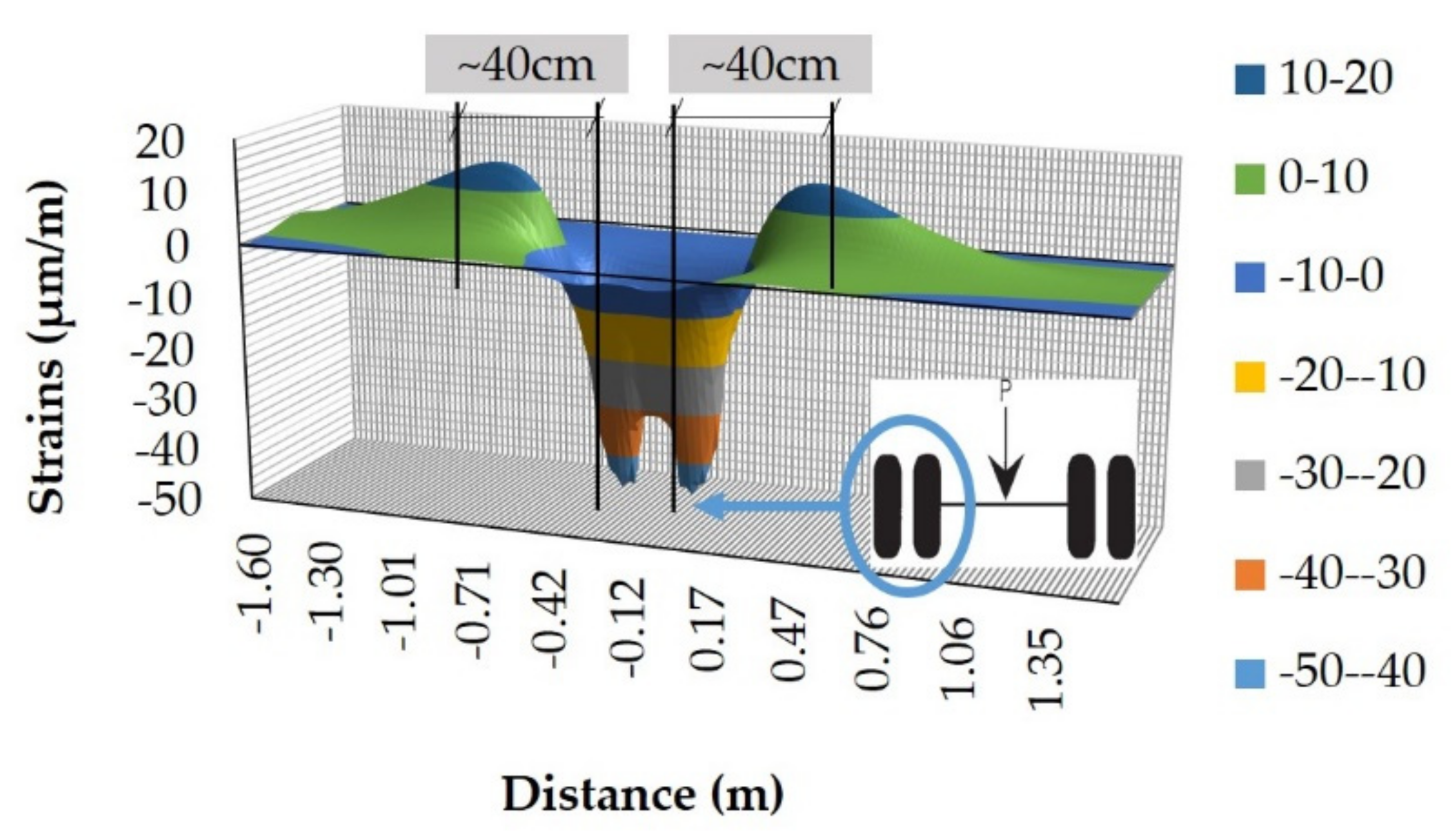

3.1. Overview of Elastic Calculations

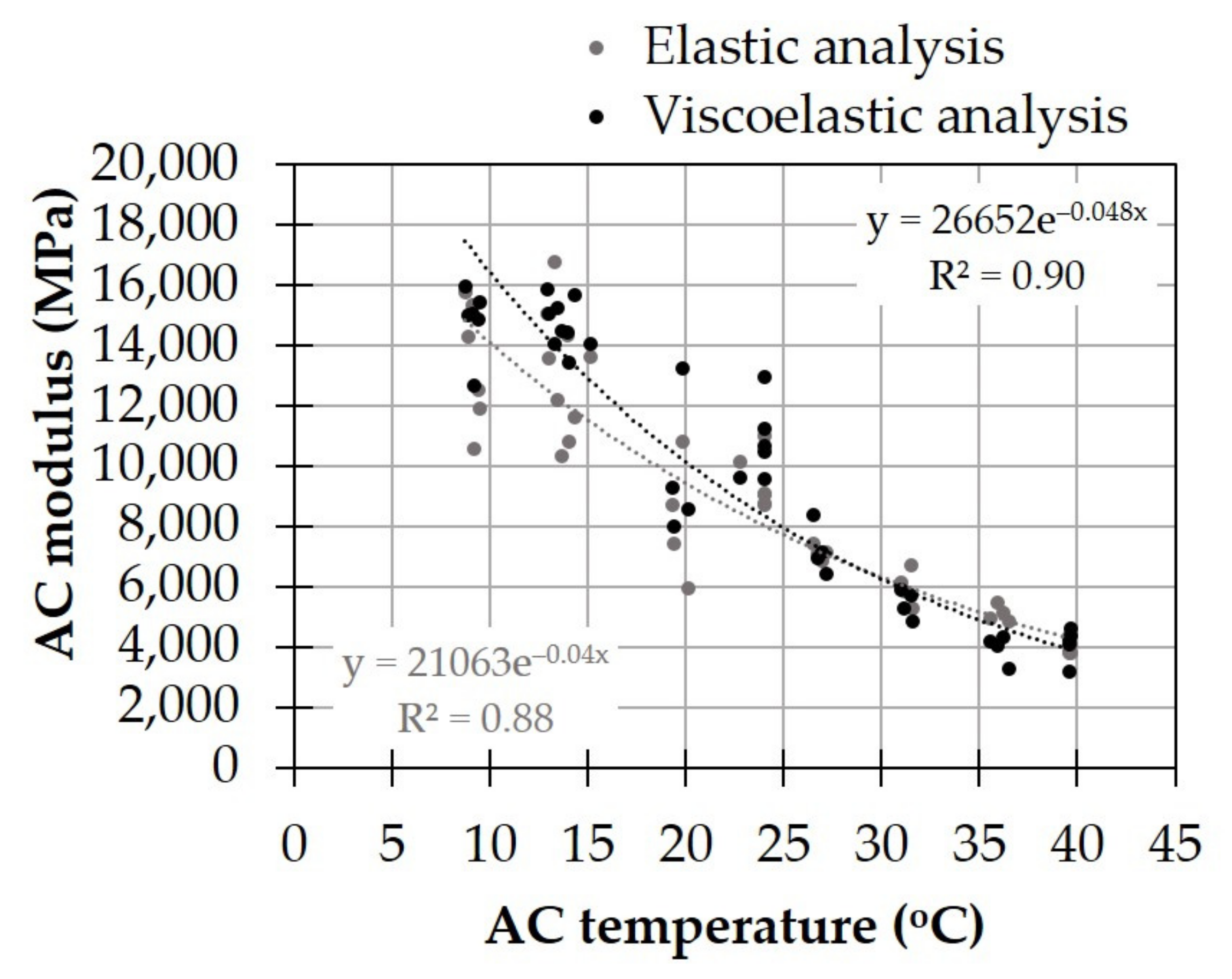

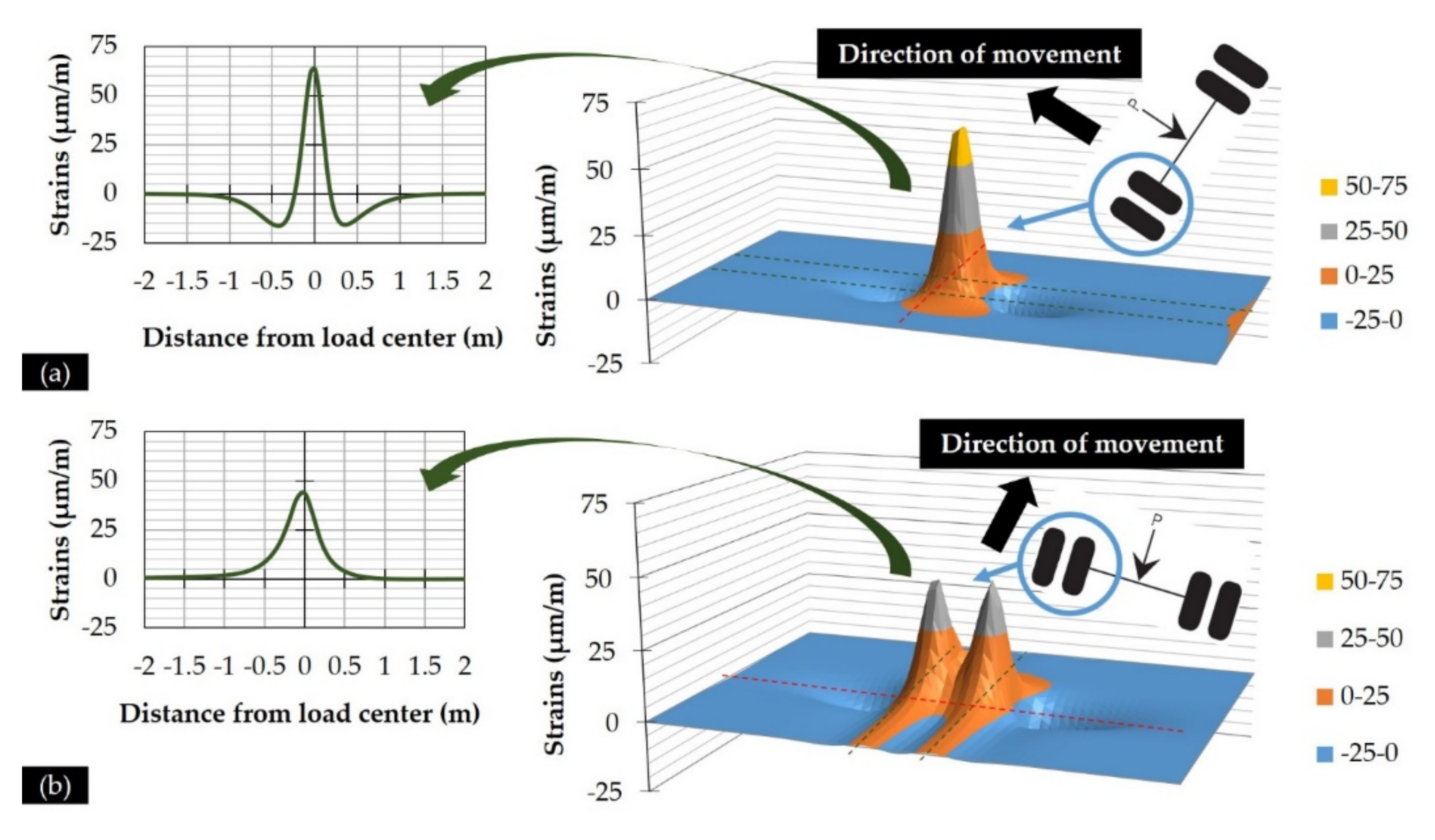

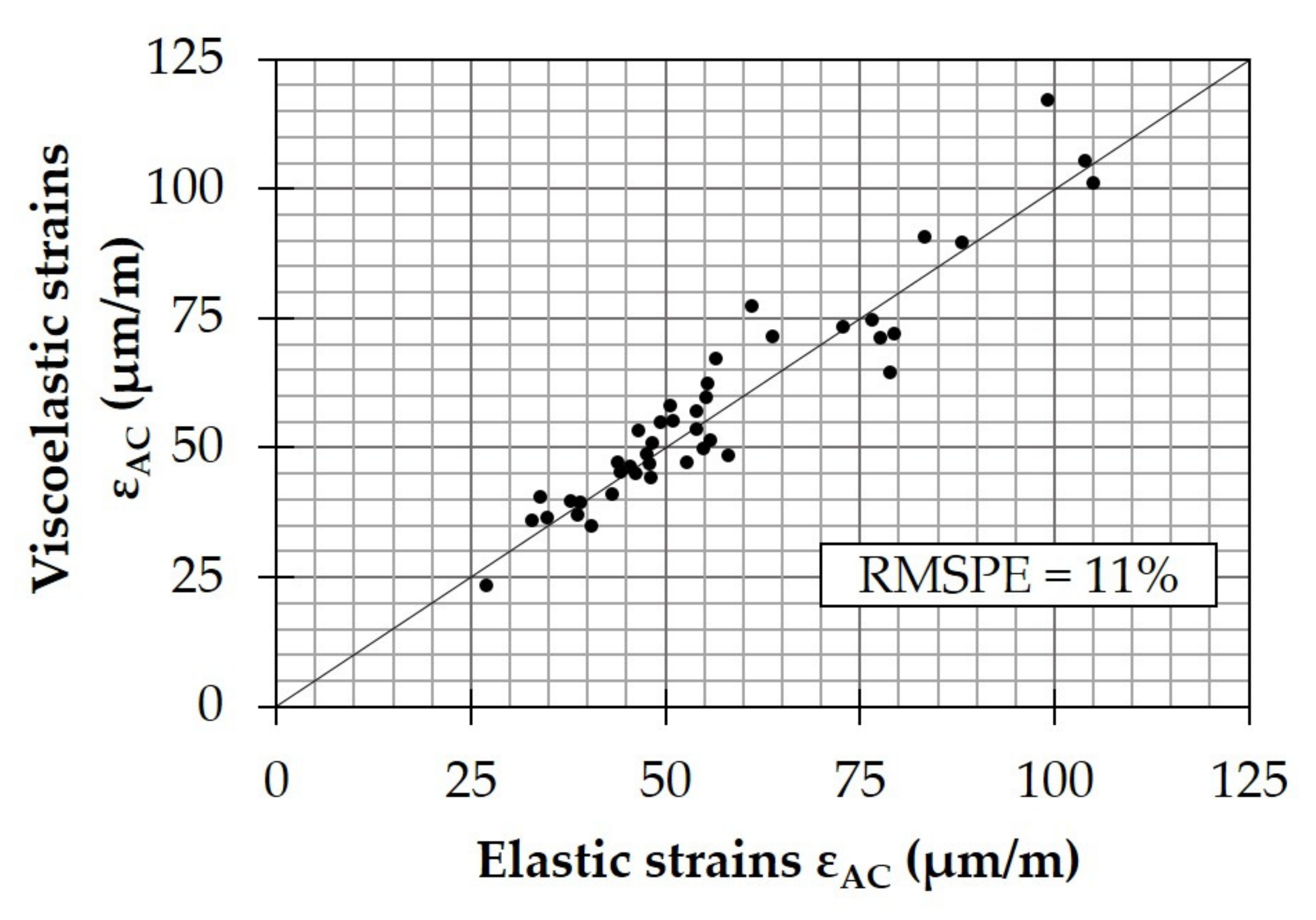

3.2. Impact of AC Behavior on Pavement Response

3.3. Impact of AC Behavior on Pavement Performance Prediction

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Plati, C.; Loizos, A.; Gkyrtis, K. Assessment of modern roadways using non-destructive geophysical surveying techniques. Surv. Geophys. 2020, 41, 395–430. [Google Scholar] [CrossRef]

- Zhao, S.; Al-Qadi, I.L.; Wang, S. Prediction of thin asphalt concrete overlay thickness and density using nonlinear optimization of GPR data. NDT E Int. 2018, 100, 20–30. [Google Scholar] [CrossRef]

- Marecos, V.; Fontul, S.; Antunes, M.L.; Solla, M. Evaluation of a highway pavement using non-destructive tests: Falling Weight Deflectometer and Ground Penetrating Radar. Constr. Build. Mater. 2017, 154, 1164–1172. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Loizos, A.; Plati, C. Integrating pavement sensing data for pavement condition evaluation. Sensors 2021, 21, 3104. [Google Scholar] [CrossRef] [PubMed]

- Rada, G.R.; Perera, R.; Prabhakar, V. Relating Ride Quality and Structural Adequacy for Pavement Rehabilitation/Design Decisions; Report No. FHWAHRT-12-035; Federal Highway Administration: Washington, DC, USA, 2012. [Google Scholar]

- Ruiz, A.; Guevara, J. Sustainable Decision-Making in Road Development: Analysis of Road Preservation Policies. Sustainability 2020, 12, 872. [Google Scholar] [CrossRef] [Green Version]

- De Bortoli, A.; Féraille, A.; Leurent, F. Towards Road Sustainability—Part I: Principles and Holistic Assessment Method for Pavement Maintenance Policies. Sustainability 2022, 14, 1513. [Google Scholar] [CrossRef]

- Pereira, P.; Pais, J. Main flexible pavement and mix design methods in Europe and challenges for the development of an European method. J. Traffic Transp. Eng. 2017, 4, 316–346. [Google Scholar] [CrossRef] [Green Version]

- Tosti, F.; Bianchini Ciampoli, L.; D’Amico, F.; Alani, A.M.; Benedetto, A. An experimental-based model for the assessment of the mechanical properties of road pavements using ground-penetrating radar. Constr. Build. Mater. 2018, 165, 966–974. [Google Scholar] [CrossRef]

- Kavussi, A.; Abbasghorbani, M.; Moghadas-Nejad, F.; Bamdad Ziksari, A. A new method to determine maintenance and repair activities at network level pavement management using falling weight deflectometer. J. Civ. Eng. Manag. 2017, 23, 338–346. [Google Scholar] [CrossRef]

- Plati, C.; Gkyrtis, K.; Loizos, A. Integrating non-destructive testing data to produce asphalt pavement critical strains. Nondestruct. Test. Eval. 2021, 36, 546–570. [Google Scholar] [CrossRef]

- Crook, A.L.; Montgomery, S.R.; Guthrie, W.S. Use of falling weight deflectometer data for network-level flexible pavement management. Transp. Res. Rec. 2012, 2304, 75–85. [Google Scholar] [CrossRef]

- Ahmed, A.; Erlingsson, S. Viscoelastic response modeling of a pavement under moving load. Transp. Res. Procedia 2016, 14, 748–757. [Google Scholar] [CrossRef] [Green Version]

- Shakiba, M.; Gamez, A.; Al-Qadi, I.L.; Little, D.N. Introducing realistic tire-pavement contact stresses into Pavement Analysis using Nonlinear Damage Approach (PANDA). Int. J. Pavement Eng. 2017, 18, 1027–1038. [Google Scholar] [CrossRef]

- Chabot, A.; Chupin, O.; Deloffre, L.; Duhamel, D. ViscoRoute 2.0: A tool for the simulation of moving load effects on asphalt pavement. Road Mater. Pavement Des. 2010, 11, 227–250. [Google Scholar] [CrossRef] [Green Version]

- Mejlun, L.; Judycki, J.; Dolzycki, B. Comparison of elastic and viscoelastic analysis of asphalt pavement at high temperature. Procedia Eng. 2017, 172, 746–753. [Google Scholar] [CrossRef]

- Ban, H.; Im, S.; Kim, Y.-R. Nonlinear viscoelastic approach to model damage-associated performance behavior of asphaltic mixture and pavement structure. Can. J. Civ. Eng. 2013, 40, 313–323. [Google Scholar] [CrossRef]

- Olard, F.; di Benedetto, H. General “2S2P1D” model and relation between the linear viscoelastic behaviors of bituminous binders and mixes. Road Mater. Pavement Des. 2003, 4, 185–224. [Google Scholar]

- Huang, Y.; Liu, Z.; Wang, X.; Li, S. Comparative study on dynamic modulus of asphalt mix with two-point bend and uniaxial compression. In Proceedings of the 4th Chinese-European Workshop on Functional Pavement Design, Delft, The Netherlands, 29 June–1 July 2016; pp. 51–58. [Google Scholar]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the Art Study on Aging of Asphalt Mixtures and Use of Antioxidant Additives. Adv. Civ. Eng. 2018, 2018, 3428961. [Google Scholar] [CrossRef] [Green Version]

- You, T.; Kim, Y.-R.; Rami, K.Z.; Little, D.N. Multiscale Modeling of Asphaltic Pavements: Comparison with Field Performance and Parametric Analysis of Design Variables. J. Transp. Eng. Part B Pavements 2018, 144, 04018012. [Google Scholar] [CrossRef]

- Losa, M.; di Natale, A. Accuracy in predicting viscoelastic response of instrumented asphalt pavements. In Proceedings of the Sustainability, Eco-efficiency and Conservation in Transportation Infrastructure Asset Management, ICTI 2014, Pisa, Italy, 22–25 April 2014; pp. 339–346. [Google Scholar]

- Grellet, D.; Dore, G.; Kerzreho, J.P.; Piau, J.M.; Chabot, A.; Hornych, P. Experimental and theoretical investigation of three dimensional strain occurring near the surface in asphalt concrete layers. In 7th Rilem International Conference on Cracking in Pavements; Springer: New York, NY, USA, 2012; pp. 1017–1027. [Google Scholar]

- Kassem, H.A.; Chehab, G.R.; Najjar, S.S. Quantification of the inherent uncertainty in the relaxation modulus and creep compliance of asphalt mixes. Mech. Time-Depend. Mater. 2018, 22, 331–350. [Google Scholar] [CrossRef]

- Maggiore, C.; Airey, G.; Marsac, P. A dissipated energy comparison to evaluate fatigue resistance using 2-point bending. J. Traffic Transp. Eng. 2014, 1, 49–54. [Google Scholar] [CrossRef] [Green Version]

- Gkyrtis, K.; Loizos, A.; Plati, C. A mechanistic framework for field response assessment of asphalt pavements. Int. J. Pavement Res. Technol. 2021, 14, 174–185. [Google Scholar] [CrossRef]

- NCHRP. Final Report: Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; NCHRP 1-37A Project; Transportation Research Board National Council: Washington, DC, USA, 2004. [Google Scholar]

- Maser, K.R. Condition assessment of transportation infrastructure using ground penetrating radar. J. Infrastruct. Syst. 1996, 2, 94–101. [Google Scholar] [CrossRef]

- AASHTO T342-11; Standard Method of Test for Determining Dynamic Modulus of Hot-Mix Asphalt Concrete Mixtures. American Association of State and Highway Transportation Officials: Washington, DC, USA, 2011.

- Bennert, T.; Williams, S.G. Precision of AASHTO TP62-07 for use in mechanistic-empirical pavement design guide for flexible pavements. Transp. Res. Rec. 2009, 2127, 115–126. [Google Scholar] [CrossRef]

- WSDOT. Everseries User’s Guide—Pavement Analysis Computer Software and Case Studies; Washington State Department of Transportation: Washington, DC, USA, 2005. [Google Scholar]

- Tarefder, R.A.; Ahmed, M.U. Consistency and accuracy of selected FWD backcalculation software for computing layer modulus of airport pavements. Int. J. Geotech. Eng. 2013, 7, 21–35. [Google Scholar] [CrossRef]

- Pan, E.; Chen, E.; Alkasawneh, W. Layered flexible pavement studies: Challenges in forward and inverse problems. Int. J. Pavement Res. Technol. 2008, 1, 12–16. [Google Scholar]

- Ulloa, A.; Hajj, E.Y.; Siddhartan, R.; Sebaaly, P.E. Equivalent Loading Frequencies for Dynamic Analysis of Asphalt Pavements. J. Mater. Civ. Eng. 2013, 25, 1162–1170. [Google Scholar] [CrossRef]

- Siddhartan, R.; Krishnamenon, N.; Sebaaly, P. Pavement Response Evaluation Using Finite-Layer Approach. Transp. Res. Rec. 2000, 1709, 43–49. [Google Scholar] [CrossRef]

- Pronk, A.C. Theory of the Four Point Dynamic Bending Test; Research Report; DWW: Wagengouw, The Netherlands, 1996. [Google Scholar]

- Canestrari, F.; Paolo Ingrassia, L. A review of top-down cracking in asphalt pavements: Causes, models, experimental tools and future challenges. J. Traffic Transp. Eng. 2020, 7, 541–572. [Google Scholar] [CrossRef]

- Roque, R.; Zou, J.; Kim, Y.R.; Baek, C.; Thirunavukkarasu, S.; Underwood, B.S.; Guddati, M.N. Top-Down Cracking of Hot-Mix Asphalt Layers: Models for Initiation and Propagation; NCHRP Project 1e42A; NCHRP: Washington, DC, USA, 2010. [Google Scholar]

- Zou, J.; Roque, R. Top-down cracking: Enhanced performance model and improved understanding of mechanisms. J. Assoc. Asph. Paving Technol. 2011, 80, 255–288. [Google Scholar]

- Sun, L.; Wang, G.; Zhang, H.; Liu, L. Initiation and propagation of top-down cracking in asphalt pavement. Appl. Sci. 2018, 8, 774. [Google Scholar] [CrossRef] [Green Version]

- Al-Qadi, I.L.; Elseifi, M.A.; Yoo, P.J.; Dessouky, S.H.; Gibson, N.; Harman, T.; D’Angelo, J.; Petros, K. Accuracy of current complex modulus selection procedure from vehicular load pulse: NCHRP project 1–37a mechanistic-empirical pavement design guide. Transp. Res. Rec. 2008, 2087, 81–90. [Google Scholar] [CrossRef]

- Cheng, H.; Liu, L.; Sun, L.; Li, Y.; Hu, Y. Comparative analysis of strain-pulse-based loading frequencies for three types of asphalt pavements via field tests with moving truck axle loading. Constr. Build. Mater. 2020, 247, 118519. [Google Scholar] [CrossRef]

- Seo, J.; Kim, Y.; Cho, J.; Jeong, S. Estimation of in situ dynamic modulus by using MEPDG dynamic modulus and FWD data at different temperatures. Int. J. Pavement Eng. 2013, 14, 343–353. [Google Scholar] [CrossRef]

- Shell Pavement Design Method, BISAR PC User Manual, Shell International Petroleum; BISAR Co., Ltd.: London, UK, 1998.

- Losa, M.; Bacci, R.; Leandri, P. A statistical model for prediction of critical strains in pavements from deflection measurements. Road Mater. Pavement Des. 2008, 9, 373–396. [Google Scholar] [CrossRef]

- Garcia, G.; Thompson, M.R. Strain and pulse design considerations for extended-life hot-mix asphalt pavement design. Transp. Res. Rec. 2008, 2087, 3–11. [Google Scholar] [CrossRef]

- Braunfelds, J.; Senkans, U.; Skels, P.; Janeliukstis , R.; Salgals, T.; Redka, D.; Lyashuk, I.; Porins, J.; Spolitis, S.; Haritonovs, V.; et al. FBG-Based Sensing for Structural Health Monitoring of Road Infrastructure. J. Sens. 2021, 2021, 8850368. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Armeni, A.; Loizos, A. A mechanistic perspective for airfield pavements evaluation focusing on the asphalt layers’ behaviour. Int. J. Pavement Eng. 2021. [Google Scholar] [CrossRef]

- Uhlmeyer, J.S.; Willoughby, K.; Pierce, L.M.; Mahoney, J.P. Top-down cracking in Washington State asphalt concrete wearing courses. Transp. Res. Rec. 2000, 1730, 110–116. [Google Scholar] [CrossRef]

- Horak, E. Benchmarking the structural condition of flexible pavements with deflection bowl parameters. J. S. Afr. Inst. Civ. Eng. 2008, 50, 2–9. [Google Scholar]

| Geophone | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Distance from center (mm) | 0 | 200 | 300 | 450 | 600 | 900 | 1200 | 1500 | 1800 |

| Failure Mode | a | b | c | d |

|---|---|---|---|---|

| Bottom-up cracking | 0.000398 | 0.003602 | 11.02 | 3.49 |

| Top-down cracking | 0.001 | 29.844 | 30.544 | 5.7357 |

| Tools (i and j) Used for Moduli Estimation | Strain AC Bottom | Strain at Top of Subgrade | ||

|---|---|---|---|---|

| Null Hypothesis: | Null Hypothesis: | |||

| EVERCALC-BAKFAA | 4.00 | Reject | 1.37 | Accept |

| EVERCALC-BackGenetic3D | −0.04 | Accept | 1.58 | Accept |

| BackGenetic3D-BAKFAA | −4.37 | Reject | −0.77 | Accept |

| Deflection Indicators (Di, Where i Is the Distance from the Loading Center) | Alligator Cracking Prediction (BC Potential) | Longitudinal Cracking Prediction (TDC Potential) | ||

|---|---|---|---|---|

| Elastic AC Behavior | Viscoelastic AC Behavior | Elastic AC Behavior | Viscoelastic AC Behavior | |

| D0 (maximum deflection—μm) | 0.82 | 0.79 | 0.47 | 0.43 |

| SCI = D0–D300 (μm) | 0.46 | 0.43 | 0.66 | 0.52 |

| BDI = D300–D600 (μm) | 0.84 | 0.81 | 0.51 | 0.43 |

| BCI = D600–D900 (μm) | 0.53 | 0.52 | 0.30 | 0.28 |

| D900–D1200 (μm) | 0.23 | 0.24 | 0.23 | 0.24 |

| D1800 (outermost deflection—μm) | 0.03 | 0.01 | 0.10 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gkyrtis, K.; Plati, C.; Loizos, A. Mechanistic Analysis of Asphalt Pavements in Support of Pavement Preservation Decision-Making. Infrastructures 2022, 7, 61. https://doi.org/10.3390/infrastructures7050061

Gkyrtis K, Plati C, Loizos A. Mechanistic Analysis of Asphalt Pavements in Support of Pavement Preservation Decision-Making. Infrastructures. 2022; 7(5):61. https://doi.org/10.3390/infrastructures7050061

Chicago/Turabian StyleGkyrtis, Konstantinos, Christina Plati, and Andreas Loizos. 2022. "Mechanistic Analysis of Asphalt Pavements in Support of Pavement Preservation Decision-Making" Infrastructures 7, no. 5: 61. https://doi.org/10.3390/infrastructures7050061