Determination of Processing Parameters for Thermoplastic Biocomposites Based on Hybrid Yarns Using Finite Elements Simulation

Abstract

:1. Introduction

2. Materials and Methods

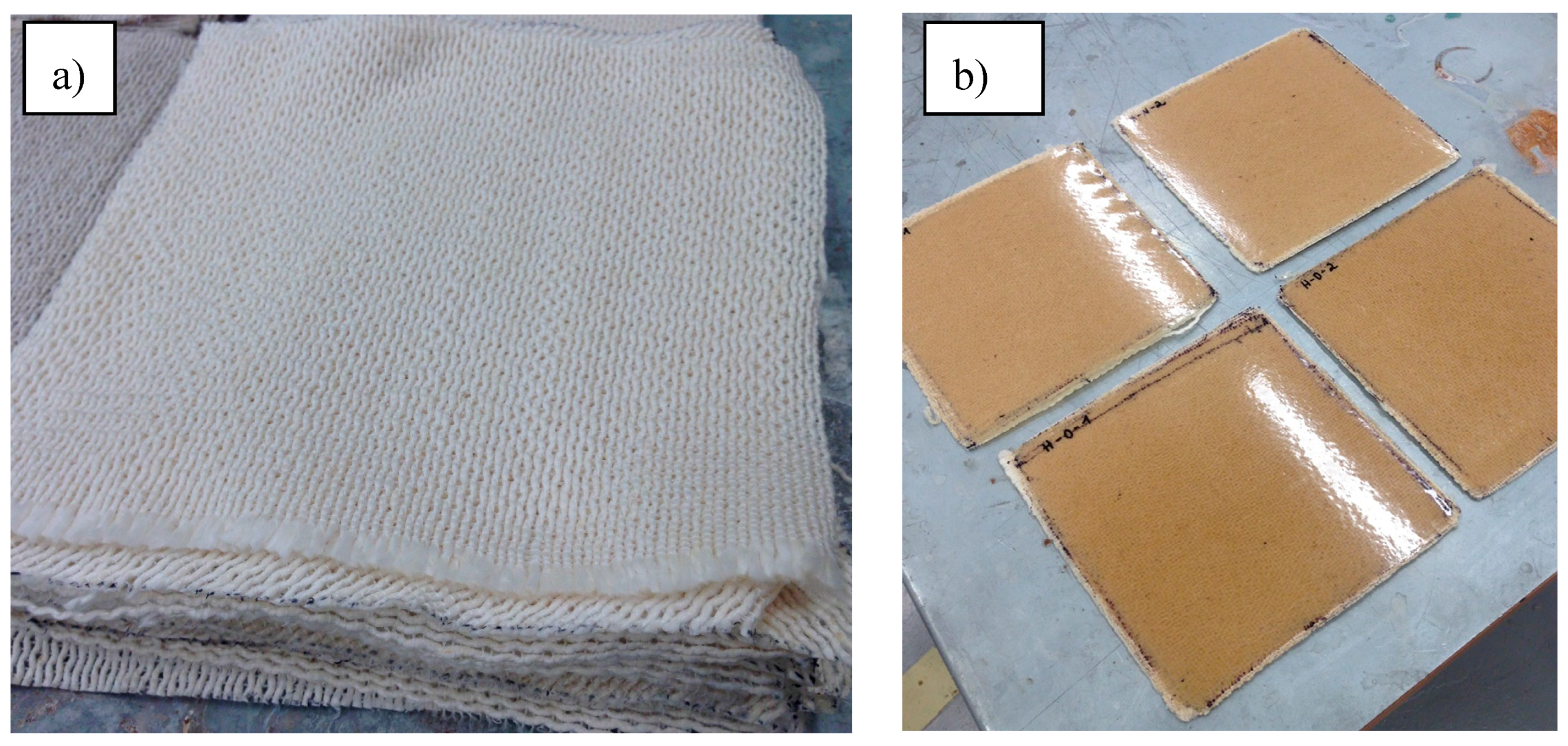

2.1. Materials

2.2. Methods

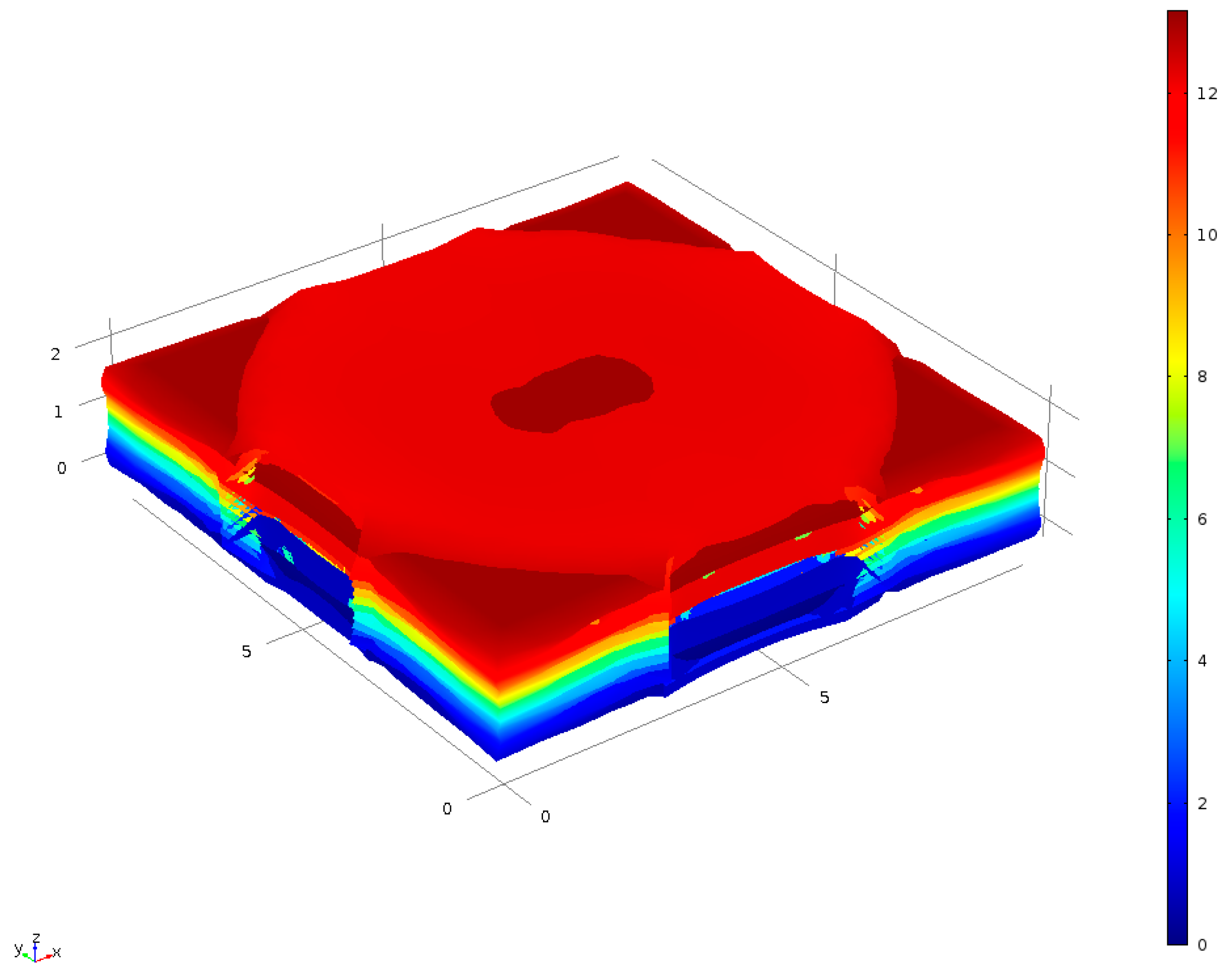

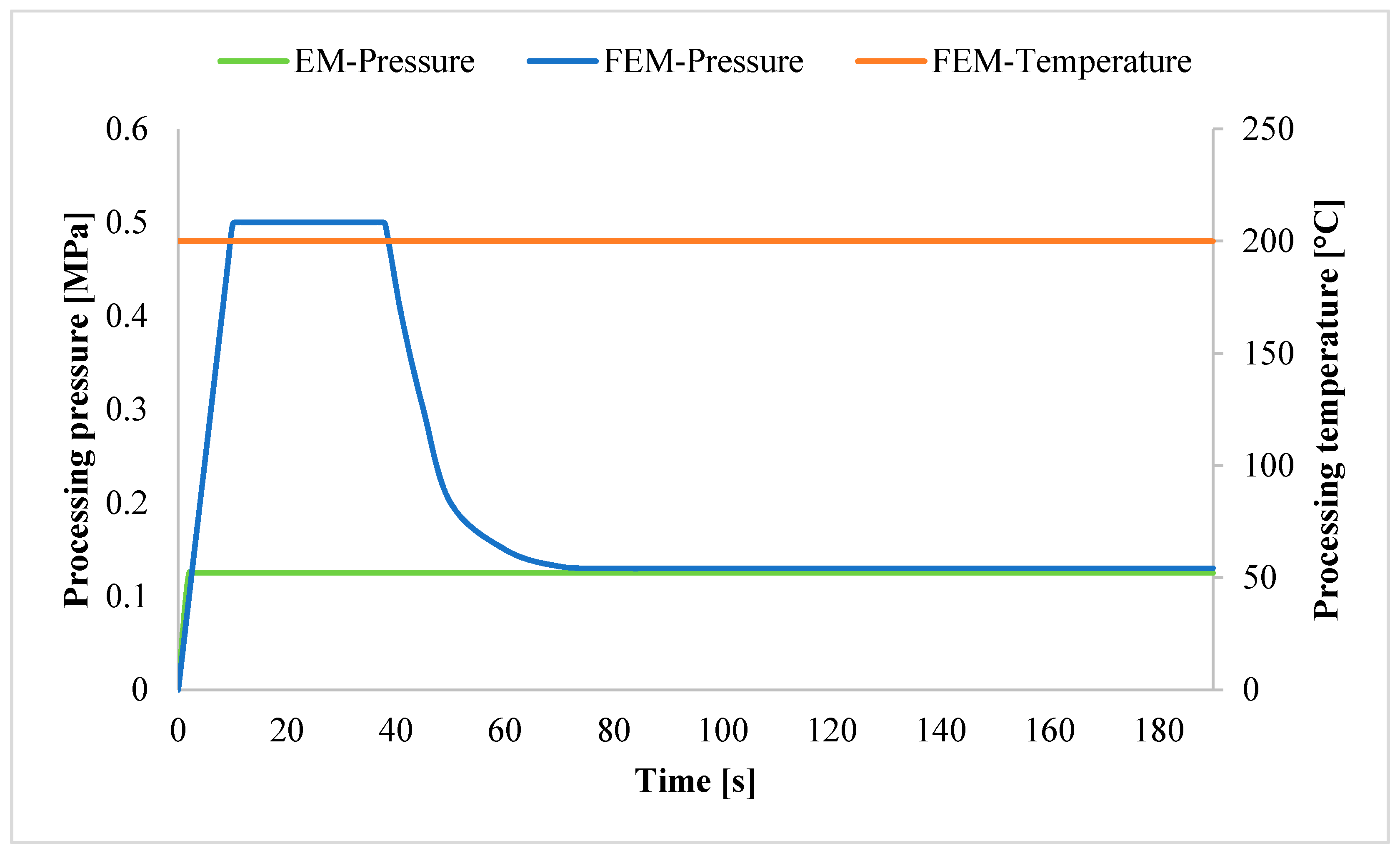

2.2.1. Finite Element Method

2.2.2. Fabrication of Composites

2.2.3. Microscopy

2.2.4. Composite Density and Porosity

2.2.5. Mechanical Testing

3. Results and Discussion

3.1. Determination of Processing Parameters with FEM

3.2. Microscopy

3.3. Composite Density and Porosity

3.4. Tensile Properties

3.5. Impact Properties

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of mechanical performance of industrial hemp fibre reinforced polylactide biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 310–319. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Review: Raw natural fiber–based polymer composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, C.H. Direct impregnation of thermoplastic melt into flax textile reinforcement for semi-structural composite parts. Ind. Crops Prod. 2017, 95, 651–663. [Google Scholar] [CrossRef]

- Kandar, M.I.M.; Akil, H.M. Application of design of experiment (DoE) for parameters optimization in compression moulding for flax reinforced biocomposites. Procedia Chem. 2016, 19, 433–440. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Masirek, R.; Kulinski, Z.; Chionna, D.; Piorkowska, E.; Pracella, M. Composites of poly(L-lactide) with hemp fibers: Morphology and thermal and mechanical properties. J. Appl. Polym. Sci. 2007, 105, 255–268. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G. Preparation and mechanical properties of novel bio-composite made of dynamically sheet formed discontinuous harakeke and hemp fibre mat reinforced PLA composites for structural applications. Ind. Crops Prod. 2016, 84, 139–150. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Salehi, M.; Bashir, T.; Rissanenm, M.; Nousiainen, P. Novel aligned hemp fibre reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M. Characterisation of polylactic acid biocomposites made from prepregs composed of woven polylactic acid/hemp—Lyocell hybrid yarn fabrics. Compos. Part A Appl. Sci. Manuf. 2016, 81, 139–144. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Manufacture and characterisation of thermoplastic composites made from PLA/hemp co-wrapped hybrid yarn prepregs. Compos. Part A Appl. Sci. Manuf. 2013, 50, 93–101. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Rissanen, M.; Ramamoorthy, S.K. Mechanical and thermal characterization of compression moulded polylactic acid natural fiber composites reinforced with hemp and lyocell fibers. J. Appl. Polym. Sci. 2014, 131, 1–10. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Characterization of thermoplastic natural fibre composites made from woven hybrid yarn prepregs with different weave pattern. Compos. Part A Appl. Sci. Manuf. 2015, 76, 154–161. [Google Scholar] [CrossRef]

- Baghaei, B. Development of Thermoplastic Biocomposites Based on Aligned Hybrid Yarns for Fast Composite Manufacturing. Ph.D. Thesis, University of Borås, Borås, Sweden, 2015. [Google Scholar]

- Bruno, A.D.; Baskaran, M. Analysing the mechanical properties of natural fiber reinforced polymer composites using FEA. Int. J. Eng. Sci. Res. Technol. 2014, 3, 269–282. [Google Scholar]

- Yu, Z.-C.; Townsley, M.; McKay, S. Natural fiber composites for mass transportation industry. In Proceedings of the 26th Annual Technical Conference of the American Society for Composites 2011: The 2nd Joint US-Canada Conference on Composites, Montreal, QC, Canada, 26–28 September 2011; Hyer, M., Ed.; Destech Publications: Lancaster, PA, USA, 2011. [Google Scholar]

- Henton, D.E.; Gruber, P.; Lunt, J.; Randall, J. Polylactic acid technology. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press Inc. M.U.A.: Boca Raton, FL, USA, 2005. [Google Scholar]

- GreenSpec. Insulation Materials and Their Thermal Properties; GreenSpec: Groningen, The Netherlands, 2017. [Google Scholar]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Pratten, N.A. The precise measurement of the density of small samples. J. Mater. Sci. 1981, 16, 1737–1747. [Google Scholar] [CrossRef]

- Madsen, B.; Thygesen, A.; Lilholt, H. Plant fibre composites—Porosity and volumetric interaction. Compos. Sci. Technol. 2007, 67, 1584–1600. [Google Scholar] [CrossRef]

- Zhou, C.; Guo, H.; Li, J.; Huang, S.; Li, H.; Meng, Y.; Yu, D.; Christiansen, J.C.; Jiang, S. Temperature dependence of poly(lactic acid) mechanical properties. RSC Adv. 2016, 6, 113762–113772. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Bismarck, A.; Mishra, S.; Lampke, T. Plant fibers as reinforcement for green composites. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press Inc. M.U.A.: Boca Raton, FL, USA, 2005; pp. 36–112. [Google Scholar]

- Tatara, R.A. Compression molding. In Applied Plastics Engineering Handbook, 2nd ed.; Kutz, M., Ed.; William Andrew Publishing: Oxford, UK, 2017; pp. 291–320. [Google Scholar]

- Graupner, N. Improvement of the mechanical properties of biodegradable hemp fiber reinforced poly(lactic acid) (PLA) composites by the admixture of man-made cellulose fibers. J. Compos. Mater. 2009, 43, 689–702. [Google Scholar] [CrossRef]

| Hemp | PLA | |

|---|---|---|

| Density ρ | 1.480 g/cm3 [13] | 1.240 g/cm3 [13] |

| Young’s modulus E | 14.00 GPa [13] | 2.91 GPa at 22 °C [13] |

| Poisson’s ratio ν | 0.221 [14] | 0.360 [13] |

| Coefficient of thermal expansion α | 10−6 1/°C [15] | 7.4 × 10−4 1/°C [16] |

| Heat capacity at constant pressure Cp | 2000 J/(kg × K) [17] | 2060 J/(kg × °C) at 190 °C [18] |

| Thermal conductivity λ | 0.040 W/(m × K) [17] | 0.195 W/(m × °C) at 190 °C [18] |

| Temperature | Pressure | Time | |

|---|---|---|---|

| Experimental method | 190 °C | 0.125 MPa | 10 min |

| FE method | 200 °C | 0.5 MPa | 28 s |

| 0.13 MPa | 2.5 min |

| Composite Density ρc [g/cm3] | Fiber Volume Fraction Vf [%] | Matrix Volume Fraction Vm [%] | Porosity Volume Fraction Vp [%] | |

|---|---|---|---|---|

| Hemp-EM | 1.28 | 34.58 | 61.90 | 3.52 |

| Hemp-FEM | 1.28 | 34.62 | 61.99 | 3.39 |

| Tensile Strength [MPa] | E-Modulus [GPa] | Impact Strength [KJ/m2] | |

|---|---|---|---|

| Hemp-EM | 49.52 (1.50) | 14.29 (2.91) | 15.09 (1.25) |

| Hemp-FEM | 51.36 (2.34) | 24.05 (6.11) | 16.56 (2.12) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vogt, S.; Baghaei, B.; Kadi, N.; Skrifvars, M. Determination of Processing Parameters for Thermoplastic Biocomposites Based on Hybrid Yarns Using Finite Elements Simulation. J. Compos. Sci. 2018, 2, 11. https://doi.org/10.3390/jcs2010011

Vogt S, Baghaei B, Kadi N, Skrifvars M. Determination of Processing Parameters for Thermoplastic Biocomposites Based on Hybrid Yarns Using Finite Elements Simulation. Journal of Composites Science. 2018; 2(1):11. https://doi.org/10.3390/jcs2010011

Chicago/Turabian StyleVogt, Sarah, Behnaz Baghaei, Nawar Kadi, and Mikael Skrifvars. 2018. "Determination of Processing Parameters for Thermoplastic Biocomposites Based on Hybrid Yarns Using Finite Elements Simulation" Journal of Composites Science 2, no. 1: 11. https://doi.org/10.3390/jcs2010011