1. Introduction

The detection, measurement and analysis of particles suspended in air is of great importance in fields like environment monitoring, health, pollution, combustion engines, the automotive field, fire detection, meteorology, and many others.

Particles in suspension in air are also called Aerosols or Particulate Matter or Airborne particles.

The size of particles suspended in air is up to 100 µm. Larger particles are not suspended, and their falling velocity is usually higher than 1 m/s.

There are several methods and sensors for analyzing the particles suspended in air. A few important methods are explained briefly in the next paragraph.

Mechanical methods consist of mechanically collecting particles in suspension from air. This can be done either with filters or with a centrifuge. If filters are used, a fan forces the air to pass through a filter which collects particles from air. The particles attached to the filter are examined with a microscope and very detailed information about the particles can be obtained. This method is simple and straightforward, but at the same time, it is laborious and time consuming. A faster, simplified mechanical method is to use selective filters with descending sizes of holes. A version of this method is the gravimetric method described in [

1]: a clean filter is weighed, then a large amount of air with particles is filtered through it. After filtering the high volume of air, the filter is weighed again. The mass difference divided by the volume of filtered air is the mass concentration of particles.

Another method for mechanical collection of suspended particles is with a centrifuge. The force applied on a particle inside a centrifuge is thousands of times higher than its weight in normal gravity. For example, a 20 µm particle falls with 1 cm/s in air in normal gravity 1 g. The same particle will have a velocity of 32 cm/s in a centrifuge with 1000× g or 1 m/s in a large centrifuge with 10,000× g. Smaller particles that do not settle down in normal gravity can be separated in a centrifuge. Then, particles attached on the circumference of the centrifuge can be analyzed with a microscope.

Mechanical methods are precise and accurate, but they are limited to laboratory measurements. They are not suitable for automated analyses or high-volume measurements or continuous monitoring of air.

A different method is by ionizing the particles suspended in air. In the middle of the twentieth century, the first smoke sensor with a radioisotope and ionization chamber appeared [

2]. Such sensors include a very small amount (0.3 µg) of Americium 241, which ionizes molecules of air inside the ionization chamber. Americium 241 is preferred because its radiation is 1% gamma and 99% alpha, which has high ionization power and also can be easily shielded. A voltage is applied between two electrodes in the chamber and the current between electrodes is monitored. If particles of smoke are inside the chamber, ions will adhere to them, and the current between electrodes will change. Therefore, the smoke can be detected. Such sensors are not very reliable and are being used less and less frequently. Sometimes they are used in conjunction with other type of sensors, especially because sensors with ionization are more sensitive for small-sized particles, unlike optical sensors, which are more sensitive for large particles.

Ionization of air molecules can be performed by Corona discharge instead of radioactivity. Article [

3] explains in detail an experimental device for analyzing the particles in the exhaust gas from a diesel engine.

The signal generated by a smoke sensor with ionization depends on both the size and density of particles; therefore, neither of these parameters can be measured. The size could be measured if the density of particles was known, following a calibration with particles of known size. However, these conditions cannot be achieved for a commercial sensor.

Optical sensors are the most widely used for detecting and analyzing particles in air. A light source illuminates a volume of air. The particles inside the illuminated volume scatter the light. A light sensor measures either the transmitted light or the scattered light, and the generated electrical signal is amplified and analyzed to obtain information about the particles.

Sensors that count particles have a light source (LED or laser) and lens that focuses the light beam to the size of a particle. A thin air flow with particles flows between light source and a photodetector, in the region where the light is focused. Each particle that passes between the light source and the photodetector will produce a pulse in the signal from the photodetector. The pulses are counted, and the density of particles can be calculated. Some detectors have additional electronics and software for analyzing each pulse and estimating the size of each particle, but the precision is very low, and they can only distinguish between dust and smoke. One of the most advanced such sensors is produced by Sensirion and is described in [

1].

Optical smoke sensors are installed in most public buildings and some houses. An LED and a photodiode are placed inside an optical chamber. They are arranged so that neither direct nor reflected light from the LED can arrive on the photodetector. Particles suspended in air that enter in the chamber scatter the light, and a certain amount of scattered light is detected by the photodiode.

Sensors with scattered light are low cost, small and reliable. They are used for detection of smoke or dust, but they cannot measure the parameters of particles. The level of signal generated by the photodetector is highly dependent on particle density, size, shape, and color; therefore, none of these parameters can be measured separately.

In recent years, more sophisticated sensors with scattered light have been developed. For example, Siemens developed a smoke sensor with two light sources placed so that the photodetector measures light scattered in two directions [

4]. Scattered light from large particles is more intense for small angles and weak for large angles. Scattered light from small particles is isotropic. The described sensor can measure the scattered light in two directions and some information about the size of particles is available. This sensor cannot measure the size of particles, it can only distinguish between smoldering fire (large particles) and open fire (small particles) and is more reliable for detection of all types of fire.

Nephelometers are used for precise measurement of concentrations of particles suspended in a fluid. They are, basically, optical sensors with scattered light at a 90° angle. Although they are expensive and sensitive, they cannot directly determine the concentration of particles. As mentioned before, the scattered light depends on the concentration, size, shape, and color of particles. The size, shape and color must be known in advance in order to measure the concentration. A nephelometer must be calibrated for a known particulate before measuring the concentration in atmosphere.

The most advanced nephelometers can measure the size distribution of particles. This objective can be achieved by Static Light Scattering (SLS) method. The nephelometers manufactured by Air Photon [

5] or TSI [

6] measure the scattered light for three wavelengths and for a scattering angle from 7° to 170°. The achieved data from three photomultipliers (for three wavelengths) is processed to obtain the size distribution and density of particles. These instruments are expensive, heavy (8 kg), and include many mobile parts and sensitive optical components.

Optical sensors with extinction measure the intensity of direct light from an LED or laser. When particles are between the source of light and detector, the intensity of light on photodetector is lower. Most sensors have an optical chamber and the distance between the light source and the photodetector is a few centimeters. Alternatively, the distance is several meters. In this case, a laser beam aims a photodetector that is located several meters away. The monitored area is thus much larger, but false detections may occur more frequently.

A few other methods are used occasionally for analyzing particulate matter. These methods have been applied in laboratory only.

A frame of four CCD linear sensors can scan all particles that pass through the frame. Detailed information about particles can be achieved after data processing [

7].

Another type of particle analyzer uses the noise produced by falling particles on a metal sheet. The sound is captured by a microphone and analyzed, and details regarding particles can be obtained [

8].

The Dynamic Light Scattering (DLS) method has been used since 1964 for measuring the size of particles suspended in liquid. The DLS method needs the same basic components as SLS or Scattered Light Sensors or nephelometers: a photodetector and a light source that must be monochromatic and coherent, i.e., a laser. The essential difference is the measured parameter of light. DLS requires the frequency of the scattered light, while all the other methods require the intensity of scattered light. The monochromatic light scattered from the particles create an interference image on the photodetector. The intensity of light on photodetector is the result of random phases of light from illuminated particles. However, the particles are moving continuously due to Brownian motion, and therefore, the phase and intensity of light on photodetector is variable. The velocity of particles in Brownian motion depends on the size of particles. The frequency of the signal generated by the photodetector is processed by a computer and the size of particles can be calculated.

Table 1 Presents an overview of the most important methods for measuring particles suspended in air.

To our knowledge, the DLS method has never been applied to particles in gas. This article proves the possibility of measuring the size of particles in suspension in air using a small, wearable, calibration free, low-cost device based on DLS in air. Details are presented further on.

3. Results and Discussion

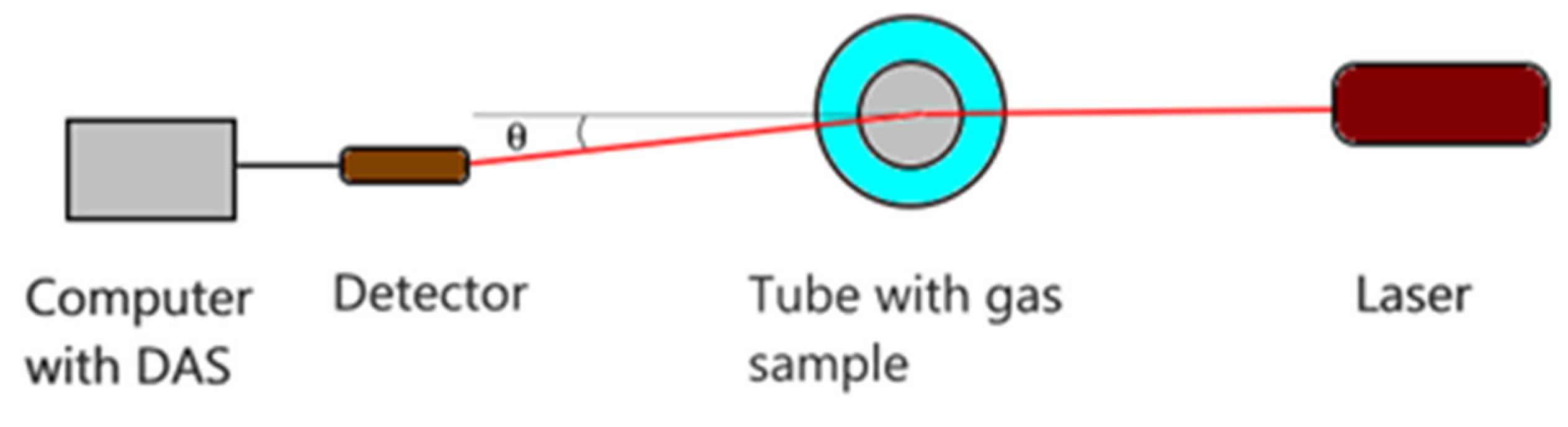

Several materials were ignited with different flame regimes to produce smoke and particles and were used as targets of the laser beam in the experimental setup, as depicted in

Figure 1. The samples that produced particles are presented in

Table 2.

Figure 4 illustrates the FS computed for the DLS time series recorded on smoke from paper burning with flame as a source of particles, after filtering the grid noise and harmonics and after fitting the Lorentzian line to the FS. We notice that the 50 Hz noise frequency and the harmonics were removed. The red, continuous line represents the Lorentzian line (Equation (1)) plotted with the parameter of best fit, where a

1 was equal to 244.2 Hz, corresponding to a larger average particle diameter in the fumes, of 565 nm.

Figure 4 also reveals that the line fits reasonably well to the computed FS, confirming that the approximation of having monodisperse particles in the sample is acceptable.

Figure 5 illustrates the FS computed for the DLS time series recording on cigarette smoke, following the same data processing procedure, after filtering the grid noise and harmonics and after fitting the Lorentzian line to the FS. The red, continuous line representing the Lorentzian line was plotted with the parameter of best fit, which, for this sample, was a

1 equal to 6166.0 Hz, corresponding to an average diameter of the particles in the cigarette smoke of 22 nm. We notice that the monodisperse particle size distribution approximation holds on this sample, which has the smallest average particle diameters, as well, because the line fits the experimental FS reasonably well.

Moreover, we notice that the turnover point in the plot with logarithmic distancing of the ticks on the axes of the plots lies within the frequency range, as expected from the simulation presented in

Section 2.2, for a smaller recording angle of 10°, as used when recording the DLS time series, proving that DLS in air, at a low acquisition rate, can be successfully accomplished.

The same aspect of the FS and the line fit to it can be noticed on the FS for the DLS time series recorded on the particles produced by a smoldering wax candle wick, where the average diameter was 78 nm, and for particles produced by smoldering paper, where the computed average diameter was 15 nm. The plots of the computed FS with the plotted Lorentzian line of best fit are not presented here, though, as they do not provide any additional insight.

So far, the samples that were analyzed and presented suggest that DLS time series recorded for particles in air as solvent with relatively low data acquisition rates can be processed using the approximation whereby the particles are assumed to possess a monodisperse or narrow size distribution. The procedure must be tested on samples with wider known particle size distributions, and the results must be compared with the real size distribution. Such a source of particles in air is a nebulizer that uses a small compressor to disperse medical drugs in aerosol particles.

Figure 6 illustrates the FS computed for the DLS time series recording on aerosol water droplets used as a sample, following the same data processing procedure. The red, continuous line represents the Lorentzian line, and was plotted with the parameters of the best fit, which, for this sample, was a

1 equal to 410.0 Hz, corresponding to an average diameter of the particles in aerosol droplets of 336 nm. The aerosol droplets had a wider distribution this time, with a maximum diameter of 2.6 μm. We notice that the low frequency part of the FS does not appear to be a plateau, and that the whole FS appears to be a sum of FSs recorded for monosized particles. The fit indicated an average diameter of 336 nm.

Even so, the fit indicated an average diameter consistent with the size distribution of the droplets, despite their wider distribution. Moreover, the size of the particles assessed using the procedure described in

Section 3 are consistent with the generic size of different particles, as reported in [

31], which states that oil smoke has a particle size in the range 0.03–1 µm, tobacco smoke is in the range 0.01–4 µm, and burning wood with flame is in the range 0.2–3 µm, which we assume to be comparable with burning paper. The tobacco smoke we used was not produced by inhaling it, but by smoldering; therefore, the size of the particles is smaller than that reported in [

31].

To better judge the hypothesis that the particle distribution can be approximated as being unimodal, and, therefore, the FS ca be approximated by the Lorentzian line described by Equation (1), the residual of the least squares fit with the Lorentzian line should be plotted. A plot of the residual on the data recorded on particles in smoke from paper burning with flame, presented in

Figure 4, is illustrated in

Figure 7. A double logarithmic plot, as in

Figure 4 through

Figure 6, would be optimal, but the residual has both positive and negative values, and therefore the frequency axis can only be represented by values displayed on a logarithmic scale. Examining the residual of the least squares fit, it can be noticed that the values are both positive and negative, but they are not quite randomly distributed around 0; rather, certain patterns are present. This is an indication that the particle distribution is not perfectly unimodal, but rather presents a certain width. Even so, the device and the procedure produce the average diameter in the DLS sense, and the average diameter is a reasonable measure of the size of the particles suspended in gas.

Another concern related to the procedure presented in this paper is related to Equations (2) and (3), which are derived from a fluid flowing around the particles in Brownian motion in the Stokes regime. To verify the flow regime, the mean free paths of the gas molecules λ should be compared with the characteristic dimension of the object, that is, the particles that scatter light in the case of this paper. The Knudsen number Kn is a dimensionless number defined as the ratio of the molecular mean free path length to a characteristic dimension of the object that is moving through the fluid, the average diameter of the particles.

In Equation (7), N/V is the number concentration of molecules per unit volume and d

gas is the diameter of the gas molecules. If we consider a Boltzman gas and we replace N/V we find for Kn:

where p is the gas pressure, T is the thermodynamic temperature and d is the diameter of the particle in suspension. The pressure was 101,100 Pa, the temperature was 22 °C, except for the particles from the paper burning with flame, where the temperature was 83 °C in the beam area of the tube. The Knudsen number was calculated for the particles we measured and is displayed as column 5 of

Table 2. Reference [

32] states that for Kn < 0.1 there is a slip flow, and for Kn between 0. 1 and 10 the flow regime is transitional to free molecular flow. Examining

Table 2, it can be noticed that the particles that were investigated using this DLS in the gas procedure undergo a Brownian motion, where the flowing of the fluid is in a transitional regime, not in a slip flow or continuum flow regime; therefore, Equation (2) should be considered an approximation. The procedure described above to be used for assessing the average particle diameters, together with the simple experimental setup should be viewed as an advanced sensor, not as a very precise procedure intended to replace existing DLS particle sizers. Nevertheless, the procedure outputs an average diameter, with a systematic error, yet reproducible and without requiring calibration, which places the device and the procedure in the advanced sensor category. Even so, the average diameters found using the procedure were in the range of the diameters reported in the literature, as pointed out before.

A very precise measurement would hardly be possible, as explained in the Introduction section. To make a precise measurement, a large quantity of particles is required, and harvesting this from smoke would take time, during which the burning regime would need to be kept at the same parameters. An alternative would be Atomic Force Microscopy (AFM), as described in papers like [

33,

34,

35], but it is affected by systematic errors as well, due to the finite radius of the AFM cantilever tip, as clearly explained in [

36] and many other papers.

The DLS technique has as an output the hydrodynamic diameter, not the physical diameter. For this reason, the diameter described above should be considered the hydrodynamic diameter (3). Particles of nonspherical shape, like nanorods or irregular shapes, diffuse in air. If they scatter a coherent light beam, the wavelets interfere, producing a DLS time series. If the time series is analyzed with the procedure describes in

Section 2.2, an average hydrodynamic diameter in the DLS sense [

37] is produced. Such a diameter should be understood as the diameter of the spherical particles that diffuse in air as the real particles do.