Sustainability Evaluation of Immobilized Acid-Adapted Microalgal Technology in Acid Mine Drainage Remediation following Emergy and Carbon Footprint Analysis

Abstract

:1. Introduction

2. Results and Discussion

2.1. Emergy Flow in Immobilized Acid-Adapted Microalgal System

2.2. Emergy Indices of Acid-Adapted Microalgal System

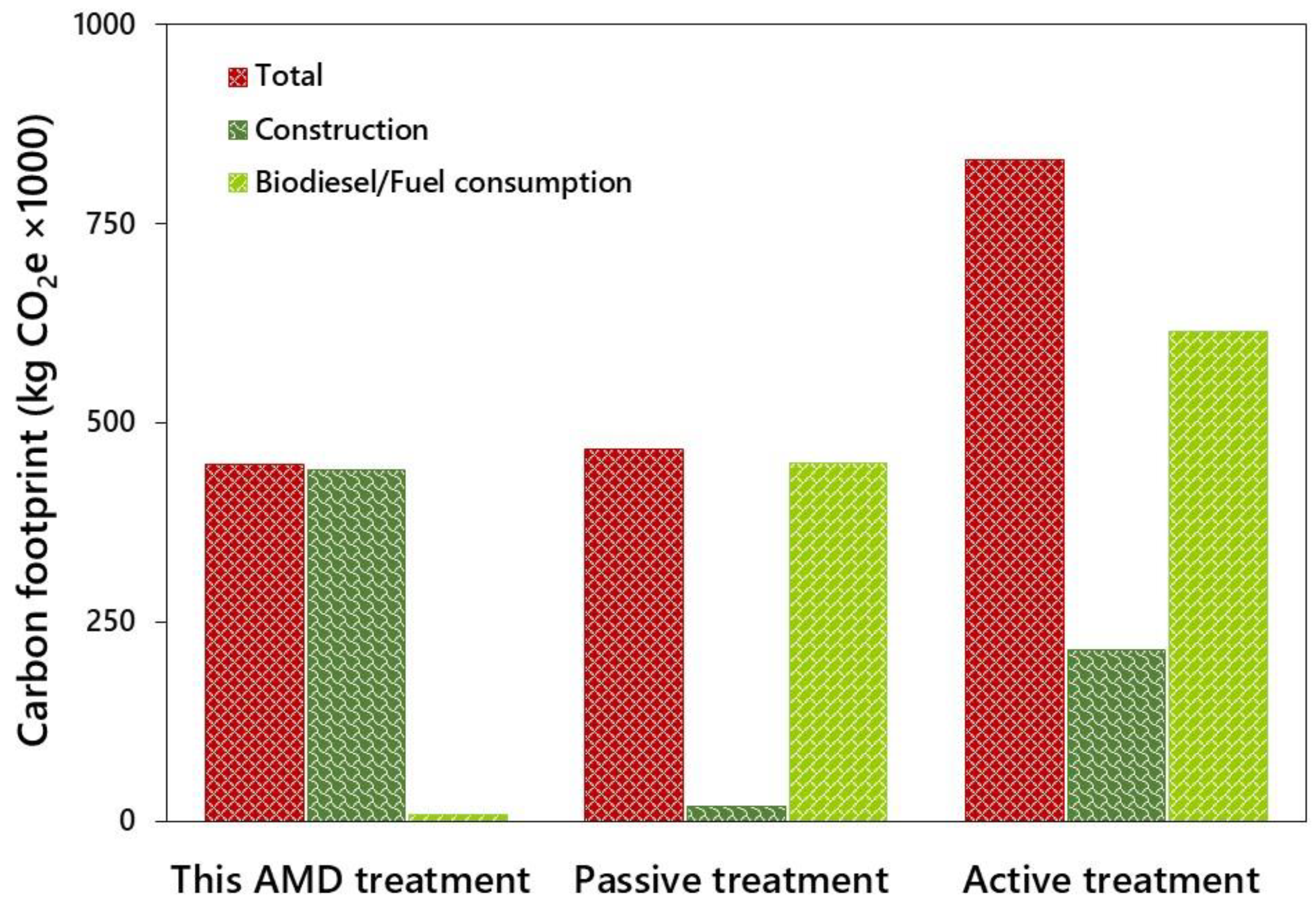

2.3. Carbon Foot Printing of Acid-Adapted Microalgal System

3. Materials and Methods

3.1. Emergy Accounting

3.2. Net Emergy and Emergy Yield Ratio

3.3. Environmental Loading Ratio

3.4. Emergy Sustainability Index

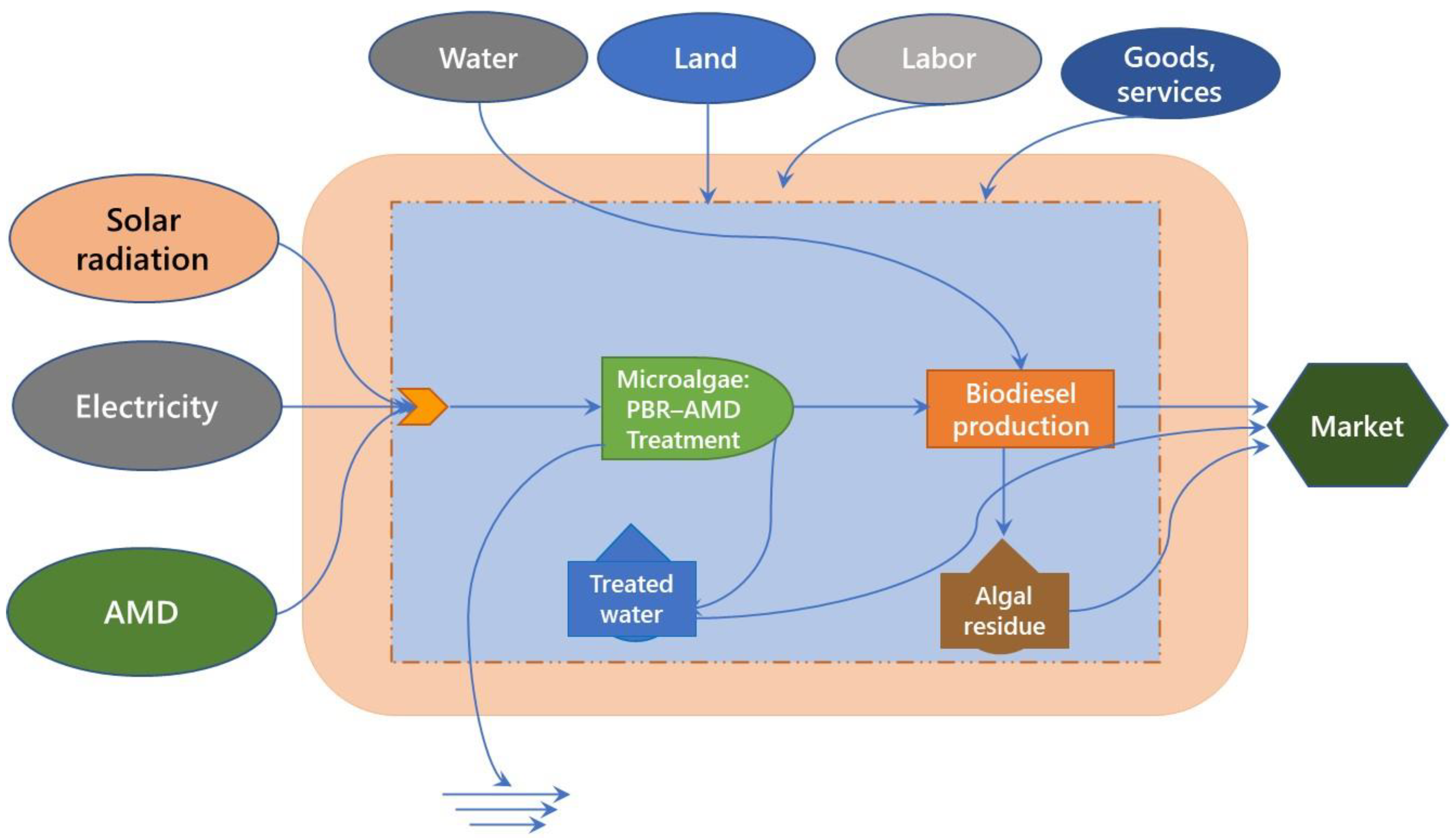

3.5. System Boundary of Acid-Adapted Microalgae in AMD Treatment

3.6. Carbon Footprint Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Abinandan, S.; Subashchandrabose, S.R.; Venkateswarlu, K.; Megharaj, M. Microalgae–bacteria biofilms: A sustainable synergistic approach in remediation of acid mine drainage. Appl. Microbiol. Biotechnol. 2018, 102, 1131–1144. [Google Scholar] [CrossRef] [PubMed]

- Johnson, D.B.; Hallberg, K.B. Acid mine drainage remediation options: A review. Sci. Total Environ. 2005, 338, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Simate, G.S.; Ndlovu, S. Acid mine drainage: Challenges and opportunities. J. Environ. Chem. Eng. 2014, 2, 1785–1803. [Google Scholar] [CrossRef]

- Abinandan, S.; Subashchandrabose, S.R.; Venkateswarlu, K.; Megharaj, M. Sustainable iron recovery and biodiesel yield by acid-adapted microalgae, Desmodesmus sp. MAS1 and Heterochlorella sp. MAS3, grown in synthetic acid mine drainage. Acs Omega 2020, 5, 6888–6894. [Google Scholar] [CrossRef] [Green Version]

- Martínez, N.M.; Basallote, M.D.; Meyer, A.; Cánovas, C.R.; Macías, F.; Schneider, P. Life cycle assessment of a passive remediation system for acid mine drainage: Towards more sustainable mining activity. J. Clean. Prod. 2019, 211, 1100–1111. [Google Scholar] [CrossRef]

- Nleya, Y.; Simate, G.S.; Ndlovu, S. Sustainability assessment of the recovery and utilisation of acid from acid mine drainage. J. Clean. Prod. 2016, 113, 17–27. [Google Scholar] [CrossRef]

- Rosso, D.; Bolzonella, D. Carbon footprint of aerobic biological treatment of winery wastewater. Water Sci. Technol. 2009, 60, 1185–1189. [Google Scholar] [CrossRef]

- Abinandan, S.; Shanthakumar, S. Challenges and opportunities in application of microalgae (Chlorophyta) for wastewater treatment: A review. Renew. Sustain. Energy Rev. 2015, 52, 123–132. [Google Scholar] [CrossRef]

- Al Ketife, A.M.; Judd, S.; Znad, H. Optimization of cultivation conditions for combined nutrient removal and CO2 fixation in a batch photobioreactor. J. Chem. Technol. Biotechnol. 2017, 92, 1085–1093. [Google Scholar] [CrossRef] [Green Version]

- Abinandan, S.; Subashchandrabose, S.R.; Venkateswarlu, K.; Megharaj, M. Nutrient removal and biomass production: Advances in microalgal biotechnology for wastewater treatment. Crit. Rev. Biotechnol. 2018, 38, 1244–1260. [Google Scholar] [CrossRef]

- Naderi, G.; Znad, H.; Tade, M.O. Investigating and modelling of light intensity distribution inside algal photobioreactor. Chem. Eng. Process. 2017, 122, 530–537. [Google Scholar] [CrossRef]

- Judd, S.J.; Al Momani, F.; Znad, H.; Al Ketife, A. The cost benefit of algal technology for combined CO2 mitigation and nutrient abatement. Renew. Sustain. Energy Rev. 2017, 71, 379–387. [Google Scholar] [CrossRef] [Green Version]

- Hena, S.; Znad, H.; Heong, K.; Judd, S. Dairy farm wastewater treatment and lipid accumulation by Arthrospira Platensis. Water Res. 2018, 128, 267–277. [Google Scholar] [CrossRef]

- Almomani, F.; Al Ketife, A.; Judd, S.; Shurair, M.; Bhosale, R.R.; Znad, H.; Tawalbeh, M. Impact of CO2 concentration and ambient conditions on microalgal growth and nutrient removal from wastewater by a photobioreactor. Sci. Total Environ. 2019, 662, 662–671. [Google Scholar] [CrossRef] [Green Version]

- ISO 14040: Environmental Management-Life Cycle Assessment-Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 1997.

- US EPA. Inventory of US Greenhouse Gas Emissions and Sinks: 1990–2009; US Environmental Protection Agency: Washington, DC, USA, 2011.

- Hengen, T.J.; Squillace, M.K.; O’Sullivan, A.D.; Stone, J.J. Life cycle assessment analysis of active and passive acid mine drainage treatment technologies. Resour. Conserv. Recycl. 2014, 86, 160–167. [Google Scholar] [CrossRef]

- Maiolo, S.; Cristiano, S.; Gonella, F.; Pastres, R. Ecological sustainability of aquafeed: An emergy assessment of novel or underexploited ingredients. J. Clean. Prod. 2021, 294, 126266. [Google Scholar] [CrossRef]

- Odum, H.T. Systems Ecology: An Introduction; Wiley and Sons: Hoboken, NJ, USA, 1983; ISBN 0471652776. [Google Scholar]

- Zhang, M.; Wang, Z.; Xu, C.; Jiang, H. Embodied energy and emergy analyses of a concentrating solar power (CSP) system. Energy Policy 2012, 42, 232–238. [Google Scholar] [CrossRef]

- Amaral, L.P.; Martins, N.; Gouveia, J.B. A review of emergy theory, its application and latest developments. Renew. Sustain. Energy Rev. 2016, 54, 882–888. [Google Scholar] [CrossRef]

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Ren, J.; Chen, Q.; Liu, W.; Zhu, X. Co-benefits accounting for the implementation of eco-industrial development strategies in the scale of industrial park based on emergy analysis. Renew. Sustain. Energy Rev. 2018, 81, 1522–1529. [Google Scholar] [CrossRef]

- Björklund, J.; Geber, U.; Rydberg, T. Emergy analysis of municipal wastewater treatment and generation of electricity by digestion of sewage sludge. Resour. Conserv. Recycl. 2001, 31, 293–316. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, S.; Wu, J.; Jiang, W. A sustainability analysis of a municipal sewage treatment ecosystem based on emergy. Ecol. Eng. 2010, 36, 685–696. [Google Scholar] [CrossRef]

- Abinandan, S.; Praveen, K.; Subashchandrabose, S.R.; Venkateswarlu, K.; Megharaj, M. Life cycle assessment for the environmental sustainability of the immobilized acid-adapted microalgal technology in iron removal from acid mine drainage. Acs Sustain. Chem. 2020, 8, 15670–15677. [Google Scholar] [CrossRef]

- Wiedmann, T. Carbon footprint and input–output analysis–an introduction. Econ. Syst. Res. 2009, 21, 175–186. [Google Scholar] [CrossRef]

- Winfrey, B.; Nairn, R.; Tilley, D.; Strosnider, W. Emergy and carbon footprint analysis of the construction of passive and active treatment systems for net alkaline mine drainage. Mine Water Environ. 2015, 34, 31–41. [Google Scholar] [CrossRef]

- NGER. National Greenhouse and Energy Reporting Scheme Measurement-Technical Guidelines for the Estimation of Emissions by Facilities in Australia (August 2016); Department of the Environment and Energy, Australian Government: Canberra, Australia, 2016. Available online: https://www.environment.gov.au (accessed on 12 December 2021).

- da Cruz, R.V.A.; do Nascimento, C.A.O. Emergy analysis of oil production from microalgae. Biomass Bioenergy 2012, 47, 418–425. [Google Scholar] [CrossRef]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; John Wiley & Sons: New York, NY, USA, 1996; ISBN 9780471114420. [Google Scholar]

- Alizadeh, S.; Zafari-Koloukhi, H.; Rostami, F.; Rouhbakhsh, M.; Avami, A. The eco-efficiency assessment of wastewater treatment plants in the city of Mashhad using emergy and life cycle analyses. J. Clean. Prod. 2020, 249, 119327. [Google Scholar] [CrossRef]

- Jarméus, C. Emergy Analysis of Biodiesel and Biogas Production from Baltic Sea Macro Algae. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2013. [Google Scholar]

- Shao, L.; Chen, G. Renewability assessment of a production system: Based on embodied energy as emergy. Renew. Sustain. Energy Rev. 2016, 57, 380–392. [Google Scholar] [CrossRef]

- Yang, H.; Li, S. Emergy analysis of cassava vinasse treatment. Process Saf. Environ. Prot. 2013, 91, 503–507. [Google Scholar] [CrossRef]

- Brown, M.; Ulgiati, S. Emergy Analysis and Environmental Accounting. In Encyclopedia of Energy; Elsevier: Oxford, UK, 2004; p. 354. [Google Scholar]

- Brown, M.T.; Ulgiati, S. Emergy evaluations and environmental loading of electricity production systems. J. Clean. Prod. 2002, 10, 321–334. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Vilpas, R.; Mattila, T. Comparison of carbon footprints and eutrophication impacts of rural on-site wastewater treatment plants in Finland. J. Clean. Prod. 2014, 65, 439–446. [Google Scholar] [CrossRef]

- Gusek, J.; Josselyn, L.; Agster, W.; Lofholm, S.; Millsap, D. In Process selection and design of a passive treatment system for the Empire Mine State Historic Park. In Proceedings of the 28th National Conference ASMR, Bismarck, ND, USA, 11–16 June 2011; pp. 232–253. [Google Scholar]

- Hau, J.L.; Bakshi, B.R. Promise and problems of emergy analysis. Ecol. Model. 2004, 178, 215–225. [Google Scholar] [CrossRef]

- Carraretto, C.; Macor, A.; Mirandola, A.; Stoppato, A.; Tonon, S. Biodiesel as alternative fuel: Experimental analysis and energetic evaluations. Energy 2004, 29, 2195–2211. [Google Scholar] [CrossRef]

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Changes in Atmospheric Constituents and in Radiative Forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., H.L. Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Marceau, M.L.; Nisbet, M.A.; Van Geem, M.G. Life Cycle Inventory of Portland Cement Concrete; Portland Cement Association: Skokie, IL, USA, 2007. [Google Scholar]

- IPCC. Emissions Factor Database. In Emissions Factor Database; IPCC: Kyoto, Japan, 2006; Available online: http://www.ipcc-nggip.iges.or.jp/EFDB/main.php (accessed on 12 December 2021).

- US EPA (US Environmental Protection Agency). Emissions Factors for Greenhouse Gas Inventories; US EPA: Washington, DC, USA, 2011.

- National Greenhouse and Energy Reporting. Emissions and Energy Threshold Calculator User Guide. 2021. Available online: http://www.cleanenergyregulator.gov.au/DocumentAssets/Pages/NGER-Emissions-and-Energy-Threshold-Calculator-2020-21.aspx (accessed on 20 December 2021).

| Type of Flow | Item of Emergy Flow (Unit) | Unit Value | Transformity (Sej/Unit) | Emergy (Sej/y) | Reference |

|---|---|---|---|---|---|

| R | Locally available renewable inputs | ||||

| Solar energy (J) | 3.69 × 1013 | 1.00 | 3.69 × 1013 | [30] | |

| AMD inflow (J) | 2.35 × 109 | 3.80 × 106 | 8.92 × 1015 | [23] | |

| N | Locally available non-renewable inputs | ||||

| Land use (m2) | 1.00 × 104 | 8.67 × 1010 | 8.67 × 1014 | [31] | |

| Water for Biodiesel (J) | 4.32 × 107 | 7.30 × 106 | 3.15 × 1014 | [32] | |

| F | Imported inputs in AMD treatment | ||||

| Algal biomass— Inoculum (g) | 1.58 × 109 | 3.16 × 107 | 5.00 × 1016 | [29] | |

| PBR − PVC (g) | 1.62 × 107 | 9.09 × 109 | 1.48 × 1017 | [18] | |

| Electricity (J) | 3.85 × 107 | 1.19 × 105 | 4.58 × 1012 | [32] | |

| PBR steel (g) | 2.40 × 108 | 1.80 × 109 | 4.32 × 1017 | ||

| PBR concrete (g) | 1.02 × 106 | 1.09 × 109 | 1.11 × 1015 | ||

| Labor (J) | 2.19 × 103 | 7.44 × 106 | 1.63 × 1010 | ||

| Y | Output after treatment | ||||

| Algal wet weight | 1.62 × 109 | 9.07 × 107 | 1.47 × 1017 | [32] | |

| Treated AMD outflow (J) | 2.35 × 109 | 4.99 × 106 | 1.17 × 1016 | [33] | |

| F | Imported inputs in Biodiesel production | ||||

| Steel (g) | 1.94 × 104 | 1.80 × 109 | 3.50 × 1013 | [32] | |

| Concrete (g) | 1.75 × 105 | 1.09 × 109 | 1.91 × 1014 | ||

| Electricity (J) | 2.31 × 109 | 1.19 × 105 | 1.20 × 1014 | ||

| Methanol (g) | 2.89 × 105 | 2.28 × 108 | 6.58 × 1013 | ||

| HCl (g) | 2.15 × 106 | 3.64 × 109 | 7.84 × 1015 | ||

| Services ($) | 1.09 × 105 | 2.22 × 1012 | 2.42 × 1017 | ||

| Labor (J) | 1.53 × 1010 | 7.44 × 106 | 1.14 × 1017 | ||

| Diesel for transportation (J) | 4.39 × 109 | 1.21 × 105 | 5.31 × 1014 | ||

| Y | Output after biodiesel production | ||||

| Residue (g) | 1.60 × 109 | 5.22 × 108 | 8.37 × 1017 | [32] | |

| Algal biodiesel (g) | 1.62 × 107 | 1.69 × 1010 | 2.74 × 1017 |

| Emergy Index | Unit/Formula | Value | ||

|---|---|---|---|---|

| This Study | PTS * | ATS * | ||

| Natural renewable | (1015 sej) | 8.96 | 134 | 25 |

| Natural non-renewable | (1015 sej) | 1.18 | NA | NA |

| Imported inputs | (1015 sej) | 996 | 1800 | 2500 |

| Yield | (1015 sej) | 1270 | NA | NA |

| Total potential energy (Ep) | R + N + F (1015 sej) | 1010 | 1900 | 2500 |

| Transformity | Y/Ep | 1.26 | NA | NA |

| EYR | (R + F)/F | 1.01 | 1.08 | 1.01 |

| ELR | (F + N)/R | 111 | 13 | 100 |

| ESI | EYR/ELR | 0.01 | 0.08 | 0.01 |

| % Renewability | R/(F + R) × 100 | 0.89 | 6.92 | 0.99 |

| Process (Transport) | Input | GHG Emissions (Scope 1) | Total Scope 1 Emission | Total Energy GJ | ||

| CO2 | CH4 | N2O | ||||

| This study | 0.317 kL diesel oil | 1 | 0 | 0 | 1 | 12 |

| PTS | 32.50 kL diesel oil | 88 | 0 | 1 | 89 | 1255 |

| 3.23 kL gasoline | 7 | 0 | 0 | 7 | 110 | |

| 96 | 1365 | |||||

| ATS | 47.50 kL diesel oil | 128 | 0 | 1 | 129 | 1834 |

| 6.22 kL gasoline | 14 | 0 | 0 | 14 | 213 | |

| 143 | 2046 | |||||

| Process (Purchased Electricity) | Input | Emission Factor | Total Scope 2 Emission | Total Energy GJ | ||

| (NSW, Australia) | ||||||

| This study | 10.69 kWh | 0.81 | 0 | 0 | ||

| 641 kWh | 1 | 2 | ||||

| PTS | – | 0.81 | – | – | ||

| ATS | – | 0.81 | – | – | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Praveen, K.; Abinandan, S.; Venkateswarlu, K.; Megharaj, M. Sustainability Evaluation of Immobilized Acid-Adapted Microalgal Technology in Acid Mine Drainage Remediation following Emergy and Carbon Footprint Analysis. Molecules 2022, 27, 1015. https://doi.org/10.3390/molecules27031015

Praveen K, Abinandan S, Venkateswarlu K, Megharaj M. Sustainability Evaluation of Immobilized Acid-Adapted Microalgal Technology in Acid Mine Drainage Remediation following Emergy and Carbon Footprint Analysis. Molecules. 2022; 27(3):1015. https://doi.org/10.3390/molecules27031015

Chicago/Turabian StylePraveen, Kuppan, Sudharsanam Abinandan, Kadiyala Venkateswarlu, and Mallavarapu Megharaj. 2022. "Sustainability Evaluation of Immobilized Acid-Adapted Microalgal Technology in Acid Mine Drainage Remediation following Emergy and Carbon Footprint Analysis" Molecules 27, no. 3: 1015. https://doi.org/10.3390/molecules27031015

APA StylePraveen, K., Abinandan, S., Venkateswarlu, K., & Megharaj, M. (2022). Sustainability Evaluation of Immobilized Acid-Adapted Microalgal Technology in Acid Mine Drainage Remediation following Emergy and Carbon Footprint Analysis. Molecules, 27(3), 1015. https://doi.org/10.3390/molecules27031015