Optimization and Stability Assessment of Monochamus alternatus Antimicrobial Peptide MaltAtt-1 in Komagataella phaffii GS115 for the Control of Pine Wood Nematode

Abstract

1. Introduction

2. Results

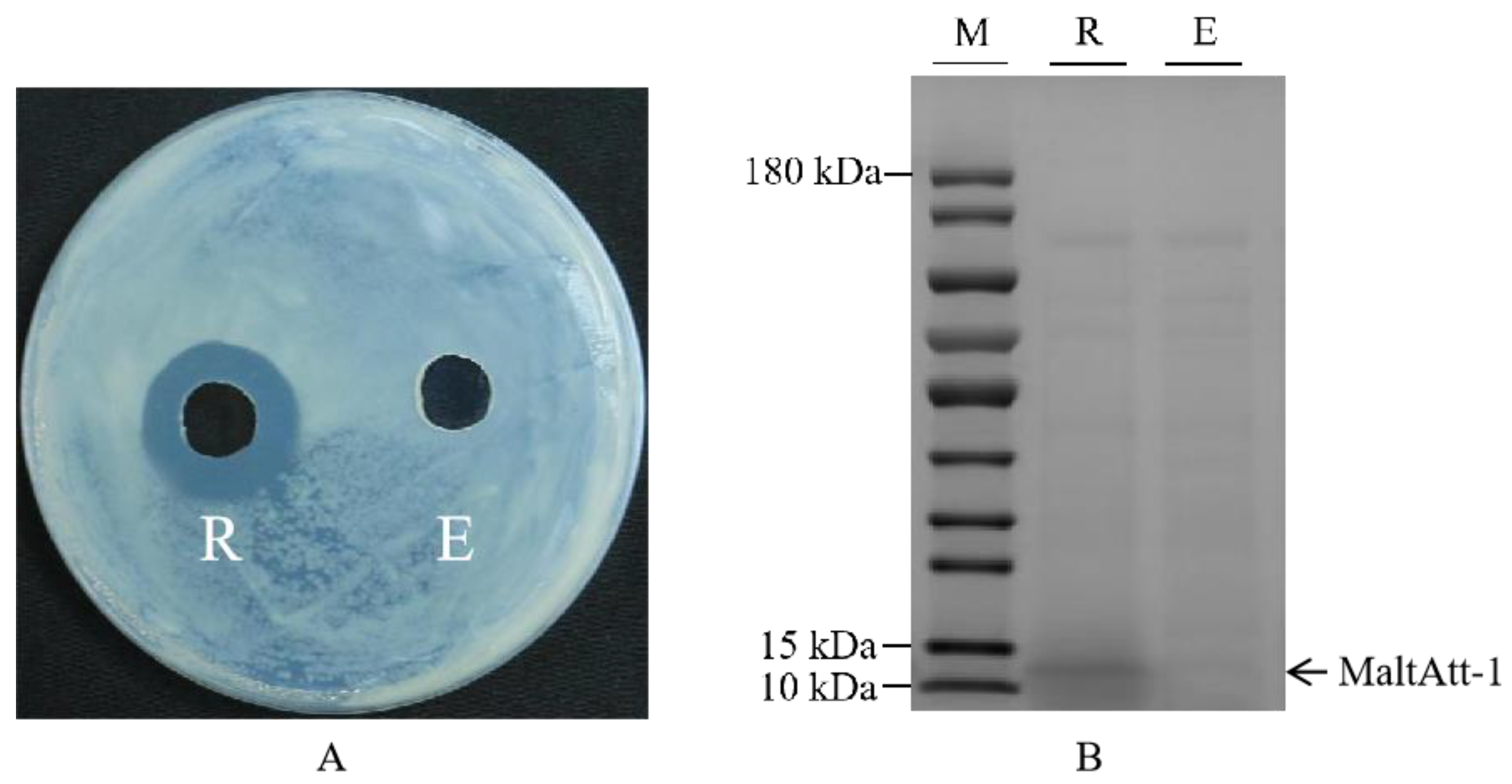

2.1. Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE) of MaltAtt-1

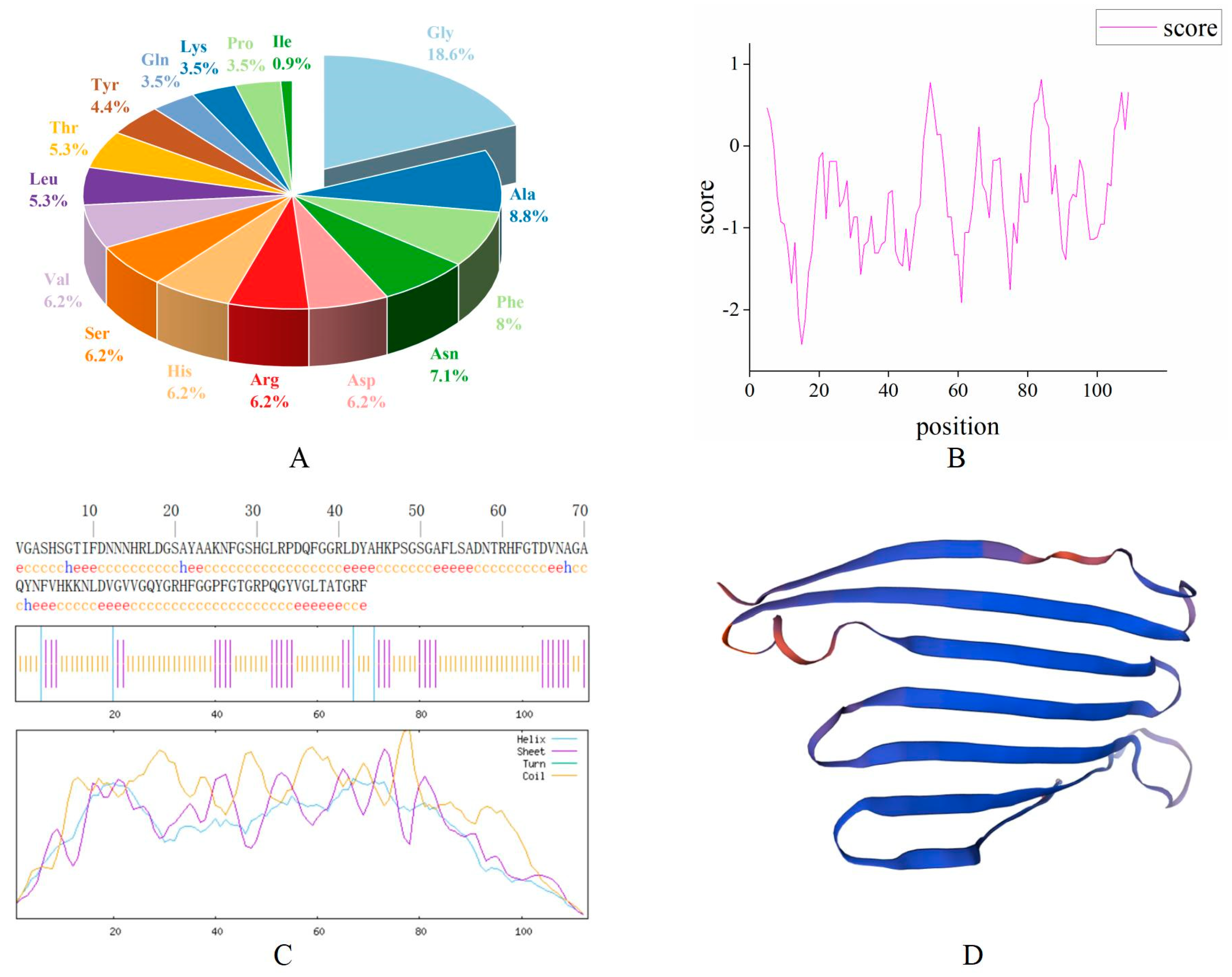

2.2. Bioinformatics Analysis of Antimicrobial Peptide MaltAtt-1

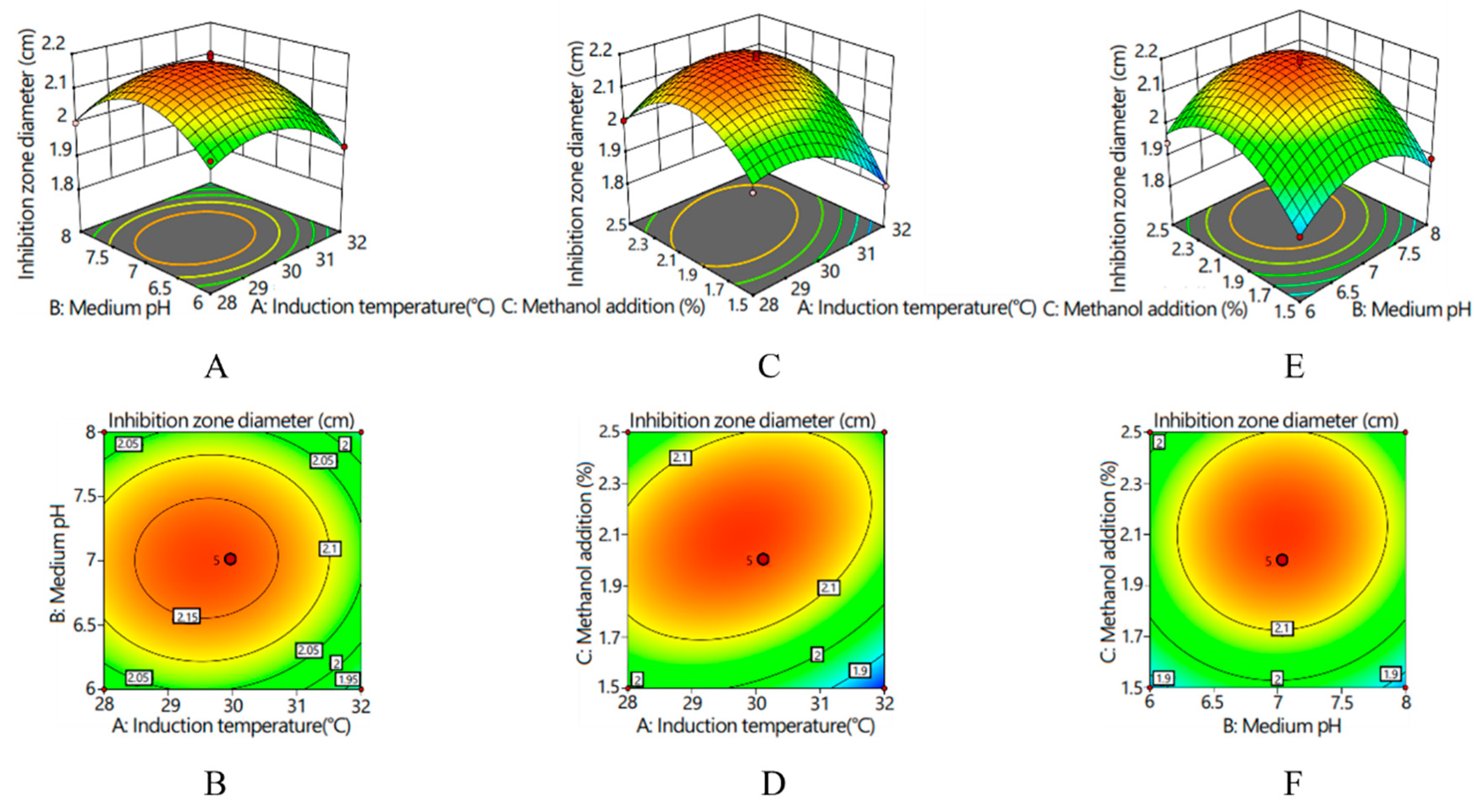

2.3. Optimization of Induction Conditions for Recombinant Protein MaltAtt-1

2.4. Model Analysis and Validation

2.5. Stability Determination of MaltAtt-1

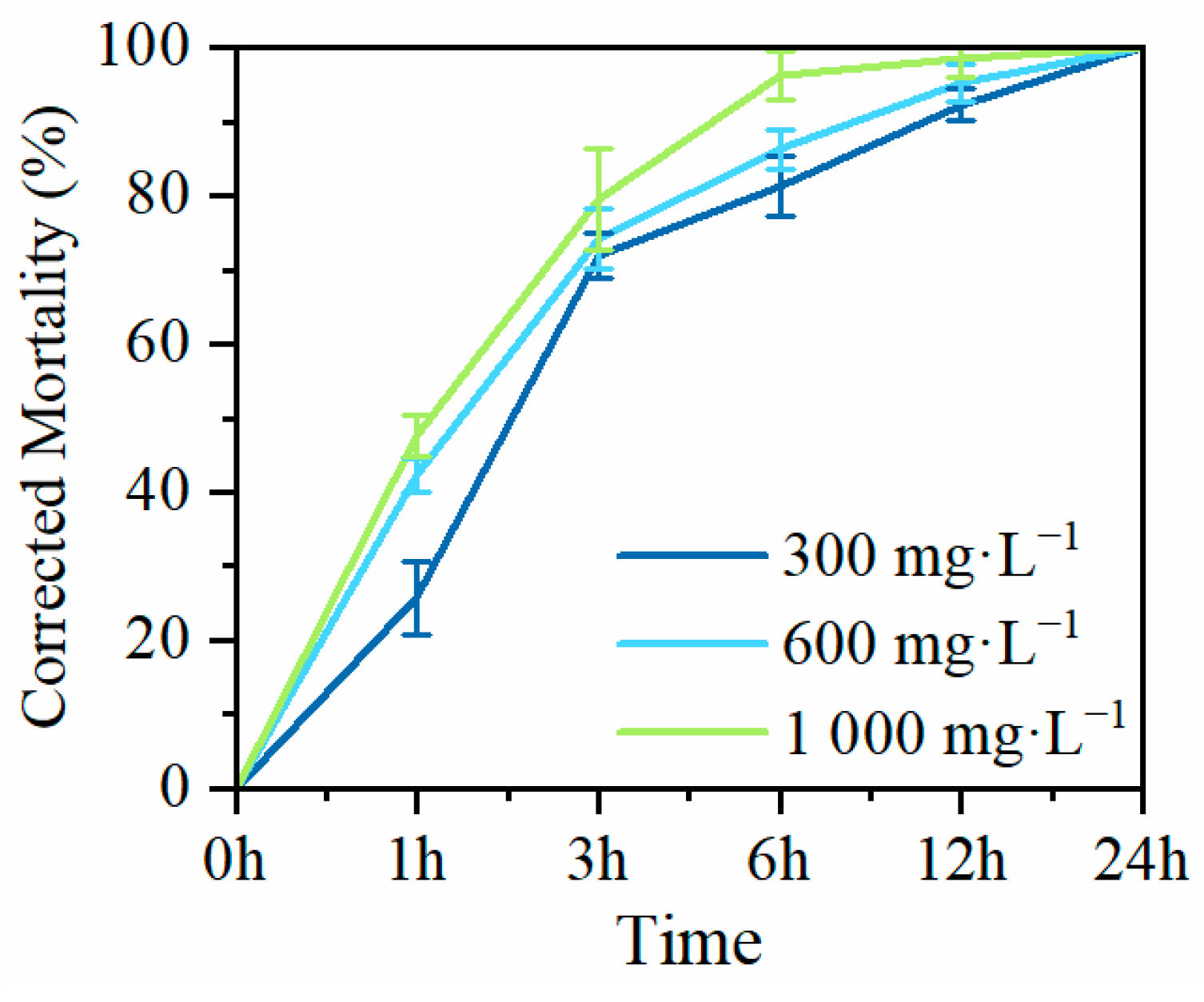

2.6. Nematocidal Activity Determination of MaltAtt-1

3. Discussion

4. Materials and Methods

4.1. Strain and Plasmid

4.2. Transformation and Expression of Recombinant Protein MaltAtt-1 in K. phaffii

4.3. Bioinformatics Analysis of Antimicrobial Peptide MaltAtt-1

4.4. Optimization of Recombinant Protein MaltAtt-1 in K. phaffii

4.5. Polyacrylamide Gel Electrophoresis Analysis

4.6. Antimicrobial Activity Detection of Recombinant Protein MaltAtt-1

4.7. Experimental Design by Response Surface Methodology

4.8. Stability Determination of Recombinant Protein MaltAtt-1

4.8.1. Thermal Stability Assay

4.8.2. pH Stability

4.8.3. Freeze-Thaw Stability

4.8.4. UV Stability

4.9. Nematocidal Activity Assay of MaltAtt-1

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Malewski, T.; Borowik, P.; Olejarski, I.; Berezovska, D.; Dyshko, V.; Behnke-Borowczyk, J.; Pusz, W.; Matic, S.; Oszako, T. Mycobiome of post-agricultural soils 20 years after application of organic substrates and planting of pine seedlings. Forests 2023, 14, 36. [Google Scholar] [CrossRef]

- Nickle, W.R.; Golden, A.M.; Mamiya, Y.; Wergin, W. On the taxonomy and morphology of the pine wood nematode, Bursaphelenchus xylophilus (Steiner & Buhrer 1934) Nickle 1970. J. Nematol. 1981, 13, 385–392. [Google Scholar] [PubMed]

- Li, N.; Huo, L.; Zhang, X. Classification of pine wilt disease at different infection stages by diagnostic hyperspectral bands. Ecol. Indic. 2022, 142, 109198. [Google Scholar] [CrossRef]

- Takai, K.; Soejima, T.; Suzuki, T.; Kawazu, K. Emamectin benzoate as a candidate for a trunk-injection agent against the pine wood nematode, Bursaphelenchus xylophilus. Pest. Manag. Sci. 2000, 56, 937–941. [Google Scholar] [CrossRef]

- Vicente, C.; Espada, M.; Vieira, P.; Mota, M. Pine wilt disease: A threat to European forestry. Eur. J. Plant Pathol. 2012, 133, 89–99. [Google Scholar] [CrossRef]

- Sousa, E.; Naves, P.; Vieira, M. Prevention of pine wilt disease induced by Bursaphelenchus xylophilus and Monochamus galloprovincialis by trunk injection of emamectin benzoate. Phytoparasitica 2013, 41, 143–148. [Google Scholar] [CrossRef]

- Xu, F.Y. Recent advances in the integrated management of the pine wood nematode in China. In Pine Wilt Disease; Zhao, B.G., Futai, K., Sutherland, J.R., Takeuchi, Y., Eds.; Springer: Tokyo, Japan, 2008; pp. 323–333. [Google Scholar]

- Kim, B.N.; Kim, J.H.; Ahn, J.Y.; Kim, S.C.; Cho, B.K.; Kim, Y.H.; Min, J. A short review of the pinewood nematode, Bursaphelenchus xylophilus. Toxicol. Environ. Health Sci. 2020, 12, 297–304. [Google Scholar] [CrossRef]

- Ngegba, P.M.; Cui, G.; Khalid, M.Z.; Zhong, G. Use of botanical pesticides in agriculture as an alternative to synthetic pesticides. Agriculture 2022, 12, 600. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Adeleke, B.S.; Akinola, S.A.; Fayose, C.A.; Adeyemi, U.T.; Gbadegesin, L.A.; Omole, R.K.; Johnson, R.M.; Uthman, Q.O.; Babalola, O.O. Biopesticides as a promising alternative to synthetic pesticides: A case for microbial pesticides, phytopesticides, and nanobiopesticides. Front. Microbiol. 2023, 14, 1040901. [Google Scholar] [CrossRef]

- Konno, K.; Rangel, M.; Oliveira, J.S.; dos Santos Cabrera, M.P.; Fontana, R.; Hirata, I.Y.; Hide, I.; Nakata, Y.; Mori, K.; Kawano, M.; et al. Decoralin, a novel linear cationic alpha-helical peptide from the venom of the solitary eumenine wasp Oreumenes decorates. Peptides 2007, 28, 2320–2327. [Google Scholar] [CrossRef]

- Chung, C.R.; Kuo, T.R.; Wu, L.C.; Lee, T.Y.; Horng, J.T. Characterization and identification of antimicrobial peptides with different functional activities. Brief. Bioinform. 2019, 21, 1098–1114. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zuo, S.; Wang, B.; Zhang, K.; Wang, Y. Antimicrobial mechanisms and clinical application prospects of antimicrobial peptides. Molecules 2022, 27, 2675. [Google Scholar] [CrossRef] [PubMed]

- Laverty, G.; Gorman, S.P.; Gilmore, B.F. The potential of antimicrobial peptides as biocides. Int. J. Mol. Sci. 2011, 12, 6566–6596. [Google Scholar] [CrossRef] [PubMed]

- Mahlapuu, M.; Bjorn, C.; Ekblom, J. Antimicrobial peptides as therapeutic agents: Opportunities and challenges. Crit. Rev. BioTechnol. 2020, 40, 978–992. [Google Scholar] [CrossRef] [PubMed]

- Soares, A.M.S.; Alencar, L.M.R.; Dias, L.P.; Lima, R.C.; Rocha Silva, C.; Santos-Oliveira, R.; Oliveira, J.T.A.; Junior, L.M.C.; Souza, P.F.N. New insights into anthelmintic mechanisms of action of a synthetic peptide: An ultrastructural and nanomechanical approach. Polymers 2021, 13, 2370. [Google Scholar] [CrossRef] [PubMed]

- Hawamda, A.I.M.; Reichert, S.; Ali, M.A.; Nawaz, M.A.; Austerlitz, T.; Schekahn, P.; Abbas, A.; Tenhaken, R.; Bohlmann, H. Characterization of an Arabidopsis defensin-like gene conferring resistance against nematodes. Plants 2022, 11, 280. [Google Scholar] [CrossRef] [PubMed]

- Chu, X.; Jiang, D.; Yu, L.; Li, M.; Wu, S.Q.; Zhang, F.P.; Hu, X. Heterologous expression and bioactivity determination of Monochamus alternatus antibacterial peptide gene in Komagataella phaffii (Pichia pastoris). Int. J. Mol. Sci. 2023, 24, 5421. [Google Scholar] [CrossRef] [PubMed]

- Karbalaei, M.; Rezaee, S.A.; Farsiani, H. Pichia pastoris: A highly successful expression system for optimal synthesis of heterologous proteins. J. Cell Physiol. 2020, 235, 5867–5881. [Google Scholar] [CrossRef] [PubMed]

- Tachioka, M.; Sugimoto, N.; Nakamura, A.; Sunagawa, N.; Ishida, T.; Uchiyama, T.; Igarashi, K.; Samejima, M. Development of simple random mutagenesis protocol for the protein expression system in Pichia pastoris. Biotechnol. Biofuels. 2016, 9, 199. [Google Scholar] [CrossRef]

- Zhao, H.L.; Xue, C.; Wang, Y.; Yao, X.Q.; Liu, Z.M. Increasing the cell viability and heterologous protein expression of Pichia pastoris mutant deficient in PMR1 gene by culture condition optimization. Appl. Microbiol. Biot. 2008, 81, 235–241. [Google Scholar] [CrossRef]

- Mao, R.; Teng, D.; Wang, X.; Zhang, Y.; Jiao, J.; Cao, X.; Wang, J. Optimization of expression conditions for a novel NZ2114-derived antimicrobial peptide-MP1102 under the control of the GAP promoter in Pichia pastoris X-33. BMC Microbiol. 2015, 15, 57. [Google Scholar] [CrossRef] [PubMed]

- Gharsallaoui, A.; Oulahal, N.; Joly, C.; Degraeve, P. Nisin as a food preservative: Part 1: Physicochemical properties, antimicrobial activity, and main uses. Crit. Rev. Food Sci. 2016, 56, 1262–1274. [Google Scholar] [CrossRef]

- Benjakul, S.; Bauer, F. Physicochemical and enzymatic changes of cod muscle proteins subjected to different freeze–thaw cycles. J. Sci. Food Agric. 2000, 80, 1143–1150. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, J.A.; Kim, Y.H.; Song, B.K. Optimization of the functional expression of Coprinus cinereus peroxidase in Pichia pastoris by varying the host and promoter. J. Microbiol. Biotechnol. 2009, 19, 966–971. [Google Scholar] [CrossRef] [PubMed]

- Pla, I.A.; Damasceno, L.M.; Vannelli, T. Evaluation of Mut+ and MutS Pichia pastoris phenotypes for high level extracellular scFv expression under feedback control of the methanol concentration. Biotechnol. Prog. 2006, 22, 881–888. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.Q.; Gao, C.J.; Yang, C.Y.; Xu, P. Optimization of an enthanol production medium in very high gravity fermentation. Biotechnol. Lett. 2007, 29, 233–236. [Google Scholar] [CrossRef] [PubMed]

- Sant’Anna, V.; Utpott, M.; Cladera-Olivera, F.; Brandelli, A. Antimicrobial activity of peptide P34 during thermal processing. Food Bioprocess. Technol. 2013, 6, 73–79. [Google Scholar] [CrossRef]

- Kim, H.; Jang, J.H.; Kim, S.C.; Cho, J.H. De novo generation of short antimicrobial peptides with enhanced stability and cell specificity. J. Antimicrob. Chemother. 2014, 69, 121–132. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhang, M.; Qiu, S.; Wang, J.; Peng, J.; Zha, P. Antimicrobial activity and stability of the D-amino acid substituted derivatives of antimicrobial peptide polybia-MPI. AMB Expr. 2016, 6, 122. [Google Scholar] [CrossRef]

- Yount, N.Y.; Bayer, A.S.; Xiong, Y.Q.; Yeaman, M.R. Advances in antimicrobial peptide immunobiology. Peptide Sci. 2006, 84, 435–458. [Google Scholar] [CrossRef]

- van Kan, E.J.M.; Demel, R.A.; van der Bent, A.; de Kruijff, B. The role of the abundant phenylalanines in the mode of action of the antimicrobial peptide clavanin. Bba-Biomembranes 2003, 1615, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Park, I.Y.; Park, C.B.; Kim, M.S.; Kim, S.C. Parasin I, an antimicrobial peptide derived from histone H2A in the catfish, Parasilurus asotus. Febs Lett. 1998, 437, 258–262. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Chen, J.; Sun, H.; Luo, L.L.; Gu, Y.X.; Yi, Y.L.; Wang, X.; Shan, Y.Y.; Liu, B.F.; Zhou, Y.; et al. Mining, heterologous expression, purification and characterization of 14 novel bacteriocins from Lactobacillus rhamnosus LS-8. Int. J. Biol. Macromol. 2020, 164, 2162–2176. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.X.; Cheng, Q.; Guo, H.N.; Zhang, R.J.; Si, D.Y. Expression of hybrid peptide EF-1 in Pichia pastoris, its purification, and antimicrobial characterization. Molecules 2020, 25, 5538. [Google Scholar] [CrossRef] [PubMed]

| Index | Argument |

|---|---|

| Amino acid quantity | 113 |

| Molecular formula | C528H782N164O158 |

| Relative molecular mass | 11,955.02 |

| Theoretical isoelectric point | 9.69 |

| Asp + Glu | 7 |

| Arg + Lys | 11 |

| Coefficient of instability | 13.68 |

| Aliphatic coefficient | 50.97 |

| GRAVY | −0.595 |

| Source | Sum of Squares | df | Mean Square | F Value | Prob > F | Significance |

|---|---|---|---|---|---|---|

| Model | 0.2281 | 9 | 0.0253 | 23.33 | 0.0002 | ** |

| A | 0.0091 | 1 | 0.0091 | 8.39 | 0.0231 | * |

| B | 0.0003 | 1 | 0.0003 | 0.2876 | 0.6084 | |

| C | 0.0288 | 1 | 0.0288 | 26.51 | 0.0013 | ** |

| AB | 0.0002 | 1 | 0.0002 | 0.2071 | 0.6628 | |

| AC | 0.0144 | 1 | 0.0144 | 13.25 | 0.0083 | ** |

| BC | 0.0004 | 1 | 0.0004 | 0.3682 | 0.5632 | |

| A2 | 0.0285 | 1 | 0.0285 | 26.22 | 0.0014 | ** |

| B2 | 0.0579 | 1 | 0.0579 | 53.28 | 0.0002 | ** |

| C2 | 0.0709 | 1 | 0.0709 | 65.25 | <0.0001 | ** |

| Residual | 0.0076 | 7 | 0.0011 | |||

| Lack of fit | 0.0039 | 3 | 0.0013 | 1.42 | 0.3601 | |

| Pure error | 0.0037 | 4 | 0.0009 | |||

| Cor total | 0.2358 | 16 | ||||

| R2 = 0.9677; R2Adj = 0.9263 | ||||||

| Influencing Factors | Encoding Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| (A) induction temperature/°C | 28 | 30 | 32 |

| (B) medium pH | 6.0 | 7.0 | 8.0 |

| (C) methanol addition/% | 1.5 | 2.0 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.; Xu, X.; Wang, Z.; Yu, C.; Wang, Z.; Xu, Y.; Chu, X.; Li, M.; Zhang, F.; Hu, X. Optimization and Stability Assessment of Monochamus alternatus Antimicrobial Peptide MaltAtt-1 in Komagataella phaffii GS115 for the Control of Pine Wood Nematode. Int. J. Mol. Sci. 2024, 25, 8555. https://doi.org/10.3390/ijms25168555

Jiang D, Xu X, Wang Z, Yu C, Wang Z, Xu Y, Chu X, Li M, Zhang F, Hu X. Optimization and Stability Assessment of Monochamus alternatus Antimicrobial Peptide MaltAtt-1 in Komagataella phaffii GS115 for the Control of Pine Wood Nematode. International Journal of Molecular Sciences. 2024; 25(16):8555. https://doi.org/10.3390/ijms25168555

Chicago/Turabian StyleJiang, Di, Xuhuizi Xu, Zeguang Wang, Chao Yu, Zeqing Wang, Yuda Xu, Xu Chu, Ming Li, Feiping Zhang, and Xia Hu. 2024. "Optimization and Stability Assessment of Monochamus alternatus Antimicrobial Peptide MaltAtt-1 in Komagataella phaffii GS115 for the Control of Pine Wood Nematode" International Journal of Molecular Sciences 25, no. 16: 8555. https://doi.org/10.3390/ijms25168555

APA StyleJiang, D., Xu, X., Wang, Z., Yu, C., Wang, Z., Xu, Y., Chu, X., Li, M., Zhang, F., & Hu, X. (2024). Optimization and Stability Assessment of Monochamus alternatus Antimicrobial Peptide MaltAtt-1 in Komagataella phaffii GS115 for the Control of Pine Wood Nematode. International Journal of Molecular Sciences, 25(16), 8555. https://doi.org/10.3390/ijms25168555