Effect of Binder on Oxidation Properties of Tungsten Carbides: A Review by a Conceptual Classification Approach

Abstract

:1. Introduction

2. Survey Methodology

2.1. Step 1: Survey Resources and Methodology to Search for and Select the Relevant Papers

2.2. Step 2: Classification of Extracted Papers

- 1.

- The number of papers according to the year of publication;

- 2.

- The title of journals, taking the number of relevant publications into account;

- 3.

- The names of the author and co–authors, taking into account the number of relevant publications;

- 4.

- Conceptual classification scheme for evaluating the extracted articles.

3. Questions and Possible Answers for Conceptual Classification of Selected Documents

3.1. Production Method

- Standard vacuum sintering

- The main idea behind this method is that cold pressing of ceramic powder and additives and producing an initial product (green body) and then sintering at high temperature is a simple and low–cost alternative for producing cermets or ceramic composites [25]. However, the most crucial challenge in this method is the porosity problem, which is a general challenge in methods based on powder compaction [26]. The cold isostatic press (CIP) increases the density of the component compared to the uniaxial press, and consequently enhances the hardness, strength, and corrosion resistance of cermets for this reason [27,28]. Furthermore, the difference in thermal expansion coefficients can show itself in the form of cracks or other defects during high–temperature sintering [29]. Among the articles that have dealt with the oxidation of tungsten carbide cermets and are reviewed in this research, various reports have used this method to produce the parts [7,8,10,11,13,15,16,19,28,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44].

- Spark plasma sintering (SPS): This relatively new production method has been developed for sintering ceramic components in a short period with minimal porosity [45]. In this method, in addition to imposing mechanical pressure, plasma is formed between the powder particles by using direct and pulsed high currents passing through a conductive mold (which is usually made of graphite) [46,47]. The condition resulting from plasma formation and ion bombardment of powder particles enhances the particles’ sintering efficiency and bond strength [48,49]. The high rate of heating, achieved by passing a high electric current, prevents particle growth and/or oxidation during the sintering process, which enables the production of nanostructured materials more easily [2,50]. Furthermore, this method can provide a density close to the theoretical one and almost complete elimination of porosity. It is worth mentioning that the SPS method has been extensively used to produce ceramic and metallic nanomaterials, composites and cermets, electronic materials, thermoelectric materials, biomaterials, etc. [45,49]. This method has also been used extensively in the research field of cemented carbides, and in particular some of the articles reviewed on the topic of oxidation have made tungsten carbide samples with this method [2,3,28,51,52,53,54].

- Hot press (HP): Hot press is a common method for densifying ceramic composites with powder raw material, which can be used both as a single method or in combination with other densification methods [55]. The main advantages of the hot press method are: (1) the concurrent use of temperature and pressure, which leads to products with low porosity, and (2) its lower equipment cost in comparison with the SPS method. In this press type, a more homogeneous structure can be achieved compared to the cold press [56]. Some articles dealing with oxidation have used this method to produce tungsten carbide [18,57,58,59,60,61,62,63].

- Hot isostatic press (HIP): In this method, the pressure is exerted uniformly from all directions through hydrostatic gas pressure at high temperatures. Therefore, complex components with homogeneous structures can be produced through this method [64]. Hot isostatic pressing is very efficient in removing any residual porosities, but it is a relatively expensive process [25]. In this densification method, the component after the sintering process can reach a density of 99.8% or even higher [65]. This method can be used for the production of cermets and ceramics, and even improving the mechanical properties of advanced alloys [66]. This method has been used to consolidate samples in research on tungsten carbide oxidation [67,68,69,70,71,72].

3.2. Type of Binder

- Cobalt (Co): cobalt is the most important and widely used metal in tungsten carbide composites due to its suitable melting temperature and proper wettability. The use of cobalt results not only in excellent wettability and adhesion to tungsten carbide, but also in increased strength at room [73,74] and elevated temperatures [75,76]. Moreover, according to Basu and Sarin [15], to a certain extent, as the weight percentage of cobalt binder increases, the oxidation resistance of tungsten carbide improves. In some studies on improving the oxidation resistance of cemented carbides, cobalt was still used as a conventional binder [9,11,20,33,34,35,39,52,53,57,58,68,69,71,77,78]. The reasons for this are explained in the results and discussion section.

- Nickel (Ni): The previous investigations showed that nickel can be a proper alternative to cobalt in the production of tungsten carbide cermets in terms of cost and availability [7]. According to Zhang et al. [73], using nickel results in creating a strong bond between tungsten carbide powder particles, proper resistance to oxidation at high temperatures, and resistance to wear in crucial condition. Therefore, in the oxidation research field, some articles worked on Ni–binder–containing cermets [13,16].

- Chromium (Cr): Using chromium as another substitute for cobalt improves oxidation and corrosion resistance. Moreover, using this element as a binder in cemented carbides increases the hardness [4].

- Molybdenum (Mo): As another carbide–forming element like chromium, molybdenum is used as a binder in tungsten carbide composites. It should be noted that the oxidation resistance of tungsten carbide at high temperature reduces with increasing molybdenum [4]. A recent investigation shows that molybdenum in the form of secondary carbide (Mo2C) also has a detrimental effect on the oxidation properties of cemented carbides [80].

- Pure iron (Fe): Based on the price parameter, pure iron has been considered as a binder used in the consolidation of tungsten carbide powder [13,42,59]. Although iron is cheaper than nickel and cobalt, its oxidation resistance is not remarkable. In addition, the hardness and fracture toughness of the iron binder is equal to those of the cobalt binder [13].

- Fe–based alloys: Fe–based alloys have been given attention as substitutes for cobalt to overcome the shortcomings of pure iron [31,32,36,41,44,59,72,74]. Due to its high affinity to carbon, iron can be an obstacle to the growth of tungsten carbide particles during the sintering thermal cycle. Nickel can efficiently play an important role in stabilizing the austenite phase up to room temperature to overcome the above–mentioned limitations [5]. Therefore, a combination of these two elements as a binder increases hardness, resistance to oxidation, corrosion, and cracking compared to cermets with the cobalt binder [36]. On the other hand, along with limitations due to the price and toxicity of cobalt, since the most important reason for the replacement of cobalt has been the oxidation problem, stainless steels have also been considered as binders [31,72]. The use of stainless steel as a binder can enhance oxidation resistance and increase the fracture toughness and wear resistance concurrently [5]. Other Fe–based alloys with the combination of alloying elements such as manganese have also received increasing attention from researchers in the area of oxidation [32,81,82].

- Nickel aluminide (Ni3Al): The intermetallic compounds have captured significant attention from both academia and industry because of the limitation of oxidation resistance in cobalt binders [83,84]. Due to its excellent physical and mechanical properties, such as high hardness and outstanding oxidation resistance, nickel aluminide has attracted wide attention among intermetallic alloys as a substitute for cobalt in cemented carbides [5,51,85,86].

- Iron aluminide (FeAl): Iron aluminide is a suitable alternative to cobalt, due to its resistance to oxidation and compatibility with better environmental conditions [2,7,40]. In this regard, increasing the amount of binder can reduce the hardness and increase the fracture toughness. In addition, WC–FeAl cermet has better behavior with respect to carbon trioxide, with a 30% longer lifetime than WC–Co [73]. The lower cost of FeAl than Ni3Al, low density, high melting point, high thermal conductivity, and protective layer of alumina against high–temperature oxidation have increased the use of this type of binder [6].

- Alumina (Al2O3): Alumina is also a cost–effective ceramic binder, with higher hardness, better corrosion/oxidation resistance, and higher chemical stability at high temperatures than cobalt, which has been used as the binder in oxidation investigations of tungsten carbides [54,61,62,63]. Furthermore, in contrast to metal binders, Al2O3 binder can not only facilitate the sintering process but also prevent the growth of tungsten carbide particles and the formation of W2C [5].

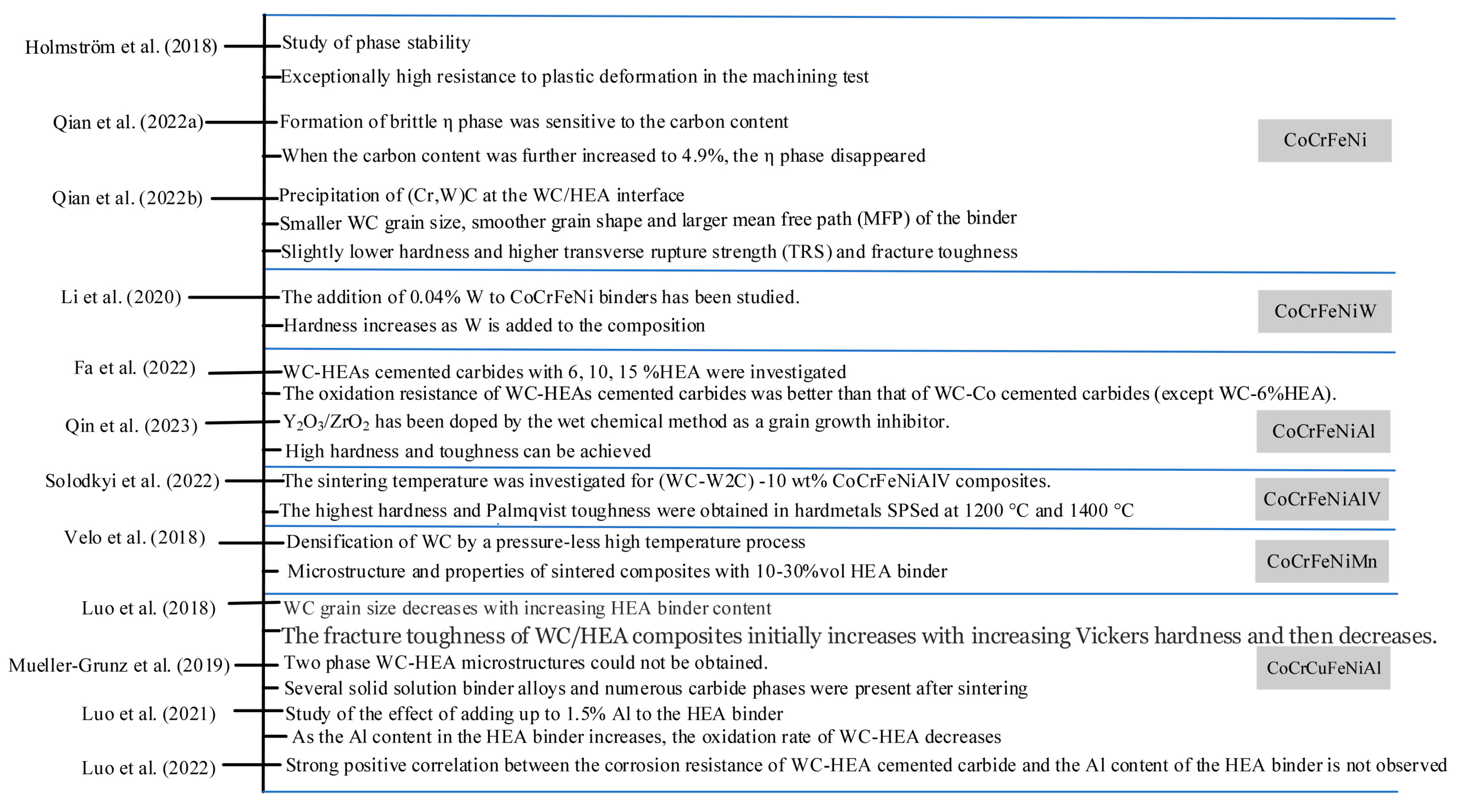

- High–entropy alloys (HEAs): The main feature of HEAs is that they provide the possibility of creating extraordinary properties by combining several different elements [87,88,89,90]. The use of HEAs as a binder in tungsten carbide compounds simultaneously increases the hardness and toughness of the product, and consequently can be a new and versatile binder compared to cobalt [5,91,92,93,94]. Regarding the attention which has been drawn to this type of binder in recent years, few articles with HEA binders have studied oxidation properties [3,95,96]. However, concerning the simultaneous improvement of hardness and toughness as two vital properties of tungsten carbide cermets, as it will be discussed in Section 4, this topic may be more researched in the coming years.

3.3. Binder Modification Approach in Oxidation Studies

- Using new binder and comparison with previous studies: In this procedure, while using a new binder to improve the oxidation resistance, the author compares the obtained results with previous ones, which are usually cermets with a cobalt binder;

- Investigating the effect of various fractions of binder on tungsten carbide: This type of research uses various percentages of a binder to investigate how the additional binder volume affects the oxidation properties of tungsten carbide;

- Studying the effect of adding a small amount of an additive to the binder: The author studies the effect of adding a small amount of a modifying additive to the binder. Note that the modifying additive in tungsten carbides is usually chromium.

3.4. Oxidation Outcome

- Significant improvement: This category includes research in which changing the binder has a beneficial effect on the oxidation resistance of tungsten carbide and reduces the oxidation rate;

- Minor improvement: This category includes binders with a small effect on reducing the oxidation rate of tungsten carbide;

- Reduction in oxidation resistance: In this category, the use of a binder other than cobalt has been identified as ineffective or destructive for oxidation resistance;

- No comparison with conventional WC–based cermets: In this category, the authors have not investigated the positive or negative effect of modification of the binder on the oxidation rate of tungsten carbide.

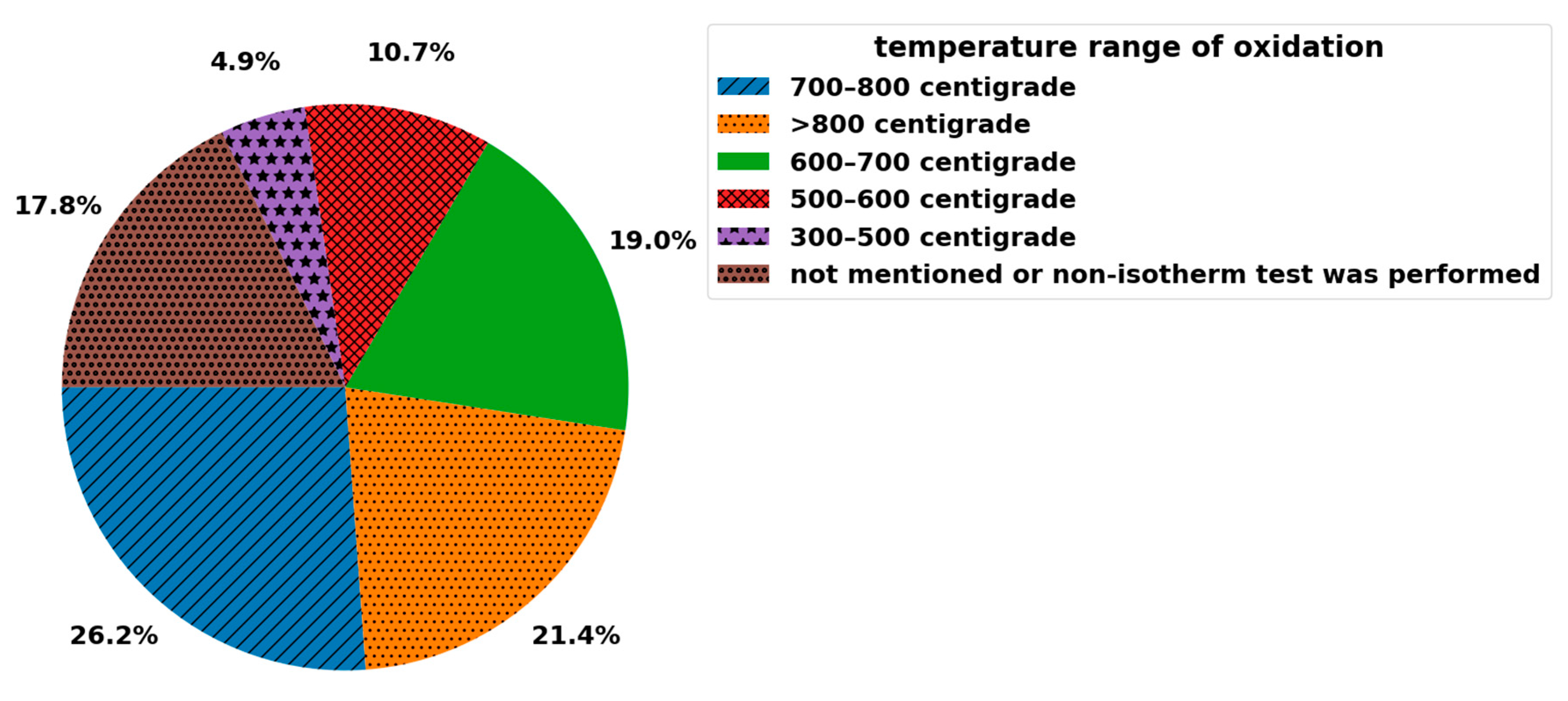

3.5. Temperature Range of Oxidation Tests

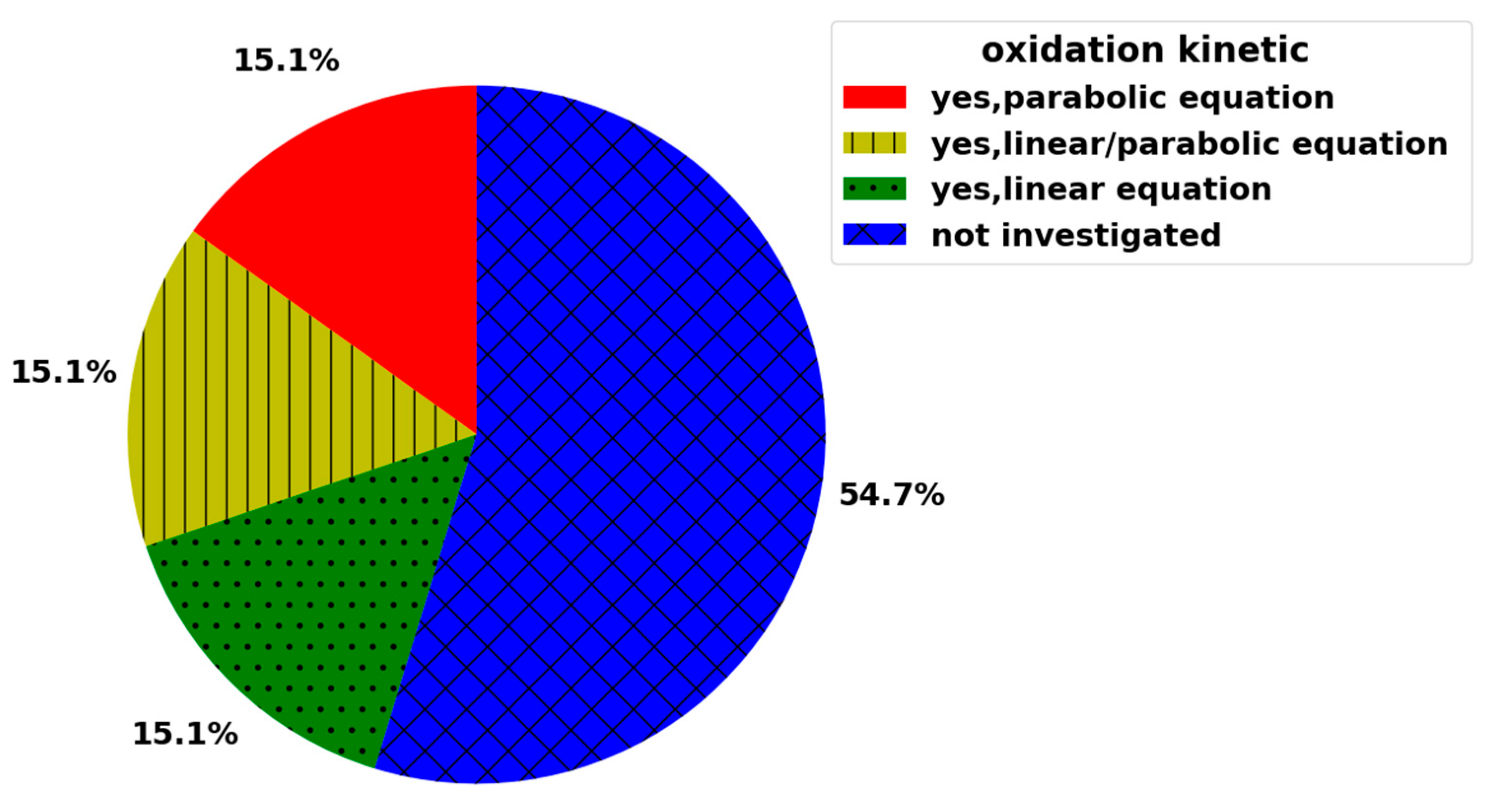

3.6. Kinetics of Oxidation

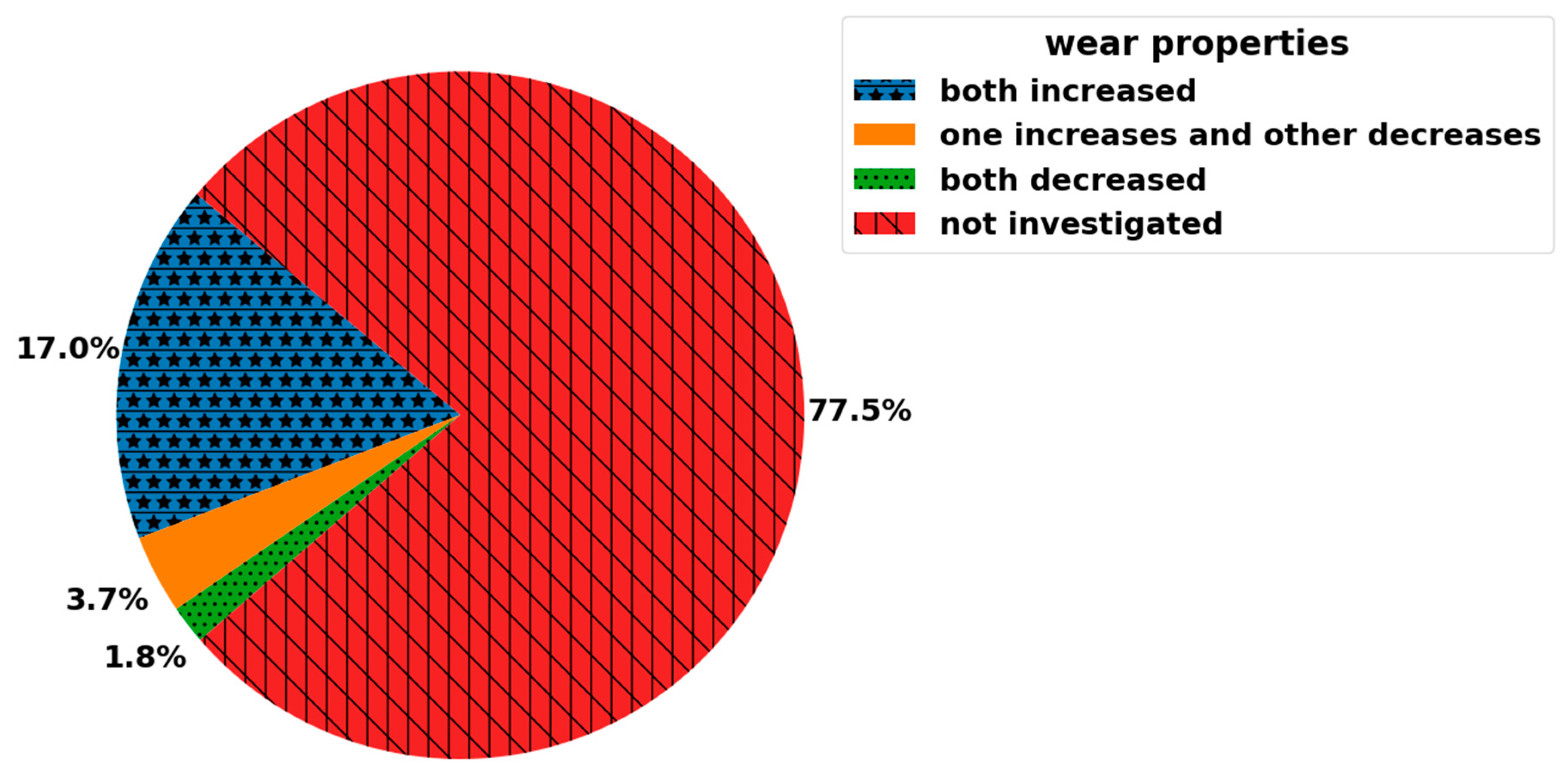

3.7. Changes of Wear Resistance in Connection with Alteration of Oxidation Resistance

- The wear properties increase as the oxidation properties increase;

- The wear properties reduce as the oxidation properties decrease;

- The wear properties reduce as the oxidation properties increases, or vice versa.

4. Statistical Discussion

5. Assessment of Statistical Analysis with Published Data

6. Conclusions and Directions for Future Research

- 1.

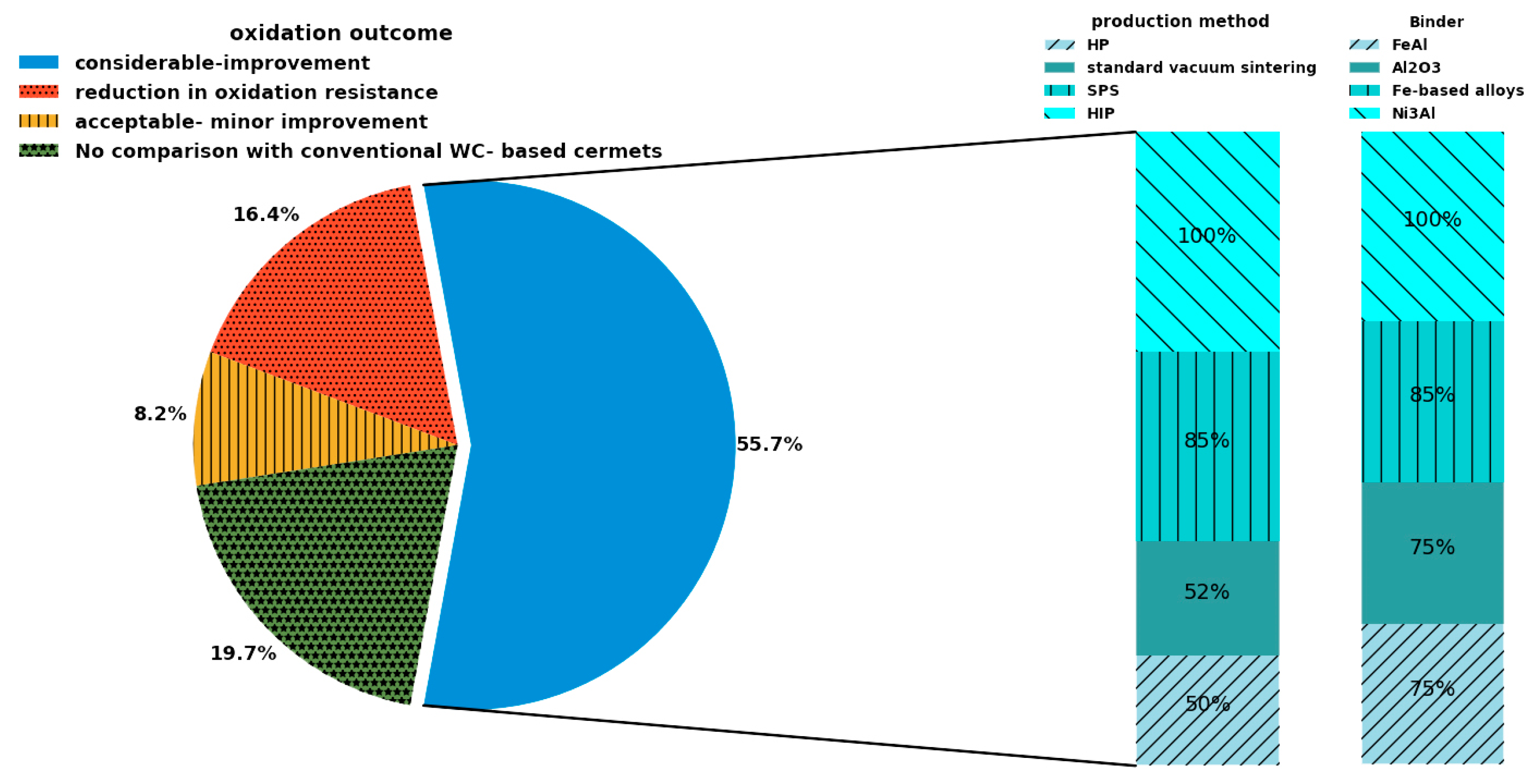

- Oxidation resistance is a crucial characteristic for tungsten carbide cermets, especially for processes with high machining speed. The findings of this survey showed that the studies that are conducted to improve the properties of this type of cermet do not all necessarily lead to the improvement of oxidation properties. It was indicated that a significant improvement of oxidation properties has been obtained in only 65.6% of the articles that changed the binder of WC–Co cemented carbides;

- 2.

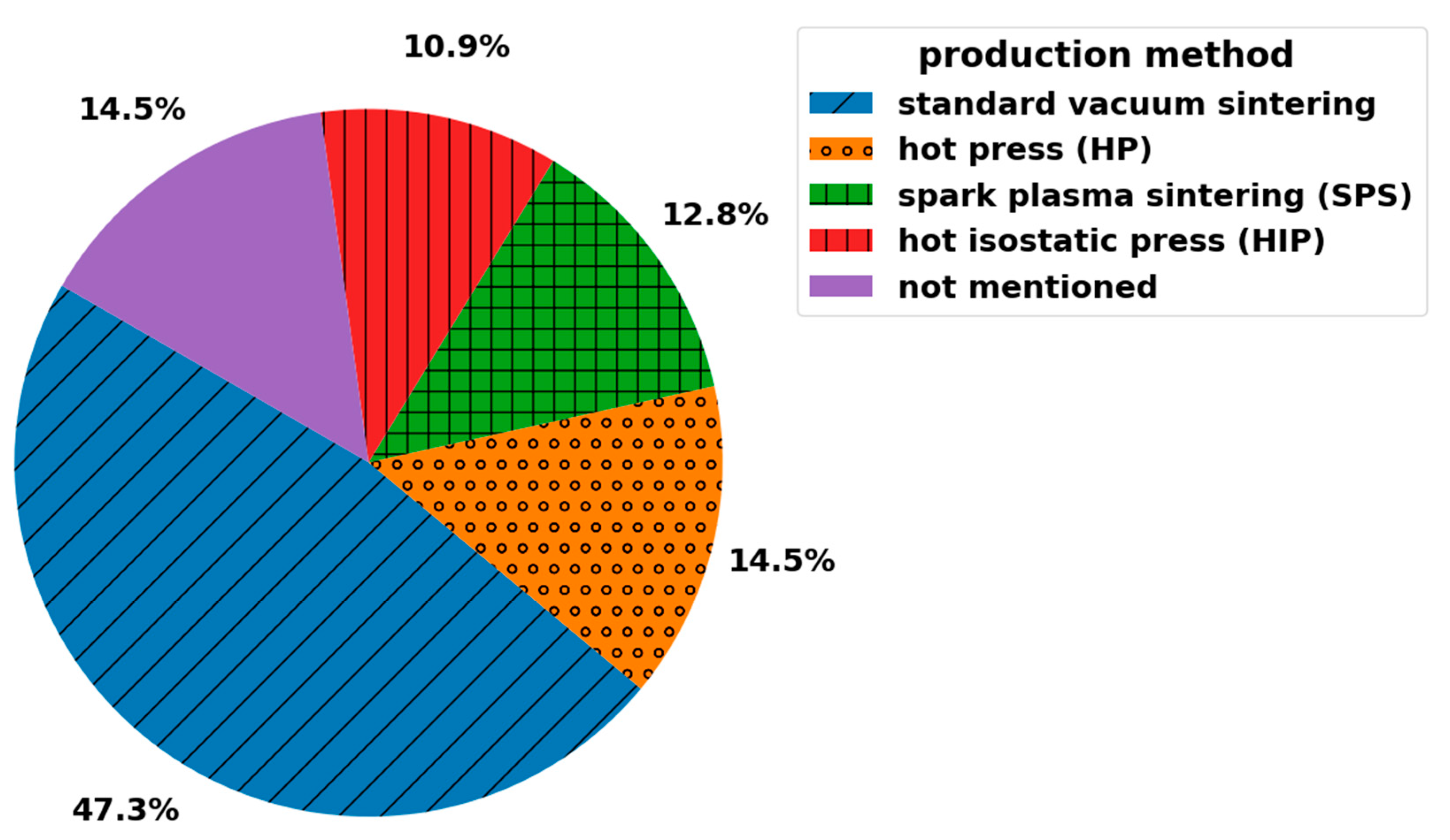

- Among the production methods reported in the reviewed articles regarding oxidation resistance, the most frequent method with a frequency of 47.3% belongs to the standard vacuum sintering technique. However, employing advanced production methods such as hot press (with a frequency of 14.5%), hot isostatic press (with a frequency of 10.9%), and spark plasma sintering (with a frequency of 12.7%) can lead to a success rate between 80 and 100 percent in oxidation improvement;

- 3.

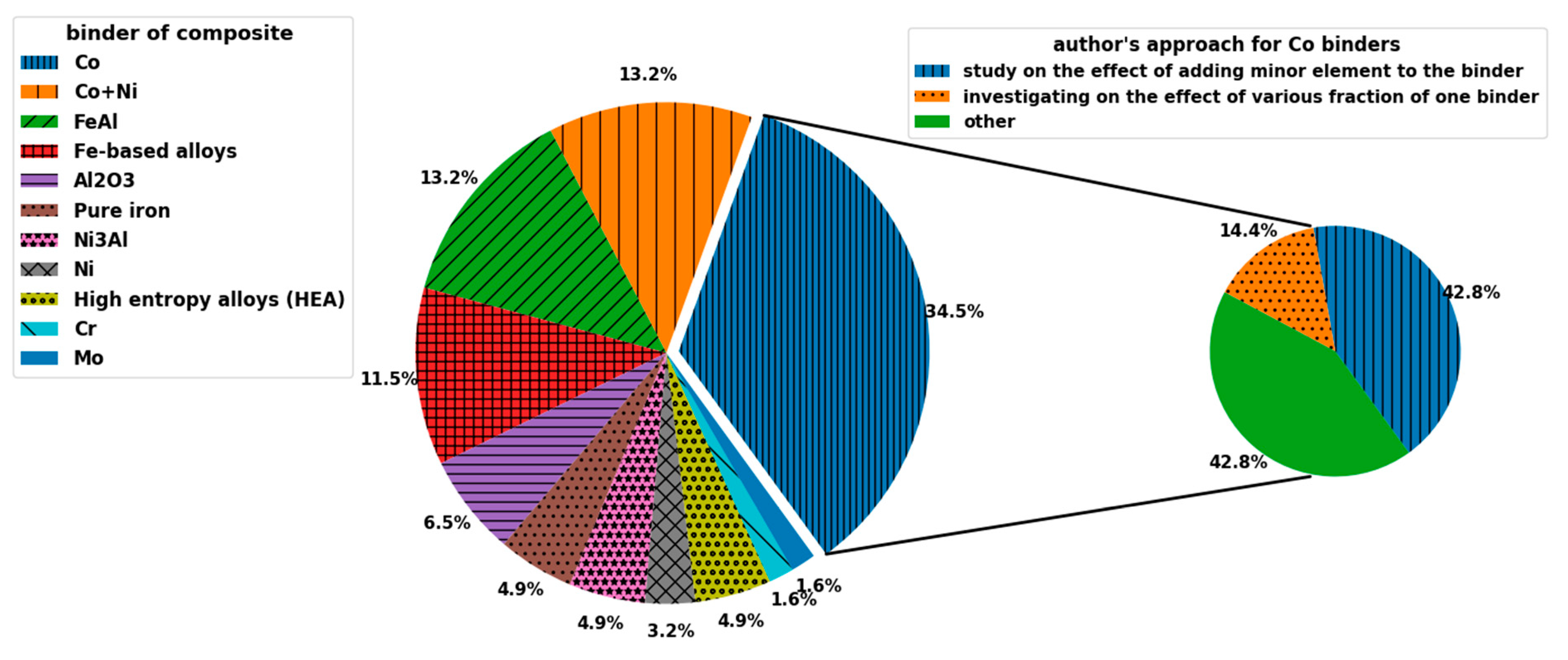

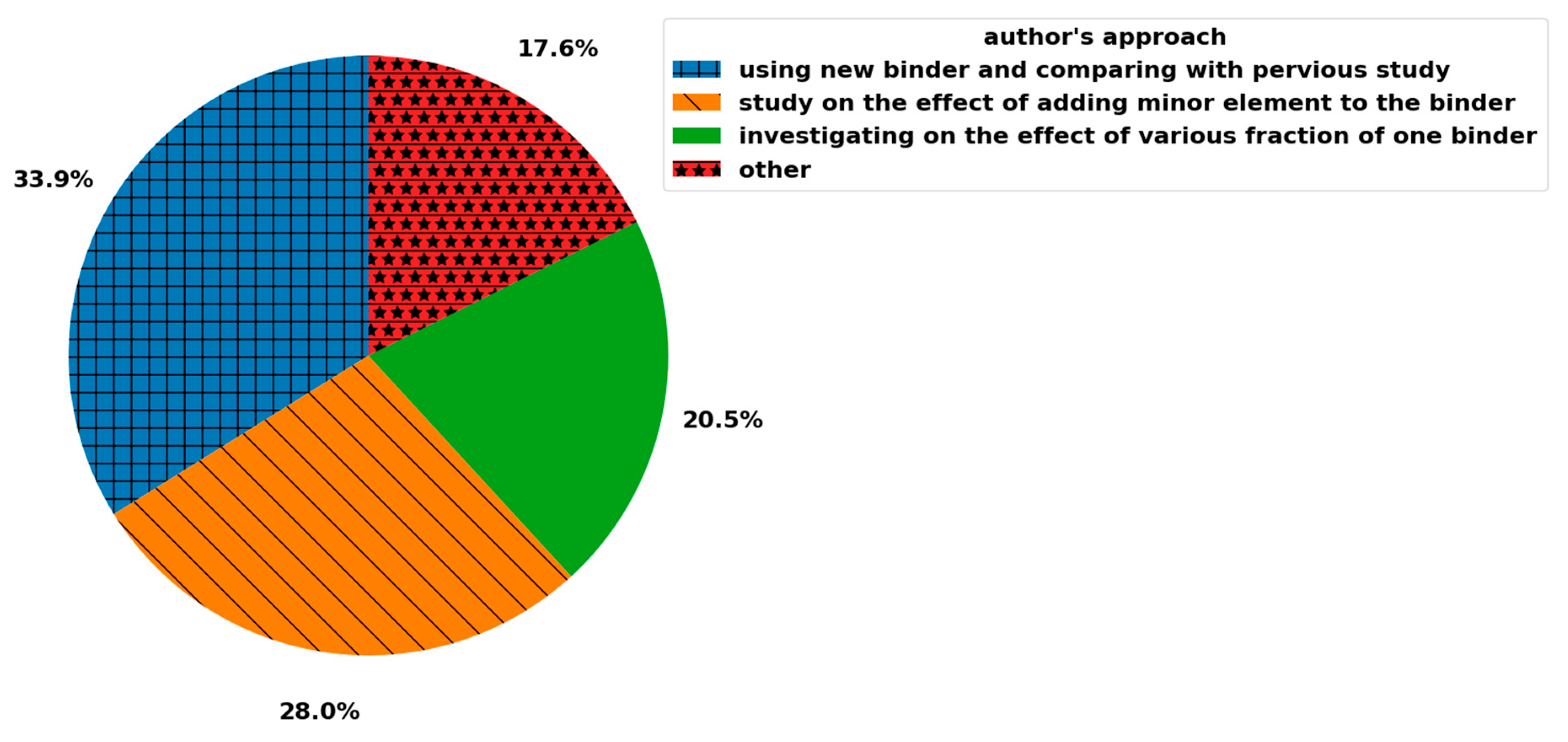

- Reviewed articles in the field of oxidation revealed that more than half of investigations (65.6%) used new binder in order to enhance oxidation resistance. It is also concluded that changing cemented carbide binders from cobalt to intermetallic compounds of Ni3Al, FeAl, Fe–based alloys, and Al2O3 accounts for the most extensive proportion of the articles that reported oxidation improvement. In recent years, replacing cobalt binders with high–entropy alloys (HEAs) for improving mechanical properties has attracted the attention of both manufacturers and researchers. However, only 4.9% of the reviewed articles focused on enhancing oxidation properties. Hence, investigation of the oxidation properties of tungsten carbide cermets with a binder of HEAs may be a potential direction for future studies;

- 4.

- The results of this research showed that the oxidation behavior of tungsten carbide cermets is reported in three modes, including parabolic, linear, and parabolic–linear, with almost the same frequency. This means the equation and trend of mass gain depend on the composition of the binder used. Furthermore, the oxidation activation energy of these cermets is reported to be around 230 kCal/mol;

- 5.

- It is proved from this survey that changing the binder to improve oxidation resistance can often maintain or improve wear resistance. From 22.7% of the articles in the field of oxidation that also examined wear resistance, 17% reported the improvement of both wear resistance and oxidation properties;

- 6.

- This survey focused on tungsten carbide as the main constituent of cermets. Several other studies have been performed to achieve higher mechanical properties using secondary carbides such as TiC, TaC, Mo2C, and VC in recent years. Meanwhile, some studies have been conducted on using some new addition such as graphene to improve mechanical properties. Furthermore, the use of cermets based on (Ti,W)(C,N) has been the subject of many studies, especially for conditions where the oxidation problem affects the cermet application. Although these three approaches were outside our survey topic, they have provided the prospect of achieving better properties, and future research in the field of oxidation may be carried out on these cermets.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Karimi, H.; Hadi, M.; Ebrahimzadeh, I.; Farhang, M.R.; Sadeghi, M. High-temperature oxidation behaviour of WC-FeAl composite fabricated by spark plasma sintering. Ceram. Int. 2018, 44, 17147–17153. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Liu, X.; Zhou, Z. Oxidation behavior of ultrafine WC-based cemented carbides with AlxCoCrCuFeNi high-entropy alloy binders. Ceram. Int. 2021, 47, 8498–8509. [Google Scholar] [CrossRef]

- Penrice, T. Alternative binders for hard metals. Carbide Tool J. 1988, 20, 12–15. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Gong, F.; Ni, X.; Li, Z. Development and application of WC-based alloys bonded with alternative binder phase. Crit. Rev. Solid State Mater. Sci. 2019, 44, 211–238. [Google Scholar] [CrossRef]

- Vilardell, A.; Cinca, N.; Tarrés, E.; Kobashi, M. Iron aluminides as an alternative binder for cemented carbides: A review and perspective towards additive manufacturing. Mater. Today Commun. 2022, 31, 103335. [Google Scholar] [CrossRef]

- Subramanian, R.; Schneibel, J. FeAl–TiC and FeAl–WC composites—Melt infiltration processing, microstructure and mechanical properties. Mater. Sci. Eng. A 1998, 244, 103–112. [Google Scholar] [CrossRef]

- Aristizabal, M.; Rodriguez, N.; Ibarreta, F.; Martinez, R.; Sanchez, J. Effect of the binder phase content and decarburization phenomena on the oxidation and wear resistance of WC-CoNiCr materials. In Proceedings of the EuroPM2009 Congress and Exhibition, Copenhagen, Denmark, 12–14 October 2009; EPMA: Shrewsbury, UK, 2009; pp. 299–306. [Google Scholar]

- Jianxin, D.; Hui, Z.; Ze, W.; Yunsong, L.; Jun, Z. Friction and wear behaviors of WC/Co cemented carbide tool materials with different WC grain sizes at temperatures up to 600 C. Int. J. Refract. Met. Hard Mater. 2012, 31, 196–204. [Google Scholar] [CrossRef]

- Chen, C.-S.; Yang, C.-C.; Chai, H.-Y.; Yeh, J.-W.; Chau, J.L.H. Novel cermet material of WC/multi-element alloy. Int. J. Refract. Met. Hard Mater. 2014, 43, 200–204. [Google Scholar] [CrossRef]

- Chen, L.; Yi, D.; Wang, B.; Liu, H.; Wu, C. Mechanism of the early stages of oxidation of WC–Co cemented carbides. Corros. Sci. 2016, 103, 75–87. [Google Scholar] [CrossRef]

- Erenkov, O.Y.; Yavorskii, D.; Kalenskii, A.; Lopushanskii, I.Y. Turning of Thermoplastics Using Ceramic Cutting Tools. Glass Ceram. 2020, 77, 194–196. [Google Scholar] [CrossRef]

- Shon, I.-J.; Jeong, I.-K.; Ko, I.-Y.; Doh, J.-M.; Woo, K.-D. Sintering behavior and mechanical properties of WC–10Co, WC–10Ni and WC–10Fe hard materials produced by high-frequency induction heated sintering. Ceram. Int. 2009, 35, 339–344. [Google Scholar] [CrossRef]

- Ojo-Kupoluyi, O.; Tahir, S.; Baharudin, B.; Azmah Hanim, M.; Anuar, M. Mechanical properties of WC-based hardmetals bonded with iron alloys—A review. Mater. Sci. Technol. 2017, 33, 507–517. [Google Scholar] [CrossRef]

- Basu, S.; Sarin, V. Oxidation behavior of WC-Co. Mater. Sci. Eng. A 1996, 209, 206–212. [Google Scholar] [CrossRef]

- Voitovich, V.; Sverdel, V.; Voitovich, R.; Golovko, E. Oxidation of WC-Co, WC-Ni and WC-Co-Ni hard metals in the temperature range 500–800 °C. Int. J. Refract. Met. Hard Mater. 1996, 14, 289–295. [Google Scholar] [CrossRef]

- Casas, B.; Ramis, X.; Anglada, M.; Salla, J.; Llanes, L. Oxidation-induced strength degradation of WC–Co hardmetals. Int. J. Refract. Met. Hard Mater. 2001, 19, 303–309. [Google Scholar] [CrossRef]

- Aly, S.; Hamad, K.; Salam, N.A.; Abdel-Hamid, S. Oxidation Kinetics of Tungsten Carbide-20cobalt Composite using Non-Isothermal Thermal Analysis. Int. J. Eng. Res. 2018, 7. [Google Scholar] [CrossRef]

- Lofaj, F.; Kaganovskii, Y.S. Kinetics of WC-Co oxidation accompanied by swelling. J. Mater. Sci. 1995, 30, 1811–1817. [Google Scholar] [CrossRef]

- Chen, L.; Wang, B.; Yi, D.; Liu, H. Non-isothermal oxidation kinetics of WC–6Co cemented carbides in air. Int. J. Refract. Met. Hard Mater. 2013, 40, 19–23. [Google Scholar] [CrossRef]

- Hachicha, W.; Ghorbel, A. A survey of control-chart pattern-recognition literature (1991–2010) based on a new conceptual classification scheme. Comput. Ind. Eng. 2012, 63, 204–222. [Google Scholar] [CrossRef]

- Kolbe, R.H.; Burnett, M.S. Content-analysis research: An examination of applications with directives for improving research reliability and objectivity. J. Consum. Res. 1991, 18, 243–250. [Google Scholar] [CrossRef]

- Maleki, M.R.; Amiri, A.; Castagliola, P. Measurement errors in statistical process monitoring: A literature review. Comput. Ind. Eng. 2017, 103, 316–329. [Google Scholar] [CrossRef]

- Maleki, M.R.; Amiri, A.; Castagliola, P. An overview on recent profile monitoring papers (2008–2018) based on conceptual classification scheme. Comput. Ind. Eng. 2018, 126, 705–728. [Google Scholar] [CrossRef]

- Jose, S.A.; John, M.; Menezes, P.L. Cermet Systems: Synthesis, Properties, and Applications. Ceramics 2022, 5, 210–236. [Google Scholar] [CrossRef]

- Liu, G.; Guo, S.; Li, J.; Chen, K.; Fan, D. Fabrication of hard cermets by in-situ synthesis and infiltration of metal melts into WC powder compacts. J. Asian Ceram. Soc. 2017, 5, 418–421. [Google Scholar] [CrossRef]

- Akimov, G.Y. Cold isostatic pressing as a method for fabricating ceramic products with high physicomechanical properties. Refract. Ind. Ceram. 1998, 39, 283–287. [Google Scholar] [CrossRef]

- Karimi, H.; Hadi, M. Effect of sintering techniques on the structure and dry sliding wear behavior of WC-FeAl composite. Ceram. Int. 2020, 46, 18487–18497. [Google Scholar] [CrossRef]

- Omanović-Mikličanin, E.; Badnjević, A.; Kazlagić, A.; Hajlovac, M. Nanocomposites: A brief review. Health Technol. 2020, 10, 51–59. [Google Scholar] [CrossRef]

- Ezquerra, B.L.; Lozada, L.; van den Berg, H.; Wolf, M.; Sánchez, J.M. Comparison of the thermal shock resistance of WC based cemented carbides with Co and Co-Ni-Cr based binders. Int. J. Refract. Met. Hard Mater. 2018, 72, 89–96. [Google Scholar] [CrossRef]

- Marques, B.; Fernandes, C.; Senos, A. Sintering, microstructure and properties of WC-AISI304 powder composites. J. Alloys Compd. 2013, 562, 164–170. [Google Scholar] [CrossRef]

- Schubert, W.; Fugger, M.; Wittmann, B.; Useldinger, R. Aspects of sintering of cemented carbides with Fe-based binders. Int. J. Refract. Met. Hard Mater. 2015, 49, 110–123. [Google Scholar] [CrossRef]

- Barbatti, C.; Garcia, J.; Brito, P.; Pyzalla, A.R. Influence of WC replacement by TiC and (Ta, Nb) C on the oxidation resistance of Co-based cemented carbides. Int. J. Refract. Met. Hard Mater. 2009, 27, 768–776. [Google Scholar] [CrossRef]

- Del Campo, L.; Pérez-Sáez, R.; González-Fernández, L.; Tello, M. Kinetics inversion in isothermal oxidation of uncoated WC-based carbides between 450 and 800 °C. Corros. Sci. 2009, 51, 707–712. [Google Scholar] [CrossRef]

- Hwang, Y.S.; Lee, D.B. High-temperature Oxidation of WC-20% TiC-10% Co Carbides. Adv. Mater. Res. 2013, 811, 93–97. [Google Scholar] [CrossRef]

- Chang, S.-H.; Chen, S.-L. Characterization and properties of sintered WC–Co and WC–Ni–Fe hard metal alloys. J. Alloys Compd. 2014, 585, 407–413. [Google Scholar] [CrossRef]

- Furushima, R.; Katou, K.; Shimojima, K.; Hosokawa, H.; Mikami, M.; Matsumoto, A. Changes in constituents and FeAl composition with oxygen content in WC–FeAl composites. Int. J. Refract. Met. Hard Mater. 2015, 50, 298–303. [Google Scholar] [CrossRef]

- Furushima, R.; Katou, K.; Shimojima, K.; Hosokawa, H.; Matsumoto, A. Control of WC grain sizes and mechanical properties in WC–FeAl composite fabricated from vacuum sintering technique. Int. J. Refract. Met. Hard Mater. 2015, 50, 16–22. [Google Scholar] [CrossRef]

- Chen, L.; Yi, D.; Wang, B.; Liu, H.; Wu, C.; Huang, X.; Li, H.; Gao, Y. The selective oxidation behaviour of WC–Co cemented carbides during the early oxidation stage. Corros. Sci. 2015, 94, 1–5. [Google Scholar] [CrossRef]

- Furushima, R.; Katou, K.; Shimojima, K.; Hosokawa, H.; Mikami, M.; Matsumoto, A. Effect of η-phase and FeAl composition on the mechanical properties of WC–FeAl composites. Intermetallics 2015, 66, 120–126. [Google Scholar] [CrossRef]

- Gille, G.; Bredthauer, J.; Gries, B.; Mende, B.; Heinrich, W. Advanced and new grades of WC and binder powder–their properties and application. Int. J. Refract. Met. Hard Mater. 2000, 18, 87–102. [Google Scholar] [CrossRef]

- Upadhyaya, G.; Bhaumik, S. Sintering of submicron WC-10wt.% Co hard metals containing nickel and iron. Mater. Sci. Eng. A 1988, 105, 249–256. [Google Scholar] [CrossRef]

- Huang, S.; Xiong, J.; Guo, Z.; Wan, W.; Tang, L.; Zhong, H.; Zhou, W.; Wang, B. Oxidation of WC-TiC-TaC-Co hard materials at relatively low temperature. Int. J. Refract. Met. Hard Mater. 2015, 48, 134–140. [Google Scholar] [CrossRef]

- de Oro Calderon, R.; Edtmaier, C.; Schubert, W.-D. Novel binders for WC-based cemented carbides with high Cr contents. Int. J. Refract. Met. Hard Mater. 2019, 85, 105063. [Google Scholar] [CrossRef]

- Chuvildeev, V.; Panov, D.; Boldin, M.; Nokhrin, A.; Blagoveshchensky, Y.V.; Sakharov, N.; Shotin, S.; Kotkov, D. Structure and properties of advanced materials obtained by Spark Plasma Sintering. Acta Astronaut. 2015, 109, 172–176. [Google Scholar] [CrossRef]

- Weston, N.; Thomas, B.; Jackson, M. Processing metal powders via field assisted sintering technology (FAST): A critical review. Mater. Sci. Technol. 2019, 35, 1306–1328. [Google Scholar] [CrossRef]

- Shchegoleva, N.; Evdokimov, S.; Modin, S.Y.; Karachevtsev, F. Investigation of the Properties of SiC–ZrB2-Based Ceramic Composite Materials Obtained by Spark Plasma Sintering. Glass Ceram. 2018, 75, 253–257. [Google Scholar] [CrossRef]

- Suárez, M.; Fernández, A.; Menéndez, J.; Torrecillas, R.; Kessel, H.; Hennicke, J.; Kirchner, R.; Kessel, T. Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials. Sinter. Appl. 2013, 13, 319–342. [Google Scholar]

- Mamedov, V. Spark plasma sintering as advanced PM sintering method. Powder Metall. 2002, 45, 322–328. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Zheng, D.; Cao, T.; Chen, J.; Qu, S. The oxidation behavior of the WC–10 wt.% Ni3Al composite fabricated by spark plasma sintering. J. Alloys Compd. 2015, 629, 148–154. [Google Scholar] [CrossRef]

- Basyir, A.; Izzuddin, H.; Hermanto, B.; Sudiro, T. Remarkable improvement in high temperature oxidation resistance of WC-12Co by the addition of CrSi2. Int. J. Refract. Met. Hard Mater. 2021, 96, 105497. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Liu, K.; Wang, B. Mechanical properties and microstructure of spark plasma sintered WC-8 wt.% Co-VC-cBN ultrafine grained cemented carbide. Ceram. Int. 2019, 45, 23658–23665. [Google Scholar] [CrossRef]

- Oh, S.-J.; Kim, B.-S.; Yoon, J.-K.; Hong, K.-T.; Shon, I.-J. Enhanced mechanical properties and consolidation of the ultra-fine WC–Al2O3 composites using pulsed current activated heating. Ceram. Int. 2016, 42, 9304–9310. [Google Scholar] [CrossRef]

- Karimi, H.; Ghasemi, A.; Hadi, M. Microstructure and oxidation behaviour of TiAl(Nb)/Ti2AlC composites fabricated by mechanical alloying and hot pressing. Bull. Mater. Sci. 2016, 39, 1263–1272. [Google Scholar] [CrossRef]

- Erdem, O. Comparative study of hot and cold press and their effect on superconducting properties of coronene added bulk MgB2. Phys. C Supercond. Its Appl. 2019, 565, 1353508. [Google Scholar] [CrossRef]

- Aly, S.; Amin, S.K.; El Sherbiny, S.; Abadir, M. Kinetics of isothermal oxidation of WC–20Co hot-pressed compacts in air. J. Therm. Anal. Calorim. 2014, 118, 1543–1549. [Google Scholar] [CrossRef]

- Tavares, E.; Costa, F.A.; Acchar, W. Mechanical characterization of alumina-doped tungsten carbide. Mater. Sci. Forum 2003, 414–416, 616–620. [Google Scholar] [CrossRef]

- Fernandes, C.; Popovich, V.; Matos, M.; Senos, A.; Vieira, M. Carbide phases formed in WC–M (M= Fe/Ni/Cr) systems. Ceram. Int. 2009, 35, 369–372. [Google Scholar] [CrossRef]

- Mottaghi, M.; Ahmadian, M. Comparison of the wear behavior of WC/(FeAl-B) and WC-Co composites at high temperatures. Int. J. Refract. Met. Hard Mater. 2017, 67, 105–114. [Google Scholar] [CrossRef]

- Dong, W.; Zhu, S.; Wang, Y.; Bai, T. Influence of VC and Cr3C2 as grain growth inhibitors on WC–Al2O3 composites prepared by hot press sintering. Int. J. Refract. Met. Hard Mater. 2014, 45, 223–229. [Google Scholar] [CrossRef]

- Su, Q.; Zhu, S.; Bai, Y.; Ding, H.; Di, P. Preparation and elevated temperature wear behavior of Ni doped WC-Al2O3 composite. Int. J. Refract. Met. Hard Mater. 2019, 81, 167–172. [Google Scholar] [CrossRef]

- Hui, J.; Han, B.; Weiwei, D.; Zhu, S. High-temperature oxidation behaviour of vacuum hot-pressed WC-15 wt% Al2O3 composites. Ceram. Int. 2022, 48, 12184–12192. [Google Scholar] [CrossRef]

- Loh, N.; Sia, K. An overview of hot isostatic pressing. J. Mater. Process. Technol. 1992, 30, 45–65. [Google Scholar] [CrossRef]

- Wang, H.; Fang, Z.Z.; Sun, P. A critical review of mechanical properties of powder metallurgy titanium. Int. J. Powder Metall. 2010, 46, 45–57. [Google Scholar]

- Adivi, H.G.; Ebrahimzadeh, I.; Hadi, M.; Tayebi, M. The effect of alumina nanoparticles addition on high-temperature wear behavior of intermetallic iron aluminide produced by the spark plasma sintering process. Surf. Rev. Lett. 2020, 27, 2050004. [Google Scholar] [CrossRef]

- Aristizabal, M.; Rodriguez, N.; Ibarreta, F.; Martinez, R.; Sanchez, J. Liquid phase sintering and oxidation resistance of WC–Ni–Co–Cr cemented carbides. Int. J. Refract. Met. Hard Mater. 2010, 28, 516–522. [Google Scholar] [CrossRef]

- Shoufa, L. Oxidation behavior of WC–Co cemented carbide in elevated temperature. Mater. Res. Express 2018, 5, 095801. [Google Scholar] [CrossRef]

- Bhaumik, S.; Balasubramaniam, R.; Upadhyaya, G.; Vaidya, M. Oxidation behaviour of hard and binder phase modified WC-10Co cemented carbides. J. Mater. Sci. Lett. 1992, 11, 1457–1459. [Google Scholar] [CrossRef]

- Aristizabal, M.; Ardila, L.; Veiga, F.; Arizmendi, M.; Fernandez, J.; Sánchez, J. Comparison of the friction and wear behaviour of WC–Ni–Co–Cr and WC–Co hardmetals in contact with steel at high temperatures. Wear 2012, 280, 15–21. [Google Scholar] [CrossRef]

- Lin, N.; He, Y.; Zou, J. Enhanced mechanical properties and oxidation resistance of tungsten carbide-cobalt cemented carbides with aluminum nitride additions. Ceram. Int. 2017, 43, 6603–6606. [Google Scholar] [CrossRef]

- Tarraste, M.; KÜBARSEPP, J.; JUHANI, K.; Arvo, M.; Viljus, M. Effect of Carbon Stabilizing Elements on WC Cemented Carbides with Chromium Steel Binder. Mater. Sci. 2019, 25, 202–206. [Google Scholar] [CrossRef]

- Zhang, J.; Saeed, M.H.; Li, S. Recent progress in development of high-performance tungsten carbide-based composites: Synthesis, characterization, and potential applications. In Advances in Ceramic Matrix Composites; Woodhead Publishing: Sawston, UK, 2018; pp. 307–329. [Google Scholar]

- Li, S.; Li, J.; Li, Y.; Liu, F.; Ao, W. Dense pure binderless WC bulk material prepared by spark plasma sintering. Mater. Sci. Technol. 2015, 31, 1749–1756. [Google Scholar] [CrossRef]

- Romaniv, O.; Vasyliv, B. Some features of formation of the structural strength of ceramic materials. Mater. Sci. 1998, 34, 149–161. [Google Scholar] [CrossRef]

- Teppernegg, T.; Klünsner, T.; Kremsner, C.; Tritremmel, C.; Czettl, C.; Puchegger, S.; Marsoner, S.; Pippan, R.; Ebner, R. High temperature mechanical properties of WC–Co hard metals. Int. J. Refract. Met. Hard Mater. 2016, 56, 139–144. [Google Scholar] [CrossRef]

- Mari, D.; Gonseth, D. A new look at carbide tool life. Wear 1993, 165, 9–17. [Google Scholar] [CrossRef]

- Luo, P.; Liang, Y.; He, G.; Yang, Y.; Tian, X. Effects of multi-layer graphene on the fracture toughness and wear resistance of WC-11Co cemented carbide. J. Asian Ceram. Soc. 2022, 10, 453–464. [Google Scholar] [CrossRef]

- Emanuelli, L.; Pellizzari, M.; Molinari, A.; Castellani, F.; Zinutti, E. Thermal fatigue behaviour of WC-20Co and WC-30 (CoNiCrFe) cemented carbide. Int. J. Refract. Met. Hard Mater. 2016, 60, 118–124. [Google Scholar] [CrossRef]

- Hadi, M.; Rafiaei, S.M.; Fernandes, F. The effect of Mo2C additions on the oxidation resistance of (Ti,W) CN cermets as base material for the production of cutting tools. Ceram. Int. 2023, 49, 21538–21545. [Google Scholar] [CrossRef]

- Karimi, H.; Zare, A.; Hadi, M.; Sadeghi, M.; Ghasemi, A. The Effect of Mn Addition on Oxidation Resistance of Ti-48Al Synthesized by Mechanical Alloying. J. Metall. Mater. Eng. 2016, 27, 93–106. [Google Scholar]

- Zare, A.; Hadi, M.; Ghasemi, A.; Karimi, H.; Sadeghi, M. Investigating the Effect of Microstructure on Oxidation Behavior of Ti47Al48Mn5 Alloy Synthesized by Mechanical Alloying. J. Adv. Mater. Eng. 2022, 34, 31–48. [Google Scholar] [CrossRef]

- Samani, M.N.; Shokuhfar, A.; Kamali, A.R.; Hadi, M. Production of a nanocrystalline Ni3Al-based alloy using mechanical alloying. J. Alloys Compd. 2010, 500, 30–33. [Google Scholar] [CrossRef]

- Hadi, M.; Kamali, A.R. Investigation on hot workability and mechanical properties of modified IC-221M alloy. J. Alloys Compd. 2009, 485, 204–208. [Google Scholar] [CrossRef]

- Ogwu, A.; Davies, T. Proposed selection rules for suitable binders in cemented hard metals with possible applications for improving ductility in intermetallics. J. Mater. Sci. 1992, 27, 5382–5388. [Google Scholar] [CrossRef]

- Sikka, V.; Mavity, J.; Anderson, K. Processing of nickel aluminides and their industrial applications. In High Temperature Aluminides and Intermetallics; Elsevier: Amsterdam, The Netherlands, 1992; pp. 712–721. [Google Scholar]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yeh, J.-W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Dewangan, S.K.; Mangish, A.; Kumar, S.; Sharma, A.; Ahn, B.; Kumar, V. A review on high-temperature applicability: A milestone for high entropy alloys. Eng. Sci. Technol. Int. J. 2022, 35, 101211. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Khallaf, A.H.; Bhlol, M.; Dawood, O.; Ghayad, I.; Elkady, O.A. Effect of tungsten carbide (WC) on electrochemical corrosion behavior, hardness, and microstructure of CrFeCoNi high entropy alloy. J. Eng. Appl. Sci. 2022, 69, 43. [Google Scholar] [CrossRef]

- Khallaf, A.H.; Bhlol, M.; Dawood, O.; Elkady, O.A. Effect of WC addition on the mechanical properties and microstructure of CrFeCoNi high entropy alloy by powder metallurgy technique. Int. J. Mech. Eng. 2022, 7, 1127–1134. [Google Scholar]

- Xu, B.; Zhou, Y.; Liu, Y.; Hu, S.; Zhang, G. Effect of different contents of WC on microstructure and properties of CrMnFeCoNi high-entropy alloy-deposited layers prepared by PTA. J. Mater. Res. 2022, 37, 719–727. [Google Scholar] [CrossRef]

- Wu, T.; Chen, Y.; Lin, B.; Yu, L.; Gui, W.; Li, J.; Wu, Y.; Zeng, D. Effects of WC on the microstructure, wear and corrosion resistance of laser-deposited CoCrFeNi high entropy alloy coatings. Coatings 2022, 12, 985. [Google Scholar] [CrossRef]

- Zhu, G.; Liu, Y.; Ye, J. Early high-temperature oxidation behavior of Ti (C, N)-based cermets with multi-component AlCoCrFeNi high-entropy alloy binder. Int. J. Refract. Met. Hard Mater. 2014, 44, 35–41. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, N.; Du, G.; Zhang, M.; Zhao, X.; Cheng, H.; Wu, J. High-temperature oxidation resistance, mechanical and wear resistance properties of Ti (C, N)-based cermets with Al0.3CoCrFeNi high-entropy alloy as a metal binder. J. Alloys Compd. 2020, 815, 152486. [Google Scholar] [CrossRef]

- Wu, X.; Shen, J.; Jiang, F.; Wu, H.; Li, L. Study on the oxidation of WC-Co cemented carbide under different conditions. Int. J. Refract. Met. Hard Mater. 2021, 94, 105381. [Google Scholar] [CrossRef]

- Penrice, T. Alternative binders for hard metals. J. Mater. Shap. Technol. 1987, 5, 35–39. [Google Scholar] [CrossRef]

- Pereira, P.; Vilhena, L.; Sacramento, J.; Senos, A.; Malheiros, L.; Ramalho, A. Tribological behaviour of different formulations of WC composites. Wear 2022, 506, 204415. [Google Scholar] [CrossRef]

- Liu, R.; Wu, X.J.; Kapoor, S.; Yao, M.X.; Collier, R. Effects of Temperature on the Hardness and Wear Resistance of High-Tungsten Stellite Alloys. Metall. Mater. Trans. A 2015, 46, 587–599. [Google Scholar] [CrossRef]

- Hadi, M.; Bayat, O.; Meratian, M.; Shafyei, A.; Ebrahimzadeh, I. Oxidation properties of a beta-stabilized TiAl alloy modified by rare earth elements. Oxid. Met. 2018, 90, 421–434. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Y.; Lin, N.; Kang, X.; Yan, Y.; Huang, J.; Liu, Y.; Qiu, S.; He, Y. Investigation of the oxidation behavior and high oxidation-resistant mechanism of Ti (C, N)-based cermets. Corros. Sci. 2020, 177, 108959. [Google Scholar] [CrossRef]

- Mostajeran, A.; Shoja-Razavi, R.; Hadi, M.; Erfanmanesh, M.; Barekat, M.; Firouzabadi, M.S. Evaluation of the mechanical properties of WC-FeAl composite coating fabricated by laser cladding method. Int. J. Refract. Met. Hard Mater. 2020, 88, 105199. [Google Scholar] [CrossRef]

- Mostajeran, A.; Shoja-Razavi, R.; Hadi, M.; Erfanmanesh, M.; Karimi, H. Wear behavior of laser cladded WC-FeAl coating on 321 stainless steel substrate. J. Laser Appl. 2020, 32, 042015. [Google Scholar] [CrossRef]

- Holmström, E.; Lizarraga, R.; Linder, D.; Salmasi, A.; Wang, W.; Kaplan, B.; Mao, H.; Larsson, H.; Vitos, L. High entropy alloys: Substituting for cobalt in cutting edge technology. Appl. Mater. Today 2018, 12, 322–329. [Google Scholar] [CrossRef]

- Qian, C.; Liu, Y.; Cheng, H.; Li, K.; Liu, B. Effect of the carbon content on the morphology evolution of the η phase in cemented carbides with the CoNiFeCr high entropy alloy binder. Int. J. Refract. Met. Hard Mater. 2022, 102, 105731. [Google Scholar] [CrossRef]

- Qian, C.; Liu, Y.; Cheng, H.; Li, K.; Liu, B.; Zhang, X. The effect of carbon content on the microstructure and mechanical properties of cemented carbides with a CoNiFeCr high entropy alloy binder. Materials 2022, 15, 5780. [Google Scholar] [CrossRef]

- Li, X.; Wei, D.; Vitos, L.; Lizarraga, R. Micro-mechanical properties of new alternative binders for cemented carbides: CoCrFeNiWx high-entropy alloys. J. Alloys Compd. 2020, 820, 153141. [Google Scholar] [CrossRef]

- Fa, C.; Jungui, Z.; Shijia, L.; Keke, G.; Pinqiang, D.; Chao, L.; Xiaofeng, Z. The microstrcture and high-temperature oxidation resistance of tungsten carbide with high entropy alloys as binder. J. Ceram. Soc. Jpn. 2022, 130, 477–486. [Google Scholar] [CrossRef]

- Qin, Y.; Yuan, J.; Zhuang, Y.; Ma, B.; Luo, L.; Wu, Y. Study on Effect of High-Entropy Alloy Binder on Microstructure and Properties of WC Cemented Carbide Doped with Rare Earth Oxide. Coatings 2023, 13, 273. [Google Scholar] [CrossRef]

- Solodkyi, I.; Teslia, S.; Bezdorozhev, O.; Trosnikova, I.; Yurkova, O.; Bogomol, I.; Loboda, P. Hardmetals prepared from WC-W2C eutectic particles and AlCrFeCoNiV high entropy alloy as a binder. Vacuum 2022, 195, 110630. [Google Scholar] [CrossRef]

- Velo, I.L.; Gotor, F.; Alcalá, M.; Real, C.; Córdoba, J. Fabrication and characterization of WC-HEA cemented carbide based on the CoCrFeNiMn high entropy alloy. J. Alloys Compd. 2018, 746, 1–8. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Luo, Y.; Wu, M. Fabrication and characterization of WC-AlCoCrCuFeNi high-entropy alloy composites by spark plasma sintering. J. Alloys Compd. 2018, 754, 163–170. [Google Scholar] [CrossRef]

- Mueller-Grunz, A.; Alveen, P.; Rassbach, S.; Useldinger, R.; Moseley, S. The manufacture and characterization of WC-(Al) CoCrCuFeNi cemented carbides with nominally high entropy alloy binders. Int. J. Refract. Met. Hard Mater. 2019, 84, 105032. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Dong, B.; Wu, Z.; Zhou, L. Corrosion resistance of WC-based cemented carbides with 10 wt% AlxCrCoCuFeNi high-entropy alloy binders. Intermetallics 2022, 151, 107738. [Google Scholar] [CrossRef]

| 1. Among the papers that investigated oxidation properties, what production method was applied? * |

| (1.1) standard vacuum sintering (1.2) spark plasma sintering (SPS) (1.3) hot press (HP) (1.4) hot isostatic press (HIP) (1.5) not mentioned |

| 2. Among the papers that investigated oxidation properties, which binder was used? ** |

| (2.1) Co (2.2) Ni (2.3) Co + Ni (2.4) Cr (2.5) Mo (2.6) pure iron (2.7) Fe–based alloys (2.8) Ni3Al (2.9) FeAl (2.10) Al2O3 (2.11) high–entropy alloys (HEAs) |

| 3. What was the author’s approach for modification of binder in oxidation studies on cemented carbides? |

| (3.1) use of new binder and comparison with previous study (3.2) investigating on the effect of various fraction of one binder (3.3) study on the effect of adding minor element to the binder (3.4) other |

| 4. What was the oxidation outcome? |

| (4.1) considerable improvement (4.2) acceptable/minor improvement (4.3) reduction in oxidation resistance (4.4) no comparison with conventional WC–based cermets |

| 5. Is the oxidation kinetics investigated? If yes, what type of equation is fitted? |

| (5.1) no (5.2) yes (5.2.1) parabolic equation (5.2.2) linear equation (5.2.3) linear/parabolic equation (5.2.4) other |

| 6. How the wear properties of cermet change with oxidation properties? |

| (6.1) not investigated (6.2) both increased (6.3) both decreased (6.4) one increases and other decreases |

| Paper | Production Method | Binder of Composite | Author’s Approach | Oxidation Outcome | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spark Plasma Sintering (SPS) | Hot Press (HP) | Cold Press (CP) + Sintering | Hot Isostatic Press (HIP) | Cold Isostatic Press (CIP) | Not Mentioned | Co | Ni | Co + Ni | Cr | Mo | Pure Iron | Fe–Based Alloys | Ni3Al | FeAl | Al2O3 | TiC0.4 | High–Entropy Alloys (HEA) | Using New Binder and Comparing with Pervious Study | Investigating on the Effect of Various Fraction of One Binder | Study on the Effect of Adding Minor Element to the Binder | Other | Considerable–Improvement | Acceptable/Minor Improvement | Reduction In Oxidation Resistance | No Comparison with Conventional WC–Based Cermets | |

| Penrice [98] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Upadhyaya and Bhaumik [42] | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||||||

| Bhaumik et al. [69] | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| Ogwu and Davies [85] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Sikka et al. [86] | √ | √ | √ | √ | ||||||||||||||||||||||

| Mari and Gonseth [77] | √ | √ | √ | √ | ||||||||||||||||||||||

| Lofaj and Kaganovskii [19] | √ | √ | √ | √ | ||||||||||||||||||||||

| Basu and Sarin [15] | √ | √ | √ | √ | ||||||||||||||||||||||

| Voitovich et al. [16] | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| Subramanian and Schneibel [7] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Gille et al. [41] | √ | √ | √ | √ | ||||||||||||||||||||||

| Casas et al. [17] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Tavare et al. [58] | √ | √ | √ | √ | ||||||||||||||||||||||

| Aristizabal et al. [8] | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| Barbatti et al. [33] | √ | √ | √ | √ | ||||||||||||||||||||||

| Del Campo et al. [34] | √ | √ | √ | √ | ||||||||||||||||||||||

| Fernandes et al. [59] | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||||||

| Shon et al. [13] | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| Aristizabal et al. [67] | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| Aristizabal et al. [70] | √ | √ | √ | √ | ||||||||||||||||||||||

| Jianxin et al. [9] | √ | √ | √ | √ | ||||||||||||||||||||||

| Barbatti et al. [31] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Chen et al. [20] | √ | √ | √ | √ | ||||||||||||||||||||||

| Hwang and Lee [35] | √ | √ | √ | √ | ||||||||||||||||||||||

| Aly et al. [57] | √ | √ | √ | √ | ||||||||||||||||||||||

| Chang and Chen [36] | √ | √ | √ | √ | ||||||||||||||||||||||

| Chen et al. [10] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Dong et al. [61] | √ | √ | √ | √ | ||||||||||||||||||||||

| Chen et al. [39] | √ | √ | √ | √ | ||||||||||||||||||||||

| Furushima et al. [40] | √ | √ | √ | √ | ||||||||||||||||||||||

| Furushima et al. [38] | √ | √ | √ | √ | ||||||||||||||||||||||

| Furushima et al. [37] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Huang et al. [43] | √ | √ | √ | √ | ||||||||||||||||||||||

| Li et al. [51] | √ | √ | √ | √ | ||||||||||||||||||||||

| Schubert et al. [32] | √ | √ | √ | √ | ||||||||||||||||||||||

| Chen et al. [11] | √ | √ | √ | √ | ||||||||||||||||||||||

| Emanuelli et al. [79] | √ | √ | √ | √ | ||||||||||||||||||||||

| Oh et al. [54] | √ | √ | √ | √ | ||||||||||||||||||||||

| Lin et al. [71] | √ | √ | √ | √ | ||||||||||||||||||||||

| Mottaghi and Ahmadian [60] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Aly et al. [18] | √ | √ | √ | √ | ||||||||||||||||||||||

| Ezquerra et al. [30] | √ | √ | √ | √ | ||||||||||||||||||||||

| Karimi et al. [2] | √ | √ | √ | √ | ||||||||||||||||||||||

| Shoufa [68] | √ | √ | √ | √ | ||||||||||||||||||||||

| de Oro Calderon et al. [44] | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| Su et al. [62] | √ | √ | √ | √ | ||||||||||||||||||||||

| Tarraste et al. [72] | √ | √ | √ | √ | √ | |||||||||||||||||||||

| Wang et al. [53] | √ | √ | √ | √ | ||||||||||||||||||||||

| Karimi and Hadi [28] | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||||

| Basyir et al. [52] | √ | √ | √ | √ | ||||||||||||||||||||||

| Luo et al. [3] | √ | √ | √ | √ | ||||||||||||||||||||||

| Wu et al. [97] | √ | √ | √ | √ | ||||||||||||||||||||||

| Hui et al. [63] | √ | √ | √ | √ | ||||||||||||||||||||||

| Paper | Oxidation Temperature | Oxidation Kinetics | Wear Properties of Cermet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300–500 °C | 500–600 °C | 600–700 °C | 700–800 °C | >800 °C | Not Mentioned or Non–Isotherm Test | No | Parabolic Equation | Linear Equation | Linear/Parabolic Equation | Other | Not Investigated | Both Increased | Both Decreased | One Increases and Other Decreases | |

| Penrice [98] | P | P | P | ||||||||||||

| Upadhyaya and Bhaumik [42] | P | P | P | ||||||||||||

| Bhaumik et al. [69] | P | P | |||||||||||||

| Ogwu and Davies [85] | P | P | P | ||||||||||||

| Sikka et al. [86] | P | ||||||||||||||

| Mari and Gonseth [77] | P | P | P | ||||||||||||

| Lofaj and Kaganovskii [19] | P | ||||||||||||||

| Basu and Sarin [15] | P | P | P | P | P | ||||||||||

| Voitovich et al. [16] | P | P | P | P | P | ||||||||||

| Subramanian and Schneibel [7] | P | P | P | ||||||||||||

| Gille et al. [41] | P | P | P | ||||||||||||

| Casas et al. [17] | P | P | P | ||||||||||||

| Tavare et al. [58] | P | P | P | ||||||||||||

| Aristizabal et al. [8] | P | P | P | P | |||||||||||

| Barbatti et al. [33] | P | P | P | P | |||||||||||

| Del Campo et al. [34] | P | P | P | P | P | P | |||||||||

| Fernandes et al. [59] | P | P | P | ||||||||||||

| Shon et al. [13] | P | P | P | ||||||||||||

| Aristizabal et al. [67] | P | P | P | ||||||||||||

| Aristizabal et al. [70] | P | P | P | P | |||||||||||

| Jianxin et al. [9] | P | P | P | ||||||||||||

| Barbatti et al. [31] | P | P | P | ||||||||||||

| Chen et al. [20] | P | P | P | ||||||||||||

| Hwang and Lee [35] | P | P | P | P | |||||||||||

| Aly et al. [57] | P | P | P | P | |||||||||||

| Chang and Chen [36] | P | P | P | ||||||||||||

| Chen et al. [10] | P | P | P | ||||||||||||

| Dong et al. [61] | P | P | P | ||||||||||||

| Chen et al. [39] | P | P | P | ||||||||||||

| Furushima et al. [40] | P | P | P | ||||||||||||

| Furushima et al. [38] | P | P | P | ||||||||||||

| Furushima et al. [37] | P | P | P | ||||||||||||

| Huang et al. [43] | P | P | P | P | P | P | P | ||||||||

| Li et al. [51] | P | P | P | P | P | ||||||||||

| Schubert et al. [32] | P | P | P | ||||||||||||

| Chen et al. [11] | P | P | P | P | |||||||||||

| Emanuelli et al. [79] | P | P | P | P | |||||||||||

| Oh et al. [54] | P | P | P | ||||||||||||

| Lin et al. [71] | P | P | P | ||||||||||||

| Mottaghi and Ahmadian [60] | P | P | P | ||||||||||||

| Aly et al. [18] | P | P | P | ||||||||||||

| Ezquerra et al. [30] | P | P | P | ||||||||||||

| Karimi et al. [2] | P | P | P | P | |||||||||||

| Shoufa [68] | P | P | P | P | P | ||||||||||

| de Oro Calderon et al. [44] | P | P | P | ||||||||||||

| Su et al. [62] | P | P | P | ||||||||||||

| Tarraste et al. [72] | P | P | P | ||||||||||||

| Wang et al. [53] | P | P | P | P | P | ||||||||||

| Karimi and Hadi [28] | P | P | P | ||||||||||||

| Basyir et al. [52] | P | P | P | ||||||||||||

| Luo et al. [3] | P | P | P | P | |||||||||||

| Wu et al. [97] | P | P | P | P | P | ||||||||||

| Hui et al. [63] | P | P | P | P | |||||||||||

| Author | Affiliation/Country | Documents |

|---|---|---|

| Aristizabal, M. | CEIT and TECNUN, Paseo Manuel de Lardizábal 15, 20018, San Sebastián, Gipuzkoa, Basque Country, Spain | 3 |

| Chen, L. | School of Materials Science and Engineering, Central South University, Changsha, Hunan 410083, China | 3 |

| Furushima, R. | National Institute of Advanced Industrial Science and Technology, 2266–98 Anagahora, Shimoshidami, Moriyama–ku, Nagoya 463–8560, Japan | 3 |

| Hosokawa, H. | National Institute of Advanced Industrial Science and Technology, 2266–98 Anagahora, Shimoshidami, Moriyama–ku, Nagoya 463–8560, Japan | 3 |

| Katou, K. | National Institute of Advanced Industrial Science and Technology, 2266–98 Anagahora, Shimoshidami, Moriyama–ku, Nagoya 463–8560, Japan | 3 |

| Liu, H. | School of Materials Science and Engineering, Central South University, Changsha, Hunan 410083, China | 3 |

| Matsumoto, A. | National Institute of Advanced Industrial Science and Technology, 2266–98 Anagahora, Shimoshidami, Moriyama–ku, Nagoya 463–8560, Japan | 3 |

| Shimojima, K. | National Institute of Advanced Industrial Science and Technology, 2266–98 Anagahora, Shimoshidami, Moriyama–ku, Nagoya 463–8560, Japan | 3 |

| Yi, D. | School of Materials Science and Engineering, Central South University, Changsha, Hunan 410083, China | 3 |

| Zhu, S. | College of Mechanical Engineering, Donghua University, Shanghai 201620, PR China | 3 |

| Aly, S.T. | The Center of Scientific Research, The Ministry of Military Production, Cairo, Egypt | 2 |

| Barbatti, C. | Max–Planck–Institut für Eisenforschung GmbH, 40237 Düsseldorf, Germany | 2 |

| Bhaumik, S.K. | Department of Metallurgical Engineering, Indian Institute of Technology, 208 016, Kanpur, India | 2 |

| Brito, P. | Max–Planck–Institut für Eisenforschung GmbH, 40237 Düsseldorf, Germany | 2 |

| Garcia, J. | Helmholtz–Zentrum Berlin für Materialien und Energie GmbH, 14109 Berlin, Germany | 2 |

| Hadi, M. | Materials Engineering Group, Golpayegan College of Engineering, Isfahan University of Technology, Iran | 2 |

| Ibarreta, F. | FMD CARBIDE S.A.L., Zorrozaurre 35, 48014, Bilbao, Spain | 2 |

| Karimi, H. | Materials Engineering Department, Malek Ashtar University of Technology, Shahin Shahr, Iran | 2 |

| Martinez, R. | FMD CARBIDE S.A.L., Zorrozaurre 35, 48014, Bilbao, Spain | 2 |

| Mikami, M. | National Institute of Advanced Industrial Science and Technology, 2266–98 Anagahora, Shimoshidami, Moriyama–ku, Nagoya 463–8560, Japan | 2 |

| Pyzalla, A.R. | Helmholtz–Zentrum Berlin für Materialien und Energie GmbH, 14109 Berlin, Germany | 2 |

| Rodriguez, N. | CEIT and TECNUN, Paseo Manuel de Lardizábal 15, 20018, San Sebastián, Gipuzkoa, Basque Country, Spain | 2 |

| Sánchez, J.M. | CEIT and TECNUN, Paseo Manuel de Lardizábal 15, 20018, San Sebastián, Gipuzkoa, Basque Country, Spain | 2 |

| Shon, I.J. | The Research Center of Advanced Materials Development, Chonbuk National University, Chonbuk 561–756, Republic of Korea | 2 |

| Schubert, W.D. | Institute of Chemical Technologies and Analytics, Vienna University of Technology, Vienna, Austria | 2 |

| Upadhyaya, G.S. | Department of Metallurgical Engineering, Indian Institute of Technology, 208 016, Kanpur, India | 2 |

| Wang, B. | School of Materials Science and Engineering, Central South University, Changsha, Hunan 410083, China | 2 |

| Journal Title | Number of Papers | Percentage |

|---|---|---|

| International Journal of Refractory Metals and Hard Materials | 20 | 37.73 |

| Ceramics International | 9 | 16.98 |

| Materials Science | 5 | 9.43 |

| Materials Science and Engineering A | 4 | 7.55 |

| Journal of Alloys and Compounds | 3 | 5.66 |

| Corrosion Science | 3 | 5.66 |

| Wear | 2 | 3.77 |

| Advanced Materials Research | 1 | 1.89 |

| Engineering Research and Technology | 1 | 1.89 |

| Intermetallics | 1 | 1.89 |

| Materials Research Express | 1 | 1.89 |

| Materials shaping technology | 1 | 1.89 |

| Powder Metallurgy | 1 | 1.89 |

| Thermal Analysis and Calorimetry | 1 | 1.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fathipour, Z.; Hadi, M.; Maleki, M.R.; Fernandes, F. Effect of Binder on Oxidation Properties of Tungsten Carbides: A Review by a Conceptual Classification Approach. Ceramics 2024, 7, 166-191. https://doi.org/10.3390/ceramics7010011

Fathipour Z, Hadi M, Maleki MR, Fernandes F. Effect of Binder on Oxidation Properties of Tungsten Carbides: A Review by a Conceptual Classification Approach. Ceramics. 2024; 7(1):166-191. https://doi.org/10.3390/ceramics7010011

Chicago/Turabian StyleFathipour, Zahra, Morteza Hadi, Mohammad Reza Maleki, and Filipe Fernandes. 2024. "Effect of Binder on Oxidation Properties of Tungsten Carbides: A Review by a Conceptual Classification Approach" Ceramics 7, no. 1: 166-191. https://doi.org/10.3390/ceramics7010011