Transverse Distribution of Concentrated Loads on Timber Composite Floors †

Abstract

:1. Introduction

2. Goals and Approach

- Timber-concrete composite (TCC) floors, composed by a concrete thin slab mechanically connected to various timber beams; and

- CLT-Steel (CLT-S) floors, composed by a CLT slab mechanically connected to various steel beams.

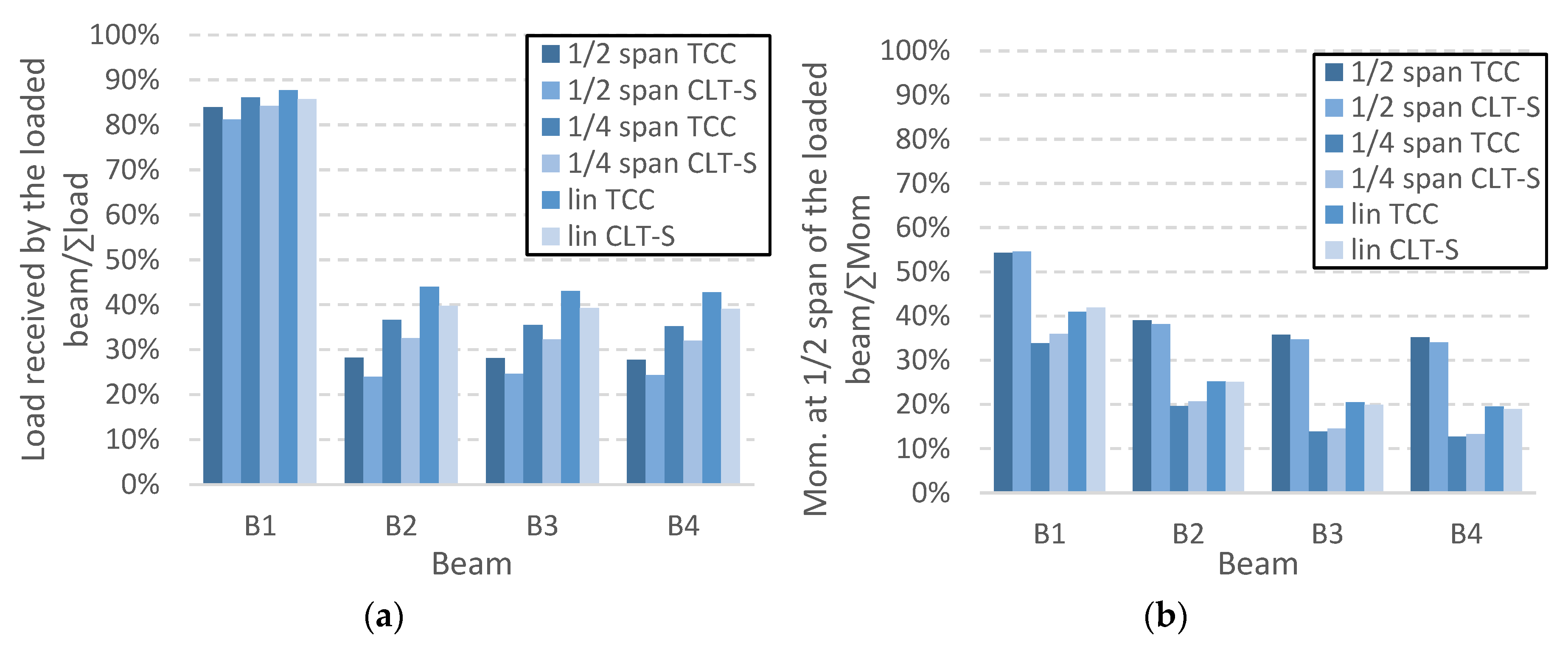

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Emperger, F. Der Holzbeton. Dinglers Polytech. J. 1920, 335, 109–112. [Google Scholar]

- Mueller, P. Decke aus hochkantig stehenden Holzbohlen oder Holzbrettern und Betondeckschicht, A.a.d.P. Patentschau aus dem Betonbau und den damit verwandten Gebieten. DE334431C, 14 March 1921. [Google Scholar]

- Seiler, J.F. Composite Wood and Concrete Construction. U.S. Patent 2,022,693, 3 December 1935. [Google Scholar]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- EN1995. Eurocode 5: Design of timber structures. In Part 1-1: General—Common Rules and Rules for Buildings; CEN, Ed.; CEN: Brussels, Belgium, 2004. [Google Scholar]

- Monteiro, S.R.S.; Dias, A.M.P.G.; Lopes, S.M.R. Transverse distribution of internal forces in timber–concrete floors under external point and line loads. Construct. Build. Mater. 2016, 102, 1049–1059. [Google Scholar] [CrossRef]

- Monteiro, S.R.S.; Dias, A.M.P.G.; Lopes, S.M.R. Bi-dimensional numerical modeling of timber–concrete slab-type structures. Mater. Struct. 2015, 48, 3391–3406. [Google Scholar] [CrossRef]

- FprEN14080. Timber structures—Glued laminated timber and glued solid timber—Requirements. In Strength Classes; CEN, Ed.; CEN: Brussels, Belgium, 2013. [Google Scholar]

- EN338. Structural timber. In Strength Classes; CEN, Ed.; CEN: Brussels, Belgium, 2003. [Google Scholar]

- EN1992. Eurocode 2: Design of concrete structures. In Part 1-1: General Rules and Rules for Buildings; Part 2: Concrete Bridges; Design and Detailing Rules; CEN, Ed.; CEN: Brussels, Belgium, 2004. [Google Scholar]

- EN1993. Eurocode 3: Design of steel structures. In Part 1-1: General Structural Rules; CEN, Ed.; CEN: Brussels, Belgium, 2005. [Google Scholar]

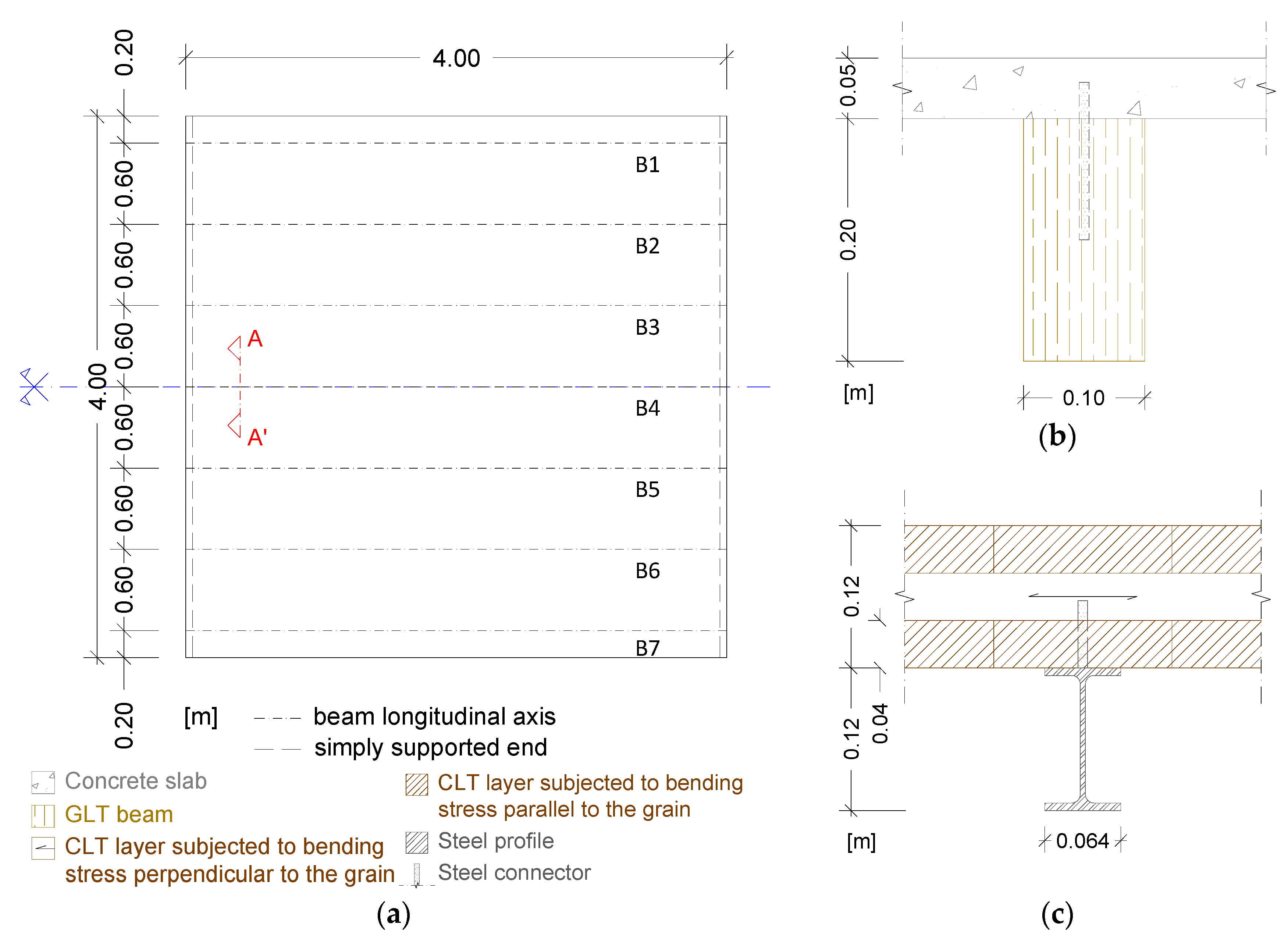

| Composite Floor | Timber Grade | Concrete | Steel |

|---|---|---|---|

| TCC | 0.10 × 0.20 m2 GL 24 h (timber layers made of laminations of graded as T14 1 (C24 2)) | 0.05 m thick C25/30 3 concrete | - |

| CLT-S | 3 layer (2 along the x-direction), 40 mm thick, CL 24 (timber layers made of laminations of graded as T14 1 (C24 2)) | - | IPE120 S275 4 profile |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monteiro, S.; Dias, A.; Lopes, S. Transverse Distribution of Concentrated Loads on Timber Composite Floors. Proceedings 2018, 2, 1421. https://doi.org/10.3390/proceedings2231421

Monteiro S, Dias A, Lopes S. Transverse Distribution of Concentrated Loads on Timber Composite Floors. Proceedings. 2018; 2(23):1421. https://doi.org/10.3390/proceedings2231421

Chicago/Turabian StyleMonteiro, Sandra, Alfredo Dias, and Sérgio Lopes. 2018. "Transverse Distribution of Concentrated Loads on Timber Composite Floors" Proceedings 2, no. 23: 1421. https://doi.org/10.3390/proceedings2231421

APA StyleMonteiro, S., Dias, A., & Lopes, S. (2018). Transverse Distribution of Concentrated Loads on Timber Composite Floors. Proceedings, 2(23), 1421. https://doi.org/10.3390/proceedings2231421