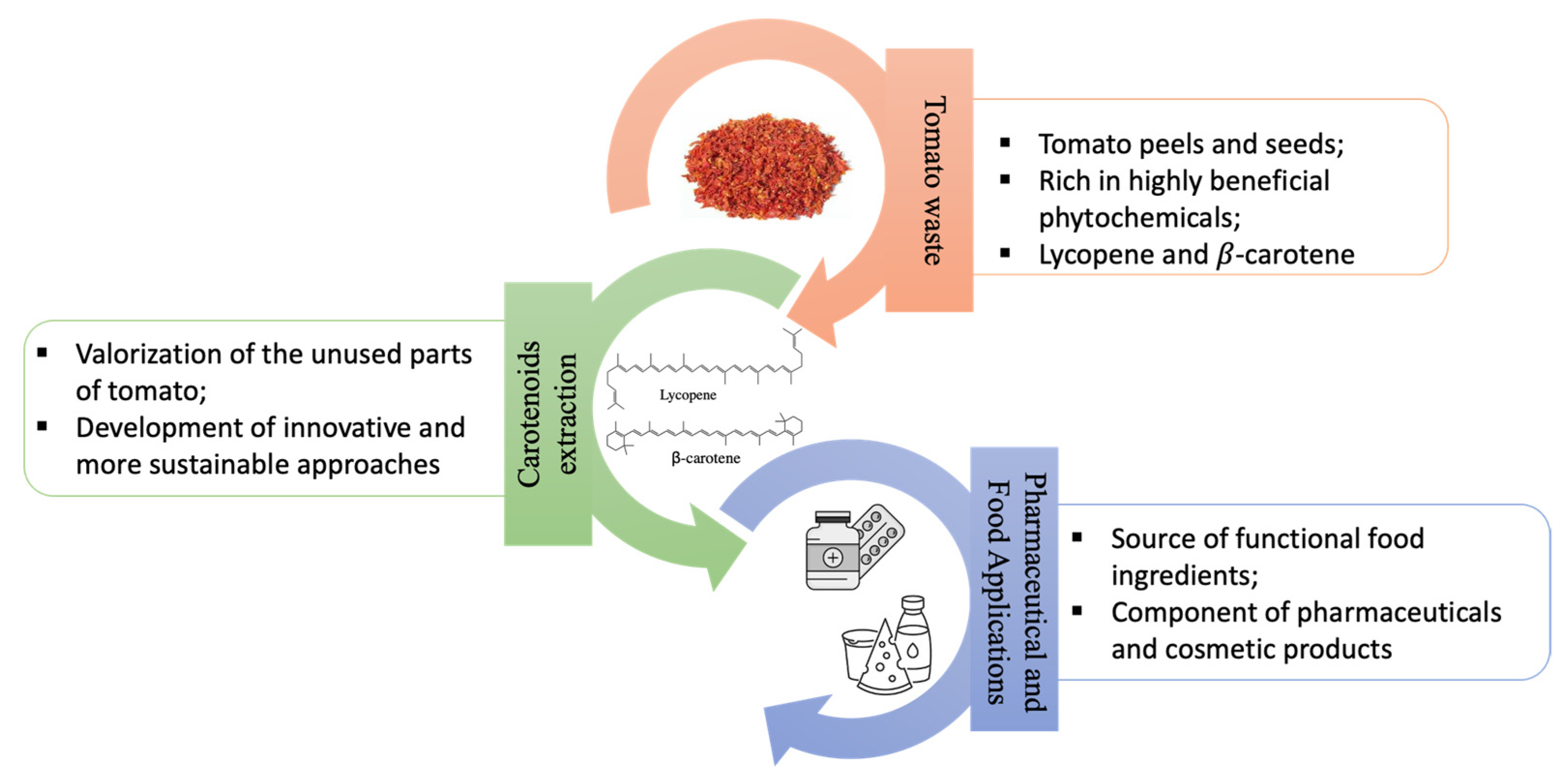

Valorization of Tomato Waste as a Source of Carotenoids

Abstract

:1. Introduction

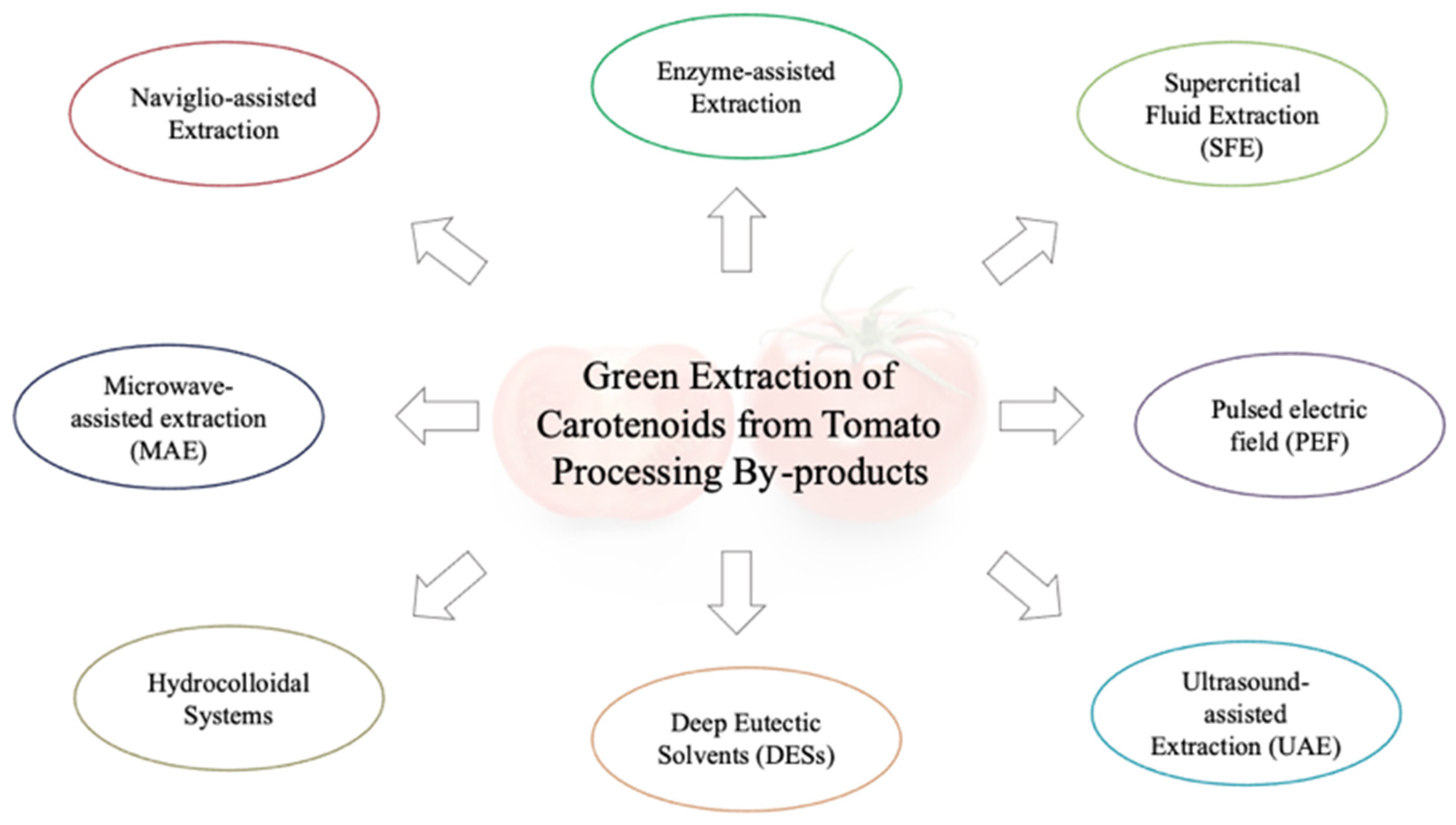

2. Alternative Processes for Tomato Carotenoid Extraction

2.1. Enzyme-Assisted Extraction

2.2. Supercritical Fluid Extraction

2.3. Pulsed Electric Field Extraction

2.4. Ultrasound-Assisted Extraction

2.5. Other Extraction Methods

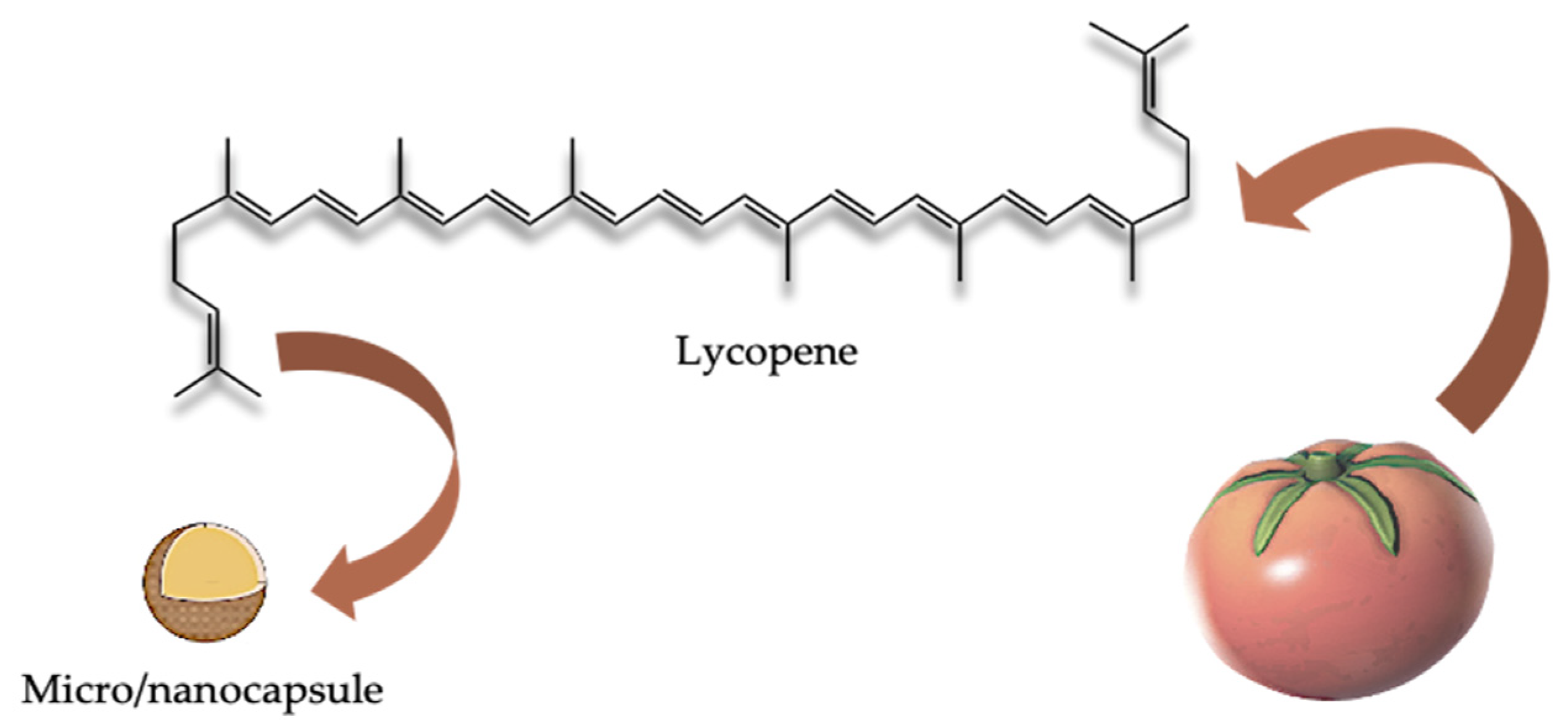

3. Protection of Tomato Carotenoids Prior to Industrial Application

4. Applications in the Food Industry

5. Applications in the Pharmaceutical and Cosmetic Industry

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, K.; Yadav, A.N.; Kumar, V.; Vyas, P.; Dhaliwal, H.S. Food waste: A potential bioresource for extraction of nutraceuticals and bioactive compounds. Bioresour. Bioprocess. 2017, 4, 18. [Google Scholar] [CrossRef] [Green Version]

- Pinela, J.; Oliveira, M.B.P.; Ferreira, I.C.F. Chapter 3 Bioactive Compounds of Tomatoes as Health Promoters. In Natural Bioactive Compounds from Fruits and Vegetables as Health Promoters Part II; Bentham Science Publishers: Sharjah, United Arab Emirates, 2016; Volume 2, pp. 48–91. [Google Scholar]

- World Processing Tomato Council (WPTC). The 2020 Processed Tomato Yearbook. 2020. Available online: http://www.tomatonews.com/pdf/yearbook/2020/index.html#48 (accessed on 30 June 2021).

- Løvdal, T.; Van Droogenbroeck, B.; Eroglu, E.C.; Kaniszewski, S.; Agati, G.; Verheul, M.; Skipnes, D. Valorization of Tomato Surplus and Waste Fractions: A Case Study Using Norway, Belgium, Poland, and Turkey as Examples. Foods 2019, 8, 229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strati, I.F.; Oreopoulou, V. Recovery of carotenoids from tomato processing by-products e a review. Food Res. Int. 2014, 65, 311–321. [Google Scholar] [CrossRef]

- Rossini, G.; Toscano, G.; Duca, D.; Corinaldesi, F.; Foppa Pedretti, E.; Riva, G. Analysis of the characteristics of the tomato manufacturing residues finalized to the energy recovery. Biomass Bioenergy 2013, 51, 177–182. [Google Scholar] [CrossRef]

- Szabo, K.; Cătoi, A.F.; Vodnar, D.C. Bioactive Compounds Extracted from Tomato Processing by-Products as a Source of Valuable Nutrients. Plant. Foods Hum. Nutr. 2018, 73, 268–277. [Google Scholar] [CrossRef]

- Kalogeropoulos, N.; Chiou, A.; Pyriochou, V.; Peristeraki, A.; Karathanos, V.T. Bioactive phytochemicals in industrial tomatoes and their processing byproducts. LWT-Food Sci. Technol. 2012, 49, 213–216. [Google Scholar] [CrossRef]

- Kaur, G.; Uisan, K.; Ong, K.L.; Ki Lin, C.S. Recent Trends in Green and Sustainable Chemistry & Waste Valorisation: Rethinking Plastics in a Circular Economy. Curr. Opin. Green Sustain. 2018, 9, 30–39. [Google Scholar] [CrossRef]

- Nayak, A.; Bhushan, B. An overview of the recent trends on the waste valorization techniques for food wastes. J. Environ. Manag. 2019, 233, 352–370. [Google Scholar] [CrossRef]

- Naziri, E.; Nenadis, N.; Mantzouridou, F.T.; Tsimidou, M.Z. Valorization of the major agrifood industrial by-products and waste from Central Macedonia (Greece) for the recovery of compounds for food applications. Food Res. Int. 2014, 65, 350–358. [Google Scholar] [CrossRef]

- Szabo, K.; Dulfb, F.V.; Diaconeasaa, Z.; Vodnara, D.C. Antimicrobial and antioxidant properties of tomato processing byproducts T and their correlation with the biochemical composition. Food Sci. Technol. 2019, 116, 108558. [Google Scholar] [CrossRef]

- Szabo, K.; Diaconeasa, Z.; Cătoi, A.-F.; Vodnar, D.C. Screening of Ten Tomato Varieties Processing Waste for Bioactive Components and Their Related Antioxidant and Antimicrobial Activities. Antioxidants 2019, 8, 292. [Google Scholar] [CrossRef] [Green Version]

- Stoica, R.-M.; Tomulescu, C.; Cășărică, A.; Soare, M.G. Tomato by-products as a source of natural antioxidants for pharmaceutical and food industries—A mini-review. Sci. Bull. Ser. F Biotechnol. 2018, 22, 200–204. [Google Scholar]

- Al-Wandawi, H.; Abdul Rehman, M.H.; Al shaikhly, K.A. Tomato processing wastes as essential raw materials source. J. Agric. Food Chem. 1985, 33, 804–807. [Google Scholar] [CrossRef]

- George, B.; Kaur, C.; Khurdiya, D.S.; Kapper, H.C. Antioxidants in tomato (Lycopersicon esculentum) as a function of genotype. Food Chem. 2004, 84, 45–51. [Google Scholar] [CrossRef]

- Zuorro, A.; Fidaleo, M.; Lavecchia, R. Enzyme-assisted extraction of lycopene from tomato processing waste. Enzym. Microb. Technol. 2011, 49, 567–573. [Google Scholar] [CrossRef]

- Pataro, G.; Sinik, M.; Capitoli, M.M.; Donsì, F.; Ferrari, G. The influence of Post- harvest UV-C and Pulsed Light treatments on quality and antioxidant properties of tomato fruits during storage. Innov. Food Sci. Emerg. Technol. 2015, 30, 103–111. [Google Scholar] [CrossRef]

- Tavani, A.; Gallus, S.; Negri, E.V.A.; Parpinel, M.; Vecchia, C.L.A. Dietary intake of carotenoids and retinol and the risk of acute myocardial infarction in Italy. Free Radic. Biol. Med. 2006, 40, 659–664. [Google Scholar] [CrossRef] [PubMed]

- Egydio, J.A.; Moraes, Â.M.; Rosa, P.T.V. Supercritical fluid extraction of lycopene from tomato juice and characterization of its antioxidation activity. J. Supercrit. Fluids 2010, 54, 159–164. [Google Scholar] [CrossRef]

- Ranveer, R.C.; Rathod, N.B.; Debaje, P.P.; Sahoo, A.K. Extraction, Purification and Characterization of Lycopene from Tomato (Cv Vijeta) Processing Industry Waste. EJNFS 2020, 12, 83–90. [Google Scholar] [CrossRef]

- Helyes, L.; Lugasi, A.; Pogonyi, Á.; Pék, Z. Effect of variety and grafting on lycopene content of tomato (Lycopersicon lycopersicum L. Karsten) fruit. Acta Aliment. 2009, 38, 27–34. [Google Scholar] [CrossRef]

- Martínez-Valverde, I.; Periafo, M.J.; Provan, G.; Chesson, A. Phenolic compounds, lycopene and antioxidant activity in commercial varieties of tomato (Lycopersicum esculentum). J. Sci. Food Agric. 2002, 82, 323–330. [Google Scholar] [CrossRef]

- Nobre, B.P.; Palavra, A.F.; Pessoa, F.L.P.; Mendes, R.L. Supercritical CO2 extraction of trans-lycopene from Portuguese tomato industrial waste. Food Chem. 2009, 116, 680–685. [Google Scholar] [CrossRef]

- Capanoglu, E.; Beekwilder, J.; Boyacioglu, D.; De Vos, R.C.; Hall, R.D. The effect of industrial food processing on potentially health-beneficial tomato antioxidants. Crit. Rev. Food Sci. Nutr. 2010, 50, 919–930. [Google Scholar] [CrossRef]

- Holzapfel, N.P.; Holzapfel, B.M.; Champ, S.; Feldthusen, J.; Clements, J.; Hutmacher, D.W. The Potential Role of Lycopene for the Prevention and Therapy of Prostate Cancer: From Molecular Mechanisms to Clinical Evidence. Int. J. Mol. Sci. 2013, 14, 14620–14646. [Google Scholar] [CrossRef] [Green Version]

- Shixian, Q.; Dai, Y.; Kakuda, Y.; Shi, J.; Mittal, G.; Yeung, D.; Jiang, Y. Synergistic anti-oxidative effects of lycopene with other bioactive compounds. Food Rev. Int. 2005, 21, 295–311. [Google Scholar] [CrossRef]

- González, I.; Valverde, V.; Alonso, J.; Periago, M. Chemical profile, functional and antioxidant properties of tomato peel fibre. Food Res. Int. 2011, 44, 1528–1535. [Google Scholar] [CrossRef]

- Mortensen, A. Carotenoids and other pigments as natural colorants. Pure Appl. Chem. 2009, 78, 1477–1491. [Google Scholar] [CrossRef]

- Carotenoids Market by Type (Astaxanthin, β-Carotene, Lutein, Lycopene, Canthaxanthin, and Zeaxanthin), Application (Feed, Food & Beverages, Dietary Supplements, Cosmetics, and Pharmaceuticals), Source, Formulation, and Region—Global Forecast to 2026. MarketsandMarkets 2016. Available online: https://www.marketsandmarkets.com/Market-Reports/carotenoid-market-158421566.html (accessed on 13 June 2021).

- FAO/WHO Joint Expert Committee on Food Additives. Lycopene Extract from Tomato (160d(ii)), FAO JEFCA Monographs 7; FAO/WHO Joint Expert Committee on Food Additives: Geneva, Switzerland, 2009. [Google Scholar]

- Strati, I.; Oreopoulou, V. Effect of extraction parameters on the carotenoid recovery from tomato waste. Int. J. Food Sci. Tech. 2010, 46, 23–29. [Google Scholar] [CrossRef]

- Roldán-Gutiérrez, J.M.; Luque de Castro, M.D. Lycopene: The need for better methods for characterization and determination. Trends Anal. Chem. 2007, 26, 163–170. [Google Scholar] [CrossRef]

- Saini, R.K.; Keum, Y.S. Carotenoid extraction methods: A review of recent developments. Food Chem. 2018, 240, 90–103. [Google Scholar] [CrossRef]

- Strati, I.F.; Oreopoulou, V. Process optimisation for recovery of carotenoids from tomato waste. Food Chem. 2011, 129, 747–752. [Google Scholar] [CrossRef]

- Zuorro, A. Enhanced Lycopene Extraction from Tomato Peels by Optimized Mixed-Polarity Solvent Mixtures. Molecules 2020, 25, 2038. [Google Scholar] [CrossRef]

- Honda, M.; Kageyama, H.; Hibino, T.; Zhang, Y.; Diono, W.; Kanda, H.; Yamaguchi, R.; Takemura, R.; Fukaya, T.; Goto, M. Improved Carotenoid Processing with Sustainable Solvents Utilizing Z-Isomerization-Induced Alteration in Physicochemical Properties: A Review and Future Directions. Molecules 2019, 24, 2149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Armenta, S.; Garrigues, S.; de la Guardia, M. The role of green extraction techniques in Green Analytical Chemistry. TrAC-Trends Anal. Chem. 2015, 71, 2–8. [Google Scholar] [CrossRef]

- Song, J.; Han, B. Green chemistry: A tool for the sustainable development of the chemical industry. Natl. Sci. Rev. 2015, 2, 255–256. [Google Scholar] [CrossRef] [Green Version]

- Cuccolini, S.; Aldini, A.; Visai, L.; Daglia, M.; Ferrari, D. Environmentally friendly lycopene purification from tomato peel waste: Enzymatic assisted aqueous extraction. J. Agric. Food Chem. 2013, 61, 1646–1651. [Google Scholar] [CrossRef] [PubMed]

- Lavecchia, R.; Zuorro, A. Improved lycopene extraction from tomato peels using cell-wall degrading enzymes. Eur. Food Res. Technol. 2008, 228, 153–158. [Google Scholar] [CrossRef]

- Lenucci, M.S.; De Caroli, M.; Marrese, P.P.; Iurlaro, A.; Rescio, L.; Böhm, V.; Dalessandro, G.; Piro, G. Enzyme-aided extraction of lycopene from high-pigment tomato cultivars by supercritical carbon dioxide. Food Chem. 2015, 170, 193–202. [Google Scholar] [CrossRef]

- Prokopov, T.; Nikolova, M.; Dobrev, G.; Taneva, D. Enzyme-assisted extraction of carotenoids from bulgarian tomato peels. Acta Aliment. 2017, 46, 84–91. [Google Scholar] [CrossRef] [Green Version]

- Catalkaya, G.; Kahveci, D. Optimization of enzyme assisted extraction of lycopene from industrial tomato waste. Sep. Purif. Technol. 2019, 219, 55–63. [Google Scholar] [CrossRef]

- Pap Papaioannoua, E.H.; Kyriakides, M.L.; Karabelas, A.J. Natural origin lycopene and its “green” downstream processing. Crit. Rev. Food Sci. Nutr. 2016, 56, 686–709. [Google Scholar] [CrossRef]

- Garcia-Mendoza, M.P.; Paula, J.T.; Paviani, L.C.; Cabral, F.A.; Martinez-Correa, H.A. Extracts from mango peel by-product obtained by supercritical CO2 and pressurized solvent processes. LWT-Food Sci. Technol. 2015, 62, 131–137. [Google Scholar] [CrossRef]

- Lenucci, M.S.; Durante, M.; Anna, M.; Dalessandro, G.; Piro, G. Possible use of the carbohydrates present in tomato pomace and in byproducts of the supercritical carbon dioxide lycopene extraction process as biomass for bioethanol production. J. Agric. Food Chem. 2013, 61, 3683–3692. [Google Scholar] [CrossRef]

- Iqbal, A.; Murtaza, A.; Muhammad, Z.; Elkhedir, A.E.; Tao, M. Inactivation, Aggregation and Conformational Changes of Polyphenol Oxidase from Quince (Cydonia oblonga Miller) Juice Subjected to Thermal and High-Pressure Carbon Dioxide Treatment. Molecules 2018, 23, 1743. [Google Scholar] [CrossRef] [Green Version]

- Kehili, M.; Kammlott, M.; Choura, S.; Zammel, A.; Zetzl, C.; Smirnova, N.A.; Sayadi, S. Supercritical CO2 extraction and antioxidant activity of lycopene and β-carotene-enriched oleoresin from tomato (Lycopersicum esculentum L.) peels by-product of a Tunisian industry. Food Bioprod. Process. 2017, 102, 340–349. [Google Scholar] [CrossRef]

- Huang, W.; Li, Z.; Niu, H.; Li, D.; Zhang, J. Optimization of operating parameters for supercritical carbon dioxide extraction of lycopene by response surface methodology. J. Food Eng. 2008, 89, 298–302. [Google Scholar] [CrossRef]

- De Andrade Lima, M.; Kestekoglou, I.; Charalampopoulos, D.; Chatzifragkou, A. Supercritical Fluid Extraction of Carotenoids from Vegetable Waste Matrices. Molecules 2019, 24, 466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Waldron, K. Handbook of Waste Management and Co-Product Recovery in Food Processing (v.1); CRC Press-Woodhead Publishing Limited: Cambridge, UK, 2007; ISBN 9781855736771. [Google Scholar]

- Pataro, G.; Carullo, D.; Bakar Siddique, M.A.; Falcone, M.; Donsì, F.; Ferrari, G. Improved extractability of carotenoids from tomato peels as side benefits of PEF treatment of tomato fruit for more energy-efficient steam-assisted peeling. J. Food Eng. 2018, 233, 65–73. [Google Scholar] [CrossRef]

- Bobinaitė, R.; Pataro, G.; Lamanauskas, N.; Satkauskas, S.; Viskelis, P.; Ferrari, G. Application of pulsed electric field in the production of juice and extraction of bioactive compounds from blueberry fruits and their by-products. J. Food Sci. Technol. 2015, 52, 5898–5905. [Google Scholar] [CrossRef] [PubMed]

- Pataro, G.; Bobinaitė, R.; Bobinas, C.; Šatkauskas, S.; Raudonis, R.; Visockis, M.; Ferrari, G.; Viškelis, P. Improving the extraction of juice and anthocyanins from blueberry fruits and their by-products by application of pulsed electric fields. Food Bioprocess. Technol. 2017, 10, 1595–1605. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Falcone, M.; Ferrari, G. Recovery of lycopene from industrially derived tomato processing by-products by pulsed electric fields-assisted extraction. Innov. Food Sci. Emerg. Technol. 2020, 63, 102369. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.; Meullemiestre, A.; Fabiano-Tixier, A.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of Ultrasound in Food Science and Technology: A Perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef] [Green Version]

- Silva, Y.P.A.; Ferreira, T.A.P.C.; Celli, G.B.; Brooks, M.S. Optimization of lycopene extraction from tomato processing waste using an eco-friendly ethyl lactate–ethyl acetate solvent: A green valorization approach. Waste Biomass Valor. 2019, 10, 2851–2861. [Google Scholar] [CrossRef]

- Ishida, B.K.; Chapman, M.H. Carotenoid extraction from plants using a novel, environmentally friendly solvent. J. Agric. Food Chem. 2009, 57, 1051–1059. [Google Scholar] [CrossRef] [PubMed]

- Silva, Y.P.A.; Pereira, V.A.; Brooks, M.S.; Ferreira, T.A.P.C. Effect of solvent on lycopene extraction yield from tomato pomace. In Proceedings of the CSBE/SCGAB Annual General Meeting and Technical Conference Joint with CIGR VI Technical Symposium, Winnipeg, MB, Canada, 6–10 August 2017; Available online: http://www.csbe-scgab.ca/publications/meeting-papers/csbe-technical-conferences/8072 (accessed on 10 July 2021).

- Ajlouni, S.; Premier, R.; Tow, W.W. Improving extraction of lycopene from tomato waste by-products using ultrasonication and freeze drying. WJARR 2020, 5, 177–185. [Google Scholar] [CrossRef]

- Silva, Y.P.A.; Ferreira, T.A.P.C.; Jiao, G.; Brooks, M.S. Sustainable approach for lycopene extraction from tomato processing by-product using hydrophobic eutectic solvents. J. Food Sci. Technol. 2019, 56, 1649–1654. [Google Scholar] [CrossRef]

- Bonacci, S.; Di Gioia, M.L.; Costanzo, P.; Maiuolo, L.; Tallarico, S.; Nardi, M. Natural Deep Eutectic Solvent as Extraction Media for the Main Phenolic Compounds from Olive Oil Processing Wastes. Antioxidants 2020, 9, 513. [Google Scholar] [CrossRef]

- Obluchinskaya, E.D.; Pozharitskaya, O.N.; Zakharova, L.V.; Daurtseva, A.V.; Flisyuk, E.V.; Shikov, A.N. Efficacy of Natural Deep Eutectic Solvents for Extraction of Hydrophilic and Lipophilic Compounds from Fucus vesiculosus. Molecules 2021, 26, 4198. [Google Scholar] [CrossRef]

- Socas-Rodríguez, B.; Torres-Cornejo, M.V.; Álvarez-Rivera, G.; Mendiola, J.A. Deep Eutectic Solvents for the Extraction of Bioactive Compounds from Natural Sources and Agricultural By-Products. Appl. Sci. 2021, 11, 4897. [Google Scholar] [CrossRef]

- Espino, M.; Fernández, M.L.A.; Gomez, F.J.V.; Silva, M.F. Natural designer solvents for greening analytical chemistry. TRAC Trend Anal. Chem. 2016, 76, 126–136. [Google Scholar] [CrossRef]

- Nagarajan, J.; Pui Kay, H.; Krishnamurthy, N.P.; Ramakrishnan, N.R.; Aldawoud, T.M.S.; Galanakis, C.M.; Wei, O.C. Extraction of Carotenoids from Tomato Pomace via Water-Induced Hydrocolloidal Complexation. Biomolecules 2020, 10, 1019. [Google Scholar] [CrossRef]

- Delazar, A.; Nahar, L.; Hamedeyazdan, S.; Sarker, S.D. Microwave-assisted extraction in natural products isolation. Methods Mol. Biol. 2012, 864, 89–115. [Google Scholar] [CrossRef]

- Lasunon, P.; Phonkerd, N.; Tettawong, P.; Sengkhamparn, N. Effect of microwave-assisted extraction on bioactive compounds from industrial tomato waste and its antioxidant activity. Food Res. 2021, 5, 468–474. [Google Scholar] [CrossRef]

- Gallo, M.; Formato, a.; Ciaravolo, M.; Langella, C.; Ctaldo, R.; Naviglio, D. A water extraction process for lycopene from tomato waste using a pressurized method: An application of a numerical simulation. Eur. Food Res. Technol. 2019, 245, 1767–1775. [Google Scholar] [CrossRef]

- Naviglio, D. Naviglio’s principle and presentation of an innovative solid–liquid extraction technology: Extractor Naviglio. Anal. Lett. 2003, 36, 1647–1659. [Google Scholar] [CrossRef]

- Rizk, E.M.; El-Kady, A.T.; El-Bialy, A.R. Charactrization of carotenoids (lyco-red) extracted from tomato peels and its uses as natural colorants and antioxidants of ice cream. Ann. Agric. Sci. 2014, 59, 53–61. [Google Scholar] [CrossRef] [Green Version]

- Luengo, E.; Alvarez, I.; Raso, J. Improving carotenoids extraction from tomato waste by pulsed electric fields. Front. Nutr. 2014, 1, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Nikolova, M.; Prokopov, T.; Ganeva, D.; Pevicharova, G. Effect of treatment parameters on the carotenoid extraction from tomato peels of Bulgarian industrial varieties. Food Environ. Saf. 2014, 13, 283–289. Available online: http://fens.usv.ro/index.php/FENS/article/view/114 (accessed on 20 March 2021).

- Saini, R.K.; Moon, S.H.; Keum, Y.S. An updated review on use of tomato pomace and crustacean processing waste to recover commercially vital carotenoids. Food Res. Int. 2018, 108, 516–529. [Google Scholar] [CrossRef]

- Janiszewska-Turak, E. Carotenoids microencapsulation by spray drying method and supercritical micronization. Food Res. Int. 2017, 99, 891–901. [Google Scholar] [CrossRef]

- Mihalcea, L.; Crăciunescu, O.; Gheonea, I.; Prelipcean, A.-M.; Enachi, E.; Barbu, V.; Bahrim, G.E.; Râpeanu, G.; Oancea, A.; Stănciuc, N. Supercritical CO2 Extraction and Microencapsulation of Lycopene-Enriched Oleoresins from Tomato Peels: Evidence on Antiproliferative and Cytocompatibility Activities. Antioxidants 2021, 10, 222. [Google Scholar] [CrossRef]

- Poshadri, A.; Aparna, K. Microencapsulation technology: A review. J. Res. ANGRAU 2010, 38, 86–102. [Google Scholar]

- Mihalcea, L.; Turturic, M.; Ghinea, I.O.; Barbu, V.; Ionită, E.; Cotârle, M.; Stănciuc, N. Encapsulation of carotenoids from sea buckthorn extracted by CO2 supercritical fuids method within whey proteins isolates matrices. Innov. Food Sci. Emerg. Technol. 2017, 42, 120–129. [Google Scholar] [CrossRef]

- Timilsena, Y.P.; Akanbi, T.O.; Khalid, N.; Adhikari, B.; Barrow, C.J. Complex coacervation: Principles, mechanisms and applications in microencapsulation. Int. J. Biol. Macromol. 2019, 121, 1276–1286. [Google Scholar] [CrossRef] [PubMed]

- Pudziuvelyte, L.; Marksa, M.; Sosnowska, K.; Winnicka, K.; Morkuniene, R.; Bernatoniene, J. Freeze-Drying Technique for Microencapsulation of Elsholtzia ciliata Ethanolic Extract Using Different Coating Materials. Molecules 2020, 25, 2237. [Google Scholar] [CrossRef] [PubMed]

- Papoutsis, K.; Golding, J.B.; Vuong, Q.; Pristijono, P.; Stathopoulos, C.E.; Scarlett, C.J.; Bowyer, M. Encapsulation of Citrus By-Product Extracts by Spray-Drying and Freeze-Drying Using Combinations of Maltodextrin with Soybean Protein and ι-Carrageenan. Foods 2018, 7, 115. [Google Scholar] [CrossRef] [Green Version]

- Gheonea (Dima), I.; Aprodu, I.; Cîciumaru, A.; Râpeanu, G.; Bahrim, G.E.; Stănciuc, N. Microencapsulation of lycopene from tomatoes peels by complex coacervation and freeze-drying: Evidences on phytochemical profile, stability and food application. J. Food Eng. 2021, 288, 110–166. [Google Scholar] [CrossRef]

- Stajčić, S.M.; Ćetković, G.S.; Čanadanović-Brunet, J.M.; Tumbas-Šaponjac, V.T.; Šeregelj, V.N. Encapsulation of carotenoids extracted from tomato waste. APTEFF 2020, 51, 149–161. [Google Scholar] [CrossRef]

- Patra, J.K.; Das, G.; Fraceto, L.F.; Campos, E.V.R.; Rodriguez-Torres, M.D.P.; Acosta-Torres, L.S.; Diaz-Torres, L.A.; Grillo, R.; Swamy, M.K.; Sharma, S.; et al. Nano based drug delivery systems: Recent developments and future prospects. J. Nanobiotechnol. 2018, 16, 71. [Google Scholar] [CrossRef] [Green Version]

- Sridhar, K.; Inbaraj, B.S.; Chen, B.-H. Recent Advances on Nanoparticle Based Strategies for Improving Carotenoid Stability and Biological Activity. Antioxidants 2021, 10, 713. [Google Scholar] [CrossRef]

- Mishra, S.B.; Kumari, N. Engineering of Crystalline Nano-Suspension of Lycopene for Potential Management of Oxidative Stress–Linked Diabetes in Experimental Animals. BioNanoScience 2021, 11, 345–354. [Google Scholar] [CrossRef]

- Albanese, D.; Adiletta, G.; D’Acunto, M.; Cinquanta, L.; Di Matteo, M. Tomato peel drying and carotenoids stability of the extracts. Int. J. Food Sci. Technol. 2014, 49, 2458–2463. [Google Scholar] [CrossRef]

- Mahfoudhi, N.; Ksouri, R.; Hamdi, S. Nanoemulsions as potential delivery systems for bioactive compounds in food systems:preparation, characterization, and applications in food industry. In Book Emulsions; Grumezescu, A.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 3, pp. 365–403. [Google Scholar] [CrossRef]

- Nour, V.; Panaite, T.D.; Ropota, M.; Turcu, R.; Trandafir, I.; Corbu, A.R. Nutritional and bioactive compounds in dried tomato processing waste. CYTA-J. Food 2018, 16, 222–229. [Google Scholar] [CrossRef]

- Silva, Y.P.A.; Borba, B.C.; Pereira, V.A.; Reis, M.G.; Caliari, M.; Su-Ling Brooks, M.; Ferreira, T.A.P.C. Characterization of tomato processing by-product for use as a potential functional food ingredient: Nutritional composition, antioxidant activity and bioactive compounds. Int. J. Food Sci. Nutr. 2019, 70, 150–160. [Google Scholar] [CrossRef] [PubMed]

- Elbadrawy, E.; Sello, A. Evaluation of nutritional value and antioxidant activity of tomato peel extracts. Arab. J. Chem. 2016, 9, S1010–S1018. [Google Scholar] [CrossRef] [Green Version]

- Andrade, M.A.; Lima, V.; Sanches Silva, A.; Vilarinho, F.; Castilho, M.C.; Khwaldia, K.; Ramos, F. Pomegranate and Grape By-Products and Their Active Compounds: Are They a Valuable Source for Food Applications? Trends Food Sci. Technol. 2019, 86, 68–84. [Google Scholar] [CrossRef]

- Domínguez, R.; Gullón, P.; Pateiro, M.; Munekata, P.E.S.; Zhang, W.; Lorenzo, J.M. Tomato as Potential Source of Natural Additives for Meat Industry. A Review. Antioxidants 2020, 9, 73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Visioli, F.; Strata, A. Milk, dairy Products, and Their Functional Effects in Humans: A Narrative Review of Recent Evidence. Adv. Nutr. 2014, 5, 131–143. [Google Scholar] [CrossRef] [Green Version]

- Zayan, A.F.; Bakry, A.M.; Abdul Alim, T.S.; Radwan, H.M.M.; Safdar, W.; Campelo, P.H.; Rashed, M.A.; Rahman, M.R.T.; Muhammad, Z.; Taha, A. Novel Processed Cheese Production Using Lycopene Oil Obtained By Green-Extraction Technique of Tomato Peels Waste. J. Nutr. Food Process. 2020, 4. [Google Scholar] [CrossRef]

- Abid, Y.; Azabou, S.; Jridi, M.; Khemakhem, I.; Bouaziz, M.; Attia, H. Storage stability of traditional Tunisian butter enriched with antioxidant extract from tomato processing by-products. Food Chem. 2017, 233, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.A.; Al Dajah, S.; Murad, A.A.; El-Salem, A.M.; Khafajah, A.M. Extraction, Purification, and Characterization of Lycopene from Jordanian Vine Tomato Cultivar, and Study of its Potential Natural Antioxidant Effect on Samen Baladi. Curr. Res. Nutr. Food Sci. 2019, 7, 532–546. [Google Scholar] [CrossRef] [Green Version]

- Nour, V.; Corbu, A.R.; Rotaru, P.; Karageorgou, I.; Lalas, S. Effect of carotenoids, extracted from dry tomato waste, on the stability and characteristics of various vegetable oils. Grasas Aceites 2018, 69, 238. [Google Scholar] [CrossRef] [Green Version]

- Freitas, I.R.; Machado, T.L.S.; Luzia, D.M.M.; Jorge, N. Tomato waste extract (Lycopersicon esculentum) as a natural antioxidant in soybean oil under heating. JBFS 2020, 7, 285. [Google Scholar] [CrossRef]

- Eletr, A.A.; Siliha, H.A.E.; Elshorbagy, G.A.; Galal, G.A. Evaluation of lycopene extracted from tomato processing waste as a natural antioxidant in some bakery products. Zagazig J. Agric. Res. 2017, 44, 1389–1401. [Google Scholar] [CrossRef]

- Mehta, D.; Prasad, P.; Sangwan, R.S.; Yadav, S.K. Tomato processing byproduct valorization in bread and muffin: Improvement in physicochemical properties and shelf life stability. J. Food Sci. Technol. 2018, 55, 2560–2568. [Google Scholar] [CrossRef]

- Liu, B.; Xu, H.; Zhao, H.; Liu, W.; Zhao, L.; Li, Y. Preparation and Characterization of Intelligent Starch/PVA Films for Simultaneous Colorimetric Indication and Antimicrobial Activity for Food Packaging Applications. Carbohydr. Polym. 2017, 157, 842–849. [Google Scholar] [CrossRef]

- Gallego, M.; Arnal, M.; Talens, P.; Toldrá, F.; Mora, L. Effect of Gelatin Coating Enriched with Antioxidant Tomato By-Products on the Quality of Pork Meat. Polymers 2020, 12, 1032. [Google Scholar] [CrossRef]

- Antoniewski, M.N.; Barringer, S.A. Meat shelf-life and extension using collagen/gelatin coatings: A review. Crit. Rev. Food Sci. Nutr. 2010, 50, 644–653. [Google Scholar] [CrossRef]

- Szabo, K.; Teleky, B.-E.; Mitrea, L.; Călinoiu, L.-F.; Martău, G.-A.; Simon, E.; Varvara, R.-A.; Vodnar, D.C. Active Packaging—Poly(Vinyl Alcohol) Films Enriched with Tomato By-Products Extract. Coatings 2020, 10, 141. [Google Scholar] [CrossRef] [Green Version]

- Concha-Meyer, A.; Palomo, I.; Plaza, A.; Gadioli Tarone, A.; Junior, M.R.M.; Sáyago-Ayerdi, S.G.; Fuentes, E. Platelet Anti-Aggregant Activity and Bioactive Compounds of Ultrasound-Assisted Extracts from Whole and Seedless Tomato Pomace. Foods 2020, 9, 1564. [Google Scholar] [CrossRef]

- Tenore, G.C.; Caruso, D.; D’Avino, M.; Buonomo, G.; Caruso, G.; Ciampaglia, R.; Schiano, E.; Maisto, M.; Annunziata, G.; Novellino, E. A Pilot Screening of Agro-Food Waste Products as Sources of Nutraceutical Formulations to Improve Simulated Postprandial Glycaemia and Insulinaemia in Healthy Subjects. Nutrients 2020, 12, 1292. [Google Scholar] [CrossRef] [PubMed]

- Meléndez-Martínez, A.J.; Stinco, C.M.; Mapelli-Brahm, P. Skin Carotenoids in Public Health and Nutricosmetics: The Emerging Roles and Applications of the UV Radiation-Absorbing Colourless Carotenoids Phytoene and Phytofluene. Nutrients 2019, 11, 1093. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Costa, A.; Marques, M.; Congiu, F.; Paiva, A.; Simões, P.; Ferreira, A.; Bronze, M.R.; Marto, J.; Ribeiro, H.M.; Simões, S. Evaluating the Presence of Lycopene-Enriched Extracts from Tomato on Topical Emulsions: Physico-Chemical Characterization and Sensory Analysis. Appl. Sci. 2021, 11, 5120. [Google Scholar] [CrossRef]

| Extraction Method | Extractive Principle | Extraction Sample | Treatment Conditions | Lycopene Extraction Yield | β-Carotene Extraction Yields | Total Carotenoids Extraction Yields | Ref. |

|---|---|---|---|---|---|---|---|

| Enzyme-assisted extraction | Enzyme-assisted hydrolysis of polysaccharide network of primary cell wall | Bulgarian tomato peel | Pretreatment with a mixture of cellulase (100 U·g−1) and endo-xylanase (400 U·g−1) for 4 h at 50 °C followed by the extraction with acetone for 30 min at 20 ± 1 °C (solid/liquid ratio: 1:30) | 15.44 mg/100 g (d.w.) | 35.85 mg/100 g (d.w.) | - | [43] |

| Tomato waste (peel and seeds) | Pretreatment with a mixture of cellulolytic and pectinolytic enzymes for 5 h at 40 °C (enzyme: substrate ratio = 0.2 mL/g) followed by extraction with acetone: ethyl acetate mixture (solvent: substrate ratio = 5 mL/g) for 1 h at RT | 11.5 mg/g | - | - | [44] | ||

| Supercritical Fluid Extraction (SFE) | Supercritical conditions enhance the solvating power of the solvent, thus favoring the extraction of intracellular compounds. | Tomato peels | Extraction at 50–80 ° C, pressures of 300–500 bar and flow rates of 4−6 g CO2/min for 105 min | 1198 ± 71.86 mg/kg (d.w.) | 27.94 ± 0.06 mg/kg (d.w.) | - | [49] |

| Tomato pomace | 57 °C, 40 MPa, and 1.8 h of extraction | 28.64 mg/100 g d.w. | - | - | [50] | ||

| Tomato flesh and peels | 59 °C, 350 bar, 15 g/min CO2, 15.5% (v/v) ethanol as co-solvent, for 30 min | 98.5 ± 2.1 in Tomato flesh and 92.5 ± 2.2 tomato peels (%, w/w) (d.b) | 99.0 ± 2.8 in tomato flesh 96.9 ± 1.7 in tomato peels (%, w/w) (d.b) | - | [51] | ||

| Pulsed Electric Field (PEF) | Lethal damage to cells or induce sub-lethal stress by transient permeabilization of cell membranes and electrophoretic movement of charged species between cellular compartments. | Tomato peels | PEF (0.25–0.75 kV/cm, 1 kJ/kg) and SB (1 min at 60 °C) pretreatment followed by extraction in acetone (4 h at 25 °C). | - | - | 37.9 mg/100 g (f.w.) | [53] |

| Industrial tomato peels residues | PEF pretreatment (5 kV/cm, 5 kJ/kg) before solvent extraction process with either acetone or ethyl lactate (1:40 g/mL) at 25 °C extraction time set at 240 | 11820 ± 141 mg/kg (d.w.) in acetone and 6311 ± 254 mg/kg (d.w) in ethyl lactate | - | - | [56] | ||

| Ultrasound-assisted Extraction (UAE) | Disruption of cells by shock waves from cavitation bubbles, thus facilitating mass transfer hence an absolute increase in the extraction yield and kinetics. | Tomato pomace freeze-dried | Ultrasound-assisted extraction with Ethyl Lactate/Ethyl Acetate (7:3) solvent mixture, 100 mL/g solvent: sample ratio for 20 min | 1334.8 µg/g (d.w.) | - | [62] | |

| Laboratory and industry generated tomato waste by-products | Combined treatment of freeze drying and ultrasonication (45 min at 50 Hz) at RT | 138.82 ± 6.64 µg/g (f.w.) | - | - | [63] | ||

| Tomato pomace | Menthol: lactic acid (8:1) DES, 120 mL/g solvent: sample, and 10 min at 70 °C in an ultrasound water bath with fixed frequency (40 kHz) and power (100 W) | 1446.6 µg/g (d.w.) | - | - | [55] | ||

| Hydrocolloidal system | Water-induced complexation of lycopene in the presence of pectin, a bioactive compound also presents in tomato pomace | Tomato pomace | water–induced complexation of carotenoid and pectin by 851 rpm of stirring speed for 10 min and with 4.69% of processed wet samples | - | - | 9.43 mg/100 g (wet) 4332.32 mg/100 g [carotenoid–pectin complex] | [68] |

| Microwave-assisted extraction (MAE) | Heating causes the evaporation of the mixture, causing moisture to, which generates tremendous pressure and the rupture of cells. This facilitates the release of the desired intracellular contents | Tomato waste | 300 w power microwave, 60 s, 95% ethanol, with a temperature not exceeding 77 °C | 5.74 mg/100 g (d.w.) | 4.83 mg/100 g (d.w.) | - | [70] |

| Naviglio extractor | Forced extraction of the not chemically bound compounds contained in the solid matrix in a suitable solvent, by the generation of a gradient pressure between the inner and the outlet of solid matrix | Tomato skin | 60 extraction cycles from tomato waste in deionized water using a Naviglio Extractor. Each cycle consisted of a 2-min static phase, followed by a dynamic phase and a delay time of 12 s before a new cycle started. 4 h is the time required for the extraction | 5 mg/200 g (d.w.) | - | - | [71] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trombino, S.; Cassano, R.; Procopio, D.; Di Gioia, M.L.; Barone, E. Valorization of Tomato Waste as a Source of Carotenoids. Molecules 2021, 26, 5062. https://doi.org/10.3390/molecules26165062

Trombino S, Cassano R, Procopio D, Di Gioia ML, Barone E. Valorization of Tomato Waste as a Source of Carotenoids. Molecules. 2021; 26(16):5062. https://doi.org/10.3390/molecules26165062

Chicago/Turabian StyleTrombino, Sonia, Roberta Cassano, Debora Procopio, Maria Luisa Di Gioia, and Eugenio Barone. 2021. "Valorization of Tomato Waste as a Source of Carotenoids" Molecules 26, no. 16: 5062. https://doi.org/10.3390/molecules26165062