Graphene Nanocomposites for Electromagnetic Interference Shielding—Trends and Advancements

Abstract

:1. Introduction

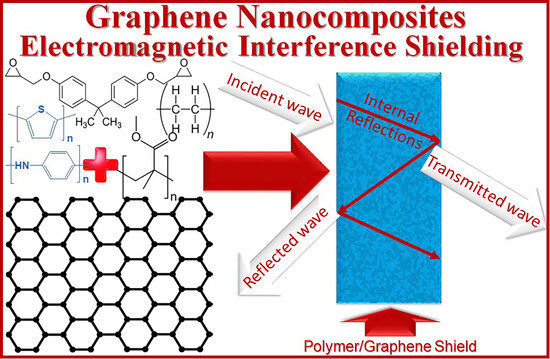

2. Graphene, Modified Forms, and Derived Nanocomposites

3. EMI Shielding

4. Graphene Nanocomposites for EMI Shielding

5. Interfacial Interactions in Polymer/Graphene Nanocomposites

6. Value of Graphene Nanocomposites in EMI Shielding

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bol-Arreba, A.; Ayala, I.G.; Cordero, N.A. Graphene Formation through Spontaneous Exfoliation of Graphite by Chlorosulfonic Acid: A DFT Study. Micro 2023, 3, 143–155. [Google Scholar] [CrossRef]

- Goustouridis, D.; Raptis, I.; Mpatzaka, T.; Fournari, S.; Zisis, G.; Petrou, P.; Beltsios, K.G. Non-Destructive Characterization of Selected Types of Films and Other Layers via White Light Reflectance Spectroscopy (WLRS). Micro 2022, 2, 495–507. [Google Scholar] [CrossRef]

- Lucido, M. Helmholtz–Galerkin Regularizing Technique for the Analysis of the THz-Range Surface-Plasmon-Mode Resonances of a Graphene Microdisk Stack. Micro 2022, 2, 295–312. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M. Shape Memory Graphene Nanocomposites—Fundamentals, Properties, and Significance. Processes 2023, 11, 1171. [Google Scholar] [CrossRef]

- Xu, F.; Gao, M.; Wang, H.; Liu, H.; Yan, F.; Zhao, H.; Yao, Q. Polymer-based graphene composite molding: A review. RSC Adv. 2023, 13, 2538–2551. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, S. Research Progress with Membrane Shielding Materials for Electromagnetic/Radiation Contamination. Membranes 2023, 13, 315. [Google Scholar] [CrossRef]

- Wu, H.; Wu, G.; Zhao, B. Special issue on electromagnetic wave absorbing materials. J. Mater. Sci. Mater. Electron. 2021, 32, 25561. [Google Scholar] [CrossRef]

- Gao, A.; Xu, D.; Li, C.; Wang, Y.; Xu, L. Interfacial reactions in graphene oxide/polyacrylonitrile composite films. Compos. Interfaces 2021, 28, 159–173. [Google Scholar] [CrossRef]

- Cao, L.; Liu, Y.; Zhang, D. Effect of esterification crosslinking on interfacial heat transfer between graphene and phase change material. Compos. Interfaces 2020, 28, 1121–1135. [Google Scholar] [CrossRef]

- Hui, J.; Ren, P.-G.; Sun, Z.-F.; Ren, F.; Xu, L.; Zhang, Z.-P.; Ji, X. Influences of interfacial adhesion on gas barrier property of functionalized graphene oxide/ultra-high-molecular-weight polyethylene composites with segregated structure. Compos. Interfaces 2017, 24, 729–741. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal, V.; Colombo, L.; Gellert, P.; Schwab, M.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Usachov, D.; Adamchuk, V.; Haberer, D.; Grüneis, A.; Sachdev, H.; Preobrajenski, A.; Laubschat, C.; Vyalikh, D. Quasifreestanding single-layer hexagonal boron nitride as a substrate for graphene synthesis. Phys. Rev. B 2010, 82, 075415. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Chen, P.; Li, Y.; Liu, M.; Gao, T.; Ma, D.; Chen, Y.; Cheng, Z.; Qiu, X. Toward single-layer uniform hexagonal boron nitride–graphene patchworks with zigzag linking edges. Nano Lett. 2013, 13, 3439–3443. [Google Scholar] [CrossRef]

- Girit, Ç.Ö.; Meyer, J.C.; Erni, R.; Rossell, M.D.; Kisielowski, C.; Yang, L.; Park, C.-H.; Crommie, M.; Cohen, M.L.; Louie, S.G. Graphene at the edge: Stability and dynamics. Science 2009, 323, 1705–1708. [Google Scholar] [CrossRef]

- Gómez-Navarro, C.; Meyer, J.C.; Sundaram, R.S.; Chuvilin, A.; Kurasch, S.; Burghard, M.; Kern, K.; Kaiser, U. Atomic structure of reduced graphene oxide. Nano Lett. 2010, 10, 1144–1148. [Google Scholar] [CrossRef]

- Huang, P.Y.; Ruiz-Vargas, C.S.; Van Der Zande, A.M.; Whitney, W.S.; Levendorf, M.P.; Kevek, J.W.; Garg, S.; Alden, J.S.; Hustedt, C.J.; Zhu, Y. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature 2011, 469, 389–392. [Google Scholar] [CrossRef]

- Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C.; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N. Electronic confinement and coherence in patterned epitaxial graphene. Science 2006, 312, 1191–1196. [Google Scholar] [CrossRef]

- Avouris, P.; Dimitrakopoulos, C. Graphene: Synthesis and applications. Mater. Today 2012, 15, 86–97. [Google Scholar] [CrossRef]

- Tour, J.M. Top-down versus bottom-up fabrication of graphene-based electronics. Chem. Mater. 2014, 26, 163–171. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Bao, Q.; Duh, J.-G.; Chang, C.-T. Top-down dispersion meets bottom-up synthesis: Merging ultranano silicon and graphene nanosheets for superior hybrid anodes for lithium-ion batteries. J. Mater. Chem. A 2016, 4, 9986–9997. [Google Scholar] [CrossRef]

- Zhang, Z.; Fraser, A.; Ye, S.; Merle, G.; Barralet, J. Top-down bottom-up graphene synthesis. Nano Futures 2019, 3, 042003. [Google Scholar] [CrossRef]

- Wei, C.; Negishi, R.; Ogawa, Y.; Akabori, M.; Taniyasu, Y.; Kobayashi, Y. Turbostratic multilayer graphene synthesis on CVD graphene template toward improving electrical performance. Jpn. J. Appl. Phys. 2019, 58, SIIB04. [Google Scholar] [CrossRef]

- Cabrero-Vilatela, A.; Weatherup, R.S.; Braeuninger-Weimer, P.; Caneva, S.; Hofmann, S. Towards a general growth model for graphene CVD on transition metal catalysts. Nanoscale 2016, 8, 2149–2158. [Google Scholar] [CrossRef]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.-H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef]

- Wang, M.; Jang, S.K.; Jang, W.J.; Kim, M.; Park, S.Y.; Kim, S.W.; Kahng, S.J.; Choi, J.Y.; Ruoff, R.S.; Song, Y.J. A Platform for Large-Scale Graphene Electronics–CVD Growth of Single-Layer Graphene on CVD-Grown Hexagonal Boron Nitride. Adv. Mater. 2013, 25, 2746–2752. [Google Scholar] [CrossRef]

- Liang, J.; Li, L.; Tong, K.; Ren, Z.; Hu, W.; Niu, X.; Chen, Y.; Pei, Q. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS Nano 2014, 8, 1590–1600. [Google Scholar] [CrossRef] [PubMed]

- Narayanam, P.K.; Botcha, V.D.; Ghosh, M.; Major, S.S. Growth and Photocatalytic Behaviour of Transparent Reduced GO-ZnO Nanocomposite Sheets. Nanotechnology 2019, 30, 485601. [Google Scholar] [CrossRef]

- Kausar, A. Potential of polymer/graphene nanocomposite in electronics. Am. J. Nanosci. Nanotechnol. Res. 2018, 6, 55–63. [Google Scholar]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, C.R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.-T.; Chang, Y.; Wang, H.; Liu, G.; Chen, S.; Wang, Y.; Liu, Y.; Cao, A. Folding/aggregation of graphene oxide and its application in Cu2+ removal. J. Colloid Interface Sci. 2010, 351, 122–127. [Google Scholar] [CrossRef]

- Wang, W.-N.; Jiang, Y.; Biswas, P. Evaporation-induced crumpling of graphene oxide nanosheets in aerosolized droplets: Confinement force relationship. J. Phys. Chem. Lett. 2012, 3, 3228–3233. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Xia, G.; Du, M.; Lu, Y.; Xu, H. Scotch-tape-like exfoliation effect of graphene quantum dots for efficient preparation of graphene nanosheets in water. Appl. Surf. Sci. 2019, 483, 52–59. [Google Scholar] [CrossRef]

- Mohan, V.B.; Lau, K.-T.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: A review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Lonkar, S.P.; Deshmukh, Y.S.; Abdala, A.A. Recent advances in chemical modifications of graphene. Nano Res. 2015, 8, 1039–1074. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C.; Mai, Y.-W.; Zhang, Y. Effect of non-covalent functionalisation on thermal and mechanical properties of graphene-polymer nanocomposites. Carbon 2016, 102, 311–318. [Google Scholar] [CrossRef]

- Criado, A.; Melchionna, M.; Marchesan, S.; Prato, M. The covalent functionalization of graphene on substrates. Angew. Chem. Int. Ed. 2015, 54, 10734–10750. [Google Scholar] [CrossRef]

- Sun, L.; Wang, L.; Tian, C.; Tan, T.; Xie, Y.; Shi, K.; Li, M.; Fu, H. Nitrogen-doped graphene with high nitrogen level via a one-step hydrothermal reaction of graphene oxide with urea for superior capacitive energy storage. Rsc. Adv. 2012, 2, 4498–4506. [Google Scholar] [CrossRef]

- Zhou, D.; Cheng, Q.-Y.; Han, B.-H. Solvothermal synthesis of homogeneous graphene dispersion with high concentration. Carbon 2011, 49, 3920–3927. [Google Scholar] [CrossRef]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The role of graphene for electrochemical energy storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef]

- Cui, C.; Huang, J.; Huang, J.; Chen, G. Size separation of mechanically exfoliated graphene sheets by electrophoresis. Electrochim. Acta 2017, 258, 793–799. [Google Scholar] [CrossRef]

- Garlow, J.A.; Barrett, L.K.; Wu, L.; Kisslinger, K.; Zhu, Y.; Pulecio, J.F. Large-area growth of turbostratic graphene on Ni (111) via physical vapor deposition. Sci. Rep. 2016, 6, 19804. [Google Scholar] [CrossRef]

- Nanjundappa, V.; Ramakrishnappa, T.; Kempahanumakkagari, S.; Prakash, H.; Praveen, B. Efficient strategies to produce Graphene and functionalized graphene materials: A review. Appl. Surf. Sci. Adv. 2023, 14, 100386. [Google Scholar]

- Fang, L.; Xue, L.; Yang, P.; Li, X.; Wang, Z. A Facile Route to 4-Polyfluoroarylquinolin-2 (1 H)-ones and 4-Polyfluoroarylcoumarins via C–H Bond Activation. Chem. Lett. 2017, 46, 1223–1226. [Google Scholar] [CrossRef]

- Eigler, S.; Hirsch, A. Chemistry with graphene and graphene oxide—Challenges for synthetic chemists. Angew. Chem. Int. Ed. 2014, 53, 7720–7738. [Google Scholar] [CrossRef]

- Mao, S.; Wen, Z.; Kim, H.; Lu, G.; Hurley, P.; Chen, J. A general approach to one-pot fabrication of crumpled graphene-based nanohybrids for energy applications. ACS Nano 2012, 6, 7505–7513. [Google Scholar] [CrossRef]

- Ebrahimi Naghani, M.; Neghabi, M.; Zadsar, M.; Abbastabar Ahangar, H. Synthesis and characterization of linear/nonlinear optical properties of graphene oxide and reduced graphene oxide-based zinc oxide nanocomposite. Sci. Rep. 2023, 13, 1496. [Google Scholar] [CrossRef]

- Brodie, B.C. XIII. On the atomic weight of graphite. Philos. Trans. R. Soc. Lond. 1859, 149, 249–259. [Google Scholar]

- Feicht, P.; Biskupek, J.; Gorelik, T.E.; Renner, J.; Halbig, C.E.; Maranska, M.; Puchtler, F.; Kaiser, U.; Eigler, S. Brodie’s or Hummers’ method: Oxidation conditions determine the structure of graphene oxide. Chem. A Eur. J. 2019, 25, 8955–8959. [Google Scholar] [CrossRef]

- Sajeev, V.; Rane, S.; Ghosh, D.; Acharyya, N.; Roy Choudhury, P.; Mukherjee, A.; Roy Chowdhury, D. Terahertz sensing of reduced graphene oxide nanosheets using sub-wavelength dipole cavities. Sci. Rep. 2023, 13, 12374. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Lee, K.S. Interlayer Distance Controlled Graphene, Supercapacitor and Method of Producing the Same. Google Patents US20150103469A1, 26 February 2019. [Google Scholar]

- Ke, Q.; Wang, J. Graphene-based materials for supercapacitor electrodes—A review. J. Mater. 2016, 2, 37–54. [Google Scholar] [CrossRef]

- Shen, X.J.; Zeng, X.L.; Dang, C.Y. Graphene Composites. In Handbook of Graphene Set; Scrivener Publishing LLC: Beverly, MA, USA, 2019; Volume 1, pp. 1–25. [Google Scholar]

- Han, J.T.; Jeong, B.H.; Seo, S.H.; Roh, K.C.; Kim, S.; Choi, S.; Woo, J.S.; Kim, H.Y.; Jang, J.I.; Shin, D.-C. Dispersant-free conducting pastes for flexible and printed nanocarbon electrodes. Nat. Commun. 2013, 4, 2491. [Google Scholar] [CrossRef]

- Han, J.T.; Jang, J.I.; Cho, J.Y.; Hwang, J.Y.; Woo, J.S.; Jeong, H.J.; Jeong, S.Y.; Seo, S.H.; Lee, G.-W. Synthesis of nanobelt-like 1-dimensional silver/nanocarbon hybrid materials for flexible and wearable electronics. Sci. Rep. 2017, 7, 4931. [Google Scholar] [CrossRef]

- Panwar, N.; Soehartono, A.M.; Chan, K.K.; Zeng, S.; Xu, G.; Qu, J.; Coquet, P.; Yong, K.-T.; Chen, X. Nanocarbons for biology and medicine: Sensing, imaging, and drug delivery. Chem. Rev. 2019, 119, 9559–9656. [Google Scholar] [CrossRef]

- Freund, P.; Senkovska, I.; Kaskel, S. Switchable conductive MOF–nanocarbon composite coatings as threshold sensing architectures. ACS Appl. Mater. Interfaces 2017, 9, 43782–43789. [Google Scholar] [CrossRef]

- Tang, C.; Titirici, M.-M.; Zhang, Q. A review of nanocarbons in energy electrocatalysis: Multifunctional substrates and highly active sites. J. Energy Chem. 2017, 26, 1077–1093. [Google Scholar] [CrossRef]

- Yanik, M.O.; Yigit, E.A.; Akansu, Y.E.; Sahmetlioglu, E. Magnetic conductive polymer-graphene nanocomposites based supercapacitors for energy storage. Energy 2017, 138, 883–889. [Google Scholar] [CrossRef]

- Ganguly, S. Preparation/processing of polymer-graphene composites by different techniques. In Polymer Nanocomposites Containing Graphene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 45–74. [Google Scholar]

- Sadeghi, A.; Moeini, R.; Yeganeh, J.K. Highly conductive PP/PET polymer blends with high electromagnetic interference shielding performances in the presence of thermally reduced graphene nanosheets prepared through melt compounding. Polym. Compos. 2019, 40, E1461–E1469. [Google Scholar] [CrossRef]

- Gill, Y.Q.; Ehsan, H.; Mehmood, U.; Irfan, M.S.; Saeed, F. A novel two-step melt blending method to prepare nano-silanized-silica reinforced crosslinked polyethylene (XLPE) nanocomposites. Polym. Bull. 2022, 79, 10077–10093. [Google Scholar] [CrossRef]

- Sanes, J.; Sánchez, C.; Pamies, R.; Avilés, M.-D.; Bermúdez, M.-D. Extrusion of polymer nanocomposites with graphene and graphene derivative nanofillers: An overview of recent developments. Materials 2020, 13, 549. [Google Scholar] [CrossRef] [PubMed]

- Tan, B.; Thomas, N.L. A review of the water barrier properties of polymer/clay and polymer/graphene nanocomposites. J. Membr. Sci. 2016, 514, 595–612. [Google Scholar] [CrossRef]

- Kausar, A. In-situ modified graphene reinforced polyamide 1010/poly (ether amide): Mechanical, thermal, and barrier properties. Mater. Res. Innov. 2019, 23, 191–199. [Google Scholar] [CrossRef]

- Owji, E.; Ostovari, F.; Keshavarz, A. Influence of the chemical structure of diisocyanate on the electrical and thermal properties of in situ polymerized polyurethane–graphene composite films. Phys. Chem. Chem. Phys. 2022, 24, 28564–28576. [Google Scholar] [CrossRef]

- Itapu, B.M.; Jayatissa, A.H. A review in graphene/polymer composites. Chem. Sci. Int. J. 2018, 23, 1–16. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, X.; Chen, D.; Chen, G. Polystyrene/graphene composite electrode fabricated by in situ polymerization for capillary electrophoretic determination of bioactive constituents in Herba Houttuyniae. Electrophoresis 2011, 32, 1906–1912. [Google Scholar] [CrossRef] [PubMed]

- Montaina, L.; Carcione, R.; Pescosolido, F.; Montalto, M.; Battistoni, S.; Tamburri, E. Three-dimensional-printed polyethylene glycol diacrylate-polyaniline composites by in situ aniline photopolymerization: An innovative biomaterial for electrocardiogram monitoring systems. ACS Appl. Electron. Mater. 2023, 5, 164–172. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Z.; Xiang, Y.; Sun, Q.; Xia, Y.; Xiong, Z. Superior Enhancement of the UHMWPE Fiber/Epoxy Interface through the Combination of Plasma Treatment and Polypyrrole In-Situ Grown Fibers. Polymers 2023, 15, 2265. [Google Scholar] [CrossRef]

- Kaczor-Urbanowicz, K.E.; Martín Carreras-Presas, C.; Kaczor, T.; Tu, M.; Wei, F.; Garcia-Godoy, F.; Wong, D.T. Emerging technologies for salivaomics in cancer detection. J. Cell. Mol. Med. 2017, 21, 640–647. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Murugadoss, V.; Kong, J.; He, Z.; Mai, X.; Shao, Q.; Chen, Y.; Guo, L.; Liu, C.; Angaiah, S. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon 2018, 140, 696–733. [Google Scholar] [CrossRef]

- González, M.; Pozuelo, J.; Baselga, J. Electromagnetic shielding materials in GHz range. Chem. Rec. 2018, 18, 1000–1009. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Sharma, S.K.; Pradhan, D.; Tai, N.-H. Ultra-light 3D reduced graphene oxide aerogels decorated with cobalt ferrite and zinc oxide perform excellent electromagnetic interference shielding effectiveness. Compos. Part A Appl. Sci. Manuf. 2019, 123, 232–241. [Google Scholar] [CrossRef]

- Jia, Y.; Li, K.; Xue, L.; Ren, J.; Zhang, S.; Li, H. Mechanical and electromagnetic shielding performance of carbon fiber reinforced multilayered (PyC-SiC) n matrix composites. Carbon 2017, 111, 299–308. [Google Scholar] [CrossRef]

- Voicu, V.; Pătru, I.; Dina, L.-A.; Nicolae, P.-M.; Smărăndescu, I.D. Shielding effectiveness evaluation using a non-standardized method. In Proceedings of the 2017 International Conference on Electromechanical and Power Systems (SIELMEN), Iasi, Romania, 11–13 October 2017. [Google Scholar]

- Kashi, S.; Gupta, R.K.; Baum, T.; Kao, N.; Bhattacharya, S.N. Morphology, electromagnetic properties and electromagnetic interference shielding performance of poly lactide/graphene nanoplatelet nanocomposites. Mater. Des. 2016, 95, 119–126. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic shielding effectiveness of carbon fibre reinforced composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Khalid, T.; Albasha, L.; Qaddoumi, N.; Yehia, S. Feasibility study of using electrically conductive concrete for electromagnetic shielding applications as a substitute for carbon-laced polyurethane absorbers in anechoic chambers. IEEE Trans. Antennas Propag. 2017, 65, 2428–2435. [Google Scholar] [CrossRef]

- Kausar, A. Thermally conducting polymer/nanocarbon and polymer/inorganic nanoparticle nanocomposite: A review. Polym. Plast. Technol. Mater. 2020, 59, 895–909. [Google Scholar] [CrossRef]

- Emerson, W. Electromagnetic wave absorbers and anechoic chambers through the years. IEEE Trans. Antennas Propag. 1973, 21, 484–490. [Google Scholar] [CrossRef]

- He, K.; Yu, L.; Sheng, L.; An, K.; Ando, Y.; Zhao, X. Doping effect of single-wall carbon nanotubes on the microwave absorption properties of nanocrystalline barium ferrite. Jpn. J. Appl. Phys. 2010, 49, 125101. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Yan, Q.; Zheng, W.-G.; He, Z.; Yu, Z.-Z. Tough graphene− polymer microcellular foams for electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, X.; Geng, L.; Liu, Z.; Zhang, X.; Li, C.; Zhang, D.; Wang, Z.; Zhao, G. Metallic Ni nanoparticles embedded in hierarchical mesoporous Ni(OH)2: A robust and magnetic recyclable catalyst for hydrogenation of 4-nitrophenol under mild conditions. Polyhedron 2019, 164, 7–12. [Google Scholar] [CrossRef]

- Banerjee, R.; Gebrekrstos, A.; Orasugh, J.T.; Ray, S.S. Nanocarbon-Containing Polymer Composite Foams: A Review of Systems for Applications in Electromagnetic Interference Shielding, Energy Storage, and Piezoresistive Sensors. Ind. Eng. Chem. Res. 2023, 62, 6807–6842. [Google Scholar] [CrossRef]

- Wiroonpochit, P.; Keawmaungkom, S.; Chisti, Y.; Hansupalak, N. A novel preparation of natural rubber films with a conducting nanocarbon network for antistatic applications. Mater. Today Commun. 2023, 34, 105349. [Google Scholar] [CrossRef]

- Kausar, A. Polymeric nanocomposite with polyhedral oligomeric silsesquioxane and nanocarbon (fullerene, graphene, carbon nanotube, nanodiamond)—Futuristic headways. Polym.-Plast. Technol. Mater. 2023, 62, 921–934. [Google Scholar] [CrossRef]

- Rayar, A.; Naveen, C.; Onkarappa, H.; Betageri, V.S.; Prasanna, G. EMI shielding applications of PANI-Ferrite nanocomposite materials: A review. Synth. Met. 2023, 295, 117338. [Google Scholar] [CrossRef]

- Idumah, C.I. Recent advancements in electromagnetic interference shielding of polymer and mxene nanocomposites. Polym. Plast. Technol. Mater. 2023, 62, 19–53. [Google Scholar] [CrossRef]

- Kausar, A. Epitome of Fullerene in Conducting Polymeric Nanocomposite—Fundamentals and Beyond. Polym. Plast. Technol. Mater. 2023, 62, 618–631. [Google Scholar] [CrossRef]

- Luo, J.; Wang, L.; Huang, X.; Li, B.; Guo, Z.; Song, X.; Lin, L.; Tang, L.-C.; Xue, H.; Gao, J. Mechanically durable, highly conductive, and anticorrosive composite fabrics with excellent self-cleaning performance for high-efficiency electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2019, 11, 10883–10894. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Jia, Z.; Feng, A.; Wang, X.; Liu, J.; Zhang, M.; Cao, H.; Wu, G. Synthesis of fish skin-derived 3D carbon foams with broadened bandwidth and excellent electromagnetic wave absorption performance. Carbon 2019, 152, 827–836. [Google Scholar] [CrossRef]

- Sheldon, R.A. The E factor at 30: A passion for pollution prevention. Green Chem. 2023, 25, 1704–1728. [Google Scholar] [CrossRef]

- Amin, A.; Wang, Z.; Shah, A.H.; Chandio, A.A. Exploring the dynamic nexus between renewable energy, poverty alleviation, and environmental pollution: Fresh evidence from E-9 countries. Environ. Sci. Pollut. Res. 2023, 30, 25773–25791. [Google Scholar] [CrossRef]

- Zhu, C.; Wu, J.; Yan, J.; Liu, X. Advanced fiber materials for wearable electronics. Adv. Fiber Mater. 2023, 5, 12–35. [Google Scholar] [CrossRef]

- Idumah, C.I. Recently emerging trends in flame retardancy of phosphorene polymeric nanocomposites and applications. J. Anal. Appl. Pyrolysis 2023, 169, 105855. [Google Scholar] [CrossRef]

- Abubakre, O.K.; Medupin, R.O.; Akintunde, I.B.; Jimoh, O.T.; Abdulkareem, A.S.; Muriana, R.A.; James, J.A.; Ukoba, K.O.; Jen, T.-C.; Yoro, K.O. Carbon nanotube-reinforced polymer nanocomposites for sustainable biomedical applications: A review. J. Sci. Adv. Mater. Devices 2023, 8, 100557. [Google Scholar] [CrossRef]

- Genix, A.-C.; Bocharova, V.; Carroll, B.; Dieudonné-George, P.; Chauveau, E.; Sokolov, A.P.; Oberdisse, J. How Tuning Interfaces Impacts the Dynamics and Structure of Polymer Nanocomposites Simultaneously. ACS Appl. Mater. Interfaces 2023, 15, 7496–7510. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, J.; Liu, M. Interphase in polymer nanocomposites. JACS Au 2022, 2, 280–291. [Google Scholar] [CrossRef]

- Kamal, A.; Ashmawy, M.; Algazzar, A.M.; Elsheikh, A.H. Fabrication techniques of polymeric nanocomposites: A comprehensive review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 4843–4861. [Google Scholar] [CrossRef]

- Gebrekrstos, A.; Ray, S.S. Superior electrical conductivity and mechanical properties of phase-separated polymer blend composites by tuning the localization of nanoparticles for electromagnetic interference shielding applications. J. Polym. Sci. 2023; early view. [Google Scholar] [CrossRef]

- Siavashani, V.S.; Gursoy, N.C.; Montazer, M.; Altay, P. Stretchable electromagnetic interference shielding textile using conductive polymers and metal nanoparticles. Fibers Polym. 2022, 23, 2748–2759. [Google Scholar] [CrossRef]

- Selvaraj, V.K.; Subramanian, J. A comparative study on bio-based PU foam reinforced with nanoparticles for EMI-shielding applications. Polymers 2022, 14, 3344. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Zhang, F.; Li, N.; Shi, J.-F.; Jia, L.-C.; Yan, D.-X.; Li, Z.-M. Carbon-based aerogels and foams for electromagnetic interference shielding: A review. Carbon 2023, 205, 10–26. [Google Scholar] [CrossRef]

- Deeraj, B.; Jayan, J.S.; Raman, A.; Saritha, A.; Joseph, K. Polymeric blends and nanocomposites for high performance EMI shielding and microwave absorbing applications. Compos. Interfaces 2022, 29, 1505–1547. [Google Scholar] [CrossRef]

- Li, Y.-K.; Du, P.-Y.; Wang, Z.-X.; Huang, H.-D.; Jia, L.-C. Aramid nanofiber-induced assembly of graphene nanosheets toward highly thermostable and freestanding films for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107063. [Google Scholar] [CrossRef]

- Das, M.; Sethy, P.P.; Sundaray, B. EMI shielding performance of graphene oxide reinforced polyaniline/polystyrene solution cast thin films. Synth. Met. 2023, 296, 117369. [Google Scholar] [CrossRef]

- Yue, L.; Jayapal, M.; Cheng, X.; Zhang, T.; Chen, J.; Ma, X.; Dai, X.; Lu, H.; Guan, R.; Zhang, W. Highly dispersed ultra-small nano Sn-SnSb nanoparticles anchored on N-doped graphene sheets as high performance anode for sodium ion batteries. Appl. Surf. Sci. 2020, 512, 145686. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, H.; Liu, Z.; Jiang, R.; Zhou, X. Functional composite electromagnetic shielding materials for aerospace, electronics and wearable fields. Mater. Today Commun. 2022, 33, 104498. [Google Scholar] [CrossRef]

- Al-Amri, A.M. Recent Progress in Printed Photonic Devices: A Brief Review of Materials, Devices, and Applications. Polymers 2023, 15, 3234. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Yip, M.; Tai, N. Electromagnetic interference shielding efficiency of polyaniline composites filled with graphene decorated with metallic nanoparticles. Compos. Sci. Technol. 2013, 80, 80–86. [Google Scholar] [CrossRef]

- Modak, P.; Kondawar, S.B.; Nandanwar, D. Synthesis and characterization of conducting polyaniline/graphene nanocomposites for electromagnetic interference shielding. Procedia Mater. Sci. 2015, 10, 588–594. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Yi, D.; Zhai, W.; Wei, X.; Zheng, W. Strong flexible polymer/graphene composite films with 3D saw-tooth folding for enhanced and tunable electromagnetic shielding. Carbon 2017, 113, 55–62. [Google Scholar] [CrossRef]

- Khasim, S. Polyaniline-Graphene nanoplatelet composite films with improved conductivity for high performance X-band microwave shielding applications. Results Phys. 2019, 12, 1073–1081. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, H.; Zhou, Z.; Bi, K. Fabrication and Electromagnetic Interference Shielding Properties of a Fe 3 O 4/Polythiophene/Au Nanocomposite Film Coated by Epoxy Resin. In Proceedings of the 2023 IEEE 18th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Jeju Island, Republic of Korea, 14–17 May 2023. [Google Scholar]

- Joshi, A.; Srivastava, R.; Dhyani, R.; Joshi, C.S. Structural, magnetic, and dielectric properties of yttrium doped cobalt ferrite and their nanocomposites with polythiophene. J. Magn. Magn. Mater. 2023, 578, 170812. [Google Scholar] [CrossRef]

- Chen, C.; Feng, W.; Wu, W.; Yu, Y.; Qian, G.; Fu, L.; Min, D. A highly strong PEDOT modified wood towards efficient electromagnetic interference shielding. Ind. Crops Prod. 2023, 202, 117109. [Google Scholar] [CrossRef]

- Orasugh, J.T.; Ray, S.S. Functional and Structural Facts of Effective Electromagnetic Interference Shielding Materials: A Review. ACS Omega 2023, 8, 8134–8158. [Google Scholar] [CrossRef]

- Guo, R.; Li, B.; Lu, T.; Lin, T.; Andre, J.; Zhang, C.; Zhi, L.; Chen, Z. Molecular Orientations at Buried Conducting Polymer/Graphene Interfaces. Macromolecules 2021, 54, 4050–4060. [Google Scholar] [CrossRef]

- Jalali, A.; Zhang, R.; Rahmati, R.; Nofar, M.; Sain, M.; Park, C.B. Recent progress and perspective in additive manufacturing of EMI shielding functional polymer nanocomposites. Nano Res. 2023, 16, 1–17. [Google Scholar] [CrossRef]

- Revanasiddappa, M.; Nayak, H.; Marudhachalam, N.; Venkatasubramanian, A.K.C.; Chandra, A.R.A.; Iyyappan, A.M.; Krishna, S.B.N. Nanoclay-Based Conductive and EMI Shielding Properties of Silver-Decorated Polyaniline and Its Nanocomposites. Mater. Adv. 2023, 1–9. [Google Scholar] [CrossRef]

- Nimra, S.S.; Rehan, Z.; Ali, S.H.; Atir, S.; Fatima, K.; Shahzadi, F.; Shakir, H.F.; Alamir, M.A.; EL-Bagory, T.M.A.A.; Shahid, I. Electrically conductive fibers fabrication and characterization via in-situ polymerization of aniline for the protection against EMI and thermal imaging signals. J. Mater. Res. Technol. 2023, 23, 2399–2409. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Cheng, C.; Song, X.; Hua, C.; Feng, L.; Yang, J.; Jiang, J.; Liu, Y. 3D Printed Epoxy Composite Microsandwich with High Strength, Toughness, and EMI Shielding Performances. Compos. Struct. 2023, 323, 117456. [Google Scholar] [CrossRef]

- Yun, J.; Zhou, C.; Guo, B.; Wang, F.; Zhou, Y.; Ma, Z.; Qin, J. Mechanically strong and multifunctional nano-nickel aerogels based epoxy composites for ultra-high electromagnetic interference shielding and thermal management. J. Mater. Res. Technol. 2023, 24, 9644–9656. [Google Scholar] [CrossRef]

- Duan, N.; Shi, Z.; Wang, J.; Zhang, X.; Zhang, C.; Zhang, C.; Wang, G. Multilayer-structured carbon fiber fabric/graphene oxide/Fe3O4/epoxy composite for highly efficient mechanical and electromagnetic interference shielding. Appl. Surf. Sci. 2023, 613, 156038. [Google Scholar] [CrossRef]

- Bheema, R.K.; Etika, K.C. The influence of hybrid decorated structures on the EMI shielding properties of epoxy composites over the X-Band. Mater. Today Proc. 2023, 76, 398–402. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, W.; Ma, J.; Bai, S.-L.; Ren, Y.; Liu, C.; Simion, D.; Qin, J. π-π stacking interface design for improving the strength and electromagnetic interference shielding of ultrathin and flexible water-borne polymer/sulfonated graphene composites. Carbon 2019, 149, 679–692. [Google Scholar] [CrossRef]

- Hamidinejad, M.; Zhao, B.; Zandieh, A.; Moghimian, N.; Filleter, T.; Park, C.B. Enhanced electrical and electromagnetic interference shielding properties of polymer–graphene nanoplatelet composites fabricated via supercritical-fluid treatment and physical foaming. ACS Appl. Mater. Interfaces 2018, 10, 30752–30761. [Google Scholar] [CrossRef]

- Anderson, L.; Govindaraj, P.; Ang, A.; Mirabedini, A.; Hameed, N. Modelling, Fabrication and Characterization of Graphene/Polymer Nanocomposites for Electromagnetic Interference Shielding Applications. Carbon Trends 2021, 4, 100047. [Google Scholar] [CrossRef]

- Pavlou, C.; Pastore Carbone, M.G.; Manikas, A.C.; Trakakis, G.; Koral, C.; Papari, G.; Andreone, A.; Galiotis, C. Effective EMI shielding behaviour of thin graphene/PMMA nanolaminates in the THz range. Nat. Commun. 2021, 12, 4655. [Google Scholar] [CrossRef]

- Lakshmi, N.; Tambe, P. EMI shielding effectiveness of graphene decorated with graphene quantum dots and silver nanoparticles reinforced PVDF nanocomposites. Compos. Interfaces 2017, 24, 861–882. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Gao, Q.; Zong, M.; Wang, M.; Qin, J. Electrically electromagnetic interference shielding microcellular composite foams with 3D hierarchical graphene-carbon nanotube hybrids. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105773. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, Q.; Yu, C.; Pan, X.; Zuo, X.; Liu, J.; Chen, M.; Li, W.; Li, Q.; Liu, L. Flexible Fe3O4/graphene foam/poly dimethylsiloxane composite for high-performance electromagnetic interference shielding. Compos. Sci. Technol. 2020, 189, 108012. [Google Scholar] [CrossRef]

- Jia, H.; Kong, Q.-Q.; Liu, Z.; Wei, X.-X.; Li, X.-M.; Chen, J.-P.; Li, F.; Yang, X.; Sun, G.-H.; Chen, C.-M. 3D graphene/carbon nanotubes/polydimethylsiloxane composites as high-performance electromagnetic shielding material in X-band. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105712. [Google Scholar] [CrossRef]

- Liang, C.; Hamidinejad, M.; Ma, L.; Wang, Z.; Park, C.B. Lightweight and flexible graphene/SiC-nanowires/poly (vinylidene fluoride) composites for electromagnetic interference shielding and thermal management. Carbon 2020, 156, 58–66. [Google Scholar] [CrossRef]

- Cheng, K.; Li, H.; Zhu, M.; Qiu, H.; Yang, J. In situ polymerization of graphene-polyaniline@ polyimide composite films with high EMI shielding and electrical properties. RSC Adv. 2020, 10, 2368–2377. [Google Scholar] [CrossRef]

- Liu, Q.; He, X.; Yi, C.; Sun, D.; Chen, J.; Wang, D.; Liu, K.; Li, M. Fabrication of ultra-light nickel/graphene composite foam with 3D interpenetrating network for high-performance electromagnetic interference shielding. Compos. Part B Eng. 2020, 182, 107614. [Google Scholar] [CrossRef]

- Song, P.; Qiu, H.; Wang, L.; Liu, X.; Zhang, Y.; Zhang, J.; Kong, J.; Gu, J. Honeycomb structural rGO-MXene/epoxy nanocomposites for superior electromagnetic interference shielding performance. Sustain. Mater. Technol. 2020, 24, e00153. [Google Scholar] [CrossRef]

- Navik, R.; Tan, H.; Zhang, H.; Liu, Z.; Xiang, Q.; Shi, L.; Lu, S.; Zhao, Y. Scalable production of polyamide-6/graphene composites with enhanced electromagnetic shielding and thermal conductivity. Chem. Eng. J. 2023, 471, 144445. [Google Scholar] [CrossRef]

- Cao, M.S.; Shu, J.C.; Wang, X.X.; Wang, X.; Zhang, M.; Yang, H.J.; Fang, X.Y.; Yuan, J. Electronic structure and electromagnetic properties for 2D electromagnetic functional materials in gigahertz frequency. Ann. Phys. 2019, 531, 1800390. [Google Scholar] [CrossRef]

- Ge, X.; Chai, Z.; Shi, Q.; Liu, Y.; Wang, W. Graphene superlubricity: A review. Friction 2023, 11, 1953–1973. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Yang, Y.; Zhou, D.; Cui, C.H.; Bianco, E.; Lou, J.; Vajtai, R.; Li, B.; Ajayan, P.M. High strain tolerant EMI shielding using carbon nanotube network stabilized rubber composite. Adv. Mater. Technol. 2017, 2, 1700078. [Google Scholar] [CrossRef]

- Wang, R.; Sun, L.; Zhu, X.; Ge, W.; Li, H.; Li, Z.; Zhang, H.; Huang, Y.; Li, Z.; Zhang, Y.F. Carbon nanotube-based strain sensors: Structures, fabrication, and applications. Adv. Mater. Technol. 2023, 8, 2200855. [Google Scholar] [CrossRef]

- Huang, C.L.; Yang, H.P.; Ye, J.Y.; Fan, Y.C.; Huang, S.P. The cocontinuous morphology induced from the graphene nanosheets percolation network structures in the immiscible high density polyethylene/polyamide 6/graphene nanosheets composites. Polym. Compos. 2023, 44, 4955–4975. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Jang, S.-H.; Hassanzadeh-Aghdam, M.K.; Nankali, M. Developing a high-efficiency predictive model for self-temperature-compensated piezoresistive properties of carbon nanotube/graphene nanoplatelet polymer-based nanocomposites. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107380. [Google Scholar] [CrossRef]

- Zare, Y.; Gharib, N.; Nam, D.-H.; Chang, Y.-W. Predicting of tunneling resistivity between adjacent nanosheets in graphene–polymer systems. Sci. Rep. 2023, 13, 12455. [Google Scholar] [CrossRef]

- Xie, Z.; Chen, H.; Hu, S.; Zhao, H.; Chen, W.; Jiang, D. Graphene/carbon nanotube/polypyrrole composite films for electromagnetic interference shielding. Polym. Compos. 2023, 44, 3798–3807. [Google Scholar] [CrossRef]

- Tarhini, A.; Tehrani-Bagha, A. Advances in Preparation Methods and Conductivity Properties of Graphene-based Polymer Composites. Appl. Compos. Mater. 2023, 1–26. [Google Scholar] [CrossRef]

- Rath, R.; Mohanty, S.; Kumar, P.; Nayak, S.K.; Unnikrishnan, L. Synergistic effect of silica-covered graphene oxide (in-situ) hybrid nanocomposites for use as a polymer electrolyte membrane for fuel cell applications. Surf. Interfaces 2023, 38, 102761. [Google Scholar] [CrossRef]

- Novikov, A.S. Non-Covalent Interactions in Polymers. Polymers 2023, 15, 1139. [Google Scholar] [CrossRef]

- Fu, X.; Lin, J.; Liang, Z.; Yao, R.; Wu, W.; Fang, Z.; Zou, W.; Wu, Z.; Ning, H.; Peng, J. Graphene oxide as a promising nanofiller for polymer composite. Surf. Interfaces 2023, 37, 102747. [Google Scholar] [CrossRef]

- Ma, J.; Meng, Q.; Michelmore, A.; Kawashima, N.; Izzuddin, Z.; Bengtsson, C.; Kuan, H.-C. Covalently bonded interfaces for polymer/graphene composites. J. Mater. Chem. A 2013, 1, 4255–4264. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Tao, M.; Lu, D.; Zheng, W. Chemical functionalization of graphene oxide toward the tailoring of the interface in polymer composites. Compos. Sci. Technol. 2013, 77, 87–94. [Google Scholar] [CrossRef]

- Omana, L.; Chandran, A.; John, R.E.; Wilson, R.; George, K.C.; Unnikrishnan, N.V.; Varghese, S.S.; George, G.; Simon, S.M.; Paul, I. Recent advances in polymer nanocomposites for electromagnetic interference shielding: A Review. ACS Omega 2022, 7, 25921–25947. [Google Scholar] [CrossRef]

- Tian, K.; Hu, D.; Wei, Q.; Fu, Q.; Deng, H. Recent progress on multifunctional electromagnetic interference shielding polymer composites. J. Mater. Sci. Technol. 2023, 134, 106–131. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Ganguly, S.; Das, P.; Das, T.K.; Bose, M.; Singha, N.K.; Das, A.K.; Das, N.C. Fabrication of reduced graphene oxide/silver nanoparticles decorated conductive cotton fabric for high performing electromagnetic interference shielding and antibacterial application. Fibers Polym. 2019, 20, 1161–1171. [Google Scholar] [CrossRef]

- Lin, C.-L.; Li, J.-W.; Chen, Y.-F.; Chen, J.-X.; Cheng, C.-C.; Chiu, C.-W. Graphene Nanoplatelet/Multiwalled Carbon Nanotube/Polypyrrole Hybrid Fillers in Polyurethane Nanohybrids with 3D Conductive Networks for EMI Shielding. ACS Omega 2022, 7, 45697–45707. [Google Scholar] [CrossRef]

- Mondal, S.; Ganguly, S.; Das, P.; Khastgir, D.; Das, N.C. Low percolation threshold and electromagnetic shielding effectiveness of nano-structured carbon based ethylene methyl acrylate nanocomposites. Compos. Part B Eng. 2017, 119, 41–56. [Google Scholar] [CrossRef]

- You, X.; Zhang, Q.; Yang, J.; Dong, S. Review on 3D-printed graphene-reinforced composites for structural applications. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107420. [Google Scholar] [CrossRef]

- Moussa, M.; El-Kady, M.F.; Zhao, Z.; Majewski, P.; Ma, J. Recent progress and performance evaluation for polyaniline/graphene nanocomposites as supercapacitor electrodes. Nanotechnology 2016, 27, 442001. [Google Scholar] [CrossRef]

- Weerasinghe, A.; Lu, C.-T.; Maroudas, D.; Ramasubramaniam, A. Multiscale shear-lag analysis of stiffness enhancement in polymer–graphene nanocomposites. ACS Appl. Mater. Interfaces 2017, 9, 23092–23098. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, D. Advances in Graphene–Polymer Nanocomposite Foams for Electromagnetic Interference Shielding. Polymers 2023, 15, 3235. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, R.; Wang, Y.; Cao, Y.; Shen, Y.; Huang, Y.; Chen, Y. Recent advances in graphene aerogels as absorption-dominated electromagnetic interference shielding materials. Carbon 2023, 205, 112–137. [Google Scholar] [CrossRef]

- Li, Y.-K.; Li, W.-J.; Wang, Z.-X.; Du, P.-Y.; Xu, L.; Jia, L.-C.; Yan, D.-X. High-efficiency electromagnetic interference shielding and thermal management of high-graphene nanoplate-loaded composites enabled by polymer-infiltrated technique. Carbon 2023, 211, 118096. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 2019, 103, 319–373. [Google Scholar] [CrossRef]

- Wu, G.; Jia, Z.; Zhou, X.; Nie, G.; Lv, H. Interlayer controllable of hierarchical MWCNTs@ C@ FexOy cross-linked composite with wideband electromagnetic absorption performance. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105687. [Google Scholar] [CrossRef]

- Manthiram, A. An outlook on lithium ion battery technology. ACS Cent. Sci. 2017, 3, 1063–1069. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Lan, X.; Wei, C.; Li, X.; Qi, X.; Xu, T.; Li, C.; Li, C.; Wang, Z. MWCNT/NiO-Fe3O4 hybrid nanotubes for efficient electromagnetic wave absorption. J. Alloys Compd. 2018, 748, 111–116. [Google Scholar] [CrossRef]

| Matrix | Nanofiller | Electrical Conductivity | Electromagnetic Interference Shielding (EMI SE) (dB) | Ref. |

|---|---|---|---|---|

| Polyaniline | Graphene | 490.3 S cm−1 | 21.3 | [138] |

| Polyimide/Polyaniline | Graphene | 490.3 S cm−1 | 16.4 | [134] |

| Polyimide/Polyaniline | Graphene/Fe3O4 | 2.5 S cm−1 | 32.4 | [139] |

| Polyamide 6 | Graphene | 29.6 S·m−1 | 41.8 | [141] |

| Polyurethane | Graphene | 460.0 S cm−1 | 30.7 | [140] |

| Poly(vinylidene fluoride) | Graphene | 0.015 S cm−1 | 32.5 | [137] |

| Poly(methyl methacrylate) | Graphene | 0.013 S cm−1 | 47.5 | [134] |

| Poly(methyl methacrylate) | Reduced graphene | 0.0292 S cm−1 | 43.4 | [134] |

| Poly(methyl methacrylate) | Reduced graphene | 0.0015 S cm−1 | 26.2 | [134] |

| Poly(dimethyl sulfoxide) | Graphene/Fe3O4 | 25 S cm−1 | 249 | [135] |

| Poly(dimethyl sulfoxide) | Graphene | 0.20 S cm−1 | 54.4 | [136] |

| Epoxy | Reduced graphene oxide | 3.87 S cm−1 | 55.0 | [140] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M.H.; Lam, T.D. Graphene Nanocomposites for Electromagnetic Interference Shielding—Trends and Advancements. J. Compos. Sci. 2023, 7, 384. https://doi.org/10.3390/jcs7090384

Kausar A, Ahmad I, Zhao T, Aldaghri O, Ibnaouf KH, Eisa MH, Lam TD. Graphene Nanocomposites for Electromagnetic Interference Shielding—Trends and Advancements. Journal of Composites Science. 2023; 7(9):384. https://doi.org/10.3390/jcs7090384

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, Tingkai Zhao, Osamah Aldaghri, Khalid H. Ibnaouf, M. H. Eisa, and Tran Dai Lam. 2023. "Graphene Nanocomposites for Electromagnetic Interference Shielding—Trends and Advancements" Journal of Composites Science 7, no. 9: 384. https://doi.org/10.3390/jcs7090384