Journal Description

International Journal of Turbomachinery, Propulsion and Power

International Journal of Turbomachinery, Propulsion and Power

is an international, peer-reviewed, open access journal on turbomachinery, propulsion and power. It is the official journal of the EUROTURBO European Turbomachinery Society and published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, ESCI (Web of Science), Inspec, Ei Compendex, and other databases.

- Journal Rank: JCR - Q2 (Engineering, Aerospace)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 53.7 days after submission; acceptance to publication is undertaken in 17.5 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

Impact Factor:

1.8 (2024);

5-Year Impact Factor:

1.7 (2024)

Latest Articles

Toward the Detection of Flow Separation for Operating Airfoils Using Machine Learning

Int. J. Turbomach. Propuls. Power 2025, 10(4), 41; https://doi.org/10.3390/ijtpp10040041 - 3 Nov 2025

Abstract

Turbulent flow separation over lifting surfaces impacts high-lift systems such as aircraft, wind turbines, and turbomachinery, and contributes to noise, lift loss, and vibrations. Accurate detection of flow separation is therefore essential to enable active control strategies and to mitigate its adverse effects.

[...] Read more.

Turbulent flow separation over lifting surfaces impacts high-lift systems such as aircraft, wind turbines, and turbomachinery, and contributes to noise, lift loss, and vibrations. Accurate detection of flow separation is therefore essential to enable active control strategies and to mitigate its adverse effects. Several machine learning models are compared for detecting flow separation from surface pressure fluctuations. The models were trained on experimental data covering various airfoils, angles of attack (0°–23°), and Reynolds numbers, with

(This article belongs to the Special Issue Advances in Industrial Fan Technologies)

Open AccessArticle

An Experimental Investigation by Particle Image Velocimetry of the Active Flow Control of the Stall Inception of an Axial Compressor

by

Olha Alekseik, Pierric Joseph, Olivier Roussette and Antoine Dazin

Int. J. Turbomach. Propuls. Power 2025, 10(4), 40; https://doi.org/10.3390/ijtpp10040040 - 3 Nov 2025

Abstract

►▼

Show Figures

This paper presents results from active flow control experiments carried out on a single stage axial compressor. The flow under various forced conditions has been investigated using 2D 2C particle image velocimetry (PIV) on three radial planes along the blades’ span and two

[...] Read more.

This paper presents results from active flow control experiments carried out on a single stage axial compressor. The flow under various forced conditions has been investigated using 2D 2C particle image velocimetry (PIV) on three radial planes along the blades’ span and two different operating points corresponding to the minimum mass flow at which the compressor naturally stalls, and to the lower stability limit reached with the control system activated. In particular, a control strategy using continuous blowing is compared with a pulsed one using the same injected mass flow. Comparison is performed with the base flow without control (when available), or with each other, based on the PIV results in the form of relative velocity maps or inlet/outlet flow characteristics.

Full article

Figure 1

Open AccessArticle

A Multi-Point Preliminary Design Method for Centrifugal Compressor Stages of Fuel Cell-Based Propulsion Systems

by

Alessandro Cappiello, Viviane Ciais and Matteo Pini

Int. J. Turbomach. Propuls. Power 2025, 10(4), 39; https://doi.org/10.3390/ijtpp10040039 - 3 Nov 2025

Abstract

►▼

Show Figures

The successful implementation of an airborne propulsion system based on hydrogen-powered fuel cell technology highly depends on the development of an efficient, lightweight and compact air supply compressor. Meeting these requirements by designing the compressor using conventional single-point preliminary design methods can be

[...] Read more.

The successful implementation of an airborne propulsion system based on hydrogen-powered fuel cell technology highly depends on the development of an efficient, lightweight and compact air supply compressor. Meeting these requirements by designing the compressor using conventional single-point preliminary design methods can be challenging, due to the very wide range of corrected mass flow rate and pressure ratio values that the air supply compressor must be able to accommodate. This article presents a multi-point design methodology for the preliminary design of centrifugal compressors of air supply systems. The method is implemented in an in-house code, called TurboSim, and allows to perform single- and multi-objective constrained optimization of vaneless centrifugal compressors. Furthermore, an automatic design point selection method is also available. The accuracy of the compressor lumped-parameter model is validated against experimental data obtained on a high-pressure-ratio single-stage vaneless centrifugal compressor from the literature. Subsequently, the design methodology is applied to optimize the compressor of the air supply system of an actual fuel cell powertrain. The results, compared to those obtained with a more conventional single-point design method, show that the multi-point method provides compressor designs that feature superior performance and that better comply with the specified constraints at the target operating points.

Full article

Figure 1

Open AccessArticle

Comparison of Different Strategies to Include Structural Mechanics in the Optimization Process of an Axial Turbine’s Runner Blade

by

Stefan Fraas, Alexander Tismer and Stefan Riedelbauch

Int. J. Turbomach. Propuls. Power 2025, 10(4), 38; https://doi.org/10.3390/ijtpp10040038 - 3 Nov 2025

Abstract

►▼

Show Figures

Different strategies to include structural mechanical aspects in the design process of hydraulic machines are compared. Therefore, an axial turbine’s runner blade is optimized using evolutionary algorithms. Four different setups with a scalar objective function are investigated. In the first two setups, structural

[...] Read more.

Different strategies to include structural mechanical aspects in the design process of hydraulic machines are compared. Therefore, an axial turbine’s runner blade is optimized using evolutionary algorithms. Four different setups with a scalar objective function are investigated. In the first two setups, structural mechanical aspects are added to the optimization process as a constraint, once with a penalty term and once with a modified selection operator. If structural mechanical aspects are considered as a constraint, the risk of a premature convergence increases. For this reason, additionally, two setups including the minimization of the maximum stress as an objective within a scalar objective function are analyzed. Furthermore, a multi-objective optimization with resolution of the Pareto front is performed. The differences in the results regarding fitness between the setups using a scalar objective function are small. However, the best result is found for a setup where the minimization of the stress is added as an objective. This demonstrates the risk of a premature convergence involved with constraint handling strategies. The worst result is found for the multi-objective optimization with resolution of the Pareto front, most likely due to a less directed search.

Full article

Figure 1

Open AccessArticle

Development of a Reduced Order Model for Turbine Blade Cooling Design

by

Andrea Pinardi, Noraiz Mushtaq and Paolo Gaetani

Int. J. Turbomach. Propuls. Power 2025, 10(4), 37; https://doi.org/10.3390/ijtpp10040037 - 8 Oct 2025

Abstract

►▼

Show Figures

Rotating detonation engines (RDEs) are expected to have higher specific work and efficiency, but the high-temperature transonic flow delivered by the combustor poses relevant design and technological difficulties. This work proposes a 1D model for turbine internal cooling design which can be used

[...] Read more.

Rotating detonation engines (RDEs) are expected to have higher specific work and efficiency, but the high-temperature transonic flow delivered by the combustor poses relevant design and technological difficulties. This work proposes a 1D model for turbine internal cooling design which can be used to explore multiple design options during the preliminary design of the cooling system. Being based on an energy balance applied to an infinitesimal control volume, the model is general and can be adapted to other applications. The model is applied to design a cooling system for a pre-existing stator blade geometry. Both the inputs and the outputs of the 1D simulation are in good agreement with the values found in the literature. Subsequently, 1D results are compared to a full conjugate heat transfer (CHT) simulation. The agreement on the internal heat transfer coefficient is excellent and is entirely within the uncertainty of the correlation. Despite some criticality in finding agreement with the thermal power distribution, the Mach number, the total pressure drop, and the coolant temperature increase in the cooling channels are accurately predicted by the 1D code, thus confirming its value as a preliminary design tool. To guarantee the integrity of the blade at the extremities, a cooling solution with coolant injection at the leading and trailing edge is studied. A finite element analysis of the cooled blade ensures the structural feasibility of the cooling system. The computational economy of the 1D code is then exploited to perform a global sensitivity analysis using a polynomial chaos expansion (PCE) surrogate model to compute Sobol’ indices.

Full article

Figure 1

Open AccessArticle

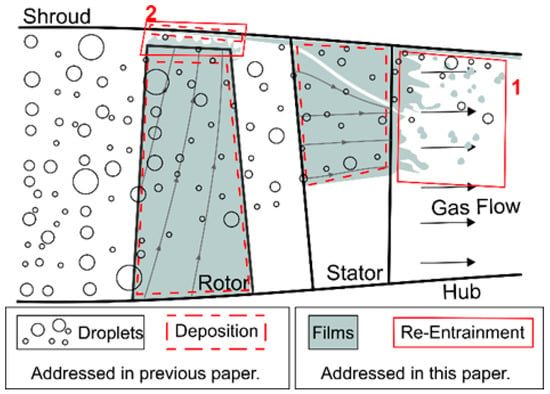

Droplet-Laden Flows in Multistage Compressors: An Overview of the Impact of Modeling Depth on Calculated Compressor Performance

by

Silvio Geist and Markus Schatz

Int. J. Turbomach. Propuls. Power 2025, 10(4), 36; https://doi.org/10.3390/ijtpp10040036 - 2 Oct 2025

Abstract

►▼

Show Figures

There are various mechanisms through which water droplets can be present in compressor flows, e.g., rain ingestion in aeroengines or overspray fogging used in heavy-duty gas turbines to boost power output. For the latter, droplet evaporation within the compressor leads to a cooling

[...] Read more.

There are various mechanisms through which water droplets can be present in compressor flows, e.g., rain ingestion in aeroengines or overspray fogging used in heavy-duty gas turbines to boost power output. For the latter, droplet evaporation within the compressor leads to a cooling of the flow as well as to a shift in the fluid properties, which is beneficial to the overall process. However, due to their inertia, the majority of droplets are deposited in the first stages of a multistage compressor. While this phenomenon is generally considered in CFD computations of droplet-laden flows, the subsequent re-entrainment of collected water, the formation of new droplets, and the impact on the overall evaporation are mostly neglected because of the additional computational effort required, especially with regard to the modeling of films formed by the deposited water. The work presented here shows an approach that allows for the integration of the process of droplet deposition and re-entrainment based on relatively simple correlations and experimental observations from the literature. Thus, the two-phase flow in multistage compressors can be modelled and analyzed very efficiently. In this paper, the models and assumptions used are described first, then the results of a study performed based on a generic multistage compressor are presented, whereby the various models are integrated step by step to allow an assessment of their impact on the droplet evaporation throughout the compressor and overall performance. It can be shown that evaporation becomes largely independent of droplet size when deposition on both rotor and stator and subsequent re-entrainment of collected water is considered. In addition, open issues with regard to the future improvement of models and correlations of two-phase flow phenomena are highlighted based on the results of the current investigation.

Full article

Figure 1

Open AccessArticle

Flutter Analysis of the ECL5 Open Fan Testcase Using Harmonic Balance

by

Christian Frey, Stéphane Aubert, Pascal Ferrand and Anne-Lise Fiquet

Int. J. Turbomach. Propuls. Power 2025, 10(4), 35; https://doi.org/10.3390/ijtpp10040035 - 2 Oct 2025

Abstract

►▼

Show Figures

This paper presents a flutter analysis of the UHBR Open Fan Testcase ECL5 for an off-design point at part speed and focuses on the second eigenmode, which has a strong torsional character near the blade tip. Recent studies by Pagès et al., using

[...] Read more.

This paper presents a flutter analysis of the UHBR Open Fan Testcase ECL5 for an off-design point at part speed and focuses on the second eigenmode, which has a strong torsional character near the blade tip. Recent studies by Pagès et al., using a time-linearized solver, showed strong negative damping for an operating point at 80% speed close to the maximal pressure ratio. This was identified as a phenomenon of convective resonance; for a certain nodal diameter and frequency, the blade vibration is in resonance with convective disturbances that are linearly unstable. In this work, a nonlinear frequency domain method (harmonic balance) is applied to the problem of aerodynamic damping prediction for this off-design operating point. It is shown that, to obtain plausible results, it is necessary to treat the turbulence model as unsteady. The impact of spurious reflections due to numerical boundary conditions is estimated for this case. While strong negative damping is not predicted by the analysis presented here, we observe particularly high sensitivity of the aerodynamic response with respect to turbulence model formulation and the frequency for certain nodal diameters. The combination of nodal diameter and frequency of maximal sensitivities are interpreted as points near resonance. We recover from these near-resonance points convective speeds and compare them to studies of the onset of nonsynchronous vibrations of the ECL5 fan at part-speed conditions.

Full article

Figure 1

Open AccessArticle

Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations

by

Hendrik Seehausen, Kenan Cengiz and Lars Wein

Int. J. Turbomach. Propuls. Power 2025, 10(4), 34; https://doi.org/10.3390/ijtpp10040034 - 2 Oct 2025

Abstract

►▼

Show Figures

In this study, the modeling of rough surfaces by eddy-viscosity-based roughness models is investigated, specifically focusing on surfaces representative of deterioration in aero-engines. In order to test these models, experimental measurements from a rough T106C blade section at a Reynolds number of 400

[...] Read more.

In this study, the modeling of rough surfaces by eddy-viscosity-based roughness models is investigated, specifically focusing on surfaces representative of deterioration in aero-engines. In order to test these models, experimental measurements from a rough T106C blade section at a Reynolds number of 400 K are adopted. The modeling framework is based on the k-ω-SST with Dassler’s roughness transition model. The roughness model is recalibrated for the k-ω-SST model. As a complement to the available experimental data, a high-fidelity test rig designed for scale-resolving simulations is built. This allows us to examine the local flow phenomenon in detail, enabling the identification and rectification of shortcomings in the current RANS models. The scale-resolving simulations feature a high-order flux-reconstruction scheme, which enables the use of curved element faces to match the roughness geometry. The wake-loss predictions, as well as blade pressure profiles, show good agreement, especially between LES and the model-based RANS. The slight deviation from the experimental measurements can be attributed to the inherent uncertainties in the experiment, such as the end-wall effects. The outcomes of this study lend credibility to the roughness models proposed. In fact, these models have the potential to quantify the influence of roughness on the aerodynamics and the aero-acoustics of aero-engines, an area that remains an open question in the maintenance, repair, and overhaul (MRO) of aero-engines.

Full article

Figure 1

Open AccessArticle

An Investigation of the Laminar–Turbulent Transition Mechanisms of Low-Pressure Turbine Boundary Layers with Linear Stability Theories

by

Alice Fischer and Frank Eulitz

Int. J. Turbomach. Propuls. Power 2025, 10(4), 33; https://doi.org/10.3390/ijtpp10040033 - 2 Oct 2025

Abstract

►▼

Show Figures

Stability theory offers a practical method on parametric studies that encompass scales in the boundary layer typically not captured in Large Eddy (LES) or Reynolds-Averaged Navier–Stokes (RANS) simulations. We investigated the transition modes of a Low-Pressure Turbine (LPT) with Linear Stability Theory (LST)

[...] Read more.

Stability theory offers a practical method on parametric studies that encompass scales in the boundary layer typically not captured in Large Eddy (LES) or Reynolds-Averaged Navier–Stokes (RANS) simulations. We investigated the transition modes of a Low-Pressure Turbine (LPT) with Linear Stability Theory (LST) and Linear Parabolized Stability Equations (LPSEs) over a wider parametric space. A parametric study was done to examine the wall-shear stress, shape factor, momentum thickness, as well as the growth rate and N-factor envelope. Additionally, the methodology was applied to active control techniques like suction and blowing. The results are consistent with the expected physical behavior and initial observations, while also offering a quantitative description of trends in frequencies, amplitude growth, and wavelengths. This confirms the suitability of the two stability theories, laying the base for their future validation to ensure accuracy and reliability.

Full article

Figure 1

Open AccessArticle

Optimising Ventilation System Preplanning: Duct Sizing and Fan Layout Using Mixed-Integer Programming

by

Julius H. P. Breuer and Peter F. Pelz

Int. J. Turbomach. Propuls. Power 2025, 10(4), 32; https://doi.org/10.3390/ijtpp10040032 - 1 Oct 2025

Abstract

Traditionally, duct sizing in ventilation systems is based on balancing pressure losses across all branches, with fan selection performed subsequently. However, this sequential approach is inadequate for systems with distributed fans in the central duct network, where pressure losses can vary significantly. Consequently,

[...] Read more.

Traditionally, duct sizing in ventilation systems is based on balancing pressure losses across all branches, with fan selection performed subsequently. However, this sequential approach is inadequate for systems with distributed fans in the central duct network, where pressure losses can vary significantly. Consequently, when designing the system topology, fan placement and duct sizing must be considered together. Recent research has demonstrated that discrete optimisation methods can account for multiple load cases and produce ventilation layouts that are both cost- and energy-efficient. However, existing approaches usually concentrate on component placement and assume that duct sizing has already been finalised. While this is sufficient for later design stages, it is unsuitable for the early stages of planning, when numerous system configurations must be evaluated quickly. In this work, we present a novel methodology that simultaneously optimises duct sizing, fan placement, and volume flow controller configuration to minimise life-cycle costs. To achieve this, we exploit the structure of the problem and formulate a mixed-integer linear program (MILP), which, unlike existing non-linear models, significantly reduces computation time while introducing only minor approximation errors. The resulting model enables fast and robust early-stage planning, providing optimal solutions in a matter of seconds to minutes, as demonstrated by a case study. The methodology is demonstrated on a case study, yielding an optimal configuration with distributed fans in the central fan station and achieving a 5% reduction in life-cycle costs compared to conventional central designs. The MILP formulation achieves these results within seconds, with linearisation errors in electrical power consumption below 1.4%, confirming the approach’s accuracy and suitability for early-stage planning.

Full article

(This article belongs to the Special Issue Advances in Industrial Fan Technologies)

►▼

Show Figures

Figure 1

Open AccessArticle

Experimental and Numerical Investigation of Suction-Side Fences for Turbine NGVs

by

Virginia Bologna, Daniele Petronio, Francesca Satta, Luca De Vincentiis, Matteo Giovannini, Gabriele Cattoli, Monica Gily and Andrea Notaristefano

Int. J. Turbomach. Propuls. Power 2025, 10(4), 31; https://doi.org/10.3390/ijtpp10040031 - 1 Oct 2025

Abstract

►▼

Show Figures

This work presents an extensive experimental and numerical analysis, aimed at investigating the impact of shelf-like fences applied on the suction side of a turbine nozzle guide vane. The cascade is constituted of vanes characterized by long chord and low aspect ratio, which

[...] Read more.

This work presents an extensive experimental and numerical analysis, aimed at investigating the impact of shelf-like fences applied on the suction side of a turbine nozzle guide vane. The cascade is constituted of vanes characterized by long chord and low aspect ratio, which are typical features of some LPT first stages directly downstream of an HPT, hence presenting high channel diffusion, especially near the tip. In particular, the present study complements existing literature by highlighting how blade fences positioned on the suction side can reduce the penetration of the large passage vortex. This is particularly effective in applications where flow turning is limited, the blades are lightly loaded at the front, and the horseshoe vortex is weak. The benefits of the present fence design in terms of losses and flow uniformity at the cascade exit plane have been demonstrated by means of a detailed experimental campaign carried out on a large-scale linear cascade in the low-speed wind tunnel installed in the Aerodynamics and Turbomachinery Laboratory of the University of Genova. Measurements mainly focused on the characterization of the flow field upstream and downstream of straight and fenced vane cascades using a five-hole pressure probe, to evaluate the impact of the device in reducing secondary flows. Furthermore, experiments were also adopted to validate both low-fidelity (RANS) and high-fidelity (LES) simulations and revealed the capability of both simulation approaches to accurately predict losses and flow deviation. Moreover, the accuracy in high-fidelity simulations has enabled an in-depth investigation of how fences act mitigating the effects of the passage vortex along the blade channel. By comparing the flow fields of the configurations with and without fences, it is possible to highlight the mitigation of secondary flows within the channel.

Full article

Figure 1

Open AccessEditorial

Fans: Noise, Aerodynamics, Applications and Systems—The Best of the International Conference FAN2025

by

Thomas Helmut Carolus and Massimo Masi

Int. J. Turbomach. Propuls. Power 2025, 10(3), 30; https://doi.org/10.3390/ijtpp10030030 - 19 Sep 2025

Abstract

Industrial fans are indispensable components in modern engineering systems [...]

Full article

(This article belongs to the Special Issue Advances in Industrial Fan Technologies)

Open AccessFeature PaperArticle

ECL5/CATANA: Comparative Analysis of Advanced Blade Vibration Measurement Techniques

by

Christoph Brandstetter, Alexandra P. Schneider, Anne-Lise Fiquet, Benoit Paoletti, Kevin Billon and Xavier Ottavy

Int. J. Turbomach. Propuls. Power 2025, 10(3), 29; https://doi.org/10.3390/ijtpp10030029 - 4 Sep 2025

Abstract

►▼

Show Figures

A comprehensive understanding of aerodynamic instabilities, such as flutter, non-synchronous vibration (NSV), rotating stall, and forced response, is crucial for the safe and efficient operation of turbomachinery, particularly fans and compressors. These instabilities impose significant limitations on the operating envelope, necessitating precise monitoring

[...] Read more.

A comprehensive understanding of aerodynamic instabilities, such as flutter, non-synchronous vibration (NSV), rotating stall, and forced response, is crucial for the safe and efficient operation of turbomachinery, particularly fans and compressors. These instabilities impose significant limitations on the operating envelope, necessitating precise monitoring and accurate quantification of vibration amplitudes during experimental investigations. This study addresses the challenge of measuring these amplitudes by comparing multiple measurement systems applied to the open-test case of the ultra-high bypass ratio (UHBR) fan ECL5. During part-speed operation, the fan exhibited a complex aeromechanical phenomenon, where an initial NSV of the second blade eigenmode near peak pressure transitioned to a dominant first-mode vibration. This mode shift was accompanied by substantial variations in blade vibration patterns, as evidenced by strain gauge data and unsteady wall pressure measurements. These operating conditions provided an optimal test environment for evaluating measurement systems. A comprehensive and redundant experimental setup was employed, comprising telemetry-based strain gauges, capacitive tip timing sensors, and a high-speed camera, to capture detailed aeroelastic behaviour. This paper presents a comparative analysis of these measurement systems, emphasizing their ability to capture high-resolution, accurate data in aeroelastic experiments. The results highlight the critical role of rigorous calibration procedures and the complementary use of multiple measurement technologies in advancing the understanding of turbomachinery instabilities. The insights derived from this investigation shed light on a complex evolution of instability mechanisms and offer valuable recommendations for future experimental studies. The open-test case has been made accessible to the research community, and the presented data can be used directly to validate coupled aeroelastic simulations under challenging operating conditions, including non-linear blade deflections.

Full article

Figure 1

Open AccessArticle

Goals and Strategies for Open Fan Design

by

Carola Rovira Sala, Thomas Dygutsch, Christian Frey, Rainer Schnell and Raul Martinez Luque

Int. J. Turbomach. Propuls. Power 2025, 10(3), 28; https://doi.org/10.3390/ijtpp10030028 - 4 Sep 2025

Abstract

►▼

Show Figures

This paper highlights recent activities associated with the design of an uninstalled open fan propulsor for next-generation civil aircraft in the high-subsonic flight regime. The concept comprises a transonic propeller–rotor and a subsequent guide vane, which are both subject to pitch-variability in order

[...] Read more.

This paper highlights recent activities associated with the design of an uninstalled open fan propulsor for next-generation civil aircraft in the high-subsonic flight regime. The concept comprises a transonic propeller–rotor and a subsequent guide vane, which are both subject to pitch-variability in order to account for the strong variations in flight conditions over the entire mission profile. The engine-scale design aimed for high technological maturity and to comply with a high number of industrially relevant requirements to ensure a competitive design, meeting performance requirements in terms of high efficiency levels at cruise and maximum climb conditions, operability in terms of stability margins, good acoustic characteristics, and structural integrity. During the design iterations, rapid 3D-RANS-based optimisations were only used as a conceptual design tool to derive sensitivities, which were used to support and justify major design choices in addition to established relations from propeller theory and common design practice. These design-driven optimisation efforts were complemented with more sophisticated CFD analysis focusing on rotor tip vortex trajectories and resulting in unsteady blade row interaction to optimise the guide vane clipping, as well as investigations of the entire propulsor under angle-of-attack conditions. The resulting open fan design will be the very basis for wind tunnel experiments of a downscaled version at low and high speed.

Full article

Figure 1

Open AccessArticle

Effect of Solidity on the Leakage Flow and Related Noise in Axial-Flow Fans with Rotating Shroud Operating at Fixed Performance

by

Tayyab Akhtar, Edward Canepa, Andrea Cattanei, Matteo Dellacasagrande and Alessandro Nilberto

Int. J. Turbomach. Propuls. Power 2025, 10(3), 27; https://doi.org/10.3390/ijtpp10030027 - 2 Sep 2025

Abstract

►▼

Show Figures

This work presents an experimental study of the effect of blade count on the flow field and the radiated noise in a low-speed axial fan with a rotating shroud. A two-component Laser Doppler Velocimetry (LDV) system and Particle Image Velocimetry (PIV) instrumentation have

[...] Read more.

This work presents an experimental study of the effect of blade count on the flow field and the radiated noise in a low-speed axial fan with a rotating shroud. A two-component Laser Doppler Velocimetry (LDV) system and Particle Image Velocimetry (PIV) instrumentation have been employed to investigate the flow in the gap region and in front of the rotor blades. Additionally, the fan has been installed in a hemi-anechoic chamber and far-field acoustic measurements have been taken with a microphone mounted on-axis upstream of the rotor to show changes in the spectral features of the radiated noise. The tested rotor is a variable-geometry one that has allowed for studying rotor configurations with different numbers of blades of the same chord and shape, i.e., of the same geometry but different solidity. Rotor pressure rise and flow rate are average quantities that have a relevant effect on the leakage flow. Keeping them fixed while varying solidity allows us to highlight the local effects of circumferential pressure non-uniformity caused by differing blade loading. The results show that, at low solidity, the flow leaving the gap is mainly directed radially outward and follows a longer path before being ingested by the rotor, thus losing strength due to mixing with the main flow. As solidity increases, the flow becomes less radial and is more rapidly ingested by the rotor. In all cases, the sound pressure level spectrum shows marked subharmonic humps and peaks originating from the interaction between the leakage flow and rotor. The departure of such peaks from the blade passing frequency increases with the solidity, while the associated energy increases up to seven blades and then decreases.

Full article

Graphical abstract

Open AccessArticle

Multi-Disciplinary Optimization of Mixed-Flow Turbine for Additive Manufacturing

by

Victor Loir, Bayindir H. Saracoglu and Tom Verstraete

Int. J. Turbomach. Propuls. Power 2025, 10(3), 26; https://doi.org/10.3390/ijtpp10030026 - 2 Sep 2025

Abstract

►▼

Show Figures

Additive manufacturing offers new perspectives for creating complex geometries with improved design features at lower cost and with reduced manufacturing time. It may even become possible to print a micro-turbojet engine in one single print, but then unconventional geometrical constraints on compressor and

[...] Read more.

Additive manufacturing offers new perspectives for creating complex geometries with improved design features at lower cost and with reduced manufacturing time. It may even become possible to print a micro-turbojet engine in one single print, but then unconventional geometrical constraints on compressor and turbine designs are inevitable. If a radial machine were printed through additive manufacturing as a standalone component, the most logical print direction would be from the radial outlet/inlet to the axial inlet/outlet to ease the process and limit the supports, with limited additional constraints compared to traditional manufacturing methods. If the rotor comprising a radial compressor and turbine needs to be printed in one single print, one of the components will be printed in a direction that is not favorable. In the present work, the radial turbine is considered to be printed in the unfavorable direction, namely, from the axial outlet to the radial inlet. These geometrical constraints orient the geometry towards a mixed-flow configuration with a trailing-edge cutback. Such design features reduce the available design space for improvement and will clearly have an unfavorable impact on performance. Therefore, a multi-disciplinary gradient-based adjoint optimization of the mixed-flow turbine is performed, striving to limit the adverse impact on total-to-total efficiency while respecting the mass flow rate and power matching with the upstream compressor. The structural constraint limits the p-Norm von Mises stress to a maximum threshold based on the material yield strength at the operating temperature. The results show that a satisfactory compromise can be found between manufacturability constraints, material limits and aerodynamic performance.

Full article

Figure 1

Open AccessArticle

Time, Space, and Dynamic Split of Loss Sources in LPT by Means of Phase-Locked Proper Orthogonal Decomposition

by

Matteo Russo, Matteo Dellacasagrande, Francesca Satta, Davide Lengani, Daniele Simoni, Juri Bellucci, Matteo Giovannini, Angelo Alberto Granata and Monica Gily

Int. J. Turbomach. Propuls. Power 2025, 10(3), 25; https://doi.org/10.3390/ijtpp10030025 - 2 Sep 2025

Abstract

►▼

Show Figures

In this study, a procedure based on Phase-locked Proper Orthogonal Decomposition (PPOD) was applied to Large Eddy Simulations (LESs) of two low-pressure turbine blades operating with unsteady inflow. This decomposition allows the inspection of the effect of blade loading on loss generation mechanisms,

[...] Read more.

In this study, a procedure based on Phase-locked Proper Orthogonal Decomposition (PPOD) was applied to Large Eddy Simulations (LESs) of two low-pressure turbine blades operating with unsteady inflow. This decomposition allows the inspection of the effect of blade loading on loss generation mechanisms, focusing especially on their variation throughout the incoming wake period. After sorting snapshots based on their phase within the wake cycle using temporal POD coefficients associated with wake migration, POD was reapplied to each sub-ensemble of snapshots at a given phase, providing an optimal representation of the dynamics at fixed wake locations. This highlighted the effects of the migration, bowing, tilting, and reorientation of the incoming wake filaments, as well as the breakup of streaky structures in the blade boundary layer and the formation of Von Karman vortices at the blade trailing edge. PPOD offered us the opportunity to observe how all these processes are modulated and change throughout the wake period. The comparison between the two analyzed blades showed that overall loss generation follows similar temporal patterns during the wake-passing cycle, increasing with the propagation of the upstream wake and reaching its maximum value when the wake is in the peak suction position. According to the specific blade loading distribution, the production of TKE was observed in different regions of the computational domain. The described procedure may contribute to the development of advanced design processes based on physically informed strategies.

Full article

Figure 1

Open AccessArticle

The Effect of a Variable Cantilevered Stator on 1.5-Stage Transonic Compressor Performance

by

Benedikt Radermacher, Fabian Sebastian Klausmann, Felix Jung, Jonas Bargon, Heinz-Peter Schiffer, Bernd Becker and Patrick Grothe

Int. J. Turbomach. Propuls. Power 2025, 10(3), 24; https://doi.org/10.3390/ijtpp10030024 - 2 Sep 2025

Abstract

►▼

Show Figures

Future aero engine designs must address environmental challenges and meet noise and emissions regulations. To increase efficiency and reduce size, axial compressors require higher pressure ratios and a more compact design, leading to necessary modifications in the variable stator vanes, especially in the

[...] Read more.

Future aero engine designs must address environmental challenges and meet noise and emissions regulations. To increase efficiency and reduce size, axial compressors require higher pressure ratios and a more compact design, leading to necessary modifications in the variable stator vanes, especially in the stator hub region. This study examines the impact of a variable cantilevered stator on the performance and aerodynamics of a 1.5-stage transonic compressor, representative of a high-pressure compressor front stage. Experimental tests at the transonic compressor test rig at Technical University of Darmstadt involved two variable stators with identical airfoil designs but different hub configurations, using the same inlet guide vane and rotor. Detailed aerodynamic analysis was conducted using steady and unsteady instrumentation. The cantilevered stator achieved a 2% increase in efficiency and a 1% increase in total pressure ratio, due to higher aerodynamic loading and reduced pressure losses. The primary performance gain comes from the reduction of the hub blockage area. The cantilevered stator also performed well at near stall conditions, unlike the shrouded stator. Time-resolved measurements indicated that loss mechanisms are closely linked to the rotor wake phase. Overall, variable cantilevered stators outperformed shrouded stators in this compressor stage.

Full article

Graphical abstract

Open AccessArticle

Trailing Edge Loss of Choked Organic Vapor Turbine Blades

by

Leander Hake and Stefan aus der Wiesche

Int. J. Turbomach. Propuls. Power 2025, 10(3), 23; https://doi.org/10.3390/ijtpp10030023 - 8 Aug 2025

Abstract

►▼

Show Figures

The present study reports the outcome of an experimental study of organic vapor trailing edge flows. As a working fluid, the organic vapor Novec 649 was used under representative pressure and temperature conditions for organic Rankine cycle (ORC) turbine applications characterized by values

[...] Read more.

The present study reports the outcome of an experimental study of organic vapor trailing edge flows. As a working fluid, the organic vapor Novec 649 was used under representative pressure and temperature conditions for organic Rankine cycle (ORC) turbine applications characterized by values of the fundamental derivative of gas dynamics below unity. An idealized vane configuration was placed in the test section of a closed-loop organic vapor wind tunnel. The effect of the Reynolds number was assessed independently from the Mach number by charging the closed wind tunnel. The airfoil surface roughness and the trailing edge shape were evaluated by experimenting with different test blades. The flow and the loss behavior were obtained using Pitot probes, static wall pressure taps, and background-oriented schlieren (BOS) optics. Isentropic exit Mach numbers up to 1.5 were investigated. Features predicted via a simple flow model proposed by Denton and Xu in 1989 were observed for organic vapor flows. Still, roughness affected the downstream loss behavior significantly due to shockwave boundary-layer interactions and flow separation. The new experimental results obtained for this organic vapor are compared with correlations from the literature and available loss data.

Full article

Figure 1

Open AccessFeature PaperArticle

ECL5/CATANA: Transition from Non-Synchronous Vibration to Rotating Stall at Transonic Speed

by

Alexandra P. Schneider, Anne-Lise Fiquet, Nathalie Grosjean, Benoit Paoletti, Xavier Ottavy and Christoph Brandstetter

Int. J. Turbomach. Propuls. Power 2025, 10(3), 22; https://doi.org/10.3390/ijtpp10030022 - 7 Aug 2025

Cited by 1

Abstract

►▼

Show Figures

Non-synchronous vibration (NSV), flutter, or rotating stall can cause severe blade vibrations and limit the operating range of compressors and fans. To enhance the understanding of these phenomena, this study investigated the corresponding mechanisms in modern composite ultra-high-bypass-ratio (UHBR) fans based on the

[...] Read more.

Non-synchronous vibration (NSV), flutter, or rotating stall can cause severe blade vibrations and limit the operating range of compressors and fans. To enhance the understanding of these phenomena, this study investigated the corresponding mechanisms in modern composite ultra-high-bypass-ratio (UHBR) fans based on the ECL5/CATANA test campaign. Extensive steady and unsteady instrumentation such as stereo-PIV, fast-response pressure probes, and rotor strain gauges were used to derive the aerodynamic and structural characteristics of the rotor at throttled operating conditions. The study focused on the analysis of the transition region from transonic to subsonic speeds where two distinct phenomena were observed. At transonic design speed, rotating stall was encountered, while NSV was observed at 90% speed. At the intermediate 95% speedline, a peculiar behavior involving a single stalled blade was observed. The results emphasize that rotating stall and NSV exhibit different wave characteristics: rotating stall comprises lower wave numbers and higher propagation speeds at around 78% rotor speed, while small-scale disturbances propagate at 57% rotor speed and lock-in with blade eigenmodes, causing NSV. Both phenomena were observed in a narrow range of operation and even simultaneously at specific conditions. The presented results contribute to the understanding of different types of operating range-limiting phenomena in modern UHBR fans and serve as a basis for the validation of numerical simulations.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Special Issues

Special Issue in

IJTPP

Selected Papers from the Conference on Modelling Fluid Flow (CMFF’25)

Guest Editors: János Gábor Vad, Csaba Horváth, Esztella Éva BallaDeadline: 2 May 2026