MgO-Doped (Zr,Sr)TiO3 Perovskite Humidity Sensors: Microstructural Effects on Water Permeation †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Materials Synthesis and Doping

2.3. Sensors Fabrication and Characterization

3. Results and Discussion

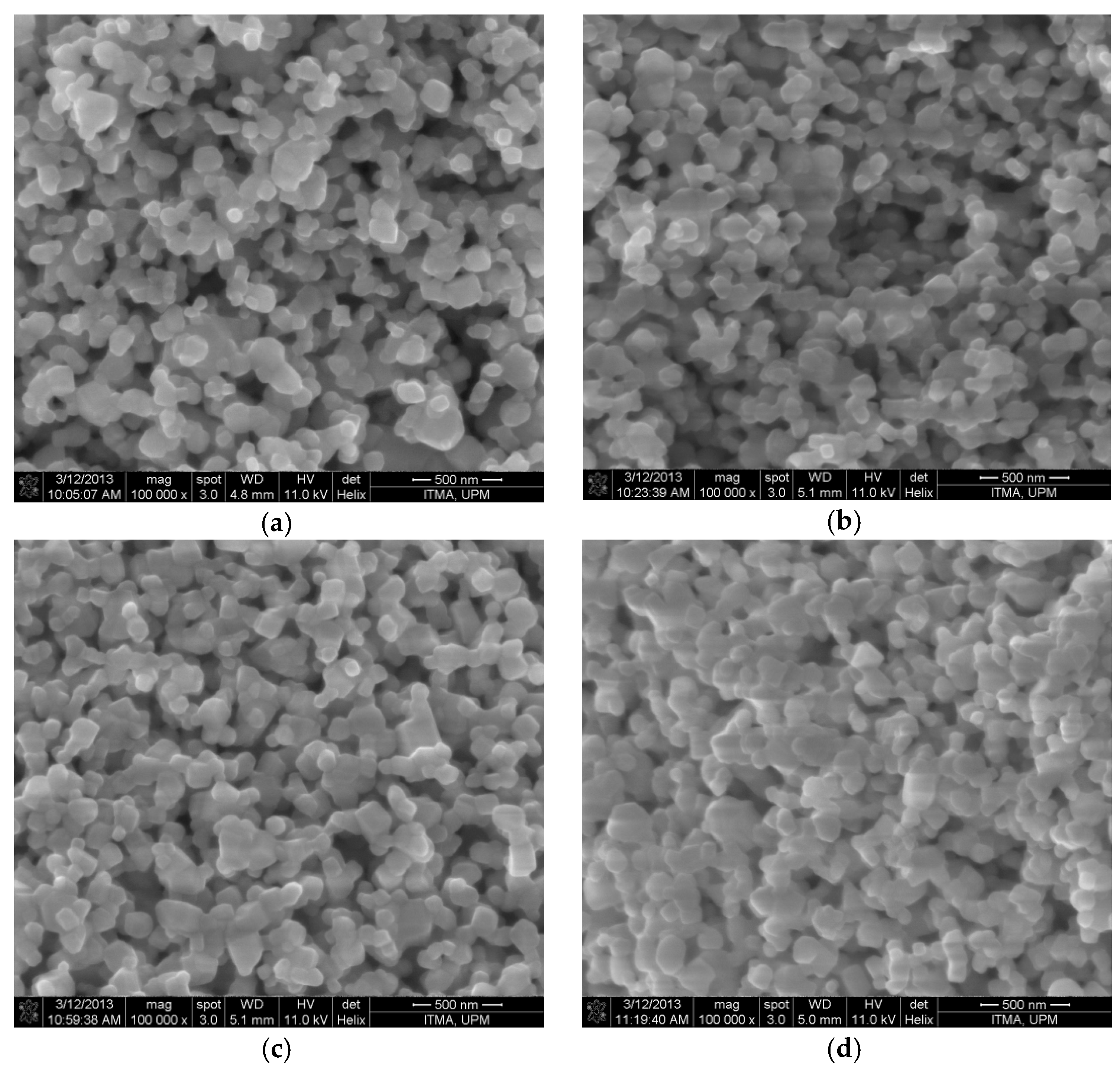

3.1. SEM Characterization

3.2. Microstructural Properties

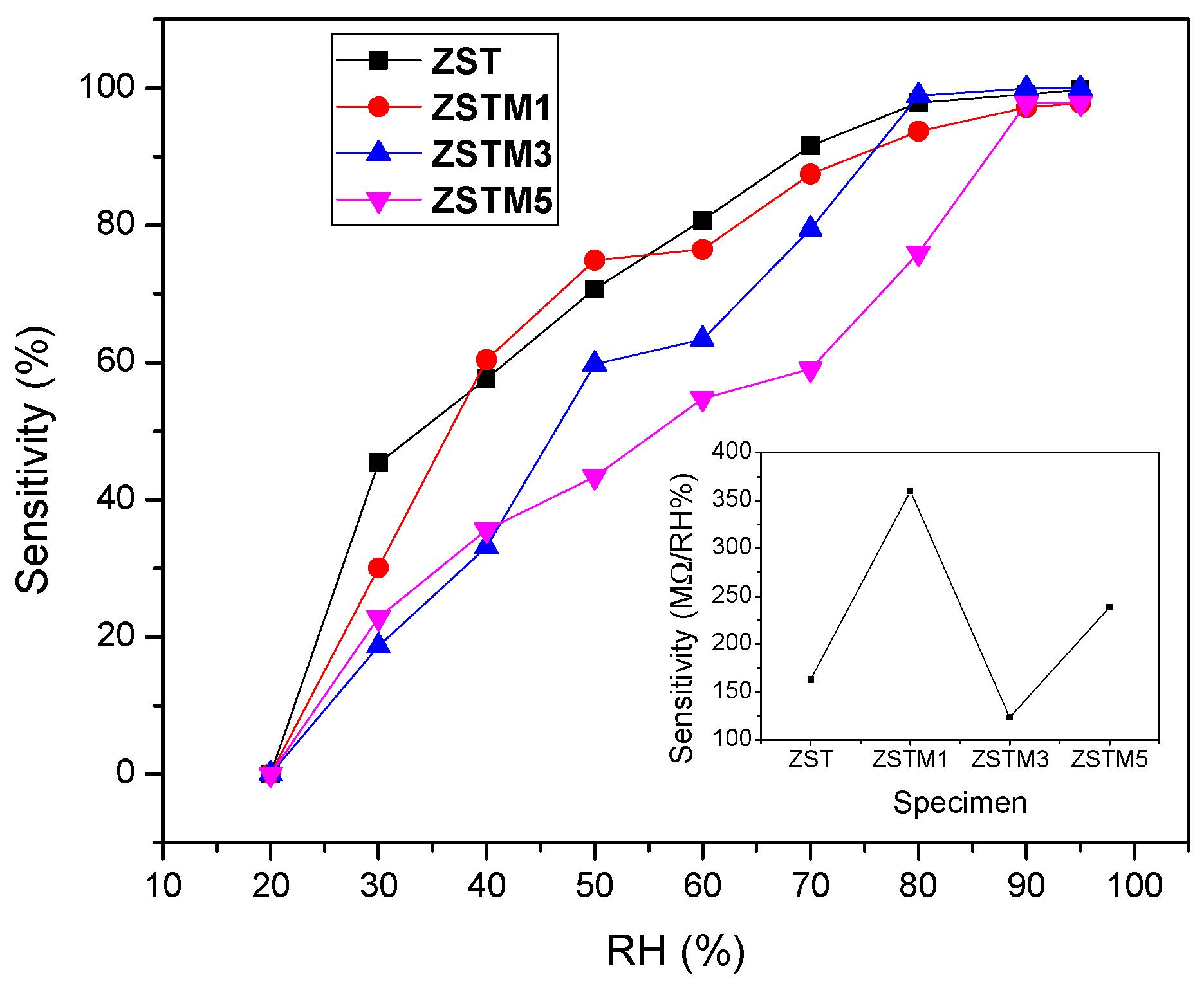

3.3. Humidity Sensing Characteristics

Sensitivity

Conflicts of Interest

References

- Oprea, A.; Courbat, J.; Bârsan, N.; Briand, D.; de Rooij, N.F.; Weimar, U. Temperature, Humidity and Gas Sensors Integrated on Plastic Foil for Low Power Applications. Sens. Actuators B Chem. 2009, 140, 227–232. [Google Scholar] [CrossRef]

- Norris, A.; Saafi, M.; Romine, P. Temperature and Moisture Monitoring in Concrete Structures Using Embedded Nanotechnology/microelectromechanical Systems (MEMS) Sensors. Constr. Build. Mater. 2008, 22, 111–120. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity Sensors Principle, Mechanism, and Fabrication Technologies: A Comprehensive Review. Sensors (Basel) 2014, 14, 7881–7939. [Google Scholar] [CrossRef] [PubMed]

- Salehi, A.; Nikfarjam, A.; Kalantari, D.J. Highly Sensitive Humidity Sensor Using Pd/Porous GaAs Schottky Contact. IEEE Sens. J. 2006, 6, 1415–1421. [Google Scholar] [CrossRef]

- Shah, J.; Kotnala, R.K.; Singh, B.; Kishan, H. Microstructure-Dependent Humidity Sensitivity of Porous MgFe2O4–CeO2 Ceramic. Sens. Actuators B Chem. 2007, 128, 306–311. [Google Scholar] [CrossRef]

- Traversa, E. Ceramic Sensors for Humidity Detection: The State-of-the-Art and Future Developments. Sens. Actuators B Chem. 1995, 23, 135–156. [Google Scholar] [CrossRef]

| Specimen | Surface Area (m2/g) | Pore Radius (nm) | Particle Size (nm) | Grain Size (nm) |

|---|---|---|---|---|

| ZST | 58 | 1.72 | 40.3 | 69 |

| ZST-MgO (1 mol%) | 11 | 97.22 | 32.9 | 77 |

| ZST-MgO (3 mol%) | 11.6 | 99.38 | 34.4 | 81 |

| ZST-MgO (5 mol%) | 11.76 | 110.37 | 36.3 | 87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farahani, H.; Wagiran, R.; Urban, G. MgO-Doped (Zr,Sr)TiO3 Perovskite Humidity Sensors: Microstructural Effects on Water Permeation. Proceedings 2017, 1, 408. https://doi.org/10.3390/proceedings1040408

Farahani H, Wagiran R, Urban G. MgO-Doped (Zr,Sr)TiO3 Perovskite Humidity Sensors: Microstructural Effects on Water Permeation. Proceedings. 2017; 1(4):408. https://doi.org/10.3390/proceedings1040408

Chicago/Turabian StyleFarahani, Hamid, Rahman Wagiran, and Gerald Urban. 2017. "MgO-Doped (Zr,Sr)TiO3 Perovskite Humidity Sensors: Microstructural Effects on Water Permeation" Proceedings 1, no. 4: 408. https://doi.org/10.3390/proceedings1040408