Enhancement of Gaseous o-Xylene Elimination by Chlorosulfonic Acid-Modified H-Zeolite Socony Mobil-5

Abstract

1. Introduction

2. Results and Discussion

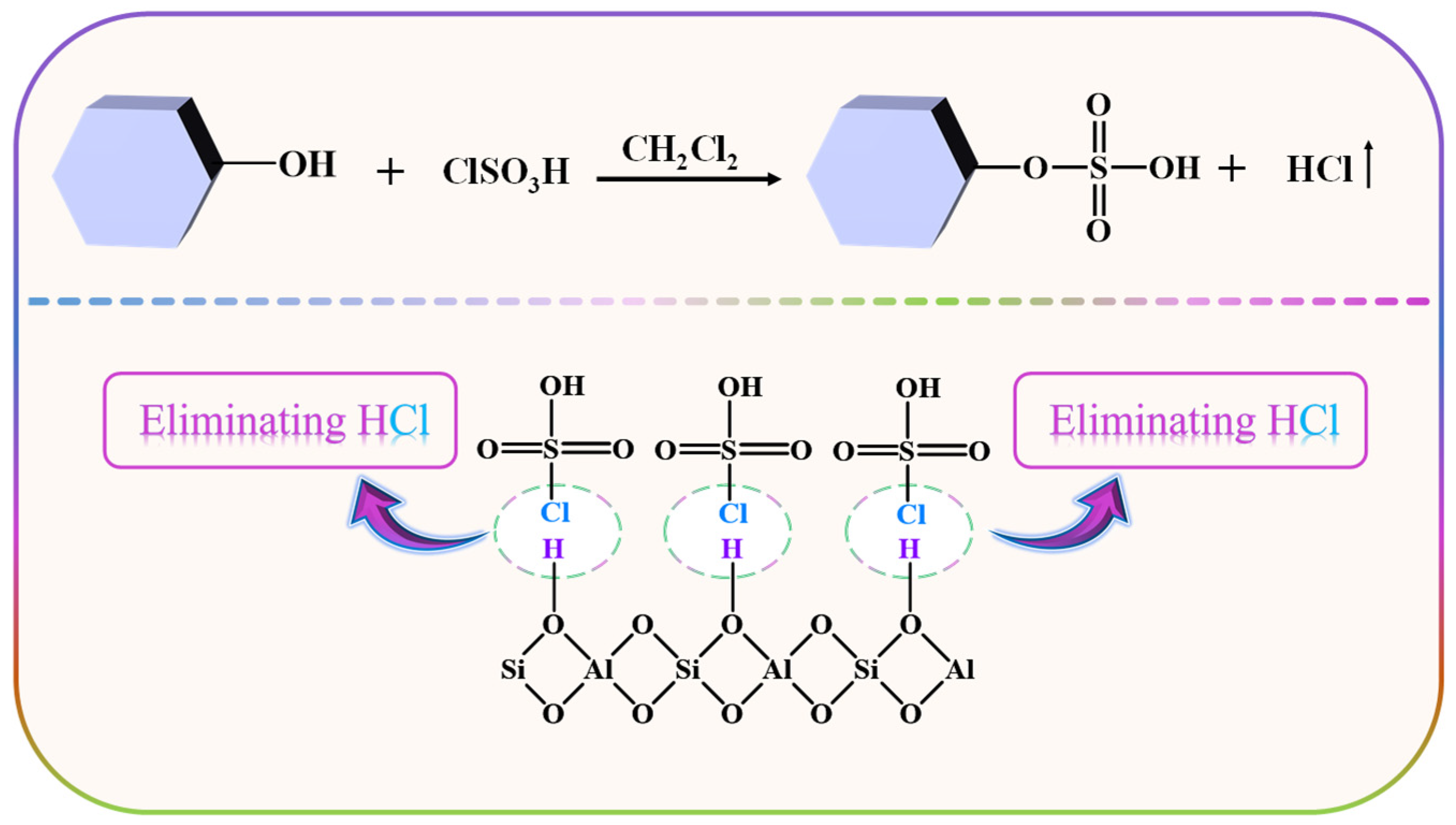

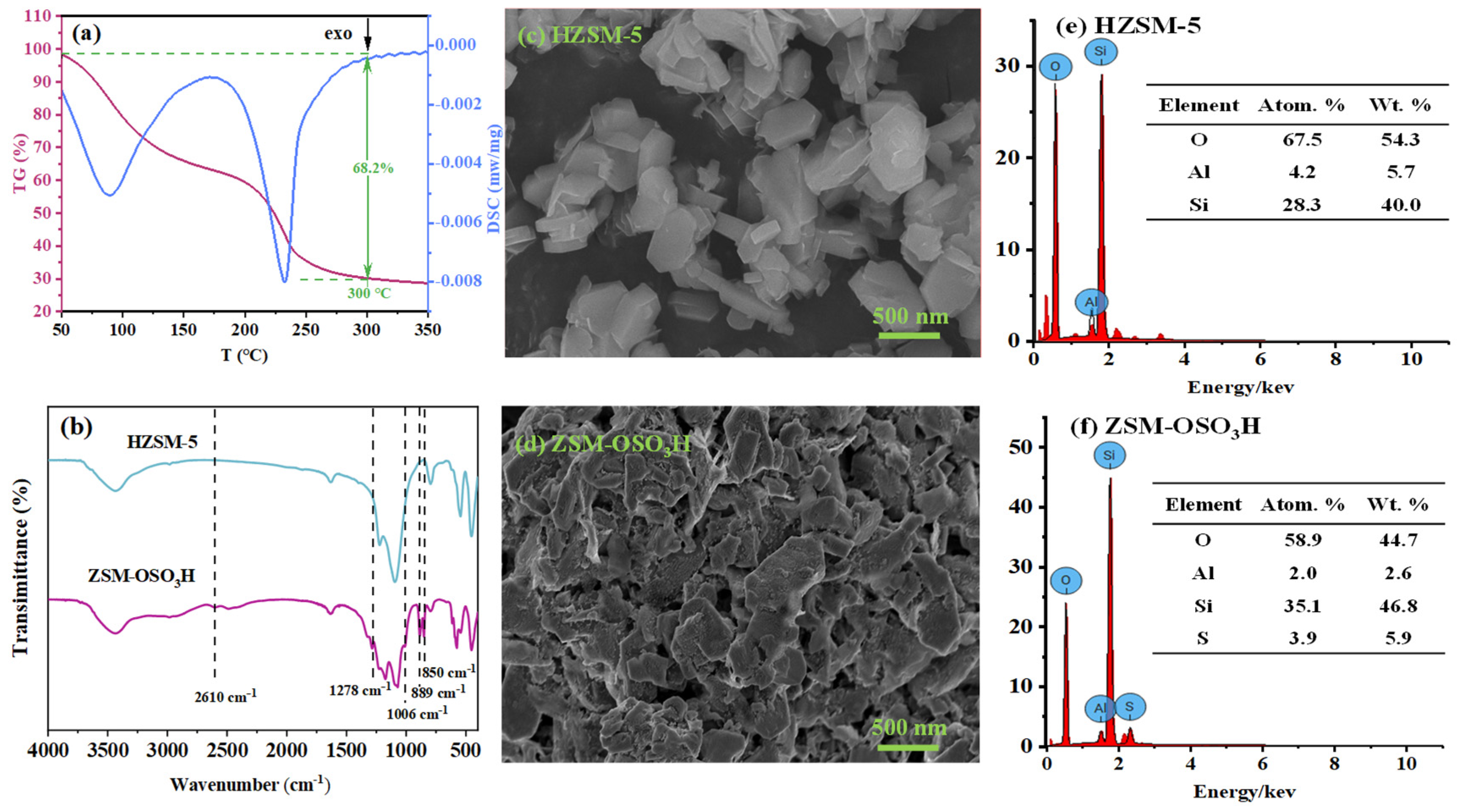

2.1. Structure and Basic Properties of Adsorbents

2.2. Enhanced Removal Performance of o-Xylene on ZSM−OSO3H

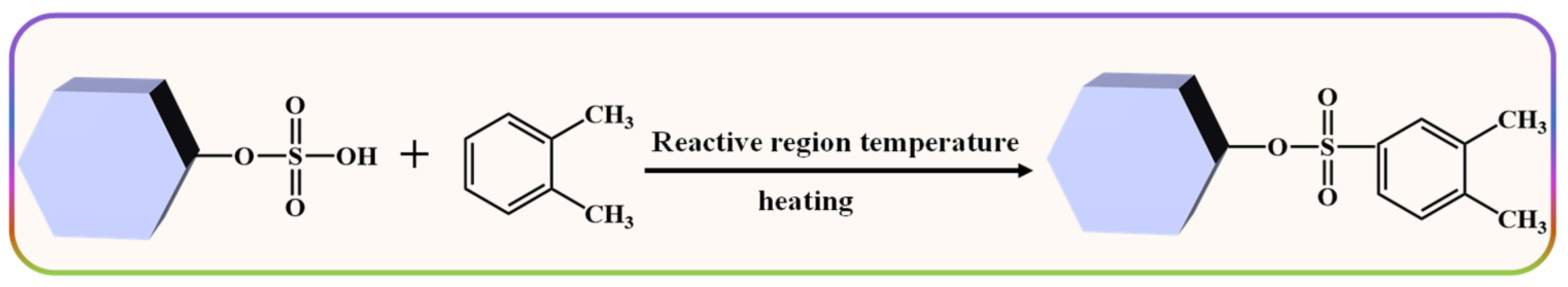

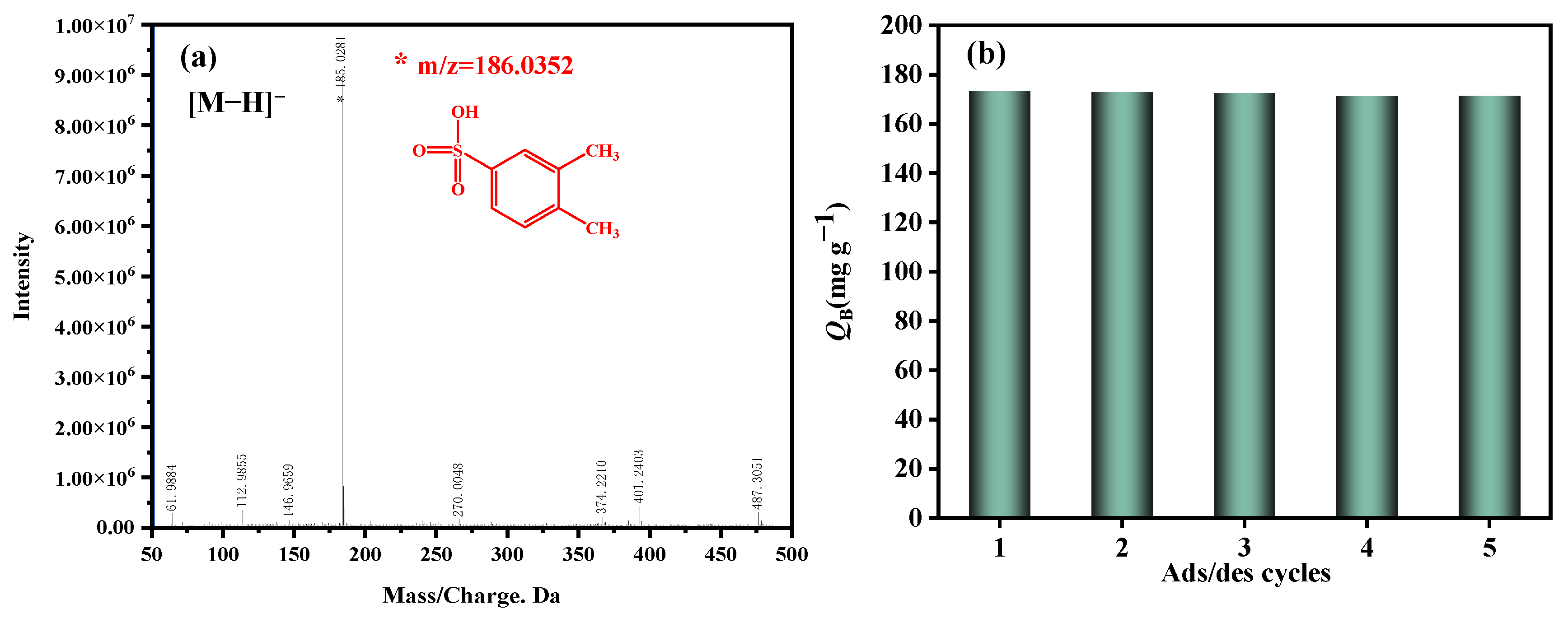

2.3. o-Xylene Reactive Adsorption and Reusability of ZSM−OSO3H

3. Materials and Methods

3.1. Materials and Chemicals

3.2. Adsorption Measurements

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, S.; Guenther, A.; Faiola, C. Effects of anthropogenic and biogenic volatile organic compounds on Los Angeles air quality. Environ. Sci. Technol. 2021, 55, 12191–12201. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; Qu, Z.; Qin, Y.; Fu, Q.; Sun, H.; Duan, X. Revealing the highly catalytic performance of spinel CoMn2O4 for toluene oxidation: Involvement and replenishment of oxygen species using in situ designed-TP techniques. ACS Catal. 2019, 9, 6698–6710. [Google Scholar] [CrossRef]

- Murindababisha, D.; Yusuf, A.; Sun, Y.; Wang, C.; Ren, Y.; Lv, J.; Xiao, H.; Chen, G.; He, J. Current progress on catalytic oxidation of toluene: A review. Environ. Sci. Pollut. R. 2021, 28, 62030–62060. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Cao, J.; Xiang, Y.; Xie, R.; Suo, Z.; Ao, Z.; Yang, X.; Huang, H. Accelerated iron cycle inducing molecular oxygen activation for deep oxidation of aromatic VOCs in MoS2 co-catalytic Fe3+/PMS system. Appl. Catal. B 2022, 309, 121235. [Google Scholar] [CrossRef]

- Liu, B.; Ji, J.; Zhang, B.; Huang, W.; Gan, Y.; Leung, D.Y.C.; Huang, H. Catalytic ozonation of VOCs at low temperature: A comprehensive review. J. Hazard. Mater. 2022, 422, 126847. [Google Scholar] [CrossRef]

- Wu, K.; Sun, Y.; Liu, J.; Xiong, J.; Wu, J.; Zhang, J.; Fu, M.; Chen, L.; Huang, H.; Ye, D. Nonthermal plasma catalysis for toluene decomposition over BaTiO3-based catalysts by Ce doping at A-sites: The role of surface-reactive oxygen species. J. Hazard. Mater. 2021, 405, 124156. [Google Scholar] [CrossRef]

- Hu, Q.; Li, J.; Hao, Z.; Li, L.; Qiao, S. Dynamic adsorption of volatile organic compounds on organofunctionalized SBA-15 materials. Chem. Eng. J. 2009, 149, 281–288. [Google Scholar] [CrossRef]

- Huang, H.; Li, W. Destruction of toluene by ozone-enhanced photocatalysis: Performance and mechanism. Appl. Catal. B 2011, 102, 449–453. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Yang, Z.; Wang, P.; Yan, Y.; Ran, J. Adsorption materials for volatile organic compounds (VOCs) and the key factors for VOCs adsorption process: A review. Sep. Purif. Technol. 2020, 235, 116213. [Google Scholar] [CrossRef]

- Hao, Z.; Liu, X.; Zhang, X.; Zhang, Y.; Zhang, Y. Ethanol-based in situ synthesis of organic-inorganic hierarchical ZSM-5 for efficient capture of toluene under humidity environment. Chem. Eng. J. 2024, 483, 149123. [Google Scholar] [CrossRef]

- Yu, Q.; Li, J.; Liu, W.; Wang, Y.; Chu, W.; Zhang, X.; Xu, L.; Zhu, X.; Li, X. Rational design of a novel Silica-Based material with abundant open micropores for efficient VOC removal. Chem. Eng. J. 2023, 454, 140077. [Google Scholar] [CrossRef]

- Zhou, B.; Sun, B.; Qiu, W.; Zhou, Y.; He, J.; Lu, X.; Lu, H. Adsorption/desorption of toluene on a hypercrosslinked polymeric resin in a highly humid gas stream. Chin. J. Chem. Eng. 2019, 27, 863–868. [Google Scholar] [CrossRef]

- Sui, H.; Liu, J.; He, L.; Li, X.; Jani, A. Adsorption and desorption of binary mixture of acetone and ethyl acetate on silica gel. Chem. Eng. Sci. 2019, 197, 185–194. [Google Scholar] [CrossRef]

- Pui, W.; Yusoff, R.; Aroua, M. A review on activated carbon adsorption for volatile organic compounds (VOCs). Rev. Chem. Eng. 2019, 35, 649–668. [Google Scholar] [CrossRef]

- Baur, G.; Yuranov, I.; Kiwi-Minsker, L. Activated carbon fibers modified by metal oxide as effective structured adsorbents for acetaldehyde. Catal. Today 2015, 249, 252–258. [Google Scholar] [CrossRef]

- Cheng, T.; Li, J.; Ma, X.; Zhou, L.; Wu, H.; Yang, L. Alkylation modified pistachio shell-based biochar to promote the adsorption of VOCs in high humidity environment. Environ. Pollut. 2022, 295, 118714. [Google Scholar] [CrossRef]

- Yin, T.; Meng, X.; Wang, S.; Yao, X.; Liu, N.; Shi, L. Study on the adsorption of low-concentration VOCs on zeolite composites based on chemisorption of metal-oxides under dry and wet conditions. Sep. Purif. Technol. 2022, 280, 119634. [Google Scholar] [CrossRef]

- Yue, X.; Wang, S.; Gao, J.; Wang, S.; Ding, W. Effects of mesopore size on ethyl acetate adsorption-desorption behaviors over hierarchical ZSM-5/MCM-41 molecular sieves. Sep. Purif. Technol. 2024, 336, 126228. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Y.; Sun, C.; Zhao, T.; Zhao, J.; Wang, Z.; Liu, W.; Lu, J.; Shi, M.; Zhao, A.; et al. Novel preparation of binder-free Y/ZSM-5 zeolite composites for VOCs adsorption. Chem. Eng. J. 2021, 417, 129172. [Google Scholar] [CrossRef]

- Mekki, A.; Boukoussa, B. Structural, textural and toluene adsorption properties of microporous-mesoporous zeolite omega synthesized by different methods. J. Mater. Sci. 2019, 54, 8096–8107. [Google Scholar] [CrossRef]

- Shim, W.; Lee, J.; Moon, H. Heterogeneous adsorption characteristics of volatile organic compounds (VOCs) on MCM-48. Sep. Sci. Technol. 2007, 41, 3693–3719. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, J.; Zhang, Q.; Liu, Z.; Li, R. Adsorption and diffusion of n-Heptane and toluene over mesoporous ZSM-5 zeolites. Ind. Eng. Chem. Res. 2014, 53, 13810–13819. [Google Scholar] [CrossRef]

- Li, R.; Xue, T.; Li, Z.; Wang, Q. Hierarchical structure ZSM-5/SBA-15 composite with improved hydrophobicity for adsorption-desorption behavior of toluene. Chem. Eng. J. 2020, 392, 124861. [Google Scholar] [CrossRef]

- Lu, S.; Liu, Q.; Han, R.; Shi, J.; Guo, M.; Song, C.; Ji, N.; Lu, X.; Ma, D. Core-shell structured Y zeolite/hydrophobic organic polymer with improved toluene adsorption capacity under dry and wet conditions. Chem. Eng. J. 2021, 409, 128194. [Google Scholar] [CrossRef]

- Ma, M.; Gao, K.; Ma, Z.; Ding, J. Influence of preparation method on the adsorptive performance of silica sulfuric acid for the removal of gaseous o-xylene. Sep. Purif. Technol. 2021, 265, 118484. [Google Scholar] [CrossRef]

- Gao, K.; Ma, M.; Liu, Y.; Ma, Z. A comparative study of the removal of o-xylene from gas streams using mesoporous silicas and their silica supported sulfuric acids. J. Hazard. Mater. 2021, 409, 124965. [Google Scholar] [CrossRef] [PubMed]

- Selvaraj, M.; Sinha, P.; Pandurangan, A. Synthesis of dypnone using SO42−/Al-MCM-41 mesoporous molecular sieves. Microporous Mesoporous Mater. 2004, 70, 81–91. [Google Scholar] [CrossRef]

- Soltan, W.; Peng, J.; Cao, Z.; Fu, Z.; Liu, H. Bimetallic Fe-Mn loaded H-ZSM-5 zeolites for excellent VOCs catalytic oxidation at low-temperatures: Synergistic effects and catalytic mechanisms. Chem. Eng. J. 2023, 475, 146251. [Google Scholar] [CrossRef]

- Ocampo, F.; Cunha, J.; de Lima Santos, M.; Tessonnier, J.; Pereira, M.; Louis, B. Synthesis of zeolite crystals with unusual morphology: Application in acid catalysis. Appl. Catal. A 2010, 390, 102–109. [Google Scholar] [CrossRef]

- Bensafi, B.; Nadjat, C.; Fatiha, D. The universal zeolite ZSM-5: Structure and synthesis strategies. A review. Coord. Chem. Rev. 2023, 496, 215397. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Z.; Cao, E.; Zheng, Y.; Ren, Q.; Cui, Y. Direct activation and hydrophobic modification of biomass-derived hierarchical porous carbon for toluene adsorption under high humidity. Chem. Eng. J. 2024, 490, 151817. [Google Scholar] [CrossRef]

- Liu, Y.; Li, C.; Peyravi, A.; Sun, Z.; Zhang, G.; Rahmani, K.; Zheng, S.; Hashisho, Z. Mesoporous MCM-41 derived from natural Opoka and its application for organic vapors removal. J. Hazard. Mater. 2021, 408, 124911. [Google Scholar] [CrossRef]

- Zhao, C.; Hu, X.; Liu, C.; Chen, D.; Yun, J.; Jiang, X.; Wei, N.; Li, M.; Chen, Z. Hierarchical architectures of ZSM-5 with controllable mesoporous and their particular adsorption/desorption performance for VOCs. J. Environ. Chem. Eng. 2022, 10, 106868. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Z.; Wu, H.; Li, J.; Yang, L. Adsorption of volatile organic compounds at medium-high temperature conditions by activated carbons. Energy Fuels 2019, 34, 3679–3690. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, Y.; Zheng, S.; Hashisho, Z. Adsorption of volatile organic compounds onto natural porous minerals. J. Hazard. Mater. 2019, 364, 317–324. [Google Scholar] [CrossRef]

- Hong, T.; Wei, L.; Cui, K.; Dong, Y.; Li, R.; Zhang, T.; Zhao, Y.; Luo, L. Adsorption performance of volatile organic compounds on activated carbon fibers in a fixed bed column. J. Environ. Chem. Eng. 2021, 9, 106347. [Google Scholar] [CrossRef]

- Ma, X.; Yang, L.; Wu, H. Removal of volatile organic compounds from the coal-fired flue gas by adsorption on activated carbon. J. Cleaner Prod. 2021, 302, 126925. [Google Scholar] [CrossRef]

- Liu, J.; Yan, Y.; Zhang, H. Adsorption dynamics of toluene in composite bed with microfibrous entrapped activated carbon. Chem. Eng. J. 2011, 173, 456–462. [Google Scholar] [CrossRef]

- Zaitan, H.; Bianchi, D.; Achak, O.; Chafik, T. A comparative study of the adsorption and desorption of o-xylene onto bentonite clay and alumina. J. Hazard. Mater. 2008, 153, 852–859. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, S.; Liu, J. Surface modification of coconut shell based activated carbon for the improvement of hydrophobic VOC removal. J. Hazard. Mater. 2011, 192, 683–690. [Google Scholar] [CrossRef]

- Gatica, J.; Rodríguez-Izquierdo, J.; Sánchez, D.; Chafik, T.; Harti, S.; Zaitan, H.; Vidal, H. Originally prepared carbon-based honeycomb monoliths with potential application as VOCs adsorbents. C. R. Chim. 2006, 9, 1215–1220. [Google Scholar] [CrossRef]

- Oh, K.; Park, D.; Kim, S.; Park, S. Breakthrough data analysis of adsorption of volatile organic compounds on granular activated carbon. Korean J. Chem. Eng. 2010, 27, 632–638. [Google Scholar] [CrossRef]

- Wang, C.; Chang, K.; Chung, T. Adsorption equilibria of aromatic compounds on activated carbon. silica gel, and 13X zeolite. J. Chem. Eng. Data 2004, 49, 527–531. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, Y.; Wang, J.; Gao, K.; Ma, Z. Silica supported sulfuric acid for the removal of gaseous o-xylene. J. Environ. Chem. Eng. 2019, 7, 102992. [Google Scholar] [CrossRef]

- Chen, Y.; Su, Y.; Jiao, F.; Chen, G. A simple and efficient synthesis protocol for sulfonation of nitrobenzene under solvent-free conditions via a microreactor. RSC Adv. 2012, 2, 5637–5644. [Google Scholar] [CrossRef]

- Yuksel, N.; Kose, A.; Fellah, M.F. A Density Functional Theory study of molecular hydrogen adsorption on Mg site in OFF type zeolite cluster. Int. J. Hydrogen Energy 2020, 45, 34983–34992. [Google Scholar] [CrossRef]

- Mie, A.; Karsten, R. Adsorption Enthalpies for Catalysis Modeling through Machine-Learned Descriptors. Acc. Chem. Res. 2021, 54, 2741–2749. [Google Scholar]

- Thorge, B.; Kristijan, K.; Rudolf, P. Survey of dilution or adsorption enthalpies of a series of hygroscopic sorption materials. J. Energy Storage 2018, 18, 171–174. [Google Scholar]

- Bruice, P. Organic Chemistry, 4th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2004; pp. 669–723. [Google Scholar]

- Koleva, G.; Galabov, B.; Kong, J.; Schaefer, H.; Schleyer, P. Electrophilic aromatic sulfonation with SO3: Concerted or classic SEAr mechanism? J. Am. Chem. Soc. 2011, 133, 19094–19101. [Google Scholar] [CrossRef]

| tB (min) | QB (mg g−1) | tm (min) | Qm (mg g−1) | ||

|---|---|---|---|---|---|

| T | 110 °C ZSM−OSO3H | 11.2 | 81.8 | 79.9 | 224.1 |

| 120 °C ZSM−OSO3H | 23.3 | 173.3 | 114.1 | 383.7 | |

| 130 °C ZSM−OSO3H | 15.1 | 112.1 | 82.6 | 286.9 | |

| 140 °C ZSM−OSO3H | 18.9 | 140.9 | 104.5 | 324.3 | |

| 30 °C HZSM-5 | 4.9 | 36.9 | 36.7 | 87.5 | |

| h | 8 mm | 7.3 | 109.2 | 58.8 | 329.9 |

| 15 mm | 23.3 | 173.3 | 114.1 | 383.7 | |

| 20 mm | 61.3 | 225.0 | 155.2 | 398.3 | |

| Vg | 0.025 L min−1 | 72.1 | 264.7 | 212.3 | 456.4 |

| 0.050 L min−1 | 23.3 | 173.3 | 114.1 | 383.7 | |

| 0.075 L min−1 | 8.8 | 97.4 | 72.8 | 260.8 | |

| Cin | 4.5 mg L−1 | 57.2 | 254.9 | 152.4 | 372.5 |

| 7.5 mg L−1 | 23.3 | 173.3 | 114.1 | 383.7 | |

| 9.5 mg L−1 | 12.7 | 119.9 | 60.9 | 230.9 |

| Adsorbent | Adsorption Capacity/(mg·g−1) | Reference |

|---|---|---|

| Bentonite | 44.5 | [39] |

| Alumina (γ-Al2O3) | 99.8 | [39] |

| GAC/NA | 187.0 | [40] |

| Carbon−based monoliths | 58.3 | [41] |

| Granular activated carbon | 90.4 | [42] |

| 13X zeolite | 17.7 | [43] |

| Silica gel | 96.5 | [43] |

| Activated carbon | 111.5 | [43] |

| ZSM−OSO3H | 456.4 | Present work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Ma, X.; Wang, H.; Zhao, D.; Liu, Y.; Ma, Z. Enhancement of Gaseous o-Xylene Elimination by Chlorosulfonic Acid-Modified H-Zeolite Socony Mobil-5. Molecules 2024, 29, 3507. https://doi.org/10.3390/molecules29153507

Wang Y, Ma X, Wang H, Zhao D, Liu Y, Ma Z. Enhancement of Gaseous o-Xylene Elimination by Chlorosulfonic Acid-Modified H-Zeolite Socony Mobil-5. Molecules. 2024; 29(15):3507. https://doi.org/10.3390/molecules29153507

Chicago/Turabian StyleWang, Yaxu, Xiaolong Ma, Hongmei Wang, Dandan Zhao, Yuheng Liu, and Zichuan Ma. 2024. "Enhancement of Gaseous o-Xylene Elimination by Chlorosulfonic Acid-Modified H-Zeolite Socony Mobil-5" Molecules 29, no. 15: 3507. https://doi.org/10.3390/molecules29153507

APA StyleWang, Y., Ma, X., Wang, H., Zhao, D., Liu, Y., & Ma, Z. (2024). Enhancement of Gaseous o-Xylene Elimination by Chlorosulfonic Acid-Modified H-Zeolite Socony Mobil-5. Molecules, 29(15), 3507. https://doi.org/10.3390/molecules29153507