Numerical Investigation of the Seismic Performance of an Innovative Type of Buckling-Restrained Brace (BRB)

Abstract

:1. Introduction

2. Tire-Derived Aggregate (TDA)

3. Buckling-Restrained Braces

4. Experimental Setup

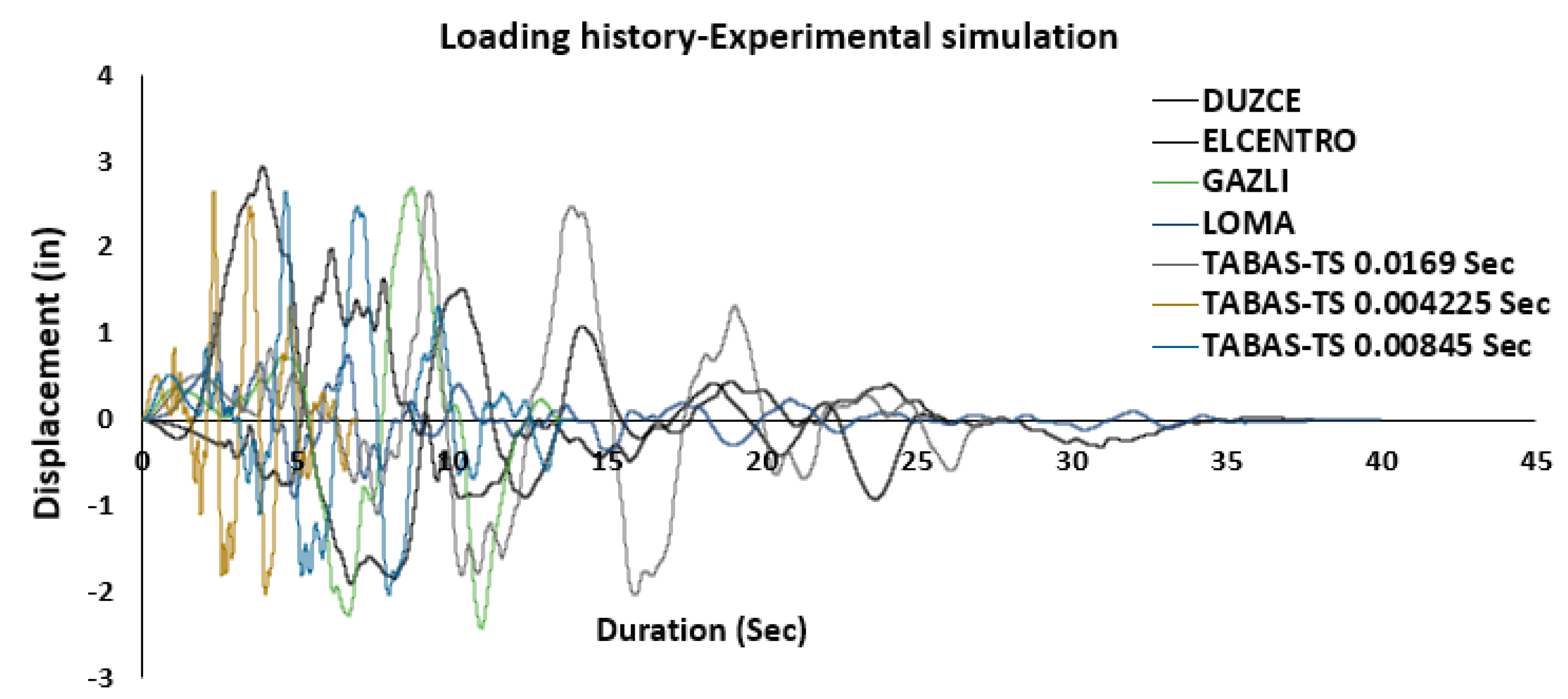

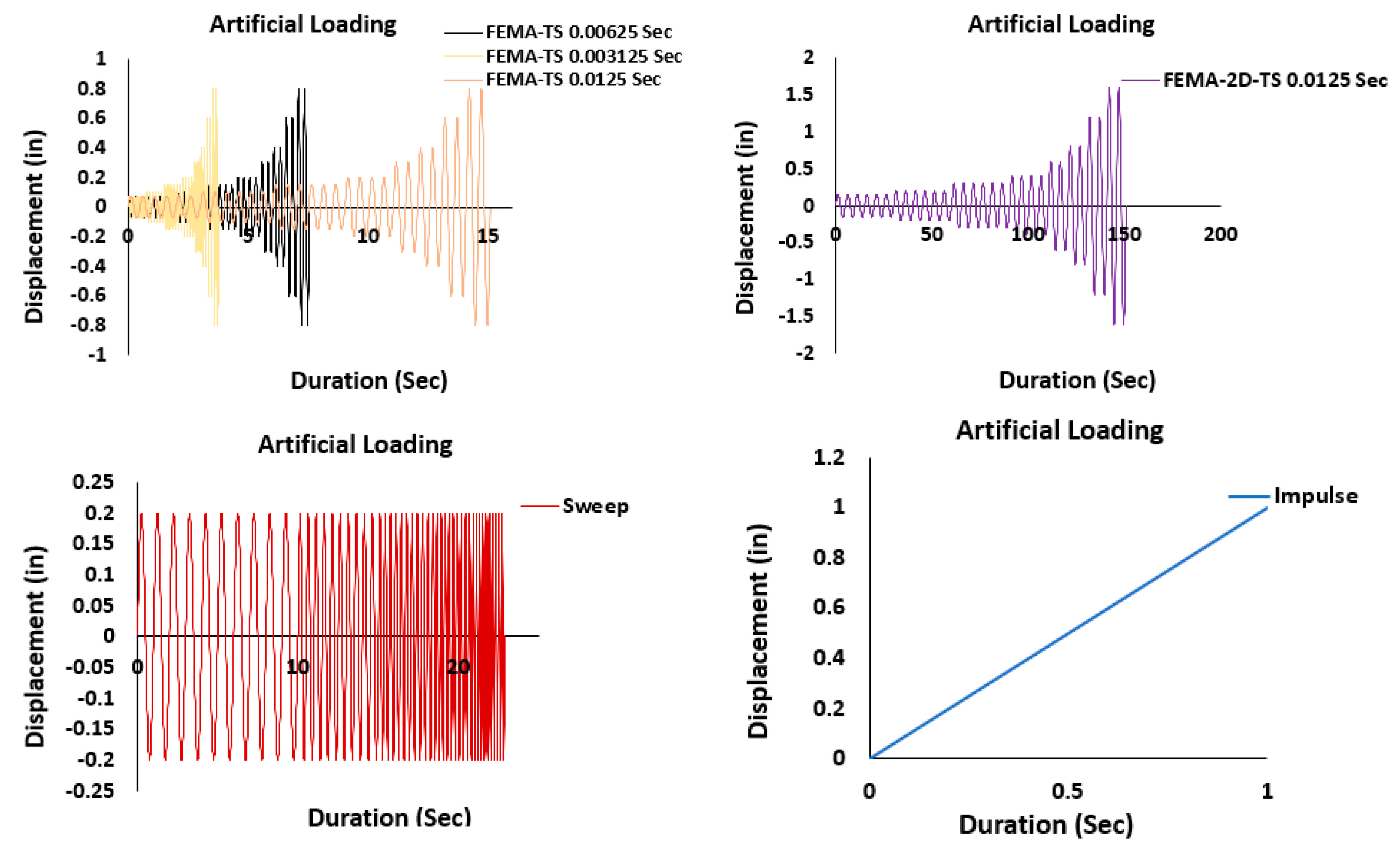

5. Loadings

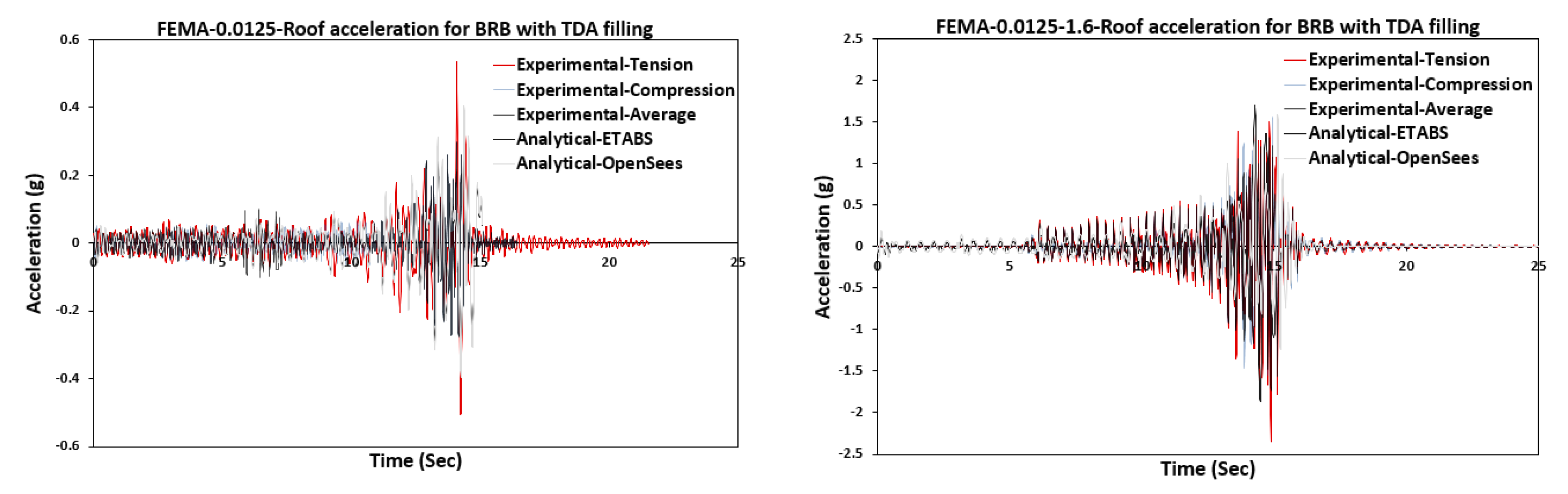

6. Simulation of Experimental Model

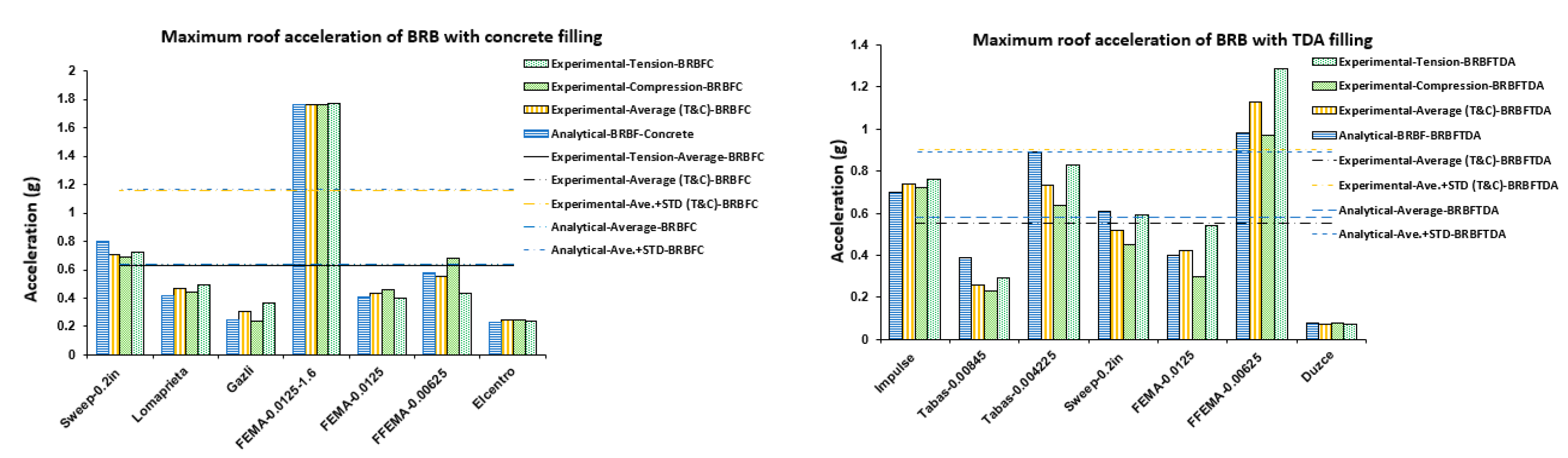

7. Results and Discussions

8. Design Guideline

9. Conclusions

- This study compares experimental and analytical outcomes for a single-story steel frame utilizing buckling-restrained braces filled with TDA and concrete. It demonstrates the effectiveness of using tire-derived aggregates (TDAs) as an alternative material. It examines the innovative buckling-restrained brace with TDA infill, considering its potential for sustainability through reduced CO2 emissions. A BRB with TDA contributes to sustainability and improves the damping properties compared to a conventional BRB with concrete infill. It provides numerical and experimental insights into structural responses, enhancing the existing knowledge. This study yields the following key conclusions:

- Analytical and experimental investigations on buckling-restrained braces (BRBs) with TDA infill have demonstrated a 25% increase in frame damping compared to a conventional BRB with a damping rate of approximately 14%. When higher damping is required, both the experimental and analytical findings suggest the use of a BRB with TDA infill. However, it is worth noting that a BRB with TDA filling offers a superior damping but reduced ductility compared to regular concrete, owing to the lower strength of TDA concrete, which cannot sufficiently delay steel core plate buckling as conventional concrete does [30].

- In general, a BRB with TDA filling reduced acceleration by approximately 20% compared to conventional concrete filling. The experimental study showed average acceleration values of 1.15 g with concrete and 0.91g with TDA fillings, while the analytical study results were 1.16 g with concrete and 0.89g with TDA fillings.

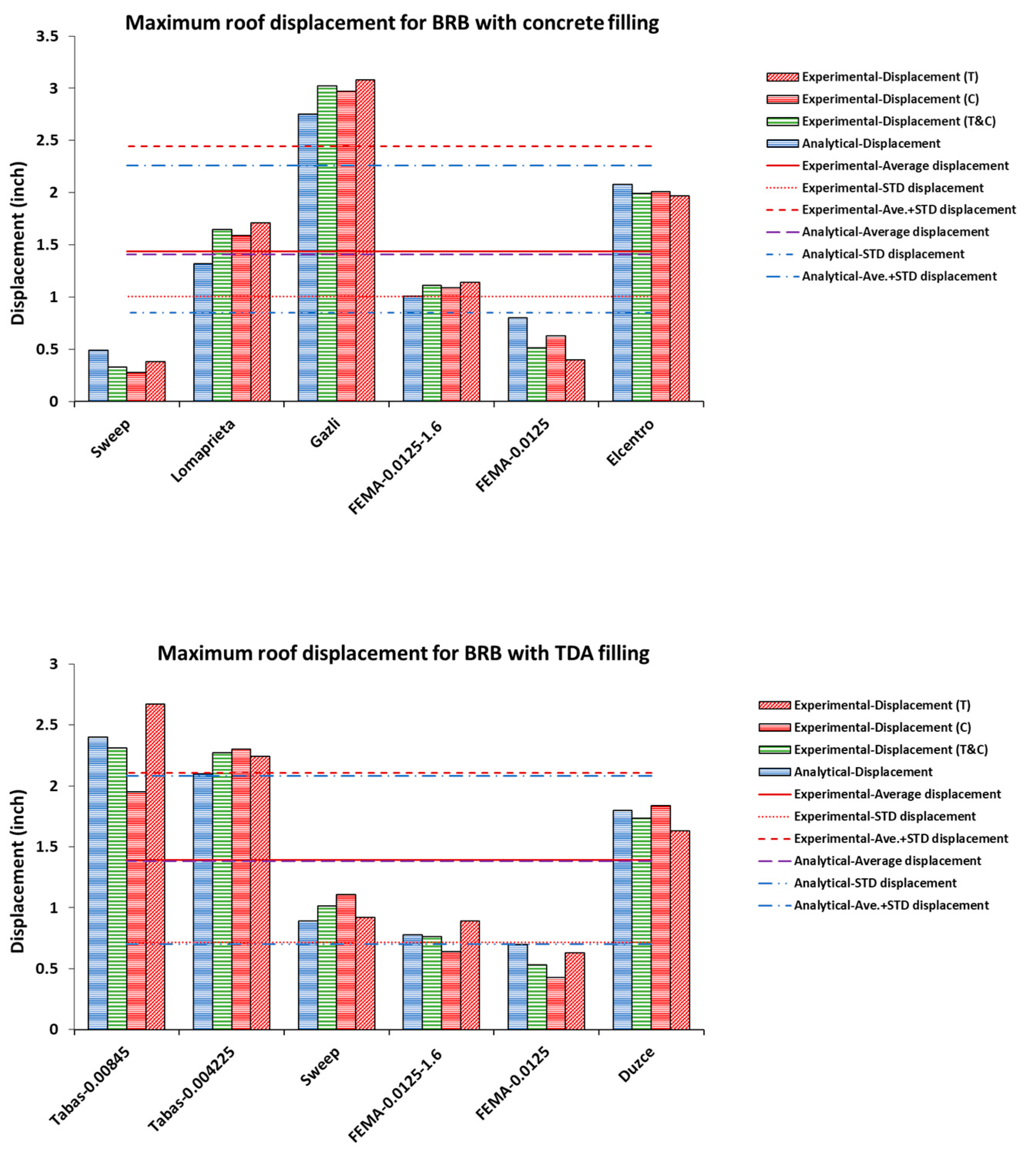

- The displacement value for the frame with the BRB and concrete infill was 2.44 (in) in the experimental and 2.26 (in) in the analytical study. Consequently, the BRB with TDA filling exhibits a lower ductility compared to the BRB with conventional concrete filling.

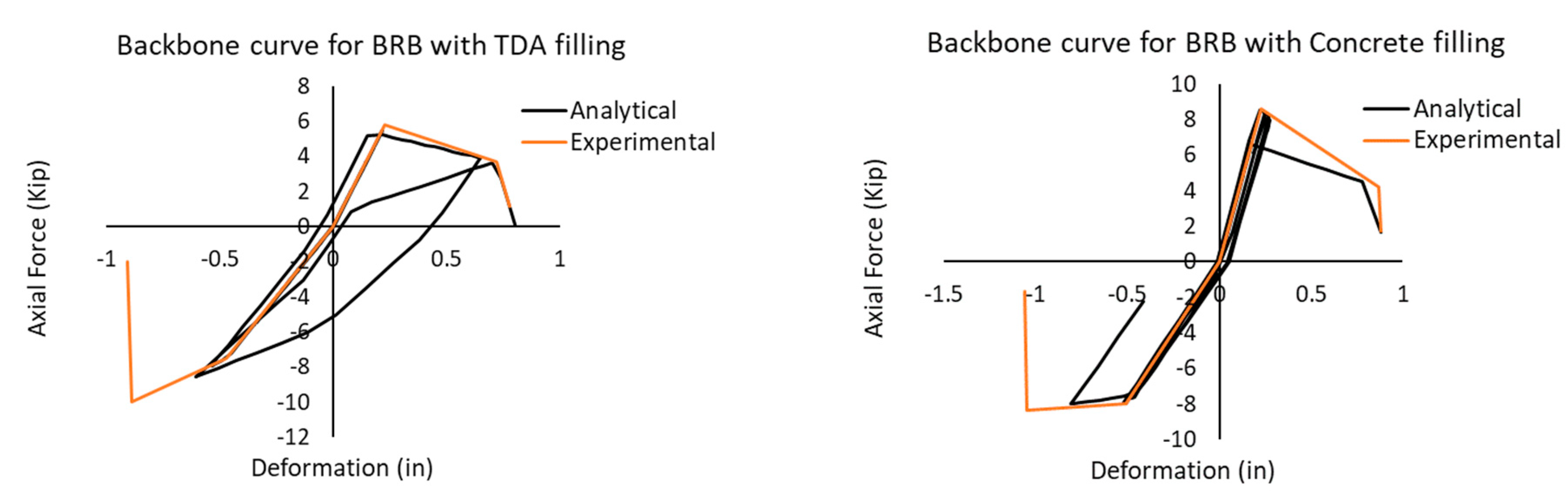

- A comparison of the hysteresis curves in both the analytical and experimental works revealed a similar trend in the backbone curves for the BRB with TDA and concrete infills subjected to FFEMA 4 loading. Furthermore, it was determined that the BRB with TDA infill absorbs less energy than the BRB with concrete infill, implying a lower ductility in the BRB with TDA infill compared to conventional concrete.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Garrick, G.; Eggers, J.; Abadie, C.; Stubblefield, M.A.; Pang, S.-S. Waste Tire Fiber Modified Concrete. Compos. Part B Eng. 2004, 35, 305–312. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of Crumb Rubber to Improve Thermal and Sound Properties of Pre-Cast Concrete Panel. Constr. Build. Mater. 2009, 23, 1084–1092. [Google Scholar] [CrossRef]

- Aslani, F. Mechanical Properties of Waste Tire Rubber Concrete. J. Mater. Civ. Eng. 2016, 28, 04015152. [Google Scholar] [CrossRef]

- Ahn, I.S.; Cheng, L.; Fox, P.J.; Wright, J.; Patenaude, S.; Fujii, B. Material Properties of Large-Size Tire Derived Aggregate for Civil Engineering Applications. J. Mater. Civ. Eng. 2015, 27, 04014258. [Google Scholar] [CrossRef]

- Ghaaowd, I.; McCartney, J.S.; Thielmann, S.S.; Sanders, M.J.; Fox, P.J. Shearing Behavior of Tire-Derived Aggregate with Large Particle Size. I: Internal and Concrete Interface Direct Shear. J. Geotech. Geoenviron. Eng. 2017, 143, 04017078. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Anwar Hossain, K.M.; Eng Swee, J.T.; Wong, G.; Abdullahi, M. Properties of Crumb Rubber Hollow Concrete Block. J. Clean. Prod. 2012, 23, 57–67. [Google Scholar] [CrossRef]

- Topçu, I.B.; Avcular, N. Collision Behaviours of Rubberized Concrete. Cem. Concr. Res. 1997, 27, 1893–1898. [Google Scholar] [CrossRef]

- Zheng, L.; Huo, X.S.; Yuan, Y. Strength, Modulus of Elasticity, and Brittleness Index of Rubberized Concrete. J. Mater. Civ. Eng. 2008, 20, 692–699. [Google Scholar] [CrossRef]

- Atahan, A.O.; Sevim, U.K. Testing and Comparison of Concrete Barriers Containing Shredded Waste Tire Chips. Mater. Lett. 2008, 62, 3754–3757. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F. Waste Tyre Rubberized Concrete: Properties at Fresh and Hardened State. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef]

- Atahan, A.O.; Yücel, A.Ö. Crumb Rubber in Concrete: Static and Dynamic Evaluation. Constr. Build. Mater. 2012, 36, 617–622. [Google Scholar] [CrossRef]

- Mohammed, B.S. Structural Behavior and m–k Value of Composite Slab Utilizing Concrete Containing Crumb Rubber. Constr. Build. Mater. 2010, 24, 1214–1221. [Google Scholar] [CrossRef]

- Son, K.S.; Hajirasouliha, I.; Pilakoutas, K. Strength and Deformability of Waste Tyre Rubber-Filled Reinforced Concrete Columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of Concrete Containing Scrap-Tire Rubber—An Overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Tehrani, F.M.; Miller, N.M. Tire-Derived Aggregate Cementitious Materials: A Review of Mechanical Properties. In Cement Based Materials; Saleh, H.E.-D.M., Rahman, R.O.A., Eds.; InTech: London, UK, 2018; ISBN 978-1-78984-153-4. [Google Scholar]

- Tehrani, F.M.; Carreon, J.; Miller, N. An Investigation of Tire-Derived Lightweight Aggregate Concrete. ACI Symp. Publ. 2019, 334, 68–98. [Google Scholar] [CrossRef]

- Treloar, L.R.G. Stress-Strain Data for Vulcanized Rubber under Various Types of Deformation. Trans. Faraday Soc. 1944, 40, 59–70. [Google Scholar] [CrossRef]

- Wood, L.A. Uniaxial Extension and Compression in Stress-Strain Relations of Rubber. J. Res. Natl. Bur. Stand. 1977, 82, 57–63. [Google Scholar] [CrossRef] [PubMed]

- Hertz, D.L., Jr. An analysis of rubber under strain from an engineering perspective. J. Elastomerics 1991. Available online: https://www.sealseastern.com/pdf/rubberunderstrain.pdf (accessed on 2 November 2021).

- Yang, H.; Jiang, L.; Zhang, Y.; Qi, P. Flexural Strength of Cement Paste Beam under Chemical Degradation: Experiments and Simplified Modeling. J. Mater. Civ. Eng. 2013, 25, 555–562. [Google Scholar] [CrossRef]

- Toutanji, H.A. The Use of Rubber Tire Particles in Concrete to Replace Mineral Aggregates. Cem. Concr. Compos. 1996, 18, 135–139. [Google Scholar] [CrossRef]

- Humphrey, D.; Blumenthal, M. The Use of Tire-Derived Aggregate in Road Construction Applications. In Green Streets and Highways 2010; American Society of Civil Engineers: Denver, CO, USA, 2010; pp. 299–313. [Google Scholar] [CrossRef]

- CSI. Integrated Building Design Software, ETABS; CSI Analysis Reference Manual, Computers and Structures; Walnut Creek, CA, USA, 2016; Available online: https://www.csiamerica.com/products/etabs (accessed on 5 January 2021).

- The Regents of the University of California. OpenSees User. 2000. Available online: https://opensees.berkeley.edu/wiki/index.php/OpenSees_User (accessed on 15 March 2021).

- ASTM D6270; Standard Practice for Use of Scrap Tires in Civil Engineering Applications. ASTM: West Conshohocken, PA, USA, 2008. Available online: https://www.astm.org/d6270-08.html (accessed on 2 November 2021).

- Miller, N.M.; Tehrani, F.M. Mechanical Properties of Rubberized Lightweight Aggregate Concrete. Constr. Build. Mater. 2017, 147, 264–271. [Google Scholar] [CrossRef]

- Tehrani, F.M.; Masswadi, N.A.; Miller, N.M.; Sadrinezhad, A. An Experimental Investigation of Dynamic Properties of Fiber-Reinforced Tire-Derived Lightweight-Aggregate Concrete. Eur. J. Eng. Technol. Res. 2020, 5, 702–707. [Google Scholar] [CrossRef]

- Kersting, R.A.; Fahnestock, L.A.; Lopez, W.A. Seismic Design of Steel Buckling-Restrained Braced Frames: A Guide for Practicing Engineers; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016; p. NIST GCR 15-917-34. [Google Scholar]

- ANSI/AISC 341; Seismic Provisions for Structural Steel Buildings. American Institute of Steel Construction: Reston, VA, USA, 2016. Available online: https://www.aisc.org/2016-Seismic-Provisions (accessed on 5 November 2021).

- Pathan, N.B.; Couch, L.; Tehrani, F.M.; Naghshineh, A.; Fischer, O. Experimental Seismic Evaluation of Novel Buckling-Restrained Braced Frames Containing Tire-Derived Aggregate Concrete. Civ. Eng. 2023, 4, 551–566. [Google Scholar] [CrossRef]

- Naghshineh, A.; Tehrani, F.M.; Fischer, O. Application of Sustainable Concrete in the Seismic Evaluation of an Innovative Type of Buckling Restrained Brace. Sustainability 2022, 14, 16344. [Google Scholar] [CrossRef]

- ASTM A36/A36M-19; Standard Specification for Carbon Structural Steel. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Ancheta, T.D.; Darragh, R.B.; Stewart, J.P.; Seyhan, E.; Silva, W.J.; Chiou, B.S.J.; Wooddell, K.E.; Graves, R.W.; Kottke, A.R.; Boore, D.M.; et al. PEER 2013/03—PEER NGA-West2 Database, PEER 2013/03; Pacific Earthquake Engineering Research Center: Berkeley, CA, USA, 2013; Available online: https://ngawest2.berkeley.edu (accessed on 15 March 2021).

- FEMA 461; Interim Testing Protocols for Determining the Seismic Performance Characteristics of Structural and Nonstructural Components. Federal Emergency Management Agency: Washington, CD, USA, 2007. Available online: https://www.atcouncil.org/pdfs/FEMA461.pdf (accessed on 15 March 2021).

- ASCE 41-17; Seismic Evaluation and Retrofit of Existing Buildings (41-17). Available online: https://sp360.asce.org/PersonifyEbusiness/Merchandise/Product-Details/productId/233163464 (accessed on 10 January 2021).

- FEMA P-2208; NEHRP Recommended Revisions to ASCE/SEI 41-17, Seismic Evaluation and Retrofit of Existing Buildings. Available online: https://www.fema.gov/sites/default/files/documents/fema_p-2208.pdf (accessed on 10 January 2021).

- McKenna, F. Object-Oriented Finite Element Programming: Frameworks for Analysis, Algorithms and Parallel Computing. Ph.D. Thesis, Civil Engineering, University of California, Berkley, CA, USA, 1997. [Google Scholar]

- McKenna, F.; Fenves, G.L.; Scott, M.H. Open System for Earthquake Engineering Simulation; University of California: Berkeley, CA, USA, 2000; Available online: http://opensees.berkeley.edu (accessed on 15 March 2021).

- Mazzoni, S.; McKenna, F.; Scott, M.H.; Fenves, G.L. OpenSees Command Language Manual; University of California: Berkeley, CA, USA, 2006; Available online: http://opensees.berkeley.edu/manuals/usermanual (accessed on 15 March 2021).

- McKenna, F.; Scott, M.H.; Fenves, G.L. Nonlinear finite-element analysis software architecture using object composition. J. Comput. Civ. Eng. 2010, 24, 95–107. [Google Scholar] [CrossRef]

- ASCE/SEI 7-22; Minimum Design Loads and Associated Criteria for Buildings and Other Structures. American Society of Civil Engineers: Reston, VA, USA, 2022.

| Cylinder Testing | Compression Strength | Cylinder Testing |

|---|---|---|

| Conventional concrete | 34.6 | 11.2 |

| TDA concrete | 10.6 | 0.36 |

| Loadings | TS (s) | T/100 (s) | T90 (s) | Selected TS-Acceleration (s) (Min: 1 TS, T/100, T90, and 0.01s) | Selected TS- Displacement (s) |

|---|---|---|---|---|---|

| DUZCE | 0.0050 | 0.0023 | 0.145 | 0.0023 | 0.0050 |

| ELCENTRO | 0.0050 | 0.0023 | 0.145 | 0.0023 | 0.0050 |

| GAZLI | 0.0066 | 0.0023 | 0.145 | 0.0023 | 0.0066 |

| LOMA | 0.0050 | 0.0023 | 0.145 | 0.0023 | 0.0050 |

| TABAS 1 | 0.0169 | 0.0023 | 0.145 | 0.0023 | 0.0169 |

| TABAS 2 | 0.004225 | 0.0023 | 0.145 | 0.0023 | 0.0042 |

| TABAS 3 | 0.00845 | 0.0023 | 0.145 | 0.0023 | 0.0084 |

| FEMA 1 | 0.00625 | 0.0023 | 0.145 | 0.0023 | 0.0062 |

| FEMA 2 | 0.003125 | 0.0023 | 0.145 | 0.0023 | 0.0031 |

| FEMA 3 | 0.0125 | 0.0023 | 0.145 | 0.0023 | 0.0125 |

| FEMA-2D-4 | 0.0125 | 0.0023 | 0.145 | 0.0023 | 0.0125 |

| Sweep | 0.0125 | 0.0023 | 0.145 | 0.0023 | 0.0125 |

| Description | Damping Ratio (%) | |||

|---|---|---|---|---|

| Experimental | Analytical | |||

| Tension | Compression | Tension | Compression | |

| BRBF with TDA filling | 16% | 26% | 25% | 25% |

| BRBF with concrete filling | 13% | 17% | 14% | 14% |

| Stiffness (Kip/in) | ||||

| Experimental | Analytical | |||

| Tension | Compression | Tension | Compression | |

| BRBF with TDA filling | 19 | 21 | 21 | 21 |

| BRBF with concrete filling | 26 | 27 | 28 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naghshineh, A.; Fischer, O.; Pathan, N.B.; Couch, L.; Tehrani, F.M. Numerical Investigation of the Seismic Performance of an Innovative Type of Buckling-Restrained Brace (BRB). Eng 2023, 4, 2978-2990. https://doi.org/10.3390/eng4040167

Naghshineh A, Fischer O, Pathan NB, Couch L, Tehrani FM. Numerical Investigation of the Seismic Performance of an Innovative Type of Buckling-Restrained Brace (BRB). Eng. 2023; 4(4):2978-2990. https://doi.org/10.3390/eng4040167

Chicago/Turabian StyleNaghshineh, Ali, Oliver Fischer, Nasreen B. Pathan, Logan Couch, and Fariborz M. Tehrani. 2023. "Numerical Investigation of the Seismic Performance of an Innovative Type of Buckling-Restrained Brace (BRB)" Eng 4, no. 4: 2978-2990. https://doi.org/10.3390/eng4040167