Agronomic and Economic Evaluations of N Fertilization in Maize under Recent Market Dynamics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Site Description

2.2. Soil Sampling and Testing

2.3. Experimental Design, Treatments and Plot Management

2.4. Harvesting and Sample Processing

2.5. Statistical Analysis

2.6. Economic Analysis

3. Results and Discussion

3.1. Weather

3.2. Initial Soil Properties

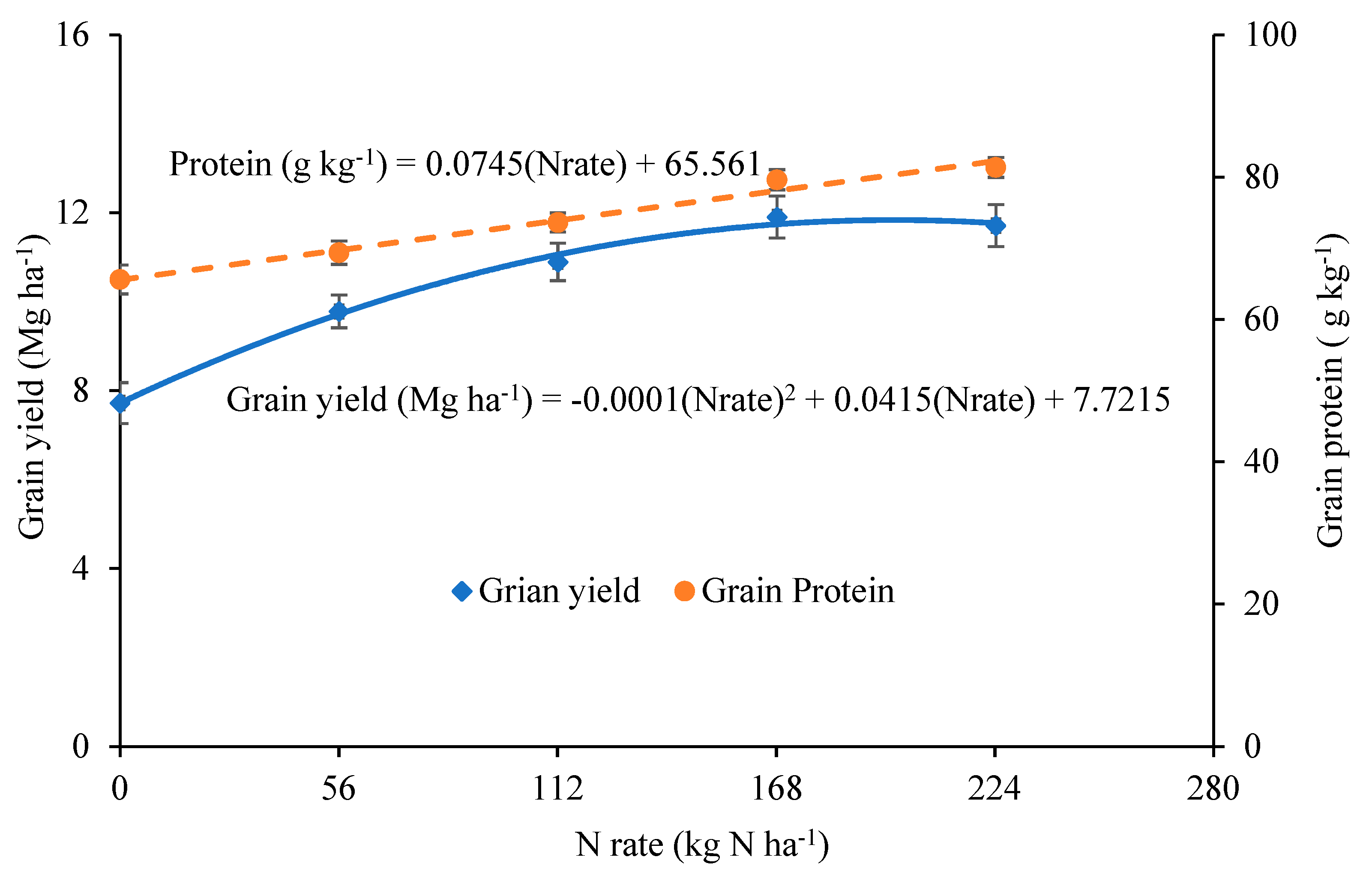

3.3. Agronomic Evalauion on Maize Yield and Yield Components

3.3.1. Interaction Effects

3.3.2. Year Effect

3.3.3. Nitrogen Application Rate

3.3.4. Nitrogen Application Time

3.3.5. Correlation

3.4. Economic Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Stewart, W.; Dibb, D.; Johnston, A.; Smyth, T. The contribution of commercial fertilizer nutrients to food production. Agrono. J. 2005, 97, 1–6. [Google Scholar] [CrossRef]

- Cao, P.; Lu, C.; Yu, Z. Historical nitrogen fertilizer use in agricultural ecosystems of the contiguous United States during 1850–2015: Application rate, timing, and fertilizer types. Earth Syst. Sci. Data 2018, 10, 969–984. [Google Scholar] [CrossRef]

- USDA-NASS. Quick Stats. Available online: https://quickstats.nass.usda.gov (accessed on 25 February 2022).

- Connor, D. Organic agriculture cannot feed the world. Field Crop Res. 2008, 106, 187–190. [Google Scholar] [CrossRef]

- Mitsch, W.J.; Day, J.W.; Gilliam, J.W.; Groffman, P.M.; Hey, D.L.; Randall, G.W.; Wang, N. Reducing nitrogen loading to the Gulf of Mexico from the Mississippi River Basin: Strategies to counter a persistent ecological problem: Ecotechnology—The use of natural ecosystems to solve environmental problems—Should be a part of efforts to shrink the zone of hypoxia in the Gulf of Mexico. BioScience 2001, 51, 373–388. [Google Scholar] [CrossRef]

- Blesh, J.; Drinkwater, L. The impact of nitrogen source and crop rotation on nitrogen mass balances in the Mississippi River Basin. Ecol. Appl. 2013, 23, 1017–1035. [Google Scholar] [CrossRef] [PubMed]

- Raun, W.R.; Johnson, G.V. Improving nitrogen use efficiency for cereal production. Agrono. J. 1999, 91, 357–363. [Google Scholar] [CrossRef]

- USDA-NASS. Minnesota Ag News—Monthly Prices. Available online: http://www.nass.usda.gov (accessed on 20 March 2022).

- Ransom, C.J.; Kitchen, N.R.; Camberato, J.J.; Carter, P.R.; Ferguson, R.B.; Fernández, F.G.; Franzen, D.W.; Laboski, C.A.; Nafziger, E.D.; Sawyer, J.E. Corn nitrogen rate recommendation tools’ performance across eight US Midwest Corn Belt States. Agrono. J. 2020, 112, 470–492. [Google Scholar] [CrossRef]

- Morris, T.F.; Murrell, T.S.; Beegle, D.B.; Camberato, J.J.; Ferguson, R.B.; Grove, J.; Ketterings, Q.; Kyveryga, P.M.; Laboski, C.A.; McGrath, J.M. Strengths and limitations of nitrogen rate recommendations for corn and opportunities for improvement. Agrono. J. 2018, 110, 1–37. [Google Scholar] [CrossRef]

- Kaiser, D.E.; Coulter, J.A.; Barber, B. Fertilizing Corn in Minnesota. Regents of the University of Minnesota. Available online: https://extension.umn.edu/crop-specific-needs/fertilizing-corn-minnesota (accessed on 8 April 2022).

- Sindelar, A.; Coulter, J.A.; Lamb, J.; Vetsch, J. Agronomic responses of continuous corn to stover, tillage, and nitrogen management. Agrono. J. 2013, 105, 1498–1506. [Google Scholar] [CrossRef]

- Dias Paiao, G.; Fernández, F.G.; Naeve, S.L. Drainage conditions influence corn-nitrogen management in the US Upper Midwest. Agronomy 2021, 11, 2491. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Dweikat, I.; Huber, D.; Warren, H. Interrelationship of nitrogen nutrition with maize (Zea mays) grain yield, nitrogen use efficiency and grain quality. J. Sci. Food Agric. 1992, 58, 1–8. [Google Scholar] [CrossRef]

- Gallais, A.; Hirel, B. An approach to the genetics of nitrogen use efficiency in maize. J. Exp. Bot. 2004, 55, 295–306. [Google Scholar] [CrossRef] [PubMed]

- Cambouris, A.N.; Ziadi, N.; Perron, I.; Alotaibi, K.D.; Luce, M.S.; Tremblay, N. Corn yield components response to nitrogen fertilizer as a function of soil texture. Can. J. Soil Sci. 2016, 96, 386–399. [Google Scholar] [CrossRef]

- Mamo, M.; Malzer, G.L.; Mulla, D.; Huggins, D.; Strock, J. Spatial and temporal variation in economically optimum nitrogen rate for corn. Agrono. J. 2003, 95, 958–964. [Google Scholar] [CrossRef]

- Vetsch, J.A.; Randall, G.W. Corn production as affected by nitrogen application timing and tillage. Agrono. J. 2004, 96, 502–509. [Google Scholar] [CrossRef]

- Bierman, P.M.; Rosen, C.J.; Venterea, R.T.; Lamb, J.A. Survey of nitrogen fertilizer use on corn in Minnesota. Agr. Syst. 2012, 109, 43–52. [Google Scholar] [CrossRef]

- Torbert, H.A.; Potter, K.N.; Morrison, J.E. Tillage system, fertilizer nitrogen rate, and timing effect on corn yields in the Texas Blackland Prairie. Agrono. J. 2001, 93, 1119–1124. [Google Scholar] [CrossRef]

- Randall, G.; Rehm, G.; Lamb, J.; Rosen, C.J. Best Management Practices for Nitrogen Use in South-Central Minnesota; University of Minnesota Extension: St Paul, MN, USA, 2008. [Google Scholar]

- FINBIN. Farm Financial and Production Benchmark Information in the World. Available online: http://www.finbin.umn.edu (accessed on 22 May 2022).

- MorrisCoop. MorrisCoop, Agronomy. Available online: http://www.morriscoop.com (accessed on 25 March 2022).

- Kuchenbuch, R.O.; Buczko, U. Re-visiting potassium-and phosphate-fertilizer responses in field experiments and soil-test interpretations by means of data mining. J. Plant Nutr. Soil Sci. 2011, 174, 171–185. [Google Scholar] [CrossRef]

- USDA-NRCS. Official Soil Series Descriptions and Series Classification. Available online: https://websoilsurvey.nrcs.usda.gov (accessed on 2 May 2022).

- APHA. Standard Methods for the Examination of Water and Wastewater, 18th ed.; American Public Health Association: Washington, DC, USA, 1992. [Google Scholar]

- Wagner, S.; Hanson, J.; Olness, A.; Voorhees, W. A volumetric inorganic carbon analysis system. Soil Sci. Soc. Am. J. 1998, 62, 690–693. [Google Scholar] [CrossRef]

- Kuo, S. Phosphorus. In Methods of Soil Analysis, Part 3, Chemical Methods; Sparks, D.L., Ed.; SSSA Book Series No 5; Soil Science Society of America and American Society of Agronomy: Madison, WI, USA, 1996; pp. 869–919. [Google Scholar]

- Helmke, P.A.; Sparks, D.L. Lithium, Sodium, Potassium, Rubidium, and Cesium; Bartels, J.M., Ed.; Soil Science Society of America and American Society of Agronomy: Madison, WI, USA, 1996; Volume 5, pp. 551–574. [Google Scholar]

- Sriperm, N.; Pesti, G.M.; Tillman, P.B. Evaluation of the fixed nitrogen-to-protein (N: P) conversion factor (6.25) versus ingredient specific N: P conversion factors in feedstuffs. J. Sci. Food Agric. 2011, 91, 1182–1186. [Google Scholar] [CrossRef]

- Baligar, V.; Fageria, N.; He, Z. Nutrient use efficiency in plants. Soil Sci. Plant Anal. 2001, 32, 921–950. [Google Scholar] [CrossRef]

- Wortmann, C.S.; Tarkalson, D.D.; Shapiro, C.A.; Dobermann, A.R.; Ferguson, R.B.; Hergert, G.W.; Walters, D. Nitrogen use efficiency of irrigated corn for three cropping systems in Nebraska. Agrono. J. 2011, 103, 76–84. [Google Scholar] [CrossRef]

- SAS Institute. SAS/STAT 9.4 User’s Guide; SAS Institute: Cary, NC, USA, 2014. [Google Scholar]

- Levene, H. Robust Tests for Equality of Variances. Contributions to Probability and Statistics; Olkin, I., Ed.; Stanford University Press: Redwood City, CA, USA, 1960. [Google Scholar]

- Johnson, J.M.; Scott, D.; Weyers, S. Radish and annual ryegrass alter corn yield response to nitrogen rate. Soil Sci. Soc. Am. J. 2021, 85, 2054–2066. [Google Scholar] [CrossRef]

- CIMMYT. From Agronomic Data to Farmer Recommendations: An Economics Training Manual, Completely Revised Edition; D.F. CIMMYT: Veracruz, Mexico, 1988. [Google Scholar]

- ISU. Iowa State University (ISU), Corn N Rate Calculator, Finding the Maximum Return to N and Most Profitable N Rate. A Regional (Corn Belt) Approach to Nitrogen Rate Guide; Agronomy Extension and Outreach; Iowa State University: Ames, IA, USA, 2022. [Google Scholar]

- Mohammed, Y.A.; Matthees, H.L.; Gesch, R.W.; Patel, S.; Forcella, F.; Aasand, K.; Steffl, N.; Johnson, B.L.; Wells, M.S.; Lenssen, A.W. Establishing winter annual cover crops by interseeding into maize and soybean. Agrono. J. 2020, 112, 719–732. [Google Scholar] [CrossRef]

- Alexander, J.R.; Baker, J.M.; Venterea, R.T.; Coulter, J.A. Kura clover living mulch reduces fertilizer N requirements and increases profitability of maize. Agronomy 2019, 9, 432. [Google Scholar] [CrossRef]

- Dhital, S.; Raun, W. Variability in optimum nitrogen rates for maize. Agrono. J. 2016, 108, 2165–2173. [Google Scholar] [CrossRef]

- Moser, S.B.; Feil, B.; Jampatong, S.; Stamp, P. Effects of pre-anthesis drought, nitrogen fertilizer rate, and variety on grain yield, yield components, and harvest index of tropical maize. Agr. Water Manag. 2006, 81, 41–58. [Google Scholar] [CrossRef]

- Andrade, F.H.; Echarte, L.; Rizzalli, R.; Della Maggiora, A.; Casanovas, M. Kernel number prediction in maize under nitrogen or water stress. Crop Sci. 2002, 42, 1173–1179. [Google Scholar] [CrossRef]

- Ciancio, N.; Parco, M.; Incognito, S.J.P.; Maddonni, G.A. Kernel setting at the apical and sub-apical ear of older and newer Argentinean maize hybrids. Field Crop Res. 2016, 191, 101–110. [Google Scholar] [CrossRef]

- DeBruin, J.L.; Schussler, J.R.; Mo, H.; Cooper, M. Grain yield and nitrogen accumulation in maize hybrids released during 1934 to 2013 in the US Midwest. Crop Sci. 2017, 57, 1431–1446. [Google Scholar] [CrossRef]

- Geng, J.; Chen, J.; Sun, Y.; Zheng, W.; Tian, X.; Yang, Y.; Li, C.; Zhang, M. Controlled release urea improved nitrogen use efficiency and yield of wheat and corn. Agrono. J. 2016, 108, 1666–1673. [Google Scholar] [CrossRef]

- Plastina, A. Estimated Costs of Crop Production in Iowa, Iowa State University. Available online: https://www.extension.iastate.edu/agdm/crops/html/a1-20.html (accessed on 16 March 2022).

- Zeffa, D.M.; Perini, L.J.; Silva, M.B.; de Sousa, N.V.; Scapim, C.A.; Oliveira, A.L.M.d.; Amaral Júnior, A.T.d.; Azeredo Goncalves, L.S. Azospirillum brasilense promotes increases in growth and nitrogen use efficiency of maize genotypes. PLoS ONE 2019, 14, e0215332. [Google Scholar] [CrossRef]

- Halvorson, A.D.; Bartolo, M.E. Nitrogen source and rate effects on irrigated corn yields and nitrogen-use efficiency. Agrono. J. 2014, 106, 681–693. [Google Scholar] [CrossRef]

- Fernandez, J.A.; DeBruin, J.; Messina, C.D.; Ciampitti, I.A. Late-season nitrogen fertilization on maize yield: A meta-analysis. Field Crop Res. 2020, 247, 107586. [Google Scholar] [CrossRef]

- Nafziger, E.D.; Rapp, D. Corn yield response to late-split nitrogen fertilizer. Agrono. J. 2021, 113, 527–536. [Google Scholar] [CrossRef]

- Shao, M.; Zhang, Y.; Du, J.; Pan, X.; Ma, L.; Wang, J.; Böhmer, D.; Guo, X. Fast analysis of maize kernel plumpness characteristics through Micro-CT technology. Int. Conf. Comput. Comput. Technol. Agric. 2017, 113, 31–39. [Google Scholar]

- Puntel, L.A.; Pagani, A.; Archontoulis, S.V. Development of a nitrogen recommendation tool for corn considering static and dynamic variables. Eur. J. Agrono. 2019, 105, 189–199. [Google Scholar] [CrossRef] [Green Version]

| Month | 2019 | 2020 | LTA | 2019 | 2020 | LTA | 2019 | 2020 |

|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Precipitation (mm) | GDD | ||||||

| January | −14.1 | −9.9 | −12 | 11 | 14 | 19 | 0 | 0 |

| February | −15.3 | −9.3 | −9.8 | 24 | 3 | 18 | 0 | 0 |

| March | −5.3 | 0.2 | −2.6 | 54 | 10 | 35 | 0 | 0 |

| April | 5.8 | 5.3 | 6.4 | 69 | 38 | 61 | 0 | 0 |

| May | 11.7 | 13.3 | 13.9 | 106 | 27 | 77 | 217 | 284 |

| June | 19.9 | 22.1 | 19.2 | 79 | 112 | 108 | 529 | 627 |

| July | 22.2 | 23.0 | 21.4 | 111 | 116 | 96 | 673 | 702 |

| August | 19.4 | 21.3 | 20.0 | 137 | 71 | 83 | 526 | 626 |

| September | 16.8 | 14.8 | 15.2 | 178 | 18 | 71 | 409 | 330 |

| October | 5.6 | 4.6 | 7.6 | 79 | 32 | 60 | 81 | 112 |

| November | −2.1 | 1.6 | −1.4 | 9 | 37 | 24 | 0 | 0 |

| December | −7.9 | −5.1 | −9.1 | 27 | 12 | 18 | 0 | 0 |

| Average/Sum | 4.7 | 6.8 | 5.7 | 884 | 490 | 670 | 2435 | 2681 |

| Year | Soil Depth (cm) | pH (in H2O) | Soil N | Soil Organic Carbon | NH4+-N | NO3−-N | P | K |

|---|---|---|---|---|---|---|---|---|

| g kg−1 | mg kg−1 | |||||||

| 2019 | 0–15 | 7.65 | 2.3 | 28.6 | 10 | 8 | 5 | 201 |

| 15–30 | 7.78 | 1.8 | 21.9 | 9 | 7 | 3 | 180 | |

| 30–60 | 8.24 | 0.8 | 9.6 | 6 | 4 | 1 | 153 | |

| 2020 | 0–15 | 7.00 | 2.2 | 24.8 | 13 | 4 | 4 | 199 |

| 15–30 | 7.66 | 1.4 | 14.8 | 7 | 2 | 3 | 185 | |

| 30–60 | 8.17 | 0.7 | 7.2 | 4 | 2 | 1 | 151 | |

| Source of Variation | Grain Yield (Mg ha−1) | Grain Protein (g kg−1) | Test Weight (kg hL−1) | Harvest Index (%) | TKW ± (g) | Plant Height (cm) | Ear Length (cm) | Ear Diameter (cm) |

|---|---|---|---|---|---|---|---|---|

| p-Values | ||||||||

| Year (YR) | <0.0001 | <0.0001 | <0.0001 | 0.6579 | 0.0701 | <0.0001 | 0.9394 | 0.1282 |

| N rate (NR) | <0.0001 | <0.0001 | 0.1851 | 0.7750 | <0.0001 | 0.0383 | 0.0008 | <0.0001 |

| N timing (NT) | 0.5666 | 0.5021 | 0.6595 | 0.0151 | 0.8097 | 0.1313 | 0.5518 | 0.3951 |

| YR × NR | 0.0760 | 0.8264 | 0.1162 | 0.8563 | 0.4596 | 0.8980 | 0.9635 | 0.7544 |

| YR × NT | 0.7892 | 0.5375 | 0.2228 | 0.8570 | 0.2190 | 0.0030 | 0.0199 | 0.9311 |

| NR × NT | 0.7823 | 0.5232 | 0.9149 | 0.9523 | 0.2799 | 0.6738 | 0.1849 | 0.2191 |

| YR × NR × NT | 0.0944 | 0.4863 | 0.6524 | 0.4844 | 0.2330 | 0.7460 | 0.6718 | 0.9955 |

| Trend analysis for N rate | ||||||||

| Linear | <0.0001 | <0.0001 | 0.8499 | 0.1157 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Quadratic | 0.0153 | 0.7482 | 0.7206 | 0.1061 | 0.3714 | 0.1862 | 0.0133 | 0.0952 |

| Cubic | 0.6522 | 0.2741 | 0.9869 | 0.5914 | 0.2170 | 0.1856 | 0.4620 | 0.6753 |

| Quartic | 0.7410 | 0.6300 | 0.9818 | 0.6966 | 0.9362 | 0.7830 | 0.9891 | 0.1987 |

| Means | ||||||||

| Year | ||||||||

| 2019 | 9.38 B | 72.0 B | 66.81 B | 64.46 A | 323 A | 237 B | 14.3 A | 4.8 A |

| 2020 | 12.01 A | 77.6 A | 74.29 A | 63.44 A | 330 A | 248 A | 14.2 A | 4.6 A |

| N timing | ||||||||

| All | 11.14 a | 75.56 a | 70.63 a | 63.37 b | 331 a | 245 a | 14.4 a | 4.8 a |

| Split | 11.01 a | 76.43 a | 70.51 a | 64.98 a | 330 a | 242 a | 14.5 a | 4.8 a |

| N Rate (kg N ha−1) | Test Weight (kg hL−1) | Harvest Index (%) | TKW ± (g) | Plant Height | Ear Length | Ear Diameter |

|---|---|---|---|---|---|---|

| cm | ||||||

| 0 | 70.42 a | 62.1 a | 298 c | 230 c | 12.1 d | 4.5 d |

| 56 | 70.89 a | 63.8 a | 308 c | 240 b | 13.7 c | 4.7 c |

| 112 | 70.74 a | 64.7 a | 327 b | 243 ab | 14.4 b | 4.8 b |

| 168 | 70.51 a | 64.2 a | 342 ab | 243 ab | 14.8 ab | 4.9 a |

| 224 | 70.14 a | 64.1 a | 343 a | 248 a | 15.1 a | 4.9 a |

| N Rate (kg N ha−1) | Adjusted Grain Yield (Mg ha−1) ± | Current Scenario | Scenario 1 | Scenario 2 | Scenario 3 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Net Benefit (USD ha−1) | MRR (%) | Net Benefit (USD ha−1) | MRR (%) | Net Benefit (USD ha−1) | MRR (%) | Net Benefit (USD ha−1) | MRR (%) | ||

| 0 | 6.95 | 1679 | 1679 | 1847 | 1511 | ||||

| 56 | 8.80 | 2003 | 261 | 1990 | 228 | 2215 | 297 | 1778 | 195 |

| 112 | 9.80 | 2120 | 94 | 2095 | 77 | 2357 | 114 | 1858 | 59 |

| 168 | 10.71 | 2215 | 77 | 2178 | 61 | 2474 | 94 | 1919 | 45 |

| 224 | 10.54 | 2050 | D¥ | 2000 | D | 2304 | D | 1745 | D |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, Y.A.; Gesch, R.W.; Johnson, J.M.F.; Wagner, S.W. Agronomic and Economic Evaluations of N Fertilization in Maize under Recent Market Dynamics. Nitrogen 2022, 3, 514-527. https://doi.org/10.3390/nitrogen3030033

Mohammed YA, Gesch RW, Johnson JMF, Wagner SW. Agronomic and Economic Evaluations of N Fertilization in Maize under Recent Market Dynamics. Nitrogen. 2022; 3(3):514-527. https://doi.org/10.3390/nitrogen3030033

Chicago/Turabian StyleMohammed, Yesuf Assen, Russ W. Gesch, Jane M. F. Johnson, and Steve W. Wagner. 2022. "Agronomic and Economic Evaluations of N Fertilization in Maize under Recent Market Dynamics" Nitrogen 3, no. 3: 514-527. https://doi.org/10.3390/nitrogen3030033