Permeable Water-Resistant Heat Insulation Panel Based on Recycled Materials and Its Physical and Mechanical Properties

Abstract

:1. Introduction

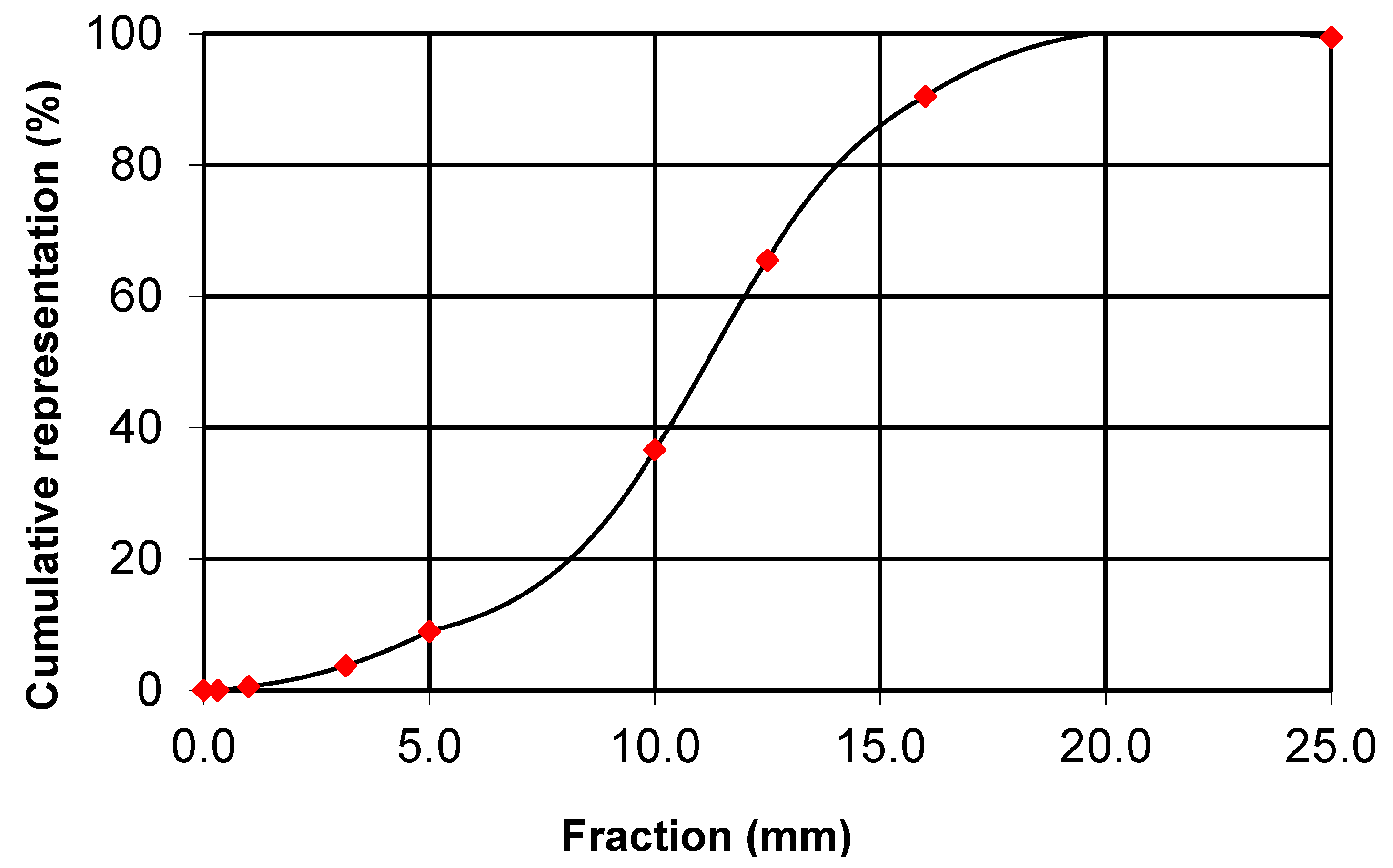

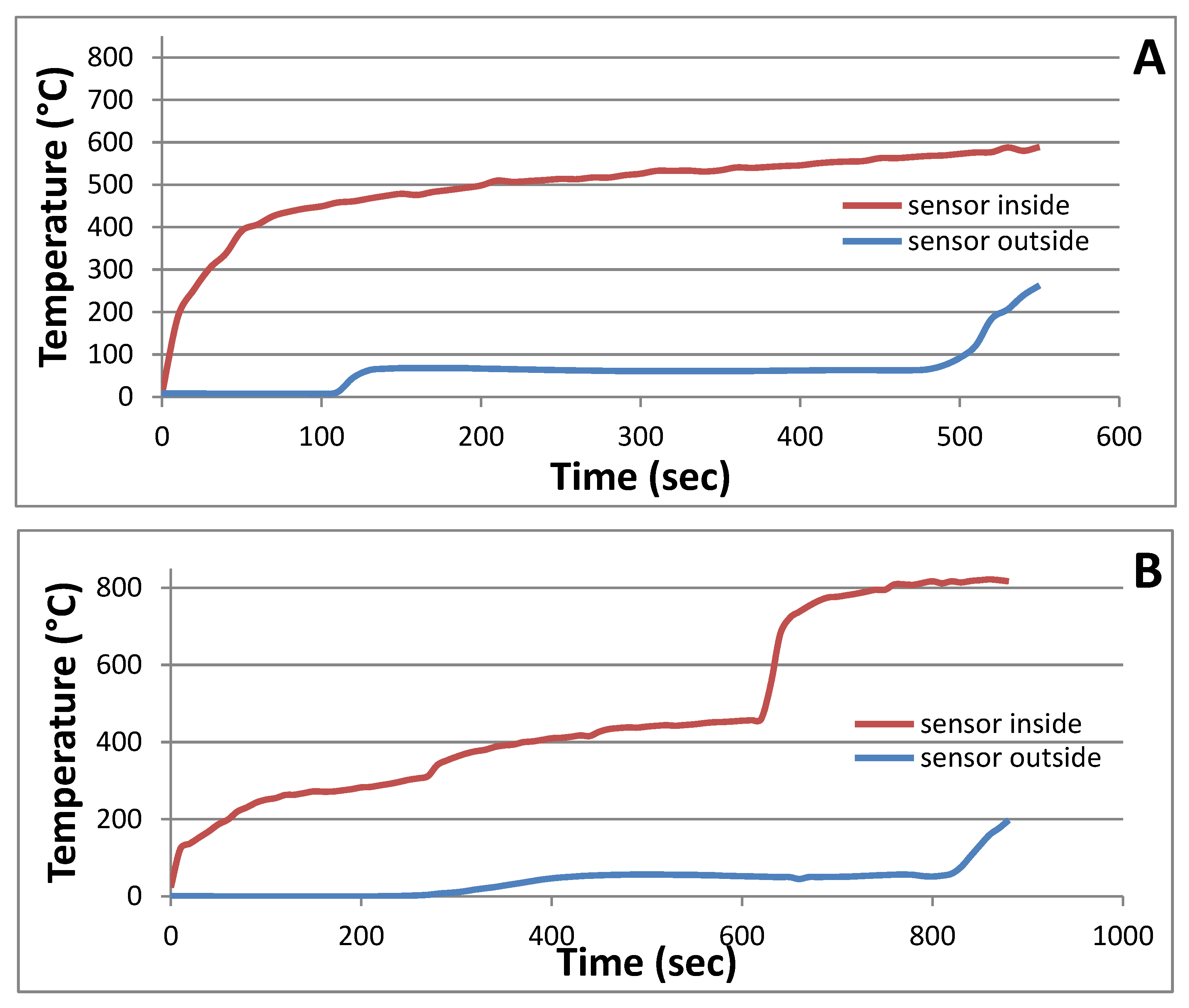

2. Materials and Methods

2.1. Heat Insulation Board Manufacturing

2.2. Geopolymer and Nanofiber Membrane Application

2.3. Physical and Mechanical Properties Estimation

2.4. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S.; Mencarelli, N. Sound absorption properties of reed. In Proceedings of the 22nd International Congress on Sound and Vibration, Florence, Italy, 12–16 July 2015. [Google Scholar]

- Yarbrough, D.W.; Wikes, K.E.; Olivier, P.A.; Graves, R.S.; Vohra, A. Apparent thermal conductivity data and related information for rice hulls and crushed pecan shells. Therm. Cond. 2005, 27, 222–230. [Google Scholar]

- Binici, H.; Eken, M.; Dolaz, M.; Aksogan, O.; Kara, M. An environmentally friendly thermal insulation material from sunflower stalk, textile waste and stubble fibres. Constr. Build. Mater. 2014, 51, 24–33. [Google Scholar] [CrossRef]

- Goodhew, S.; Griffiths, R. Sustainable earth walls to meet the building regulations. Energy Build 2005, 37, 451–459. [Google Scholar] [CrossRef]

- Hýsek, Š.; Podlena, M.; Bartsch, H.; Wenderdel, C.; Böhm, M. Effect of wheat husk surface pre-treatment on the properties of husk-based composite materials. Ind. Crops Prod. 2018, 125, 105–113. [Google Scholar] [CrossRef]

- Kozłowski, R.; Mieleniak, B.; Muzyczek, M.; Mankowski, J. Development of insulation composite based on FR bast fibers and wool. In International Conference on Flax and Other Bast Plants; Saskatchewan Flax Development Commission: Saskatoon, SK, Canada, 2008; ID number: 68; pp. 353–363. [Google Scholar]

- Battegazzore, D.; Alongi, J.; Duraccio, D.; Frache, A. Reuse and valorisation of hemp fibres and rice husk particles for fire resistant fibreboards and particleboards. J. Polymers Env. 2018, 26, 3731–3744. [Google Scholar] [CrossRef]

- Kain, G.; Lienbacher, B.; Barbu, M.C.; Senck, S.; Petutschnigg, A. Water vapour diffusion resistance of larch (Larix decidua) bark insulation panels and application considerations based on numeric modeling. Constr. Build. Mater. 2018, 164, 308–316. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S. Recycling in buildings: an LCA case study of a thermal insulation panel made of polyester fiber, recycled from post-consumer PET bottles. Int. J. Life Cycle Assess. 2011, 16, 306–315. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Das, D.; Pradhan, A.K.; Chattopadhyay, R.; Singh, S.N. Composite nonwovens. Text. Prog. 2012, 44, 1–84. [Google Scholar] [CrossRef]

- Hýsek, Š.; Frydrych, M.; Herclík, M.; Louda, P.; Fridrichová, L.; Le Van, S.; Le Chi, H. Fire-resistant sandwich-structured composite material based on alternative materials and its physical and mechanical properties. Materials 2019, 12, 1432. [Google Scholar] [CrossRef] [PubMed]

- Dufkova, I.; Kovacic, V.; Louda, P. The effect of adding micro and inorganic nanoparticles on properties of geosilicate cured at temperature. In Proceedings of the 9th International Conference on Nanomaterials-Research and Application (Nanocon), Brno, Czech, 18–20 October 2017. [Google Scholar]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceramics Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Behera, P.; Baheti, V.; Militky, J.; Louda, P. Elevated temperature properties of basalt microfibril filled geopolymer composites. Constr. Build. Mater. 2018, 163, 850–860. [Google Scholar] [CrossRef]

- Rovnaník, P.; Al, S.O. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Degirmenci, F.N. Freeze-thaw and fire resistance of geopolymer mortar based on natural and waste pozzolans. Ceram. Silik. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Villaquirán-Caicedo, M.A.; de Gutiérrez, R.M.; Sulekar, S.; Davis, C.; Nino, J.C. Thermal properties of novel binary geopolymers based on metakaolin and alternative silica sources. Appl. Clay Sci. 2015, 118, 276–282. [Google Scholar] [CrossRef]

- Hung, T.D.; Pernica, D.; Kroisova, D.; Bortnovsky, O.; Louda, P.; Rylichova, V. Composites Base on Geopolymer Matrices: Preliminary Fabrication, Mechanical Properties and Future Applications. Adv. Mater. Res. 2018, 55–57, 477–480. [Google Scholar] [CrossRef]

- Le Chi, H.; Louda, P.; Periyasamy, A.P.; Bakalova, T.; Kovacic, V. Flexural behavior of carbon textile-reinforced geopolymer composite thin plate. Fibers 2018, 6, 87. [Google Scholar] [CrossRef]

- Bastien, D.; Winther-Gaasvig, M. Influence of driving rain and vapour diffusion on the hygrothermal performance of a hygroscopic and permeable building envelope. Energy 2018, 164, 288–297. [Google Scholar] [CrossRef]

- Arundel, A.V.; Sterling, E.M.; Biggin, J.H.; Sterling, T.D. Indirect health effects of relative humidity in indol environments. Environ. Health Perspect. 1986, 65, 351–361 101289/ehp8665351. [Google Scholar]

- Simonson, C.J.; Salaonvaara, M.; Ojanen, T. Heat and mass transfer between indoor air and a permeable and hygroscopic building envelope: Part I – field measurements. J. Build. Phys. 2004, 28, 63–101 101177/1097196304044395. [Google Scholar] [CrossRef]

- Simonson, C.J.; Salaonvaara, M.; Ojanen, T. Heat and mass transfer between indoor air and a permeable and hygroscopic building envelope: Part II – verification and numerical studies. J. Build. Phys. 2004, 28, 161–185. [Google Scholar] [CrossRef]

- Fridrichová, L.; Frydrych, M.; Herclík, M.; Knížek, R.; Mayerová, K. Nanofibrous membrane as a moisture barrier. In Proceedings of the AIP Conference, Milano, Italy, 3–7 August 2018. [Google Scholar]

- EN 323:1993—Wood-Based Panels. Determination of Density; Eur. Comm. for Stand.: Brussels, Belgium, 1993.

- EN 319:1993—Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board; Eur. Comm. for Stand.: Brussels, Belgium, 1993.

- Neuberger, P.; Kic, P. The use of unsteady method for determination of thermal conductivity of porous construction materials in real conditions. Agronomy Res. 2017, 15, 1119–1126. [Google Scholar]

- EN 1363-2:1999—Fire Resistance Tests. Alternative and Additional Procedures; Eur. Comm. for Stand.: Brussels, Belgium, 1999.

- Ferrández-García, C.-E.; Ferrández-García, A.; Ferrández-Villena, M.; Hidalgo-Cordero, J.F.; García-Ortuño, T.; Ferrández-García, M.-T. Physical and mechanical properties of particleboard made from palm tree prunings. Forests 2018, 9, 755. [Google Scholar] [CrossRef]

- Yuan, L.; Batra, R.C. Optimum first failure load design of one/two-core sandwich plates under blast loads, and their ultimate loads. Compos. Struct. 2019, 224. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Zheng, F.; Li, H.; Lu, C. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- Pavelek, M.; Prajer, M.; Trgala, K. Static and dynamic thermal characterization of timber frame/wheat (Triticum Aestivum) chaff thermal insulation panel for sustainable building construction. Sustainability 2018, 10, 2363. [Google Scholar] [CrossRef]

- Czajkowski, L.; Wojcieszak, D.; Olek, W.; Prybyl, J. Thermal properties of fractions of corn stover. Construct. Building Mater. 2019, 210, 709–712. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pisello, A.L.; DˇAlessandro, F.; Bianchi, F.; Fabiani, C.; Cornicchia, M.; Rotili, A. Experimental and numerical characterization of innovative cardboard-based panels: Thermal and acoustic performance analysis and life cycle assessment. Building Env. 2016, 95, 145–159. [Google Scholar] [CrossRef]

- EN 13162:2012+A1:2015—Thermal Insulation Products for Buildings. Factory Made Mineral Wool (MW) Products. Specification; Eur. Comm. for Stand.: Brussels, Belgium, 2015.

- Tayeb, A.H.; Amini, E.; Ghasemi, S.; Tajvidi, M. Cellulose nanomaterials-binding properties and applications: A review. Molecules 2018, 23, 2684. [Google Scholar] [CrossRef] [PubMed]

- Taveri, G.; Bernardo, E.; Dlouhy, I. Mechanical performance of glass-based geopolymer matrix composites reinforced with cellulose fibers. Materials 2018, 11, 2395. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: All samples are available from the authors. |

| Component | Percentage of Individual Components |

|---|---|

| Cement Baucis Lk | 43.2% |

| Activator Baucis Lk | 38.9% |

| KEMA MIKROSILIKA | 4.3% |

| Mineral wool ISOVER | 13.0% |

| Aluminum powder | 0.6% |

| Permeable Water-Resistant Heat Insulation Panel | ||||

|---|---|---|---|---|

| Recycled PUR:wheat husk ratio | 1:0 | 3:1 | ||

| Nanofiber membrane | 0 | 1 | 0 | 1 |

| Recycled PUR:Wheat Husk Ratio | Heat Insulation Board Density (kg/m3) | Geopolymer Density (kg/m3) | λ20/65 (W/(m·K)) |

|---|---|---|---|

| 1:0 | 49.4 (1.7) | 885 (32) | 0.049 (0.006) |

| 3:1 | 51.6 (4.2) | 885 (32) | 0.051 (0.006) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hýsek, Š.; Frydrych, M.; Herclík, M.; Fridrichová, L.; Louda, P.; Knížek, R.; Le Van, S.; Le Chi, H. Permeable Water-Resistant Heat Insulation Panel Based on Recycled Materials and Its Physical and Mechanical Properties. Molecules 2019, 24, 3300. https://doi.org/10.3390/molecules24183300

Hýsek Š, Frydrych M, Herclík M, Fridrichová L, Louda P, Knížek R, Le Van S, Le Chi H. Permeable Water-Resistant Heat Insulation Panel Based on Recycled Materials and Its Physical and Mechanical Properties. Molecules. 2019; 24(18):3300. https://doi.org/10.3390/molecules24183300

Chicago/Turabian StyleHýsek, Štěpán, Miroslav Frydrych, Miroslav Herclík, Ludmila Fridrichová, Petr Louda, Roman Knížek, Su Le Van, and Hiep Le Chi. 2019. "Permeable Water-Resistant Heat Insulation Panel Based on Recycled Materials and Its Physical and Mechanical Properties" Molecules 24, no. 18: 3300. https://doi.org/10.3390/molecules24183300

APA StyleHýsek, Š., Frydrych, M., Herclík, M., Fridrichová, L., Louda, P., Knížek, R., Le Van, S., & Le Chi, H. (2019). Permeable Water-Resistant Heat Insulation Panel Based on Recycled Materials and Its Physical and Mechanical Properties. Molecules, 24(18), 3300. https://doi.org/10.3390/molecules24183300