Effect of Molar Substitution on the Properties of γ-Hydroxypropyl Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of γ-HPS

2.3. Determination of MS

2.4. Wide-Angle X-ray Diffractometry

2.5. Scanning Electron Microscopy

2.6. Thermal Characterization

2.7. Transmittance

2.8. Starch Solubility

2.9. Retrogradation

2.10. Freeze–Thaw Stability

2.11. Apparent Viscosity

3. Results and Discussion

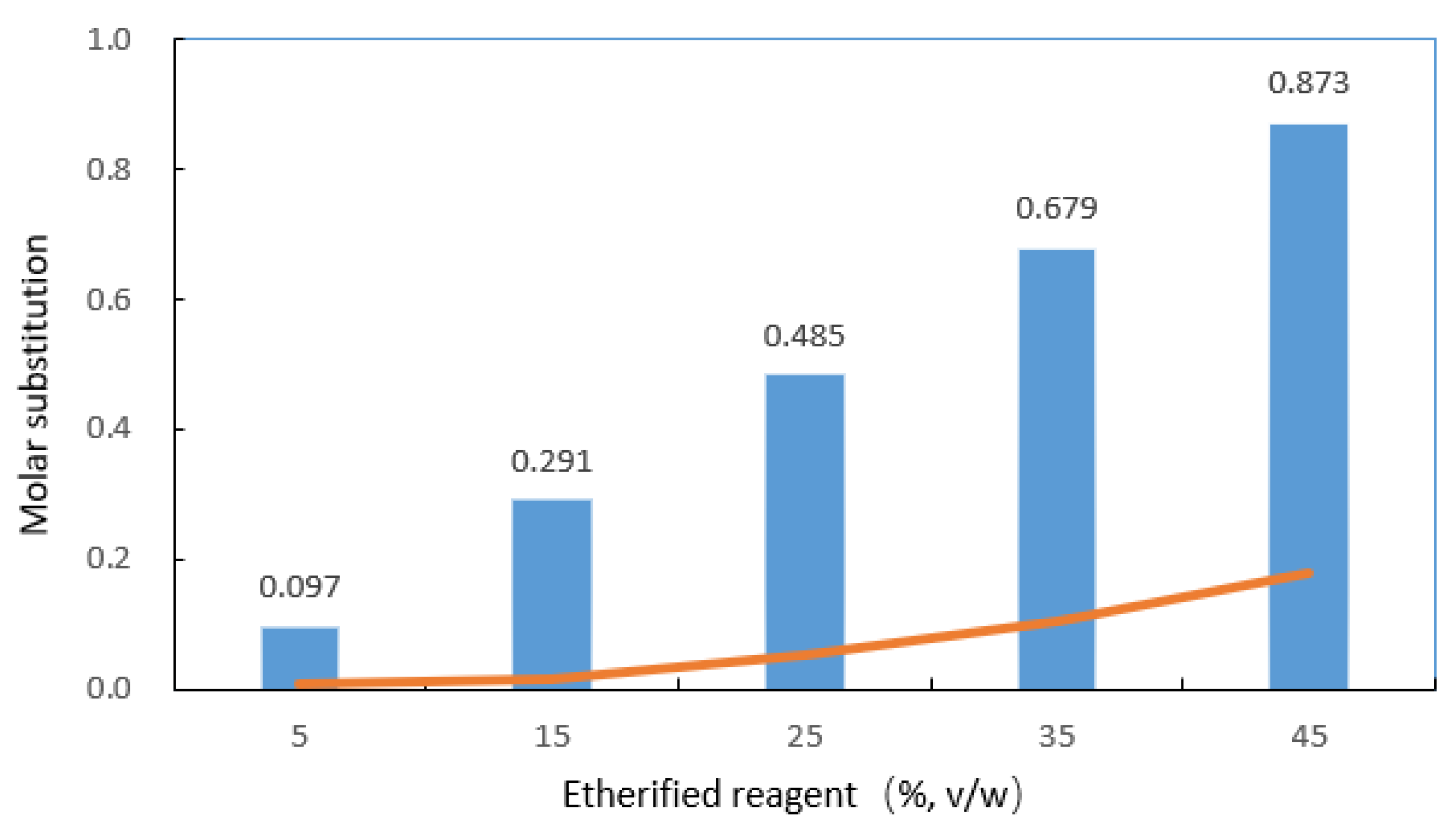

3.1. MS and Reaction Efficiency

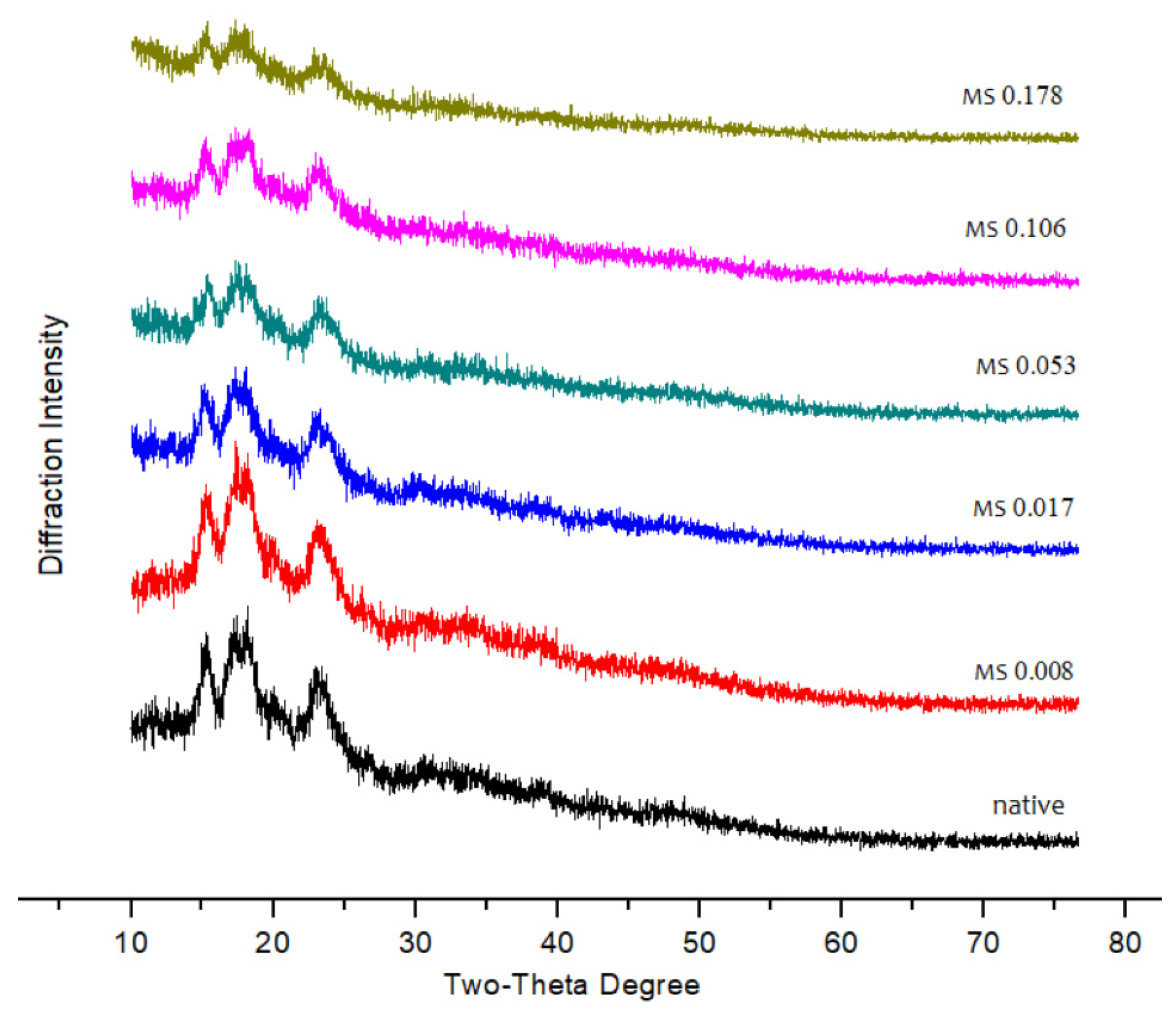

3.2. Wide-Angle X-ray Diffraction Pattern

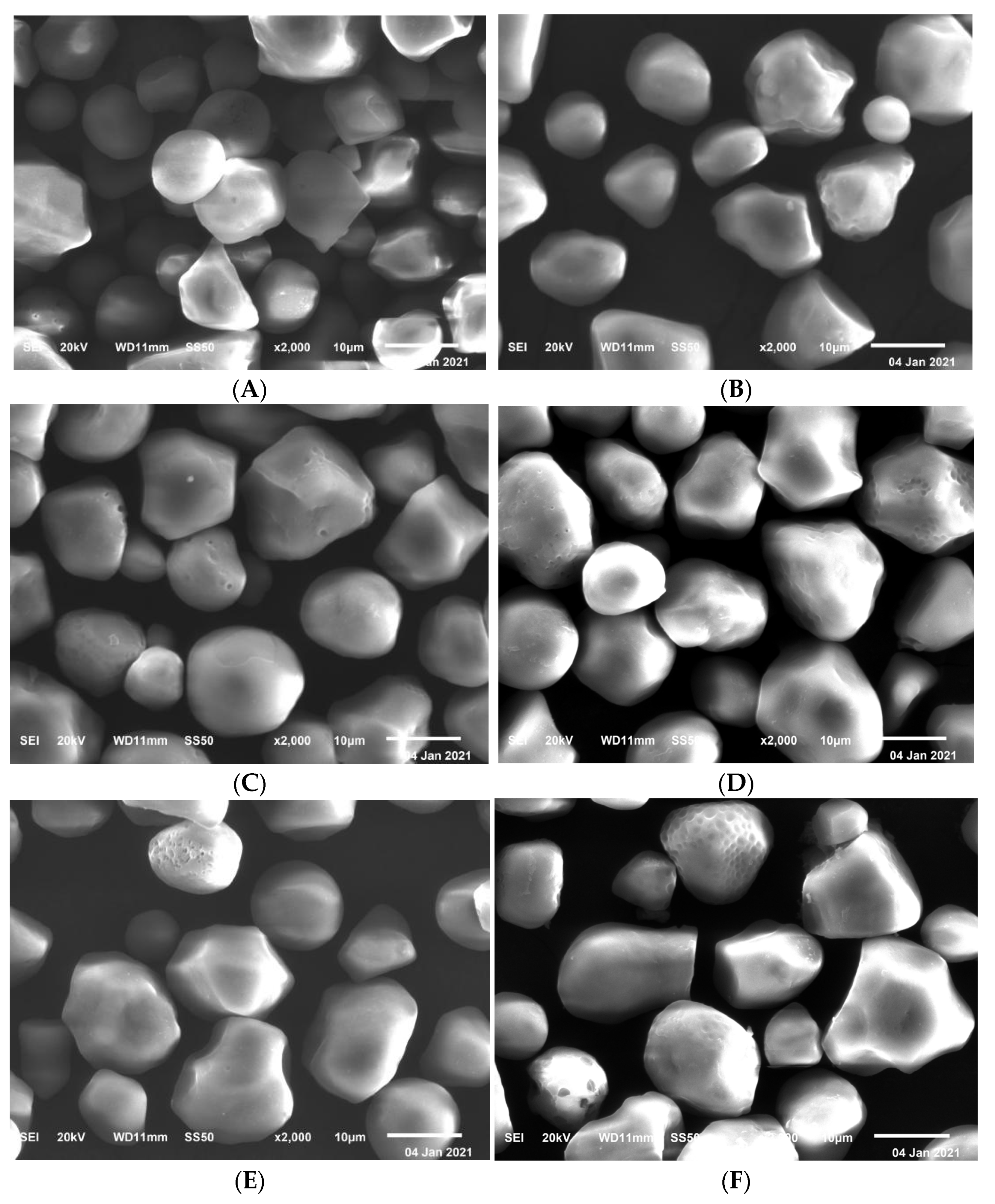

3.3. Morphology of γ-HPS

3.4. Thermal Properties

3.5. Paste Clarity

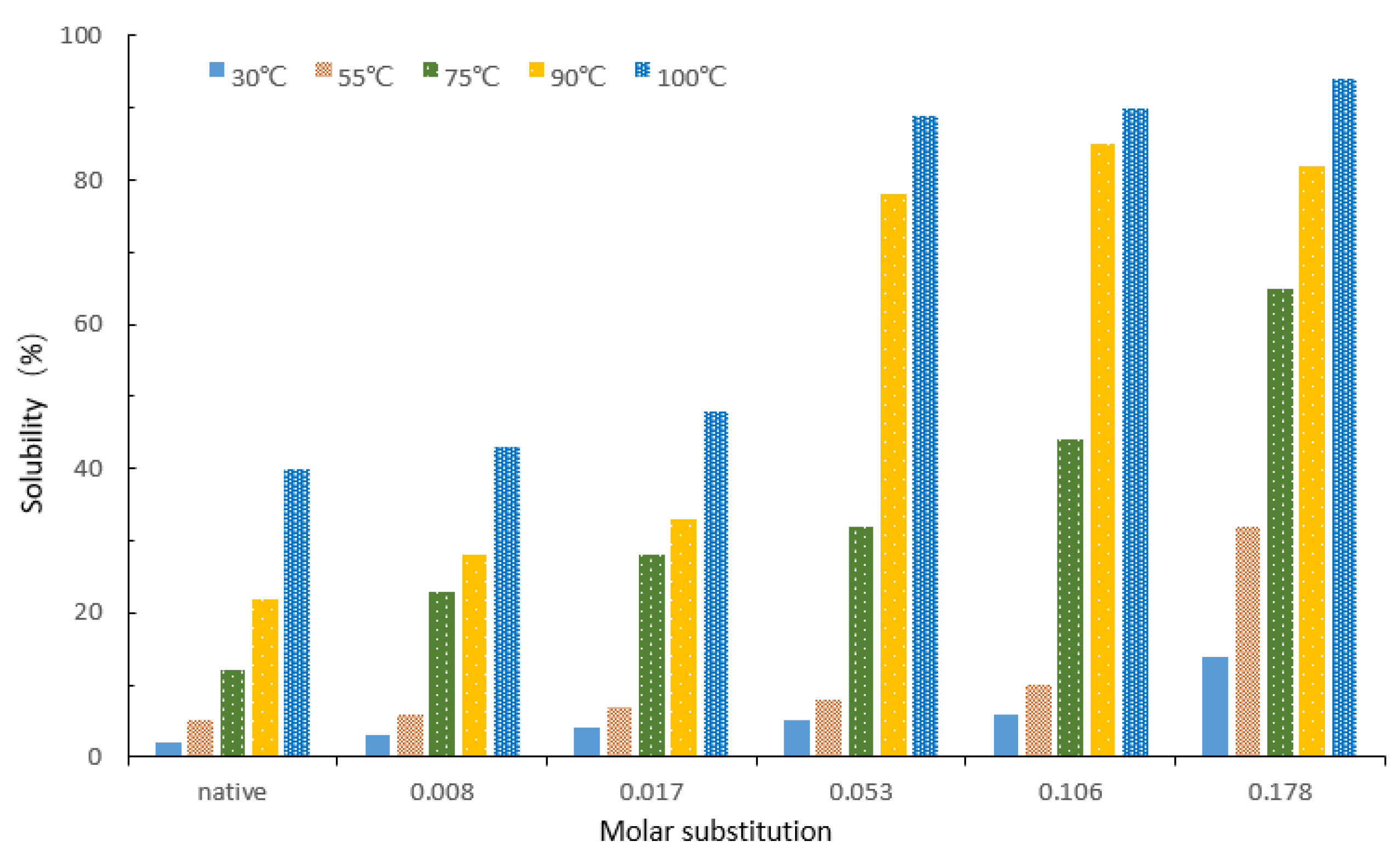

3.6. Solubility

3.7. Freeze–Thaw Stability

3.8. Retrogradation

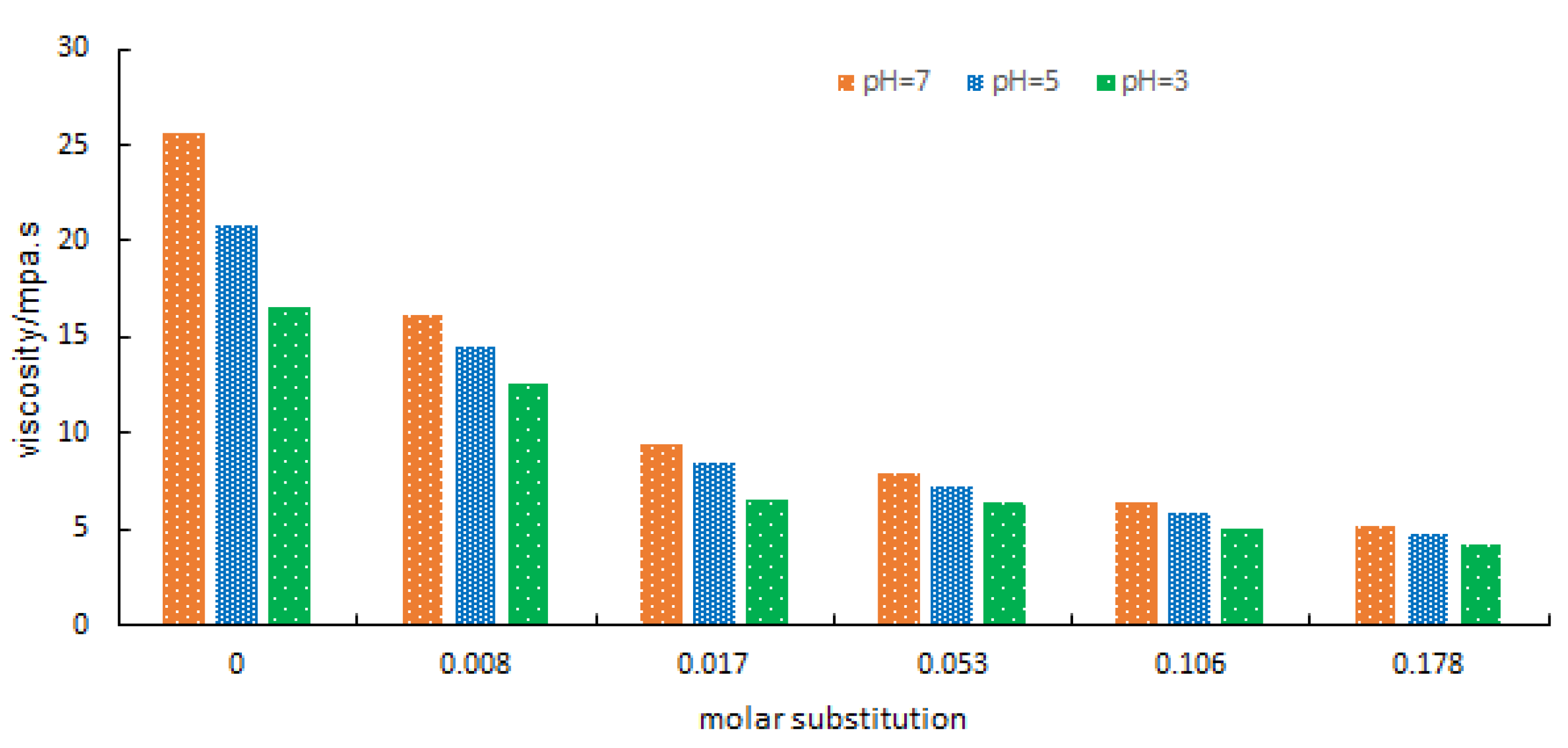

3.9. Apparent Viscosity and Acid Resistivity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Bangar, S.P.; Whiteside, W.S.; Ashogbon, A.O.; Kumar, M. Recent advances in thermoplastic starches for food packaging: A review. Food Packag. Shelf Life 2021, 30, 100743. [Google Scholar] [CrossRef]

- Garcia, M.A.V.T.; Garcia, C.F.; Faraco, A.A.G. Pharmaceutical and Biomedical Applications of Native and Modified Starch: A Review. Starch 2020, 72, 1900270. [Google Scholar] [CrossRef]

- Gilet, A.; Quettier, C.; Wiatz, V.; Bricout, H.; Ferreira, M.; Rousseau, C.; Monflier, E.; Tilloy, S. Unconventional media and technologies for starch etherification and esterification. Green Chem. 2018, 20, 1152–1168. [Google Scholar] [CrossRef]

- Masina, N.; Choonara, Y.E.; Kumar, P.; Toit, L.C.D.; Govender, M.; Indermun, S.; Pillay, V. A review of the chemical modification techniques of starch. Carbohydr. Polym. 2017, 157, 1226–1236. [Google Scholar] [CrossRef]

- Zia-ud-Din; Xiong, H.G.; Peng, F. Physical and Chemical Modification of Starches: A Review. Crit. Rev. Food Sci. 2015, 57, 2691–2705. [Google Scholar] [CrossRef]

- Yan, Y.; Feng, L.; Shi, M.; Cui, C.; Liu, Y. Effect of plasma-activated water on the structure and in vitro digestibility of waxy and normal maize starches during heat-moisture treatment. Food Chem. 2020, 306, 125589. [Google Scholar] [CrossRef]

- Tang, H.T.; Tang, H.B.; Li, Y.P. Synthesis, Optimization, Characterization and Property of Oxidized Hydroxypropyl Mung Bean Starch. J. Food Process. Preserv. 2017, 41, e12763. [Google Scholar]

- Shen, Y.; Zhang, N.; Xu, Y.R.; Huang, J.J.; Yuan, M.A.; Wu, D.X.; Shu, X.L. Physicochemical properties of hydroxypropylated and cross-linked rice starches differential in amylose content. Int. J. Biol. Macromol. 2019, 128, 775–781. [Google Scholar] [CrossRef]

- Chen, Y.; Hao, Y.C.; Li, S.; Luo, Z.G.; Gao, Q.Y. Preparation of hydroxybutyl starch with a high degree of substitution and its application in temperature-sensitive hydrogels. Food Chem. 2021, 355, 129472. [Google Scholar] [CrossRef]

- Zhu, W.X.; Pan, J.H.; Yu, X.Y.; He, G.C.; Liu, C.; Yang, S.Y.; Zeng, Y.H.; Zeng, A.; Liu, T.T. The flotation separation of fluorite from calcite using hydroxypropyl starch as a depressant. Colloid Surf. A 2021, 616, 126168. [Google Scholar] [CrossRef]

- Fu, Z.; Zhang, L.; Ren, M.H.; Bemiller, J.N. Developments in Hydroxypropylation of Starch: A Review. Starch 2019, 71, 1800167. [Google Scholar] [CrossRef] [Green Version]

- Yeh, A.I.; Yeh, S.L. Some characteristics of hydroxypropylated and cross-linked rice starch. Cereal Chem. 1993, 70, 596–601. [Google Scholar]

- Lee, H.L.; Yoo, B. Effect of hydroxypropylation on physical and rheological properties of sweet potato starch. LWT-Food Sci. Technol. 2011, 44, 765–770. [Google Scholar] [CrossRef]

- Kim, H.Y.; Jane, J.L.; Lamsal, B. Hydroxypropylation improves film properties of high amylose corn starch. Ind. Crop. Prod. 2017, 95, 175–183. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.L.; Zhang, K.; Hu, Y.; Zhang, Z.J.; Chen, J.; Ma, T.L.; Wang, J.J. Determination of Molar Substitution of γ-Hydroxypropyl Starch. Starch 2020, 73, 2000013. [Google Scholar] [CrossRef]

- Schmitz, C.S.; Simas, K.N.D.; Santos, K.; Joao, J.J.; Amboni, R.D.D.M.C.; Amante, E.R. Cassava starch functional properties by etherification-hydroxypropylation. Int. J. Food Sci. Technol. 2010, 41, 681–687. [Google Scholar] [CrossRef]

- Chun, S.Y.; Yoo, B. Effect of Molar Substitution on Rheological Properties of Hydroxypropylated Rice Starch Pastes. Starch 2007, 59, 334–341. [Google Scholar] [CrossRef]

- Shao, K.; Han, B.Q.; Gao, J.N.; Song, F.L.; Yang, Y.; Liu, W.S. Synthesis and Characterization of a Hydroxyethyl Derivative of Chitosan and Evaluation of Its Biosafety. J. Ocean Univ. China 2015, 14, 703–709. [Google Scholar] [CrossRef]

- Chun, E.H.; Oh, S.M.; Kim, H.Y.; Kim, B.Y.; Baik, M.Y. Effect of high hydrostatic pressure treatment on conventional hydroxypropylation of maize starch. Carbohydr. Polym. 2016, 146, 328–336. [Google Scholar] [CrossRef]

- Reddy, I.; Seib, P.A. Paste properties of modified starches from partial waxy wheats. Cereal Chem. 1999, 76, 341–349. [Google Scholar] [CrossRef]

- El-Sheikh, M.A. Carboxymethylation of maize starch at mild conditions. Carbohydr. Polym. 2009, 79, 875–881. [Google Scholar] [CrossRef]

- Kaur, L.; Singh, N.; Singh, J. Factors influencing the properties of hydroxypropylated potato starches. Carbohydr. Polym. 2004, 55, 211–223. [Google Scholar] [CrossRef]

- Chuenkamol, B.; Puttanlek, C.; Rungsardthong, V.; Uttapap, D. Characterization of low-substituted hydroxypropylated canna starch. Food Hydrocoll. 2007, 21, 1123–1132. [Google Scholar] [CrossRef]

- Lawal, O.S. Hydroxypropylation of pigeon pea (Cajanus cajan) starch: Preparation, functional characterizations and enzymatic digestibility. LWT-Food Sci. Technol. 2011, 44, 771–778. [Google Scholar] [CrossRef] [Green Version]

- Lawal, O.S.; Ogundiran, O.O.; Adesogan, E.K.; Ogunsanwo, B.M.; Sosanwo, O.A. Effect of Hydroxypropylation on the Properties of White Yam (Dioscorea rotundata) Starch. Starch 2008, 60, 340–348. [Google Scholar] [CrossRef]

- Lawal, O.S.; Ogundiran, O.O.; Awokoya, K.; Ogunkunle, A.O. The low-substituted propylene oxide etherified plantain (Musa paradisiaca normalis) starch: Characterization and functional parameters. Carbohydr. Polym. 2008, 74, 717–724. [Google Scholar] [CrossRef]

- Han, J.A.; BeMiller, J.N. Influence of reaction conditions on MS values and physical properties of waxy maize starch derivatized by reaction with propylene oxide. Carbohydr. Polym. 2006, 64, 158–162. [Google Scholar] [CrossRef]

- Zhang, G.X.; She, Y.; You, Y.Q.; Yan, L.X.; Shi, B. The application of an advanced visualized method in synthesis process optimization of carboxymethyl hydroxyethyl starch. Carbohydr. Polym. 2010, 79, 673–676. [Google Scholar] [CrossRef]

- Yang, L.P.; Zhou, Y.B.; Wu, Y.M.; Meng, X.; Jiang, Y.M.; Zhang, H.W.; Wang, H.S. Preparation and physicochemical properties of three types of modified glutinous rice starches. Carbohydr. Polym. 2016, 137, 305–313. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Jackson, D.S. Phase transition of cross-linked and hydroxypropylated corn (Zea mays L.) starches. LWT-Food Sci. Technol. 2008, 41, 346–358. [Google Scholar] [CrossRef]

- Kittipongpatana, O.S.; Kittipongpatana, N. Preparation and physicochemical properties of modified jackfruit starches. LWT-Food Sci. Technol. 2011, 44, 1766–1773. [Google Scholar] [CrossRef]

- Balsamo, V.; Lopez-Carrasquero, F.; Laredo, E.; Conto, K.; Contreras, J.; Feijoo, J.L. Preparation and thermal stability of carboxymethyl starch/quaternary ammonium salts complexes. Carbohydr. Polym. 2011, 83, 1680–1689. [Google Scholar] [CrossRef]

- Li, Q.Q.; Liu, F.; Zhang, L.; Nelson, B.J.; Zhang, S.H.; Ma, C.; Tao, X.Y.; Cheng, J.P.; Zhang, X.B. In situ construction of potato starch-based carbon nanofiber/activated carbon hybrid structure for high-performance electrical double layer capacitor. J. Power Sources 2012, 207, 199–204. [Google Scholar] [CrossRef]

- Pal, J.; Singhal, R.S.; Kulkarni, P.R. Physicochemical properties of hydroxypropyl derivative from corn and amaranth starch. Carbohydr. Polym. 2002, 48, 49–53. [Google Scholar] [CrossRef]

- Aminian, M.; Nafchi, A.M.; Bolandi, M.; Alias, A.K. Preparation and characterization of high degree substituted sago (Metroxylon sagu) starch with propylene oxide. Starch 2013, 65, 686–693. [Google Scholar] [CrossRef]

- Wattanachant, S.; Muhammad, K.; Hashim, D.M.; Rahman, R.A. Effect of crosslinking reagents and hydroxypropylation levels on dual-modified sago starch properties. Food Chem. 2003, 80, 463–471. [Google Scholar] [CrossRef]

| Time/Sample 1 | Native | A | B | C | D | E |

|---|---|---|---|---|---|---|

| 6 h | 3.6% | - | - | - | - | - |

| 12 h | 12.5% | 2.2% | 1.3% | - | - | - |

| 24 h | 25.2% | 9.8% | 5.1% | 3.3% | - | - |

| 36 h | 36.1% | 21.5% | 13% | 7.6% | 4.6% | - |

| 48 h | 53.2% | 32.4% | 24.6% | 23.8% | 18.6% | 5.6% |

| 72 h | 59.5% | 43.2% | 36.8% | 27.6% | 25.2% | 10.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.-L.; Chen, Y.-F.; Yang, J.-J.; Li, S.-J.; Xie, H.-L.; Ma, T.-L. Effect of Molar Substitution on the Properties of γ-Hydroxypropyl Starch. Molecules 2022, 27, 2119. https://doi.org/10.3390/molecules27072119

Liu X-L, Chen Y-F, Yang J-J, Li S-J, Xie H-L, Ma T-L. Effect of Molar Substitution on the Properties of γ-Hydroxypropyl Starch. Molecules. 2022; 27(7):2119. https://doi.org/10.3390/molecules27072119

Chicago/Turabian StyleLiu, Xue-Li, Yi-Fan Chen, Jing-Jing Yang, Si-Jin Li, Hua-Le Xie, and Tian-Lin Ma. 2022. "Effect of Molar Substitution on the Properties of γ-Hydroxypropyl Starch" Molecules 27, no. 7: 2119. https://doi.org/10.3390/molecules27072119

APA StyleLiu, X.-L., Chen, Y.-F., Yang, J.-J., Li, S.-J., Xie, H.-L., & Ma, T.-L. (2022). Effect of Molar Substitution on the Properties of γ-Hydroxypropyl Starch. Molecules, 27(7), 2119. https://doi.org/10.3390/molecules27072119