Localized and In-Situ Integration of Different Nanowire Materials for Electronic Nose Applications †

Abstract

:1. Introduction

2. Materials and Methods

3. Results

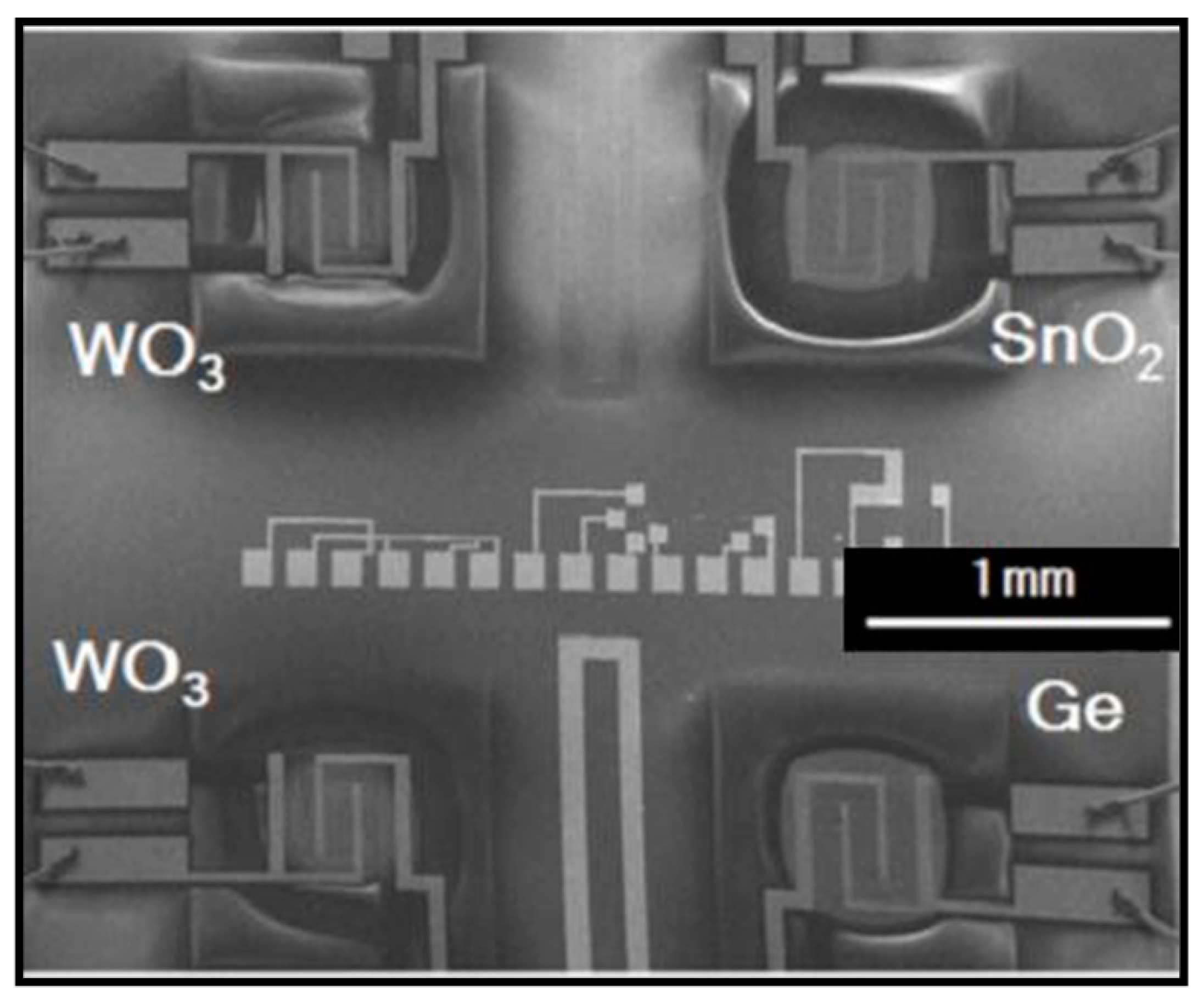

3.1. Nanowire Growth

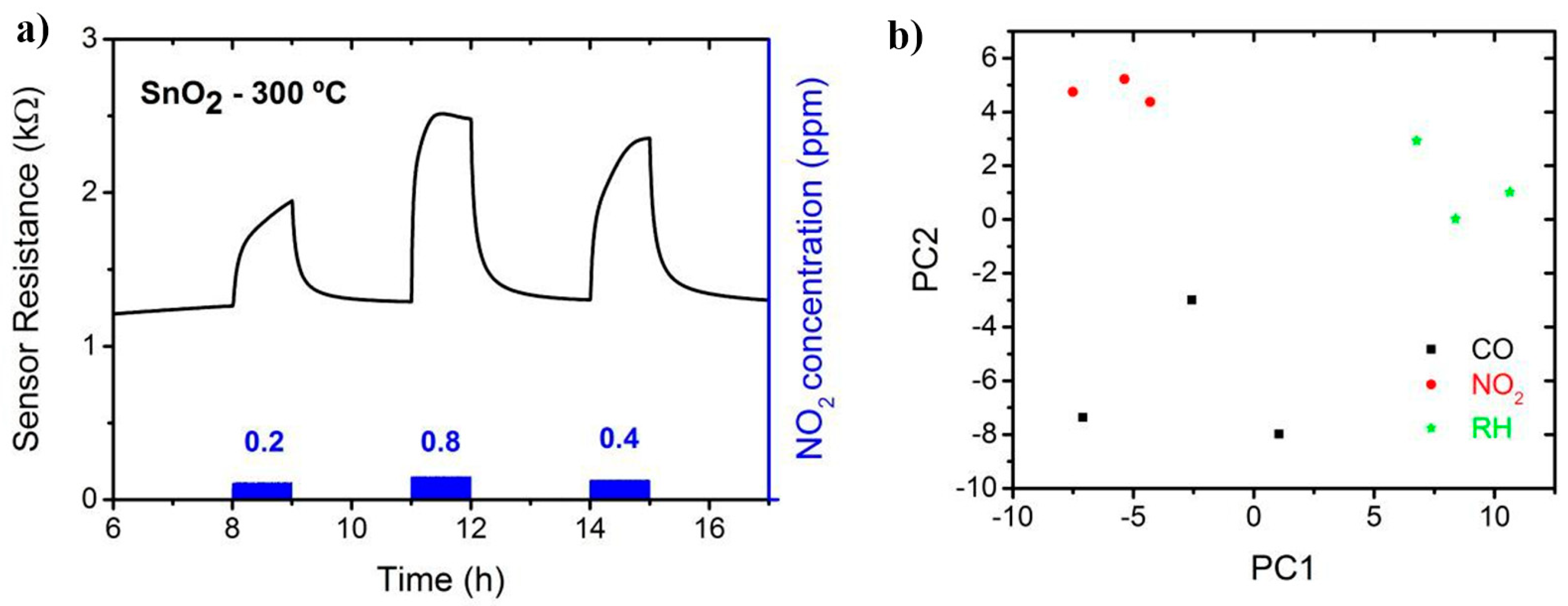

3.2. Gas Sensing

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Comini, E.; Baratto, C.; Faglia, G.; Ferroni, M.; Vomiero, A.; Sberveglieri, G. Quasi-One Dimensional Metal Oxide Semiconductors: Preparation, Characterization and Application as Chemical Sensors. Prog. Mater. Sci. 2009, 54, 1–67. [Google Scholar] [CrossRef]

- Hrachowina, L.; Domènech-Gil, G.; Pardo, A.; Seifner, M.S.; Gràcia, I.; Cané, C.; Romano-Rodríguez, A.; Barth, S. Site-specific growth and in situ integration of different nanowire material networks on a single chip: Towards a nanowire-based electronic nose for gas detection. ACS Sens. 2018, 3, 727–734; [Google Scholar] [CrossRef] [PubMed]

- Puigcorbé, J.; Vogel, D.; Michel, B.; Vilà, A.; Gràcia, I.; Cané, C.; Morante, J.R. Thermal and Mechanical Analysis of Micromachined Gas Sensors. J. Micromech. Microeng. 2003, 13, 548. [Google Scholar] [CrossRef]

- Samà, J.; Seifner, M.S.; Domènech-Gil, G.; Santander, J.; Calaza, C.; Moreno, M.; Gràcia, I.; Barth, S.; Romano-Rodríguez, A. Low Temperature Humidity Sensor Based on Ge Nanowires Selectively Grown on Suspended Microhotplates. Sens. Actuators B 2017, 243, 669–677. [Google Scholar] [CrossRef]

- Barth, S.; Jimenez-Diaz, R.; Sama, J.; Daniel Prades, J.; Gracia, I.; Santander, J.; Cane, C.; Romano-Rodriguez, A. Localized Growth and in situ Integration of Nanowires for Device Applications. Chem. Commun. 2012, 48, 4734–4736. [Google Scholar] [CrossRef] [PubMed]

- Yamazoe, N.; Sakai, G.; Shimanoe, K. Oxide Semiconductor Gas Sensors. Catal. Surv. Asia 2003, 7, 63–75. [Google Scholar] [CrossRef]

- Chang, S.C. Oxygen chemisorption on tin oxide: Correlation between electrical conductivity and EPR measurements. J. Vac. Sci. Technol. 1980, 17, 366–369. [Google Scholar] [CrossRef]

- Yamazoe, N.; Shimanoe, K. Theory of Power Laws for Semiconductor Gas Sensors. Sens. Actuators B 2008, 128, 566–573. [Google Scholar] [CrossRef]

- European-Environment-Agency Air Quality Standards. Available online: https://www.eea.europa.eu/themes/air/air-quality-standards (accessed on 21 January 2018).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domènech-Gil, G.; Hrachowina, L.; Pardo, A.; Seifner, M.S.; Gràcia, I.; Cané, C.; Barth, S.; Romano-Rodríguez, A. Localized and In-Situ Integration of Different Nanowire Materials for Electronic Nose Applications. Proceedings 2018, 2, 957. https://doi.org/10.3390/proceedings2130957

Domènech-Gil G, Hrachowina L, Pardo A, Seifner MS, Gràcia I, Cané C, Barth S, Romano-Rodríguez A. Localized and In-Situ Integration of Different Nanowire Materials for Electronic Nose Applications. Proceedings. 2018; 2(13):957. https://doi.org/10.3390/proceedings2130957

Chicago/Turabian StyleDomènech-Gil, Guillem, Lukas Hrachowina, Antonio Pardo, Michael S. Seifner, Isabel Gràcia, Carles Cané, Sven Barth, and Albert Romano-Rodríguez. 2018. "Localized and In-Situ Integration of Different Nanowire Materials for Electronic Nose Applications" Proceedings 2, no. 13: 957. https://doi.org/10.3390/proceedings2130957

APA StyleDomènech-Gil, G., Hrachowina, L., Pardo, A., Seifner, M. S., Gràcia, I., Cané, C., Barth, S., & Romano-Rodríguez, A. (2018). Localized and In-Situ Integration of Different Nanowire Materials for Electronic Nose Applications. Proceedings, 2(13), 957. https://doi.org/10.3390/proceedings2130957