Facile Fabrication of Absorption-Dominated Biodegradable Poly(lactic acid)/Polycaprolactone/Multi-Walled Carbon Nanotube Foams towards Electromagnetic Interference Shielding

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Samples Preparation

2.3. Methods of Characterization

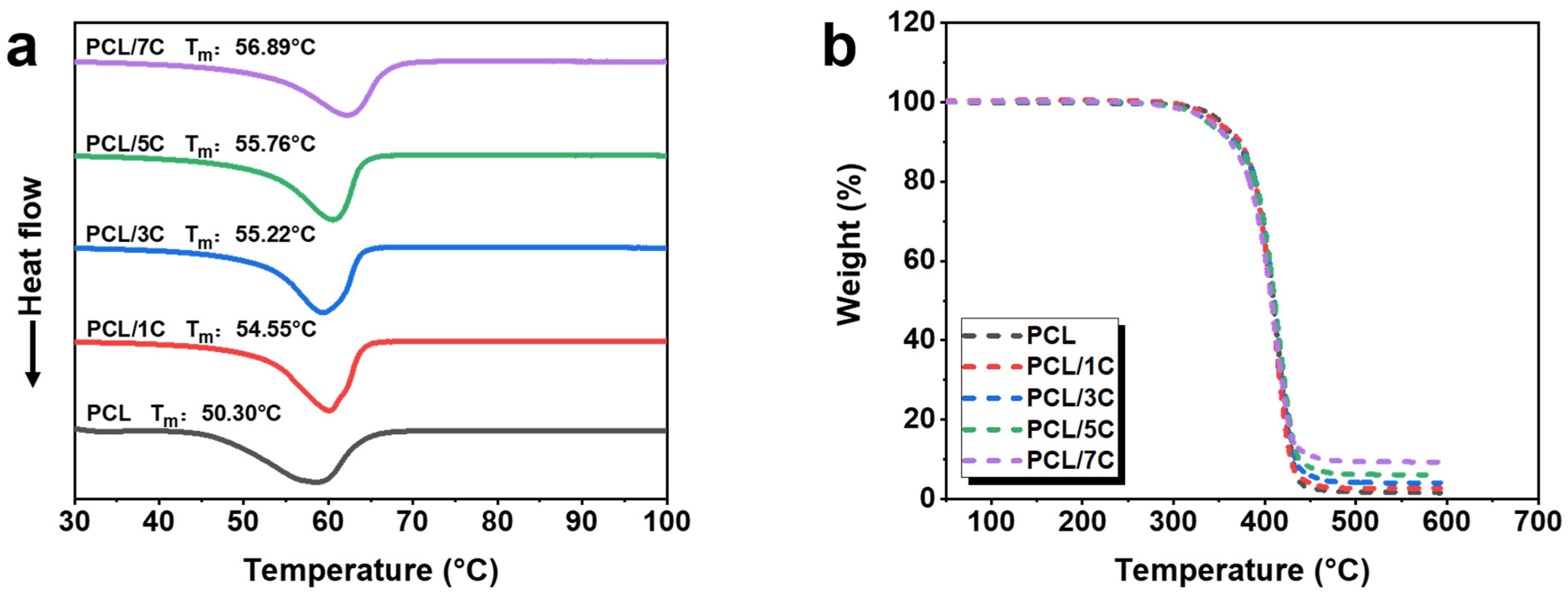

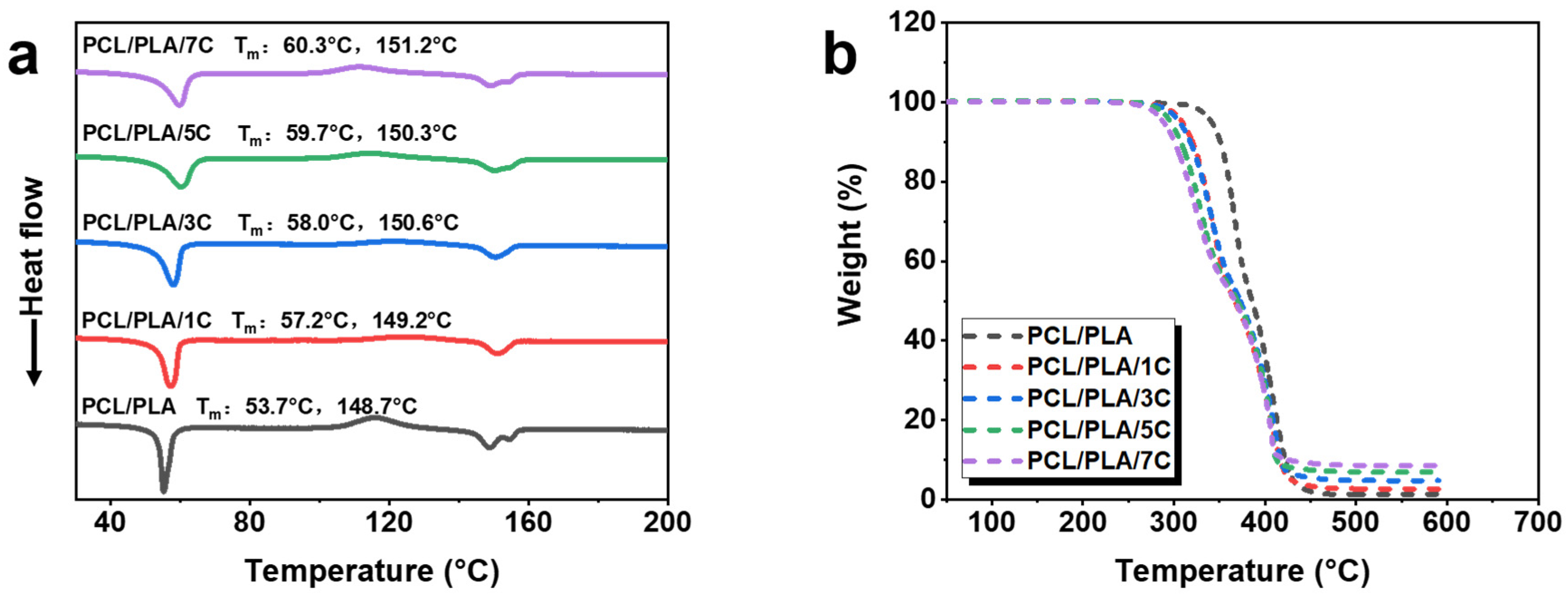

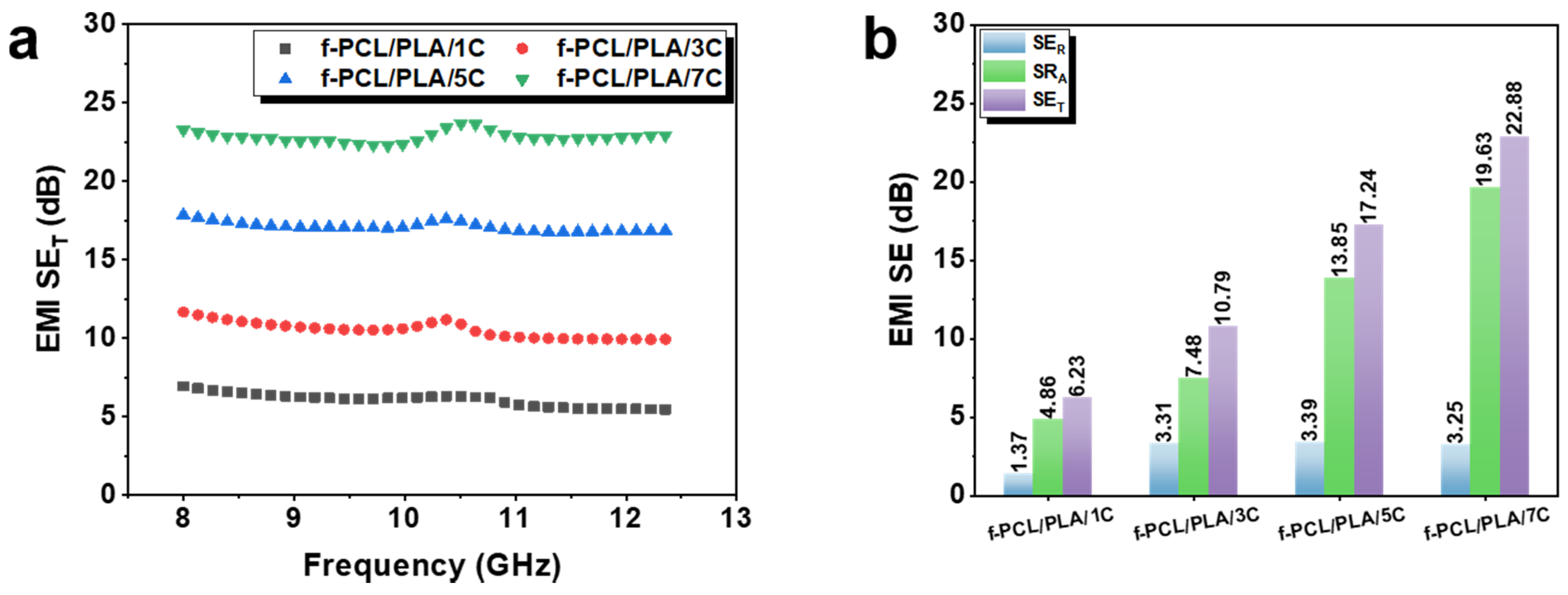

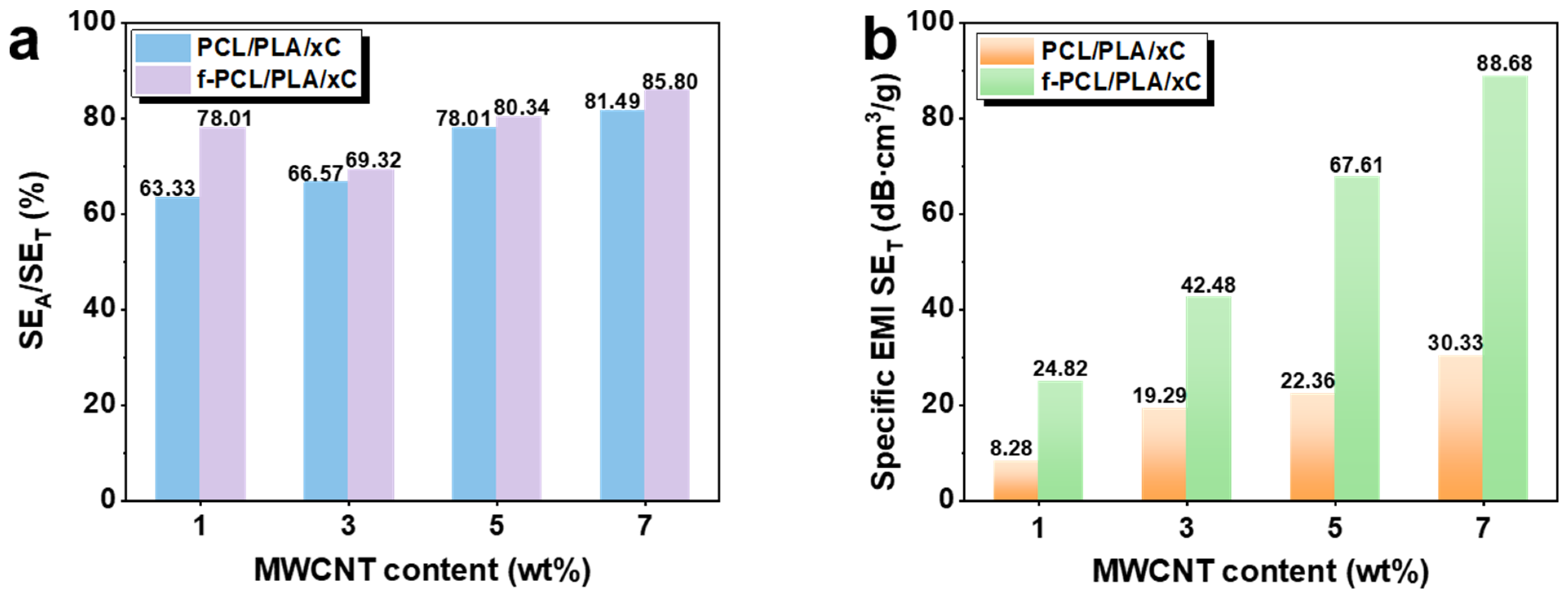

3. Phase Morphology and Crystal Structure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, C.; Gu, Z.; Zhang, Y.; Ma, Z.; Qiu, H.; Gu, J. Structural design strategies of polymer matrix composites for electromagnetic interference shielding: A review. Nano-Micro Lett. 2021, 13, 181. [Google Scholar] [CrossRef]

- Ju, J.; Kuang, T.; Ke, X.; Zeng, M.; Chen, Z.; Zhang, S.; Peng, X. Lightweight multifunctional polypropylene/carbon nanotubes/carbon black nanocomposite foams with segregated structure, ultralow percolation threshold and enhanced electromagnetic interference shielding performance. Compos. Sci. Technol. 2020, 193, 108116. [Google Scholar] [CrossRef]

- Wang, M.; Tang, X.-H.; Cai, J.-H.; Wu, H.; Shen, J.-B.; Guo, S.-Y. Construction, mechanism and prospective of conductive polymer composites with multiple interfaces for electromagnetic interference shielding: A review. Carbon 2021, 177, 377–402. [Google Scholar] [CrossRef]

- Zhan, Y.; Santillo, C.; Meng, Y.; Lavorgna, M. Recent advances and perspectives on silver-based polymer composites for electromagnetic interference shielding. J. Mater. Chem. C 2023, 11, 859–892. [Google Scholar] [CrossRef]

- Luo, J.; Sun, W.; Zhou, H.; Zhang, Y.; Wen, B.; Xin, C. Bioderived and biodegradable poly (3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites based on carbon nanotubes: Microstructure observation and EMI shielding property improvement. ACS Sustain. Chem. Eng. 2021, 9, 10785–10798. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Yan, X.; Liao, X.; Wang, H.; Liu, C.; Wu, H.; Zhou, Y.; Gao, H.; Xia, Y. Construction of in-situ grid conductor skeleton and magnet core in biodegradable poly (butyleneadipate-co-terephthalate) for efficient electromagnetic interference shielding and low reflection. Compos. Sci. Technol. 2023, 240, 110093. [Google Scholar] [CrossRef]

- Luo, J.; Zhu, M.; Wang, L.; Zhou, H.; Wen, B.; Wang, X.; Zhang, Y. CO2-based fabrication of biobased and biodegradable poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/graphene nanoplates nanocomposite foams: Toward EMI shielding application. Polymer 2022, 253, 125034. [Google Scholar] [CrossRef]

- Xu, P.; Huang, B.; Tang, R.; Wang, Z.; Tu, J.; Ding, Y. Improved mechanical and EMI shielding properties of PLA/PCL composites by controlling distribution of PIL-modified CNTs. Adv. Compos. Hybrid Mater. 2022, 5, 991–1002. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, P.; Du, Z.; Liu, C.; Shen, C.; Wang, Y. Electromagnetic interference shielding enhancement of poly (lactic acid)-based carbonaceous nanocomposites by poly (ethylene oxide)-assisted segregated structure: A comparative study of carbon nanotubes and graphene nanoplatelets. Adv. Compos. Hybrid Mater. 2022, 5, 209–219. [Google Scholar] [CrossRef]

- Tao, J.-R.; Tang, X.-H.; He, Q.-M.; Wang, M. Effect of surface conductivity on electromagnetic shielding of multi-walled carbon nanotubes/Poly (ε-caprolactone) composites. Compos. Sci. Technol. 2022, 229, 109715. [Google Scholar] [CrossRef]

- Kashi, S.; Gupta, R.K.; Bhattacharya, S.N.; Varley, R.J. Experimental and simulation study of effect of thickness on performance of (butylene adipate-co-terephthalate) and poly lactide nanocomposites incorporated with graphene as stand-alone electromagnetic interference shielding and metal-backed microwave absorbers. Compos. Sci. Technol. 2020, 195, 108186. [Google Scholar]

- Tian, G.; He, H.; Xu, M.; Liu, Y.; Gao, Q.; Zhu, Z. Ultralow percolation threshold biodegradable PLA/PBS/MWCNTs with segregated conductive networks for high-performance electromagnetic interference shielding applications. J. Appl. Polym. Sci. 2023, 140, e53558. [Google Scholar] [CrossRef]

- Huang, B.; Wang, Z.; Tu, J.; Liu, C.; Xu, P.; Ding, Y. Interfacial distribution and compatibilization of imidazolium functionalized CNTs in poly (lactic acid)/polycaprolactone composites with excellent EMI shielding and mechanical properties. Int. J. Biol. Macromol. 2023, 227, 1182–1190. [Google Scholar] [CrossRef] [PubMed]

- Hou, M.; Feng, Y.; Yang, S.; Wang, J. Multi-hierarchically Structural Polycaprolactone Composites with Tunable Electromagnetic Gradients for Absorption-Dominated Electromagnetic Interference Shielding. Langmuir 2023, 39, 6038–6050. [Google Scholar] [CrossRef]

- Tao, J.-R.; Luo, C.-L.; Huang, M.-L.; Weng, Y.-X.; Wang, M. Construction of unique conductive networks in carbon nanotubes/polymer composites via poly (ε-caprolactone) inducing partial aggregation of carbon nanotubes for microwave shielding enhancement. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107304. [Google Scholar] [CrossRef]

- Wu, B.; Zhu, H.; Yang, Y.; Huang, J.; Liu, T.; Kuang, T.; Jiang, S.; Hejna, A.; Liu, K. Effect of different proportions of CNTs/Fe3O4 hybrid filler on the morphological, electrical and electromagnetic interference shielding properties of poly (lactic acid) nanocomposites. e-Polymers 2023, 23, 20230006. [Google Scholar] [CrossRef]

- Álvarez, M.; Santos, X.; Fest, A.; Sánchez, D.E.; Baselga, J.; Pozuelo, J. Lightweight Nanostructures of Cellulose Nanofibers and Ti3C2Tx MXenes for Their Application in Electromagnetic Interference Shielding. ACS Appl. Eng. Mater. 2023, 1, 1881–1891. [Google Scholar] [CrossRef]

- Yan, K.; Wu, C.; Xie, L.; Zeng, L.; Jiang, Y.; Jiang, Z.; Chang, G.; Xue, B.; Zheng, Q. High EMI shielding effectiveness and superhydrophobic properties based on step-wise asymmetric structure constructed by one-step method. Nano Res. 2023, 16, 10483–10492. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Liu, C.; Wang, H.; Yan, X.; Chai, X.; Chen, Z.; Xia, Y.; Gao, H.; Zhang, H. Constructing 3D expanded graphite-silver segregated network structure for ultra-efficient EMI shielding and low reflection. J. Mater. Res. Technol. 2023, 23, 5115–5126. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Yang, L.; Yin, S. Conductive fabrics based on carbon nanotube/Ti3C2Tx MXene/polyaniline/liquid metal quaternary composites with improved performance of EMI shielding and joule heating. Compos. Commun. 2023, 38, 101476. [Google Scholar] [CrossRef]

- Yao, Y.; Jin, S.; Wang, M.; Gao, F.; Xu, B.; Lv, X.; Shu, Q. MXene hybrid polyvinyl alcohol flexible composite films for electromagnetic interference shielding. Appl. Surf. Sci. 2022, 578, 152007. [Google Scholar] [CrossRef]

- Tan, Z.; Zhao, H.; Sun, F.; Ran, L.; Yi, L.; Zhao, L.; Wu, J. Fabrication of Chitosan/MXene multilayered film based on layer-by-layer assembly: Toward enhanced electromagnetic interference shielding and thermal management capacity. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106809. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Y.-Y.; Song, Y.-N.; Jia, L.-C.; Zhong, G.-J.; Xu, L.; Yan, D.-X.; Lei, J.; Li, Z.-M. Ultrathin, flexible and sandwich-structured PHBV/silver nanowire films for high-efficiency electromagnetic interference shielding. J. Mater. Chem. C 2021, 9, 3307–3315. [Google Scholar] [CrossRef]

- Kim, J.; Kim, G.; Kim, S.-Y.; Lee, S.; Kim, Y.; Lee, J.; Kim, J.; Jung, Y.C.; Kwon, J.; Han, H. Fabrication of highly flexible electromagnetic interference shielding polyimide carbon black composite using hot-pressing method. Compos. Part B Eng. 2021, 221, 109010. [Google Scholar] [CrossRef]

- Zhang, C.; Lv, Q.; Liu, Y.; Wang, C.; Wang, Q.; Wei, H.; Liu, L.; Li, J.; Dong, H. Rational design and fabrication of lightweight porous polyimide composites containing polyaniline modified graphene oxide and multiwalled carbon nanotube hybrid fillers for heat-resistant electromagnetic interference shielding. Polymer 2021, 224, 123742. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Y.; Wang, Z.; Sun, N.; Li, H. Enhancement of electrical conductivity by changing phase morphology for composites consisting of polylactide and poly (ε-caprolactone) filled with acid-oxidized multiwalled carbon nanotubes. ACS Appl. Mater. Interfaces 2011, 3, 4858–4864. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Bai, H.; Luo, Y.; Zhang, Q.; Fu, Q. Achieving a low electrical percolation threshold and superior mechanical performance in poly (l-lactide)/thermoplastic polyurethane/carbon nanotubes composites via tailoring phase morphology with the aid of stereocomplex crystallites. RSC Adv. 2017, 7, 11076–11084. [Google Scholar] [CrossRef]

- Chen, J.; Cui, X.; Zhu, Y.; Jiang, W.; Sui, K. Design of superior conductive polymer composite with precisely controlling carbon nanotubes at the interface of a co-continuous polymer blend via a balance of π-π interactions and dipole-dipole interactions. Carbon 2017, 114, 441–448. [Google Scholar] [CrossRef]

- Chen, J.; Du, X.-C.; Zhang, W.-B.; Yang, J.-H.; Zhang, N.; Huang, T.; Wang, Y. Synergistic effect of carbon nanotubes and carbon black on electrical conductivity of PA6/ABS blend. Compos. Sci. Technol. 2013, 81, 1–8. [Google Scholar] [CrossRef]

- Chen, J.; Shen, Y.; Yang, J.-h.; Zhang, N.; Huang, T.; Wang, Y.; Zhou, Z.-w. Trapping carbon nanotubes at the interface of a polymer blend through adding graphene oxide: A facile strategy to reduce electrical resistivity. J. Mater. Chem. C 2013, 1, 7808–7811. [Google Scholar] [CrossRef]

- Ma, L.; Hamidinejad, M.; Wei, L.; Zhao, B.; Park, C.B. Absorption-dominant EMI shielding polymer composite foams: Microstructure and geometry optimization. Mater. Today Phys. 2023, 30, 100940. [Google Scholar] [CrossRef]

- Park, C.B.; Ma, L.; Hamidinejad, M.; Wei, L. Layered Polymer Composite Foams for Broadband Ultra-Low Reflectance EMI Shielding: A Computationally Guided Fabrication Approach. Mater. Horiz. 2023. [Google Scholar] [CrossRef]

- Fu, H.; Duan, S.; Zhou, H.; Gong, W. Structure design of multi-layered ABS/CNTs composite foams for EMI shielding application with low reflection and high absorption characteristics. Appl. Surf. Sci. 2023, 624, 157168. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, K.; Zhang, X.; Hou, J.; Chen, J. Lightweight electromagnetic interference shielding poly (L-lactic acid)/poly (D-lactic acid)/carbon nanotubes composite foams prepared by supercritical CO2 foaming. Int. J. Biol. Macromol. 2022, 210, 11–20. [Google Scholar] [CrossRef]

- Kuang, T.; Ju, J.; Chen, F.; Liu, X.; Zhang, S.; Liu, T.; Peng, X. Coupled effect of self-assembled nucleating agent, Ni-CNTs and pressure-driven flow on the electrical, electromagnetic interference shielding and thermal conductive properties of poly (lactic acid) composite foams. Compos. Sci. Technol. 2022, 230, 109736. [Google Scholar] [CrossRef]

- Sushmita, K.; Ghosh, D.; Nilawar, S.; Bose, S. Absorption dominated directional electromagnetic interference shielding through asymmetry in a multilayered construct with an exceptionally high green index. ACS Appl. Mater. Interfaces 2022, 14, 49140–49157. [Google Scholar] [CrossRef]

- Bera, R.; Das, A.K.; Maitra, A.; Paria, S.; Karan, S.K.; Khatua, B.B. Salt leached viable porous Fe3O4 decorated polyaniline–SWCNH/PVDF composite spectacles as an admirable electromagnetic shielding efficiency in extended Ku-band region. Compos. Part B Eng. 2017, 129, 210–220. [Google Scholar] [CrossRef]

- Xu, L.; Jia, L.-C.; Yan, D.-X.; Ren, P.-G.; Xu, J.-Z.; Li, Z.-M. Efficient electromagnetic interference shielding of lightweight carbon nanotube/polyethylene composites via compression molding plus salt-leaching. RSC Adv. 2018, 8, 8849–8855. [Google Scholar] [CrossRef]

- Yang, H.; Yu, Z.; Wu, P.; Zou, H.; Liu, P. Electromagnetic interference shielding effectiveness of microcellular polyimide/in situ thermally reduced graphene oxide/carbon nanotubes nanocomposites. Appl. Surf. Sci. 2018, 434, 318–325. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gu, Z.; Huang, J.; He, W.; Liu, P. Rational design of hierarchical yolk-double shell Fe@ NCNs/MnO2 via thermal-induced phase separation toward wideband microwave absorption. Carbon 2023, 204, 305–314. [Google Scholar] [CrossRef]

- Sang, G.; Xu, P.; Yan, T.; Murugadoss, V.; Naik, N.; Ding, Y.; Guo, Z. Interface engineered microcellular magnetic conductive polyurethane nanocomposite foams for electromagnetic interference shielding. Nano-Micro Lett. 2021, 13, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Zhang, Z. Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Xiao, H.; Lv, J.-B.; Tan, W.; He, X.; Chen, M.-H.; Zeng, K.; Hu, J.-H.; Yang, G. Ultrasound-assisted freeze-drying process for polyimide aerogels. Chem. Eng. J. 2022, 450, 138344. [Google Scholar] [CrossRef]

- Duan, H.; Zhu, H.; Gao, J.; Yan, D.-X.; Dai, K.; Yang, Y.; Zhao, G.; Liu, Y.; Li, Z.-M. Asymmetric conductive polymer composite foam for absorption dominated ultra-efficient electromagnetic interference shielding with extremely low reflection characteristics. J. Mater. Chem. A 2020, 8, 9146–9159. [Google Scholar] [CrossRef]

- Zhao, B.; Hamidinejad, M.; Wang, S.; Bai, P.; Che, R.; Zhang, R.; Park, C.B. Advances in electromagnetic shielding properties of composite foams. J. Mater. Chem. A 2021, 9, 8896–8949. [Google Scholar] [CrossRef]

- Kuang, T.; Chang, L.; Chen, F.; Sheng, Y.; Fu, D.; Peng, X. Facile preparation of lightweight high-strength biodegradable polymer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 2016, 105, 305–313. [Google Scholar] [CrossRef]

- Kuang, T.; Zhang, M.; Chen, F.; Fei, Y.; Yang, J.; Zhong, M.; Wu, B.; Liu, T. Creating poly (lactic acid)/carbon nanotubes/carbon black nanocomposites with high electrical conductivity and good mechanical properties by constructing a segregated double network with a low content of hybrid nanofiller. Adv. Compos. Hybrid Mater. 2023, 6, 48. [Google Scholar] [CrossRef]

- Sanchez-Garcia, M.; Lagaron, J.; Hoa, S. Effect of addition of carbon nanofibers and carbon nanotubes on properties of thermoplastic biopolymers. Compos. Sci. Technol. 2010, 70, 1095–1105. [Google Scholar] [CrossRef]

- Ma, Z.; Li, J.; Zhang, J.; He, A.; Dong, Y.; Tan, G.; Ning, M.; Man, Q.; Liu, X. Ultrathin, flexible, and high-strength Ni/Cu/metallic glass/Cu/Ni composite with alternate magneto-electric structures for electromagnetic shielding. J. Mater. Sci. Technol. 2021, 81, 43–50. [Google Scholar] [CrossRef]

- Qi, X.-D.; Yang, J.-H.; Zhang, N.; Huang, T.; Zhou, Z.-W.; Kühnert, I.; Pötschke, P.; Wang, Y. Selective localization of carbon nanotubes and its effect on the structure and properties of polymer blends. Prog. Polym. Sci. 2021, 123, 101471. [Google Scholar] [CrossRef]

- Vega, J.F.; Fernández-Alcázar, J.; López, J.V.; Michell, R.M.; Pérez-Camargo, R.A.; Ruelle, B.; Martínez-Salazar, J.; Arnal, M.L.; Dubois, P.; Müller, A.J. Competition between supernucleation and plasticization in the crystallization and rheological behavior of PCL/CNT-based nanocomposites and nanohybrids. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1310–1325. [Google Scholar] [CrossRef]

- Zong, R.; Hu, X.; Shang, M.; Wu, C.; Shentu, B. Phase Morphology and Conductive Properties of PBT/POE-g-GMA/PP/CNT Nanocomposites with a Tri-Continuous Structure via Thermal Annealing. Ind. Eng. Chem. Res. 2023, 62, 8289–8296. [Google Scholar] [CrossRef]

- Tao, J.-R.; Yang, D.; Yang, Y.; He, Q.-M.; Fei, B.; Wang, M. Migration mechanism of carbon nanotubes and matching viscosity-dependent morphology in Co-continuous Poly(lactic acid)/Poly(ε-caprolactone) blend: Towards electromagnetic shielding enhancement. Polymer 2022, 252, 124963. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Zhang, K.; Shen, Z.; Yu, E.; Zheng, S.; Liu, S.; Yang, J. Heterostructured composite foam with highly efficient absorption-dominant EMI shielding capability and mechanical robustness. Compos. Commun. 2023, 40, 101603. [Google Scholar] [CrossRef]

- Salerno, A.; Zeppetelli, S.; Di Maio, E.; Iannace, S.; Netti, P.A. Processing/structure/property relationship of multiscaled PCL and PCL-HA composite scaffolds prepared via gas foaming and NaCl reverse templating. Biotechnol. Bioeng. 2011, 108, 963–976. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Feng, H.; Zeng, W.; Jin, C.; Kuang, T. Facile Fabrication of Absorption-Dominated Biodegradable Poly(lactic acid)/Polycaprolactone/Multi-Walled Carbon Nanotube Foams towards Electromagnetic Interference Shielding. J. Compos. Sci. 2023, 7, 395. https://doi.org/10.3390/jcs7090395

Liu T, Feng H, Zeng W, Jin C, Kuang T. Facile Fabrication of Absorption-Dominated Biodegradable Poly(lactic acid)/Polycaprolactone/Multi-Walled Carbon Nanotube Foams towards Electromagnetic Interference Shielding. Journal of Composites Science. 2023; 7(9):395. https://doi.org/10.3390/jcs7090395

Chicago/Turabian StyleLiu, Tong, Huiyao Feng, Weiqiang Zeng, Chenhong Jin, and Tairong Kuang. 2023. "Facile Fabrication of Absorption-Dominated Biodegradable Poly(lactic acid)/Polycaprolactone/Multi-Walled Carbon Nanotube Foams towards Electromagnetic Interference Shielding" Journal of Composites Science 7, no. 9: 395. https://doi.org/10.3390/jcs7090395