Thermal and/or Microwave Treatment: Insight into the Preparation of Titania-Based Materials for CO2 Photoreduction to Green Chemicals

Abstract

1. Introduction

2. Results and Discussion

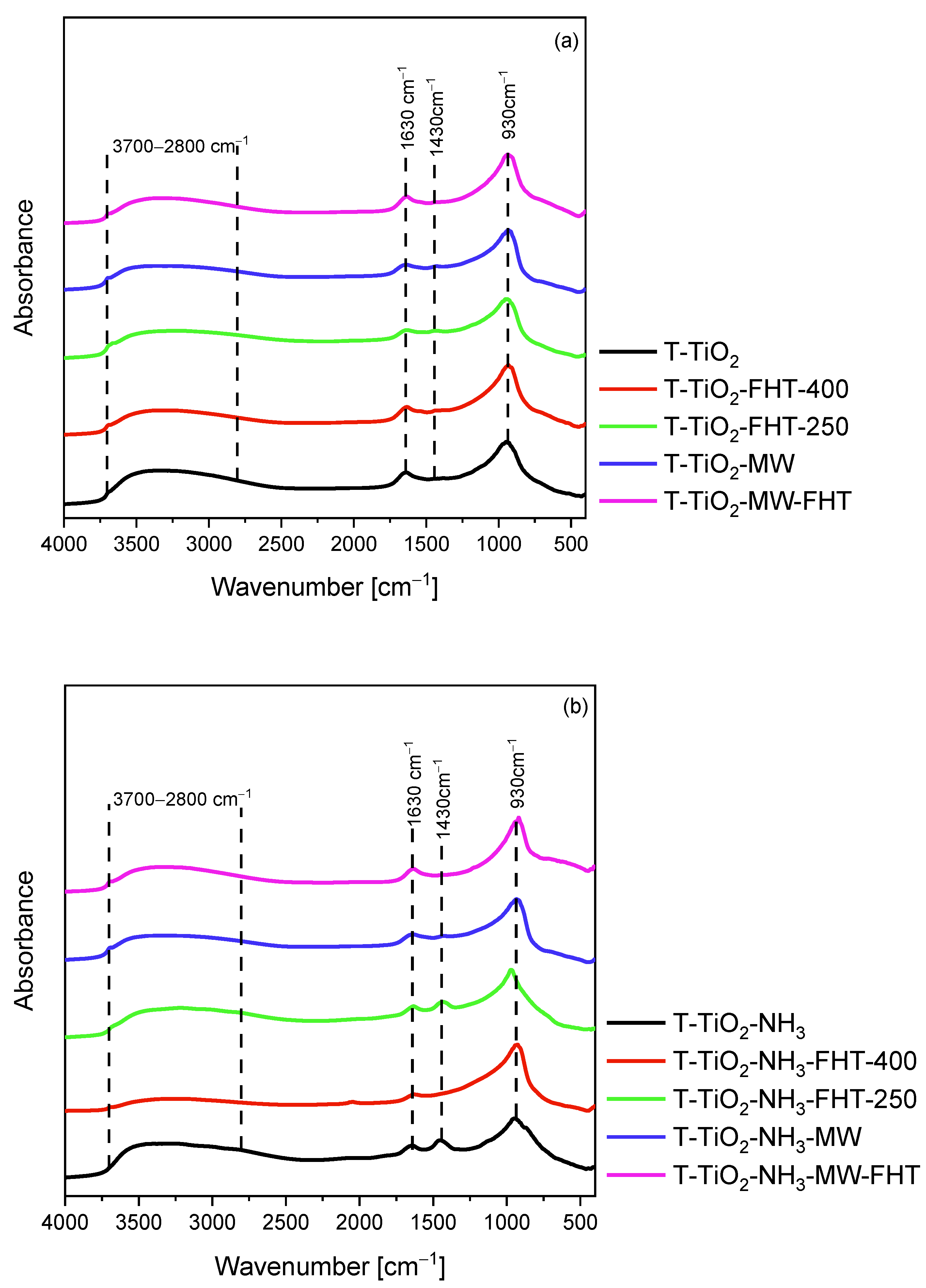

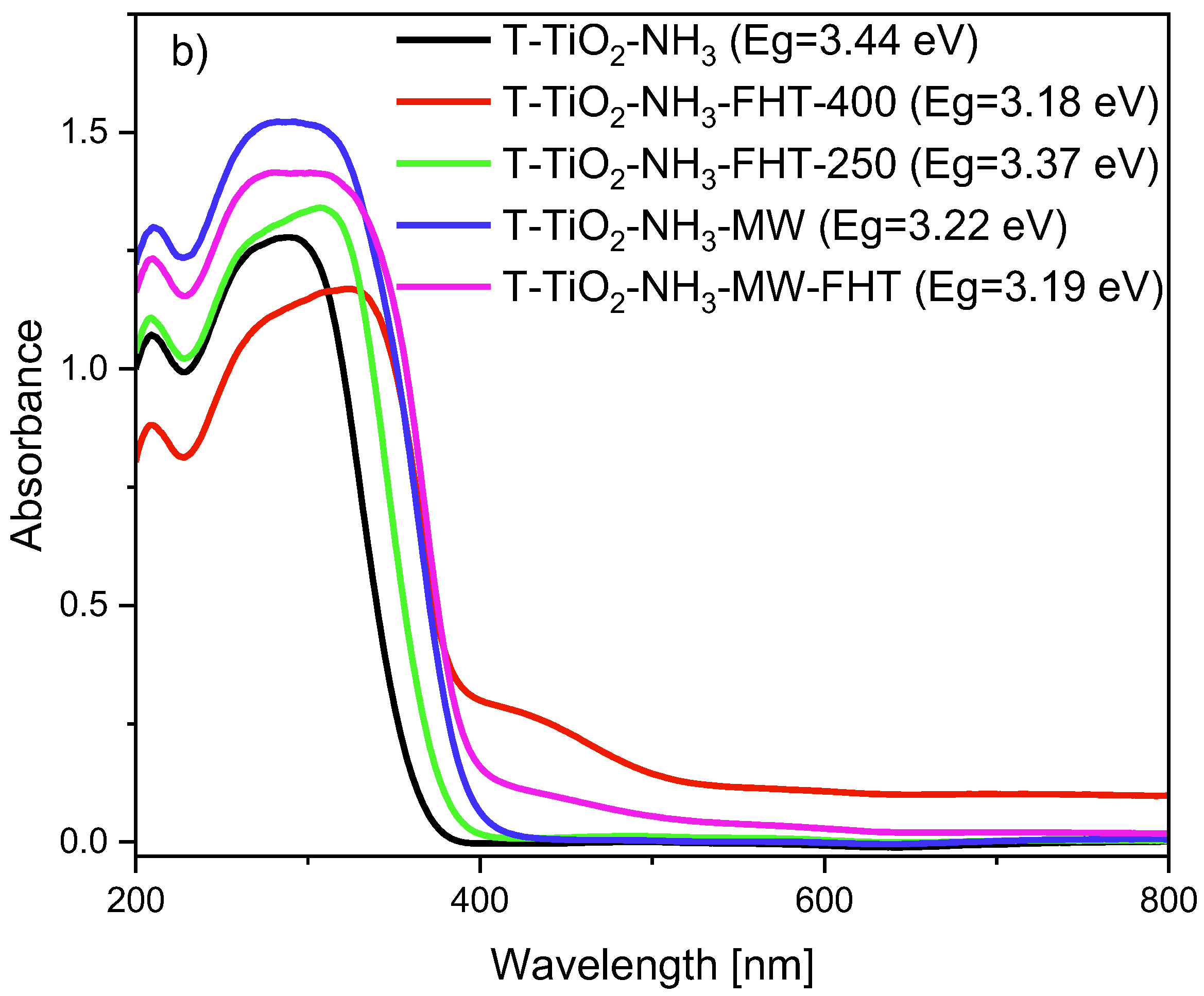

2.1. Characteristics of the Obtained Materials

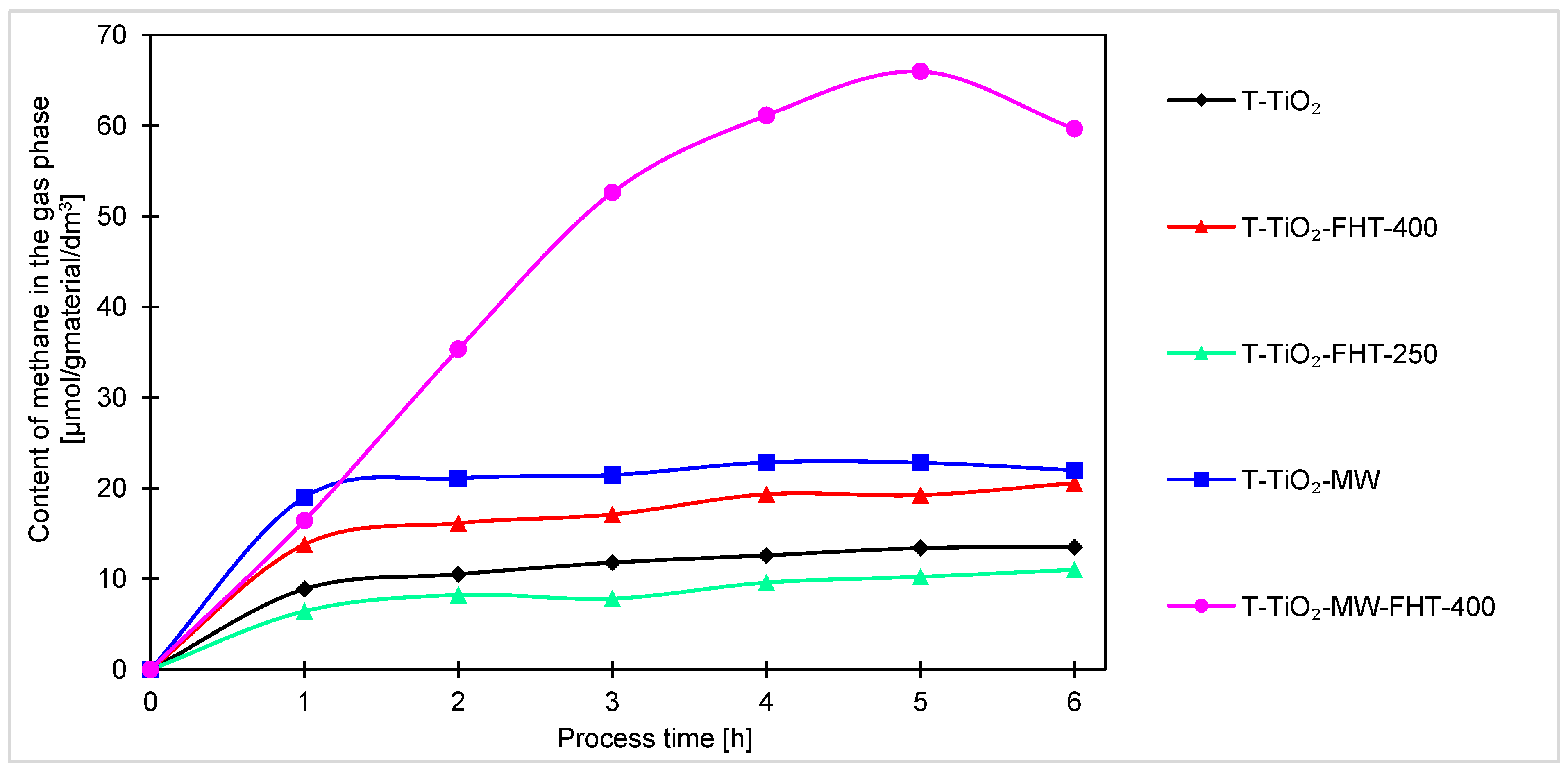

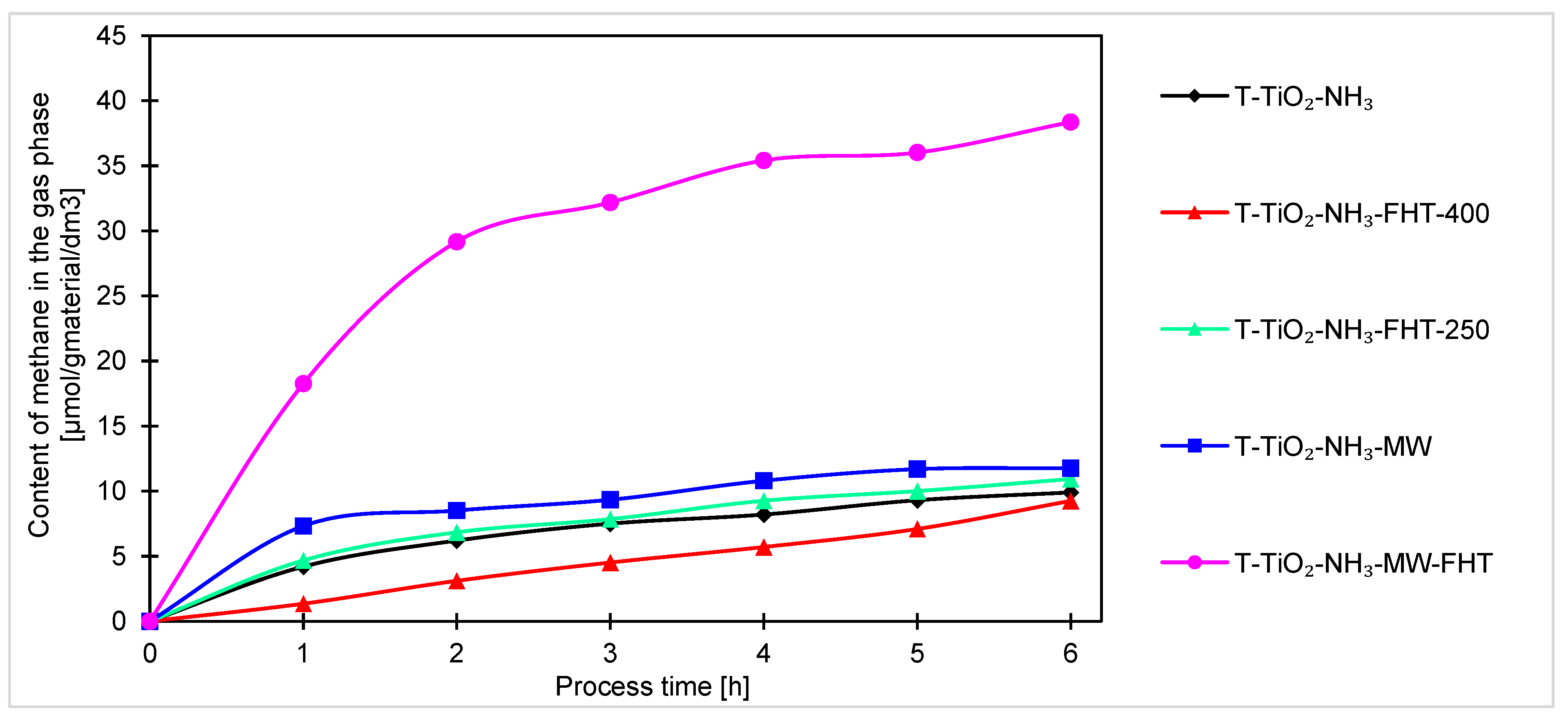

2.2. CO2 Photoreduction Processes Involving Titanium Dioxide Samples Obtained under Neutral and Basic Conditions

2.3. Selectivity of Titanium Dioxide Samples Obtained under Neutral and Basic Conditions in the Carbon Dioxide Photoreduction Process

3. Materials and Methods

3.1. Materials Preparation

3.2. Material Characteristics

3.3. Photocatalytic Process

3.4. Selectivity of the Obtained Materials in the Carbon Dioxide Photoreduction Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pörtner, H.-O.; Roberts, D.C.; Tignor, M.; Poloczanska, E.S.; Mintenbeck, K.; Alegría, A.; Craig, M.; Langsdorf, S.; Löschke, S.; Möller, V.; et al. (Eds.) IPCC Climate Change 2022: Impacts, Adaptation and Vulnerability. In Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; ISBN 978-1-00-932584-4. [Google Scholar]

- Safaei-Farouji, M.; Misch, D.; Sachsenhofer, F.R. A review of influencing factors and study methods of carbon capture and storage (CCS) potential in coals. Int. J. Coal Geol. 2023, 277, 10435. [Google Scholar] [CrossRef]

- Ekemezie, I.O.; Digitemie, N.W. Carbon capture and utilization (CCU): A review of emerging applications and challenges. Eng. Sci. Technol. J. 2024, 5, 949–961. [Google Scholar] [CrossRef]

- Al-Enizi, M.A.; Karim, A.; Yousef, A. A novel method for fabrication of electrospun cadmium sulfide nanoparticles- decorated zinc oxide nanofibers as effective photocatalyst for water photosplitting. Alex. Eng. J. 2023, 65, 825–835. [Google Scholar] [CrossRef]

- Dalal, C.; Garg, A.K.; Jain, N.; Naziruddin, A.R.; Prajapati, R.K.; Choudhary, S.K.; Sonkar, S.K. Sunlight-assisted photocatalytic degradation of azo-dye using zinc-sulfide embedded reduced graphene oxide. Sol. Energy 2023, 251, 315–324. [Google Scholar] [CrossRef]

- Rayappan, E.; Pandi, M.; Muthaian, J.R.; Rosenkranz, A.; Raji, A.; Manoj, D. Superior photocatalytic and antibacterial activity of cadmium selenide nanoparticles doped by titanium or lanthanum. Adv. Eng. Mater. 2023, 25, 2300637. [Google Scholar] [CrossRef]

- Sandali, Y.; Butt, F.K.; Farooq, M.H. Zinc vanadium Oxide/g-C3N4 nanosheets as potential material for ascorbic acid sensing and photocatalytic reduction of CO2. Int. J. Hydrog. Energy 2024, 68, 843–852. [Google Scholar] [CrossRef]

- Annam Renita, A.; Sathish, S.; Senthil Kumar, P.; Prabu, D.; Manikandan, N.; Mohamed Iqbal, A.; Rajesh, G.; Rangasamy, G. Emerging aspects of metal ions-doped zinc oxide photocatalysts in degradation of organic dyes and pharmaceutical pollutants—A review. J. Environ. Manag. 2023, 344, 118614. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, G.; Duan, M.; Liu, Y.; Cai, Y.; Xu, M.; Zhao, K.; Tai, H.; Jiang, Y.; Su, Y. Zinc Oxide Nanorods for Light-Activated Gas Sensing and Photocatalytic Applications. ACS Appl. Nano Mater. 2023, 6, 17445–17456. [Google Scholar] [CrossRef]

- Thuan, V.D.; Ngo, L.H.; Thi, P.H.; Chu, T.T.H. Photodegradation of hazardous organic pollutants using titanium oxides—based photocatalytic: A review. Environ. Res. 2023, 229, 116000. [Google Scholar] [CrossRef]

- Xu, P.; Ding, C.; Li, Z.; Yu, R.; Cui, H.; Gao, S. Photocatalytic degradation of air pollutant by modified nano titanium oxide (TiO2) in a fluidized bed photoreactor: Optimizing and kinetic modeling. Chemosphere 2023, 319, 137995. [Google Scholar] [CrossRef]

- Liang, S.; Huang, L.; Gao, Y.; Wang, Q.; Liu, B. Electrochemical Reduction of CO2 to CO over Transition Metal/N-Doped Carbon Catalysts: The Active Sites and Reaction Mechanism. Adv. Sci. 2021, 8, 2102886. [Google Scholar] [CrossRef]

- Monteiro, M.C.O.; Philips, M.F.; Schouten, K.J.P.; Koper, M.T.M. Efficiency and selectivity of CO2 reduction to CO on gold gas diffusion electrodes in acidic media. Nat. Commun. 2021, 12, 4943. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ji, G.; Liu, Y.; Gondal, M.; Chang, X. Cu2O/TiO2 heterostructure nanotube arrays prepared by an electrodeposition method exhibiting enhanced photocatalytic activity for CO2 reduction to methanol. Catal. Commun. 2014, 46, 17–21. [Google Scholar] [CrossRef]

- Graciani, J.; Mudiyanselage, K.; Xu, F.; Baber, A.E.; Evans, J.; Senanayake, S.D.; Stacchiola, D.J.; Liu, P.; Hrbek, J.; Sanz, J.F.; et al. Highly active copper-ceria and copper-ceria-titania catalysts for methanol synthesis from CO2. Science 2014, 345, 546–550. [Google Scholar] [CrossRef] [PubMed]

- Reñones, P.; Moya, A.; Fresno, F.; Collado, L.; Vilatela, J.J.; de la Peña O’Shea, V.A. Hierarchical TiO2 nanofibres as photocatalyst for CO2 reduction: Influence of morphology and phase composition on catalytic activity. J. CO2 Util. 2016, 15, 24–31. [Google Scholar] [CrossRef]

- Morawski, A.W.; Ćmielewska, K.; Witkowski, K.; Kusiak-Nejman, E.; Pełech, I.; Staciwa, P.; Ekiert, E.; Sibera, D.; Wanag, A.; Gano, M.; et al. CO2 Reduction to Valuable Chemicals on TiO2-Carbon Photocatalysts Deposited on Silica Cloth. Catalysts 2022, 12, 31. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Bilal, M.; Hou, J.; Butt, F.K.; Ahmad, J.; Ali, S.; Hussain, A. Photocatalytic CO2 Reduction Using TiO2-Based Photocatalysts and TiO2 Z-Scheme Heterojunction Composites: A Review. Molecules 2022, 27, 2069. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.S.; Zou, L.; Hu, E. Photocatalytic reduction of carbon dioxide into gaseous hydrocarbon using TiO2 pellets. Catal. Today 2006, 115, 269–273. [Google Scholar] [CrossRef]

- Galli, F.; Compagnoni, M.; Vitali, D.; Pirola, C.; Bianchi, C.L.; Villa, A.; Prati, L.; Rossetti, I. CO2 photoreduction at high pressure to both gas and liquid products over titanium dioxide. Appl. Catal. B Environ. 2017, 200, 386–391. [Google Scholar] [CrossRef]

- Garay-Rodríguez, L.F.; Torres-Martínez, L.M. Photocatalytic CO2 reduction over A2Ti6O13 (A = Na and K) titanates synthesized by different pH-catalyzed sol–gel. J. Sol-Gel Sci. Technol. 2020, 93, 428–437. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhu, X.; Gao, X.; An, C.; Wang, Z.; Zuo, C.; Dionysiou, D.D.; He, H.; Jiang, Z. Enhancing photocatalytic CO2 reduction with TiO2-based materials: Strategies, mechanisms, challenges, and perspectives. Env. Sci. Ecotechnol. 2023, 20, 100368. [Google Scholar] [CrossRef] [PubMed]

- Ozin, G. Accelerated optochemical engineering solutions to CO2 photocatalysis for a sustainable future. Matter 2022, 5, 2594–2614. [Google Scholar] [CrossRef]

- Aboualigaledari, N.; Rahmani, M. A review on the synthesis of the TiO2-based photocatalyst for the environmental purification. J. Compos. Compd. 2021, 3, 25–42. [Google Scholar] [CrossRef]

- Wang, Y.; He, Y.; Lai, Q.; Fan, M. Review of the progress in preparing nano TiO2: An important environmental engineering material. J. Environ. Sci. 2014, 26, 2139–2177. [Google Scholar] [CrossRef] [PubMed]

- Ullattil, S.G.; Periyat, P. Sol-Gel Synthesis of Titanium Dioxide. In Sol-Gel Materials for Energy, Environment and Electronic Applications. Advances in Sol-Gel Derived Materials and Technologies; Pillai, S., Hehir, S., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Schubert, U. Chemical modification of titanium alkoxides for sol–gel processing. J. Mater. Chem. 2005, 15, 3701–3715. [Google Scholar] [CrossRef]

- Periyat, P.; Baiju, K.V.; Mukundan, P.; Pillai, P.K.; Warrier, K.G.K. Aqueous colloidal sol–gel route to synthesize nanosized ceria-doped titania having high surface area and increased anatase phase stability. J. Sol-Gel Sci. Technol. 2007, 43, 299–304. [Google Scholar] [CrossRef]

- Baiju, K.V.; Periyat, P.; Wunderlich, W.; Pillai, P.K.; Mukundan, P.; Warrier, K.G.K. Enhanced photoactivity of neodymium doped mesoporous titania synthesized through aqueous sol–gel method. J. Sol-Gel Sci. Technol. 2007, 43, 283–290. [Google Scholar] [CrossRef]

- Kirupavasam, E.K.; Raj, G.A.G. Preparation, Characterization and Photocatalytic Behaviour of Codoped Nanophotocatalyst. Chem. Sci. Trans. 2013, 2, 1282–1287. [Google Scholar] [CrossRef][Green Version]

- Milea, C.; Bogatu, C.; Duta, A. The influence of parameters in silica sol-gel process. Bull. Transilv. Univ. Bras. 2011, 4, 53. [Google Scholar]

- Ren, G.; Gao, Y.; Liu, X.; Xing, A.; Liu, H.; Yin, J. Synthesis of high-activity F-doped TiO2 photocatalyst via a simple one-step hydrothermal process. Reac. Kinet. Mech. Cat. 2010, 100, 487–497. [Google Scholar] [CrossRef]

- Gomathi Thanga Keerthana, B.; Solaiyammal, T.; Muniyappan, S.; Murugakoothan, P. Hydrothermal synthesis and characterization of TiO2 nanostructures prepared using different solvents. Mater. Lett. 2018, 220, 20–23. [Google Scholar] [CrossRef]

- Mamaghani, A.H.; Haghighat, F.; Lee, C.-S. Hydrothermal/solvothermal synthesis and treatment of TiO2 for photocatalytic degradation of air pollutants: Preparation, characterization, properties, and performance. Chemosphere 2019, 219, 804–825. [Google Scholar] [CrossRef] [PubMed]

- Akram, M.; Hussein, R.; Butt, F.K.; Latif, M. Study of the effect of microwave holdingtime on the physicochemical properties of titanium oxide. Mater. Res. Express. 2019, 6, 8. [Google Scholar] [CrossRef]

- Rahimi, N.; Pax, R.A.; Gray, E.M.A. Review of functional titanium oxides. I: TiO2 and its modifications. Prog. Solid State Chem. 2016, 44, 86–105. [Google Scholar] [CrossRef]

- Imoisili, P.E.; Jen, T.; Safaei, B. Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant. Nanotechnol. Rev. 2021, 10, 126–136. [Google Scholar] [CrossRef]

- Andrade-Guel, M.; Díaz-Jiménez, L.; Cortés-Hernández, D.; Cabello-Alvarado, C.; Ávila-Orta, C.; Bartolo-Pérez, P.; Gamero-Melo, P. Microwave assisted sol–gel synthesis of titanium dioxide using hydrochloric and acetic acid as catalysts. Boletín Soc. Española Cerámica Vidr. 2019, 58, 171–177. [Google Scholar] [CrossRef]

- Vlăduț, C.M.; Mocioiu, O.-C.; Preda, S.; Pandele-Cusu, J.; Bratan, V.; Trusca, R.; Zaharescu, M. Effect of Thermal Treatment on the Structure and Morphology of Vanadium Doped ZnO Nanostructures Obtained by Microwave Assisted Sol–Gel Method. Gels 2022, 8, 811. [Google Scholar] [CrossRef]

- Divya, G.; Genji, J.; Siva Rao, T.; Chippada, M.V.; Divyja Lakshmi, K.V.; Sai Supryja, S. Improved catalytic efficiency by N-doped TiO2 via sol gel under microwave irradiation: Dual applications in degrada-tion of dye and microbes. Hybrid Adv. 2022, 1, 100010. [Google Scholar] [CrossRef]

- Predoană, L.; Petcu, G.; Preda, S.; Pandele-Cușu, J.; Petrescu, S.V.; Băran, A.; Apostol, N.G.; Costescu, R.M.; Surdu, V.-A.; Vasile, B.Ş.; et al. Copper-/Zinc-Doped TiO2 Nanopowders Synthesized by Microwave-Assisted Sol–Gel Method. Gels 2023, 9, 267. [Google Scholar] [CrossRef]

- May-Masnou, A.; Soler, L.; Torras, M.; Salles, P.; Llorca, J.; Roig, A. Fast and simple microwave synthesis of TiO2/Au nanoparticles for gas-phase photocatalytic hydrogen generation. Front. Chem. 2018, 12, 110. [Google Scholar] [CrossRef]

- Li, M.; Wang, M.; Zhu, L.; Li, Y.; Yan, Z.; Shen, Z.; Cao, X. Facile microwave assisted synthesis of N-rich carbon quantum dots/dual-phase TiO2 heterostructured nanocomposites with high activity in CO2 photoreduction. Appl. Catal. B Environ. 2018, 231, 269–276. [Google Scholar] [CrossRef]

- Yang, Z.-Z.; He, L.-N.; Zhao, Y.-N.; Li, B.; Yu, B. CO2 capture and activation by superbase/polyethylene glycol and its subsequent conversion. Energy Environ. Sci. 2011, 4, 3971–3975. [Google Scholar] [CrossRef]

- Liu, A.-H.; Ma, R.; Song, C.; Yang, Z.Z.; Yu, A.; Cai, Y.; He, L.-N.; Zhao, Y.-N.; Yu, B.; Song, Q.-Q. Equimolar CO2 Capture by N-Substituted Amino Acid Salts and Subsequent Conversion. Ang. Chem. Int. Ed. 2012, 51, 11306–11310. [Google Scholar] [CrossRef]

- Kothandaraman, J.; Goeppert, A.; Czaun, M.; Olah, G.A.; Surya Prakash, G.K. CO2 capture by amines in aqueous media and its subsequent conversion to formate with reusable ruthenium and iron catalysts. Green Chem. 2016, 18, 5831–5838. [Google Scholar] [CrossRef]

- Kar, S.; Goeppert, A.; Surya Prakash, G.K. Integrated CO2 Capture and Conversion to Formate and Methanol: Connecting Two Threads. Acc. Chem. Res. 2019, 52, 2892–2903. [Google Scholar] [CrossRef]

- Saravanan, S.; Balamurugan, M.; Soga, T. Synthesis of titanium dioxide nanoparticles with desired ratio of anatase and rutile phases and the effect of high temperature annealing. Trans. Mater. Res. Soc. Jpn. 2018, 43, 255–261. [Google Scholar] [CrossRef]

- Schossberger, F. Z. Kristallogr., Kristallgeom., Kristallphys., Kristallchem. 1942, 104, 358. [Google Scholar]

- Meagher, E.P.; Lager, G.A. Polyhedral thermal expansion in the TiO2 polymorphs; refinement of the crystal structures of rutile and brookite at high temperature. Can. Mineral. 1979, 17, 77–85. [Google Scholar]

- Mohamed, I.M.A.; Dao, V.-D.; Barakat, N.A.M.; Yasin, A.S.; Yousef, A.; Choi, H.-S. Efficiency enhancement of dye-sensitized solar cells by use of ZrO2-doped TiO2 nanofibers photoanode. J. Colloid Interface Sci. 2016, 476, 9–19. [Google Scholar] [CrossRef]

- Kibasomba, P.M.; Dhlamini, S.; Maaza, M.; Liu, C.-P.; Rashad, M.M.; Rayan, D.A.; Mwakikunga, B.W. Strain and grain size of TiO2 nanoparticles from TEM, Raman spectroscopy and XRD: The revisiting of the Williamson-Hall plot method. Results Phys. 2018, 9, 628–635. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Weng, C.-H.; Srivastav, A.L.; Lin, Y.-T.; Tzeng, J.-H. Facile synthesis and characterization of N-doped TiO2 photocatalyst and its visible-light activity for photo-oxidation of ethylene. J. Nanomater. 2015, 1, 807394. [Google Scholar] [CrossRef]

- Winter, M.; Hamal, D.; Yang, X.; Kwen, H.; Jones, D.; Rajagopalan, S.; Klabunde, K.J. Defining reactivity of solid sorbents: What is the most appropriate metric? Chem. Mater. 2009, 21, 2367–2374. [Google Scholar] [CrossRef]

- Abdullah, S.M.A.; Chong, F.K. Dual-effects of adsorption and photodegradation of methylene blue by tungsten-loaded titanium dioxide. Chem. Eng. J. 2010, 158, 418–425. [Google Scholar] [CrossRef]

- Praveen, P.; Viruthagiri, G.; Mugundan, S.; Shanmugam, N. Structural, optical and morphological analyses of pristine titanium di-oxide nanoparticles—Synthesized via sol–gel route. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 117, 622–629. [Google Scholar] [CrossRef]

- Liu, Z.; Jian, Z.; Fang, J.; Xu, X.; Zhu, X.; Wu, S. Low-temperature reverse microemulsion synthesis, characterization, and photocatalytic performance of nanocrystalline titanium dioxide. Int. J. Photoenergy 2012, 1, 702503. [Google Scholar] [CrossRef]

- Choina, J.; Dolat, D.; Kusiak-Nejman, E.; Janus, M.; Morawski, A.W. TiO2 modified by ammonia as a long lifetime photocatalyst for dyes decomposition. Pol. J. Chem. Technol. 2009, 11, 1–6. [Google Scholar] [CrossRef]

- Tryba, B.; Tygielska, M.; Colbeau-Justin, C.; Kusiak-Nejman, E.; Kapica-Kozar, J.; Wróbel, R.; Żołnierkiewicz, G.; Guskos, N. Influence of pH of sol-gel solution on phase composition and photocatalytic activity of TiO2 under UV and visible light. Mater. Res. Bull. 2016, 84, 152–161. [Google Scholar] [CrossRef]

- Zhu, L.; Zhong, Z.; Yang, H.; Wang, C. NH3-SCR performance of Mn-Fe/TiO2 catalysts at low temperature in the absence and presence of water vapor. Water Air Soil Pollut. 2016, 227, 476. [Google Scholar] [CrossRef]

- Suda, Y.; Kawasaki, H.; Ueda, T.; Ohshima, T. Preparation of high quality nitrogen doped TiO2 thin film as a photocatalyst using a pulsed laser deposition method. Thin Solid Films 2004, 453–454, 162–166. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Weng, C.-H.; Hsu, H.-J.; Lin, Y.-H.; Shiesh, C.-C. The synergistic effect of nitrogen dopant and calcination temperature on the visible-light-induced photoactivity of N-doped TiO2. Int. J. Photoenergy 2013, 1, 268723. [Google Scholar] [CrossRef]

- Asahi, R.; Morikawa, T.; Ohwaki, T.; Aoki, K.; Taga, Y. Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 2001, 293, 269–271. [Google Scholar] [CrossRef]

- Amano, F.; Nogami, K.; Tanaka, M.; Ohtani, B. Correlation between Surface Area and Photocatalytic Activity for Acetaldehyde Decomposition over Bismuth Tungstate Particles with a Hierarchical Structure. Langmuir 2010, 26, 7174–7180. [Google Scholar] [CrossRef]

- Muthuswamy, E.; Iskandar, A.S.; Amador, M.M.; Kauzlarich, S.M. Facile Synthesis of Germanium Nanoparticles with Size Control: Microwave versus Conventional Heating. Chem. Mater. 2013, 25, 1416–1422. [Google Scholar] [CrossRef]

- Wang, Z.M.; Wang, H.; Xiao, M.Q.; Chen, X.; Dai, W.; Yu, Y.; Fu, X. Constructing a channel to regulate the electron transfer behavior of CO adsorption and light-driven CO reduction by H2 over CuO-ZnO. ACS Appl. Mater. Interfaces 2022, 14, 22531–22543. [Google Scholar] [CrossRef]

- Li, H.; Bharti, B.; Manikandam, V.; Al Salhi, M.S.; Asemi, N.N.; Wang, Y.; Jin, W.; Ouyang, F. Nitrogen-fluorine co-doped TiO2/SiO2 nanoparticles for the photocatalytic degradation of acrylonitrile: Deactivation and regeneration. Chemosphere 2023, 340, 139986. [Google Scholar] [CrossRef]

- Haghighi, P.; Haghighat, F. TiO2-based photocatalytic oxidation process for indoor air VOCs removal: A comprehensive review. Build. Environ. 2024, 249, 111108. [Google Scholar] [CrossRef]

- Ricka, R.; Wanag, A.; Kusiak-Nejman, E.; Moszyński, D.; Filip Edelmannová, M.; Reli, M.; Baďura, Z.; Zoppellaro, G.; Zbořil, R.; Morawski, A.W.; et al. Photocatalytic reduction of CO2 over Ti3+ self-doped TiO2-based nanomaterials. J. CO2 Util. 2024, 80, 102701. [Google Scholar] [CrossRef]

- Rios, R.B.; Stragliotto, F.M.; Peixoto, H.R.; Torres, A.E.B.; Bastos-Neto, M.; Azevedo, D.C.S.; Cavalcante, C.L., Jr. Studies on the Adsorption Behavior of CO2-CH4 Mixtures Using Activated Carbon. Braz. J. Chem. Eng. 2013, 30, 939–951. [Google Scholar] [CrossRef]

- Ismail, A.F.; Khulbe, K.; Matsuura, T. Gas Separation Membranes: Polymeric and Inorganic; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Matteucci, S.; Yampolskii, Y.; Freeman, B.D.; Pinnau, I. Transport of Gases and Vapors in Glassy and Rubbery Polymers. In Materials Science of Membranes for Gas and Vapor Separation; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006. [Google Scholar] [CrossRef]

- Ali, S.H.; Mohammed, S.S.; Al-Dokheily, M.E.; Algharagholy, L. Photocatalytic Activity of Defective TiO2-X for Water Treatment/Methyl Orange Dye Degradation. Chem. Chem. Technol. 2022, 16, 639–651. [Google Scholar] [CrossRef]

- Jubu, P.R.; Obaseki, O.S.; Nathan-Abutu, A.; Yam, F.K.; Yusof, Y.; Ochang, M.B. Dispensability of the conventional Tauc’s plot for accurate bandgap determination from UV–vis optical diffuse reflectance data. Results Opt. 2022, 9, 100273. [Google Scholar] [CrossRef]

- Morawski, A.W.; Gano, M.; Ćmielewska, K.; Kusiak-Nejman, E.; Pełech, I.; Staciwa, P.; Ekiert, E.; Narkiewicz, U. Photocatalytic reduction efficiency of CO2 depending on ZnO particle size. Catalysts 2023, 13, 1270. [Google Scholar] [CrossRef]

- IUPAC Compendium of Chemical Terminology, 3rd ed.; International Union of Pure and Applied Chemistry: Research Triangle Park, NC, USA, 2006. [CrossRef]

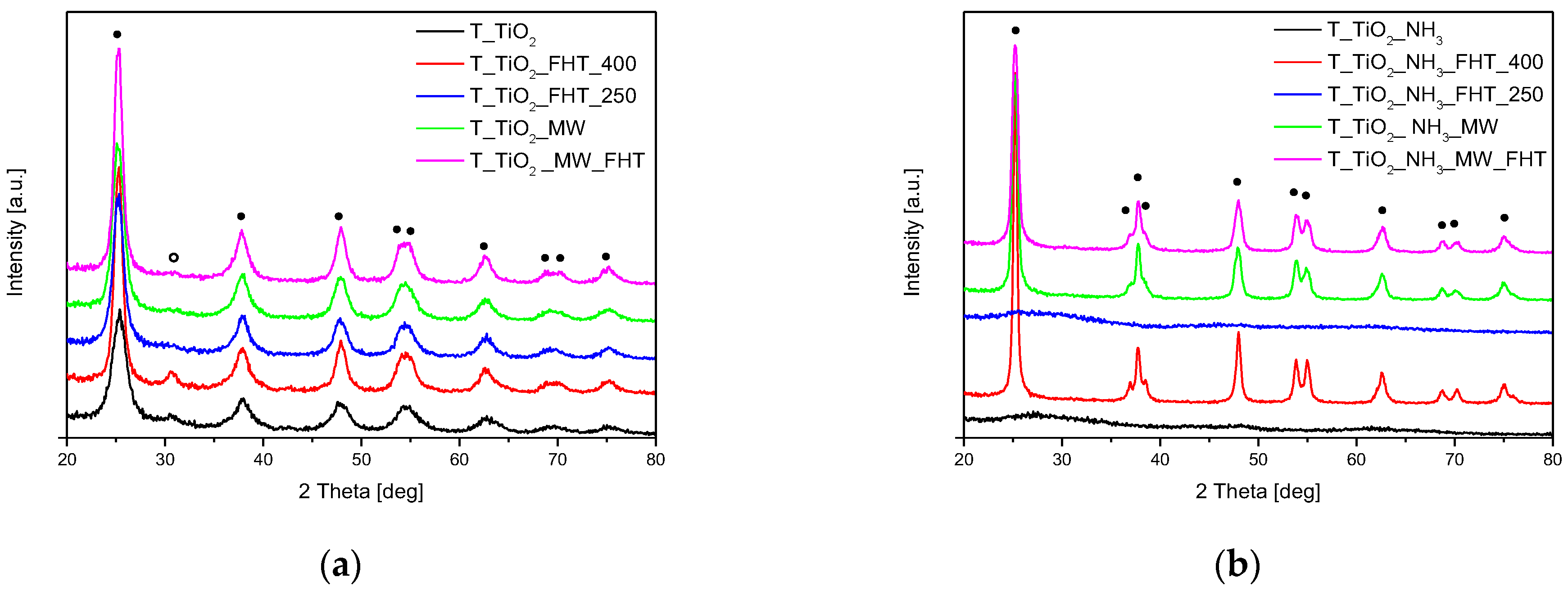

| Ds | DW-H | ΣW-H | Lattice Parameter | ||

|---|---|---|---|---|---|

| [nm] | [nm] | a = b [Å] | c [Å] | ||

| Neutral conditions (without ammonia water) | |||||

| T-TiO2 | 5.1 | 4.9 | 0.0021 | 3.795 | 9.487 |

| T-TiO2-FHT-400 | 8.8 | 6.0 | 0.0022 | 3.794 | 9.478 |

| T-TiO2-FHT-250 | 6.8 | 6.5 | 0.0010 | 3.793 | 9.475 |

| T-TiO2-MW | 6.3 | 6.8 | 0.0026 | 3.791 | 9.485 |

| T-TiO2-MW-FHT | 9.0 | 9.6 | 0.0042 | 3.788 | 9.493 |

| Basic conditions (with ammonia water) | |||||

| T-TiO2-NH3 | - | - | - | - | - |

| T-TiO2-NH3-FHT-400 | 21.9 | 16.0 | 0.0022 | 3.781 | 9.489 |

| T-TiO2-NH3-FHT-250 | - | - | - | - | - |

| T-TiO2-NH3-MW | 14.3 | 16.0 | 0.0021 | 3.785 | 9.489 |

| T-TiO2-NH3-MW-FHT | 13.5 | 16.2 | 0.0015 | 3.782 | 9.488 |

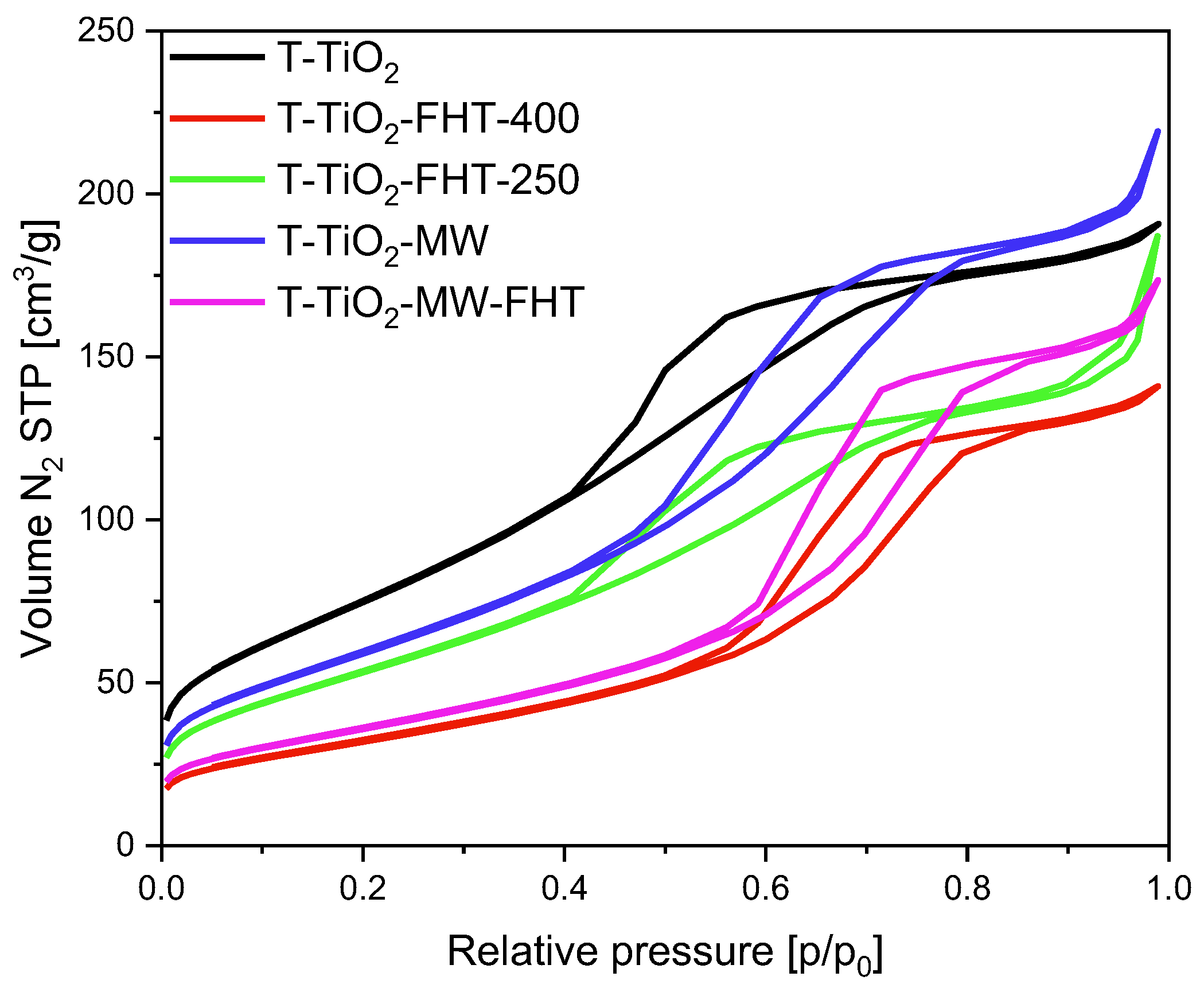

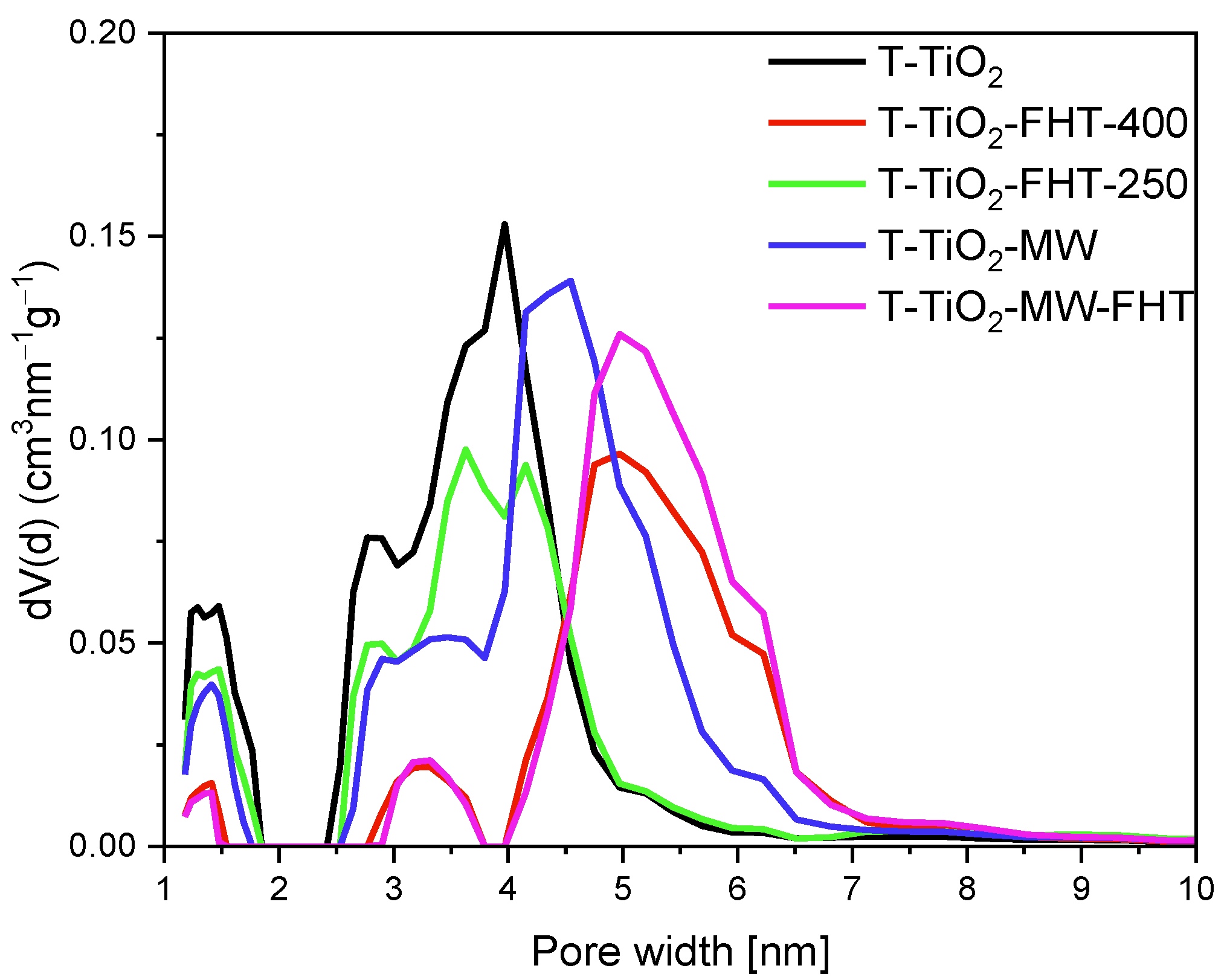

| SBET [m2/g] | TPV [cm3/g] | Vmicro [cm3/g] | Vmeso [cm3/g] | |

|---|---|---|---|---|

| Neutral conditions (without ammonia water) | ||||

| T-TiO2 | 281 | 0.30 | 0.04 | 0.26 |

| T-TiO2-FHT-400 | 117 | 0.22 | 0.01 | 0.21 |

| T-TiO2-FHT-250 | 199 | 0.29 | 0.03 | 0.26 |

| T-TiO2-MW | 220 | 0.34 | 0.02 | 0.32 |

| T-TiO2-MW-FHT | 131 | 0.27 | 0.01 | 0.26 |

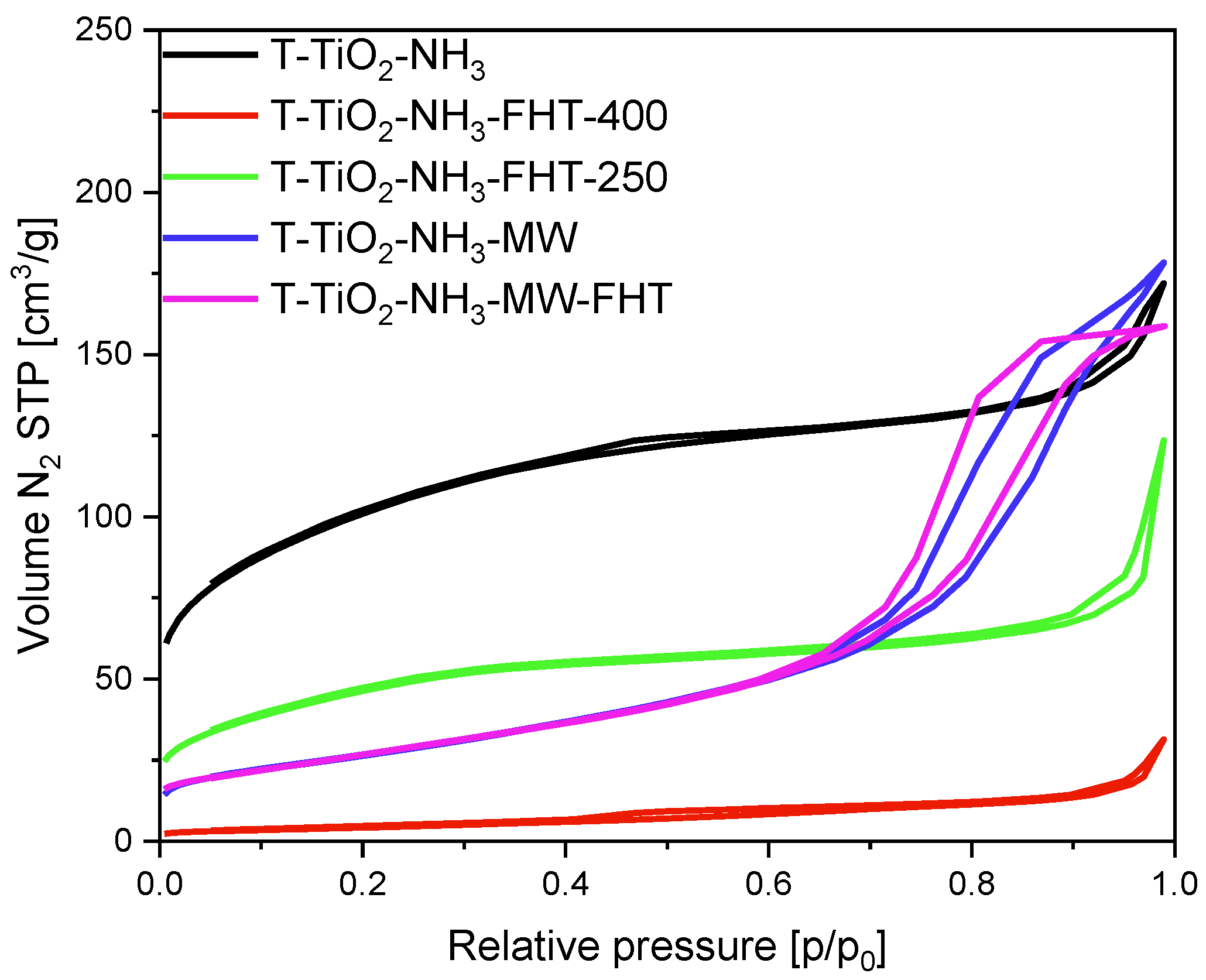

| Basic conditions (with ammonia water) | ||||

| T-TiO2-NH3 | 342 | 0.27 | 0.11 | 0.16 |

| T-TiO2-NH3-FHT-400 | 16 | 0.05 | 0.00 | 0.05 |

| T-TiO2-NH3-FHT-250 | 163 | 0.19 | 0.01 | 0.18 |

| T-TiO2-NH3-MW | 98 | 0.28 | 0.01 | 0.27 |

| T-TiO2-NH3-MW-FHT | 99 | 0.25 | 0.00 | 0.25 |

| Selectivity [%] | |||||

|---|---|---|---|---|---|

| of CO2 Conversion | Relative to the Total Amount of H2 in the Gas Phase | ||||

| Material | CO | CH4 | H2 | CO | CH4 |

| Neutral conditions (without ammonia water) | |||||

| T-TiO2 | 70.3 | 29.7 | 53.6 | 17.3 | 29.1 |

| T-TiO2-FHT-400 | 80.0 | 20.0 | 65.8 | 17.1 | 17.1 |

| T-TiO2-FHT-250 | 83.2 | 16.8 | 50.8 | 27.2 | 22.0 |

| T-TiO2-MW | 68.2 | 31.8 | 68.1 | 11.1 | 20.8 |

| T-TiO2-MW-FHT-400 | 78.9 | 21.1 | 45.9 | 26.1 | 28.0 |

| Basic conditions (with ammonia water) | |||||

| T-TiO2-NH3 | 91.2 | 8.8 | 34.1 | 47.5 | 18.4 |

| T-TiO2-NH3-FHT-400 | 92.8 | 7.2 | 28.2 | 54.9 | 16.9 |

| T-TiO2-NH3-FHT-250 | 88.5 | 11.5 | 34.7 | 42.9 | 22.4 |

| T-TiO2-NH3-MW | 82.6 | 17.4 | 59.6 | 21.9 | 18.5 |

| T-TiO2-NH3-MW-FHT | 84.4 | 15.6 | 44.0 | 32.2 | 23.8 |

| Heat Treatment | Temperature [°C] | |

|---|---|---|

| Neutral conditions (without ammonia water) | ||

| T-TiO2 | - | - |

| T-TiO2-FHT-400 | High-temperature furnace | 400 |

| T-TiO2-FHT-250 | High-temperature furnace | 250 |

| T-TiO2-MW | Microwave reactor | ~250 |

| T-TiO2-MW-FHT | Microwave reactor; high-temperature furnace | ~250, 400 |

| Basic conditions (with ammonia water) | ||

| T-TiO2-NH3 | - | - |

| T-TiO2-NH3-FHT-400 | High-temperature furnace | 400 |

| T-TiO2-NH3-FHT-250 | High-temperature furnace | 250 |

| T-TiO2-NH3-MW | Microwave reactor | ~250 |

| T-TiO2-NH3-MW-FHT | Microwave reactor; high-temperature furnace | ~250, 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pełech, I.; Sibera, D.; Staciwa, P.; Sobczuk, K.; Kusiak-Nejman, E.; Wanag, A.; Morawski, A.W.; Schneider, K.; Blom, R.; Narkiewicz, U. Thermal and/or Microwave Treatment: Insight into the Preparation of Titania-Based Materials for CO2 Photoreduction to Green Chemicals. Molecules 2024, 29, 3646. https://doi.org/10.3390/molecules29153646

Pełech I, Sibera D, Staciwa P, Sobczuk K, Kusiak-Nejman E, Wanag A, Morawski AW, Schneider K, Blom R, Narkiewicz U. Thermal and/or Microwave Treatment: Insight into the Preparation of Titania-Based Materials for CO2 Photoreduction to Green Chemicals. Molecules. 2024; 29(15):3646. https://doi.org/10.3390/molecules29153646

Chicago/Turabian StylePełech, Iwona, Daniel Sibera, Piotr Staciwa, Konrad Sobczuk, Ewelina Kusiak-Nejman, Agnieszka Wanag, Antoni W. Morawski, Kenneth Schneider, Richard Blom, and Urszula Narkiewicz. 2024. "Thermal and/or Microwave Treatment: Insight into the Preparation of Titania-Based Materials for CO2 Photoreduction to Green Chemicals" Molecules 29, no. 15: 3646. https://doi.org/10.3390/molecules29153646

APA StylePełech, I., Sibera, D., Staciwa, P., Sobczuk, K., Kusiak-Nejman, E., Wanag, A., Morawski, A. W., Schneider, K., Blom, R., & Narkiewicz, U. (2024). Thermal and/or Microwave Treatment: Insight into the Preparation of Titania-Based Materials for CO2 Photoreduction to Green Chemicals. Molecules, 29(15), 3646. https://doi.org/10.3390/molecules29153646