Effects of Periodic Incoming Wakes on the Aerodynamics of a High-Speed Low-Pressure Turbine Cascade †

Abstract

:1. Introduction

2. Experimental Setup

2.1. The SPLEEN C1 Cascade with Wake Generator

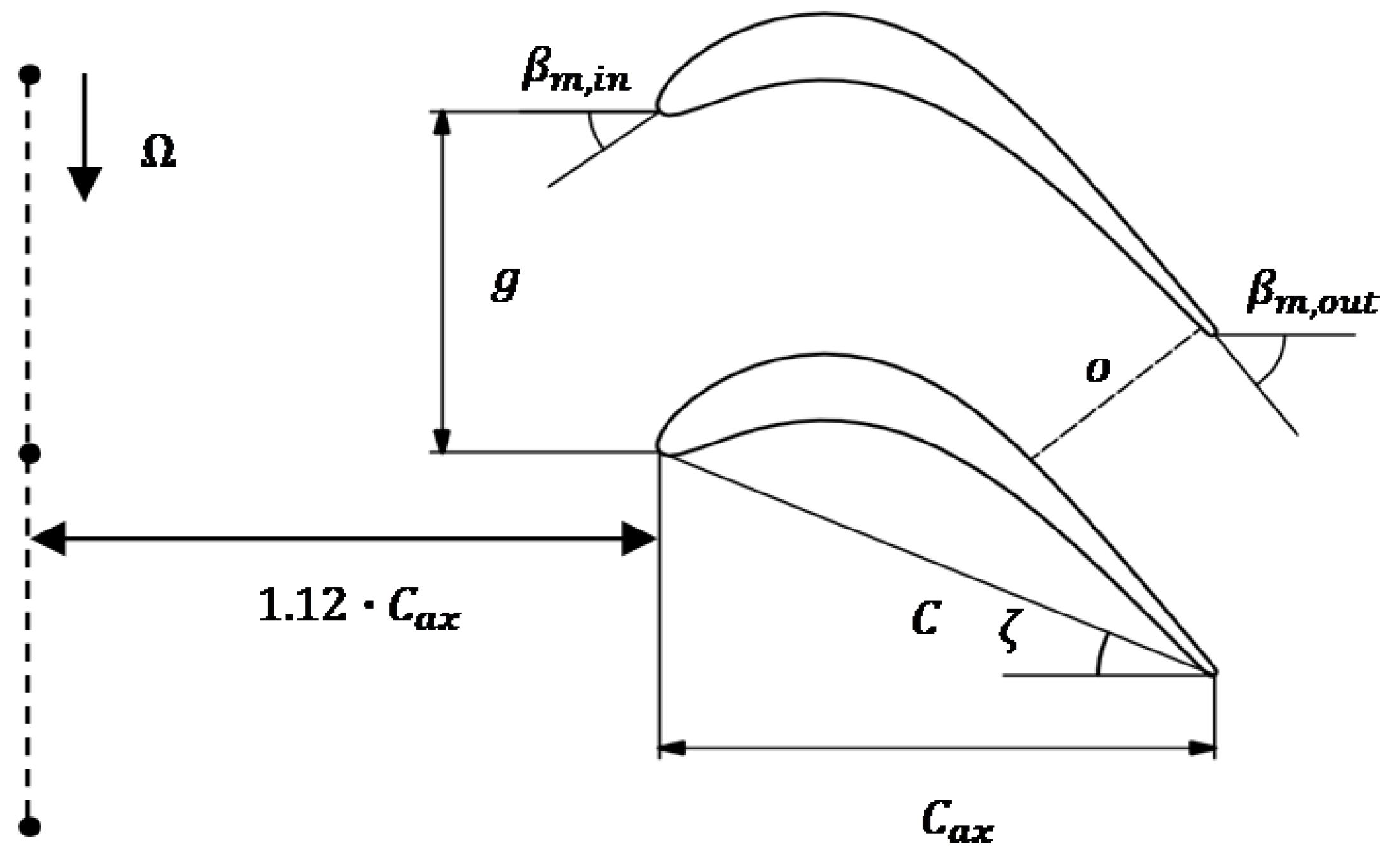

2.2. SPLEEN C1 Blade Design

2.3. Test Conditions

3. Experimental Methodology

3.1. Blade Measurements

3.2. Inlet and Outlet Flow Field

4. Results and Discussion

4.1. Cascade Inlet Flow

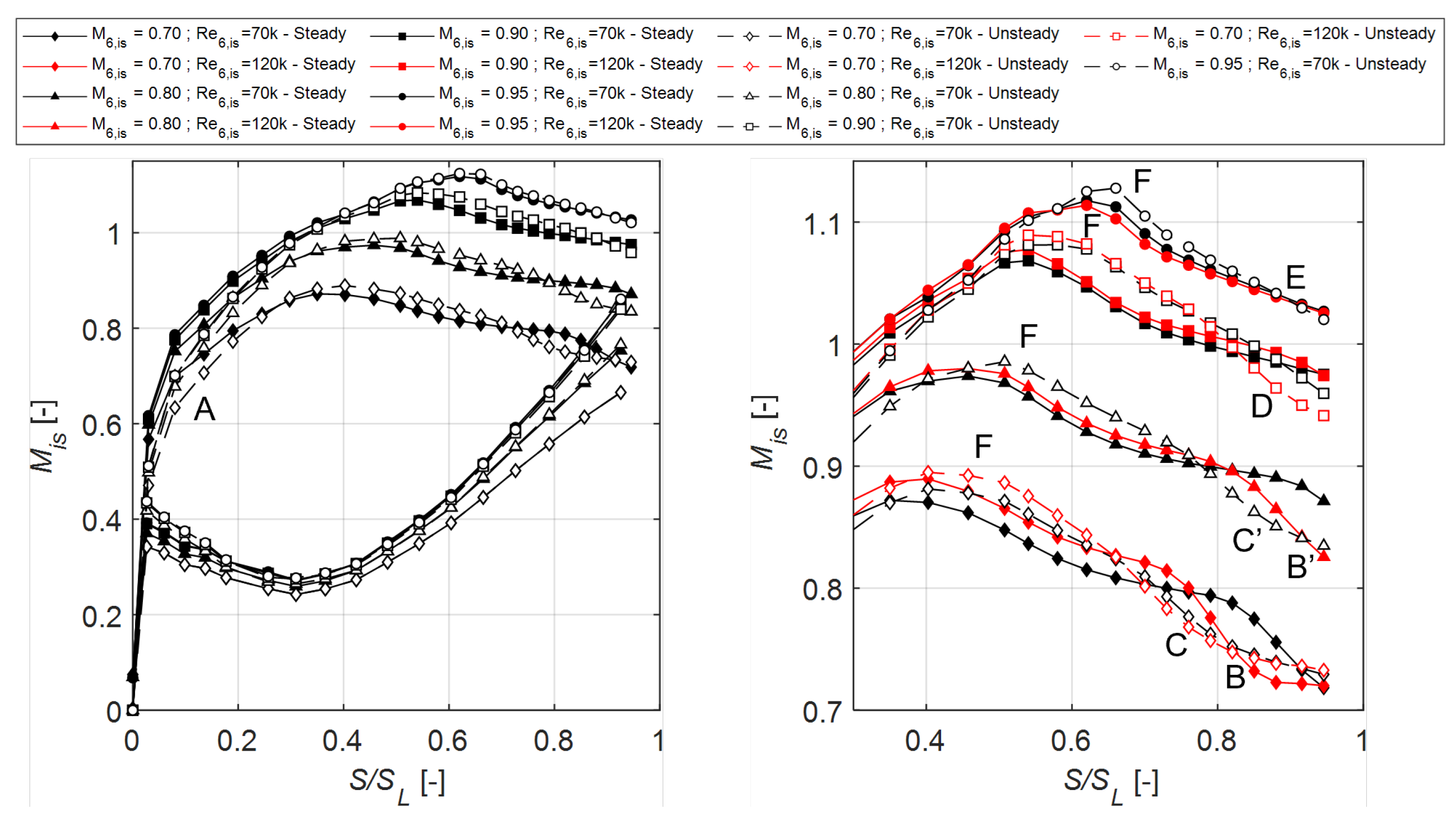

4.2. Blade Pneumatic Taps

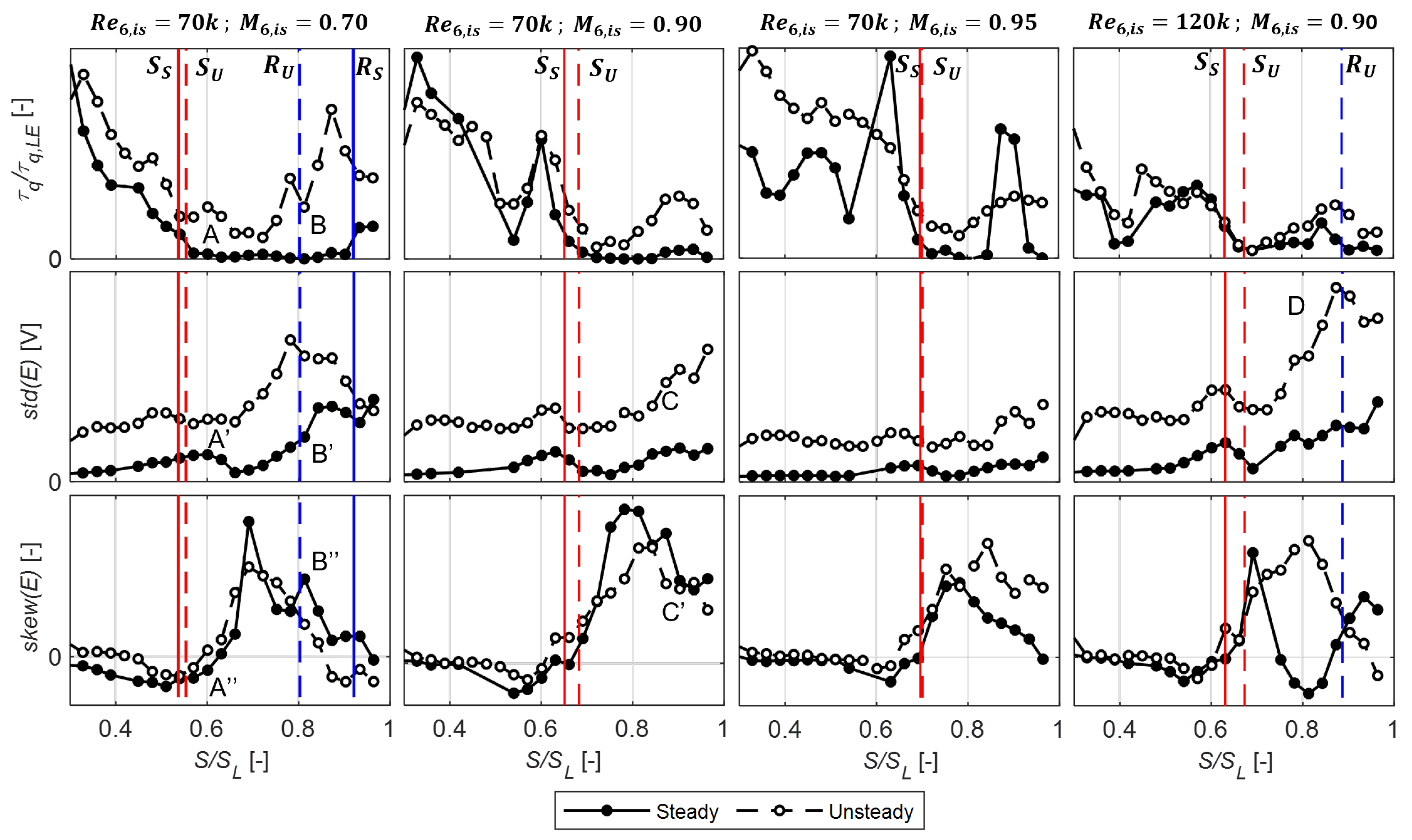

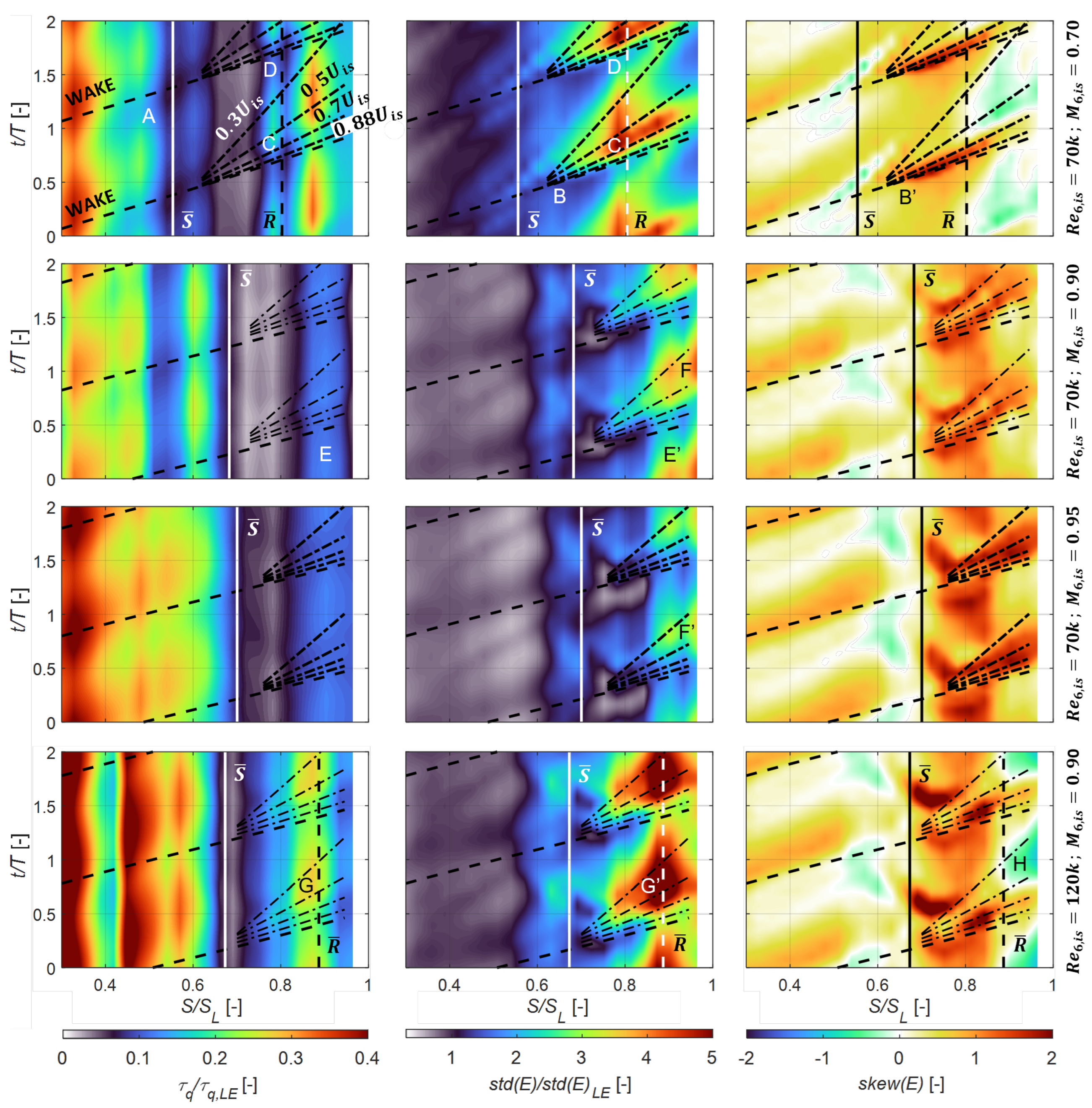

4.3. Blade Hot-Film Sensors

4.4. Cascade Outlet Flow

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CTA | constant temperature anemometry |

| DF | diffusion factor, |

| DR | deceleration rate, |

| FSTI | freestream turbulence intensity |

| HF | surface-mounted hot-film |

| LE | leading edge |

| L5HP | L-shaped five-hole probe |

| LPT | low-pressure turbine |

| PS | pressure side |

| SS | suction side |

| TE | trailing edge |

| TG | turbulence grid |

| WG | wake generator |

| Roman | |

| C | true chord |

| E | bridge voltage |

| f | frequency |

| bar-reduced frequency, | |

| g | cascade pitch |

| H | cascade span |

| i | incidence, |

| acceleration parameter, | |

| M | Mach number |

| o | throat |

| P | pressure |

| heat flux | |

| R | reattachment, resistance |

| Reynolds number, | |

| S | separation line, location along surface length |

| skewness | |

| surface length | |

| standard deviation | |

| T | temperature |

| U | bar peripheral speed |

| V | absolute velocity |

| location along axial chord, pitchwise and spanwise direction | |

| Greek letters | |

| yaw angle | |

| primary flow direction, | |

| ratio of specific heats, pitch angle | |

| trailing edge thickness | |

| wedge angle | |

| stagger angle | |

| dynamic viscosity | |

| kinetic energy loss coefficient, | |

| density | |

| quasi-wall shear stress | |

| flow coefficient, | |

| Subscripts and superscripts | |

| a | ambient, area-averaged |

| ax | axial |

| bar | bar |

| F | flow |

| fs | freestream |

| End | endwall |

| in | inlet |

| is | isentropic |

| m | mass-averaged |

| met | metallic |

| out | outlet |

| Prof | profile |

| q | quasi |

| S | sensor, substrate |

| sec | secondary |

| w | wall |

| 0 | flow-off, cold, total |

| 2 | at Plane 02 |

| 6 | at Plane 06 |

| time-averaged quantity |

References

- Kurzke, J. Fundamental Differences Between Conventional and Geared Turbofans. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; Volume 1. [Google Scholar] [CrossRef]

- Malzacher, F.J.; Gier, J.; Lippl, F. Aerodesign and Testing of an Aeromechanically Highly Loaded LP Turbine. J. Turbomach. 2003, 128, 643–649. [Google Scholar] [CrossRef]

- Vázquez, R.; Torre, D. The Effect of Mach Number on the Loss Generation of LP Turbines. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; Volume 8. [Google Scholar] [CrossRef]

- Ladwig, M.; Fottner, L. Experimental Investigations of the Influence of Incoming Wakes on the Losses of a Linear Turbine Cascade. In Proceedings of the ASME 1993 International Gas Turbine and Aeroengine Congress and Exposition, Cincinnati, OH, USA, 24–27 May 1993; Volume 3C. [Google Scholar] [CrossRef]

- Mayle, R.E. The 1991 IGTI Scholar Lecture: The Role of Laminar-Turbulent Transition in Gas Turbine Engines. J. Turbomach. 1991, 113, 509–536. [Google Scholar] [CrossRef]

- Schulte, V.; Hodson, H.P. Unsteady Wake-Induced Boundary Layer Transition in High Lift LP Turbines. J. Turbomach. 1998, 120, 28–35. [Google Scholar] [CrossRef]

- Stieger, R.D.; Hodson, H.P. The Unsteady Development of a Turbulent Wake Through a Downstream Low-Pressure Turbine Blade Passage. J. Turbomach. 2005, 127, 388–394. [Google Scholar] [CrossRef]

- Howell, R.J.; Hodson, H.P.; Schulte, V.; Stieger, R.D.; Schiffer, H.P.; Haselbach, F.; Harvey, N.W. Boundary Layer Development in the BR710 and BR715 LP Turbines—The Implementation of High-Lift and Ultra-High-Lift Concepts. J. Turbomach. 2002, 124, 385–392. [Google Scholar] [CrossRef]

- Coull, J.D.; Hodson, H.P. Unsteady boundary-layer transition in low-pressure turbines. J. Fluid Mech. 2011, 681, 370–410. [Google Scholar] [CrossRef]

- Clinckemaillie, J.; Fattorini, L.; Fontani, T.; Nuyts, C.; Wain, G.; Arts, T. Aerodynamic performance of a very-high-lift low-pressure turbine airfoil (T106C) at low Reynolds and high Mach number including the effect of incoming periodic wakes. In Proceedings of the 11th European Conference on Turbomachinery Fluid Dynamics and Thermodynamics, ETC 2015, Madrid, Spain, 23–27 March 2015. [Google Scholar]

- Mahallati, A.; Sjolander, S.A. Aerodynamics of a Low-Pressure Turbine Airfoil at Low Reynolds Numbers—Part II: Blade-Wake Interaction. J. Turbomach. 2012, 135, 011011. [Google Scholar] [CrossRef]

- Brunner, S.; Fottner, L.; Schiffer, H.-P. Comparison of Two Highly Loaded Low Pressure Turbine Cascades Under the Influence of Wake-Induced Transition. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000; Volume 3. [Google Scholar] [CrossRef]

- Vera, M.; Hodson, H.; Vázquez, R. The Effect of Mach Number on lp Turbinewake-Blade Interaction. In Unsteady Aerodynamics, Aeroacoustics and Aeroelasticity of Turbomachines; Hall, K.C., Kielb, R.E., Thomas, J.P., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 203–216. [Google Scholar]

- Vázquez, R.; Antoranz, A.; Cadrecha, D.; Armanãnzas, L. The Influence of Reynolds Number, Mach Number and Incidence Effects on Loss Production in Low Pressure Turbine Airfoils. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; Volume 6. [Google Scholar] [CrossRef]

- Coull, J.D.; Thomas, R.L.; Hodson, H.P. Velocity Distributions for Low Pressure Turbines. J. Turbomach. 2010, 132, 041006. [Google Scholar] [CrossRef]

- Curtis, E.M.; Hodson, H.P.; Banieghbal, M.R.; Denton, J.D.; Howell, R.J.; Harvey, N.W. Development of Blade Profiles for Low-Pressure Turbine Applications. J. Turbomach. 1997, 119, 531–538. [Google Scholar] [CrossRef]

- González, P.; Ulizar, I.; Vázquez, R.; Hodson, H.P. Pressure and Suction Surfaces Redesign for High-Lift Low-Pressure Turbines. J. Turbomach. 2002, 124, 161–166. [Google Scholar] [CrossRef]

- Canepa, E.; Lengani, D.; Nilberto, A.; Petronio, D.; Simoni, D.; Ubaldi, M.; Zunino, P. Flow Coefficient and Reduced Frequency Effects on Wake-Boundary Layer Interaction in Highly Accelerated LPT Cascade. Int. J. Turbomach. Propuls. Power 2021, 6, 32. [Google Scholar] [CrossRef]

- Wakelam, C.T.; Hoeger, M.; Niehuis, R. A Comparison of Three Low Pressure Turbine Designs. J. Turbomach. 2013, 135, 051026. [Google Scholar] [CrossRef]

- Arts, T. Aerodynamic performance of two very high lift low pressure turbine airfoils (T106C–T2) at low Reynolds and high Mach numbers. In Proceedings of the 5th European Conference for Aerospace Sciences, Munich, Germany, 1–5 July 2013. [Google Scholar]

- Simonassi, L.; Lopes, G.; Gendebien, S.; Torre, A.F.M.; Patinios, M.; Lavagnoli, S.; Zeller, N.; Pintat, L. An Experimental Test Case for Transonic Low-Pressure Turbines–Part I: Rig Design, Instrumentation and Experimental Methodology, In Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022; Volume 10B. [CrossRef]

- Lopes, G.; Simonassi, L.; Torre, A.F.M.; Patinios, M.; Lavagnoli, S. An Experimental Test Case for Transonic Low-Pressure Turbines–Part 2: Cascade Aerodynamics at On- and Off-Design Reynolds and Mach Numbers. In Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022; Volume 10B. [Google Scholar] [CrossRef]

- Simonassi, L.; Lopes, G.; Lavagnoli, S. Effects of Periodic Incoming Wakes on the Aerodynamics of a High-Speed Low-Pressure Turbine Cascade. In Proceedings of the 15th European Conference on Turbomachinery Fluid Dynamics and Thermodynamics, Paper n. ETC2023-293. Budapest, Hungary, 24–28 April 2023; Available online: https://www.euroturbo.eu/publications/conference-proceedings-repository/ (accessed on 12 June 2023).

- Pfeil, H.; Eifler, J. Turbulence characteristics behind rotating cylinder grids. Forsch. Ingenieurwesen 1976, 42, 27–32. [Google Scholar] [CrossRef]

- Berrino, M.; Simoni, D.; Ubaldi, M.; Zunino, P.; Bertini, F. Off-Design Performance of a Highly Loaded LP Turbine Cascade Under Steady and Unsteady Incoming Flow Conditions. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Dusseldorf, Germany, 16–20 June 2014; Volume 2D. [Google Scholar] [CrossRef]

- Hodson, H. The detection of boundary-layer transition and separation in high speed turbine cascades. In Measurement Techniques for Transonic and Supersonic Flow—Proc. 7th Symposium; University of Cambridge: Cambridge, UK, 1984. [Google Scholar]

- Hultmark, M.; Smits, A.J. Temperature corrections for constant temperature and constant current hot-wire anemometers. Meas. Sci. Technol. 2010, 21, 105404. [Google Scholar] [CrossRef]

- Ligrani, P.; Baun, L.; Singer, B. Spatial resolution and downwash velocity corrections for multiple-hole pressure probes in complex flows. Exp. Fluids 1989, 7, 424–426. [Google Scholar] [CrossRef]

- Cukurel, B.; Acarer, S.; Arts, T. A novel perspective to high-speed cross-hot-wire calibration methodology. Exp. Fluids 2012, 53, 1073–1085. [Google Scholar] [CrossRef]

- Boufidi, E.; Fontaneto, F. Towards a more reliable application of hot-wire anemometry in complex compressible flows. In Proceedings of the XXIII Biannual Symposium on Measuring Techniques in Turbomachinery, Transonic and Supersonic Flow in Cascades and Turbomachines, Stuttgart, Germany, 1–2 September 2016. [Google Scholar]

- Gomes, R.A.; Stotz, S.; Blaim, F.; Niehuis, R. Hot-Film Measurements on a Low Pressure Turbine Linear Cascade with Bypass Transition. J. Turbomach. 2015, 137, 091007. [Google Scholar] [CrossRef]

- Börner, M.; Niehuis, R. Dynamics of Shock Waves Interacting with Laminar Separated Transonic Turbine Flow Investigated by High-Speed Schlieren and Surface Hot-Film Sensors. J. Turbomach. 2021, 143, 051010. [Google Scholar] [CrossRef]

- Schubauer, G.B.; Klebanoff, P.S. Contributions on the Mechanics of Boundary-Layer Transition; Technical Report; NASA: Washington, DC, USA, 1956. [Google Scholar]

| True chord, C | 52.285 | mm |

| Axial chord, | 47.614 | mm |

| Cascade pitch, g | 32.950 | mm |

| Pitch-to-chord ratio | 0.630 | - |

| Cascade span, H | 165.000 | mm |

| Max thickness/Chord | 0.127 | - |

| TE thickness, | 0.870 | mm |

| Throat opening, o | 19.400 | mm |

| Stagger angle, | 24.400 | ° |

| Wedge angle, | 6.480 | ° |

| Inlet metal angle, | 37.300 | ° |

| Outlet metal angle, | 53.800 | ° |

| Nominal Conditions | Off-Design Conditions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.9 | 65k | 70k | 100k | 120k | ||||||||

| 70k | 0.70 | 0.90 | 0.70 | 0.80 | 0.90 | 0.95 | 0.70 | 0.90 | 0.70 | 0.90 | ||

| 0.46 | 1.18 | 0.95 | 1.18 | 1.05 | 0.95 | 0.9 | 1.18 | 0.95 | 1.18 | 0.95 | ||

| 0.95 | 0.72 | 0.77 | 0.72 | 0.77 | 0.80 | 0.80 | 0.72 | 0.80 | 0.72 | 0.80 | ||

| 0.80 | F | X | X | X | X | |||||||

| B Pneu | X | X | X | X | X | X | X | X | X | X | ||

| B HF | X | X | X | X | ||||||||

| Steady | ±0.24 | 0.65 | 2.30 | |

| Unsteady | ±0.40 | 0.75 | 4.10 |

[] | [-] | DF [-] | DR [-] | Separation [] | Reattachment [] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | U | S | U | S | U | S | U | S | U | S | U | ||

| 70k | 0.70 | 0.37 | 0.41 | 0.874 | 0.882 | 0.25 | 0.26 | 0.39 | 0.41 | 0.54 | 0.55 | 0.92 | 0.8 |

| 70k | 0.80 | 0.46 | 0.5 | 0.975 | 0.986 | 0.22 | 0.23 | 0.41 | 0.43 | 0.56 | 0.57 | ND | 0.87 |

| 70k | 0.90 | 0.53 | 0.56 | 1.070 | 1.082 | 0.19 | 0.2 | 0.4 | 0.43 | 0.65 | 0.68 | ND | ND |

| 70k | 0.95 | 0.63 | 0.65 | 1.120 | 1.130 | 0.18 | 0.19 | 0.48 | 0.51 | 0.7 | 0.7 | ND | ND |

| 120k | 0.70 | 0.39 | 0.41 | 0.891 | 0.896 | 0.27 | 0.28 | 0.45 | 0.46 | 0.54 | 0.57 | 0.86 | 0.75 |

| 120k | 0.80 | 0.44 | - | 0.981 | - | 0.26 | - | 0.4 | - | 0.56 | - | 0.92 | - |

| 120k | 0.90 | 0.53 | 0.55 | 1.079 | 1.090 | 0.2 | 0.21 | 0.42 | 0.45 | 0.63 | 0.67 | ND | 0.89 |

| 120k | 0.95 | 0.62 | - | 1.114 | - | 0.17 | - | 0.45 | - | 0.69 | - | ND | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Simonassi, L.; Lopes, G.; Lavagnoli, S. Effects of Periodic Incoming Wakes on the Aerodynamics of a High-Speed Low-Pressure Turbine Cascade. Int. J. Turbomach. Propuls. Power 2023, 8, 35. https://doi.org/10.3390/ijtpp8030035

Simonassi L, Lopes G, Lavagnoli S. Effects of Periodic Incoming Wakes on the Aerodynamics of a High-Speed Low-Pressure Turbine Cascade. International Journal of Turbomachinery, Propulsion and Power. 2023; 8(3):35. https://doi.org/10.3390/ijtpp8030035

Chicago/Turabian StyleSimonassi, Loris, Gustavo Lopes, and Sergio Lavagnoli. 2023. "Effects of Periodic Incoming Wakes on the Aerodynamics of a High-Speed Low-Pressure Turbine Cascade" International Journal of Turbomachinery, Propulsion and Power 8, no. 3: 35. https://doi.org/10.3390/ijtpp8030035

APA StyleSimonassi, L., Lopes, G., & Lavagnoli, S. (2023). Effects of Periodic Incoming Wakes on the Aerodynamics of a High-Speed Low-Pressure Turbine Cascade. International Journal of Turbomachinery, Propulsion and Power, 8(3), 35. https://doi.org/10.3390/ijtpp8030035