Development of New Efficient Adsorbent by Functionalization of Mg3Al-LDH with Methyl Trialkyl Ammonium Chloride Ionic Liquid

Abstract

:1. Introduction

2. Results and Discussion

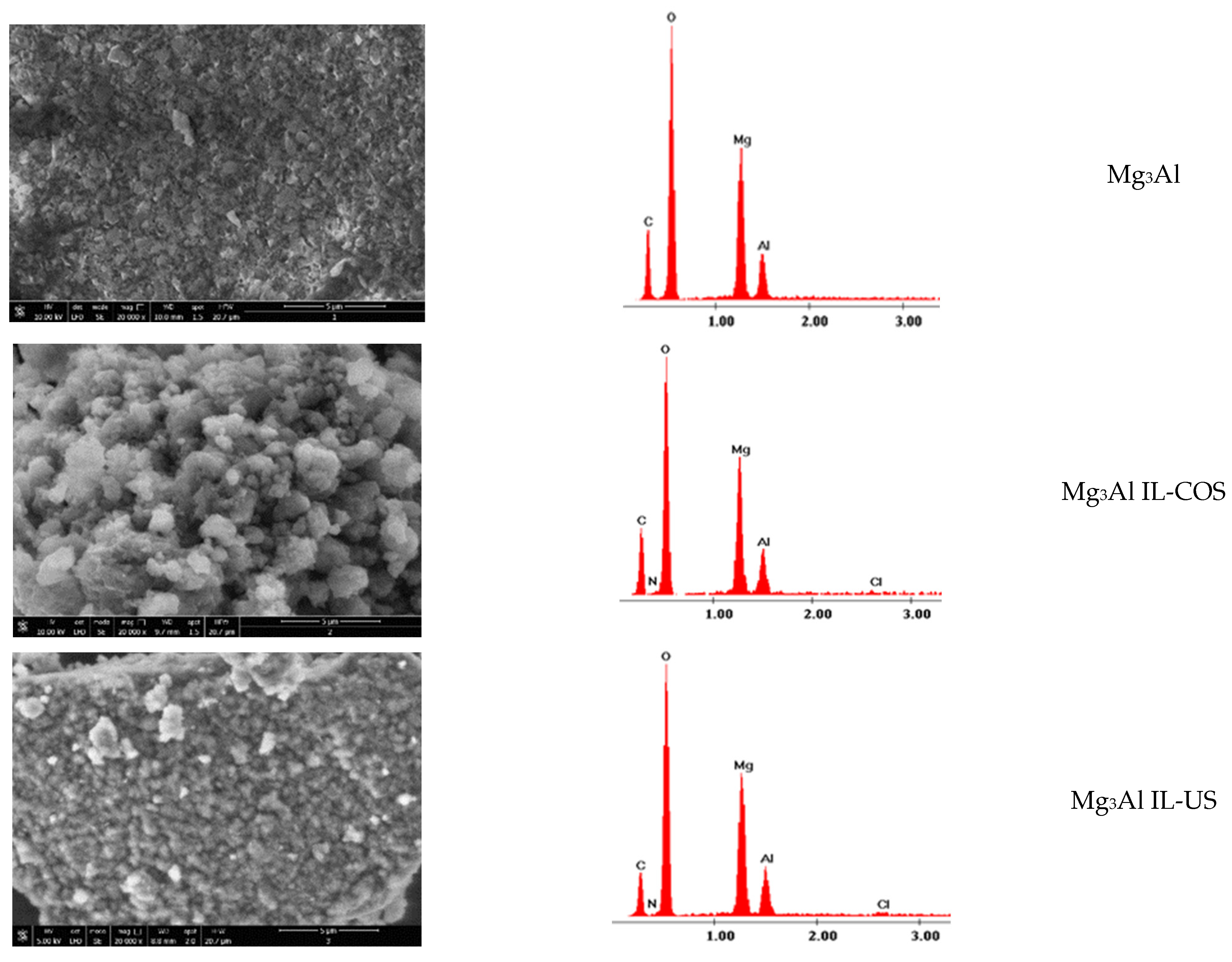

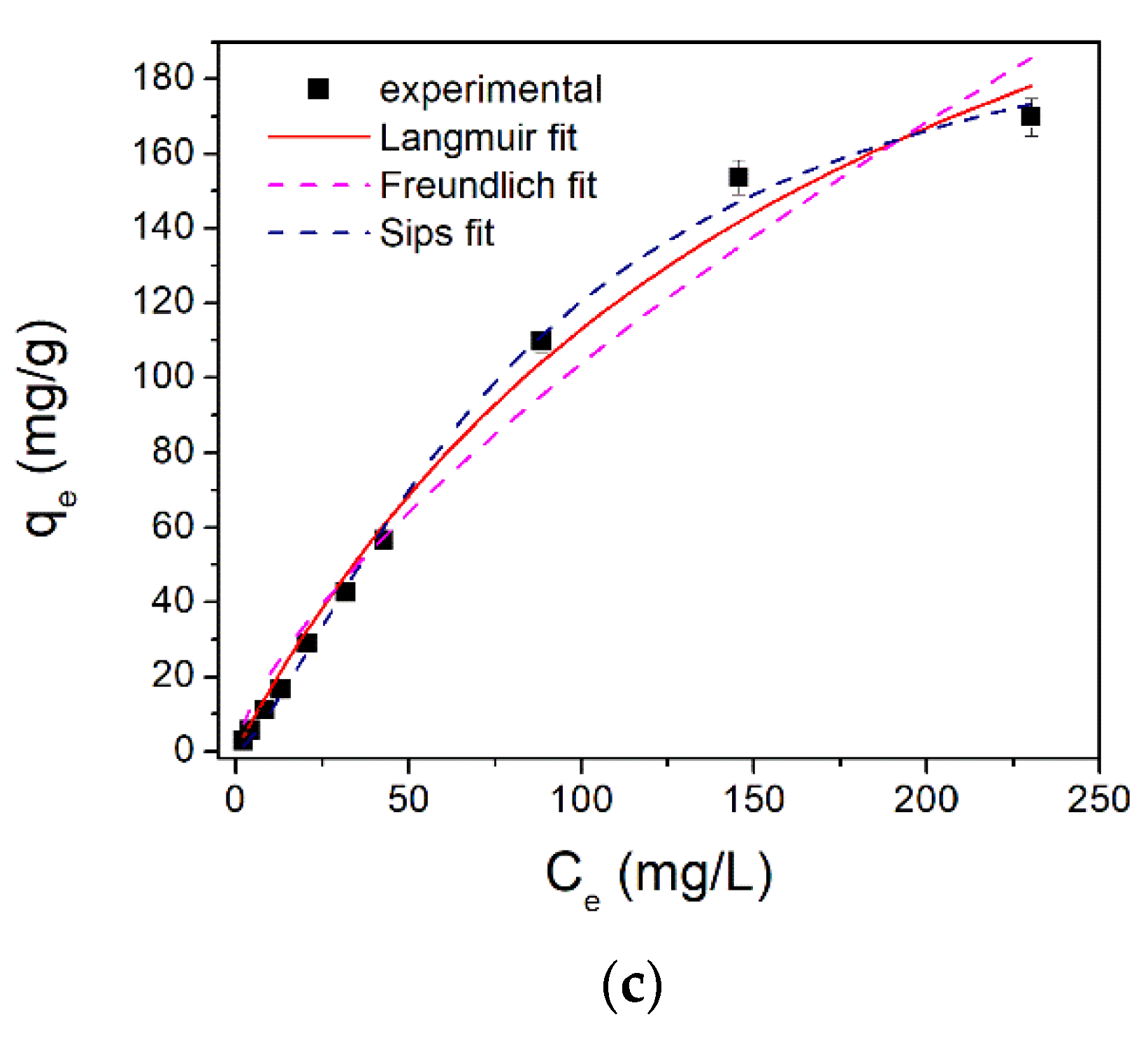

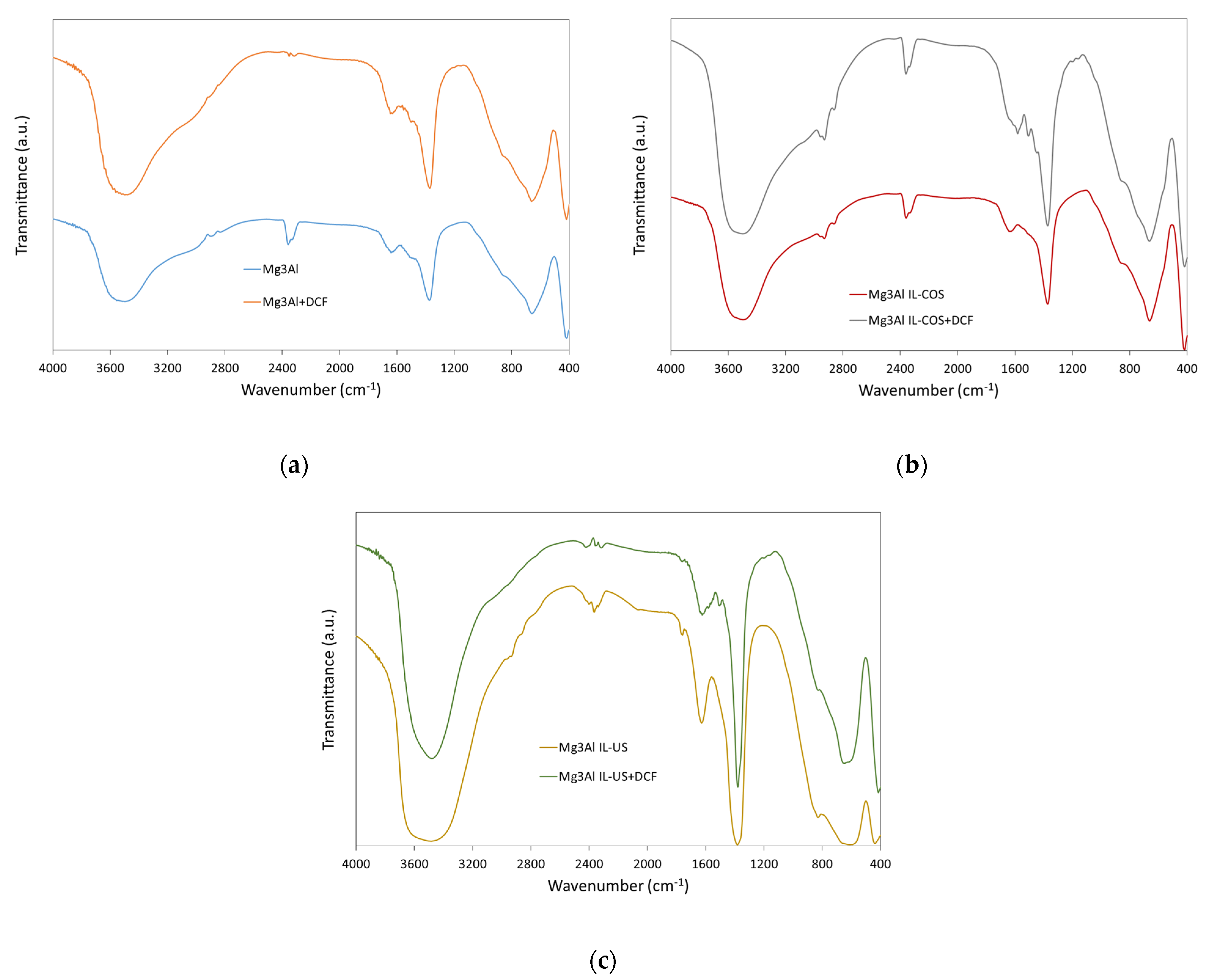

2.1. Adsorbent Materials Characterization

2.2. Adsorption Studies

2.2.1. pH Influence upon the Adsorption Capacity Developed by the Studied Materials

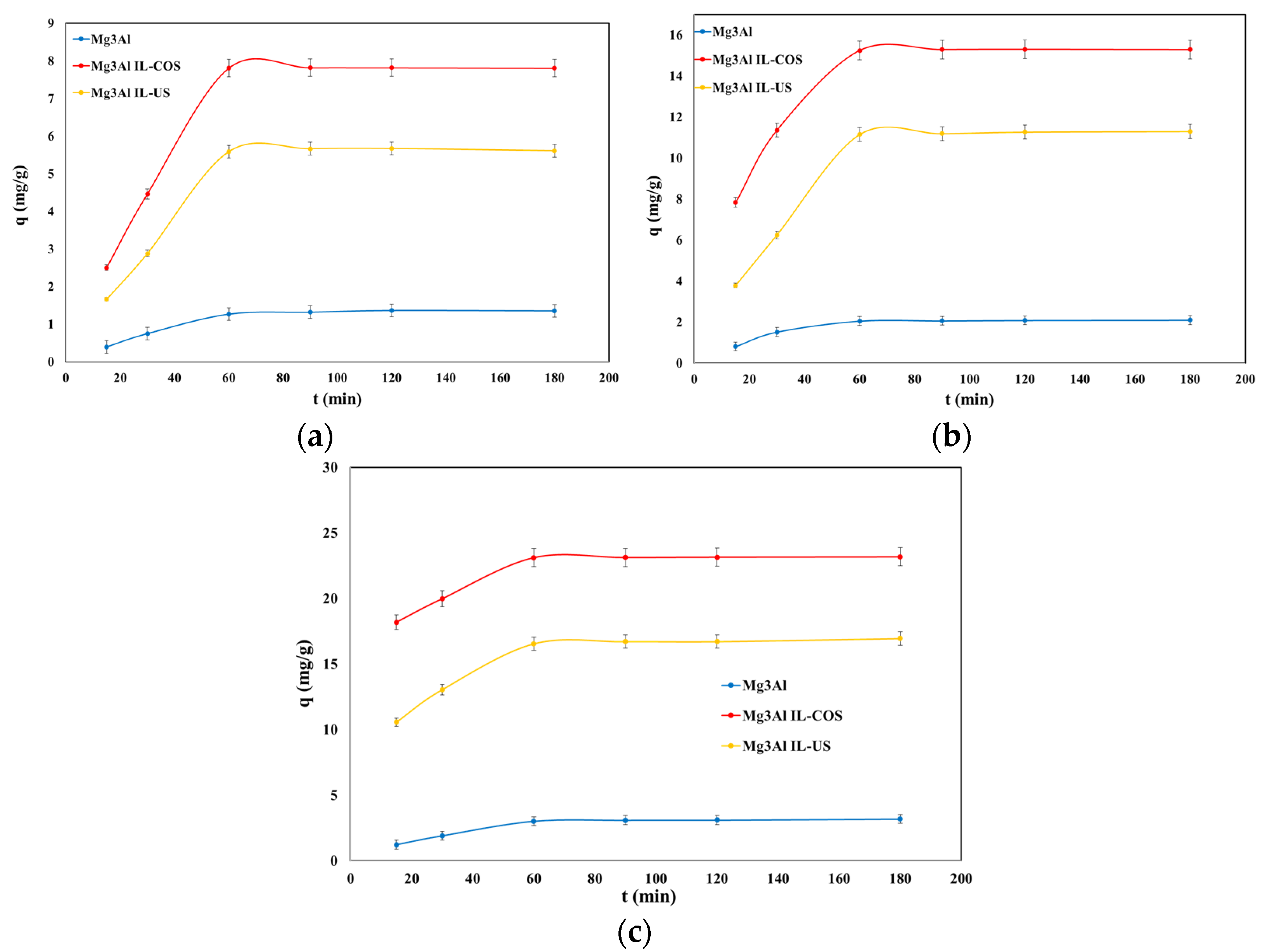

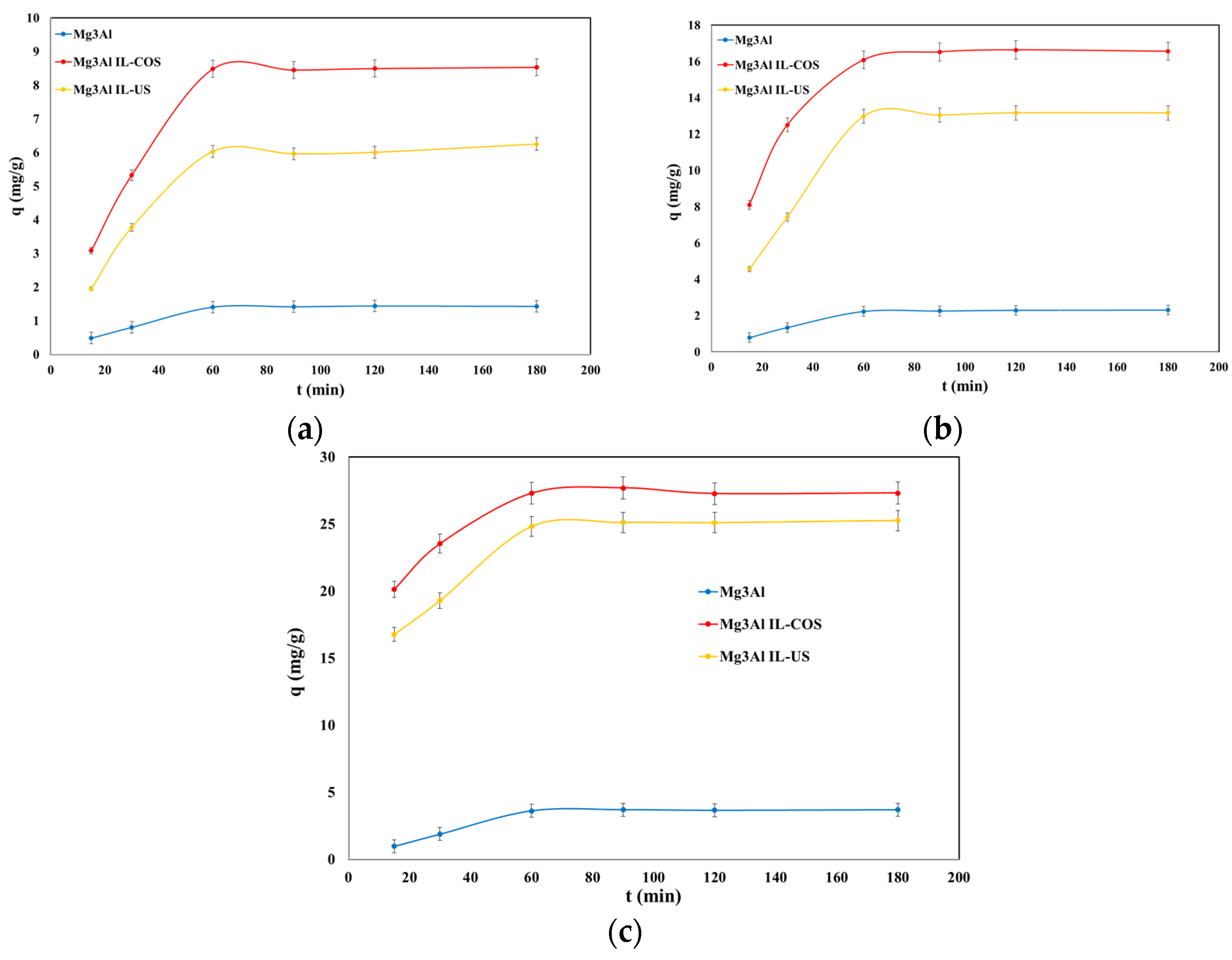

2.2.2. Kinetic Studies

- qt—adsorption capacity of the adsorbent at time t, mg/g;

- qe—adsorption capacity of the adsorbent at equilibrium, mg/g;

- k1—adsorption rate constant, min−1;

- t—stirring time, min.

- k2—the rate constant of the pseudo-second-order kinetic adsorption model (g/mg/min)

- qe—the amount of DCF adsorbed at equilibrium (mg/g);

- qt—the amount of DCF adsorbed at time t (mg/g).

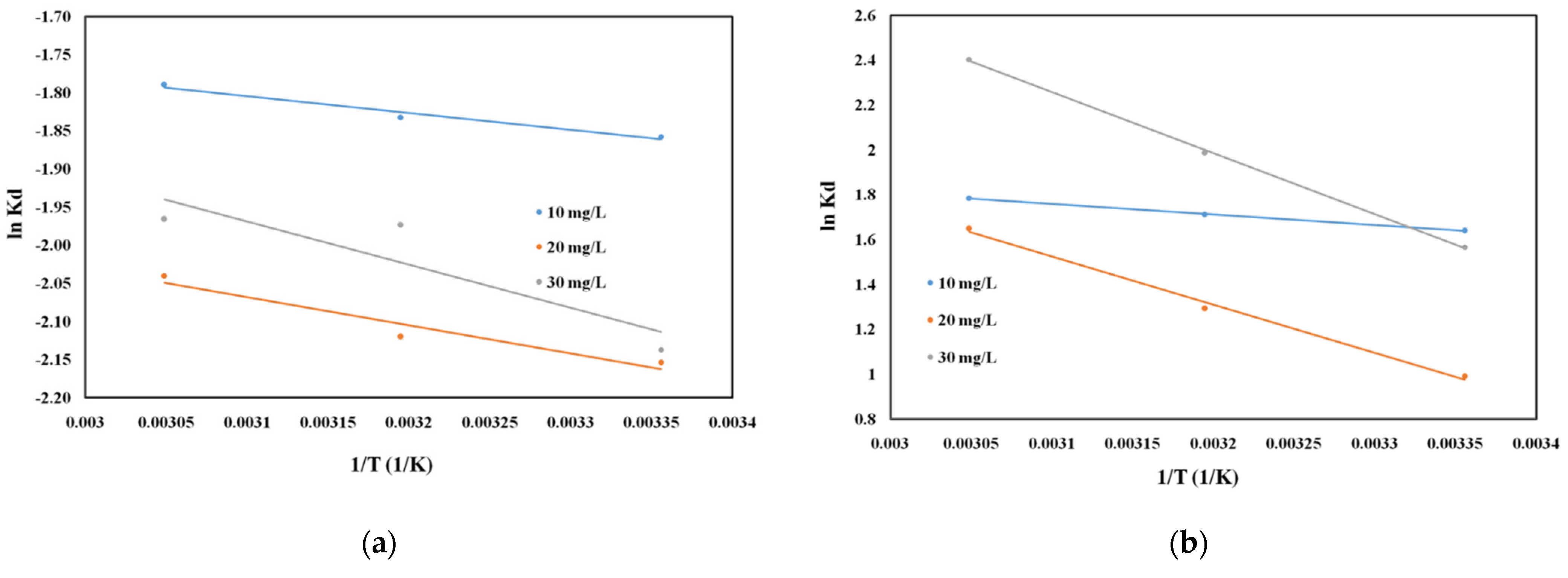

2.2.3. Thermodynamic Studies

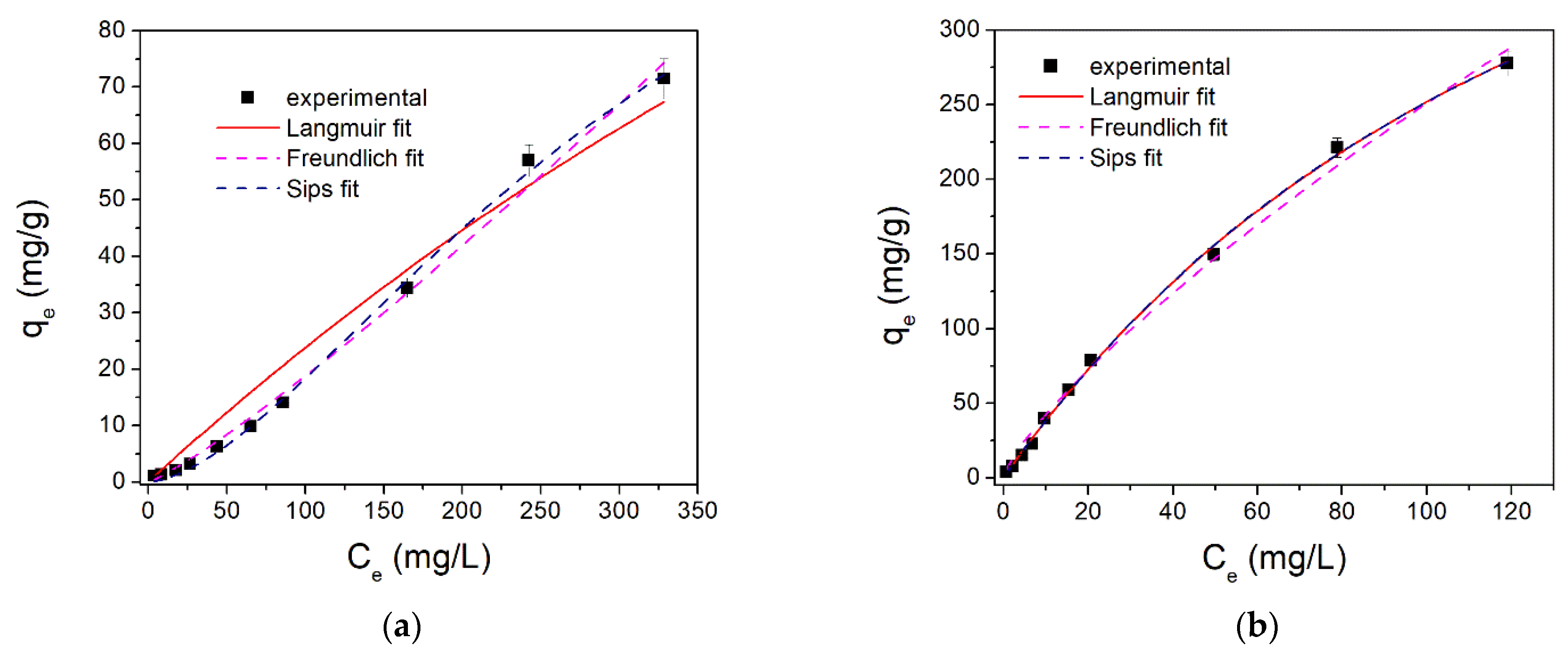

2.2.4. Equilibrium Studies

- qe—amount of DCF adsorbed at equilibrium (mg/g)

- Ce—equilibrium concentration of DCF in solution (mg/L)

- qm—maximum adsorption capacity in Langmuir model (mg/g)

- KL—Langmuir constant (L/mg).

- KF—Freundlich isotherm constant (mg1−1/n L1/n/g)

- n—Freundlich exponent.

- qmS—maximum adsorption capacity in Sips model (mg/g)

- KS—Sips isotherm constant (Lm/mgm)

- m—Sips exponent.

3. Materials and Methods

3.1. Materials

3.2. Adsorbent Obtaining and Characterization

3.3. Adsorption Studies

- qe—equilibrium capacity developed by adsorbent materials, mg DCF/g adsorbent material.

- C0—initial concentration of DCF in aqueous solutions, mg/L.

- Ce—equilibrium concentration of DCF, mg/L.

- V—volume of the solution containing DCF used in the adsorption process, L.

- m—mass of adsorbent material used in the adsorption process, g.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Abo El-Reesh, G.Y.; Farghali, A.A.; Taha, M.; Mahmoud, R.K. Novel Synthesis of Ni/Fe Layered Double Hydroxides Using Urea and Glycerol and Their Enhanced Adsorption Behavior for Cr (VI) Removal. Sci. Rep. 2020, 10, 587. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pourfaraj, R.; Fatemi, S.J.; Kazemi, S.Y.; Biparva, P. Synthesis of Hexagonal Mesoporous MgAl LDH Nanoplatelets Adsorbent for the Effective Adsorption of Brilliant Yellow. J. Colloid Interface Sci. 2017, 508, 65–74. [Google Scholar] [CrossRef]

- Souza dos Santos, G.E.; Ide, A.H.; Silva Duarte, J.L.; McKay, G.; Sousa Silva, A.O.; Meili, L. Adsorption of Anti-Inflammatory Drug Diclofenac by MgAl/Layered Double Hydroxide Supported on Syagrus Coronata Biochar. Powder Technol. 2020, 364, 229–240. [Google Scholar] [CrossRef]

- Maranescu, B.; Lupa, L.; Mihali, M.T.-L. Synthesis, Characterizations and Pb (II) Sorption Properties of Cobalt Phosphonate Materials. Pure Appl. Chem. 2016, 88, 979–992. [Google Scholar] [CrossRef] [Green Version]

- Lupa, L.; Cocheci, L.; Trica, B.; Coroaba, A.; Popa, A. Photodegradation of Phenolic Compounds from Water in the Presence of a Pd-Containing Exhausted Adsorbent. Appl. Sci. 2020, 10, 8440. [Google Scholar] [CrossRef]

- Choy, J.; Choi, S.; Oh, J.; Park, T. Clay Minerals and Layered Double Hydroxides for Novel Biological Applications. Appl. Clay Sci. 2007, 36, 122–132. [Google Scholar] [CrossRef]

- Mohapi, M.; Sefadi, J.S.; Mochane, M.J.; Magagula, S.I.; Lebelo, K. Effect of LDHs and Other Clays on Polymer Composite in Adsorptive Removal of Contaminants: A Review. Crystals 2020, 10, 957. [Google Scholar] [CrossRef]

- Benhiti, R.; Ichou, A.A.; Zaghloul, A.; Aziam, R.; Carja, G.; Zerbet, M.; Sinan, F.; Chiban, M. Synthesis, Characterization, and Comparative Study of MgAl-LDHs Prepared by Standard Coprecipitation and Urea Hydrolysis Methods for Phosphate Removal. Environ. Sci. Pollut. Res. 2020, 27, 45767–45774. [Google Scholar] [CrossRef]

- Tonelli, D.; Gualandi, I.; Musella, E.; Scavetta, E. Synthesis and Characterization of Layered Double Hydroxides as Materials for Electrocatalytic Applications. Nanomaterials 2021, 11, 725. [Google Scholar] [CrossRef]

- Golban, A.; Lupa, L.; Cocheci, L.; Pode, R. Synthesis of MgFe Layered Double Hydroxide from Iron-Containing Acidic Residual Solution and Its Adsorption Performance. Crystals 2019, 9, 514. [Google Scholar] [CrossRef] [Green Version]

- Cocheci, L.; Lupa, L.; Lazău, R.; Vodă, R.; Pode, R. Zinc Recovery from Waste Zinc Ash—A New “Green” Route for the Preparation of Zn-Al Layered Double Hydroxide Used for Molybdate Retention. J. Alloy. Compd. 2019, 787, 332–343. [Google Scholar] [CrossRef]

- Lu, L.; Li, J.; Dickon, H.L.N.; Yang, P.; Song, P.; Zuo, M. Synthesis of Novel Hierarchically Porous Fe3O4@MgAl–LDH Magnetic Microspheres and Its Superb Adsorption Properties of Dye from Water. J. Ind. Eng. Chem. 2017, 46, 315–323. [Google Scholar] [CrossRef]

- Maranescu, B.; Popa, A.; Lupa, L.; Maranescu, V.; Visa, A. Use of Chitosan Complex with Aminophosphonic Groups and Cobalt for the Removal of Sr2+ Ions. Sep. Sci. Technol. 2018, 53, 1058–1064. [Google Scholar] [CrossRef]

- Lupa, L.; Cocheci, L.; Pode, R.; Hulka, I. Phenol Adsorption Using Aliquat 336 Functionalized Zn-Al Layered Double Hydroxide. Sep. Purif. Technol. 2018, 196, 82–95. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Kujawski, W.; Fatyeyeva, K.; Kujawa, J. A Review on Ionic Liquids-Based Membranes for Middle and High Temperature Polymer Electrolyte Membrane Fuel Cells (PEM FCs). Int. J. Mol. Sci. 2021, 22, 5430. [Google Scholar] [CrossRef] [PubMed]

- Farrokhara, M.; Dorosti, F. New High Permeable Polysulfone/Ionic Liquid Membrane for Gas Separation. Chin. J. Chem. Eng. 2020, 28, 2301–2311. [Google Scholar] [CrossRef]

- Lupa, L.; Popa, A.; Drăgan, E.S.; Ciopec, M.; Negrea, A.; Negrea, P. Adsorption Performance of the Organic Solid Support Impregnated with Ionic Liquid in the Removal Process of Tl(I) from Aqueous Solutions. Process Saf. Environ. Prot. 2017, 108, 67–73. [Google Scholar] [CrossRef]

- Gallardo, V.; Navaro, R.; Saucedo, I.; Avila, M.; Guibal, E. Zinc (II) Extraction from Hydrochloric Acid Solutions Using Amberlite XAD7 Impregnated with Cyphos IL101 (Tetradecyl(Trihexyl) Phosphonium Chloride). Sep. Sci. Technol. 2008, 43, 2434–2459. [Google Scholar] [CrossRef]

- Huang, W.; Wu, X.; Qi, J.; Zhu, Q.; Wu, W.; Lu, Y.; Chen, Z. Ionic Liquids: Green and Tailor-Made Solvents in Drug Delivery. Drug Discov. Today 2020, 25, 901–908. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Preng, B.; Ji, Y.; Chen, J.; Li, D. The Solid—Liquid Extraction of Yttrium from Rare Earths by Solvent (Ionic Liquid) Impregnated Resin Coupled with Complexing Method. Sep. Purif. Technol. 2008, 63, 61–68. [Google Scholar] [CrossRef]

- Han, D.; Row, K.H. Recent Applications of Ionic Liquids in Separation Technology. Molecules 2010, 15, 2405–2426. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cocheci, L.; Lupa, L.; Ţolea, N.S.; Muntean, C.; Negrea, P. Sequential Use of Ionic Liquid Functionalized Zn-Al Layered Double Hydroxide as Adsorbent and Photocatalyst. Sep. Purif. Technol. 2020, 250, 117104. [Google Scholar] [CrossRef]

- Lupa, L.; Negrea, A.; Ciopec, M.; Negrea, P.; Raluca, V. Ionic liquids Impregnated onto Inorganic Support Used for Thallium Adsorption from Aqueous Solutions. Sep. Purif. Technol. 2015, 155, 75–82. [Google Scholar] [CrossRef]

- Sulaiman, S.M.; Al-Jabari, M.H. Enhanced Adsorptive Removal of Diclofenac Sodium from Aqueous Solution by Bentonite-Supported Nanoscale Zero-Valent Iron. Arab. J. Basic Appl. Sci. 2021, 28, 51–63. [Google Scholar] [CrossRef]

- Martinez-Costa, J.I.; Leyva-Ramos, R.; Padilla-Ortega, E. Sorption of Diclofenac from Aqueous Solution on an Organobentonite and Adsorption of Cadmium on Organobentonite Saturated with Diclofenac. Clays Clay Min. 2018, 66, 515–528. [Google Scholar] [CrossRef]

- Ragab, A.H.; Hussein, H.S.; Ahmed, I.A.; Abualnaja, K.M.; AlMasoud, N. An Efficient Strategy for Enhancing the Adsorption of Antibiotics and Drugs from Aqueous Solutions Using an Effective Limestone-Activated Carbon—Alginate Nanocomposite. Molecules 2021, 26, 5180. [Google Scholar] [CrossRef] [PubMed]

- Genç, N.; Durna, E.; Erkişi, E. Optimization of the Adsorption of Diclofenac by Activated Carbon and the Acidic Regeneration of Spent Activated Carbon. Water Sci. Technol. 2021, 83, 396–408. [Google Scholar] [CrossRef]

- Shamsudin, M.S.; Azha, S.F.; Sellaoui, L.; Badawi, M.; Bonilla-Petriciolet, A.; Ismail, S. Performance and Interactions of Diclofenac Adsorption Using Alginate/Carbon-Based Films: Experimental Investigation and Statistical Physics Modeling. Chem. Eng. J. 2022, 428, 131929. [Google Scholar] [CrossRef]

- Liang, D.; Yue, W.; Sun, G.; Zheng, D.; Ooi, K.; Yang, X. Direct Synthesis of Unilamellar MgAl-LDH Nanosheets and Stacking in Aqueous Solution. Langmuir 2015, 31, 12464–12471. [Google Scholar] [CrossRef]

- Pizzoferrato, R.; Ciotta, E.; Ferrari, I.V.; Narducci, R.; Pasquini, L.; Varone, A.; Richeta, M.; Antonaroli, S.; Braglia, M.; Knauth, P.; et al. Layered Double Hydroxides Containing an Ionic Liquid: Ionic Conductivity and Use in Composite Anion Exchange Membranes. ChemElectroChem 2018, 5, 2781–2788. [Google Scholar] [CrossRef]

- Krajišnik, D.; Daković, A.; Milojević, M.; Malenović, A.; Kragović, M.; Bogdanović, D.B.; Condur, V.; Milić, J. Properties of Diclofenac Sodium Sorption onto Natural Zeolite Modified with Cetylpyridinium Chloride. Colloids Surf. B: Biointerfaces 2011, 83, 165–172. [Google Scholar] [CrossRef]

- Pereira, K.A.A.; Osório, L.R.; Silva, M.P.; Sousa, K.S.; da Silva Filho, E.C. Chemical Modification of Chitosan in the Absence of Solvent for Diclofenac Sodium Removal: pH and Kinetics Studies. Mater. Res. 2014, 17, 141–145. [Google Scholar] [CrossRef] [Green Version]

- Khatem, R.; Real Ojeda, M.; Abdellah, B. Use of Synthetic Clay for Removal of Diclofenac Anti-Inflammatory. Eurasian J. Soil Sci. 2015, 4, 126–136. [Google Scholar] [CrossRef] [Green Version]

- Cong, L.; Jianping, C. Potential Role of Intraparticle Diffusion in Dynamic Partitioning of Secondary Organic Aerosols. Atmos. Pollut. Res. 2019, 9, 1131–1136. [Google Scholar]

- Frost, R.L.; Spratt, H.J.; Palmer, S.J. Infrared and Near-Infrared Spectroscopic Study of Synthetic Hydrotalcites with Variable Divalent/Trivalent Cationic Ratios. Spectrochim. Acta 2009, 72, 984–988. [Google Scholar] [CrossRef]

- Cocheci, L.; Barvinschi, P.; Pode, R.; Popovici, E.; Seftel, E.M. Structural Characterization of some Mg/Zn-Al Type Hydrotalcites Prepared for Chromate Sorption from Wastewater. Chem. Bull. Politehnica Univ. (Timisoara) 2010, 55, 40–45. [Google Scholar]

- Viscusi, G.; Gorassi, G. Facile Preparation of Layered Double Hydroxide (LDH)-Alginate Beads as Sustainable System for the Triggered Release of Diclofenac: Effect of pH and Temperature on Release Rate. Int. J. Biol. Macromol. 2021, 184, 271–281. [Google Scholar] [CrossRef]

- Boukhalfa, N.; Boutahala, M. Synthesis and Characterization of ZnAl-Layered Double Hydroxide and Organo-K10 Montmorillonite for the Removal of Diclofenac from Aqueous Solution. Ads. Sci. Technol. 2017, 35, 20–36. [Google Scholar] [CrossRef]

- Cavani, F.; Trifirò, F.; Vaccari, A. Hydrotalcite-Type Anionic Clays: Preparation, Properties and Applications. Catal. Today 1991, 11, 173–301. [Google Scholar] [CrossRef]

| Sample | a (Å) | c (Å) | D (nm) |

|---|---|---|---|

| Mg3Al | 3.0730 | 23.58 | 4.86 |

| Mg3Al IL-COS | 3.0725 | 24.39 | 3.38 |

| Mg3Al IL-US | 3.0710 | 23.53 | 4.45 |

| Adsorbent | qe Exp (mg/g) | Pseudo-First-Order | Pseudo-Second-Order | Intraparticle Diffusion | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| qe Calc (mg/g) | k1 (min−1) | R2 | qe Calc (mg/g) | k2·10−3 (min/(mg/g)) | R2 | kint (mg/g min−1/2) | C | R2 | ||

| C0 = 10 mg/L | ||||||||||

| Mg3Al | 1.38 | 0.845 | 0.0250 | 0.8045 | 1.71 | 16.3 | 0.9650 | 0.102 | 0.209 | 0.7741 |

| Mg3Al IL-COS | 8.02 | 2.89 | 0.0197 | 0.5748 | 9.48 | 3.67 | 0.9665 | 0.556 | 1.65 | 0.7146 |

| Mg3Al IL-US | 6.00 | 2.70 | 0.0149 | 0.5821 | 7.11 | 3.92 | 0.9511 | 0.429 | 0.873 | 0.7231 |

| C0 = 20 mg/L | ||||||||||

| Mg3Al | 2.29 | 0.934 | 0.0112 | 0.6465 | 2.37 | 23.0 | 0.9866 | 0.123 | 0.722 | 0.6941 |

| Mg3Al IL-COS | 15.5 | 3.78 | 0.0217 | 0.6082 | 16.6 | 5.15 | 0.9945 | 0.744 | 7.07 | 0.6993 |

| Mg3Al IL-US | 11.9 | 5.23 | 0.0162 | 0.6440 | 13.7 | 2.54 | 0.9711 | 0.800 | 2.36 | 0.7328 |

| C0 = 30 mg/L | ||||||||||

| Mg3Al | 3.38 | 1.64 | 0.0141 | 0.7576 | 3.69 | 11.5 | 0.9876 | 0.204 | 0.852 | 0.7689 |

| Mg3Al IL-COS | 23.4 | 3.07 | 0.0197 | 0.6411 | 23.9 | 10.4 | 0.9994 | 0.524 | 17.4 | 0.7246 |

| Mg3Al IL-US | 17.1 | 4.96 | 0.0205 | 0.8069 | 17.9 | 6.33 | 0.9984 | 0.653 | 9.42 | 0.7502 |

| Adsorbent | qe Exp (mg/g) | Pseudo-First-Order | Pseudo-Second-Order | Intraparticle Diffusion | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| qe Calc (mg/g) | k1 (min−1) | R2 | qe Calc (mg/g) | k2·10−3 (min/(mg/g)) | R2 | kint (mg/g min−1/2) | C | R2 | ||

| C0 = 10 mg/L | ||||||||||

| Mg3Al | 1.59 | 0.771 | 0.0096 | 0.6149 | 1.79 | 26.1 | 0.9810 | 0.218 | −0.342 | 0.9908 |

| Mg3Al IL-COS | 8.58 | 3.25 | 0.0207 | 0.6035 | 11.1 | 3.07 | 0.9579 | 1.53 | −3.51 | 0.9998 |

| Mg3Al IL-US | 5.95 | 2.44 | 0.0185 | 0.5729 | 7.36 | 3.59 | 0.9429 | 1.09 | −2.77 | 0.9918 |

| C0 = 20 mg/L | ||||||||||

| Mg3Al | 2.35 | 1.27 | 0.0121 | 0.6278 | 2.53 | 16.5 | 0.9758 | 0.356 | −0.613 | 0.9902 |

| Mg3Al IL-COS | 15.8 | 5.41 | 0.0255 | 0.7992 | 16.9 | 4.92 | 0.9962 | 1.82 | 1.26 | 0.9795 |

| Mg3Al IL-US | 12.7 | 6.24 | 0.0237 | 0.7595 | 15.2 | 2.13 | 0.9701 | 2.08 | −4.23 | 0.9939 |

| C0 = 30 mg/L | ||||||||||

| Mg3Al | 3.87 | 1.89 | 0.0153 | 0.6699 | 4.57 | 6.32 | 0.9605 | 0.656 | −1.53 | 0.9960 |

| Mg3Al IL-COS | 26.6 | 3.24 | 0.0206 | 0.5313 | 27.3 | 7.84 | 0.9990 | 1.70 | 13.1 | 0.9928 |

| Mg3Al IL-US | 34.4 | 5.97 | 0.0232 | 0.7534 | 25.5 | 5.01 | 0.9981 | 2.04 | 7.87 | 0.9912 |

| Adsorbent | qe Exp (mg/g) | Pseudo-First-Order | Pseudo-Second-Order | Intraparticle Diffusion | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| qe Calc (mg/g) | k1 (min−1) | R2 | qe Calc (mg/g) | k2·10−3 (min/(mg/g)) | R2 | kint (mg/g min−1/2) | C | R2 | ||

| C0 = 10 mg/L | ||||||||||

| Mg3Al | 1.64 | 0.834 | 0.0103 | 0.6260 | 1.83 | 20.4 | 0.9720 | 0.241 | −0.475 | 0.9946 |

| Mg3Al IL-COS | 8.73 | 3.22 | 0.0198 | 0.6406 | 11.1 | 4.35 | 0.9802 | 1.39 | −2.31 | 1.000 |

| Mg3Al IL-US | 6.45 | 3.26 | 0.0174 | 0.7714 | 7.48 | 4.57 | 0.9754 | 1.05 | −2.06 | 0.9987 |

| C0 = 20 mg/L | ||||||||||

| Mg3Al | 2.51 | 1.23 | 0.0128 | 0.6927 | 2.76 | 13.1 | 0.9780 | 0.375 | −0.685 | 0.9991 |

| Mg3Al IL-COS | 16.8 | 5.38 | 0.0220 | 0.7210 | 19.1 | 3.91 | 0.9947 | 2.03 | 0.675 | 0.9751 |

| Mg3Al IL-US | 13.4 | 5.63 | 0.0235 | 0.7014 | 15.8 | 2.31 | 0.9742 | 2.19 | −4.18 | 0.9933 |

| C0 = 30 mg/L | ||||||||||

| Mg3Al | 3.88 | 1.02 | 0.0162 | 0.6330 | 4.78 | 5.16 | 0.9404 | 0.687 | −1.76 | 0.9935 |

| Mg3Al IL-COS | 27.9 | 3.76 | 0.0153 | 0.4527 | 28.2 | 8.11 | 0.9989 | 1.83 | 13.2 | 0.9952 |

| Mg3Al IL-US | 25.5 | 6.59 | 0.0231 | 0.7785 | 26.6 | 4.72 | 0.9981 | 2.10 | 8.31 | 0.9872 |

| Adsorbent | C0 (mg/L) | ΔH (KJ/mol) | ΔS (J/mol·K) | ΔG (KJ/mol) | R2 | ||

|---|---|---|---|---|---|---|---|

| 298 (K) | 313 (K) | 328 (K) | |||||

| Mg3Al | 10 | 1.83 | −9.31 | 4.60 | 4.74 | 4.88 | 0.9697 |

| 20 | 3.06 | −7.69 | 5.35 | 5.46 | 5.58 | 0.9352 | |

| 30 | 4.69 | −1.81 | 5.22 | 5.25 | 5.28 | 0.8038 | |

| Mg3Al IL-COS | 10 | 3.93 | 26.8 | −4.08 | −4.48 | −4.88 | 0.9992 |

| 20 | 17.8 | 63.9 | −1.23 | −2.19 | −3.14 | 0.9944 | |

| 30 | 22.6 | 88.9 | −3.86 | −5.20 | −6.53 | 0.9995 | |

| Mg3Al IL-US | 10 | 6.40 | 23.4 | −0.597 | −0.949 | −1.30 | 0.8538 |

| 20 | 8.95 | 32.9 | −0.881 | −1.37 | −1.87 | 0.9989 | |

| 30 | 16.4 | 64.1 | −2.70 | −3.66 | −4.63 | 0.9819 | |

| Model | Parameter | Mg3Al | Mg3Al IL-COS | Mg3Al IL-US |

|---|---|---|---|---|

| Langmuir | qmL (mg/g) KL (L/mg) R2 | 334 0.00077 0.9712 | 648 0.00635 0.9987 | 320 0.00547 0.9905 |

| Freundlich | KF (mg1−1/n L1/n/g) 1/n R2 | 0.0922 0.155 0.9935 | 7.25 0.770 0.9948 | 4.16 0.698 0.9700 |

| Sips | qmS (mg/g) KS (Lm/mgm) m R2 | 143 0.00008 1.62 0.9982 | 628 0.00635 1.01 0.9987 | 217 0.00207 1.39 0.9974 |

| Adsorbent Materials | pH | qm (mg/g) | References |

|---|---|---|---|

| MgAl/layered double hydroxide supported on Syagrus coronata biochar | 5.65 | 168 | [3] |

| Organobentonite with hexadecyltrimethylammonium (OBHDTMA) | 7.0 | 388 | [25] |

| GAC | 4.0 | 6.847 | [27] |

| Alginate/Carbon-based Films | 3.0 | 29.9 | [28] |

| MgAl-CO3 | 10 | 562.4 | [33] |

| K10 montmorillonite intercalated with cetyltrimethyl-ammonium bromide cations | 7.0 | 55.46 | [38] |

| Zn Al—LDH | 7.0 | 94.32 | |

| ZnAl—LDH calcinated | 7.0 | 737.02 | |

| Mg3Al | 7.0 | 143 | Present paper |

| Mg3Al IL-US | 7.0 | 217 | |

| Mg3Al IL-COS | 7.0 | 628 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Țolea, S.N.; Cocheci, L.; Lupa, L.; Vodă, R.; Pode, R. Development of New Efficient Adsorbent by Functionalization of Mg3Al-LDH with Methyl Trialkyl Ammonium Chloride Ionic Liquid. Molecules 2021, 26, 7384. https://doi.org/10.3390/molecules26237384

Țolea SN, Cocheci L, Lupa L, Vodă R, Pode R. Development of New Efficient Adsorbent by Functionalization of Mg3Al-LDH with Methyl Trialkyl Ammonium Chloride Ionic Liquid. Molecules. 2021; 26(23):7384. https://doi.org/10.3390/molecules26237384

Chicago/Turabian StyleȚolea, Samuel Nick, Laura Cocheci, Lavinia Lupa, Raluca Vodă, and Rodica Pode. 2021. "Development of New Efficient Adsorbent by Functionalization of Mg3Al-LDH with Methyl Trialkyl Ammonium Chloride Ionic Liquid" Molecules 26, no. 23: 7384. https://doi.org/10.3390/molecules26237384

APA StyleȚolea, S. N., Cocheci, L., Lupa, L., Vodă, R., & Pode, R. (2021). Development of New Efficient Adsorbent by Functionalization of Mg3Al-LDH with Methyl Trialkyl Ammonium Chloride Ionic Liquid. Molecules, 26(23), 7384. https://doi.org/10.3390/molecules26237384