A Study on Miniaturized In-Situ Self-Calibrated Thermometers Based on Ga and Ga-Zn Fixed Points

Abstract

:1. Introduction

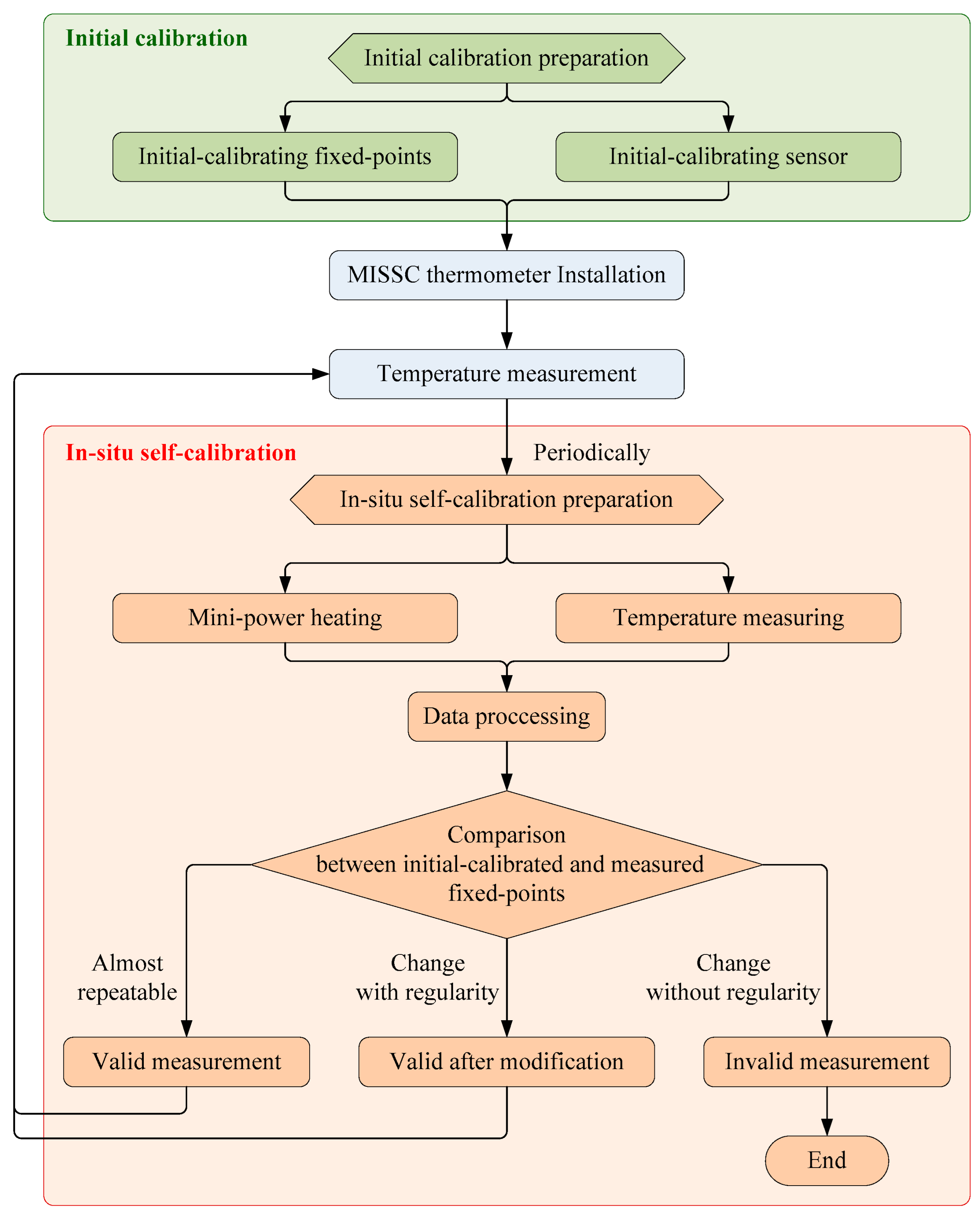

2. Self-Calibration Method

3. Hardware Fabrication & Integration

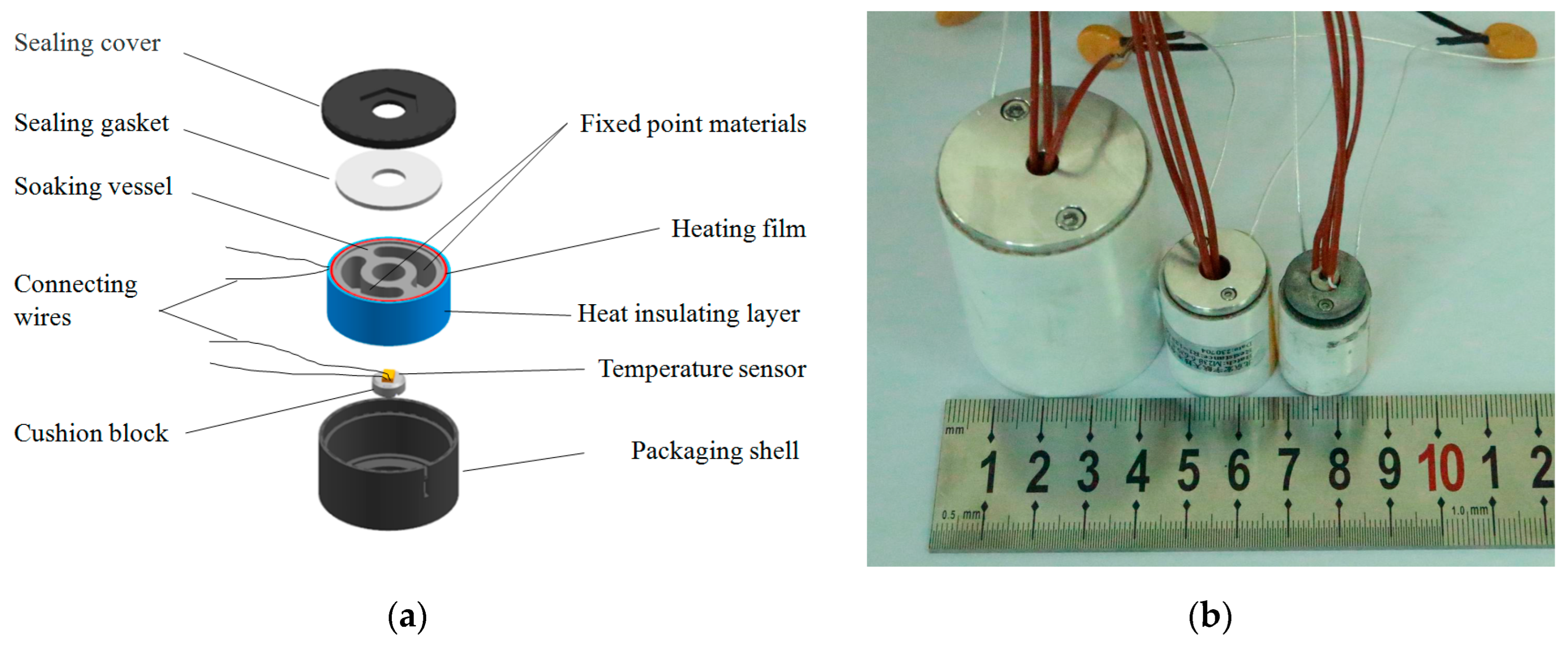

3.1. Fabrication of MISSC Thermometers

- A temperature sensing component. The copper-constantan (type T) thermocouple manufactured by Chengdu Shuangtie Instrument Co., Ltd. (Chengdu, China) was chosen as the temperature measurement sensor. It also can be replaced by other sensors such as platinum resistance;

- A fixed point container. It is a cylindrical soaking block shell with two fixed point material cells, separately filled with Ga and Ga-Zn. The cylindrical soaking block shell was made of graphite to guarantee a uniform temperature field;

- A flexible heating resistance film. It was uniformly pasted and wrapped around the cylindrical soaking block shell and could be used to heat the fixed point container when self-calibration was carried out. For safety considerations, a fuse is adopted and connected between the film and the power wire. An asbestos heat insulation layer was wrapped on the outermost wall.

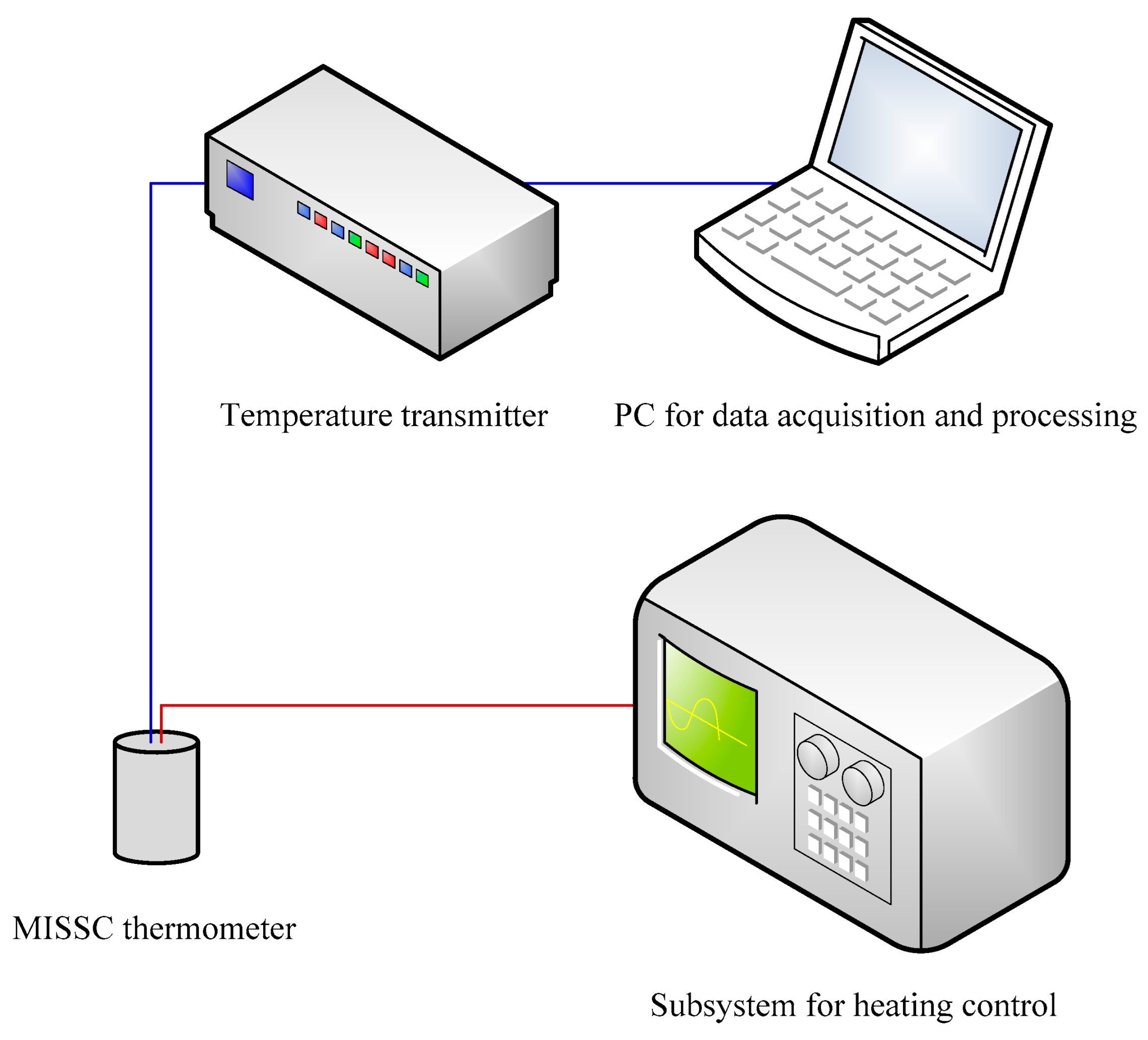

3.2. Integration of M&C System

- A heating control subsystem. It mainly includes a direct current (DC) power (DH1799M) made by Beijing Dahua Radio Instrument Co., Ltd. (Beijing, China) and a renewable fuse, which are used to control the heating power and ensure the temperature rising rate of the fixed-point materials.

- A temperature measurement subsystem. It is adopted to measure the temperature according to the temperature-sensing component in the MISSC thermometer. In detail, it consists of two parts: one is the temperature transmitter that can transmit the weak electromotive force signal generated by the thermocouple to a normalized voltage signal; the other is the data acquisition system whose hardware and software were installed in a personal computer (PC).

- A data processing subsystem. It is a self-developed software installed in the PC that is used to collect and process the temperature data obtained during mini-power heating for in-situ self-calibration and presenting a calibration result.

4. Experimental Results and Discussion

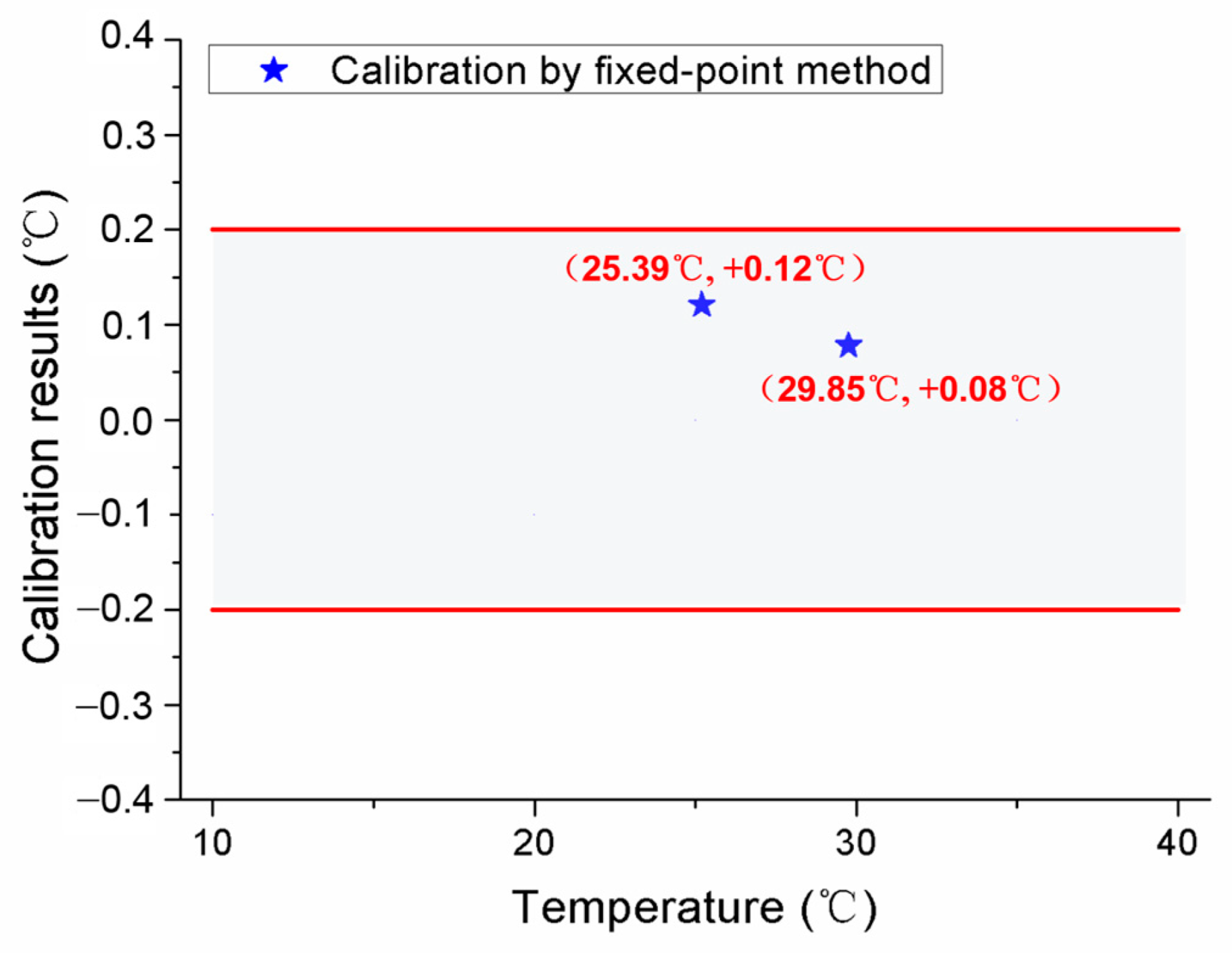

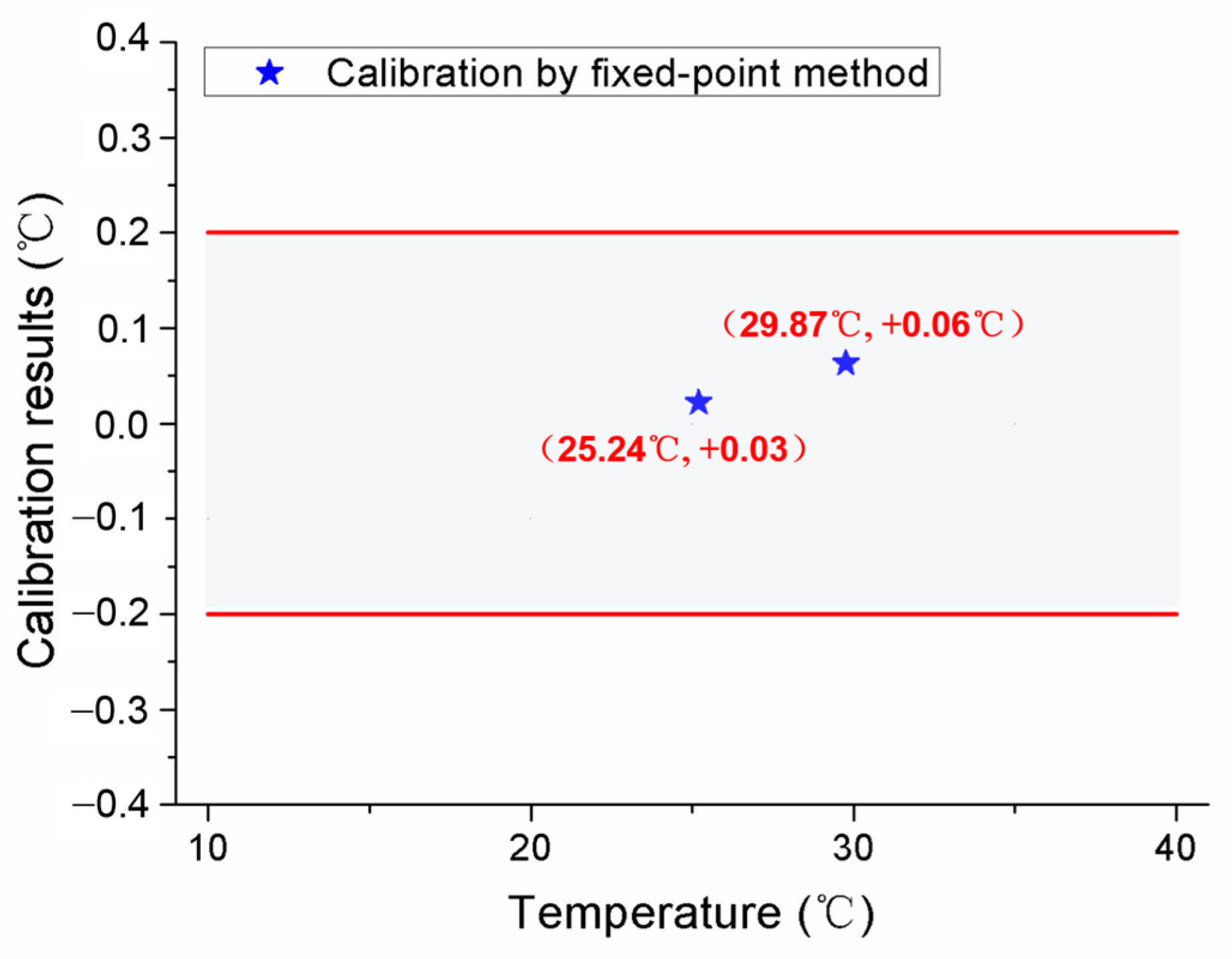

4.1. Initial Calibration

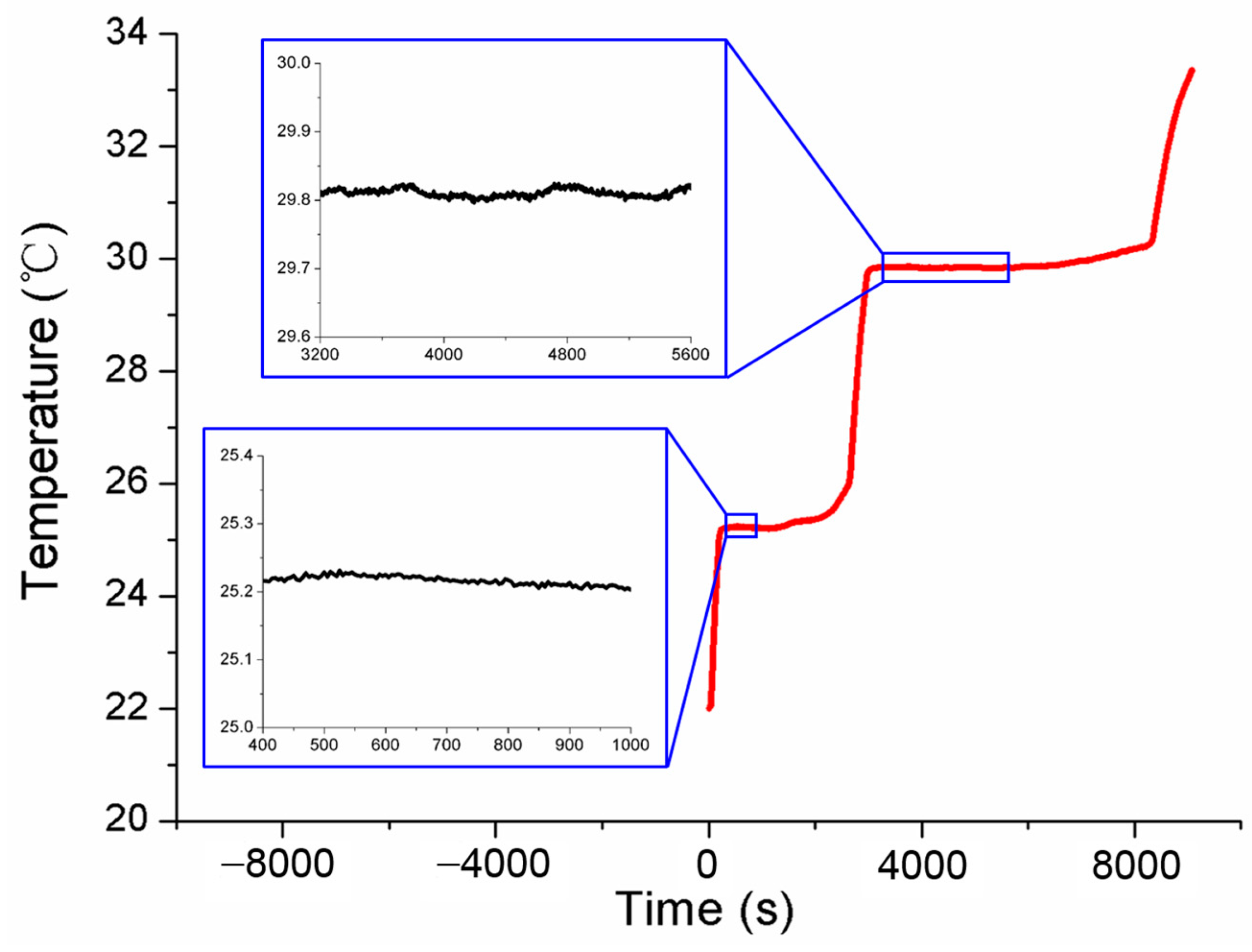

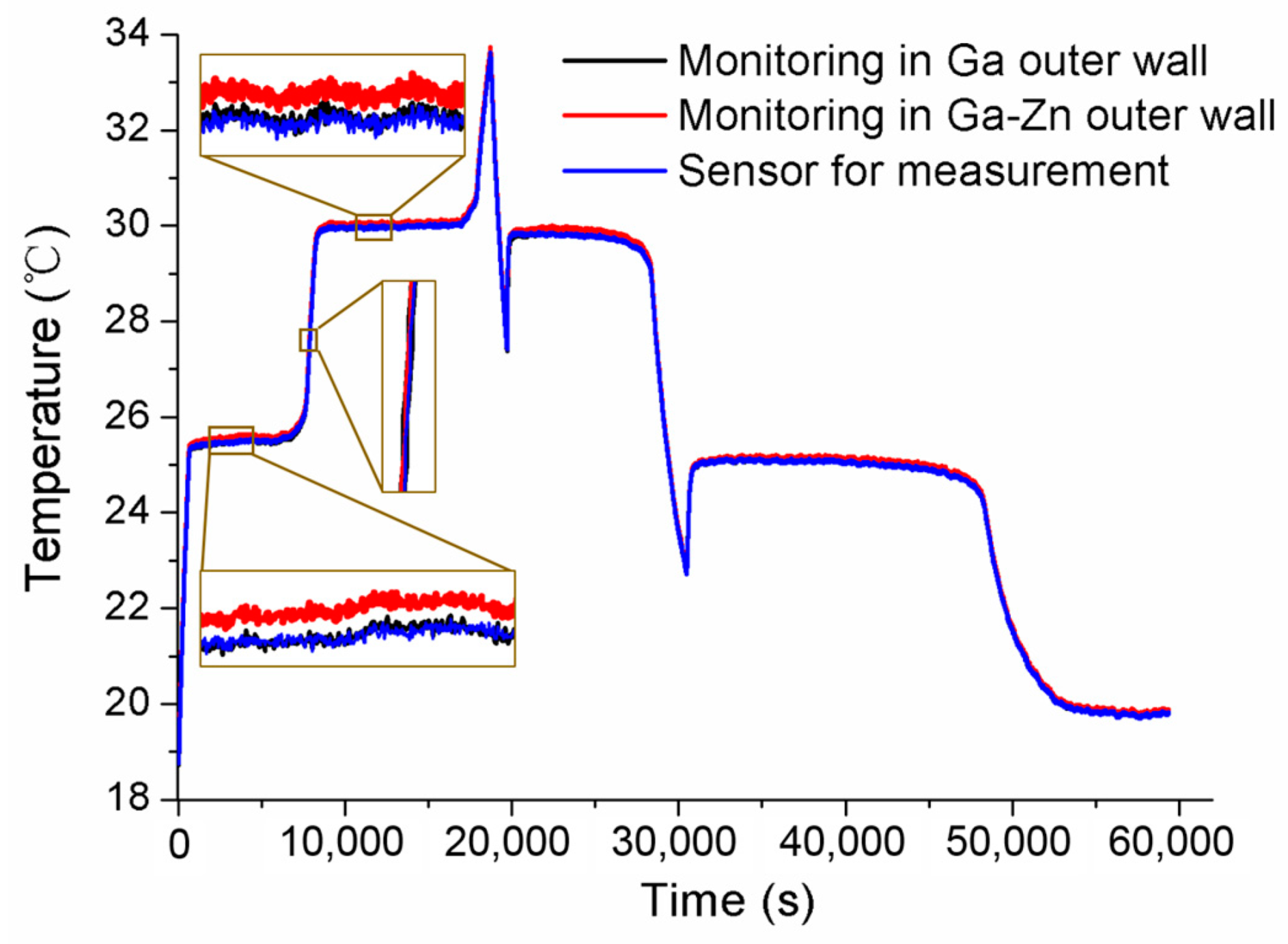

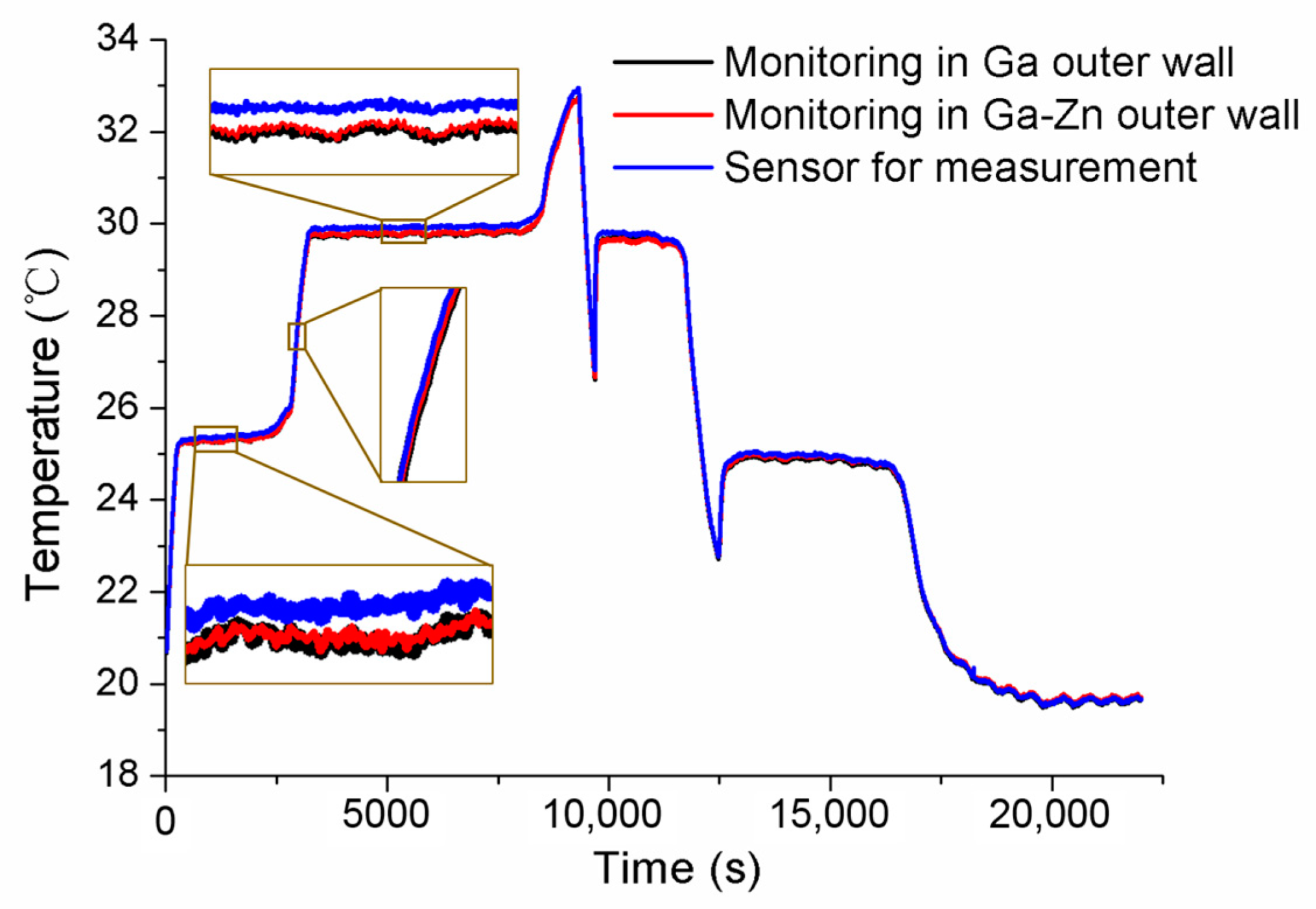

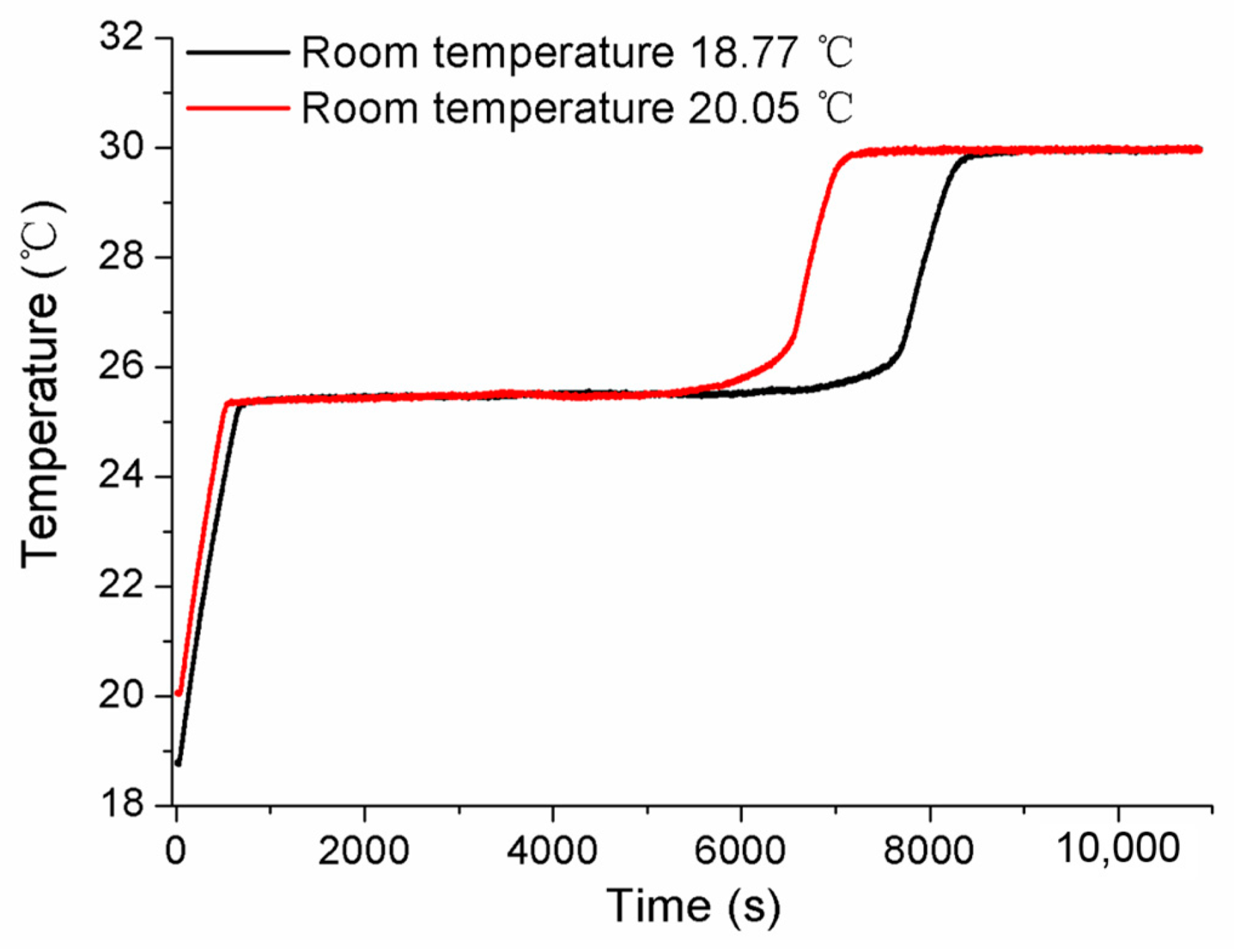

4.2. Self-Calibration

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rao, X.T.; Song, T.; Gao, J.K.; Cui, Y.J.; Yang, Y.; Wu, C.D.; Chen, B.L.; Qian, G.D. A highly sensitive mixed lanthanide metal–organic framework self-calibrated luminescent thermometer. J. Am. Chem. Soc. 2013, 135, 15559–15564. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.H.; Li, M.; Zheng, J.; Huang, X.C.; Li, D. A dual-emitting Cu6-Cu2-Cu6 cluster as a self-calibrated, wide-range luminescent molecular thermometer. Chem. Commun. 2014, 50, 9115–9118. [Google Scholar] [CrossRef] [PubMed]

- Takei, Y.; Arai, S.; Murata, A.; Takabayashi, M.; Oyama, K.; Ishiwata, S.; Takeoka, S.; Suzuki, M. A nanoparticle-based ratio metric and self-calibrated fluorescent thermometer for single living cells. ACS Nano 2014, 8, 198–206. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.Q.; Wan, Z.Y.; Liu, S. Highly sensitive dual-phase nano glass-ceramics self-calibrated optical thermometer. Anal. Chem. 2016, 88, 4099–4106. [Google Scholar] [CrossRef] [PubMed]

- Ding, M.Y.; Xu, M.; Chen, D.Q. A new non-contact self-calibrated optical thermometer based on Ce3+→Tb3+→Eu3+ energy transfer process. J. Alloys Compd. 2017, 713, 236–247. [Google Scholar] [CrossRef]

- Wu, Y.F.; Suo, H.; Zhao, X.Q.; Zhou, Z.W.; Guo, C.F. Self-calibrated optical thermometer LuNbO4:Pr3+/Tb3+ based on intervalence charge transfer transitions. Inorg. Chem. Front. 2018, 5, 2456–2461. [Google Scholar] [CrossRef]

- Chen, X.Y.; Zheng, Z.G.; Teng, L.M.; Wei, R.F.; Hu, F.F.; Guo, H. Self-calibrated optical thermometer based on luminescence from SrLu2O4:Bi3+, Eu3+ phosphors. RSC Adv. 2018, 8, 35422–35428. [Google Scholar] [CrossRef]

- Bao, J.Y.; Zong, X.Y.; Li, L.X.; Yu, K.; Liu, Y.F. Liquid crystal filled dual-channel self-calibration optical-fiber surface plasmon resonance thermometer. Appl. Opt. 2020, 59, 720–725. [Google Scholar] [CrossRef]

- Wan, Y.T.; Yu, L.B.; Xia, T.F. A dye-loaded nonlinear metal-organic framework as self-calibrated optical thermometer. Dye. Pigment. 2022, 202, 110234. [Google Scholar] [CrossRef]

- Li, Y.Y.; You, W.W.; Zhao, J.; Zhang, X.M.; Pan, G.C.; Mao, Y.L. A highly sensitive blue-LED-excitable self-calibrated luminescent thermometer based on Cr3+/Eu3+ Co-doped Al2W3O12. J. Lumin. 2023, 253, 119464. [Google Scholar] [CrossRef]

- Preston-Thomas, H. The international temperature scale of 1990(ITS-90). Metrologia 1990, 27, 3–10. [Google Scholar] [CrossRef]

- Burdakin, A.; Khlevnoy, B.; Samoylov, M.; Sapritsky, V.; Ogarev, S.; Panfilov, A.; Bingham, G.; Privalsky, V.; Tansock, J.; Humpherys, T. Melting points of gallium and of binary eutectics with gallium realized in small cells. Metrologia 2008, 45, 75–82. [Google Scholar] [CrossRef]

- Burdakin, A.; Khlevnoy, B.; Samoylov, M.; Sapritsky, V.; Ogarev, S.; Panfilov, A.; Prokhorenko, S. Development of gallium and gallium-based small-size eutectic melting fixed points for calibration procedures on autonomous platforms. Int. J. Thermophys. 2009, 30, 20–35. [Google Scholar] [CrossRef]

- Ivanova, A.G.; Gerasimov, S.F. Fixed point on the basis of Ga-In eutectic alloy for rapid monitoring of thermometers and temperature measurement systems. Meas. Tech. 2008, 51, 498–502. [Google Scholar] [CrossRef]

- Ivanova, A.G.; Gerasimov, S.F. The dependence of the phase transition temperature of Ga-Zn eutectic alloy on its morphology. Meas. Tech. 2009, 52, 52–56. [Google Scholar] [CrossRef]

- Marin, S.; Hohmann, M.; Schalles, M.; Krapf, G.; Frohlich, T. Insert with a multiple fixed-point cell for a dry block calibrator. Tech. Mess. Sensoren Gerate Syst. 2015, 82, 402–410. [Google Scholar] [CrossRef]

- Ongrai, O.; Pearce, J.V.; Machin, G.; Norranim, U. Multi-mini-eutectic fixed-point cell for type C thermocouple self-calibration. Int. J. Thermophys. 2015, 36, 423–432. [Google Scholar] [CrossRef]

- Ongrai, O.; Pearce, J.V.; Machin, G.; Sweeney, S. A miniature high-temperature fixed point for self-validation of type C thermocouples. Meas. Sci. Technol. 2011, 22, 105103. [Google Scholar] [CrossRef]

- Kim, Y.G.; Gam, K.S.; Yang, I. First measurement using three-in-one cell: A new design of the fixed-point cell for the calibration of thermometers. Metrologia 2008, 45, 356–361. [Google Scholar] [CrossRef]

- Ragay-Enot, M.; Lee, Y.H.; Kim, Y.G. Fabrication of a mini multi-fixed-point cell for the calibration of industrial platinum resistance thermometers. Meas. Sci. Technol. 2017, 28, 075007. [Google Scholar] [CrossRef]

- Hao, X.P.; Sun, J.P.; Xu, C.Y.; Wen, P.; Song, J.; Xu, M.; Gong, L.Y.; Ding, L.; Liu, Z.L. Miniature Fixed Points as Temperature Standards for In Situ Calibration of Temperature Sensors. Int. J. Thermophys. 2017, 38, 90. [Google Scholar] [CrossRef]

- Sun, J.P.; Hao, X.P.; Zeng, F.C.; Zhang, L.; Fang, X.Y. Onsite calibration of a precision IPRT based on gallium and gallium-based small-size eutectic points. Int. J. Thermophys. 2017, 38, 47. [Google Scholar] [CrossRef]

- Elliott, C.J.; Failleau, G.; Deuzé, T.; Sadli, M.; Pearce, J.V.; Machin, G. Long-term monitoring of thermocouple stability with miniature fixed-point cells. Int. J. Thermophys. 2014, 35, 560–573. [Google Scholar] [CrossRef]

- Edler, F.; Haupt, S.; Mokdad, S.A.; Failleau, G.; Sadli, M. Investigation of self-validating thermocouples with integrated fixed-point units. Int. J. Metrol. Qual. Eng. 2015, 6, 103. [Google Scholar] [CrossRef]

- Liu, Z.W.; Bando, Y.; Mitome, M.; Zhan, J.H. Unusual freezing and melting of gallium encapsulated in carbon nanotubes. Phys. Rev. Lett. 2004, 93, 095504. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.Y.; Kim, Y.G.; Yang, I. Study on the melting and freezing behaviour of high temperature binary eutectic fixed points using differential scanning calorimetry. Metrologia 2010, 47, 248–252. [Google Scholar] [CrossRef]

- Vasilev, A.A.; Podorozhkin, D.Y.; Nefedov, D.Y.; Charnaya, E.V.; Mikushev, V.M.; Kumzerov, Y.A.; Fokin, A.V. Structure transformations and supercooling in nanostructured gallium alloys. Appl. Magn. Reson. 2022, 53, 1649–1659. [Google Scholar] [CrossRef]

| No. | Diameter/mm | Height/mm | Ga Mass/g | Ga-Zn Mass/g |

|---|---|---|---|---|

| 1 | 40 | 50 | 86.44 | 87.21 |

| 2 | 20 | 30 | 8.87 | 8.92 |

| 3 | 16 | 25 | 4.04 | 4.18 |

| No. | Resistance/Ω | Applied Current/A | Heating Power/W |

|---|---|---|---|

| 1 | 455.9 | 0.06 | 1.64 |

| 2 | 128.1 | 0.06 | 0.46 |

| 3 | 83.6 | 0.08 | 0.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Cai, W.; Mao, Y.; Wan, K.; Wen, Y.; Han, Y.; Zhang, Q.; Zhang, R.; Zheng, X. A Study on Miniaturized In-Situ Self-Calibrated Thermometers Based on Ga and Ga-Zn Fixed Points. Sensors 2024, 24, 5744. https://doi.org/10.3390/s24175744

Huang H, Cai W, Mao Y, Wan K, Wen Y, Han Y, Zhang Q, Zhang R, Zheng X. A Study on Miniaturized In-Situ Self-Calibrated Thermometers Based on Ga and Ga-Zn Fixed Points. Sensors. 2024; 24(17):5744. https://doi.org/10.3390/s24175744

Chicago/Turabian StyleHuang, Haiying, Wenlu Cai, Yongjian Mao, Kun Wan, Yong Wen, Yuqiang Han, Qiang Zhang, Rong Zhang, and Xing Zheng. 2024. "A Study on Miniaturized In-Situ Self-Calibrated Thermometers Based on Ga and Ga-Zn Fixed Points" Sensors 24, no. 17: 5744. https://doi.org/10.3390/s24175744

APA StyleHuang, H., Cai, W., Mao, Y., Wan, K., Wen, Y., Han, Y., Zhang, Q., Zhang, R., & Zheng, X. (2024). A Study on Miniaturized In-Situ Self-Calibrated Thermometers Based on Ga and Ga-Zn Fixed Points. Sensors, 24(17), 5744. https://doi.org/10.3390/s24175744