Multi-Scale Polymer Processing

(Closed)

Share This Topical Collection

Editor

Prof. Dr. Dagmar R. D'hooge

Prof. Dr. Dagmar R. D'hooge

Prof. Dr. Dagmar R. D'hooge

Prof. Dr. Dagmar R. D'hooge

E-Mail

Website

Collection Editor

Centre for Textiles Science and Engineering, Ghent University, Technologiepark 70a, 9052 Ghent, Belgium

Interests: multi-scale modeling; polymer design; polymerization kinetics; polymer processing; polymer reycling

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Polymer processing is an important research field with many applications in various industrial sectors. A traditional focus has been on macroscale processing research, at the scale of the processing unit such as the extruder or injection molding equipment. At a fundamental level, polymer processing has a strong multiscale character, and therefore, the consideration of smaller scales and the connection to these smaller scales is crucial. The goal of this Topical Collection is to make this multiscale aspect clear. Contributions should either focus on a specific scale or connect scales. Examples of associated topics are polymer rheology, 3D printing and additive manufacturing, extrusion, injection molding, reactive processing, multiscale design, flow simulations, morphology control, and durability.

Prof. Dr. Dagmar R. D'hooge

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Published Papers (4 papers)

Open AccessReview

Principles and Guidelines for In-Line Viscometry in Cereal Extrusion

by

Elia Dalle Fratte, Dagmar R. D’hooge, Mia Eeckhout and Ludwig Cardon

Cited by 2 | Viewed by 1974

Abstract

In the food industry, extrusion cooking finds numerous applications thanks to its high productivity and nutrient retention. More specifically, cereal extrusion, e.g., for savory snacks and breakfast products has an important market share. For such applications, rheology, which addresses viscous and elastic contributions,

[...] Read more.

In the food industry, extrusion cooking finds numerous applications thanks to its high productivity and nutrient retention. More specifically, cereal extrusion, e.g., for savory snacks and breakfast products has an important market share. For such applications, rheology, which addresses viscous and elastic contributions, plays an important role in developing, optimizing, and controlling the extrusion manufacturing technique. In this context, conventional off-line rheometers are not ideal for providing data, as the goal is to replicate the exact thermomechanical history to which the food is subjected in the extrusion process. Hence, to achieve reliable analyses, in-line viscometers that have mostly been tested using oil-based polymers were introduced. Biopolymers (e.g., starch), however, are highly sensitive to both heat and mechanical degradation, and the viscometer design has to be adapted accordingly to produce an accurate measurement. Alongside a discussion of the different designs available, this review will address the most common methodologies for measuring the steady shear viscosity, extensional viscosity, and the first normal stress difference for food applications, providing researchers in the biopolymer and food engineering fields with a general introduction to this emerging topic.

Full article

►▼

Show Figures

Open AccessReview

Infrared Linear Dichroism for the Analysis of Molecular Orientation in Polymers and in Polymer Composites

by

Liliane Bokobza

Cited by 7 | Viewed by 3180

Abstract

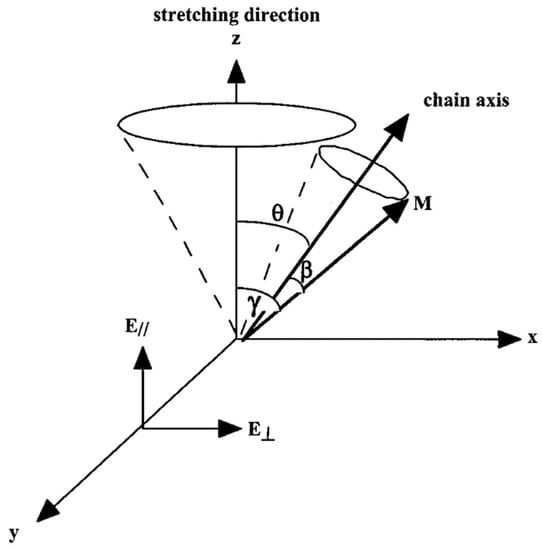

The mechanical properties of polymeric materials are strongly affected by molecular orientation occurring under processing conditions. Infrared dichroism is particularly well suited for characterizing polymer chain orientation at a molecular level. The usefulness of this technique has been demonstrated through various applications in

[...] Read more.

The mechanical properties of polymeric materials are strongly affected by molecular orientation occurring under processing conditions. Infrared dichroism is particularly well suited for characterizing polymer chain orientation at a molecular level. The usefulness of this technique has been demonstrated through various applications in homopolymers, semi-crystalline polymers, copolymers, polymer blends, as well as in polymer composites. Determination of molecular orientation can be carried out in the mid- and near-infrared ranges and very small dichroic effects can be detected with the use of a photoelastic modulator. Chain orientation in polymer composites is seen to increase with the filler content in the case of a strong interface between the two phases, making possible a quantification of the degree of bonding between the host polymeric matrix and the incorporated inclusions.

Full article

►▼

Show Figures

Open AccessArticle

Lifting the Sustainability of Modified Pet-Based Multilayer Packaging Material with Enhanced Mechanical Recycling Potential and Processing

by

Lynn Trossaert, Matthias De Vel, Ludwig Cardon and Mariya Edeleva

Cited by 6 | Viewed by 2737

Abstract

Sustainability and recyclability are among the main driving forces in the plastics industry, since the pressure on crude oil resources and the environment is increasing. The aim of this research is to develop a sustainable thermoformable multilayer food packaging, based on co-polyesters, which

[...] Read more.

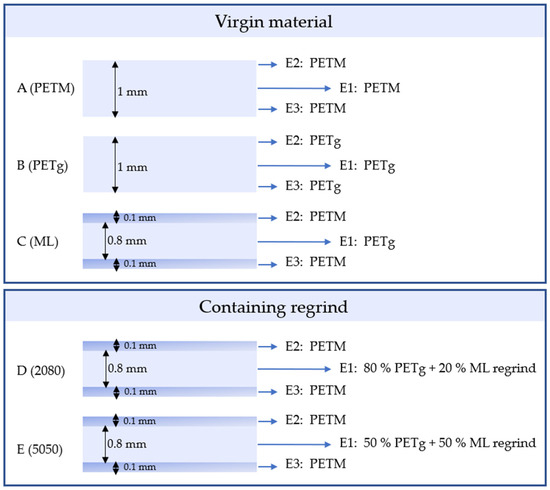

Sustainability and recyclability are among the main driving forces in the plastics industry, since the pressure on crude oil resources and the environment is increasing. The aim of this research is to develop a sustainable thermoformable multilayer food packaging, based on co-polyesters, which is suitable for hot-fill applications and allows for recycling in a conventional waste stream. As a polymer material for the outer layer, we selected a modified polyethylene terephthalate (PETM), which is an amorphous co-polyester with a high glass transition temperature (±105 °C) and thus high thermal stability and transparency. The inner layer consists of 1,4-cyclohexylene dimethanol-modified polyethylene terephthalate (PETg), which is allowed to be recycled in a PET stream. Multilayers with a total thickness of 1 mm and a layer thickness distribution of 10/80/10 have been produced. To test the recyclability, sheets which contained 20% and 50% regrind of the initial multilayer in their middle PETg layer have been produced as well. The sheet produced from virgin pellets and the one containing 20% regrind in the middle layer showed no visible haze. This was not the case for the one containing 50% regrind in the middle layer, which was confirmed by haze measurements. The hot-fill test results showed no shrinkage or warpage for the multilayer trays for all temperatures applied, namely 95, 85, 75 and 65 °C. This is a remarkable improvement compared to pure PETg trays, which show a visible deformation after exposure to hot-fill conditions of 95 °C and 85 °C.

Full article

►▼

Show Figures

Open AccessArticle

Interplay of Structural Factors in Formation of Microphase-Separated or Microphase-Mixed Structures of Polyurethanes Revealed by Solid-State NMR and Dielectric Spectroscopy

by

Stepan A. Ostanin, Maxim V. Mokeev, Dmitry V. Pikhurov, Aleksandr S. Sakhatskii and Vjacheslav V. Zuev

Cited by 7 | Viewed by 1687

Abstract

A set of aromatic-oxyaliphatic polyurethanes (PUs) with different mass fractions of components also containing fluorinated fragments was synthesized and studied using various solid-state NMR techniques and dielectric spectroscopy. In contrast to the common model suggested by Cooper and Tobolsky in 1966, the rigid

[...] Read more.

A set of aromatic-oxyaliphatic polyurethanes (PUs) with different mass fractions of components also containing fluorinated fragments was synthesized and studied using various solid-state NMR techniques and dielectric spectroscopy. In contrast to the common model suggested by Cooper and Tobolsky in 1966, the rigid domains of microphase separated PUs are formed, not only by units containing urethane bonds, but also by oxyethylene fragments that form a common rigid phase. The urethane bonds and oxyethylene fragments are incorporated into both rigid and soft phases. Good agreement with the Cooper and Tobolsky model is observed only when solubility parameters are significantly different for the hard and soft segments, such as hydrocarbon aromatics and perfluoroaliphatic blocks.

Full article

►▼

Show Figures