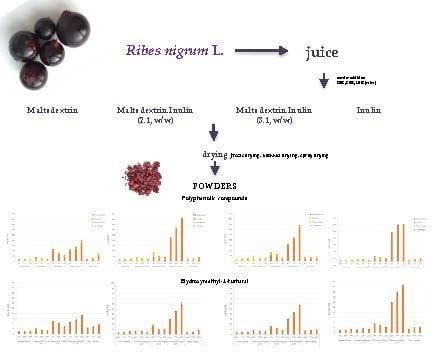

The Influence of Inulin on the Retention of Polyphenolic Compounds during the Drying of Blackcurrant Juice

Abstract

1. Introduction

2. Results and Discussion

2.1. Polyphenolic Compounds

2.2. Hydroxymethyl-l-Furfural

2.3. Antioxidant Capacity

2.4. Principal Component Analysis

3. Materials and Methods

3.1. Material

3.2. Methods

3.2.1. Drying methods

3.2.2. Dry Basis

3.2.3. Polyphenolic Content Measured by UPLC

3.2.4. Hydroxymethyl-l-Furfural Content

3.2.5. Antioxidant Capacity

3.2.6. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| FD | Freeze drying |

| VD | Vacuum drying |

| SD | Spray drying |

| TEAC ABTS | Trolox equivalent antioxidant capacity by ABTS |

| FRAP | Ferric reducing antioxidant potential |

References

- Brennan, R.M. Currants and gooseberries. In Temperate fruit crop breeding: Germplasm to genomics; Hancock, J.F., Ed.; Springer: Dordrecht, The Netherlands, 2008; pp. 177–196. ISBN 978-1-4020-6907-9. [Google Scholar]

- Tridage Blackcurrant production. Available online: www.tridge.com (accessed on 15 July 2019).

- Mattila, P.H.; Hellström, J.; McDougall, G.; Dobson, G.; Pihlava, J.-M.; Tiirikka, T.; Stewart, D.; Karjalainen, R. Polyphenol and vitamin C contents in European commercial blackcurrant juice products. Food Chem. 2011, 127, 1216–1223. [Google Scholar] [CrossRef]

- Alba, K.; MacNaughtan, W.; Laws, A.P.; Foster, T.J.; Campbell, G.M.; Kontogiorgos, V. Fractionation and characterisation of dietary fibre from blackcurrant pomace. Food Hydrocoll. 2018, 81, 398–408. [Google Scholar] [CrossRef]

- Woznicki, T.L.; Sønsteby, A.; Aaby, K.; Martinsen, B.K.; Heide, O.M.; Wold, A.-B.; Remberg, S.F. Ascorbate pool, sugars and organic acids in black currant (Ribes nigrum L.) berries are strongly influenced by genotype and post-flowering temperature. J. Sci. Food Agric. 2017, 97, 1302–1309. [Google Scholar] [CrossRef]

- Paunović, S.M.; Nikolić, M.; Miletić, R.; Maskovic, P. Vitamin and mineral content in black currant (Ribes nigrum L.) fruits as affected by soil management system. Acta Sci. Pol. Hortorum Cultus 2017, 16, 135–144. [Google Scholar] [CrossRef]

- Tabart, J.; Franck, T.; Kevers, C.; Pincemail, J.; Serteyn, D.; Defraigne, J.-O.; Dommes, J. Antioxidant and anti-inflammatory activities of Ribes nigrum extracts. Food Chem. 2012, 131, 1116–1122. [Google Scholar] [CrossRef]

- Bishayee, A.; Mbimba, T.; Thoppil, R.J.; Háznagy-Radnai, E.; Sipos, P.; Darvesh, A.S.; Folkesson, H.G.; Hohmann, J. Anthocyanin-rich black currant (Ribes nigrum L.) extract affords chemoprevention against diethylnitrosamine-induced hepatocellular carcinogenesis in rats. J. Nutr. Biochem. 2011, 22, 1035–1046. [Google Scholar] [CrossRef] [PubMed]

- Gopalan, A.; Reuben, S.C.; Ahmed, S.; Darvesh, A.S.; Hohmann, J.; Bishayee, A. The health benefits of blackcurrants. Food Funct. 2012, 3, 795–809. [Google Scholar] [CrossRef] [PubMed]

- Archaina, D.; Sosa, N.; Rivero, R.; Schebor, C. Freeze-dried candies from blackcurrant (Ribes nigrum L.) and yoghurt. Physicochemical and sensorial characterization. LWT 2019, 100, 444–449. [Google Scholar] [CrossRef]

- Kandy. Available online: https://www.kandy.pl (accessed on 15 July 2019).

- IBA—International Blackcurrant Association—Blackcurrant Beer—Another Nice Polish Initiative. Available online: https://www.blackcurrant-iba.com/blackcurrant-beer (accessed on 15 July 2019).

- Michalska, A.; Wojdyło, A.; Łysiak, G.P.; Lech, K.; Figiel, A. Functional relationships between phytochemicals and drying conditions during the processing of blackcurrant pomace into powders. Adv. Powder Technol. 2017, 28, 1340–1348. [Google Scholar] [CrossRef]

- Michalska, A.; Wojdyło, A.; Lech, K.; Łysiak, G.P.; Figiel, A. Effect of different drying techniques on physical properties, total polyphenols and antioxidant capacity of blackcurrant pomace powders. LWT Food Sci. Technol. 2017, 78, 114–121. [Google Scholar] [CrossRef]

- Rose, P.M.; Cantrill, V.; Benohoud, M.; Tidder, A.; Rayner, C.M.; Blackburn, R.S. Application of anthocyanins from blackcurrant (Ribes nigrum L.) fruit waste as renewable hair dyes. J. Agric. Food Chem. 2018, 66, 6790–6798. [Google Scholar] [CrossRef] [PubMed]

- Michalska, A.; Wojdyło, A.; Łysiak, G.P.; Figiel, A. Chemical composition and antioxidant properties of powders obtained from different plum juice formulations. Int. J. Mol. Sci. 2017, 18, 176. [Google Scholar] [CrossRef] [PubMed]

- Jakubczyk, E.; Gondek, E.; Głod, K. Charakterystyka właściwości fizycznych proszku jabłkowego otrzymanego metodą suszenia pianowo-sublimacyjnego. Acta Agrophysica 2010, 15. [Google Scholar]

- Bhandari, B. 1 - Introduction to food powders. In Handbook of Food Powders; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead: Sawston, Cambridge, UK, 2013; pp. 1–25. ISBN 978-0-85709-513-8. [Google Scholar]

- Horszwald, A.; Julien, H.; Andlauer, W. Characterisation of Aronia powders obtained by different drying processes. Food Chem. 2013, 141, 2858–2863. [Google Scholar] [CrossRef] [PubMed]

- Shishir, M.R.I.; Chen, W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 2017, 65, 49–67. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, health benefits and food applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Landbo, A.-K.; Meyer, A.S. Effects of different enzymatic maceration treatments on enhancement of anthocyanins and other phenolics in black currant juice. Innov. Food Sci. Emerg. Technol. 2004, 5, 503–513. [Google Scholar] [CrossRef]

- Mäkilä, L.; Laaksonen, O.; Kallio, H.; Yang, B. Effect of processing technologies and storage conditions on stability of black currant juices with special focus on phenolic compounds and sensory properties. Food Chem. 2017, 221, 422–430. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- Gagneten, M.; Corfield, R.; Mattson, M.G.; Sozzi, A.; Leiva, G.; Salvatori, D.; Schebor, C. Spray-dried powders from berries extracts obtained upon several processing steps to improve the bioactive components content. Powder Technol. 2019, 342, 1008–1015. [Google Scholar] [CrossRef]

- Bakowska-Barczak, A.M.; Kolodziejczyk, P.P. Black currant polyphenols: Their storage stability and microencapsulation. Ind. Crops Prod. 2011, 34, 1301–1309. [Google Scholar] [CrossRef]

- Do Carmo, E.L.; Teodoro, R.A.R.; Félix, P.H.C.; de Barros Fernandes, R.V.; de Oliveira, É.R.; Veiga, T.R.L.A.; Borges, S.V.; Botrel, D.A. Stability of spray-dried beetroot extract using oligosaccharides and whey proteins. Food Chem. 2018, 249, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Anttonen, M.J.; Karjalainen, R.O. High-performance liquid chromatography analysis of black currant (Ribes nigrum L.) fruit phenolics grown either conventionally or organically. J. Agric. Food Chem. 2006, 54, 7530–7538. [Google Scholar] [CrossRef]

- Moyer, R.A.; Hummer, K.E.; Finn, C.E.; Frei, B.; Wrolstad, R.E. Anthocyanins, phenolics, and antioxidant capacity in diverse small fruits: Vaccinium, Rubus, and Ribes. J. Agric. Food Chem. 2002, 50, 519–525. [Google Scholar] [CrossRef]

- Cyboran, S.; Bonarska-Kujawa, D.; Pruchnik, H.; Żyłka, R.; Oszmiański, J.; Kleszczyńska, H. Phenolic content and biological activity of extracts of blackcurrant fruit and leaves. Food Res. Int. 2014, 65, 47–58. [Google Scholar] [CrossRef]

- Skrede, G.; Wrolstad, R.E.; Durst, R.W. Changes in anthocyanins and polyphenolics during juice processing of highbush blueberries (Vaccinium corymbosum L.). J. Food Sci. 2000, 65, 357–364. [Google Scholar] [CrossRef]

- Patras, A.; Brunton, N.P.; O’Donnell, C.; Tiwari, B.K. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci. Technol. 2010, 21, 3–11. [Google Scholar] [CrossRef]

- Lima, E.M.F.; Madalão, M.; Benincá, D.; Saraiva, S.; Silva, P. Effect of encapsulating agent and drying air temperature on the characteristics of microcapsules of anthocyanins and polyphenols from juçara (Euterpe edulis Martius). Int. Food Res. J. 2019, 26, 607–617. [Google Scholar]

- Kuster, B.F.M. 5-Hydroxymethylfurfural (HMF). A review focusing on its manufacture. Starch Stärke 1990, 42, 314–321. [Google Scholar] [CrossRef]

- Yang, F.; Liu, Q.; Bai, X.; Du, Y. Conversion of biomass into 5-hydroxymethylfurfural using solid acid catalyst. Bioresour. Technol. 2011, 102, 3424–3429. [Google Scholar] [CrossRef] [PubMed]

- Kothe, L.; Zimmermann, B.F.; Galensa, R. Temperature influences epimerization and composition of flavanol monomers, dimers and trimers during cocoa bean roasting. Food Chem. 2013, 141, 3656–3663. [Google Scholar] [CrossRef] [PubMed]

- Mikkonen, T.P.; Määttä, K.R.; Hukkanen, A.T.; Kokko, H.I.; Törrönen, A.R.; Kärenlampi, S.O.; Karjalainen, R.O. Flavonol content varies among black currant cultivars. J. Agric. Food Chem. 2001, 49, 3274–3277. [Google Scholar] [CrossRef] [PubMed]

- Michalska, A.; Wojdyło, A.; Honke, J.; Ciska, E.; Andlauer, W. Drying-induced physico-chemical changes in cranberry products. Food Chem. 2018, 240, 448–455. [Google Scholar] [CrossRef] [PubMed]

- Pinelo, M.; Landbo, A.-K.R.; Vikbjerg, A.F.; Meyer, A.S. Effect of clarification techniques and rat intestinal extract incubation on phenolic composition and antioxidant activity of black currant juice. J. Agric. Food Chem. 2006, 54, 6564–6571. [Google Scholar] [CrossRef]

- Fitzpatrick, K.; Kendrick, B.; Santos, C.; Green, P.; Zhang, B.; Hunt, D.; Ronk, M.; Ying, L. Freeze-dry mediated formation of 5-(hydroxylmethyl)furfural. ACS 2013, 8, 129–145. [Google Scholar]

- Zhang, Z.; Zou, Y.; Wu, T.; Huang, C.; Pei, K.; Zhang, G.; Lin, X.; Bai, W.; Ou, S. Chlorogenic acid increased 5-hydroxymethylfurfural formation when heating fructose alone or with aspartic acid at two pH levels. Food Chem. 2016, 190, 832–835. [Google Scholar] [CrossRef]

- Kurata, T.; Sakurai, Y. Degradation of L-ascorbic acid and mechanism of nonenzymic browning reaction. Agric. Biol. Chem. 1967, 31, 170–184. [Google Scholar]

- Rada-Mendoza, M.; Sanz, M.L.; Olano, A.; Villamiel, M. Formation of hydroxymethylfurfural and furosine during the storage of jams and fruit-based infant foods. Food Chem. 2004, 85, 605–609. [Google Scholar] [CrossRef]

- Murkovic, M.; Pichler, N. Analysis of 5-hydroxymethylfurfual in coffee, dried fruits and urine. Mol. Nutr. Food Res. 2006, 50, 842–846. [Google Scholar] [CrossRef]

- Figiel, A. Drying kinetics and quality of vacuum-microwave dehydrated garlic cloves and slices. J. Food Eng. 2009, 94, 98–104. [Google Scholar] [CrossRef]

- Wojdyło, A.; Oszmiański, J.; Bielicki, P. Polyphenolic composition, antioxidant activity, and polyphenol oxidase (PPO) activity of quince (Cydonia oblonga Miller) varieties. J. Agric. Food Chem. 2013, 61, 2762–2772. [Google Scholar] [CrossRef] [PubMed]

- Gökmen, V.; Şenyuva, H.Z. Improved method for the determination of hydroxymethylfurfural in baby foods using liquid chromatography–mass spectrometry. J. Agric. Food Chem. 2006, 54, 2845–2849. [Google Scholar] [CrossRef] [PubMed]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

Sample Availability: Not available. |

| Carrier/Concentration | Anthocyanins | Flavan-3-ol | ||||||

|---|---|---|---|---|---|---|---|---|

| Delphinidin-3-O-glucoside | Delphinidin-3-O-rutinoside | Cyanidin-3-O-glucoside | Cyanidin-3-O-rutinoside | Petunidin-3-O-rutinoside | Peonidin-3-O-rutinoside | (+)-catechin | ||

| Freeze Drying | ||||||||

| Maltodextrin | 40% | 229.5 ± 5.4 ab | 555.1 ± 5.9 ab | 4.0 ± 0.1 bc | 765.2 ± 9.6 ab | 23.5 ± 4.0 a | 16.6 ± 0.4 a | ND |

| 35% | 252.1 ± 11.5 ab | 620.3 ± 29.6 abc | 4.7 ± 0.1 abc | 888.4 ± 14.6 abcd | 22.9 ± 2.9 a | 17.7 ± 0.9 a | ND | |

| 30% | 279.6 ± 34.1 abc | 718.4 ± 46.0 cdef | 5.3 ± 0.4 a | 1059.7 ± 19.0 cde | 23.2 ± 1.2 a | 23.3 ± 1.0 a | ND | |

| Maltodextrin:Inulin (2:1) | 40% | 212.3 ± 3.6 a | 527.0 ± 3.7 a | 3.7 ± 0.0 b | 740.8 ± 4.9 ab | 23.6 ± 3.2 a | 15.3 ± 8.8 a | ND |

| 35% | 269.4 ± 1.5 abc | 643.2 ± 3.3 abcde | 4.4 ± 0.1 abc | 878.9 ± 17.9 abcd | 32.1 ± 0.5 abc | 18.4 ± 0.1 a | ND | |

| 30% | 334.8 ± 8.9 ab | 772.7 ± 15.9 def | 5.5 ± 0.1 a | 1084.8 ± 14.1 de | 49.3 ± 0.5 d | 26.8 ± 1.5 a | ND | |

| Maltodextrin:Inulin (3:1) | 40% | 212.3 ± 2.5 a | 522.2 ± 3.7 a | 3.7 ± 0.0 b | 717.6 ± 1.9 a | 27.9 ± 0.5 ab | 17.4 ± 0.9 a | ND |

| 35% | 269.4 ± 7.0 abc | 629.2 ± 12.5 abcd | 4.5 ± 0.2 abc | 868.4 ± 10.2 abc | 29.4 ± 2.1 abc | 16.6 ± 1.8 a | ND | |

| 30% | 341.1 ± 0.4 c | 782.7 ± 16.9 ef | 5.6 ± 0.2 a | 1079.4 ± 39.2 cde | 38.5 ± 4.8 c | 24.5 ± 2.1 a | ND | |

| Inulin | 40% | 234.7 ± 1.6 ab | 537.0 ± 4.21 ab | 4.0 ± 0.1 bc | 736.4 ± 12.8 ab | 22.5 ± 1.2 a | 21.5 ± 0.2 a | ND |

| 35% | 296.0 ± 13.4 bc | 680.5 ± 15.0 bcdef | 5.1 ± 0.1 ac | 941.2 ± 8.7 bdec | 32.7 ± 3.2 abc | 27.8 ± 10.5 a | ND | |

| 30% | 333.5 ± 50.6 c | 802.5 ± 116.2 f | 5.5 ± 1.0 a | 1140.2 ± 178.4 e | 34.2 ± 2.7 bc | 17.1 ± 0.2 a | ND | |

| Vacuum Drying 50 °C | ||||||||

| Maltodextrin | 40% | 321.2 ± 24.1 ab | 873.1 ± 31.6 ef | 5.5 ± 0.2 a | 1205.2 ± 28.7 de | 34.1 ± 0.3 abc | 19.5 ± 1.5 abd | 634.4 ± 11.0 g |

| 35% | 244.0 ± 12.4 c | 640.2 ± 15.6 c | 4.3 ± 0.1 d | 887.1 ± 22.5 c | 29.9 ± 3.9 ac | 16.8 ± 0.5 aa | 433.1 ± 2.0 f | |

| 30% | 193.7 ± 2.6 c | 512.5 ± 9.6 h | 3.4 ± 0.1 e | 697.0 ± 23.0 f | 22.7 ± 1.2 c | 14.0 ± 1.8 d | 280.5 ± 9.9 e | |

| Maltodextrin:Inulin (2:1) | 40% | 412.3 ± 8.2 efg | 1021.5 ± 19.0 b | 6.8 ± 0.2 bc | 1426.7 ± 18.9 b | 45.5 ± 4.7 bd | 32.1 ± 0.8 ef | 155.7 ± 14.7 ab |

| 35% | 379.8 ± 19.3 def | 940.0 ± 24.3 fg | 6.6 ± 0.3 b | 1308.8 ± 26.5 e | 41.9 ± 0.2 abd | 30.7 ± 4.6 ef | 151.6 ± 4.92abc | |

| 30% | 243.5 ± 0.8 c | 591.0 ± 2.3 c | 4.4 ± 0.2 d | 838.3 ± 15.6 c | 32.0 ± 2.4 abc | 21.2 ± 2.3 abcd | 111.0 ± 17.4cd | |

| Maltodextrin:Inulin (3:1) | 40% | 432.4 ± 11.0 g | 1060.9 ± 23.7 b | 7.4 ± 0.2 c | 1492.1 ± 45 b | 49.6 ± 7.9 d | 33.4 ± 1.4 f | 261.7 ± 12.9 e |

| 35% | 328.8 ± 4.7 abd | 788.7 ± 7.7 ad | 5.6 ± 0.0 a | 1087.6 ± 6.4 a | 35.6 ± 1.4 abc | 22.3 ± 1.1 abc | 148.4 ± 7.0abc | |

| 30% | 311.5 ± 17.6 ab | 759.4 ± 19.4 a | 5.4 ± 0.4 a | 1053.6 ± 29.6 a | 35.1 ± 1.6 abc | 20.9 ± 0.7 abcd | 128.5 ± 12.8acd | |

| Inulin | 40% | 362.8 ± 15.3 bde | 854.4 ± 26.4 de | 6.2 ± 0.4 ab | 1197.6 ± 34.8 d | 36.4 ± 3.9 abd | 24.4 ± 2.1 abce | 169.6 ± 0.5 ab |

| 35% | 415.3 ± 12.7 fg | 1009.5 ± 13.1 bg | 7.0 ± 0.1 bc | 1427.7 ± 10.4 b | 35.4 ± 3.2 abc | 25.9 ± 2.5 bcef | 178.4 ± 15.8 b | |

| 30% | 307.3 ± 3.2 a | 760.0 ± 5.7 a | 5.4 ± 0.1 a | 1073.3 ± 27.5 a | 43.1 ± 2.0 abd | 28.4 ± 0.4 cef | 92.8 ± 3.0 d | |

| Vacuum Drying 70 °C | ||||||||

| Maltodextrin | 40% | 87.8 ± 2.2 b | 310.4 ± 5.2 d | 1.8 ± 0.0 c | 433.6 ± 6.5 d | 9.2 ± 0.6 e | 8.0 ± 0.2 e | 9994.1 ± 458.5 h |

| 35% | 103.6 ± 6.1 b | 341.9 ± 6.5 de | 1.9 ± 0.2 cd | 480.9 ± 18.2 de | 14.1 ± 1.1 de | 12.9 ± 2.9 de | 7053.3 ± 6.3 g | |

| 30% | 135.4 ± 5.4 b | 390.5 ± 3.8 e | 2.6 ± 0.0 d | 553.1 ± 0.9 e | 24.8 ± 4.8 abd | 14.4 ± 2.4 bde | 4309.0 ± 221.6 d | |

| Maltodextrin:Inulin (2:1) | 40% | 452.0 ± 10.5 d | 1167.9 ± 28.6 h | 7.7 ± 0.3 f | 1651.4 ± 62.3 g | 52.8 ± 2.2 f | 43.4 ± 1.7 f | 4636.9 ± 141.7 de |

| 35% | 314.7 ± 17.4 a | 799.7 ± 38.5 ab | 5.5 ± 0.4 ab | 1126.6 ± 39.4 bc | 36.3 ± 0.4 abc | 27.2 ± 7.0 a | 2066.6 ± 82.6 a | |

| 30% | 324.2 ± 2.1 a | 831.8 ± 1.7 ac | 5.6 ± 0.0 ab | 1176.0 ± 2.7 c | 36.6 ± 1.4 bc | 28.2 ± 1.6 a | 1403.8 ± 0.4 b | |

| Maltodextrin:Inulin (3:1) | 40% | 306.5 ± 1.4 a | 787.7 ± 4.9 ab | 5.5 ± 0.1 ab | 1111.0 ± 10.8 abc | 31.8 ± 2.4 abc | 21.5 ± 0.5 abcd | 5280.2 ± 75.7 f |

| 35% | 299.3 ± 8.0 a | 743.2 ± 10.0 bf | 5.0 ± 0.1 a | 1039.6 ± 4.1 ab | 33.5 ± 4.6 abc | 22.4 ± 0.6 abcd | 3481.9 ± 22.1 c | |

| 30% | 207.9 ± 1.8 c | 527.5 ± 4.2 g | 3.7 ± 0.0 e | 752.1 ± 12.1 f | 24.6 ± 1.6 ad | 16.4 ± 0.7 bcde | 1995.2 ± 13.7 ab | |

| Inulin | 40% | 341.6 ± 3.0 a | 863.5 ± 0.7 c | 6.0 ± 0.3 b | 1204.6 ± 30.2 c | 43.6 ± 5.8 cf | 26.4 ± 1.6 ac | 5031.8 ± 35.5 ef |

| 35% | 338.2 ± 36.6 a | 823.7 ± 12.2 ac | 5.3 ± 0.2 ab | 1062.2 ± 38.8 ab | 34.5 ± 3.7 abc | 23.1 ± 2.2 abc | 3462.2 ± 0.0 c | |

| 30% | 291.7 ± 5.4 a | 715.6 ± 0.6 f | 5.0 ± 0.0 a | 1008.5 ± 2.8 a | 30.5 ± 0.4 ab | 23.9 ± 1.3 abc | 2149.0 ± 1.2 a | |

| Vacuum Drying 90 °C | ||||||||

| Maltodextrin | 40% | 167.7 ± 2.4 f | 434.9 ± 7.5 c | 2.9 ± 0.1 ef | 605.7 ± 12.5 c | 22.5 ± 4.6 abc | 16.7 ± 2.3 abc | 9759.3 ± 175.6 a |

| 35% | 192.4 ± 5.9 g | 507.1± 8.3 g | 3.4 ± 0.2 fg | 716.7 ± 5.8 g | 25.1 ± 3.8 ab | 22.5 ± 1.3 ac | 11393.2 ± 167.2 a | |

| 30% | 216.6 ± 5.0 h | 583.7 ± 1.3 h | 3.8 ± 0.1 g | 816.3 ± 3.6 h | 28.4 ± 6.0 b | 24.7 ± 0.9 a | 17945.7 ± 2.1 f | |

| Maltodextrin:Inulin (2:1) | 40% | 95.3 ± 16.5 c | 300.5 ± 6.3 e | 1.7 ± 0.4 a | 420.2 ± 9.2 e | 11.7 ± 2.0 cd | 12.8 ± 0.2 b | 22266.3 ± 135.9 b |

| 35% | 116.0 ± 3.6 cd | 346.8 ± 10.6 a | 2.2 ± 0.0 ab | 484.2 ± 3.9 a | 20.7 ± 1.4 abc | 18.0 ± 2.0 abc | 30796.3 ± 832.1 c | |

| 30% | 117.3 ± 1.7 cd | 360.6 ± 1.5 a | 2.1 ± 0.1 ab | 506.1 ± 1.1 a | 23.0 ± 2.0 abc | 17.7 ± 4.2 abc | 40205.2 ± 218.7g | |

| Maltodextrin:Inulin (3:1) | 40% | 124.4 ± 3.9 de | 354.0 ± 2.7 a | 2.3 ± 0.0 abd | 497.3 ± 4.0 a | 15.8 ± 3.3 ac | 13.0 ± 0.1 bc | 15327.5 ± 140.0 e |

| 35% | 140.0 ± 0.2 ef | 408.3 ± 13.6 f | 2.5 ± 0.0 bde | 583.8 ± 8.6 c | 17.3 ± 0.5 abc | 21.4 ± 1.0 abc | 21339.8 ± 790.5 b | |

| 30% | 157.3 ± 2.4 fg | 452.4 ± 0.6 c | 2.7 ± 0.1 de | 634.4 ± 12.1 f | 24.2 ± 5.1 ab | 23.0 ± 6.3 a | 32298.7 ± 310.4 c | |

| Inulin | 40% | 22.0 ± 2.0 a | 70.3 ± 2.2 d | 0.3 ± 0.0 c | 99.4 ± 1.4 d | ND | ND | 43485.5 ± 43.5 h |

| 35% | 9.9 ± 2.1 a | 27.8 ± 0.8 b | 0.1 ± 0.0 c | 46.8 ± 2.6 b | ND | ND | 54606.9 ± 1041.4 d | |

| 30% | 6.8 ± 1.6 a | 26.7 ± 3.7 b | 0.2 ± 0.1 c | 42.3 ± 0.4 b | ND | ND | 55693.0 ± 223.0d | |

| Spray Drying | ||||||||

| Maltodextrin | 40% | 135.7 ± 7.4 f | 350.1 ± 12.1 f | 2.3 ± 0.0 d | 465.8 ± 6.3 f | 21.3 ± 2.6 a | 14.6 ± 2.4 a | 1194.4 ± 25.9 a |

| 35% | 194.4 ± 12.7 ab | 489.8 ± 17.5 a | 3.2 ± 0.3 ade | 657.4 ± 23.3 ab | 26.4 ± 4.1 ab | 19.3 ± 0.2 ab | 1679.4 ± 30.1 b | |

| 30% | 230.6 ± 2.5 bcd | 600.7 ± 8.2 cf | 4.1 ± 0.2 abc | 833.7 ± 7.9 dg | 28.0 ± 3.8 ab | 29.7 ± 4.7 b | 5546.5 ± 182.4 f | |

| Maltodextrin:Inulin (2:1) | 40% | 1355 ± 4.3 f | 340.8 ± 13.8 f | 2.4 ± 0.1 de | 478.0 ± 3.0 f | 19.7 ± 6.2 a | 14.3 ± 3.6 a | 709.2 ± 19.3 d |

| 35% | 203.7 ± 6.2 abc | 522.0 ± 9.6 ab | 3.5 ± 0.0 ac | 731.3 ± 3.0 bc | 22.9 ± 1.5 a | 13.9 ± 5.5 a | 992.6 ± 58.4 a | |

| 30% | 283.3 ± 22.1 e | 708.0 ± 34.1 d | 4.8 ± 0.7 b | 986.4 ± 35.1 e | 30.0 ± 3.9 ab | 18.5 ± 5.3 ab | 1785.0 ± 8.0 bc | |

| Maltodextrin:Inulin (3:1) | 40% | 188.3 ± 5.7 a | 475.2 ± 23.0 a | 3.3 ± 0.1 ae | 662.2 ± 35.1 ab | 20.7 ± 3.1 a | 20.7 ± 1.2 ab | 1590.5 ± 78.6 b |

| 35% | 231.0 ± 5.6 bcd | 580.8 ± 2.8 bc | 3.9 ± 0.2 abc | 794.8 ± 4.2 cd | 28.1 ± 1.2 ab | 19.8 ± 1.6 ab | 1973.3 ± 62.0 c | |

| 30% | 278.4 ± 4.4 e | 693.2 ± 2.1 d | 4.7 ± 0.1 b | 955.0 ± 9.7 e | 31.2 ± 0.5 ab | 18.6 ± 0.7 ab | 1654.7 ± 24.8 b | |

| Inulin | 40% | 189.4 ± 9.2 a | 462.6 ± 19.3 a | 3.2 ± 0.2 ade | 630.3 ± 18.1 a | 26.3 ± 2.7 ab | 18.00 ± 2.8 ab | 1122.1 ± 38.0 a |

| 35% | 232.6 ± 11.2 cd | 581.9 ± 28.0 bc | 4.0 ± 0.1 abc | 798.8 ± 49.0 cd | 31.2 ± 1.5 ab | 21.9 ± 1.6 ab | 1138.3 ± 7.8 a | |

| 30% | 256.6 ± 6.8 de | 661.3 ± 15.9 df | 4.4 ± 0.1 bc | 908.5 ± 15.8 eg | 38.5 ± 2.5 b | 31.5 ± 5.5 b | 3195.5 ± 23.2 e | |

| Carrier/Concentration | Myr-3-O-rutinoside | Myr-3-O-galactoside | Q-3-O-rutinoside | Q-3-O-glucoside | Q-3-O-malonylglucoside | Der of Flavonol 1 | K-3-O-rutinoside | Der of Flavonols | |

|---|---|---|---|---|---|---|---|---|---|

| Freeze Drying | |||||||||

| Maltodextrin | 40% | 20.4 ± 1.5 a | 40.1 ± 5.6 a | 71.6 ± 1.6 ad | 20.3 ± 0.5 a | 25.1 ± 1.7 ab | 33.0 ± 0.2 abc | 12.3 ± 1.0 bc | 9.3 ± 1.0 ac |

| 35% | 26.8 ± 1.2 d | 46.5 ± 2.0 abc | 82.8 ± 0.8 b | 22.5 ± 0.3 abc | 26.6 ± 1.5 ab | 38.5 ± 0.9 ad | 13.4 ± 0.9 abc | 10.3 ± 0.7 acd | |

| 30% | 30.8 ± 0.7 c | 54.0 ± 1.3 bcd | 96.4 ± 0.2 c | 30.2 ± 2.0 d | 34.8 ± 1.0 c | 47.4 ± 2.4 f | 19.2 ± 1.2 ad | 16.1 ± 0.2 ef | |

| Maltodextrin:Inulin (2:1) | 40% | 21.5 ± 0.6 ab | 42.8 ± 1.3 ab | 69.0 ± 4.3 ad | 21.1 ± 0.9 ab | 24.4 ± 0.4 ab | 31.9 ± 0.8 abc | 16.9 ± 0.1 abcd | 9.0 ± 0.4 a |

| 35% | 25.1 ± 0.9 bd | 44.9 ± 0.2 ab | 82.3 ± 5.3 b | 23.9 ± 0.2 bc | 28.2 ± 2.7 abd | 37.5 ± 1.8 acd | 18.2 ± 1.3 abcd | 12.0 ± 0.5 bcd | |

| 30% | 33.8 ± 0.9 c | 59.8 ± 2.6 d | 99.5 ± 1.0 c | 31.4 ± 0.1 d | 36.3 ± 0.6 | 46.0 ± 2.0 ef | 23.1 ± 0.8 d | 18.6 ± 1.4 f | |

| Maltodextrin:Inulin (3:1) | 40% | 21.6 ± 1.1 ab | 40.0 ± 0.8 a | 65.4 ± 2.8 a | 19.7 ± 0.3 a | 25.1 ± 2.1 ab | 30.8 ± 0.7 bc | 11.7 ± 0.7 b | 13.4 ± 1.0 be |

| 35% | 22.6 ± 0.4 ab | 45.7 ± 3.0 ab | 78.3 ± 0.2 bd | 25.4 ± 0.8 c | 33.5 ± 2.3 cde | 36.0 ± 2.6 abc | 19.1 ± 1.1 ad | 14.9 ± 0.6 be | |

| 30% | 31.4 ± 0.9 c | 57.5 ± 4.1 cd | 100.1 ± 3.5 c | 29.4 ± 0.5 d | 34.4 ± 0.3 ce | 43.8 ± 1.5 def | 18.8 ± 1.4 acd | 12.6 ± 0.3 bd | |

| Inulin | 40% | 21.9 ± 0.6 ab | 39.1 ± 1.0 a | 66.7 ± 1.5 a | 20.5 ± 0.7 a | 22.5 ± 0.7 a | 30.0 ± 0.7 b | 13.0 ± 0.0 abc | 10.1 ± 0.3 acd |

| 35% | 26.7 ± 0.5 d | 47.0 ± 0.4 abc | 82.6 ± 3.2 b | 24.1 ± 0.4 bc | 28.7 ± 1.1 bde | 39.4 ± 0.6 ade | 13.2 ± 0.1 abc | 8.7 ± 0.7 a | |

| 30% | 32.2 ± 1.6 c | 58.0 ± 5.7 cd | 100.8 ± 0.9 c | 30.2 ± 0.7 d | 34.0 ± 1.0 cde | 46.3 ± 4.2 ef | 20.2 ± 4.9 d | 13.6 ± 1.0 be | |

| Vacuum Drying 50 °C | |||||||||

| Maltodextrin | 40% | 50.3 ± 3.1 ef | 96.6 ± 8.5 bc | 175.4 ± 1.9 g | 45.2 ± 3.9 e | 64.4 ± 1.9 f | 77.5 ± 1.2 b | 29.2 ± 2.7 acd | 32.5 ± 0.8 ab |

| 35% | 34.1 ± 0.2 abc | 67.1 ± 1.3 ae | 113.7 ± 7.4 bce | 29.6 ± 0.8 ab | 41.0 ± 2.8 ac | 52.5 ± 4.8 a | 21.0 ± 1.4 ab | 25.0 ± 1.3 de | |

| 30% | 27.6 ± 1.8 a | 50.1 ± 2.7 de | 83.4 ± 2.0 a | 25.8 ± 2.3 a | 30.9 ± 0.0 b | 42.1 ± 1.0 e | 19.4 ± 0.9 ab | 20.9 ± 0.2 cd | |

| Maltodextrin:Inulin (2:1) | 40% | 45.6 ± 1.6 def | 82.7 ± 3.6 c | 145.7 ± 2.5 d | 41.1 ± 0.3 def | 53.0 ± 2.5 de | 69.2 ± 0.4 bd | 32.4 ± 1.1 cd | 33.0 ± 2.7 ab |

| 35% | 42.6 ± 1.8 cde | 81.1 ± 1.1 ab | 131.8 ± 1.6 def | 39.1 ± 0.5 cdef | 47.5 ± 1.0 ad | 65.7 ± 3.3 cd | 29.5 ± 2.8 acd | 30.7 ± 1.7 abe | |

| 30% | 28.9 ± 0.7 a | 49.2 ± 1.5 d | 86.8 ± 0.3 a | 26.1 ± 2.0 a | 31.2 ± 0.3 b | 38.4 ± 1.2 e | 20.6 ± 0.9 ab | 14.2 ± 4.2 f | |

| Maltodextrin:Inulin (3:1) | 40% | 52.7 ± 1.7 f | 110.6 ± 3.2 ab | 149.1 ± 3.1 d | 47.2 ± 0.6 e | 56.3 ± 3.1 e | 75.1 ± 0.1 b | 33.1 ± 3.0 d | 35.4 ± 1.4 b |

| 35% | 37.8 ± 0.7 bcd | 82.3 ± 4.3 ab | 105.6 ± 2.4 bc | 33.3 ± 3.3 abce | 44.9 ± 1.8 ac | 56.2 ± 0.1 a | 20.8 ± 4.3 ab | 16.7 ± 0.3 cf | |

| 30% | 34.2 ± 4.0 abc | 75.8 ± 7.0 a | 96.6 ± 5.2 ab | 32.5 ± 0.5 abc | 37.4 ± 1.1 bc | 51.4 ± 0.4 a | 22.6 ± 1.2 abc | 18.3 ± 0.7 ef | |

| Inulin | 40% | 40.3 ± 2.6 bcd | 80.3 ± 4.4 ab | 118.8 ± 2.0 cef | 36.6 ± 3.8 bcef | 46.8 ± 1.8 ad | 60.1 ± 2.5 ac | 26.4 ± 0.2 abcd | 30.8 ± 0.2 abe |

| 35% | 46.1 ± 3.5 def | 96.6 ± 1.5 bc | 133.3 ± 11.8 df | 44.0 ± 0.8 ef | 47.9 ± 3.0 ad | 68.9 ± 2.9 bcd | 28.6 ± 5.7 acd | 26.4 ± 0.0 ade | |

| 30% | 33.6 ± 0.2 ab | 74.9 ± 5.1 a | 101.3 ± 0.9 abc | 32.0 ± 1.0 abc | 38.0 ± 0.7 bc | 51.3 ± 2.9 a | 17.6 ± 0.4 b | 22.0 ± 1.1 cd | |

| Vacuum Drying 70 °C | |||||||||

| Maltodextrin | 40% | 39.8 ± 0.4 abc | 93.6 ± 1.0 b | 123.9 ± 0.5 bd | 29.4 ± 1.2 bd | 53.9 ± 6.1 def | 62.0 ± 3.1 a | 17.9 ± 2.2 acd | 19.5 ± 1.2 ab |

| 35% | 36.6 ± 1.7 ab | 76.9 ± 5.5 a | 101.7 ± 2.6 a | 24.8 ± 0.6 cd | 39.0 ± 2.0 abc | 50.0 ± 1.6 bd | 14.6 ± 0.9 d | 18.2 ± 2.5 abc | |

| 30% | 25.4 ± 2.2 d | 59.4 ± 4.8 c | 78.8 ± 2.6 e | 20.8 ± 0.3 c | 30.7 ± 3.5 c | 39.4 ± 0.4 cd | 12.5 ± 1.5 d | 18.6 ± 0.6 abc | |

| Maltodextrin:Inulin (2:1) | 40% | 51.9 ± 1.0 e | 115.8 ± 2.2 d | 162.2 ± 1.7 f | 44.6 ± 0.5 e | 61.7 ± 1.3 | 74.7 ± 0.7 e | 32.9 ± 2.6 e | 20.2 ± 0.4 ab |

| 35% | 37.4 ± 1.1 ab | 75.6 ± 2.8 a | 109.8 ± 3.5 ac | 33.1 ± 1.2 ab | 43.6 ± 5.8 abd | 53.2 ± 3.7 ab | 26.1 ± 2.7 be | 17.2 ± 0.4 abc | |

| 30% | 35.9 ± 1.6 a | 77.1 ± 2.5 a | 110.4 ± 3.9 ac | 33.6 ± 1.1 ab | 44.9 ± 2.3 abd | 56.6 ± 2.5 ab | 22.0 ± 0.6 abc | 15.8 ± 1.6 ac | |

| Maltodextrin:Inulin (3:1) | 40% | 42.1 ± 1.7 bc | 86.5 ± 6.8 ab | 123.2 ± 1.4 bd | 34.4 ± 1.4 ab | 47.6 ± 0.1 abde | 57.1 ± 1.8 ab | 24.3 ± 2.6 ab | 17.2 ± 0.1 abc |

| 35% | 36.8 ± 2.8 ab | 78.9 ± 6.4 ab | 113.9 ± 0.0 cd | 31.0 ± 0.1 ab | 38.2 ± 0.6 ac | 55.7 ± 3.9 ab | 22.5 ± 2.5 abc | 20.8 ± 3.4 ab | |

| 30% | 27.2 ± 2.3 d | 56.4 ± 3.9 c | 80.1 ± 2.8 e | 24.0 ± 1.7 cd | 31.5 ± 0.2 c | 37.8 ± 1.2 c | 15.9 ± 0.3 cd | 12.5 ± 1.4 c | |

| Inulin | 40% | 43.6 ± 0.2 c | 89.3 ± 0.4 ab | 128.3 ± 0.0 b | 36.6 ± 0.0 a | 50.3 ± 1.3 bdef | 62.3 ± 3.0 a | 22.0 ± 0.8 abc | 15.0 ± 1.1 ac |

| 35% | 44.7 ± 0.0 c | 86.5 ± 1.0 ab | 128.9 ± 6.9 b | 36.8 ± 1.8 a | 59.0 ± 0.0 ef | 59.0 ± 4.8 ab | 22.5 ± 1.3 abc | 23.1 ± 0.8 b | |

| 30% | 34.6 ± 0.4 a | 77.1 ± 1.4 a | 100.1 ± 2.8 a | 33.4 ± 3.9 ab | 41.9 ± 3.7 abc | 53.4 ± 1.3 ab | 24.8 ± 1.0 ab | 23.5 ± 2.9 b | |

| Vacuum Drying 90 °C | |||||||||

| Maltodextrin | 40% | 22.3 ± 0.6 abc | 50.0 ± 3.6 abcd | 64.9 ± 4.8 ace | 17.8 ± 1.2 ab | 24.9 ± 2.0 abc | 32.7 ± 1.1 ae | 13.4 ± 1.6 abc | 9.3 ± 0.2 ab |

| 35% | 24.5 ± 1.6 ad | 55.2 ± 0.4 cde | 74.0 ± 2.2 de | 22.2 ± 2.5 ab | 31.0 ± 2.6 abcd | 39.4 ± 1.7 ce | 15.7 ± 0.1 bc | 14.2 ± 2.3 ac | |

| 30% | 27.0 ± 0.5 d | 66.5 ± 2.0 f | 89.6 ± 6.2 f | 24.5 ± 2.9 b | 35.0 ± 2.8 cd | 44.5 ± 2.1 c | 16.6 ± 1.1 c | 16.5 ± 2.6 c | |

| Maltodextrin:Inulin (2:1) | 40% | 19.4 ± 0.6 bc | 45.6 ± 1.7 abc | 57.5 ± 1.4 ab | 15.4 ± 0.7 acd | 21.9 ± 2.1 a | 29.3 ± 3.8 ab | 14.9 ± 1.0 bc | 10.4 ± 1.6 abc |

| 35% | 23.6 ± 0.6 acd | 54.3 ± 6.0 bcde | 70.5 ± 1.1 cde | 19.4 ± 4.5 ab | 31.2 ± 6.3 abcd | 33.4 ± 1.4 ae | 10.6 ± 1.7 abd | 12.1 ± 1.5 abc | |

| 30% | 24.9 ± 0.3 ad | 62.3 ± 0.0 ef | 77.8 ± 1.5 d | 18.8 ± 2.0 ab | 36.7 ± 0.7 d | 41.1 ± 1.3 cd | 13.2 ± 2.5 abc | 14.0 ± 2.8 ac | |

| Maltodextrin:Inulin (3:1) | 40% | 20.8 ± 1.4 abc | 44.9 ± 1.1 ab | 57.6 ± 1.1 ab | 16.7 ± 0.6 ad | 24.5 ± 1.0 ab | 30.8 ± 0.6 ab | 11.0 ± 0.7 abcd | 10.0 ± 1.0 ab |

| 35% | 24.3 ± 0.9 ad | 56.2 ± 1.4 de | 62.8 ± 0.8 ac | 21.4 ± 1.0 ab | 28.9 ± 1.3 abcd | 46.7 ± 0.8 d | 12.6 ± 0.7 abc | 12.5 ± 0.63 abc | |

| 30% | 28.2 ± 0.0 d | 69.3 ± 3.8 f | 78.3 ± 1.4 d | 22.2 ± 1.5 ab | 32.6 ± 1.8 bcd | 43.1 ± 0.6 cd | 12.6 ± 1.8 abc | 12.9 ± 1.8 abc | |

| Inulin | 40% | 17.8 ± 0.1 a | 43.6 ± 0.4 a | 49.4 ± 1.3 b | 9.5 ± 0.2 cd | 25.1 ± 0.6 abc | 24.2 ± 0.8 b | 8.5 ± 1.2 ad | 8.5 ± 0.2 ab |

| 35% | 19.1 ± 1.4 bc | 45.0 ± 0.4 ab | 55.6 ± 0.9 ab | 9.6 ± 0.5 cd | 24.6 ± 3.6 abc | 28.7 ± 1.2 ab | 8.7 ± 2.3 ad | 8.8 ± 0.4 ab | |

| 30% | 21.7 ± 2.8 abc | 55.0 ± 0.1 cde | 62.9 ± 0.6 ac | 8.7 ± 0.1 c | 26.9 ± 0.2 abcd | 30.9 ± 2.7 ab | 6.1 ± 1.1 d | 7.7 ± 0.4 b | |

| Spray Drying | |||||||||

| Maltodextrin | 40% | 21.9 ± 3.9 ad | 47.7 ± 0.5 ad | 55.9 ± 2.6 a | 18.1 ± 2.5 ad | 23.8 ± 0.0 abd | 28.8 ± 1.7 a | 13.2 ± 0.3 ab | 9.1 ± 0.2 ab |

| 35% | 29.5 ± 1.9 abc | 59.9 ± 2.3 be | 73.0 ± 5.1 be | 26.3 ± 1.7 abc | 27.9 ± 3.2 abc | 36.9 ± 1.8 be | 18.4 ± 2.2 abcd | 9.0 ± 0.5 ab | |

| 30% | 31.1 ± 0.5 abc | 67.8 ± 1.1 bc | 82.1 ± 2.4 bc | 26.4 ± 2.1 abc | 31.6 ± 4.0 bce | 42.4 ± 1.0 bcd | 16.0 ± 0.8 abcd | 12.7 ± 1.3 a | |

| Maltodextrin:Inulin (2:1) | 40% | 13.5 ± 1.0 d | 30.9 ± 0.4 f | 38.0 ± 1.1 f | 14.9 ± 0.4 d | 17.3 ± 1.4 d | 20.9 ± 2.0 f | 13.6 ± 0.7 abc | 6.1 ± 0.5 b |

| 35% | 23.1 ± 3.2 ad | 49.4 ± 0.4 ad | 57.4 ± 1.2 a | 20.2 ± 2.3 ad | 24.7 ± 0.3 abd | 30.0 ± 0.7 a | 12.1 ± 1.3 a | 11.7 ± 2.6 abc | |

| 30% | 30.0 ± 0.7 abc | 67.8 ± 0.9 bc | 82.8 ± 0.7bcc | 28.9 ± 0.8 bc | 30.4 ± 1.27 abce | 48.2 ± 2.0 d | 20.3 ± 1.2 bcd | 14.8 ± 0.6 a | |

| Maltodextrin:Inulin (3:1) | 40% | 23.0 ± 4.0 ad | 47.1 ± 3.7 a | 61.1 ± 2.7 ad | 19.5 ± 2.5 ad | 22.7 ± 3.36 ad | 28.4 ± 2.0 a | 13.1 ± 0.6 ab | 14.7 ± 3.1 a |

| 35% | 26.6 ± 2.6 abc | 56.2 ± 0.2 de | 69.6 ± 1.7 de | 23.6 ± 1.0 ab | 29.1 ± 0.5 abc | 36.6 ± 0.9 be | 18.0 ± 0.4 abcd | 11.7 ± 0.2 ab | |

| 30% | 32.9 ± 3.7 bc | 68.9 ± 5.2 abc | 88.4 ± 2.1 c | 31.3 ± 3.0 bc | 33.2 ± 0.6 ce | 44.8 ± 0.0 cd | 20.6 ± 4.0 cd | 11.9 ± 2.3 abc | |

| Inulin | 40% | 23.4 ± 1.3 ab | 45.2 ± 0.9 a | 58.2 ± 4.1 a | 20.3 ± 0.8 ad | 27.8 ± 2.6 abc | 33.4 ± 2.4 ae | 13.6 ± 0.9 abc | 10.4 ± 1.9 ab |

| 35% | 25.5 ± 2.0 abc | 58.7 ± 1.4 e | 71.7 ± 3.3 bde | 26.0 ± 1.3 abc | 27.6 ± 0.3 abc | 41.4 ± 0.9 bc | 20.8 ± 0.7 cd | 9.8 ± 0.0 ab | |

| 30% | 34.6 ± 0.4 c | 68.8 ± 1.3 bc | 89.4 ± 4.0 c | 32.5 ± 4.3 c | 38.3 ± 1.6 e | 45.6 ± 0.6 cd | 21.3 ± 3.7 d | 11.1 ± 1.2 ab | |

| Carrier/Concentration | Neochlorogenic Acid | p-Coumaric Acid | Chlorogenic Acid | Derivative of p-Coumaric | |

|---|---|---|---|---|---|

| Freeze Drying | |||||

| Maltodextrin | 40% | 5.5 ± 0.8 ad | 6.2 ± 0.4 c | 44.5 ± 2.2 b | 19.2 ± 1.6 abc |

| 35% | 5.0 ± 0.2 abcd | 9.0 ± 0.5 abcd | 54.7 ± 0.4 acd | 22.1 ± 0.3 bcde | |

| 30% | 5.5 ± 0.3 ad | 10.6 ± 0.7 b | 65.9 ± 0.6 fg | 24.3 ± 0.7 ef | |

| Maltodextrin:Inulin (2:1) | 40% | 4.2 ± 0.5 bcd | 7.4 ± 0.2 acd | 45.8 ± 0.3 ab | 18.4 ± 1.2 ab |

| 35% | 4.2 ± 0.0 bc | 8.6 ± 0.2 abcd | 55.4 ± 1.1 acde | 19.7 ± 0.3 abcd | |

| 30% | 6.0 ± 0.2 a | 11.3 ± 0.5 b | 69.7 ± 1.4 | 28.3 ± 0.9 g | |

| Maltodextrin:Inulin (3:1) | 40% | 3.7 ± 0.2 b | 7.1 ± 0.5 ac | 45.7 ± 1.3 ab | 19.1 ± 0.0 ab |

| 35% | 4.8 ± 0.1 abcd | 9.7 ± 0.4 abd | 56.7 ± 0.9 cdef | 23.3 ± 0.8 def | |

| 30% | 5.4 ± 0.3 acd | 10.3 ± 1.1 bd | 64.9 ± 2.4 efg | 27.2 ± 0.2 fg | |

| Inulin | 40% | 4.1 ± 0.1 bc | 7.0 ± 1.6 ac | 47.4 ± 2.2 abc | 17.9 ± 1.9 a |

| 35% | 4.9 ± 0.1 abcd | 9.0 ± 0.6 abcd | 59.1 ± 0.9 def | 23.0 ± 0.2 cde | |

| 30% | 5.8 ± 0.4 a | 9.7 ± 1.3 abd | 73.2 ± 7.1 g | 28.3 ± 1.5 g | |

| Vacuum Drying 50 °C | |||||

| Maltodextrin | 40% | 6.7 ± 0.3 ab | 15.1 ± 0.2 d | 99.8 ± 0.0 a | 42.5 ± 1.6 b |

| 35% | 4.3 ± 0.1 a | 9.6 ± 0.4 abc | 66.9 ± 1.0 bg | 28.6 ± 0.7 ac | |

| 30% | 4.1 ± 0.2 a | 8.0 ± 1.3 a | 52.4 ± 1.7 f | 24.1 ± 0.9 cf | |

| Maltodextrin:Inulin (2:1) | 40% | 6.7 ± 0.3 ab | 12.8 ± 0.4 bcd | 96.4 ± 2.8 a | 39.6 ± 1.9 be |

| 35% | 6.6 ± 0.5 ab | 13.1 ± 1.8 bd | 89.1 ± 3.0 ade | 36.2 ± 2.6 de | |

| 30% | 4.0 ± 0.0 a | 8.3 ± 0.7 a | 54.7 ± 0.6 fg | 23.2 ± 0.4 f | |

| Maltodextrin:Inulin (3:1) | 40% | 7.5 ± 0.6 b | 13.3 ± 2.3 bd | 97.2 ± 8.5 a | 41.6 ± 1.4 a |

| 35% | 5.4 ± 0.3 ab | 10.4 ± 1.1 abc | 77.2 ± 0.9 bcd | 32.0 ± 0.4 ad | |

| 30% | 5.6 ± 0.5 ab | 9.6 ± 0.3 abc | 71.8 ± 0.8 bc | 29.5 ± 0.9 b | |

| Inulin | 40% | 5.2 ± 1.3 ab | 10.5 ± 0.2 abc | 81.5 ± 4.5 cde | 32.3 ± 0.8 ad |

| 35% | 6.5 ± 1.2 ab | 12.0 ± 0.1 abcd | 94.0 ± 2.9 ae | 38.5 ± 0.7 be | |

| 30% | 5.9 ± 1.4 ab | 8.8 ± 0.1 ac | 71.5 ± 0.9 bc | 28.5 ± 0.7 ac | |

| Vacuum Drying 70 °C | |||||

| Maltodextrin | 40% | 4.3 ± 0.1 bd | 11.2 ± 1.5 abd | 64.9 ± 4.0 ac | 33.9 ± 2.4 bc |

| 35% | 4.2 ± 0.3 bd | 9.2 ± 0.1 ace | 57.4 ± 0.1 cd | 28.1 ± 1.4 abd | |

| 30% | 3.1 ± 0.4 e | 7.4 ± 0.5 e | 47.5 ± 3.5 d | 22.5 ± 0.7 de | |

| Maltodextrin:Inulin (2:1) | 40% | 7.7 ± 0.0 g | 14.6 ± 0.1 f | 104.8 ± 3.9 e | 43.6 ± 0.1 f |

| 35% | 4.9 ± 0.2 ab | 9.6 ± 0.9 abce | 70.8 ± 2.6 ab | 29.8 ± 0.6 ab | |

| 30% | 5.3 ± 0.3 ac | 10.6 ± 1.1 abcd | 74.6 ± 1.9 ab | 32.2 ± 1.1 abc | |

| Maltodextrin:Inulin (3:1) | 40% | 5.4 ± 0.2 ac | 11.5 ± 0.0 abd | 72.0 ± 0.8 ab | 31.2 ± 0.3 abc |

| 35% | 4.7 ± 0.0 ab | 10.6 ± 0.1 abcd | 67.7 ± 0.3 abc | 28.2 ± 1.4 abd | |

| 30% | 3.7 ± 0.1 de | 8.1 ± 0.2 ce | 50.3 ± 0.2 d | 21.3 ± 0.6 e | |

| Inulin | 40% | 6.1 ± 0.2 cf | 12.2 ± 1.1 bdf | 80.1 ± 1.8 b | 31.8 ± 4.0 abc |

| 35% | 6.3 ± 0.0 f | 12.7 ± 0.1 df | 79.2 ± 8.1 b | 36.3 ± 0.0 c | |

| 30% | 5.3 ± 0.3 ac | 9.8 ± 0.1 abce | 65.4 ± 0.1 ac | 27.5 ± 0.3 ad | |

| Vacuum Drying 90 °C | |||||

| Maltodextrin | 40% | 5.0 ± 0.5 abc | 6.0 ± 1.0 abc | 39.3 ± 2.1 abc | 18.2 ± 2.5 ad |

| 35% | 4.7 ± 0.3 ac | 7.7 ± 0.2 ab | 47.3 ± 0.2 cf | 20.3 ± 0.9 de | |

| 30% | 5.9 ± 0.4 ab | 7.9 ± 0.3 b | 52.6 ± 1.7 f | 23.6 ± 0.7 e | |

| Maltodextrin:Inulin (2:1) | 40% | 4.1 ± 0.4 cd | 6.1 ± 1.4 abc | 31.3 ± 4.4 ade | 13.4 ± 0.3 abc |

| 35% | 5.5 ± 0.2 ab | 7.1 ± 0.0 abc | 35.2 ± 1.1 abe | 13.5 ± 1.4 abc | |

| 30% | 6.2 ± 0.8 b | 7.4 ± 1.6 ab | 39.6 ± 2.2 abc | 14.9 ± 1.9 abc | |

| Maltodextrin:Inulin (3:1) | 40% | 4.6 ± 0.0 ac | 6.7 ± 0.9 abc | 36.3 ± 0.4 abe | 15.5 ± 0.1 acd |

| 35% | 5.3 ± 0.1 abc | 7.6 ± 0.0 ab | 40.0 ± 0.2 abc | 16.7 ± 0.2 ad | |

| 30% | 5.8 ± 0.0 ab | 7.3 ± 0.6 ab | 43.1 ± 0.6 bcf | 17.0 ± 0.3 ad | |

| Inulin | 40% | 2.8 ± 0.4 d | 4.4 ± 0.2 ac | 23.5 ± 2.0 d | 9.9 ± 1.0 b |

| 35% | 3.1 ± 0.2 d | 3.7 ± 0.5 c | 22.0 ± 0.4 d | 11.3 ± 0.9 bc | |

| 30% | 2.8 ± 0.0 d | 4.7 ± 1.4 abc | 28.3 ± 5.6 de | 14.9 ± 2.1 abc | |

| Spray Drying | |||||

| Maltodextrin | 40% | 3.3 ± 0.1 ce | 7.1 ± 0.7 ab | 42.7 ± 0.9 a | 18.7 ± 1.3 a |

| 35% | 4.5 ± 0.1 ab | 8.2 ± 0.6 acd | 55.1 ± 0.7 bc | 23.0 ± 2.0 abc | |

| 30% | 5.7 ± 0.5 d | 9.4 ± 0.4 cde | 62.3 ± 1.2 cd | 28.8 ± 0.4 d | |

| Maltodextrin:Inulin (2:1) | 40% | 2.7 ± 0.2 e | 5.2 ± 0.7 b | 29.3 ± 0.6 e | 12.6 ± 0.6 e |

| 35% | 3.8 ± 0.6 ac | 6.1 ± 0.1 ab | 44.4 ± 0.0 a | 19.1 ± 1.4 ab | |

| 30% | 5.4 ± 0.1 bd | 7.9 ± 1.4 acd | 60.9 ± 5.0 bcd | 27.1 ± 0.5 cd | |

| Maltodextrin:Inulin (3:1) | 40% | 3.8 ± 0.3 ace | 6.4 ± 0.9 ab | 45.2 ± 1.7 a | 19.4 ± 0.5 ab |

| 35% | 4.6 ± 0.1 ab | 8.1 ± 0.2 acd | 53.9 ± 0.3 b | 21.9 ± 0.9 ab | |

| 30% | 5.5 ± 0.2 | 9.7 ± 0.2 de | 65.6 ± 1.7 d | 27.3 ± 0.7 cd | |

| Inulin | 40% | 4.1 ± 0.4 ac | 6.9 ± 0.1 ab | 44.9 ± 1.9 a | 18.9 ± 2.1 a |

| 35% | 4.6 ± 0.0 ab | 7.2 ± 0.2 abc | 56.8 ± 0.1 bc | 23.5 ± 0.0 bc | |

| 30% | 5.4 ± 0.0 bd | 10.9 ± 0.0 e | 66.6 ± 1.7 d | 28.1 ± 1.2 d | |

| Carrier/Concentration | HMF | TEAC ABTS | FRAP | |

|---|---|---|---|---|

| Freeze Drying | ||||

| Maltodextrin | 40% | 3.6 ± 0.3 a | 31.0 ± 0.3 g | 27.2 ± 0.8 e |

| 35% | 3.7 ± 0.1 ab | 36.4 ± 1.0 a | 29.9 ± 2.4 e | |

| 30% | 5.4 ± 0.1 cd | 45.8 ± 0.8 d | 39.0 ± 2.5 ab | |

| Maltodextrin:Inulin (2:1) | 40% | 3.9 ± 0.9 ab | 39.6 ± 0.8 b | 37.9 ± 0.3 ab |

| 35% | 4.8 ± 0.1 abcd | 42.8 ± 0.5 c | 38.9 ± 1.4 ab | |

| 30% | 5.9 ± 0.1 de | 55.9 ± 1.8 f | 46.1 ± 1.9 d | |

| Maltodextrin:Inulin (3:1) | 40% | 4.5 ± 0.2 abc | 36.6 ± 0.3 a | 33.8 ± 0.7 f |

| 35% | 4.8 ± 0.2 abcd | 43.6 ± 2.0 cd | 38.6 ± 1.8 ab | |

| 30% | 5.0 ± 0.2 bcd | 49.8 ± 0.6 e | 43.8 ± 1.0 cd | |

| Inulin | 40% | 4.4 ± 0.1 abc | 39.8 ± 1.1 b | 35.5 ± 1.2 af |

| 35% | 5.2 ± 0.2 cd | 49.4 ± 1.1 e | 40.3 ± 1.9 bc | |

| 30% | 6.9 ± 0.4 e | 58.7 ± 1.6 f | 43.8 ± 1.3 cd | |

| Vacuum Drying 50 °C | ||||

| Maltodextrin | 40% | 9.3 ± 0.4 g | 26.9 ± 2.7 e | 25.1 ± 2.5 h |

| 35% | 7.4 ± 0.1 def | 35.9 ± 2.4 d | 30.1 ± 2.8 f | |

| 30% | 5.6 ± 0.3 abc | 40.4 ± 2.1 a | 36.8 ± 1.9 ab | |

| Maltodextrin:Inulin (2:1) | 40% | 6.9 ± 0.4 bdef | 36.6 ± 0.4 d | 33.5 ± 0.8 af |

| 35% | 6.6 ± 0.5 abde | 47.1 ± 1.6 b | 43.1 ± 0.6 dg | |

| 30% | 5.0 ± 0.1 c | 53.8 ± 1.1 c | 46.9 ± 1.4 e | |

| Maltodextrin:Inulin (3:1) | 40% | 8.1 ± 0.6 fg | 41.7 ± 1.3 a | 34.8 ± 0.3 a |

| 35% | 6.3 ± 0.1 abd | 49.2 ± 1.6 b | 40.5 ± 0.9 cg | |

| 30% | 6.1 ± 0.2 abc | 56.9 ± 0.7 c | 44.7 ± 1.5 de | |

| Inulin | 40% | 5.5 ± 0.2 ac | 40.6 ± 0.6 a | 36.9 ± 0.6 abc |

| 35% | 7.8 ± 0.5 ef | 46.0 ± 0.2 b | 39.2 ± 0.5 bc | |

| 30% | 6.1 ± 0.0 abcd | 54.7 ± 0.9 c | 45.8 ± 1.4 de | |

| Vacuum Drying 70 °C | ||||

| Maltodextrin | 40% | 25.0 ± 3.7 e | 22.4 ± 0.9 e | 22.5 ± 0.1 d |

| 35% | 20.5 ± 0.2 d | 26.2 ± 0.4 f | 25.5 ± 0.3 d | |

| 30% | 13.1 ± 0.7 ab | 39.2 ± 0.1 ad | 33.2 ± 1.6 ab | |

| Maltodextrin:Inulin (2:1) | 40% | 18.1 ± 0.6 cd | 37.1 ± 1.1 a | 33.6 ± 1.9 ab |

| 35% | 10.2 ± 0.6 a | 47.0 ± 0.7 b | 40.4 ± 1.3 c | |

| 30% | 9.8 ± 0.4 a | 56.4 ± 2.6 c | 48.6 ± 2.7 e | |

| Maltodextrin:Inulin (3:1) | 40% | 16.0 ± 0.1 bcd | 37.2 ± 0.6 a | 30.0 ± 0.4 b |

| 35% | 12.7 ± 0.1 ab | 45.2 ± 0.5 b | 32.1 ± 0.3 ab | |

| 30% | 9.1 ± 0.3 a | 52.8 ± 2.7 c | 42.5 ± 1.9 c | |

| Inulin | 40% | 17.7 ± 0.4 cd | 41.2 ± 0.8 d | 35.6 ± 0.5 a |

| 35% | 15.3 ± 0.2 bc | 46.0 ± 2.3 b | 35.3 ± 1.0 a | |

| 30% | 10.2 ± 0.2 a | 53.3 ± 1.7 c | 42.9 ± 2.9 c | |

| Vacuum Drying 90 °C | ||||

| Maltodextrin | 40% | 22.7 ± 0.7 a | 25.1 ± 0.9 f | 22.9 ± 0.2 d |

| 35% | 27.2 ± 0.8 ab | 30.0 ± 1.4 g | 25.0 ± 1.8 d | |

| 30% | 36.7 ± 0.3 bc | 38.5 ± 0.5 ab | 32.0 ± 2.0 ab | |

| Maltodextrin:Inulin (2:1) | 40% | 30.5 ± 2.3 ab | 39.4 ± 0.5 ab | 30.6 ± 1.2 ab |

| 35% | 45.3 ± 0.4 c | 41.8 ± 0.4 b | 33.2 ± 0.5 a | |

| 30% | 59.3 ± 2.9 d | 48.1 ± 0.6 c | 38.1 ± 2.5 c | |

| Maltodextrin:Inulin (3:1) | 40% | 29.8 ± 0.8 ab | 34.5 ± 1.2 d | 29.2 ± 1.3 b |

| 35% | 42.9 ± 0.5 c | 38.1 ± 2.6 ae | 30.6 ± 0.4 ab | |

| 30% | 57.5 ± 1.0 d | 49.5 ± 3.2 c | 40.0 ± 0.8 c | |

| Inulin | 40% | 59.8 ± 0.7 d | 34.9 ± 0.8 de | 29.7 ± 1.7 ab |

| 35% | 77.7 ± 5.0 e | 39.7 ± 1.5 ab | 32.8 ± 0.9 a | |

| 30% | 93.4 ± 6.0 f | 49.9 ± 0.5 c | 39.6 ± 2.1 c | |

| Spray Drying | ||||

| Maltodextrin | 40% | 11.1 ± 0.4 e | 34.4 ± 0.7 b | 32.5 ± 2.2 a |

| 35% | 13.1 ± 0.6 f | 37.5 ± 0.5 ab | 35.1 ± 1.8 ab | |

| 30% | 17.7 ± 0.3 g | 41.0 ± 2.2 a | 38.4 ± 1.4 cd | |

| Maltodextrin:Inulin (2:1) | 40% | 4.6 ± 0.0 b | 27.6 ± 0.9 e | 25.9 ± 1.0 g |

| 35% | 4.7 ± 0.4 b | 40.3 ± 3.1 a | 37.7 ± 3.5 abc | |

| 30% | 9.5 ± 0.4 a | 55.0 ± 0.8 d | 45.2 ± 4.3 de | |

| Maltodextrin:Inulin (3:1) | 40% | 7.3 ± 0.5 c | 40.7 ± 0.8 a | 37.1 ± 0.9 abc |

| 35% | 8.8 ± 0.1 a | 48.7 ± 1.0 c | 43.9 ± 1.4 de | |

| 30% | 9.6 ± 0.3 ad | 54.9 ± 2.5 d | 48.8 ± 1.9 ef | |

| Inulin | 40% | 6.9 ± 0.4 c | 40.8 ± 0.8 a | 36.2 ± 0.7 ab |

| 35% | 9.5 ± 0.5 a | 47.8 ± 0.9 c | 41.9 ± 1.2 cd | |

| 30% | 11.1 ± 0.1 de | 60.6 ± 1.2 f | 50.7 ± 1.9 f | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalska, A.; Wojdyło, A.; Brzezowska, J.; Majerska, J.; Ciska, E. The Influence of Inulin on the Retention of Polyphenolic Compounds during the Drying of Blackcurrant Juice. Molecules 2019, 24, 4167. https://doi.org/10.3390/molecules24224167

Michalska A, Wojdyło A, Brzezowska J, Majerska J, Ciska E. The Influence of Inulin on the Retention of Polyphenolic Compounds during the Drying of Blackcurrant Juice. Molecules. 2019; 24(22):4167. https://doi.org/10.3390/molecules24224167

Chicago/Turabian StyleMichalska, Anna, Aneta Wojdyło, Jessica Brzezowska, Joanna Majerska, and Ewa Ciska. 2019. "The Influence of Inulin on the Retention of Polyphenolic Compounds during the Drying of Blackcurrant Juice" Molecules 24, no. 22: 4167. https://doi.org/10.3390/molecules24224167

APA StyleMichalska, A., Wojdyło, A., Brzezowska, J., Majerska, J., & Ciska, E. (2019). The Influence of Inulin on the Retention of Polyphenolic Compounds during the Drying of Blackcurrant Juice. Molecules, 24(22), 4167. https://doi.org/10.3390/molecules24224167