Manufacturing and Mechanical Properties of Graphene Coated Glass Fabric and Epoxy Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

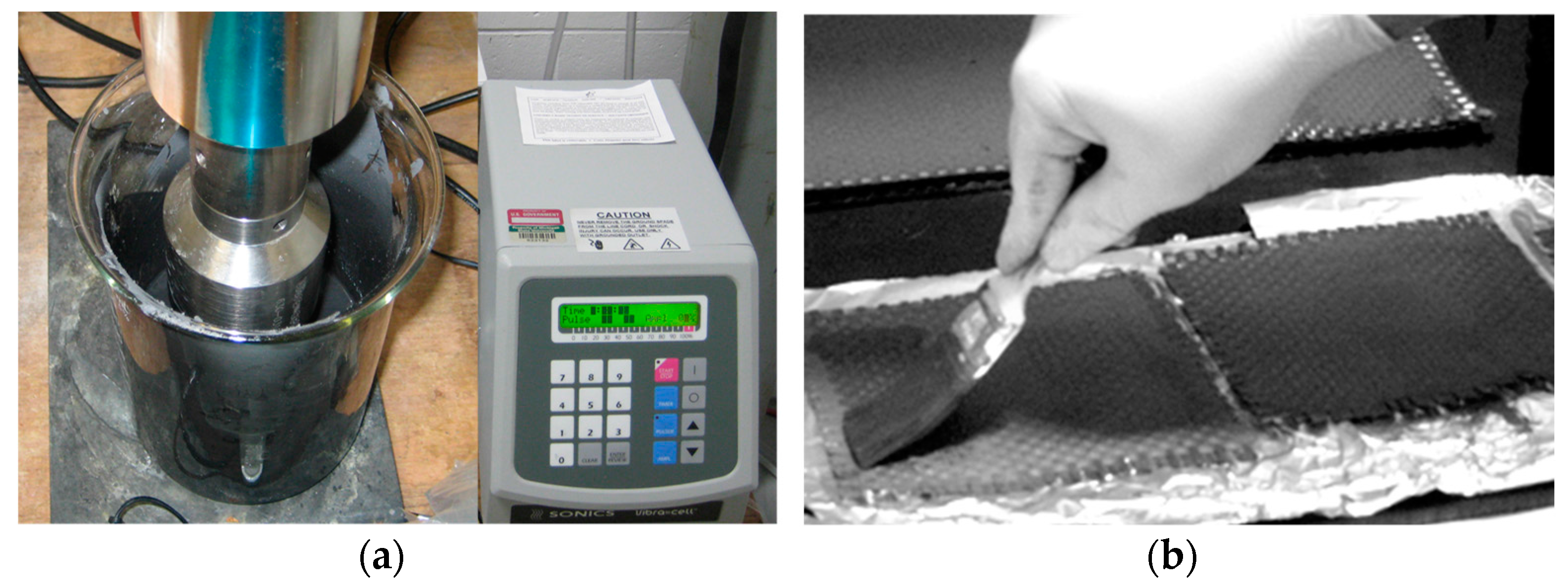

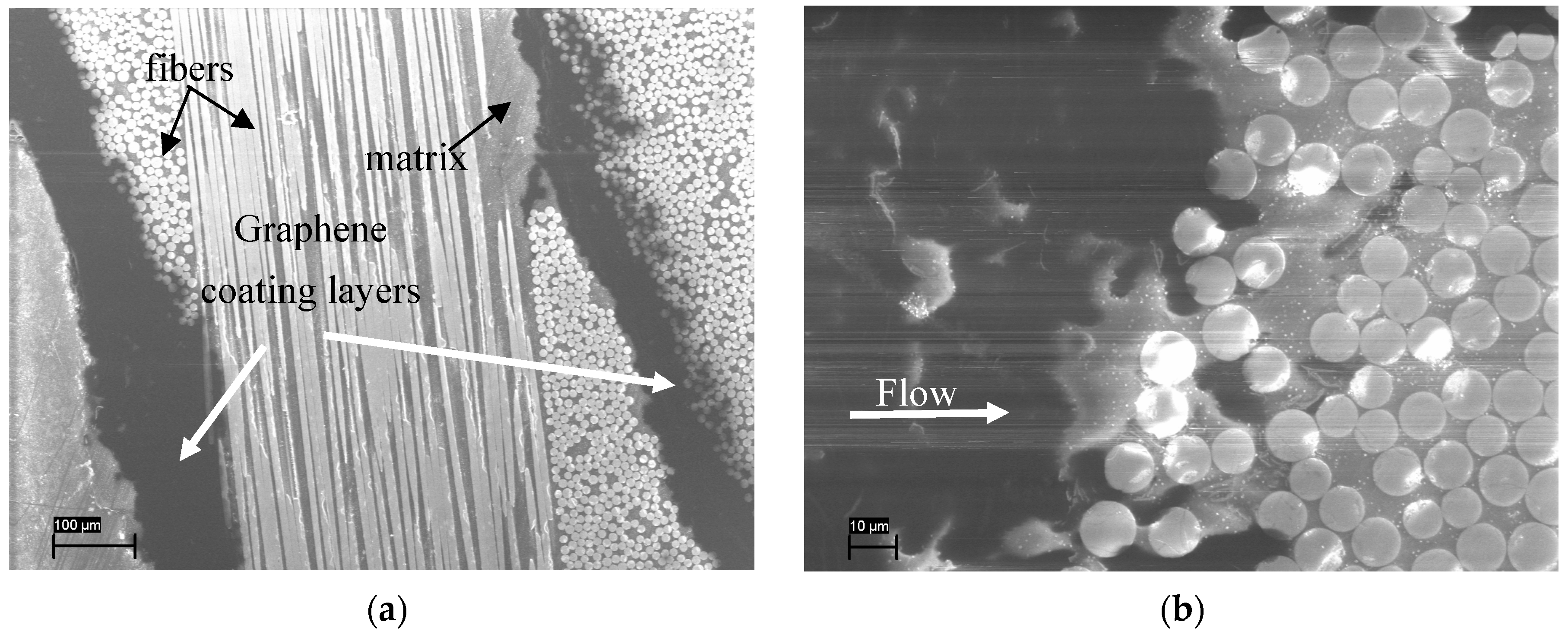

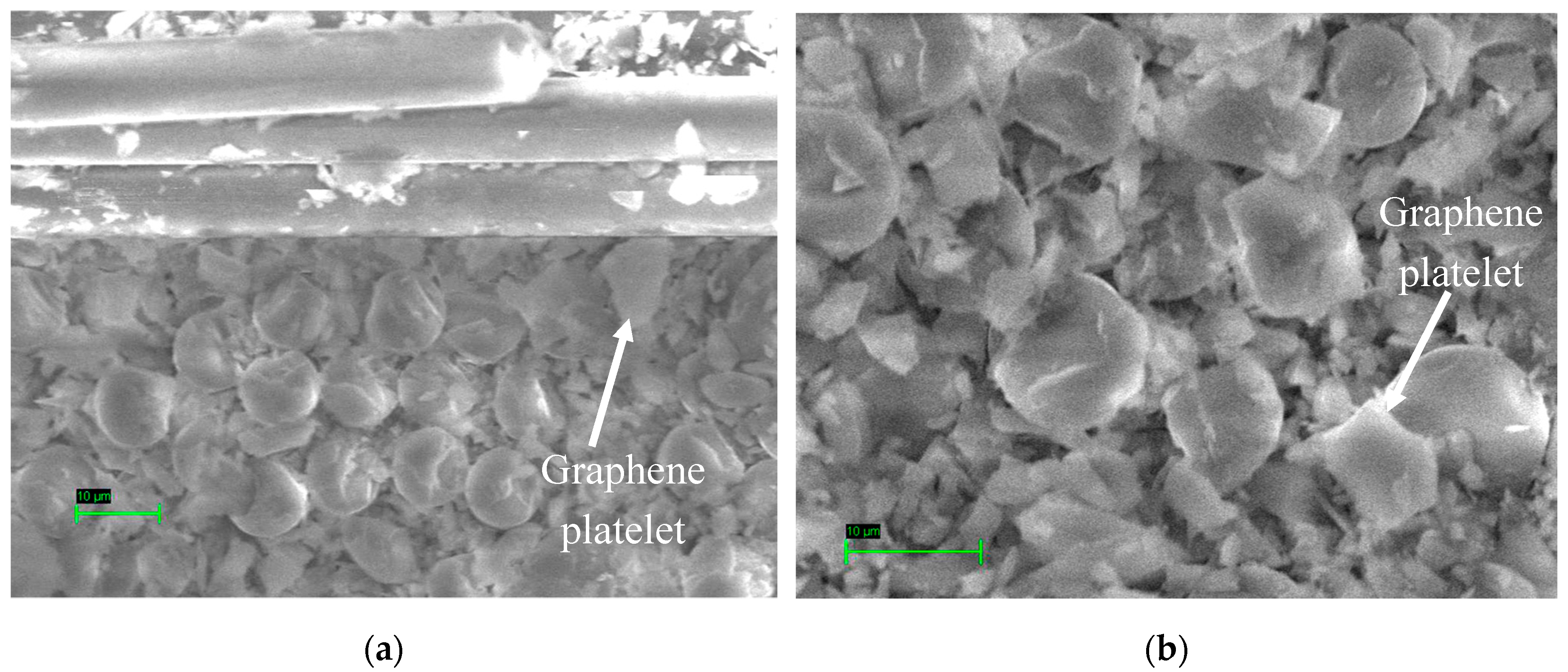

2.2. Graphene Coating Process

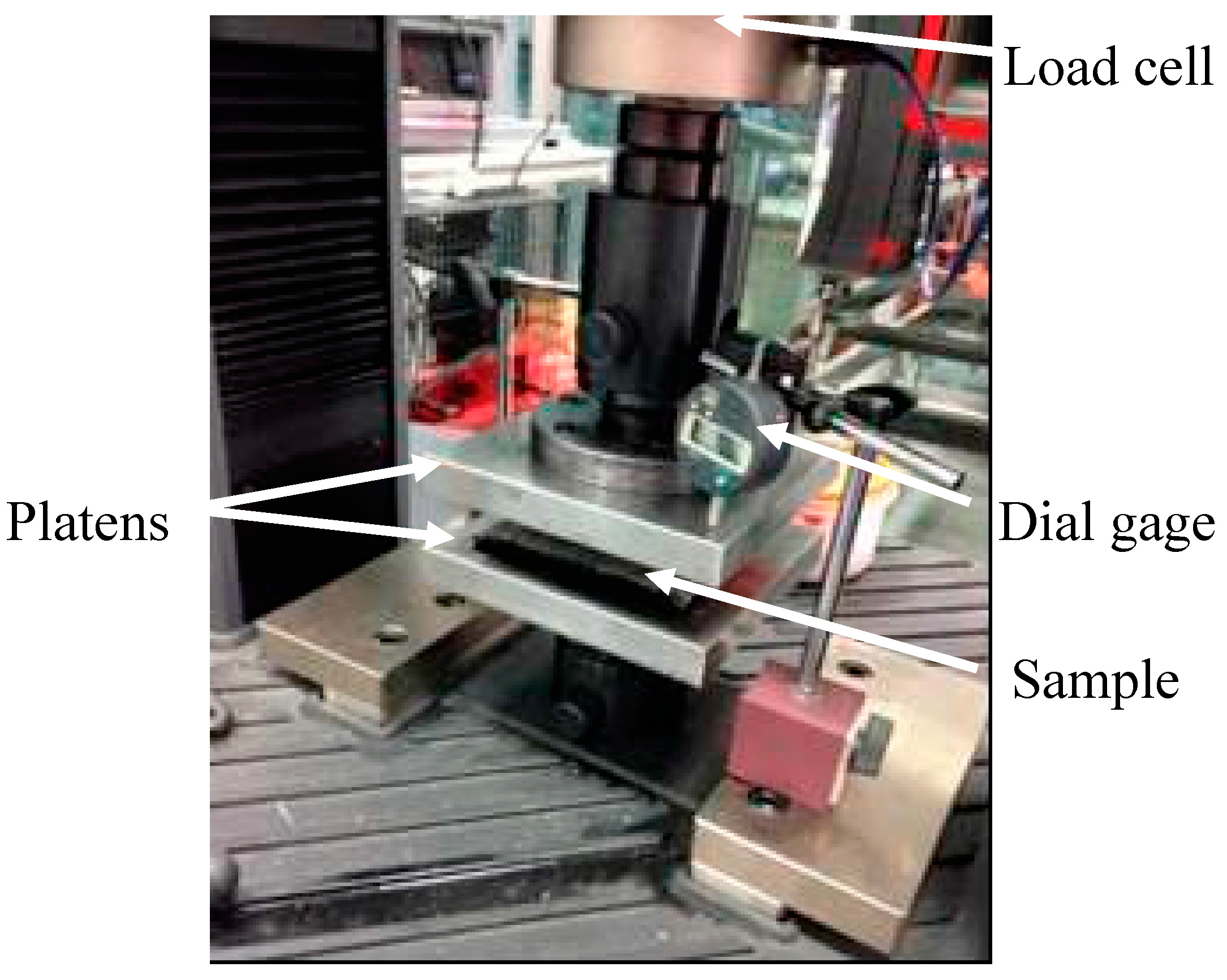

2.3. Compaction Characterization

2.4. Permeability Characterization

2.5. Composite Manufacture

2.6. Mechanical Properties

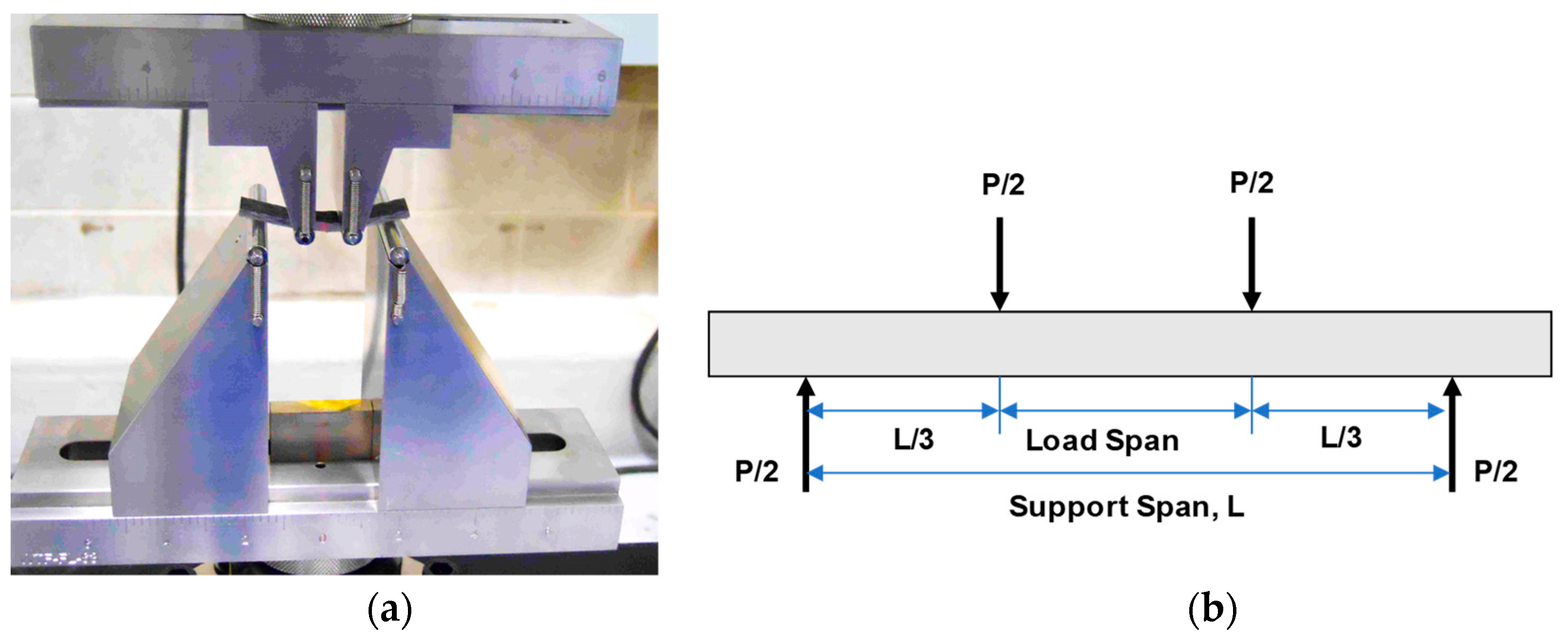

2.6.1. Flexural Testing

2.6.2. Low Velocity Impact

2.6.3. Ultrasonic Non-Destructive Evaluation

3. Results and Discussion

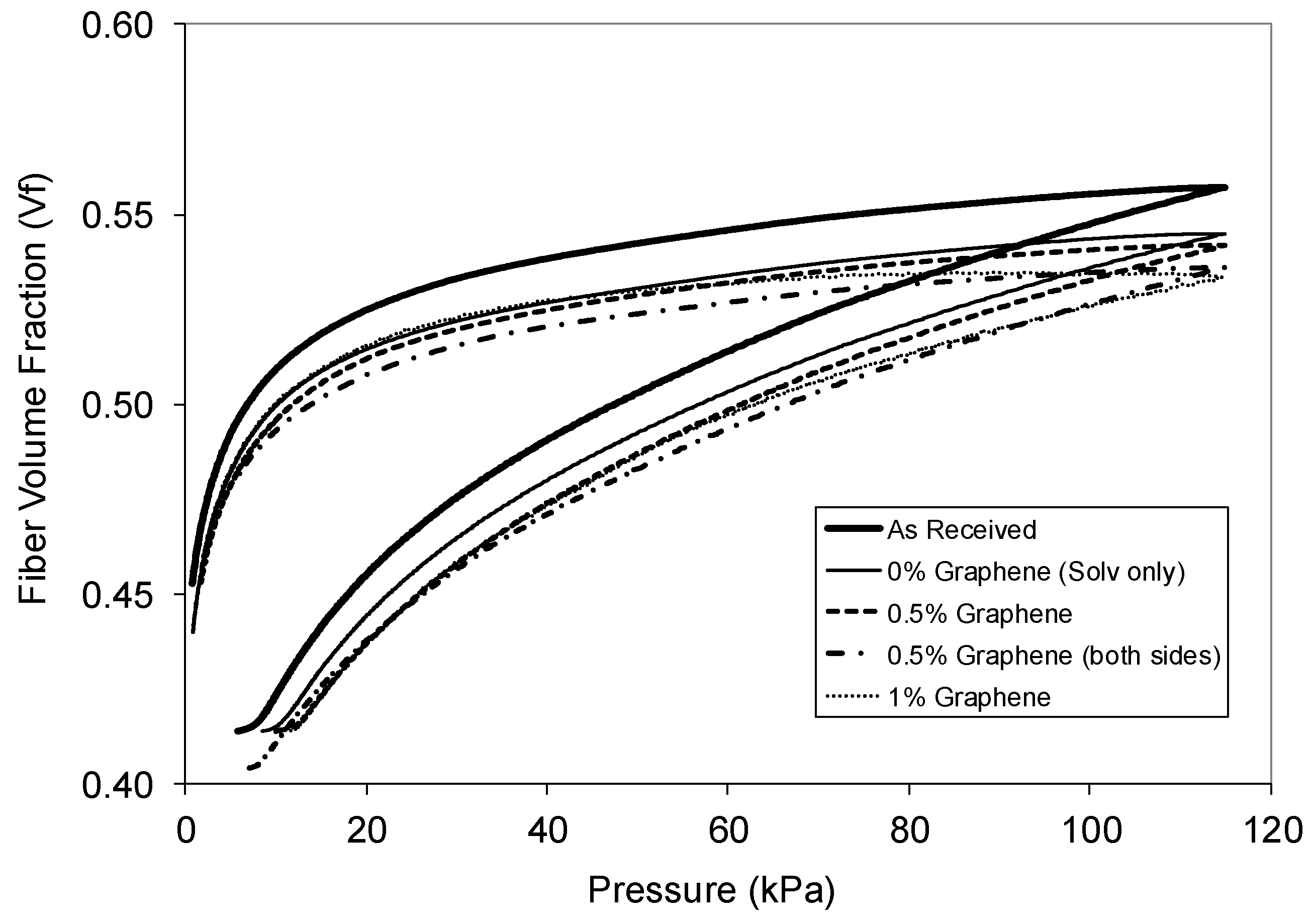

3.1. Compaction

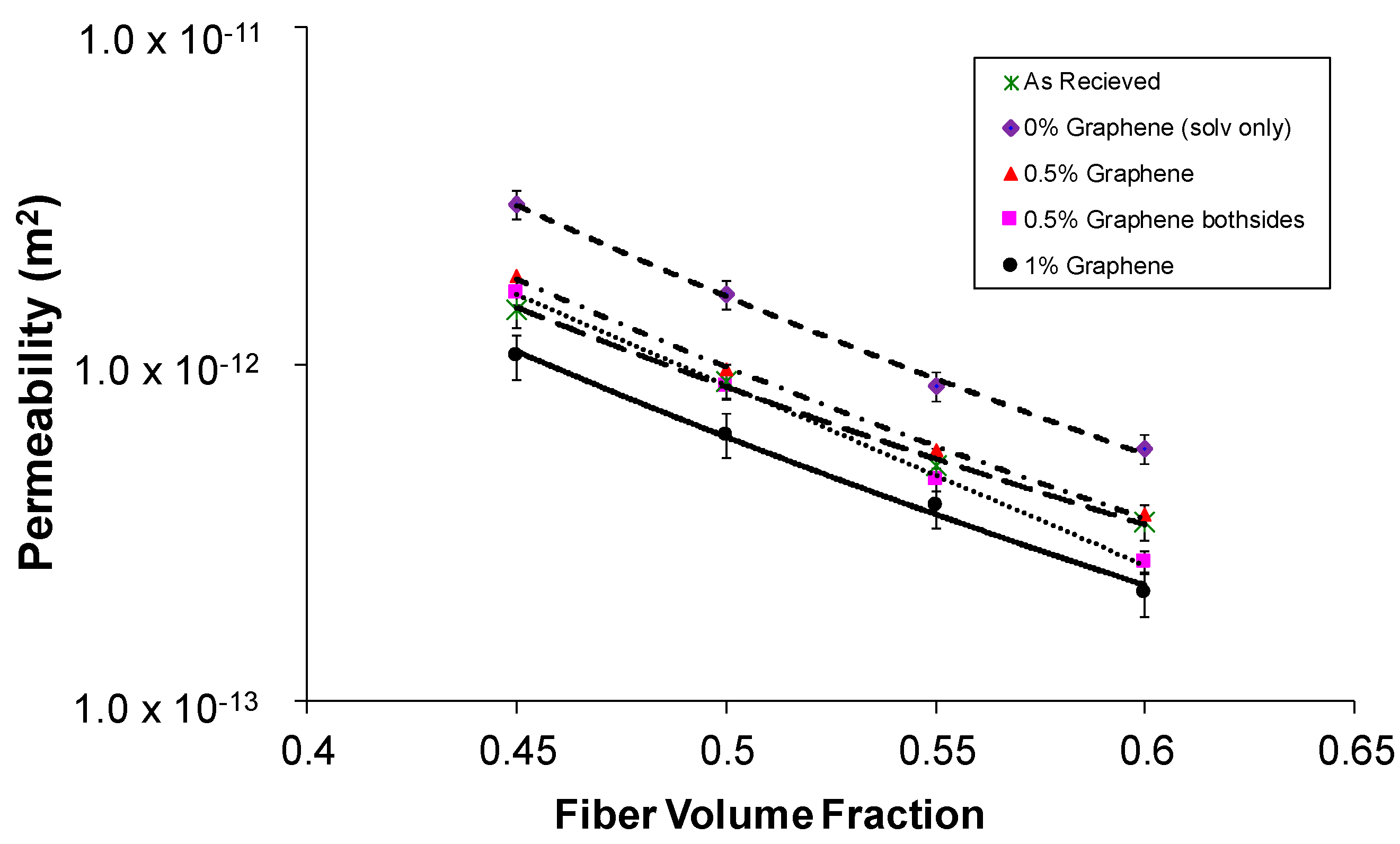

3.2. Permeability

3.3. Mechanical Properties

3.3.1. Flexural Properties

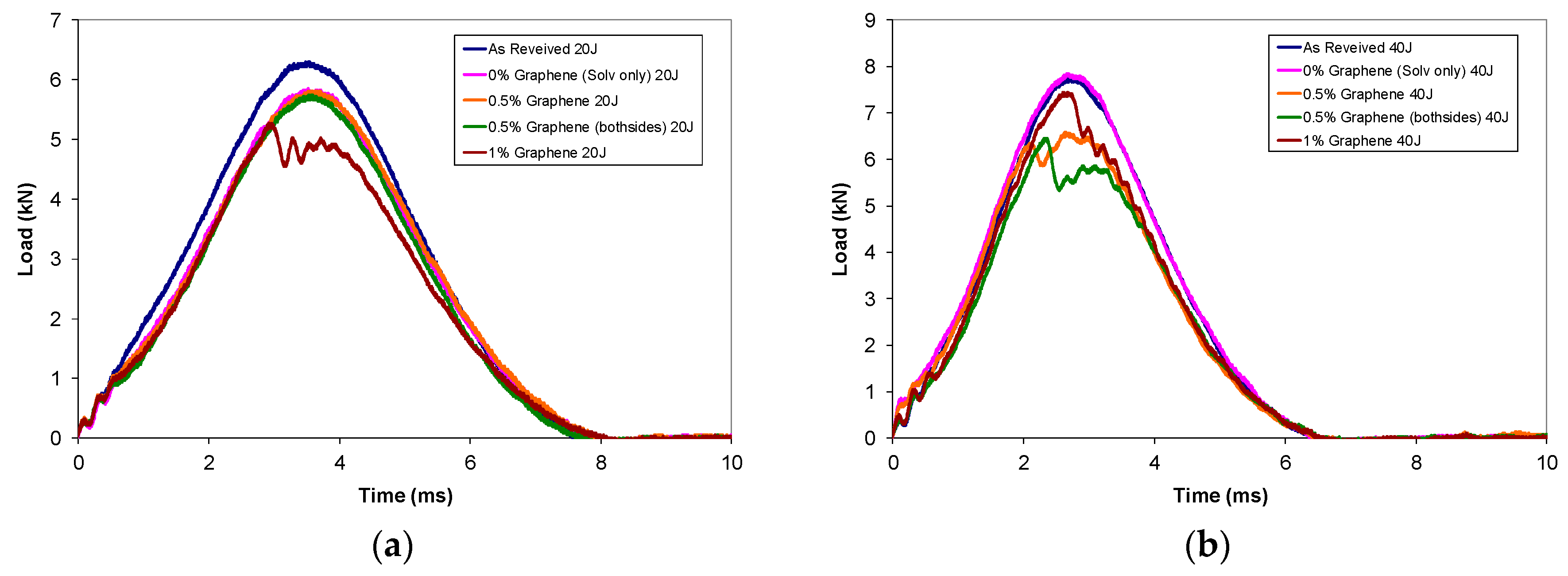

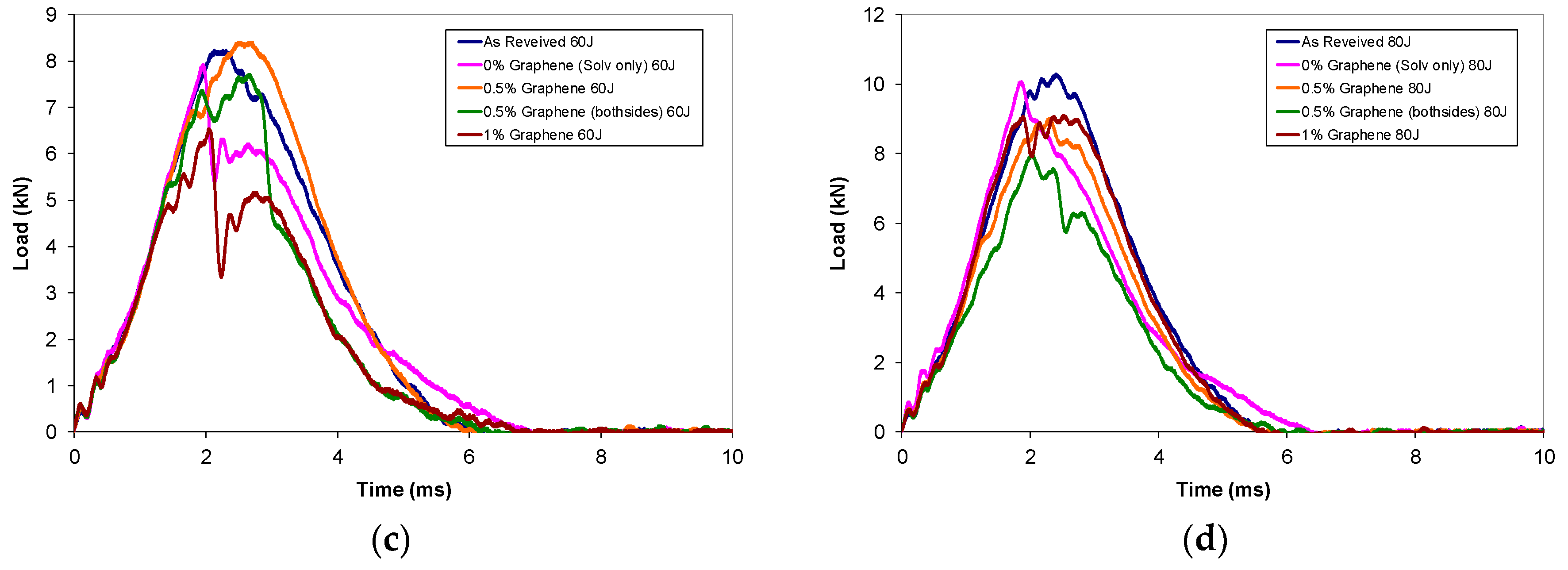

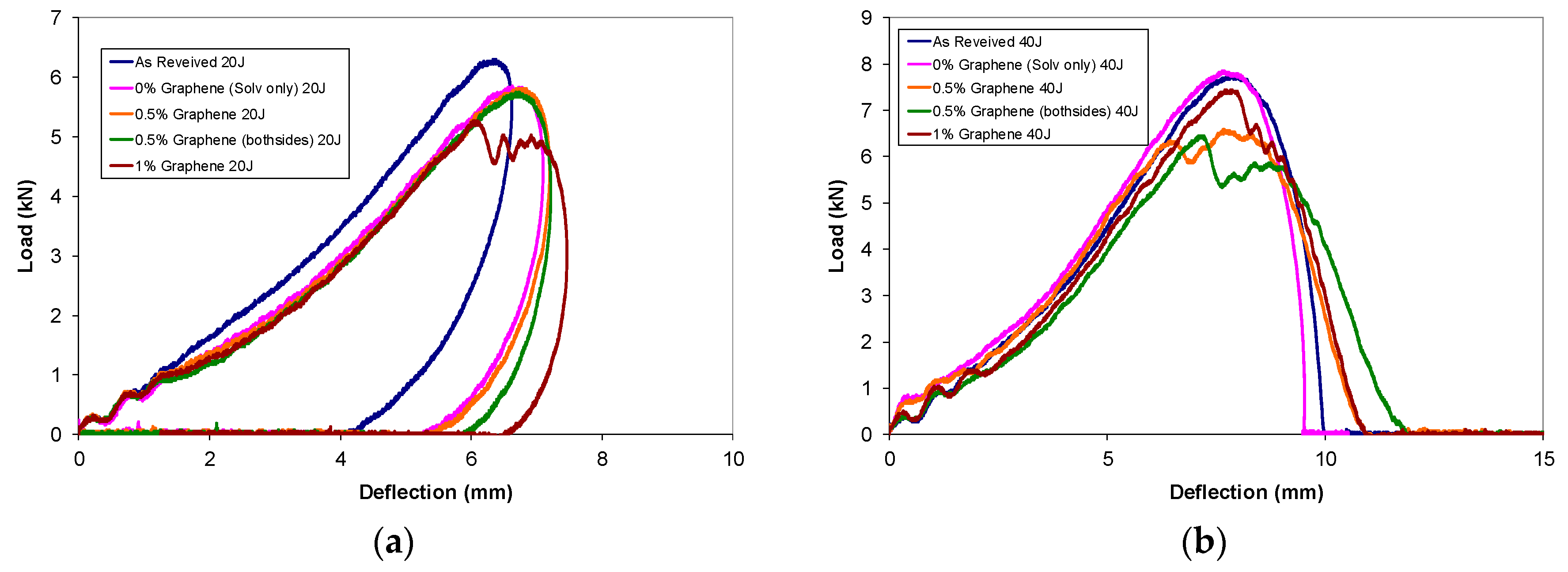

3.3.2. Low Velocity Impact

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Xu, Y.; Hong, W.; Bai, H.; Li, C.; Shi, G. Preparation and characterization of graphene/poly(vinyl alcohol) nanocomposites. Carbon 2009, 47, 3538–3543. [Google Scholar] [CrossRef]

- Samad, Y.; Li, Y.; Alhassan, S.; Liao, K. Novel Graphene Foam Composite with Adjustable Sensitivity for Sensor Applications. ACS Appl. Mater. Interfaces 2015, 7, 9195–9202. [Google Scholar] [CrossRef] [PubMed]

- Ponnamma, D.; Guo, Q.; Krupa, I.; Al-Maadeed, M.A.S.A.; Varughese, K.T.V.; Thomas, S.; Sadasivuni, K.K. Graphene and graphitic derivative filled polymer composites as potential sensors. Phys. Chem. Chem. Phys. 2015, 17, 3954–3981. [Google Scholar] [CrossRef] [PubMed]

- Lee, X.; Yang, T.; Li, X.; Zhang, R.; Zhu, M.; Zhang, H.; Xie, D.; Wei, J.; Zhong, M.; Wang, K. Flexible graphene woven fabrics for touch sensing. Appl. Phys. Lett. 2013, 102, 163117. [Google Scholar] [CrossRef]

- Aguilera-Servin, J.; Miao, T.; Bockrath, M. Nanoscale pressure sensors realized from suspended graphene membrane devices. Appl. Phys. Lett. 2015, 106, 083103. [Google Scholar] [CrossRef]

- Zhu, S.; Ghatkesar, M.; Zhang, C.; Janssen, G. Graphene based piezoresistive pressure sensor. Appl. Phys. Lett. 2013, 102, 161904. [Google Scholar] [CrossRef]

- Kim, S.; Drzal, L.T. Thermal stability and dynamic mechanical behavior of exfoliated graphite nanoplatelets–LLDPE composites. Polym. Compos. 2009, 31, 755–761. [Google Scholar] [CrossRef]

- Jiang, X.; Drzal, L.T. Multifunctional high density polyethylene nanocomposites produced by incorporation of exfoliated graphite nanoplatelets 1: Morphology and mechanical properties”. Polym. Compos. 2010, 31, 1091–1098. [Google Scholar] [CrossRef]

- Biswas, S.; Fukushima, H.; Drzal, L.T. Mechanical and electrical property enhancement in exfoliated graphene nanoplatelet/liquid crystalline polymer nanocomposites. Compos. Part A 2011, 42, 371–375. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nat. Lett. 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Gibson, R.F.; Gordaninejad, F.; Suhr, J. Energy absorption capability of nanocomposites: A review. Compos. Sci. Technol. 2009, 69, 2392–2409. [Google Scholar] [CrossRef]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Ávila, A.F.; Soares, M.I.; Neto, A.S. A Study on nanostructured laminated plates behavior under low-velocity impact loadings. Int. J. Impact Eng. 2007, 34, 28–41. [Google Scholar] [CrossRef]

- Fan, Z.; Hsiao, K.T.; Advani, S.G. Experimental investigation of dispersion during flow of multi-walled carbon nanotube/polymer suspension in fibrous porous media. Carbon 2004, 42, 871–876. [Google Scholar] [CrossRef]

- Lin, L.Y.; Lee, J.H.; Hong, C.E.; Yoo, G.H.; Advani, S.G. Preparation and characterization of layered silicate/glass fiber/epoxy hybrid nanocomposites via vacuum-assisted resin transfer molding (VARTM). Compos. Sci. Technol. 2006, 66, 2116–2125. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Rangari, V.K.; Jeelani, S. Fabrication and evaluation of carbon nano fiber filled carbon/epoxy composite. Mater. Sci. Eng. A 2006, 426, 221–228. [Google Scholar] [CrossRef]

- Movva, S.; Zhou, G.; Guerra, D.; Lee, L.J. Effect of Carbon nano fibres on mold filling in a vacuum assisted resin transfer molding system. J. Compos. Mater. 2009, 43, 611–620. [Google Scholar] [CrossRef]

- Peila, R.; Seferis, J.C.; Karaki, T.; Parker, G. Effects of nanoclay on the thermal and rheological properties of a VARTM Epoxy Resin. J. Therm. Anal. Calorim. 2009, 96, 587–592. [Google Scholar] [CrossRef]

- Mahrholz, T.; Stängle, J.; Sinapius, M. Quantification of the reinforcement effect of silica nanoparticles in epoxy resins used in liquid composite molding processes. Compos. Part A 2009, 40, 235–243. [Google Scholar] [CrossRef]

- Umer, R.; Li, Y.; Dong, Y.; Haroosh, H.J.; Liao, K. The effect of graphene oxide (GO) nanoparticles on the processing of epoxy/glass fiber composites using resin infusion. Int. J. Adv. Manuf. Technol. 2015, 81, 2183–2192. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Samad, Y.A.; Liao, K.; Cantwell, W.J. Graphene coated piezo-resistive fabrics for liquid composite molding process monitoring. Compos. Sci. Technol. 2017, 148, 106–114. [Google Scholar] [CrossRef]

- Wu, H.; Rook, B.; Drzal, L.T. Dispersion optimization of exfoliated graphite nanoplatelets in polyetherimide nanocomposites: Extrusion vs. precoating vs. solid state ball milling. Polym. Compos. 2009, 34, 426–432. [Google Scholar] [CrossRef]

- Maenosono, S.; Okubo, T.; Yamaguchi, Y. Overview of nanoparticle array formation by wet coating. J. Nanopart. Res. 2003, 5, 5–15. [Google Scholar] [CrossRef]

- Rachmadini, Y.; Tan, V.B.C.; Tay, T.E. Enhancement of Mechanical Properties of Composites through Incorporation of CNT in VARTM-A Review. J. Reinf. Plast. Compos. 2010, 29, 2782–2807. [Google Scholar] [CrossRef]

- Yavari, F.; Rafiee, M.A.; Rafiee, J.; Yu, Z.Z.; Koratkar, N. Dramatic increase in fatigue life in hierarchical graphene composites. ACS Appl. Mater. Interfaces 2010, 2, 2738–2743. [Google Scholar] [CrossRef] [PubMed]

- Simmons, C.T.; Darcy, H. Immortalised by his scientific legacy. Hydrogeol. J. 2008, 16, 1023–1038. [Google Scholar] [CrossRef]

| As Received | 0% Graphene | 0.5% Graphene | 0.5% Graphene Bothsides | 1% Graphene | |

|---|---|---|---|---|---|

| 20 J | |||||

| Peak Load (kN) | 6.3 | 5.86 | 5.81 | 5.75 | 5.27 |

| Absorbed energy (J) | 0.1 | 0.49 | 0.14 | 1.44 | 5.75 |

| 40 J | |||||

| Peak Load (kN) | 7.74 | 7.85 | 6.59 | 6.45 | 7.44 |

| Absorbed energy (J) | 12.05 | 11.71 | 13.57 | 18.7 | 14.21 |

| 60 J | |||||

| Peak Load (kN) | 8.23 | 7.92 | 8.4 | 7.71 | 6.53 |

| Absorbed energy (J) | 26.48 | 29.86 | 21.1 | 14.33 | 24.93 |

| 80 J | |||||

| Peak Load (kN) | 10.29 | 10.07 | 9.02 | 7.95 | 9.11 |

| Absorbed energy (J) | 24.12 | 39.02 | 29.1 | 33.55 | 23.79 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umer, R. Manufacturing and Mechanical Properties of Graphene Coated Glass Fabric and Epoxy Composites. J. Compos. Sci. 2018, 2, 17. https://doi.org/10.3390/jcs2020017

Umer R. Manufacturing and Mechanical Properties of Graphene Coated Glass Fabric and Epoxy Composites. Journal of Composites Science. 2018; 2(2):17. https://doi.org/10.3390/jcs2020017

Chicago/Turabian StyleUmer, Rehan. 2018. "Manufacturing and Mechanical Properties of Graphene Coated Glass Fabric and Epoxy Composites" Journal of Composites Science 2, no. 2: 17. https://doi.org/10.3390/jcs2020017

APA StyleUmer, R. (2018). Manufacturing and Mechanical Properties of Graphene Coated Glass Fabric and Epoxy Composites. Journal of Composites Science, 2(2), 17. https://doi.org/10.3390/jcs2020017