State of the Art in Metal Matrix Composites Research: A Bibliometric Analysis

Abstract

:1. Introduction

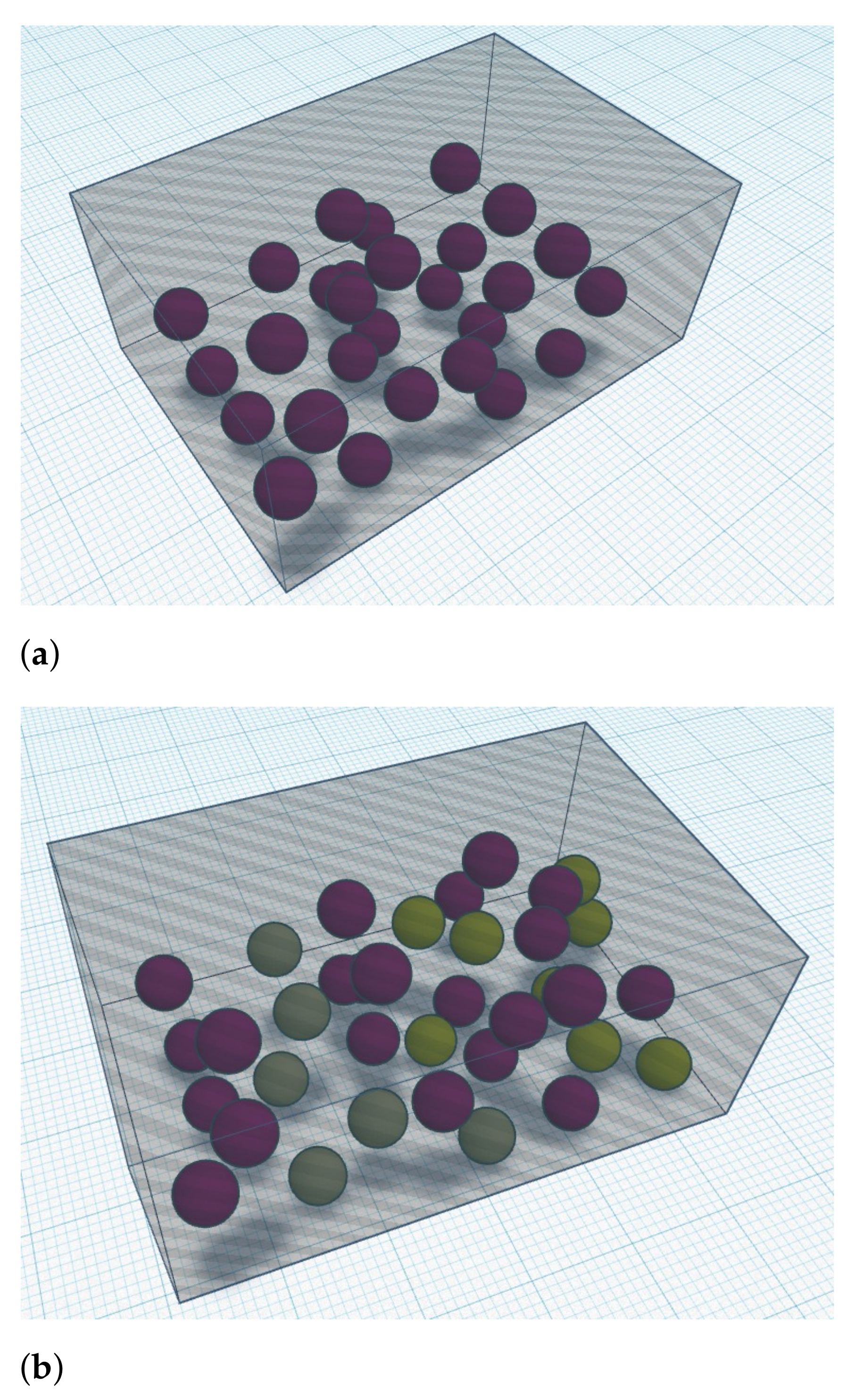

1.1. Metal Matrix Composites

1.2. Bibliometric Studies

1.3. Data Selection and Extraction

2. Publication Distribution along Various Verticals

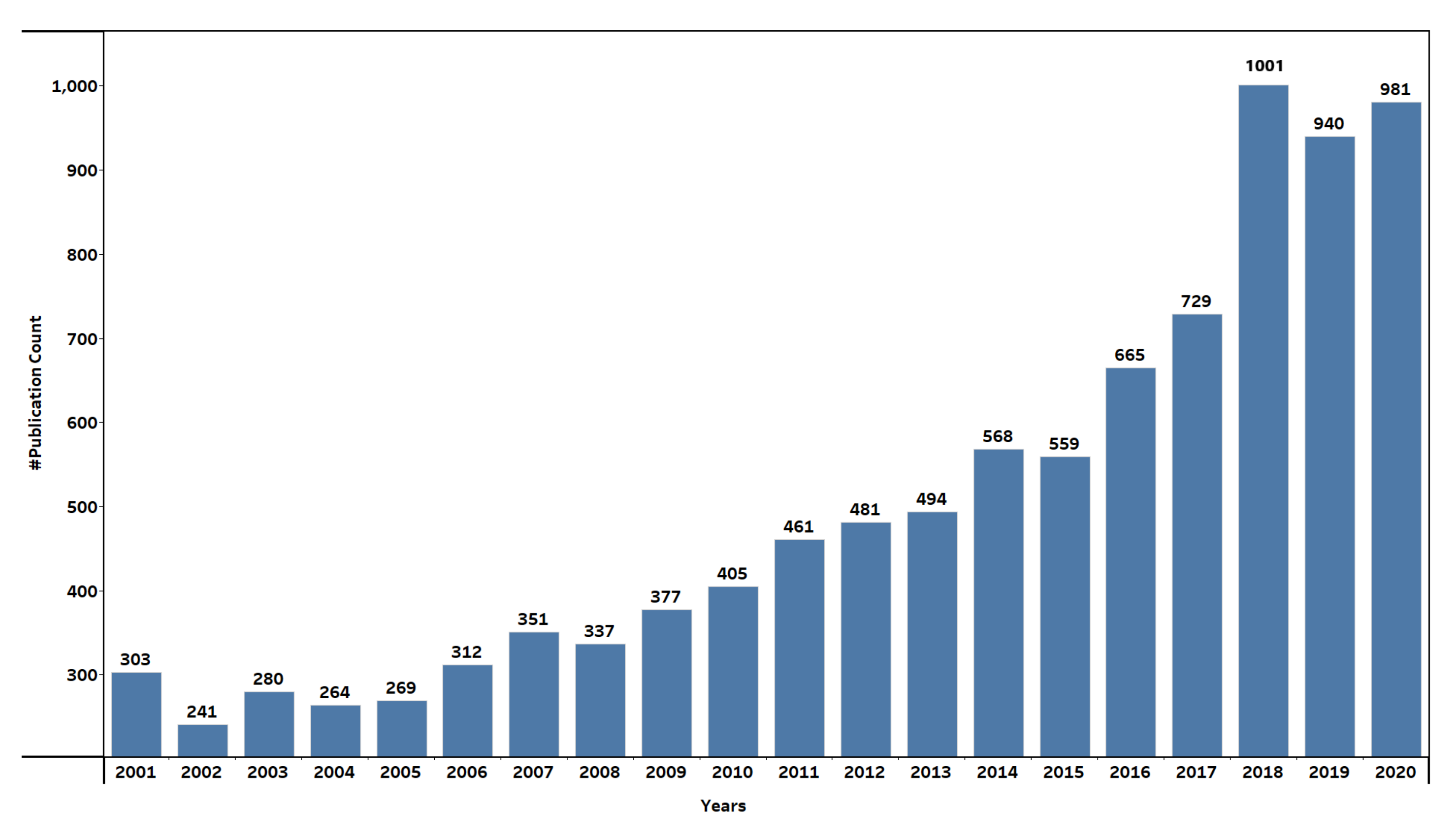

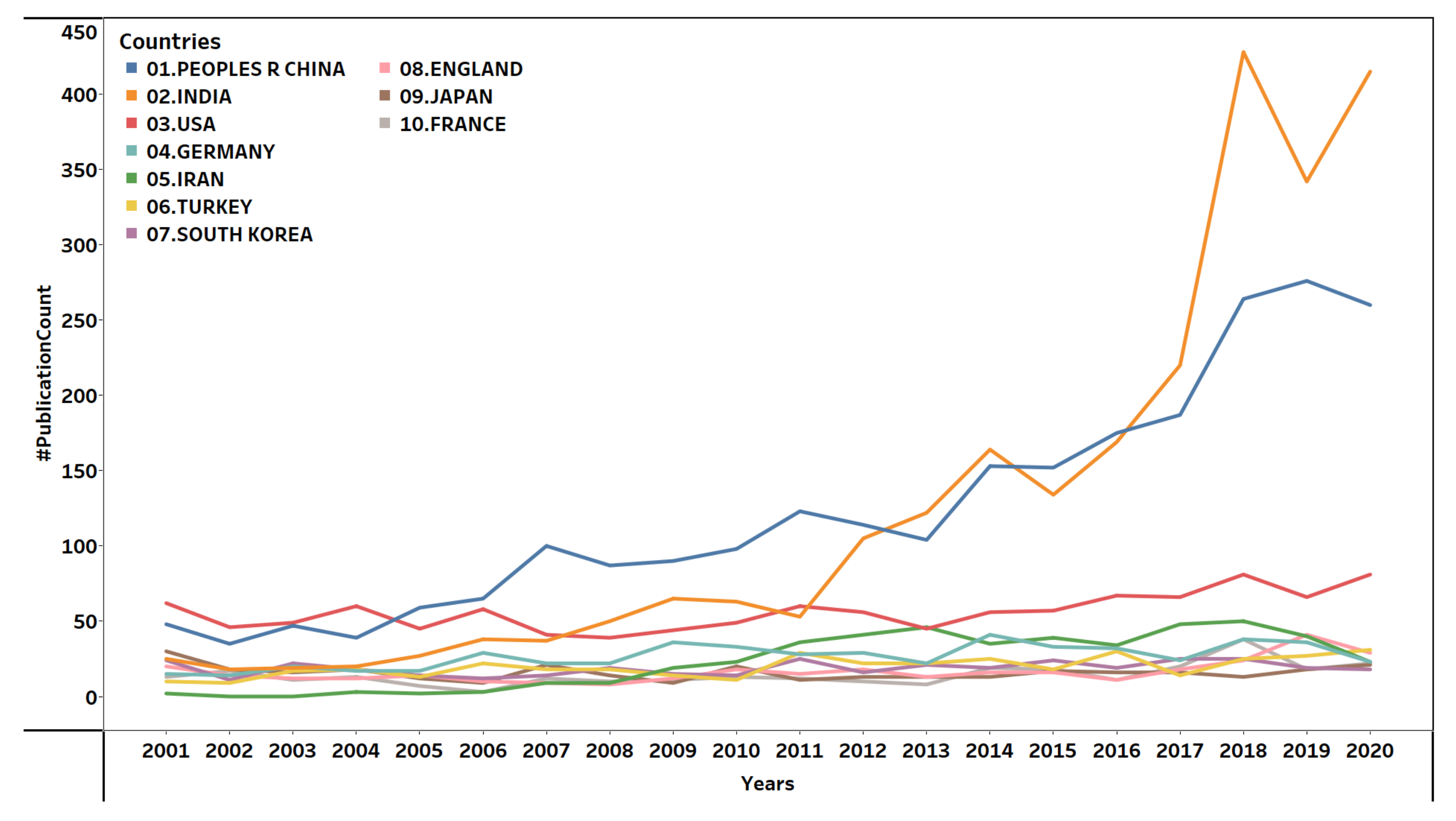

2.1. Year on Year Vertical

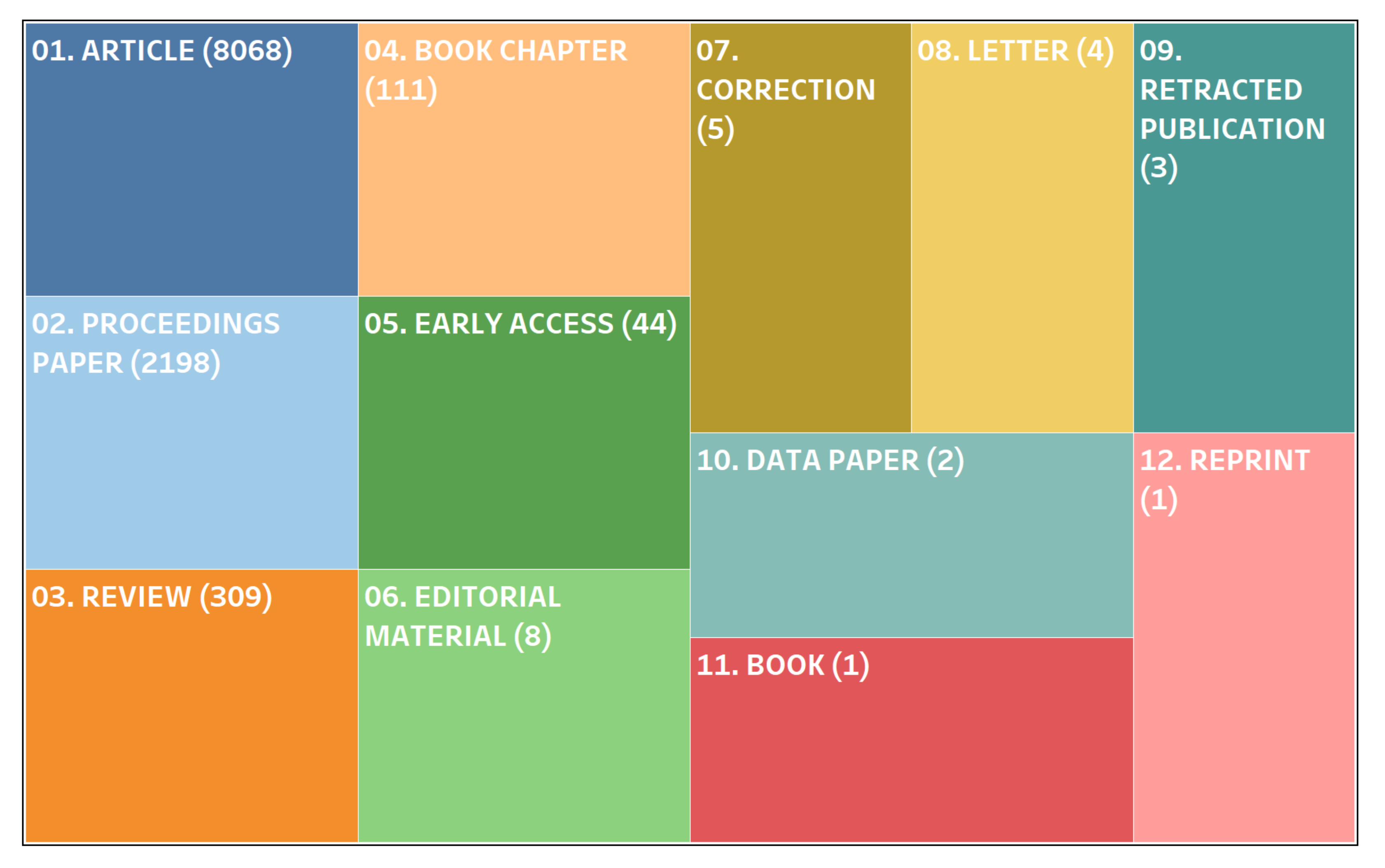

2.2. Publication Types

2.3. Publication Sources

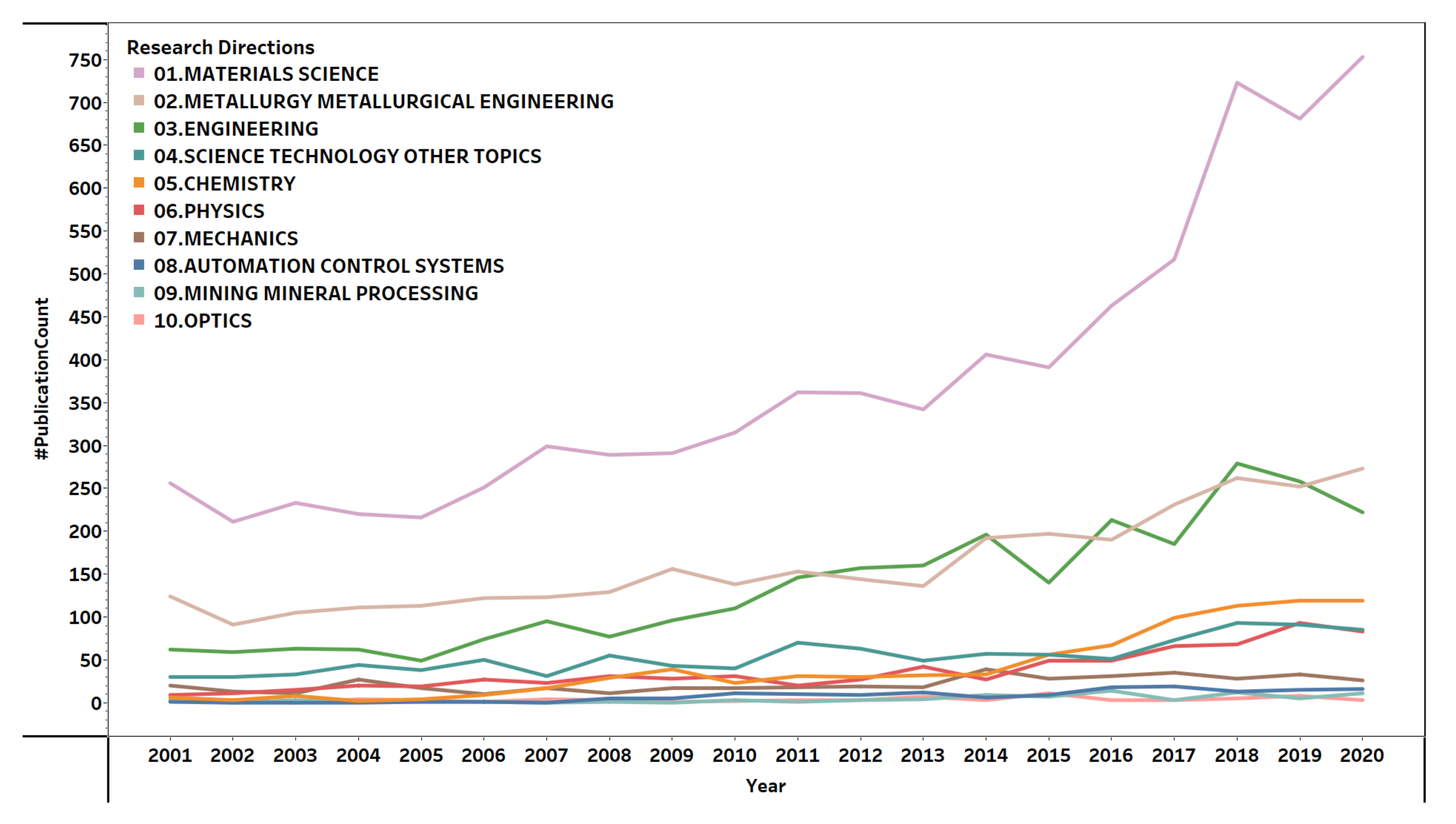

2.4. Research Directions

2.5. Popular Places Vertical

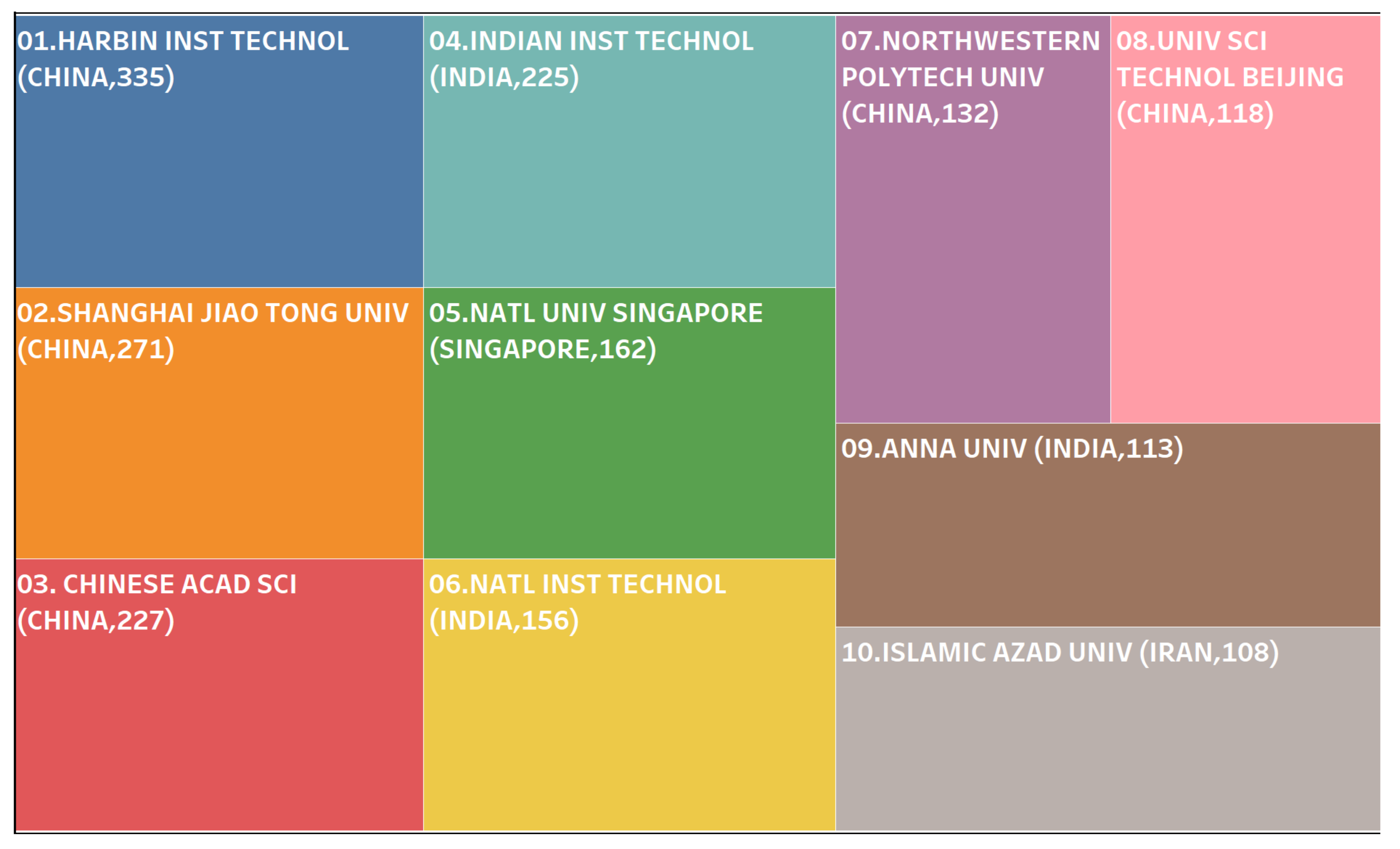

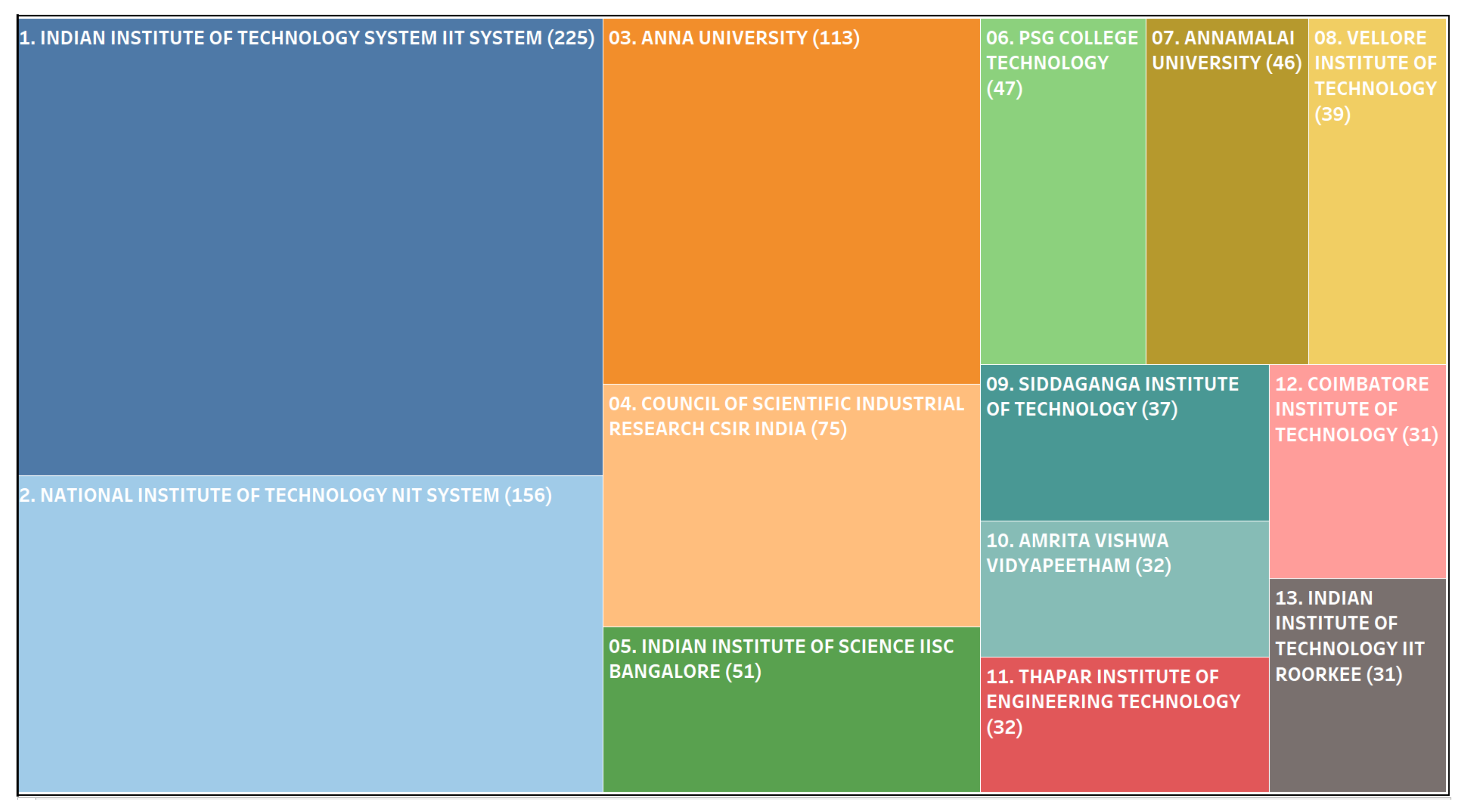

2.6. Productive Organizations and Researchers Vertical

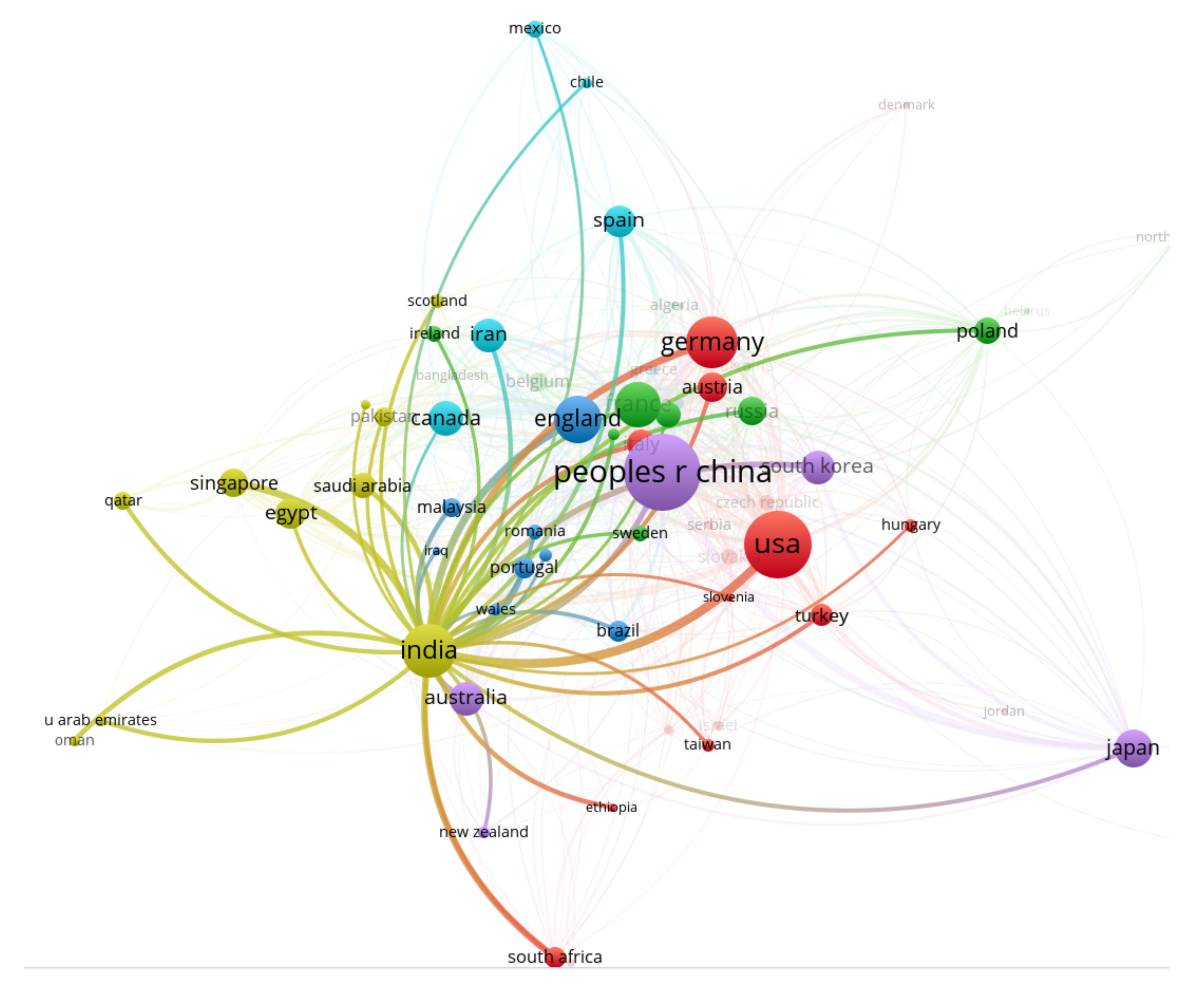

3. Collaboration Analysis

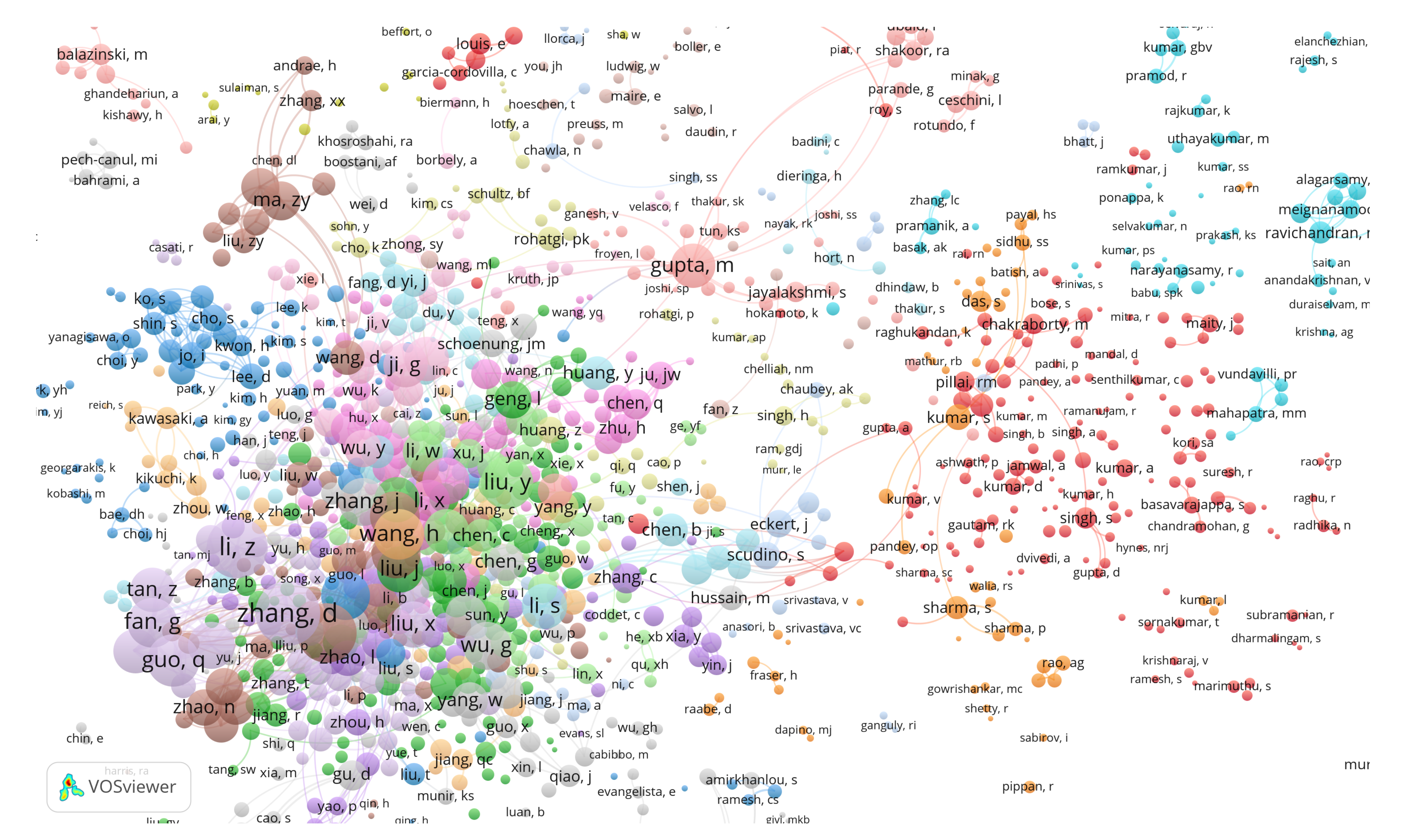

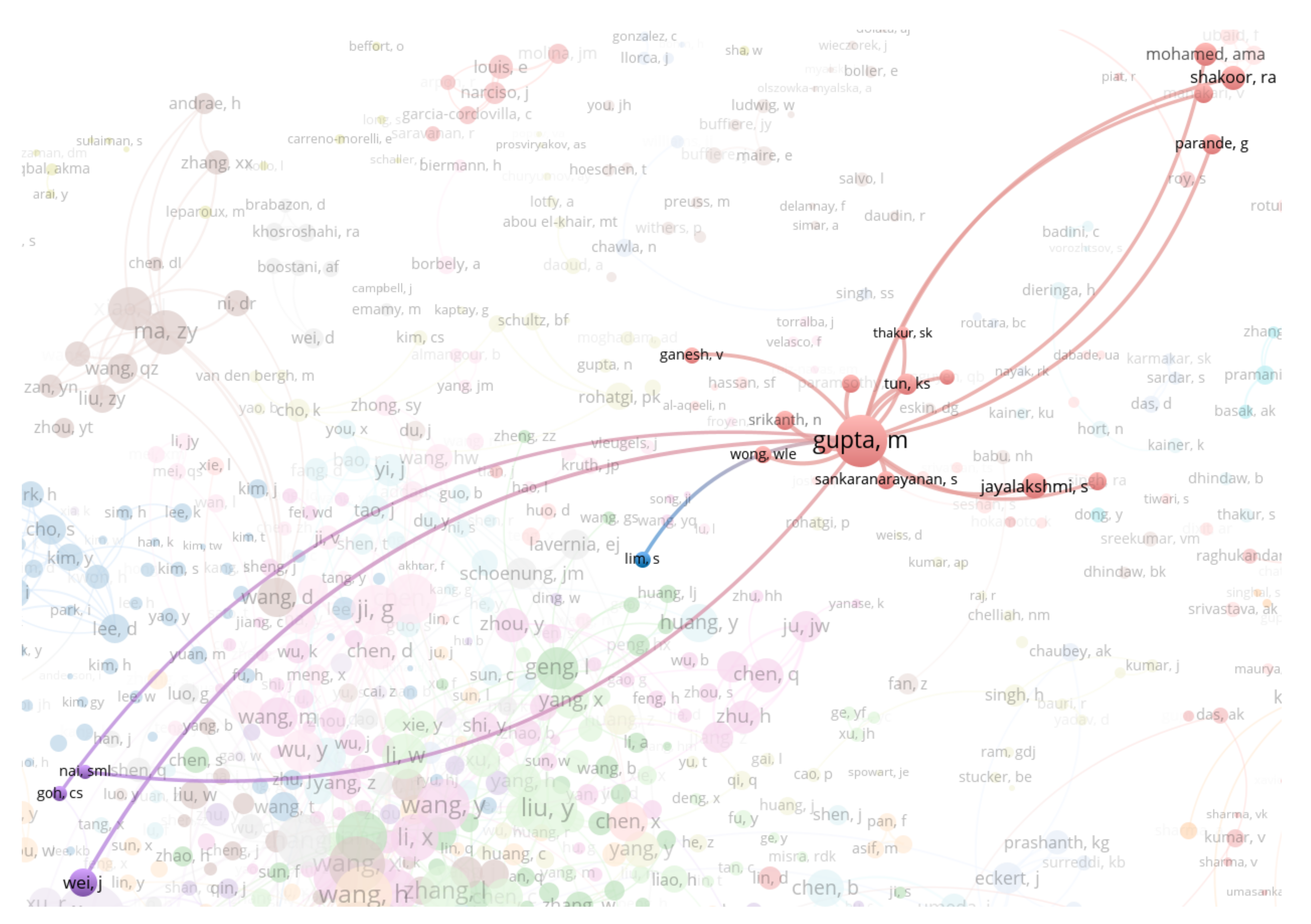

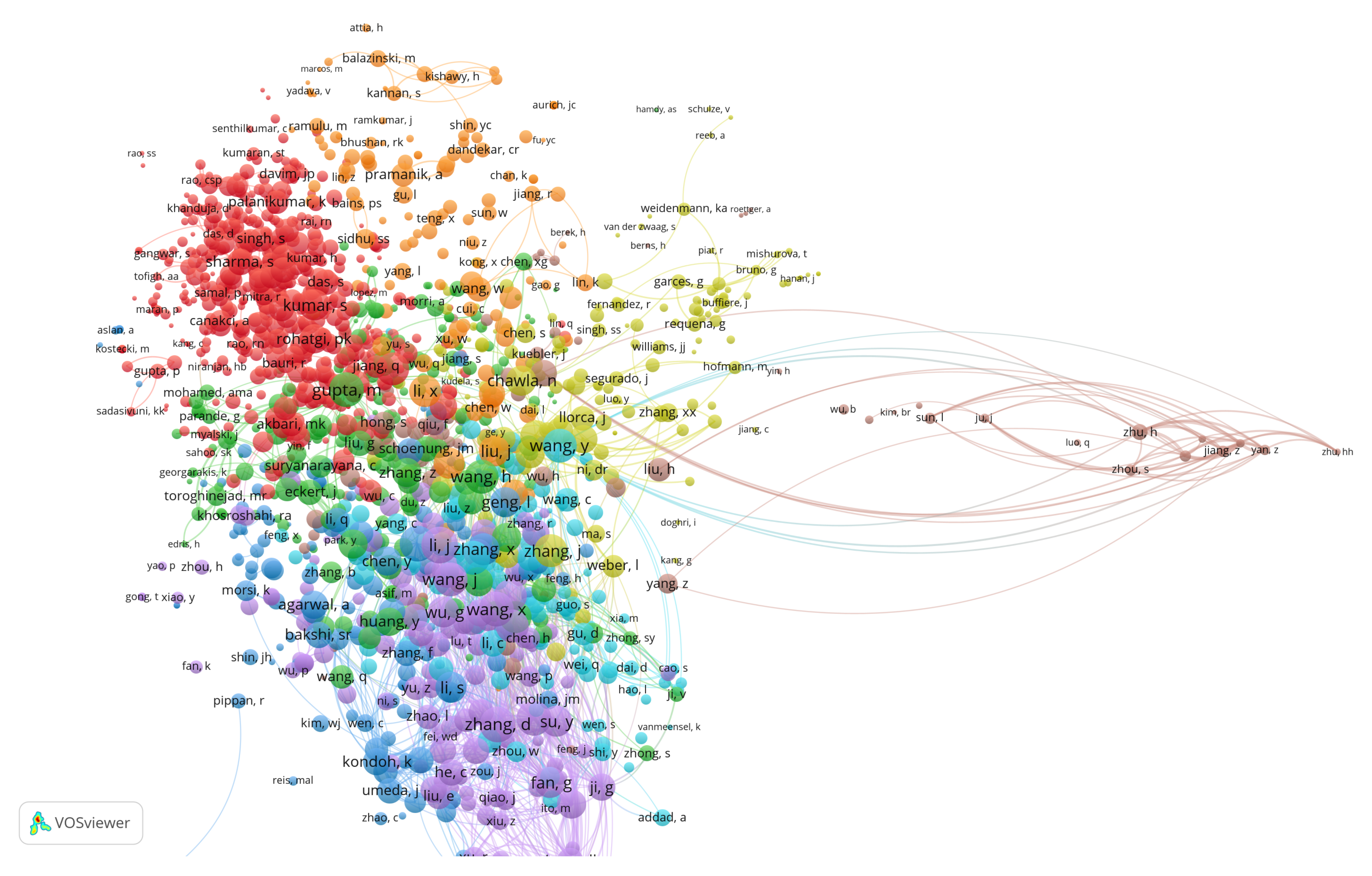

3.1. Collaboration among Researchers

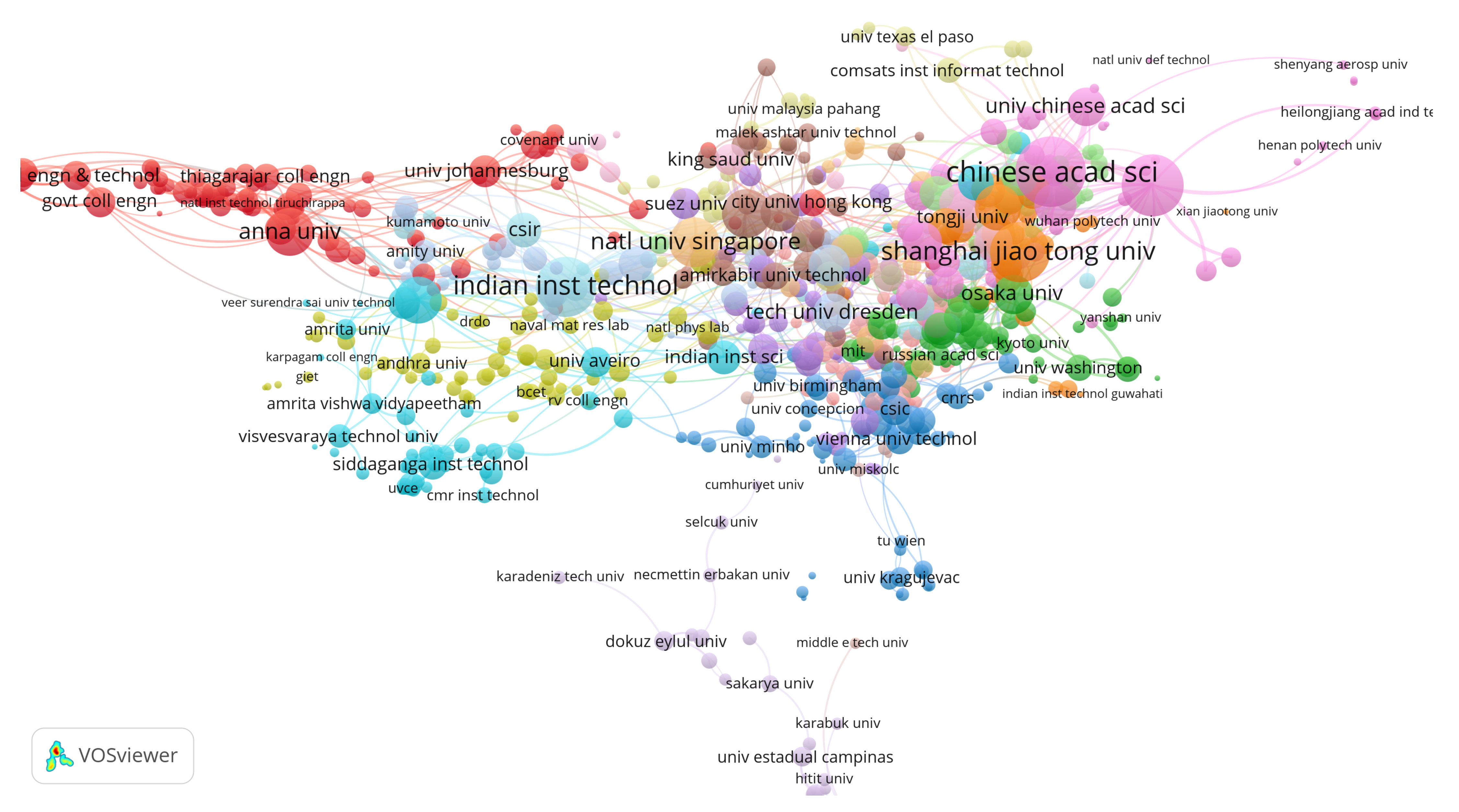

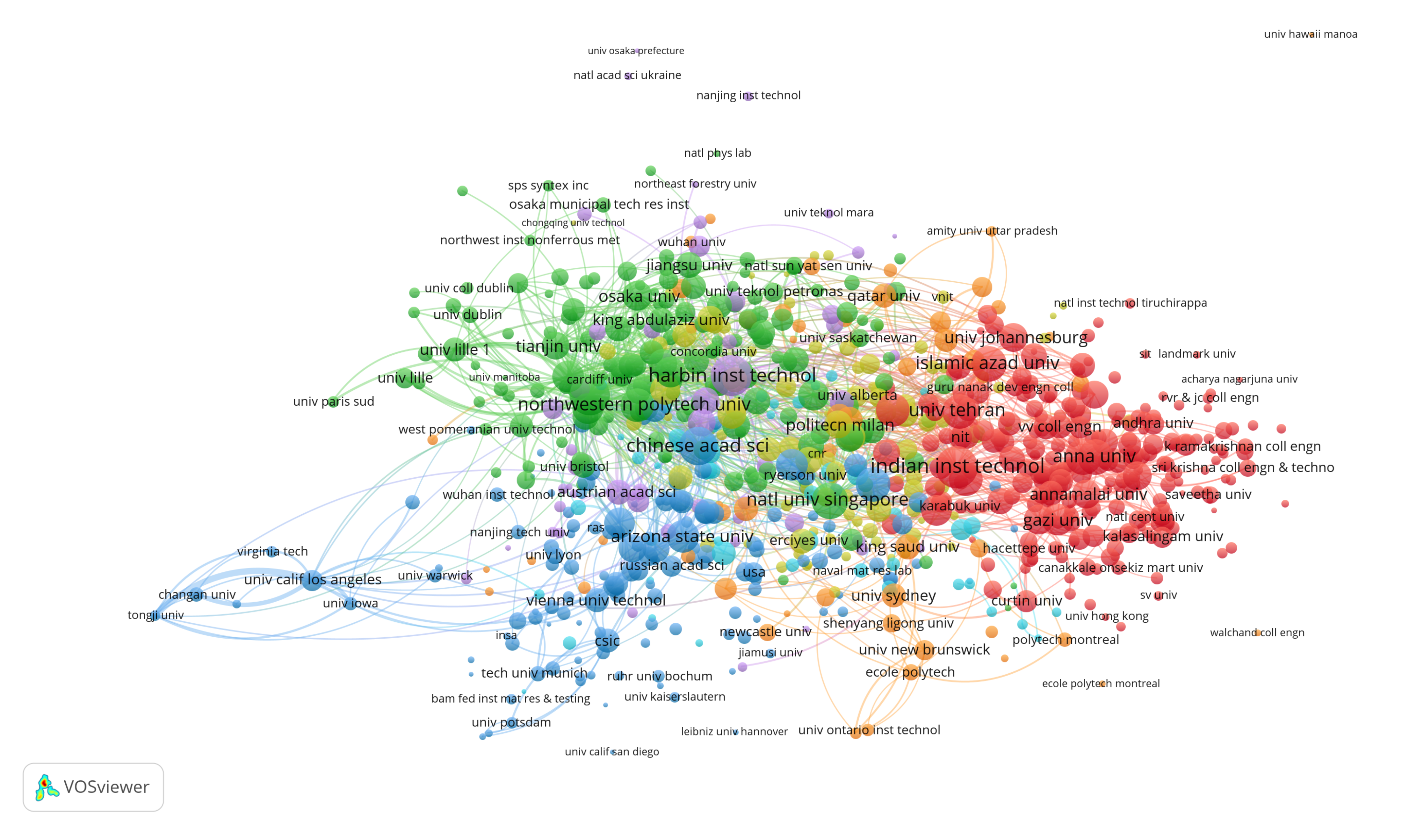

3.2. Collaboration among Organizations

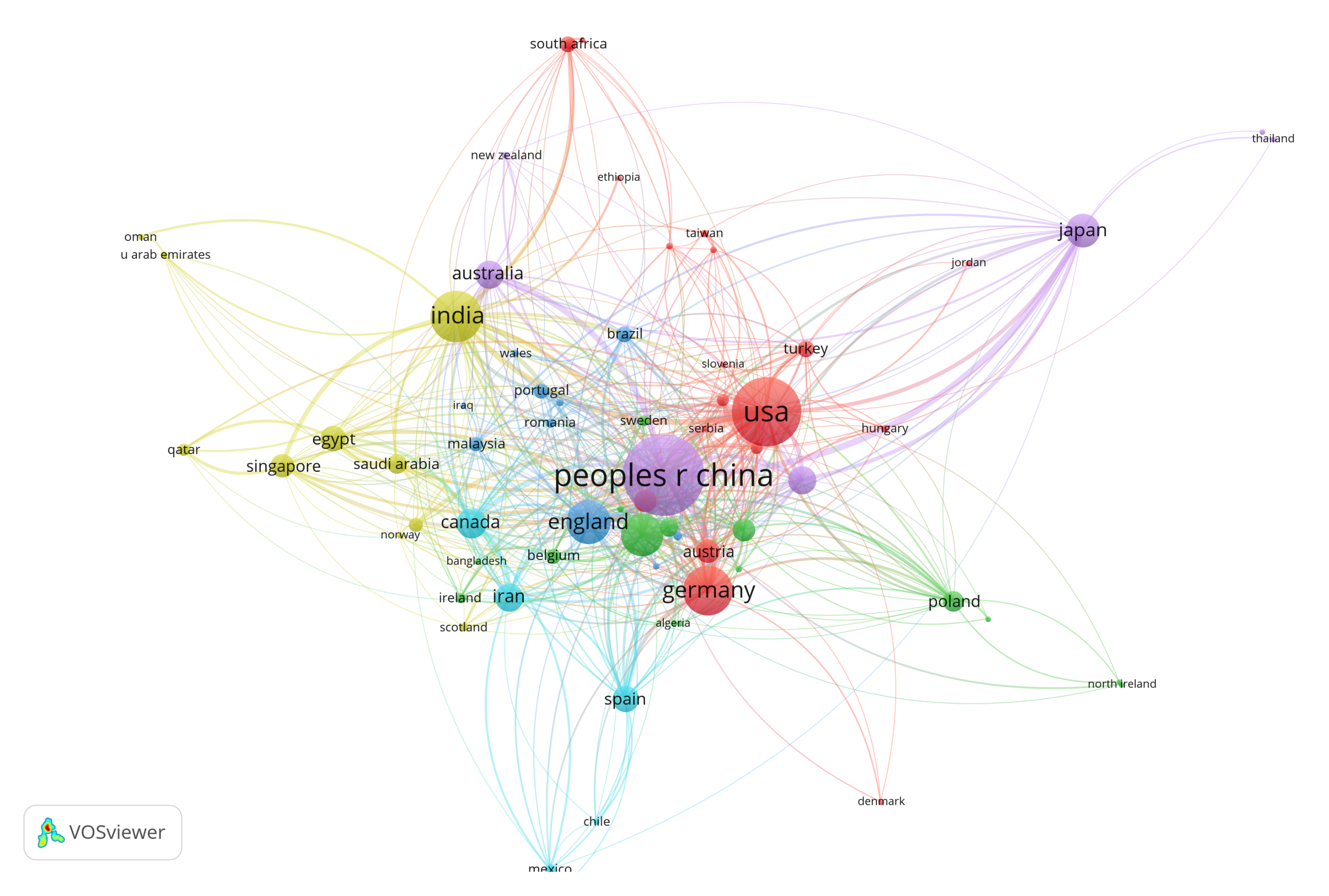

3.3. Collaboration among Places

4. Citation Landscapes

4.1. Citation Landscape of Published Articles

4.2. Citation Landscape of Researchers

4.3. Citation Landscape of Organizations

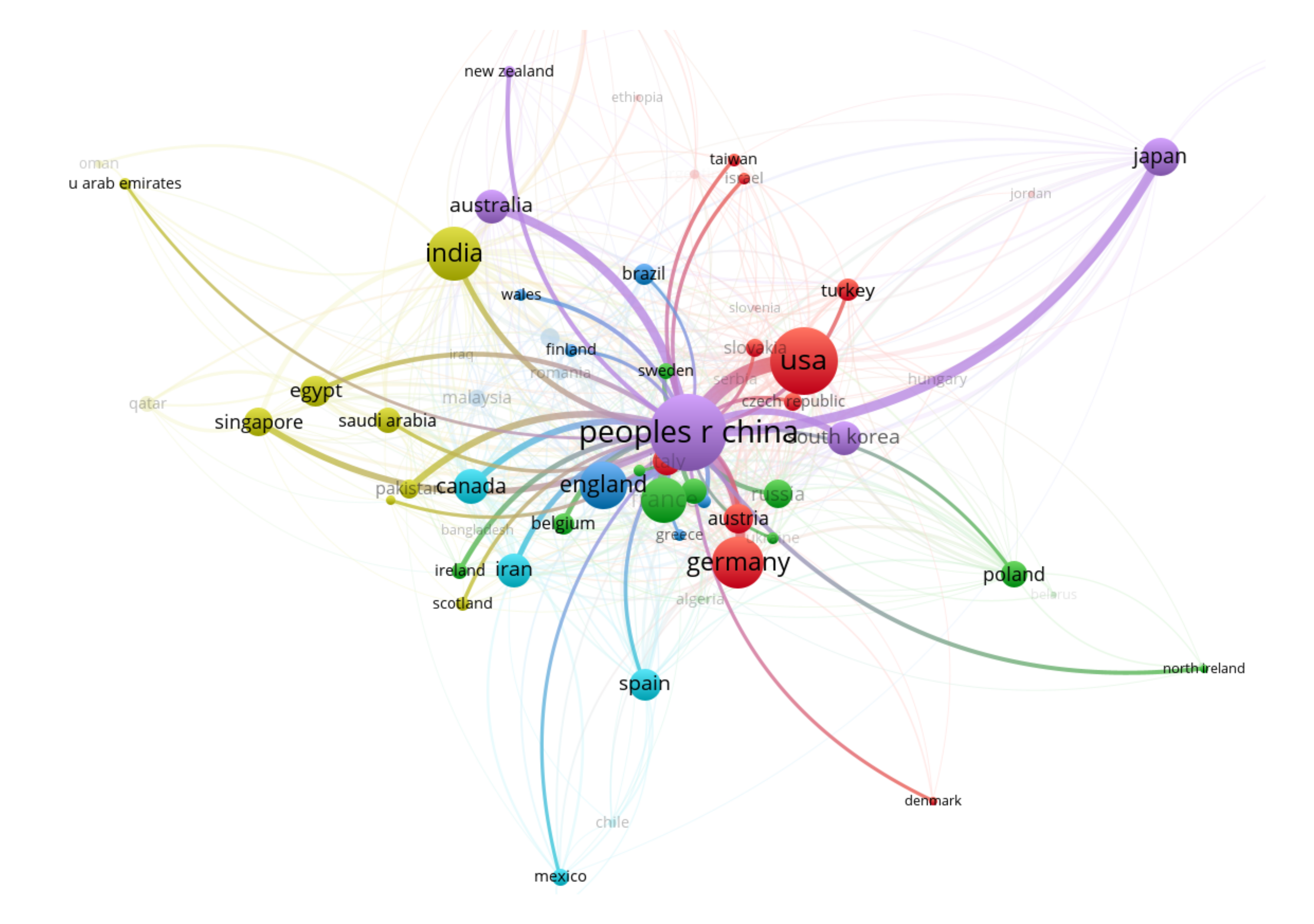

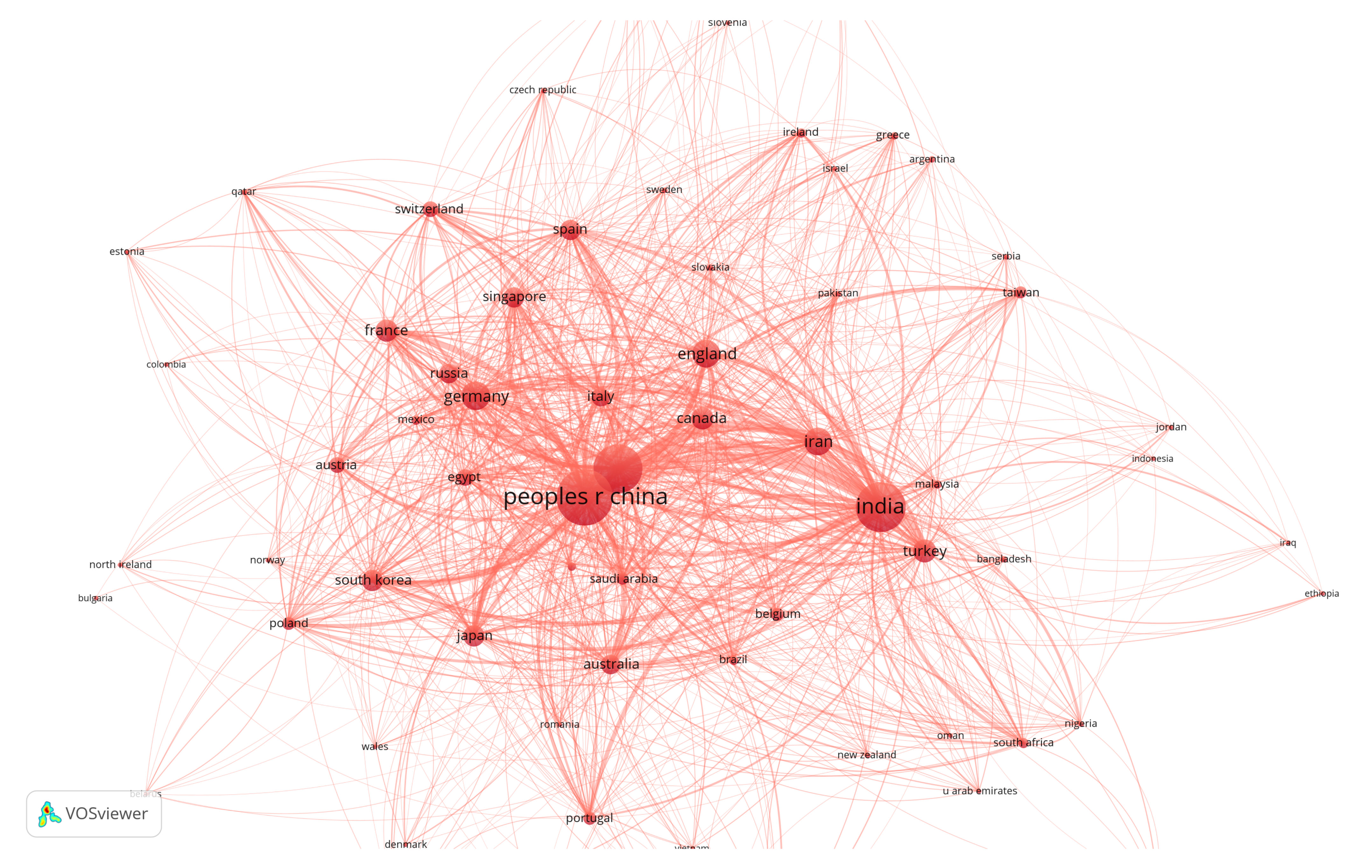

4.4. Citation Landscape of Places

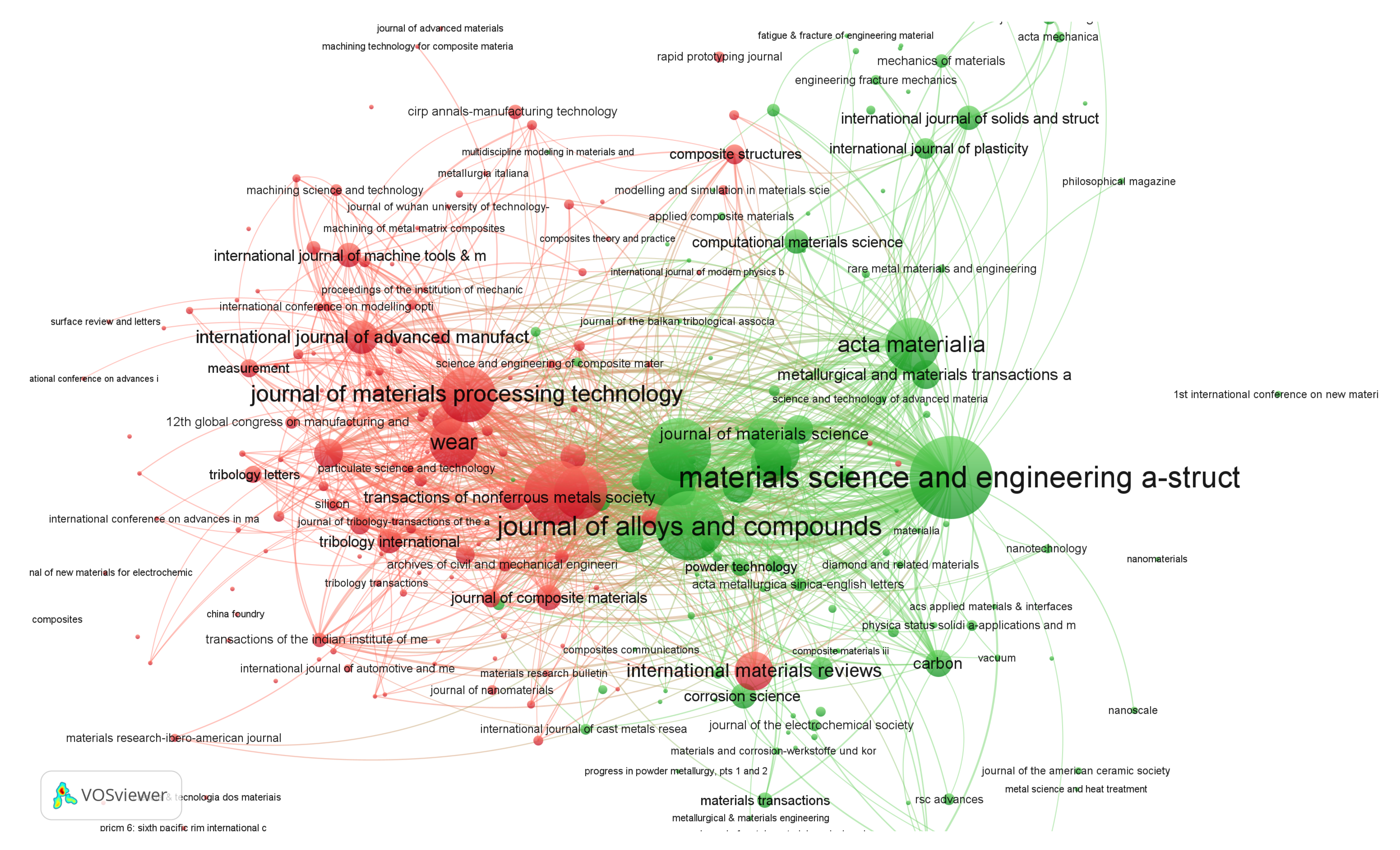

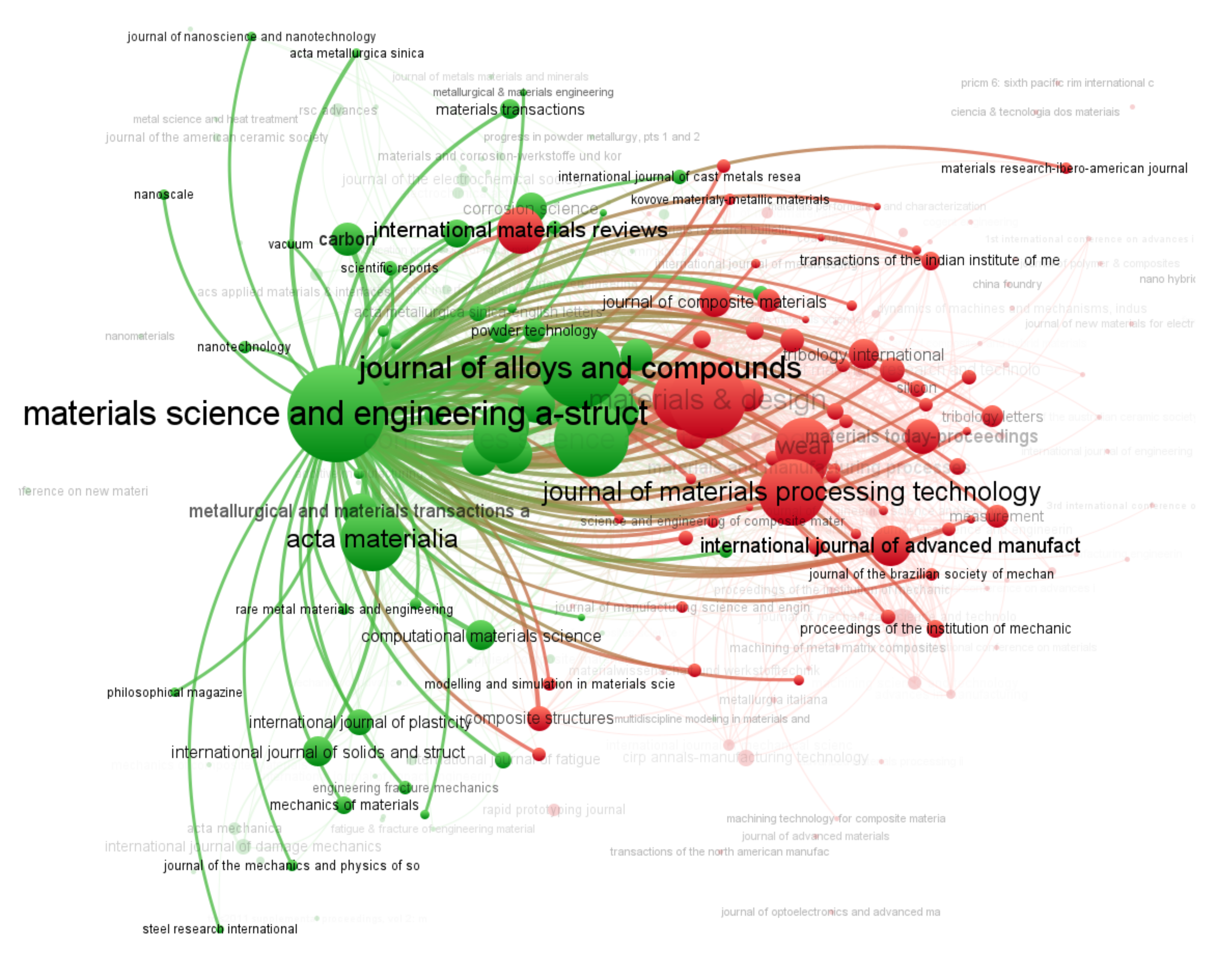

4.5. Citation Landscape of Sources

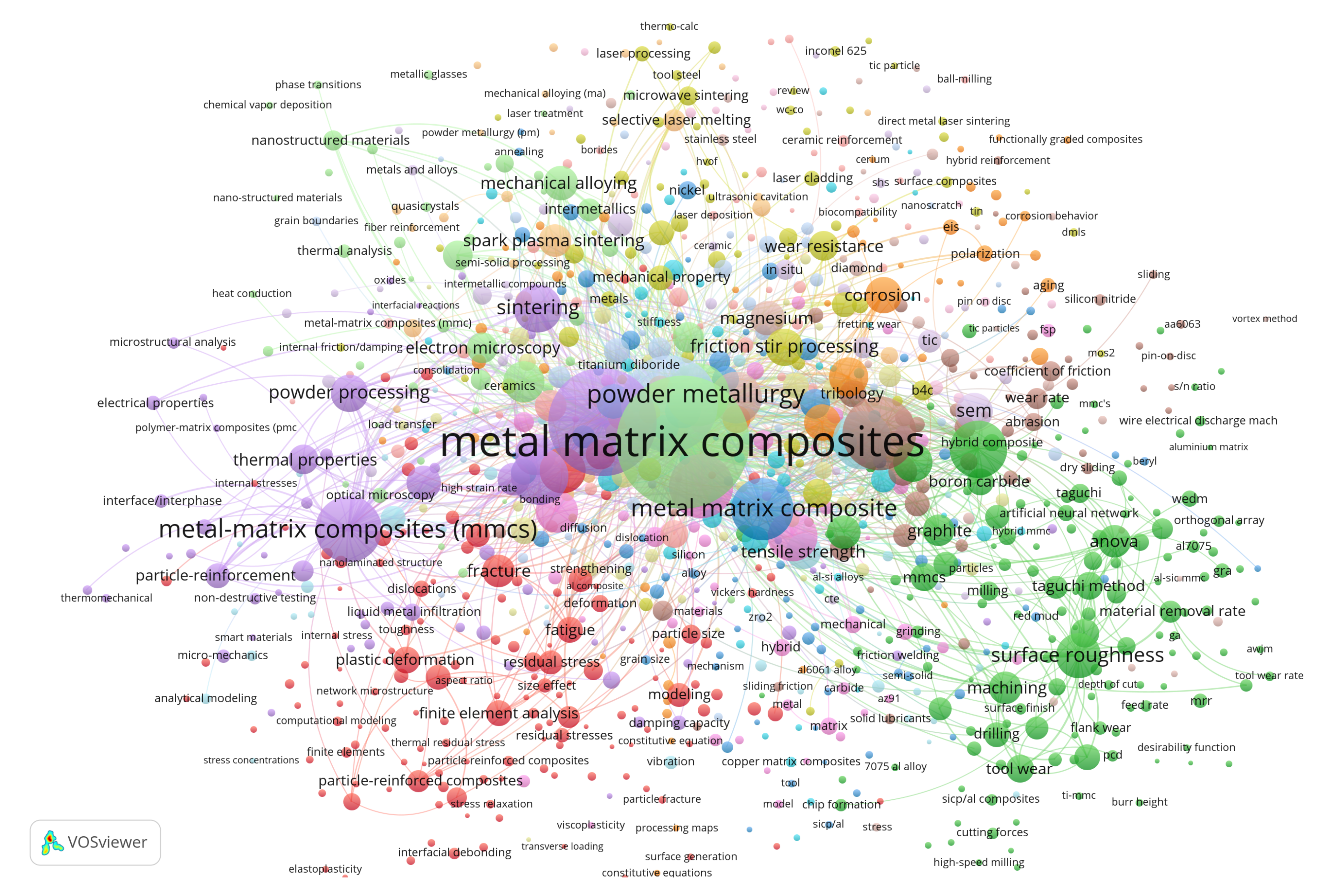

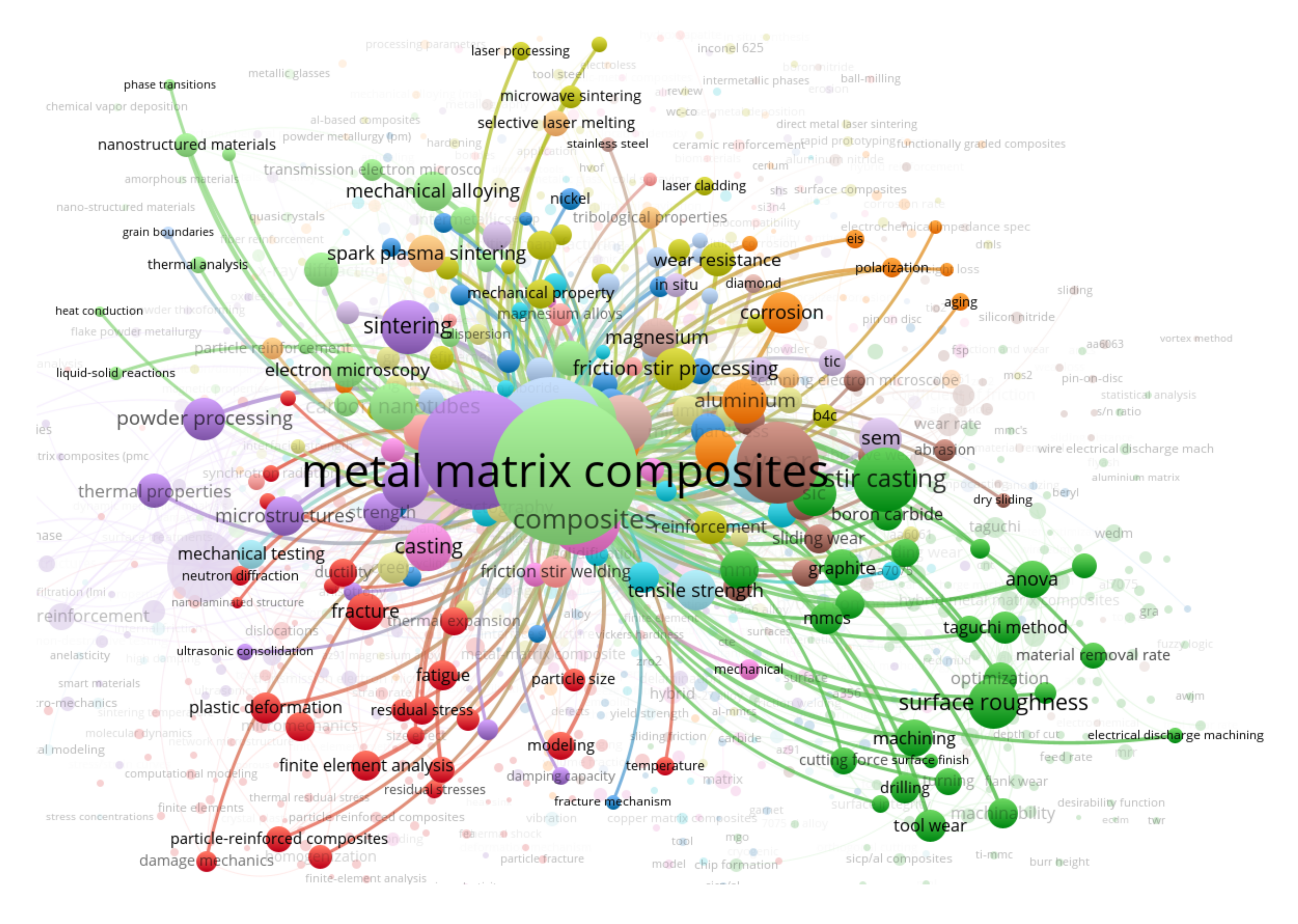

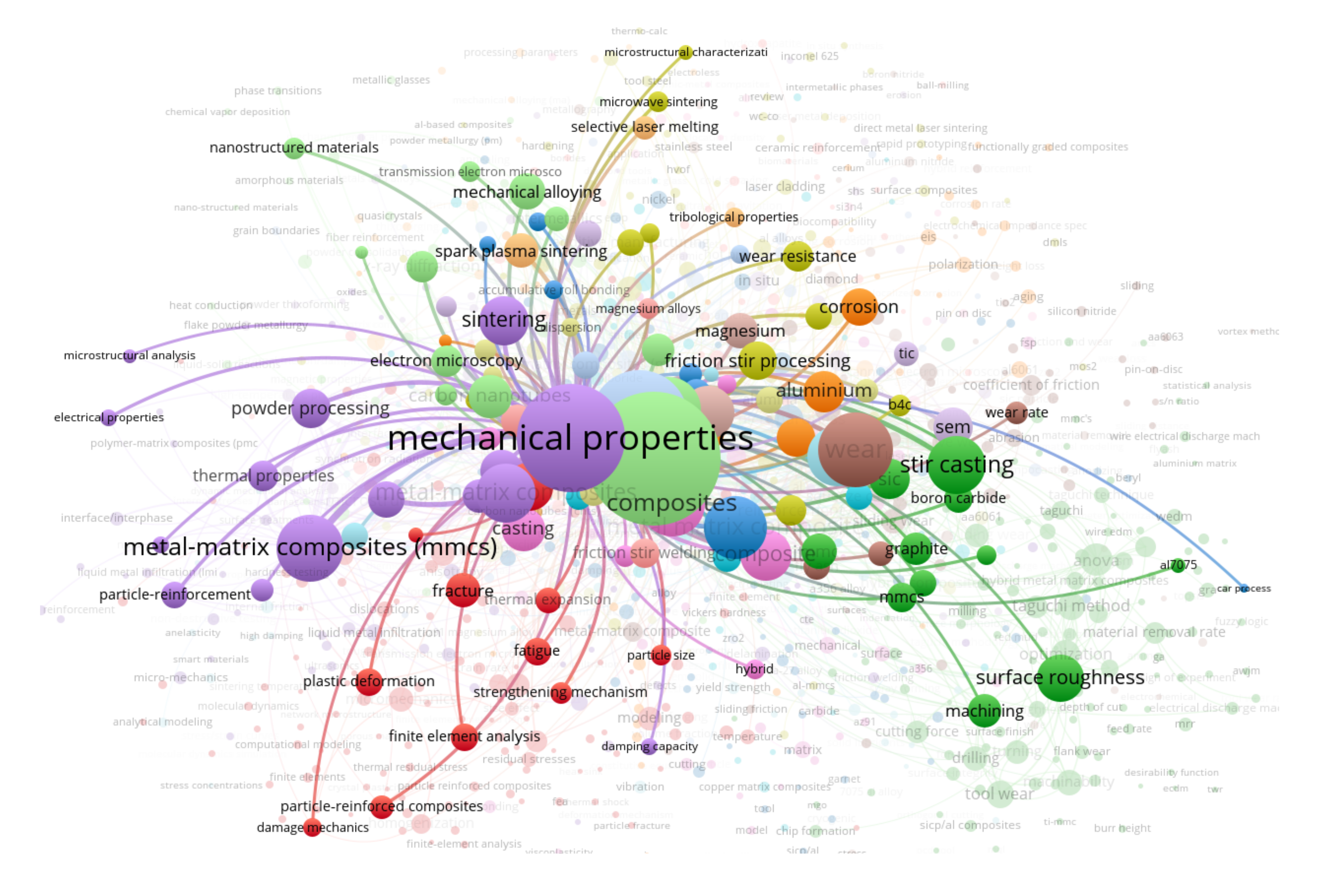

4.6. Co-Occurrence Landscape of Keywords

5. Burst Detection Analysis

5.1. Keyword Burst Detection

5.2. Reference Burst Detection

6. Conclusions

- 1.

- The MMC related keywords’ search yielded a total of 10,018 articles from the WoS database.

- 2.

- The number of MMC publications in WoS started rising after 2005. In 2018, 1001 articles were published as compared to just 269 in 2005.

- 3.

- Research articles comprised 80.54% of all publications. Other publication types include proceedings (21.94%), review articles (3.08%), book chapters (1.11%) and early access manuscripts (0.44%).

- 4.

- The journal ‘Materials Science and Engineering A: Structural Materials, Properties, Microstructure and Processing’ published the maximum MMC articles (640 papers) in WoS (6.39% of total corpus). The ‘Journal of Alloys and Compounds’ published 468 (4.67%) articles whereas ‘Materials Today Proceedings’ contributed 435 (4.34%) papers in WoS.

- 5.

- ‘Materials science’ emerged as the most significant research direction with 7580 (75.66%) WoS publications. ‘Metallurgy/metallurgical engineering’ was the second most important research direction with 3242 (32.36%) articles. The third highest number of MMC articles (2703, 26.98%) were categorized under the general research direction of ‘engineering’, dealing with the various engineering aspects of MMCs. These three research directions witnessed steadily increasing publication trends during 2001–2020.

- 6.

- There is a lot of scope in the MMC research directions pertaining to ‘automation control systems’, ‘mining mineral processing’ and ‘optics’.

- 7.

- Researchers affiliated with the USA published the most MMC articles during 2001–2004 (60 papers in 2004). From 2005 to 2012, Chinese authors published the maximum number of WoS papers (114 papers in 2012). Post 2012, Indian investigators contributed maximum articles in WoS (415 papers in 2020).

- 8.

- Globally, the Harbin Institute of Technology, China published the maximum number of WOS papers (335, 3.34%) in the field of metal matrix composites. The Shanghai Jiao Tong University, China (271 papers, 2.71%) and the Chinese Academy of Sciences (227 papers, 2.27%) contributed the second and third highest number of MMC articles in WoS.

- 9.

- Among Indian organizations, the Indian Institutes of Technology published the maximum articles (225) followed by National Institutes of Technology (156 papers) and Anna University (113 papers).

- 10.

- Gupta M (Singapore) published the most MMC papers (140, 1.40%) followed by Zhang D (China) and Wu Gouhua (China) with 97 (0.97%) and 86 (0.86%) publications, respectively.

- 11.

- Zhang D, Li Z and Li J emerged as the MMC researchers with the topmost collaboration based total link strength (TLS) values of 499, 443 and 421, respectively. They published 113, 97 and 117 papers with 108, 110 and 184 co-authors, respectively. Gupta M did not make it to the top ten collaborative TLS list despite having maximum MMC publications due to less co-author linkages and respective link strengths.

- 12.

- The top three organizations with the maximum inter-institute collaborative TLS values are the Chinese Academy of Science (papers 227, links 73, TLS 212), Harbin Institute of Technology, China (papers 335, links 7, TLS 162) and the Indian Institutes of Technology (papers 223, links 71, TLS 154).

- 13.

- Among the Indian organizations, Anna University attained better inter-organizational collaborative TLS value of 95 as compared to the National Institutes of Technology (TLS 91) despite publishing fewer MMC papers in WoS.

- 14.

- The People’s Republic of China, the USA and India attained the highest international collaborative TLS values of 681, 537 and 350, respectively. The authors affiliated with these countries published 2475 (links 42), 1104 (links 47) and 2509 (links 45) articles, respectively.

- 15.

- The MMC researchers of India, Japan, Iran and Spain need to improve international collaborative linkages in proportion to their respective MMC publication outputs.

- 16.

- 17.

- Zhang D, Li Z, Fan G (all from China) were the top ranked MMC researchers with the highest mutual citations based TLS values of 7016, 5921, 4662 with 3278 (links 777), 2617 (links 733) and 2168 (links 581) citations, respectively. Gupta M figured at rank 8 of this list despite having maximum citations (3546) due to lesser mutual citations with the documents of other MMC researchers.

- 18.

- The Shanghai Jiao Tong University, Harbin Institute of Technology and the Indian Institutes of Technology attained the maximum citations network based TLS of 4433, 3938 and 3272, respectively. The authors affiliated with these organizations bagged 5323, 5659 and 5109 citations with 544, 565 and 592 links, respectively.

- 19.

- The top three countries with the highest international linkage based TLS rankings are the People’s Republic of China (TLS 20878), India (TLS 17501) and the USA (13112). These nations have citations based linkages with 66 countries each. Their authors have obtained 43,374, 34,715 and 33,038 WoS citations, respectively.

- 20.

- Iran obtained the fourth highest TLS (5938) based on its international citation linkages (63), whereas it was ranked only ninth in the international co-authored MMC research linkages (links 26, TLS 145).

- 21.

- The top three MMC publication sources with the highest citations based TLS values are the ‘Materials Science and Engineering: A—Structural Materials: Properties, Microstructure and Processing’ (TLS 6634), ‘Journal of Alloys and Compounds’ (TLS 4377) and ‘Materials & Design’ (TLS 4364). Their WoS articles have received 18,715 (links 242), 12,992 (links 2313) and 11,299 (links 229) citations, respectively.

- 22.

- The top three MMC related keywords with the highest co-occurrence based TLS are ‘Metal Matrix Composites’(TLS 5566), ‘Mechanical Properties’ (TLS 3643) and ‘Microstructure’ (TLS 2922). These keywords have occurred in 2135, 1255 and 962 documents with 845, 599 and 597 co-occurrence based links with other MMC keywords, respectively. The other MMC keywords (with high co-occurrence based TLS) are related to MMC materials, processing techniques, properties and analyses.

- 23.

- Keyword burst detection analysis revealed that ‘graphene’, ‘stengthening mechanism’, ‘stir casting’ ‘nanocomposite’ and ‘B4C’ have witnessed significant citation bursts in the last four years. The citation burst strengths of these keywords are 33.6453 (2018–2020), 20.45 (2017–2020), 19.9426 (2018–2020), 16.9666 (2016–2018) and 13.6994 (2018–2020), respectively. This analysis indicates that the current research trend is related to processing and characterisation of nanocomposites with special emphasis on graphene reinforced MMCs.

- 24.

- Reference burst detection analysis showed that all of the top fifteen documents with the highest citation burst strengths were published before 2001. All of these documents witnessed their respective citation bursts during 2001–2005, when the annual number of MMC publications in WoS was the lowest! None of the top cited MMC articles featured in the top fifteen citation burst strength rankings. These top fifteen citation burst documents dealt with a general review of MMCs, methods of preparation, characterisation as well as investigations into their specific functional properties and applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mali, A.S.; Vagge, S.; Kolekar, A. Tribological behaviour of LM25 hybrid metal matrix composites by using Taguchi’s techniques. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Ogawa, F.; Masuda, C. Fabrication and the mechanical and physical properties of nanocarbon-reinforced light metal matrix composites: A review and future directions. Mater. Sci. Eng. A 2021, 820, 141542. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Z.; Cui, Y.; Wang, L.; Wang, M.; Liu, J.; Zhong, S.; Wang, H. The effect of TiB2 ceramic particles on Portevin–Le Chatelier behavior of TiB2/AlMg metal matrix composites. J. Mater. Res. Technol. 2021, 14, 2302–2311. [Google Scholar] [CrossRef]

- Vasanth Kumar, R.; Keshavamurthy, R.; Perugu, C.S.; Alipour, M.; Siddaraju, C. Influence of hot rolling on friction and wear behaviour of Al6061-ZrB2 in-situ metal matrix composites. J. Manuf. Process. 2021, 69, 473–490. [Google Scholar] [CrossRef]

- Huang, J.; Li, W.; He, Y.; Li, Y.; Zhang, X.; Yang, M.; Zheng, S.; Ma, Y. Temperature dependent ultimate tensile strength model for short fiber reinforced metal matrix composites. Compos. Struct. 2021, 267, 113890. [Google Scholar] [CrossRef]

- Bharat, N.; Bose, P. An overview on the effect of reinforcement and wear behaviour of metal matrix composites. Mater. Today Proc. 2021, 46, 707–713. [Google Scholar] [CrossRef]

- Sahoo, B.P.; Das, D.; Chaubey, A.K. Strengthening mechanisms and modelling of mechanical properties of submicron-TiB2 particulate reinforced Al 7075 metal matrix composites. Mater. Sci. Eng. A 2021, 825, 141873. [Google Scholar] [CrossRef]

- Sekhar, R.; Singh, T. Mechanisms in turning of metal matrix composites: A review. J. Mater. Res. Technol. 2015, 4, 197–207. [Google Scholar] [CrossRef] [Green Version]

- Phutane, P.; Jatti, V.K.S.; Sekhar, R.; Singh, T. Synthesis and characterization of SiC reinforced HE-30 Al alloy particulate MMCs. Int. J. Eng. Technol. (IJET) 2013, 5, 2866–2870. [Google Scholar]

- Rathod, S.; Shekhar, R.; Jatti, V.; Singh, T. Optimization of tool shape and size in EDM Al alloy metal matrix composites. Int. J. Appl. Eng. Res. 2013, 8, 639–646. [Google Scholar]

- Sekhar, R.; Singh, T. Determination of Johnson Cook parameters in turning of micro and nano reinforced aluminum composites using trust region reflective algorithm. Int. J. Innov. Technol. Explor. Eng. (IJITEE) 2019, 9, 1712–1716. [Google Scholar]

- Shah, P.; Sekhar, R.; Kulkarni, A.J.; Siarry, P. Metaheuristic Algorithms in Industry 4.0; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Sekhar, R.; Singh, T.; Shah, P. Machine learning based predictive modeling and control of surface roughness generation while machining micro boron carbide and carbon nanotube particle reinforced Al-Mg matrix composites. Part. Sci. Technol. 2021, 1–18. [Google Scholar] [CrossRef]

- Sekhar, R.; Singh, T.P.; Shah, P. Complex order PIα Dγ design for surface roughness control in machining CNT Al-Mg hybrid composites. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 299–306. [Google Scholar] [CrossRef]

- Sekhar, R.; Singh, T.; Shah, P. Micro and nano particle composite machining: Fractional order control of surface roughness. In Proceedings of the Third International Conference on Powder, Granule and Bulk Solids: Innovations and Applications PGBSIA, Patiala, India, 26–28 February 2020; pp. 35–42. [Google Scholar]

- Sekhar, R.; Singh, T.; Shah, P. ARX/ARMAX modeling and fractional order control of surface roughness in turning nano-composites. In Proceedings of the 2019 International Conference on Mechatronics, Robotics and Systems Engineering (MoRSE), Bali, Indonesia, 4–6 December 2019; pp. 97–102. [Google Scholar]

- Sekhar, R.; Singh, T.; Shah, P. System identification of tool chip interface friction while machining CNT-Mg-Al composites. AIP Conf. Proc. 2021, 2317, 020019-1–020019-9. [Google Scholar]

- Vishwakarma, P.; Sekhar, R.; Singh, T. Finite element analysis of force variation with cutting speed in orthogonal turning of aluminum AA6351 alloy. Int. J. Appl. Eng. Res. 2015, 10, 10055–10064. [Google Scholar]

- Jatti, V.; Sekhar, R.; Patil, R. Study of ball nose end milling of LM6 Al alloy: Surface roughness optimisation using genetic algorithm. Int. J. Eng. Technol. 2013, 5, 2859–2865. [Google Scholar]

- Jatti, V.S.; Sekhar, R. Surface Roughness Study on LM6 Al-Alloy: A Taguchi Approach. In Proceedings of the International Conference on Advanced Research in Engineering and Technology (ICARET 2013)—International Technology Innovation, Gunt, India, 8–9 February 2013; pp. 550–553. [Google Scholar]

- Xu, H.; Huang, H. Plasma remelting and injection method for fabricating metal matrix composite coatings reinforced with tungsten carbide. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.; Chin, E. The compressive viscoplastic response of an A359/SiCp metal–matrix composite and of the A359 aluminum alloy matrix. Int. J. Solids Struct. 2000, 37, 7547–7562. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.; Chin, E. The mechanical response of an A359/SiCp MMC and the A359 aluminum matrix to dynamic shearing deformations. Mater. Sci. Eng. A 2004, 382, 162–170. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.; Chin, E. Viscoplastic deformations and compressive damage in an A359/SiCp metal–matrix composite. Acta Mater. 2000, 48, 1563–1573. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K. Influence of particle volume fraction, shape, and aspect ratio on the behavior of particle-reinforced metal–matrix composites at high rates of strain. Acta Mater. 1998, 46, 5633–5646. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal-matrix composites: Part I: Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Li, X.; Seah, W. Tool wear acceleration in relation to workpiece reinforcement percentage in cutting of metal matrix composites. Wear 2001, 247, 161–171. [Google Scholar] [CrossRef]

- Ding, X.; Liew, W.; Liu, X. Evaluation of machining performance of MMC with PCBN and PCD tools. Wear 2005, 259, 1225–1234. [Google Scholar] [CrossRef]

- Chambers, A. The machinability of light alloy MMCs. Compos. Part A Appl. Sci. Manuf. 1996, 27, 143–147. [Google Scholar] [CrossRef]

- Ciftci, I.; Turker, M.; Seker, U. Evaluation of tool wear when machining SiCp-reinforced Al-2014 alloy matrix composites. Mater. Des. 2004, 25, 251–255. [Google Scholar] [CrossRef]

- Jaspers, S.; Dautzenberg, J. Material behaviour in metal cutting: Strains, strain rates and temperatures in chip formation. J. Mater. Process. Technol. 2002, 121, 123–135. [Google Scholar] [CrossRef]

- Lin, C.; Hung, Y.; Liu, W.C.; Kang, S.W. Machining and fluidity of 356Al/SiCp composites. J. Mater. Process. Technol. 2001, 110, 152–159. [Google Scholar] [CrossRef]

- Davim, J. Diamond tool performance in machining metal–matrix composites. J. Mater. Process. Technol. 2002, 128, 100–105. [Google Scholar] [CrossRef]

- Heath, P.J. Developments in applications of PCD tooling. J. Mater. Process. Technol. 2001, 116, 31–38. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Mai, Y.W. Particle effects on friction and wear of aluminium matrix composites. J. Mater. Sci. 1995, 30, 5999–6004. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, L. Single-point scratching of 6061 Al alloy reinforced by different ceramic particles. Appl. Compos. Mater. 1994, 1, 431–447. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal matrix composites: Part II: Workpiece surface integrity. J. Mater. Process. Technol. 1998, 83, 277–285. [Google Scholar] [CrossRef]

- Hung, N.P.; Venkatesh, V.; Loh, N. Machining of metal matrix composites. Manuf. Eng. Mater. Process. 1999, 53, 295–356. [Google Scholar]

- Yuan, Z.; Geng, L.; Dong, S. Ultraprecision machining of SiCw/Al composites. CIRP Ann. 1993, 42, 107–109. [Google Scholar] [CrossRef]

- Arsenault, R.; Wang, L.; Feng, C. Strengthening of composites due to microstructural changes in the matrix. Acta Metall. Mater. 1991, 39, 47–57. [Google Scholar] [CrossRef]

- Arsenault, R.; Shi, N. Dislocation generation due to differences between the coefficients of thermal expansion. Mater. Sci. Eng. 1986, 81, 175–187. [Google Scholar] [CrossRef]

- Miller, W.; Humphreys, F. Strengthening mechanisms in particulate metal matrix composites. Scr. Metall. Mater. 1991, 25, 33–38. [Google Scholar] [CrossRef]

- Kannan, S.; Kishawy, H.; Deiab, I. Cutting forces and TEM analysis of the generated surface during machining metal matrix composites. J. Mater. Process. Technol. 2009, 209, 2260–2269. [Google Scholar] [CrossRef]

- Black, J.T. Flow stress model in metal cutting. J. Eng. Ind. 1979, 101, 403–415. [Google Scholar] [CrossRef]

- Basinski, Z.; Jackson, P. The instability of the work hardened state. I. Slip in extraneously deformed crystals. Phys. Status Solidi (b) 1965, 9, 805–823. [Google Scholar] [CrossRef]

- Basinski, Z.; Jackson, P. The instability of the work hardened state. II. Slip in “Alien” dislocation distributions. Phys. Status Solidi (b) 1965, 10, 45–56. [Google Scholar] [CrossRef]

- Venkatesh, R.; Hariharan, A.; Muthukrishnan, N. Machinability studies of Al/SiC/(20p) MMC by using PCD insert (1300 grade). In Proceedings of the World Congress on Engineering, London, UK, 1–3 July 2009; Volume 2, pp. 1–3. [Google Scholar]

- Arokiadass, R.; Palaniradja, K.; Alagumoorthi, N. Predictive modeling of surface roughness in end milling of Al/SiCp metal matrix composite. Arch. Appl. Sci. Res. 2011, 3, 228–236. [Google Scholar]

- Muthukrishnan, N.; Davim, J.P. Optimization of machining parameters of Al/SiC-MMC with ANOVA and ANN analysis. J. Mater. Process. Technol. 2009, 209, 225–232. [Google Scholar] [CrossRef]

- Ge, Y.; Xu, J.; Yang, H.; Luo, S.; Fu, Y. Workpiece surface quality when ultra-precision turning of SiCp/Al composites. J. Mater. Process. Technol. 2008, 203, 166–175. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.; Arsecularatne, J. Prediction of cutting forces in machining of metal matrix composites. Int. J. Mach. Tools Manuf. 2006, 46, 1795–1803. [Google Scholar] [CrossRef] [Green Version]

- Pramanik, A.; Zhang, L.; Arsecularatne, J. Machining of metal matrix composites: Effect of ceramic particles on residual stress, surface roughness and chip formation. Int. J. Mach. Tools Manuf. 2008, 48, 1613–1625. [Google Scholar] [CrossRef] [Green Version]

- Sikder, S.; Kishawy, H. Analytical model for force prediction when machining metal matrix composite. Int. J. Mech. Sci. 2012, 59, 95–103. [Google Scholar] [CrossRef]

- Kishawy, H.; Kannan, S.; Balazinski, M. An energy based analytical force model for orthogonal cutting of metal matrix composites. CIRP Ann. 2004, 53, 91–94. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J. Appl. Phys. 1945, 16, 267–275. [Google Scholar] [CrossRef]

- Kronenberg, M. Machining Science and Application. Theory and Practice for Operation and Development of Machining Processes; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Colwell, L. Predicting the angle of chip flow for single-point cutting tools. Trans. ASME 1954, 76, 199–204. [Google Scholar]

- Johnson, G.R. A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In Proceedings of the Seventh International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- van Raan, A.F. For your citations only? Hot topics in bibliometric analysis. Meas. Interdiscip. Res. Perspect. 2005, 3, 50–62. [Google Scholar] [CrossRef]

- Ye, Q.; Song, H.; Li, T. Cross-institutional collaboration networks in tourism and hospitality research. Tour. Manag. Perspect. 2012, 2, 55–64. [Google Scholar] [CrossRef]

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2015, 18, 429–472. [Google Scholar] [CrossRef]

- Sharma, D.; Gupta, P.K.; Andreu-Perez, J. A Review on Cyber Physical Systems and Smart Computing: Bibliometric Analysis. In Metaheuristic Algorithms in Industry 4.0; Shah, P., Sekhar, R., Kulkarni, A.J., Siarry, P., Eds.; Routledge: London, UK, 2021; Chapter 1; pp. 1–31, In press. [Google Scholar]

- Jiang, Y.; Ritchie, B.W.; Benckendorff, P. Bibliometric visualisation: An application in tourism crisis and disaster management research. Curr. Issues Tour. 2019, 22, 1925–1957. [Google Scholar] [CrossRef]

- Borgman, C.L.; Furner, J. Scholarly communication and bibliometrics. Annu. Rev. Inf. Sci. Technol. 2002, 36, 2–72. [Google Scholar] [CrossRef] [Green Version]

- Thelwall, M. Bibliometrics to webometrics. J. Inf. Sci. 2008, 34, 605–621. [Google Scholar] [CrossRef]

- Jamal, T.; Smith, B.; Watson, E. Ranking, rating and scoring of tourism journals: Interdisciplinary challenges and innovations. Tour. Manag. 2008, 29, 66–78. [Google Scholar] [CrossRef]

- McKercher, B. Influence ratio: An alternate means to assess the relative influence of hospitality and tourism journals on research. Int. J. Hosp. Manag. 2012, 31, 962–971. [Google Scholar] [CrossRef]

- Phillips, W.; Canter, D.; Abbot, J. Hospitality and Tourism Research Rankings by Author, University, and Country Using Six Major Journals: The First Decade of the New Millennium. J. Hosp. Tour. Res. 2011, 35, 381–416. [Google Scholar]

- Zhao, W.; Ritchie, J.B. An investigation of academic leadership in tourism research: 1985–2004. Tour. Manag. 2007, 28, 476–490. [Google Scholar] [CrossRef]

- Benckendorff, P. Themes and Trends in Australian and New Zealand Tourism Research: A Social Network Analysis of Citations in Two Leading Journals (1994–2007). J. Hosp. Tour. Manag. 2009, 16, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Benckendorff, P.; Zehrer, A. A network analysis of tourism research. Ann. Tour. Res. 2013, 43, 121–149. [Google Scholar] [CrossRef]

- Hu, C.; Racherla, P. Visual representation of knowledge networks: A social network analysis of hospitality research domain. Int. J. Hosp. Manag. 2008, 27, 302–312. [Google Scholar] [CrossRef]

- White, H.D.; McCain, K.W. Visualizing a discipline: An author co-citation analysis of information science, 1972–1995. J. Am. Soc. Inf. Sci. 1998, 49, 327–355. [Google Scholar] [CrossRef]

- Baggio, R.; Scott, N.; Arcodia, C. Collaboration in the events literature: A co-authorship network study. In Proceedings of the EUTO, Nottingham, UK, 24–25 September 2008. [Google Scholar]

- Yuan, Y.; Gretzel, U.; Tseng, Y.H. Revealing the nature of contemporary tourism research: Extracting common subject areas through bibliographic coupling. Int. J. Tour. Res. 2015, 17, 417–431. [Google Scholar] [CrossRef]

- McKercher, B. A citation analysis of tourism scholars. Tour. Manag. 2008, 29, 1226–1232. [Google Scholar] [CrossRef]

- Howey, R.M.; Savage, K.S.; Verbeeten, M.J.; Van Hoof, H.B. Tourism and hospitality research journals: Cross-citations among research communities. Tour. Manag. 1999, 20, 133–139. [Google Scholar] [CrossRef]

- Ying, T.; Xiao, H. Knowledge linkage: A social network analysis of tourism dissertation subjects. J. Hosp. Tour. Res. 2012, 36, 450–477. [Google Scholar] [CrossRef]

- Ballantyne, R.; Packer, J.; Axelsen, M. Trends in tourism research. Ann. Tour. Res. 2009, 36, 149–152. [Google Scholar] [CrossRef]

- Cheng, C.K.; Li, X.R.; Petrick, J.F.; O’Leary, J.T. An examination of tourism journal development. Tour. Manag. 2011, 32, 53–61. [Google Scholar] [CrossRef]

- McKercher, B.; Law, R.; Lam, T. Rating tourism and hospitality journals. Tour. Manag. 2006, 27, 1235–1252. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Chen, C. Searching for intellectual turning points: Progressive knowledge domain visualization. Proc. Natl. Acad. Sci. USA 2004, 101, 5303–5310. [Google Scholar] [CrossRef] [Green Version]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef] [Green Version]

- Davi, A.; Haughton, D.; Nasr, N.; Shah, G.; Skaletsky, M.; Spack, R. A review of two text-mining packages: SAS TextMining and WordStat. Am. Stat. 2005, 59, 89–103. [Google Scholar] [CrossRef]

- Pan, S.; Chon, K.; Song, H. Visualizing tourism trends: A combination of ATLAS. ti and BiPlot. J. Travel Res. 2008, 46, 339–348. [Google Scholar] [CrossRef] [Green Version]

- Persson, O.; Danell, R.; Schneider, J.W. How to use Bibexcel for various types of bibliometric analysis. Celebr. Sch. Commun. Stud. Festschr. Olle Persson His 60th Birthd. 2009, 5, 9–24. [Google Scholar]

- Börner, K.; Huang, W.; Linnemeier, M.; Duhon, R.; Phillips, P.; Ma, N.; Zoss, A.; Guo, H.; Price, M. Rete-netzwerk-red: Analyzing and visualizing scholarly networks using the Network Workbench Tool. Scientometrics 2010, 83, 863–876. [Google Scholar] [CrossRef] [Green Version]

- Herr, B.W.; Huang, W.; Penumarthy, S.; Börner, K. Designing highly flexible and usable cyberinfrastructures for convergence. Ann. N. Y. Acad. Sci. 2006, 1093, 161. [Google Scholar] [CrossRef] [PubMed]

- Porter, A.L.; Cunningham, S.W. Tech Mining: Exploiting New Technologies for Competitive Advantage; John Wiley & Sons: Hoboken, NJ, USA, 2004; Volume 29. [Google Scholar]

- Brandes, U.; Kenis, P.; Raab, J.; Schneider, V.; Wagner, D. Explorations into the visualization of policy networks. J. Theor. Politics 1999, 11, 75–106. [Google Scholar] [CrossRef] [Green Version]

- Scott, N.; Baggio, R.; Cooper, C. Network Analysis and Tourism; Channel View Publications: Bristol, UK, 2008. [Google Scholar]

- Van Eck, N.J.; Waltman, L. VOS: A new method for visualizing similarities between objects. In Advances in Data Analysis; Springer: Berlin/Heidelberg, Germany, 2007; pp. 299–306. [Google Scholar]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science mapping software tools: Review, analysis, and cooperative study among tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Datkhile, R.; Laad, M.; Ghule, B. Research trend of metal matrix composites reinforced with silica extracted by green route: A Bibliometric Analysis. Libr. Philos. Pract. 2021, 1–14. Available online: https://digitalcommons.unl.edu/libphilprac/4730/ (accessed on 30 October 2021).

- Vencl, A.; Vaxevanidis, N.M.; Kandeva, M. A bibliometric analysis of scientific research on tribology of composites in Southeastern Europe. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 1–8. [Google Scholar] [CrossRef]

- Saxena, P.; Bongale, A.; Kumar, S. Evaluation of friction stir processing for fabrication of composites in the context of Industry 4.0: A Bibliometric Review. Libr. Philos. Pract. 2021, 1–22. Available online: https://digitalcommons.unl.edu/libphilprac/5058/ (accessed on 30 October 2021).

- Ghule, B.; Laad, D. A bibliometric survey on polymer composites in energy storage applications. Libr. Philos. Pract. 2020, 1–17. Available online: https://digitalcommons.unl.edu/libphilprac/4497/ (accessed on 30 October 2021).

- Koo, Y.D.; Jeong, D.H. Analysis of Research Trend of Composite Material Using CNT; Key Engineering Materials; Trans Tech Publications: Bach, Switzerland, 2017; Volume 730, pp. 60–64. [Google Scholar]

- Costa, R.; Moura, E. A Bibliometric Analysis of the Strategy and Performance Measurement of the Polymer Matrix Nanomaterials Development Scenario Globally, and the Participation of Brazil; Springer: Cham, Switzerland, 2020; pp. 329–342. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural fibre composites and their applications: A review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Xiang, Y.; Shao, D.; Yu, Z.; Zheng, N.; Chen, W.; Ma, L. Bibliometrics and Visualization Analysis of Knowledge Map in Metallurgical Field; Springer: Cham, Switzerland, 2018; pp. 361–366. [Google Scholar] [CrossRef]

- Kumar, D.; Karwasra, K.; Soni, G. Bibliometric analysis of artificial neural network applications in materials and engineering. Mater. Today: Proc. 2020, 28, 1629–1634. [Google Scholar] [CrossRef]

- Mohan, S.; Gupta, B.; Dhawan, S. Materials science research and development in India: A scientometric analysis of international collaborative output. DESIDOC J. Libr. Inf. Technol. 2003, 23, 11–23. [Google Scholar]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites-a review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Torralba, J.d.; Da Costa, C.; Velasco, F. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Chawla, N.; Shen, Y.L. Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. Particle distribution in cast metal matrix composites—Part I. J. Mater. Process. Technol. 2002, 123, 251–257. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Laoui, T.; Haseeb, A.A.; Celis, J.P.; Froyen, L. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study. J. Mater. Process. Technol. 2003, 142, 738–743. [Google Scholar] [CrossRef]

- Miracle, D. Metal matrix composites–from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Mortensen, A.; Llorca, J. Metal matrix composites. Annu. Rev. Mater. Res. 2010, 40, 243–270. [Google Scholar] [CrossRef]

- Lloyd, D. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Ibrahim, I.; Mohamed, F.; Lavernia, E. Particulate reinforced metal matrix composites—A review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Rohatgi, P.; Asthana, R.; Das, S. Solidification, structures, and properties of cast metal-ceramic particle composites. Int. Met. Rev. 1986, 31, 115–139. [Google Scholar] [CrossRef]

- Christman, T.; Needleman, A.; Suresh, S. An experimental and numerical study of deformation in metal-ceramic composites. Acta Metall. 1989, 37, 3029–3050. [Google Scholar] [CrossRef]

- Whitehouse, A.; Clyne, T. Cavity formation during tensile straining of particulate and short fibre metal matrix composites. Acta Metall. Mater. 1993, 41, 1701–1711. [Google Scholar] [CrossRef]

- Nardone, V.; Prewo, K. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 1986, 20, 43–48. [Google Scholar] [CrossRef]

- Bao, G.; Hutchinson, J.; McMeeking, R. Particle reinforcement of ductile matrices against plastic flow and creep. Acta Metall. Mater. 1991, 39, 1871–1882. [Google Scholar] [CrossRef]

- Lloyd, D. Aspects of fracture in particulate reinforced metal matrix composites. Acta Metall. Mater. 1991, 39, 59–71. [Google Scholar] [CrossRef]

- Brechet, Y.; Embury, J.; Tao, S.; Luo, L. Damage initiation in metal matrix composites. Acta Metall. Mater. 1991, 39, 1781–1786. [Google Scholar] [CrossRef]

- Vogelsang, M.; Arsenault, R.; Fisher, R. An in situ HVEM study of dislocation generation at Al/SiC interfaces in metal matrix composites. Metall. Trans. A 1986, 17, 379–389. [Google Scholar] [CrossRef] [Green Version]

- McDanels, D.L. Analysis of stress-strain, fracture, and ductility behavior of aluminum matrix composites containing discontinuous silicon carbide reinforcement. Metall. Trans. A 1985, 16, 1105–1115. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Tjong, S.; Ma, Z. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. Ser. Math. Phys. Sci. 1957, 241, 376–396. [Google Scholar]

| Rank | Author | Country | Record | % of 10,018 |

|---|---|---|---|---|

| 1 | Gupta, M. | Singapore | 140 | 1.40% |

| 2 | Zhang, Di | China | 97 | 0.97% |

| 3 | Wu, Gouhua | China | 86 | 0.86% |

| 4 | Li, Zhiqiang | China | 65 | 0.65% |

| 5 | Geng, L. | China | 64 | 0.64% |

| 6 | Ma, Z. Y. | China | 58 | 0.58% |

| 7 | Wang, H. W. | China | 57 | 0.57% |

| 8 | Liu, Ying | China | 55 | 0.55% |

| 9 | Xiao, B. L. | China | 51 | 0.51% |

| 10 | Guo, Qiang | China | 48 | 0.48% |

| Rank | Author | Country | P | Links | TLS |

|---|---|---|---|---|---|

| 1 | Zhang, D | China | 113 | 108 | 499 |

| 2 | Li, Z | China | 93 | 110 | 443 |

| 3 | Li, J | China | 117 | 184 | 421 |

| 4 | Liu, | China | 94 | 161 | 319 |

| 5 | Guo, Q | China | 50 | 57 | 317 |

| 6 | Wang, H | China | 90 | 112 | 300 |

| 7 | Fan, G | China | 46 | 48 | 288 |

| 8 | Wang, X | China | 80 | 133 | 286 |

| 9 | Zhang, Y | China | 85 | 133 | 276 |

| 10 | Li, Y | China | 85 | 149 | 273 |

| Sr. No. | Linked Author | Link Strength |

|---|---|---|

| 1 | Li, Z | 41 |

| 2 | Zhang, D | 39 |

| 3 | Guo, Q | 33 |

| 4 | Tan, Z | 28 |

| 5 | Xiong, Db | 26 |

| 6 | Su, Y | 22 |

| 7 | Ji, G | 11 |

| 8 | Xu, R | 10 |

| 9 | Zhang, J | 8 |

| 10 | Guo, C | 7 |

| Sr. No. | Linked Author | Link Strength |

|---|---|---|

| 1 | Zhang, H | 17 |

| 2 | Zhang, Y | 17 |

| 3 | Li, J | 14 |

| 4 | Wang, L | 8 |

| 5 | Kim, Mj | 7 |

| 6 | Wang, J | 7 |

| 7 | Che, Z | 6 |

| 8 | Wu, K | 5 |

| 9 | Zhang, X | 5 |

| 10 | Hu, X | 5 |

| Rank | Organization | Country | P | Links | TLS |

|---|---|---|---|---|---|

| 1 | Chinese Academy Science | China | 227 | 73 | 212 |

| 2 | Harbin Institute of Technology | China | 335 | 70 | 162 |

| 3 | Indian Institutes of Technology | India | 223 | 71 | 154 |

| 4 | Shanghai Jiao Tong University | China | 270 | 71 | 151 |

| 5 | National University of Singapore | Singapore | 160 | 47 | 102 |

| 6 | Islamic Azad University | Afghanistan | 108 | 36 | 97 |

| 7 | Anna University | India | 112 | 45 | 95 |

| 8 | National Institutes of Technology | India | 155 | 45 | 91 |

| 9 | Northwestern Polytechnic University | USA | 132 | 45 | 85 |

| 10 | University of Science and Technology Beijing | China | 118 | 39 | 72 |

| 11 | Leibniz Institute for Solid State and Materials Research | Germany | 33 | 25 | 68 |

| 12 | Nanjing University of Aeronautics and Astronautics (NUAA) | China | 78 | 22 | 63 |

| 13 | Osaka University | Japan | 51 | 21 | 61 |

| Sr. No. | Linked Organization | Country | Link Strength |

|---|---|---|---|

| 1 | Sri Sivasubramaniya Nadar College of Engineering | India | 10 |

| 2 | University College of Engineering Kancheepuram | India | 7 |

| 3 | University of the Witwatersrand | South Africa | 6 |

| 4 | K Ramakrishnan College of Engineering | India | 5 |

| 5 | Sri Sairam Institute of Technology | India | 5 |

| 6 | Sri Sairam Engineering College | India | 4 |

| 7 | Thiagarajar College of Engineering | India | 4 |

| 8 | Annamalai University | India | 3 |

| 9 | National Institutes of Technology | India | 3 |

| 10 | Sri Venkateswara College of Engineering (SVCE) | India | 3 |

| Sr. No. | Linked Organization | Country | Link Strength |

|---|---|---|---|

| 1 | Indian Institutes of Technology | India | 12 |

| 2 | Jadavpur University | India | 6 |

| 3 | Chendhuran College of Engineering and Technology | India | 5 |

| 4 | Amrita Vishwa Vidyapeetham University | India | 4 |

| 5 | Indian Institute of Science | India | 4 |

| 6 | National Metallurgical Laboratory | India | 4 |

| 7 | Visvesvaraya Technological University | India | 4 |

| 8 | National University of Singapore | Singapore | 3 |

| 9 | Amrita Vishwa Vidyapeetham University | India | 3 |

| 10 | Anna University | India | 3 |

| Rank | Country | P | Links | TLS |

|---|---|---|---|---|

| 1 | Peoples Republic of China | 2475 | 42 | 681 |

| 2 | USA | 1104 | 47 | 537 |

| 3 | India | 2509 | 45 | 350 |

| 4 | Germany | 525 | 43 | 332 |

| 5 | England | 325 | 40 | 274 |

| 6 | France | 282 | 36 | 259 |

| 7 | Japan | 312 | 28 | 186 |

| 8 | Canada | 259 | 27 | 155 |

| 9 | Iran | 463 | 26 | 145 |

| 10 | South Korea | 372 | 25 | 143 |

| 11 | Australia | 172 | 23 | 142 |

| 12 | Spain | 245 | 26 | 130 |

| 13 | Egypt | 157 | 17 | 124 |

| Sr. No. | Linked Country | Link Strength |

|---|---|---|

| 1 | People Republic of China | 171 |

| 2 | India | 50 |

| 3 | South Korea | 26 |

| 4 | Japan | 24 |

| 5 | France | 23 |

| 6 | Egypt | 19 |

| 7 | Canada | 18 |

| 8 | Turkey | 16 |

| 9 | England | 15 |

| 10 | Germany | 15 |

| Sr. No. | Linked Country | Link Strength |

|---|---|---|

| 1 | USA | 50 |

| 2 | England | 30 |

| 3 | Singapore | 28 |

| 4 | Germany | 25 |

| 5 | South Africa | 22 |

| 6 | Australia | 19 |

| 7 | Portugal | 16 |

| 8 | South Korea | 16 |

| 9 | People Republic of China | 13 |

| 10 | Oman | 9 |

| Rank | Title of Article | Authors | Year | Journal | Citations | Links |

|---|---|---|---|---|---|---|

| 1 | Metal matrix composites—from science to technological significance [113] | D.B. Miracle | 2005 | Composites Science and Technology | 1006 | 333 |

| 2 | Carbon nanotube reinforced metal matrix composites—a review [105] | S. R. Bakshi, D. Lahiri and A. Agarwal | 2010 | International Materials Reviews | 879 | 212 |

| 3 | Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets [106] | S.C. Tjong | 2013 | Materials Science & Engineering R: Reports | 552 | 200 |

| 4 | Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites [108] | M.Kok | 2005 | Journal of Materials Processing Technology | 407 | 130 |

| 5 | P/M aluminum matrix composites: An overview [109] | J.M. Torralba, C.E. da Costa and F. Velasco | 2003 | Journal of Materials Processing Technology | 458 | 130 |

| 6 | Mechanical behavior of particle reinforced metal matrix composites [110] | N. Chawla and Y.L. Shen | 2001 | Advanced engineering materials | 436 | 128 |

| 7 | Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties [107] | S.C. Tjong | 2007 | Advanced engineering materials | 348 | 122 |

| 8 | Metal Matrix Composites [114] | A. Mortensen and J. Llorca | 2010 | Annual Review of Materials Research | 207 | 116 |

| 9 | Particle distribution in cast metal matrix composites—Part I [111] | J. Hashim, L. Looney and M.S.J. Hashmi | 2002 | Journal of Materials Processing Technology | 287 | 114 |

| 10 | Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study [112] | K.M. Shorowordi, T. Laoui, A.S.M.A. Haseeb, J.P. Celis and L. Froyen | 2003 | Journal of Materials Processing Technology | 397 | 110 |

| Rank | Author | Country | P | Citations | Links | TLS |

|---|---|---|---|---|---|---|

| 1 | Zhang, D | China | 113 | 3278 | 777 | 7016 |

| 2 | Li, Z | China | 93 | 2617 | 733 | 5921 |

| 3 | Fan, G | China | 46 | 2168 | 581 | 4662 |

| 4 | Guo, Q | China | 50 | 1536 | 525 | 4230 |

| 5 | Li, J | China | 117 | 1903 | 815 | 3936 |

| 6 | Wang, x | China | 80 | 2088 | 740 | 3622 |

| 7 | Su, Y | China | 46 | 1244 | 567 | 3330 |

| 8 | Gupta, M | Singapore | 140 | 3546 | 738 | 3287 |

| 9 | Tan, Z | China | 34 | 1064 | 423 | 3233 |

| 10 | Ji, G | China | 40 | 927 | 459 | 3164 |

| 11 | Xiong, Db | China | 34 | 1028 | 427 | 3091 |

| 12 | Wu, G | China | 70 | 1185 | 591 | 2805 |

| 13 | chen, z | Australia | 50 | 1443 | 634 | 2804 |

| Sr. No. | Linked Author | Link Strength |

|---|---|---|

| 1 | Li, Z | 334 |

| 2 | Guo, Q | 283 |

| 3 | Fan, G | 259 |

| 4 | Xiong, Db | 209 |

| 5 | Su, Y | 207 |

| 6 | Tan, Z | 184 |

| 7 | Ji, G | 97 |

| 8 | Zhang, J | 93 |

| 9 | Zhao, L | 87 |

| 10 | Li, J | 70 |

| Sr. No. | Linked Author | Link Strength |

|---|---|---|

| 1 | Tun, Ks | 112 |

| 2 | Wong, Wle | 62 |

| 3 | Sankaranarayanan, S | 61 |

| 4 | Jayalakshmi, S | 60 |

| 5 | Habibi, Mk | 51 |

| 6 | Nguyen, Qb | 47 |

| 7 | Paramsothy, M | 41 |

| 8 | Shakoor, Ra | 34 |

| 9 | Perez, P | 31 |

| 10 | Adeva, P | 31 |

| Rank | Organization | Country | P | Citations | Links | TLS |

|---|---|---|---|---|---|---|

| 1 | Shanghai Jiao Tong University | China | 270 | 5323 | 544 | 4433 |

| 2 | Harbin Institute of Technology | China | 335 | 5659 | 565 | 3938 |

| 3 | Indian Institutes of Technology | India | 223 | 5109 | 592 | 3272 |

| 4 | Chinese Academy Science | China | 227 | 3925 | 498 | 3010 |

| 5 | National University of Singapore | Singapore | 160 | 4185 | 456 | 2277 |

| 6 | National Institutes of Technology | India | 155 | 2499 | 461 | 2187 |

| 7 | University of Science and Technology Beijing | China | 118 | 3199 | 341 | 1822 |

| 8 | Islamic Azad University | Afghanistan | 108 | 2249 | 433 | 1816 |

| 9 | Northwestern Polytechnic University | USA | 132 | 1780 | 395 | 1715 |

| 10 | Anna University | India | 112 | 2124 | 424 | 1602 |

| 11 | Osaka University | Japan | 51 | 2223 | 297 | 1584 |

| 12 | University of Tehran | Iran | 72 | 2389 | 403 | 1509 |

| 13 | University of Wisconsin-Madison | USA | 60 | 2524 | 417 | 1337 |

| Sr. No. | Linked Organization | Country | Link Strength |

|---|---|---|---|

| 1 | Indian Institutes of Technology | India | 73 |

| 2 | Anna University | India | 49 |

| 3 | National University of Singapore | Singapore | 43 |

| 4 | Amrita Vishwa Vidyapeetham University | India | 42 |

| 5 | Council of Scientific and Industrial Research | India | 32 |

| 6 | Gazi University | Turkey | 30 |

| 7 | Jadavpur University | India | 30 |

| 8 | Harbin Institute of Technology | China | 29 |

| 9 | University of Tehran | Iran | 26 |

| 10 | Annamalai University | India | 23 |

| Sr. No. | Linked Organization | Country | Link Strength |

|---|---|---|---|

| 1 | National Institutes of Technology | India | 49 |

| 2 | Indian Institutes of Technology | India | 36 |

| 3 | Harbin Institute of Technology | China | 29 |

| 4 | K Ramakrishnan College of Engineering | India | 20 |

| 5 | PSG College Of Technology | India | 20 |

| 6 | Sri Krishna College of Engineering and Technology | India | 19 |

| 7 | Annamalai University | India | 17 |

| 8 | University of Wisconsin-Madison | USA | 16 |

| 9 | Gazi University | Turkey | 15 |

| 10 | Kongu Engineering College | India | 15 |

| Rank | Country | P | Citations | Links | TLS |

|---|---|---|---|---|---|

| 1 | Peoples Republic of China | 2475 | 43,374 | 66 | 20,878 |

| 2 | India | 2509 | 34,715 | 66 | 17,501 |

| 3 | USA | 1104 | 33,038 | 66 | 13,112 |

| 4 | Iran | 463 | 10,830 | 63 | 5938 |

| 5 | Germany | 525 | 11,654 | 64 | 5042 |

| 6 | Turkey | 392 | 7784 | 62 | 4678 |

| 7 | England | 325 | 10,849 | 64 | 3799 |

| 8 | South Korea | 372 | 6264 | 62 | 3598 |

| 9 | Japan | 312 | 6452 | 64 | 3489 |

| 10 | France | 282 | 7011 | 61 | 3397 |

| 11 | Australia | 172 | 5240 | 64 | 3077 |

| 12 | Canada | 259 | 6846 | 59 | 2922 |

| 13 | Spain | 245 | 5763 | 61 | 2797 |

| Sr. No. | Linked Country | Link Strength |

|---|---|---|

| 1 | India | 1407 |

| 2 | Peoples Republic of China | 988 |

| 3 | USA | 568 |

| 4 | Turkey | 261 |

| 5 | South Korea | 184 |

| 6 | Australia | 160 |

| 7 | Germany | 153 |

| 8 | England | 150 |

| 9 | Egypt | 145 |

| 10 | Japan | 140 |

| Rank | Source | P | Citations | Links | TLS |

|---|---|---|---|---|---|

| 1 | Materials Science and Engineering: A-Structural Materials: Properties, Microstructure and Processing | 640 | 18,715 | 242 | 6634 |

| 2 | Journal of Alloys and Compounds | 468 | 12,992 | 213 | 4377 |

| 3 | Materials & Design | 273 | 11,299 | 229 | 4364 |

| 4 | Composites Science and Technology | 185 | 10,482 | 225 | 3109 |

| 5 | Composites Part A: Applied Science and Manufacturing | 200 | 8708 | 222 | 2987 |

| 6 | Journal of Materials Processing Technology | 157 | 8198 | 218 | 2895 |

| 7 | Composites Part B: Engineering | 200 | 7212 | 194 | 2254 |

| 8 | Materials Today: Proceedings | 435 | 2024 | 160 | 2155 |

| 9 | Acta Materialia | 131 | 7726 | 172 | 1983 |

| 10 | Wear | 129 | 6007 | 191 | 1883 |

| 11 | The International Journal of Advanced Manufacturing Technology | 133 | 2755 | 146 | 1575 |

| 12 | Scripta Materialia | 100 | 5105 | 161 | 1397 |

| 13 | Journal of Materials Science | 139 | 2667 | 158 | 1257 |

| Sr. No. | Linked Journal | Link Strengtp |

|---|---|---|

| 1 | Journal of Materials Processing Technology | 187 |

| 2 | International Journal of Machine Tools & manufacture | 111 |

| 3 | Materials and Manufacturing Processes | 87 |

| 4 | Wear | 67 |

| 5 | Materials & Design | 52 |

| 6 | Materials Science and Engineering a-structural Materials Properties | 50 |

| 7 | Materials Today-proceedings | 46 |

| 8 | Composites Science and Technology | 44 |

| 9 | Advances in Manufacturing | 41 |

| 10 | International Journal of Mechanical Sciences | 38 |

| Sr. No. | Linked Journal | Link Strength |

|---|---|---|

| 1 | Materials Science and Engineering: A-Structural Materials: Properties, Microstructure and Processing | 172 |

| 2 | Journal of Alloys and Compounds | 138 |

| 3 | Materials & Design | 95 |

| 4 | Composites Part a-applied Science and Manufacturing | 80 |

| 5 | Acta Materialia | 67 |

| 6 | Composites Part b-engineering | 52 |

| 7 | Composites Science and Technology | 46 |

| 8 | Advanced Engineering Materials | 37 |

| 9 | Carbon | 34 |

| 10 | Journal of Materials Science | 33 |

| Rank | Keyword | P | Links | TLS |

|---|---|---|---|---|

| 1 | Metal Matrix Composites | 2135 | 845 | 5566 |

| 2 | Mechanical Properties | 1255 | 599 | 3643 |

| 3 | Microstructure | 962 | 597 | 2922 |

| 4 | Wear | 511 | 429 | 1701 |

| 5 | Metal-Matrix Composites (mmcs) | 485 | 280 | 1383 |

| 6 | Composites | 437 | 425 | 1284 |

| 7 | Powder Metallurgy | 423 | 360 | 1272 |

| 8 | Metal Matrix Composite | 457 | 466 | 1222 |

| 9 | Hardness | 295 | 338 | 1081 |

| 10 | Metal-Matrix Composites | 403 | 374 | 1060 |

| 11 | Stir Casting | 328 | 309 | 1026 |

| 12 | Aluminum | 256 | 300 | 852 |

| 13 | Composite | 264 | 327 | 794 |

| Rank | Keywords | Year | Strength | Begin | End | 2001–2020 |

|---|---|---|---|---|---|---|

| 1 | Graphene | 2001 | 33.6453 | 2018 | 2020 |  |

| 2 | Fracture | 2001 | 24.5309 | 2001 | 2009 |  |

| 3 | Damage | 2001 | 24.1626 | 2001 | 2009 |  |

| 4 | Deformation | 2001 | 22.9149 | 2001 | 2008 |  |

| 5 | Strengthening Mechanism | 2001 | 20.45 | 2017 | 2020 |  |

| 6 | Creep | 2001 | 20.4049 | 2001 | 2010 |  |

| 7 | Stir Casting | 2001 | 19.9426 | 2018 | 2020 |  |

| 8 | Nanocomposite | 2001 | 16.9666 | 2016 | 2018 |  |

| 9 | Flow | 2001 | 16.3026 | 2001 | 2010 |  |

| 10 | Residual Stresses | 2001 | 15.6975 | 2001 | 2008 |  |

| 11 | Particulate Composite | 2001 | 15.6215 | 2001 | 2010 |  |

| 12 | Powder Processing | 2001 | 15.1708 | 2007 | 2016 |  |

| 13 | Metal Matrix Composites (mmc) | 2001 | 14.8633 | 2006 | 2011 |  |

| 14 | Pressureless Infiltration | 2001 | 14.2745 | 2006 | 2011 |  |

| 15 | B4C | 2001 | 13.6994 | 2018 | 2020 |  |

| Rank | References | Year | Strength | Begin | End | 2001–2020 |

|---|---|---|---|---|---|---|

| 1 | LLOYD DJ, 1994, INT MATER REV, V39, P1 [115] | 1994 | 72.1562 | 2001 | 2005 |  |

| 2 | IBRAHIM IA, 1991, J MATER SCI, V26, P1137 [116] | 1991 | 38.8436 | 2001 | 2005 |  |

| 3 | CHRISTMAN T, 1989, ACTA METALL MATER, V37, P3029 [118] | 1989 | 33.77 | 2001 | 2005 |  |

| 4 | Clyne TW, 1993, INTRO METAL MATRIX C, V0, P0 [119] | 1993 | 33.2064 | 2001 | 2005 |  |

| 5 | ESHELBY JD, 1957, PROC R SOC LON SER-A, V241, P376 [128] | 1957 | 32.0793 | 2001 | 2005 |  |

| 6 | BAO G, 1991, ACTA METALL MATER, V39, P1871 [121] | 1991 | 29.2619 | 2001 | 2005 |  |

| 7 | LLOYD DJ, 1991, ACTA METALL MATER, V39, P59 [122] | 1991 | 26.4452 | 2001 | 2005 |  |

| 8 | ARSENAULT RJ, 1986, MATER SCI ENG, V81, P175 [41] | 1986 | 26.4452 | 2001 | 2005 |  |

| 9 | MCDANELS DL, 1985, METALL TRANS A, V16, P1105 [125] | 1985 | 22.5029 | 2001 | 2005 |  |

| 10 | MORI T, 1973, ACTA METALL MATER, V21, P571 [126] | 1973 | 21.9398 | 2001 | 2005 |  |

| 11 | NARDONE VC, 1986, SCRIPTA METALL MATER, V20, P43 [120] | 1986 | 21.9398 | 2001 | 2005 |  |

| 12 | VOGELSANG M, 1986, METALL TRANS A, V17, P379 [124] | 1986 | 19.6878 | 2001 | 2005 |  |

| 13 | TJONG SC, 2000, MAT SCI ENG R, V29, P49 [127] | 2000 | 19.628 | 2002 | 2005 |  |

| 14 | BRECHET Y, 1991, ACTA METALL MATER, V39, P1781 [123] | 1991 | 18.7652 | 2001 | 2004 |  |

| 15 | ROHATGI P K, 1986, INTERNATIONAL METALS REVIEWS, V31, P115 [117] | 1986 | 17.999 | 2001 | 2005 |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sekhar, R.; Sharma, D.; Shah, P. State of the Art in Metal Matrix Composites Research: A Bibliometric Analysis. Appl. Syst. Innov. 2021, 4, 86. https://doi.org/10.3390/asi4040086

Sekhar R, Sharma D, Shah P. State of the Art in Metal Matrix Composites Research: A Bibliometric Analysis. Applied System Innovation. 2021; 4(4):86. https://doi.org/10.3390/asi4040086

Chicago/Turabian StyleSekhar, Ravi, Deepak Sharma, and Pritesh Shah. 2021. "State of the Art in Metal Matrix Composites Research: A Bibliometric Analysis" Applied System Innovation 4, no. 4: 86. https://doi.org/10.3390/asi4040086