Improvement of Temperature Measurement Accuracy of Hot Airflow Using Ultrafine Thermo-Sensitive Fluorescent Wires of Lumisis Phosphor

Abstract

:1. Introduction

2. Measurement Methods and Experimental Setup

2.1. Laser-Induced Fluorescence (LIF)

- (1)

- The relationship between IA/IB and the temperature is known.

- (2)

- The concentration ratio CA/CB is kept constant.

2.2. Lumisis Phosphor

2.3. Two-Wavelength Spectral Optics

2.4. Measurement of Wavelength Distribution of Lumisis Phosphor

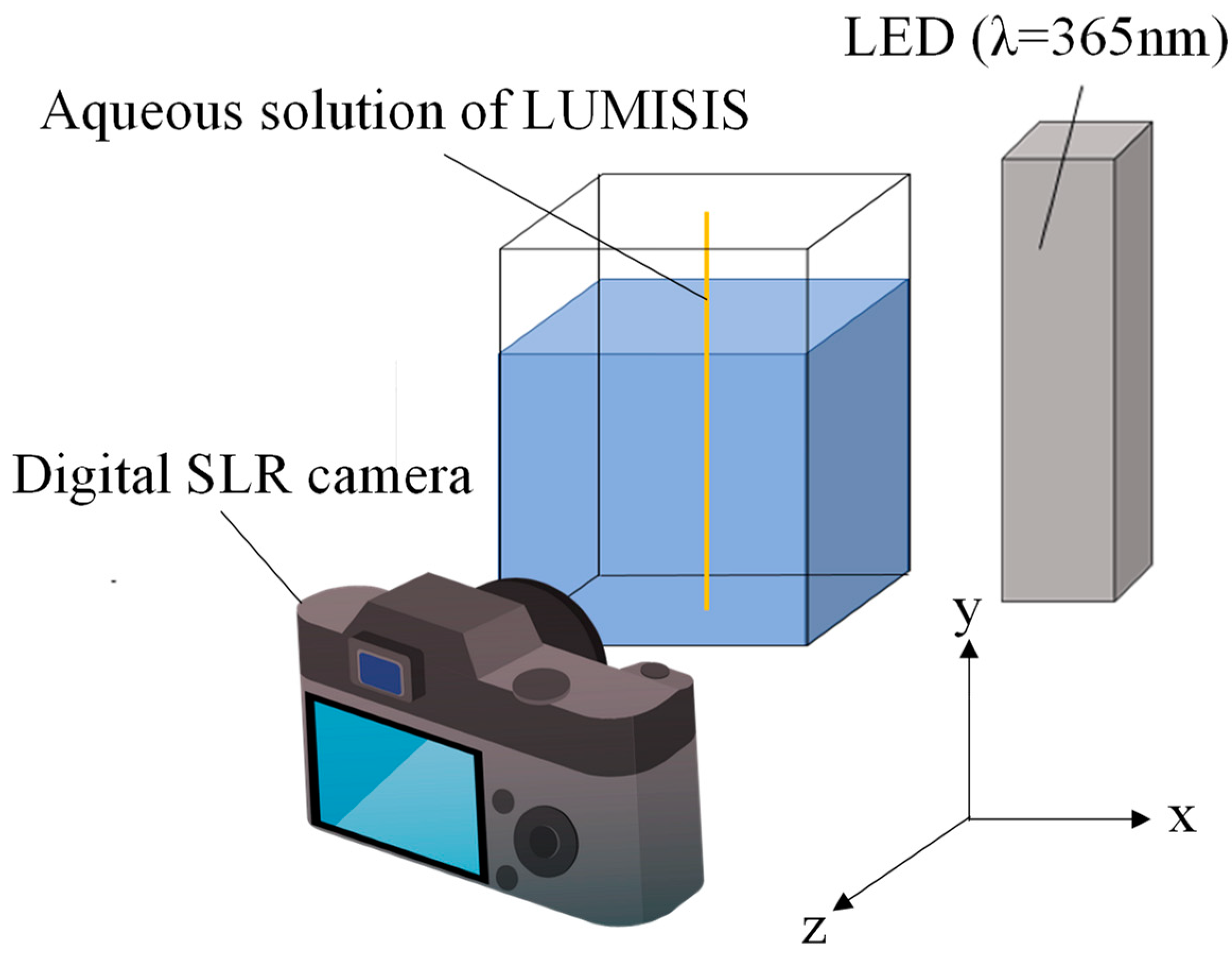

2.5. Evaluation of Temperature Measurement Accuracy

- (1)

- Fill the glass tank with water.

- (2)

- Fix the fluorescent wire vertically at the center of the tank.

- (3)

- Set the camera in an optimal position such that the entire fluorescent wire can be observed.

- (4)

- Shine an ultraviolet LED light on the fluorescent wire.

- (5)

- Increase the water temperature from 20 °C to 50 °C at 10 °C intervals and capture the images of the fluorescent wire at each temperature.

- (6)

- Calculate the temperature of the entire fluorescent wire (at each temperature) from the data obtained via image analysis and compare it with the corresponding temperature in water to evaluate the measurement error.

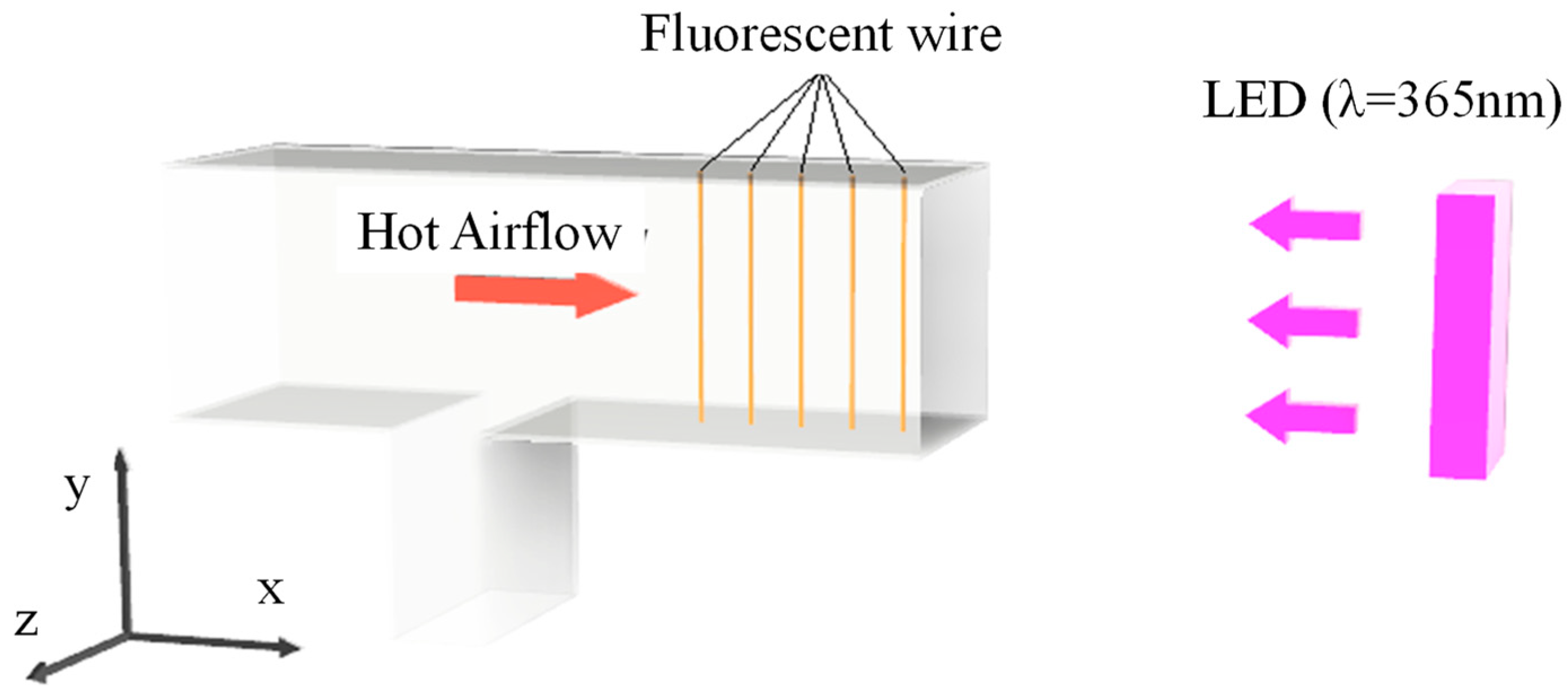

2.6. Experimental Setup for Measurement of Temperature Distribution Using Lumisis Phosphor

- (1)

- Fix the Lumisis phosphor wire in the measurement area of the experimental setup.

- (2)

- Position the camera equipment perpendicular to the measurement area.

- (3)

- Switch off the room light.

- (4)

- Increase the temperature in the measurement area from 20 °C to 80 °C at 10 K intervals using a heater, mix the air to keep the temperature uniform, and then capture images of the fluorescent wire at each temperature.

- (5)

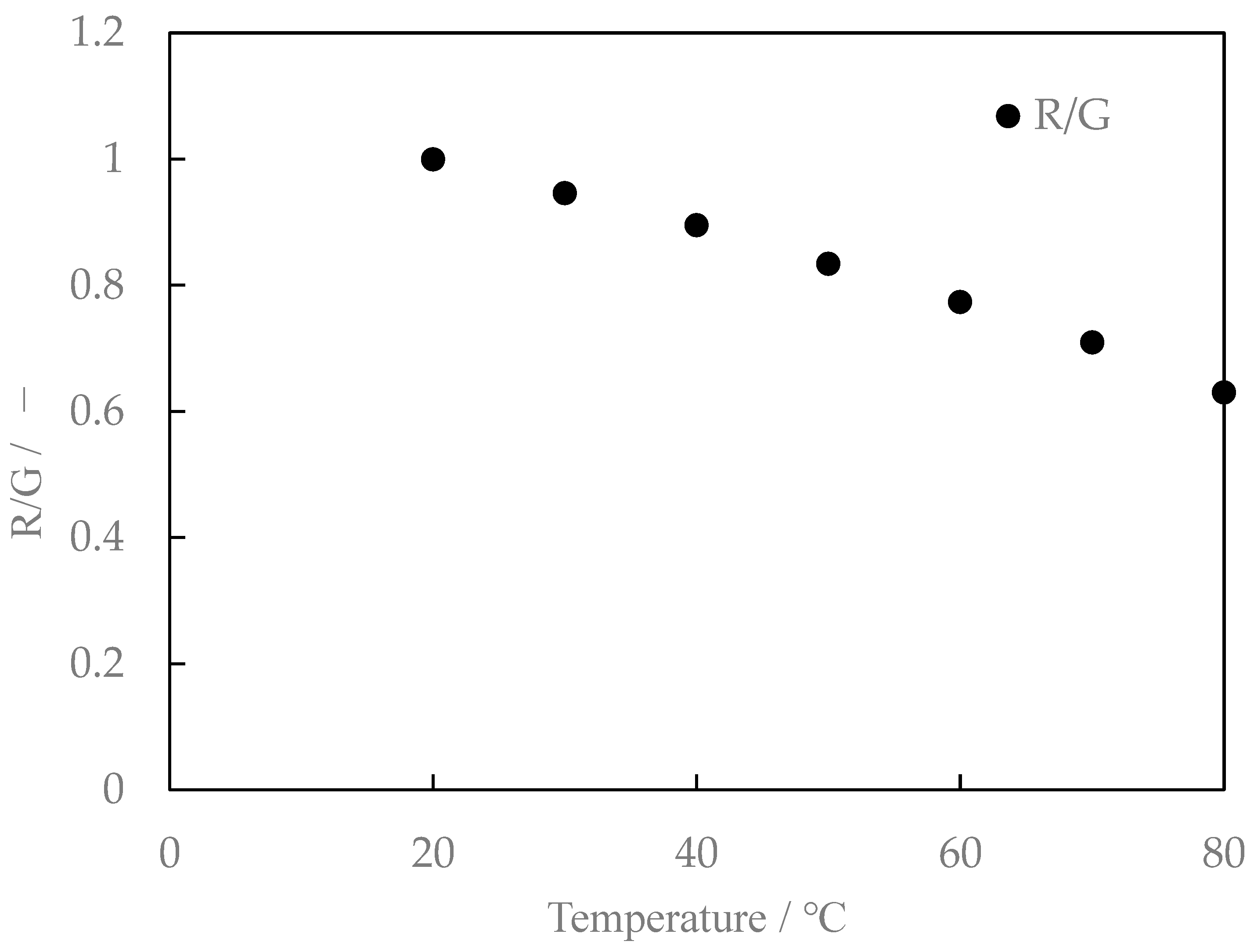

- Calculate the relationship between the temperature and luminance ratio.

- (6)

- Take images and acquire R and G values of the wire surface.

- (7)

- Convert the luminance ratios of the R and G values of the wire surface into temperature values.

- (8)

- Calculate the 2D temperature distribution via the linear interpolation of the obtained temperature values for each wire surface.

3. Results

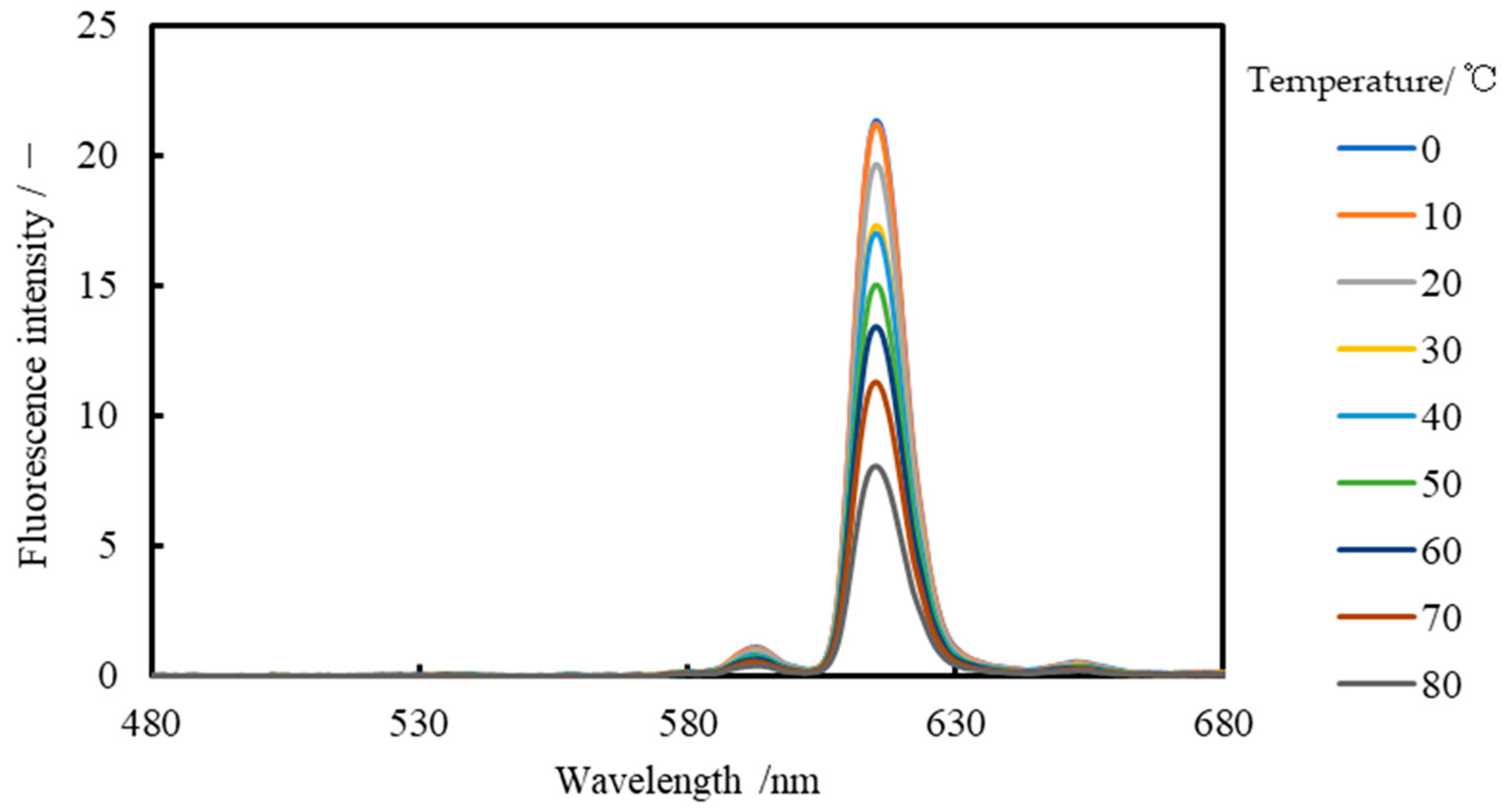

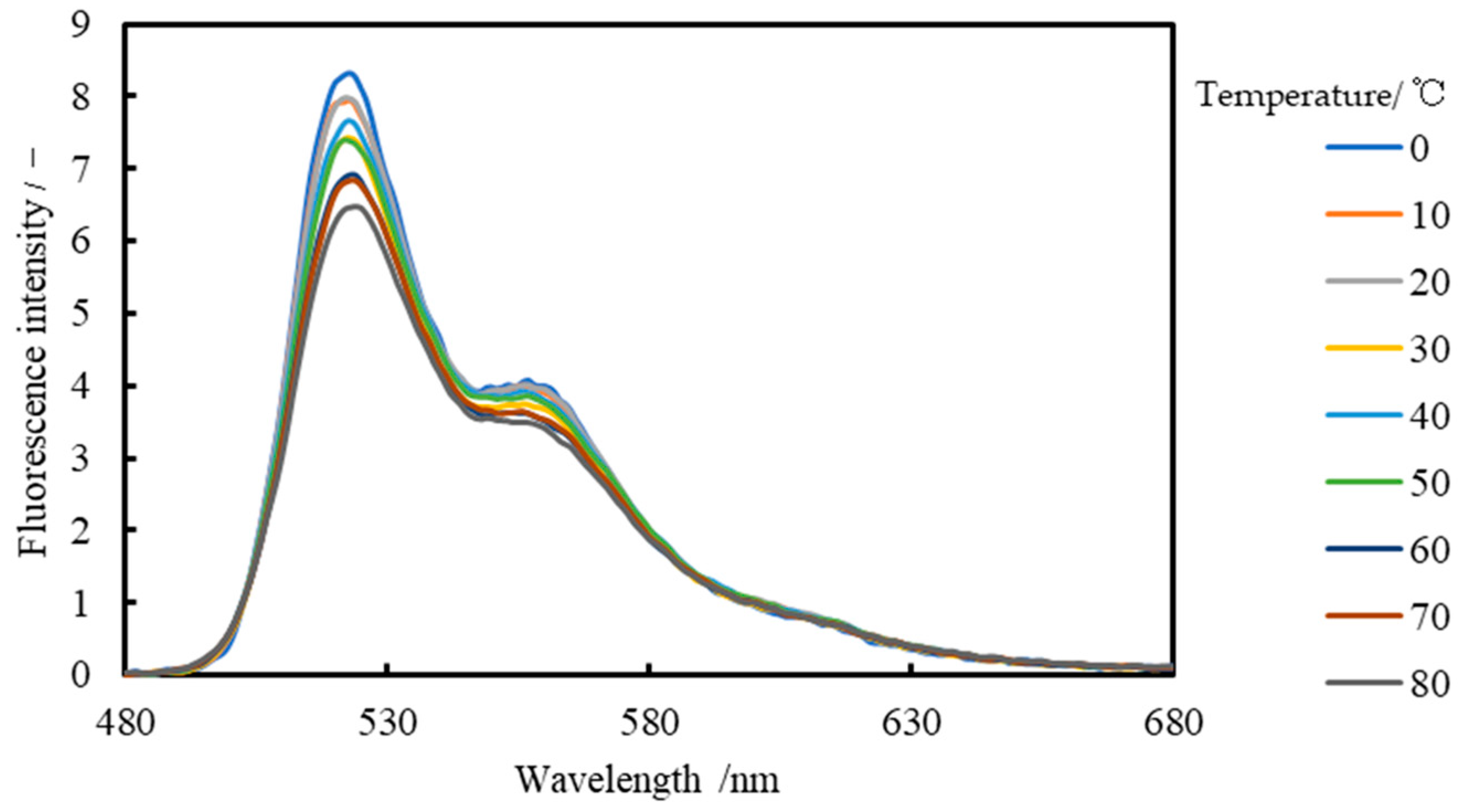

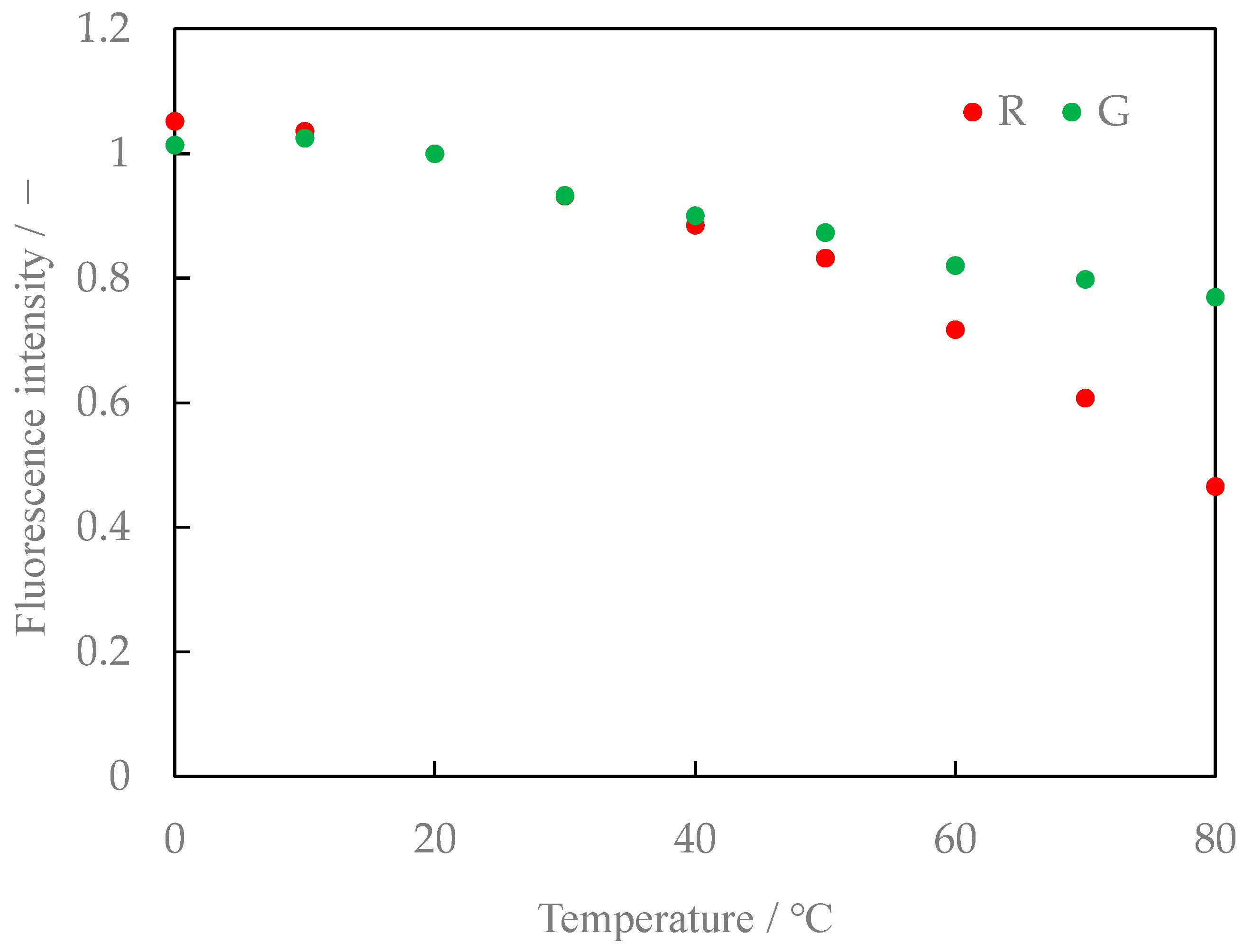

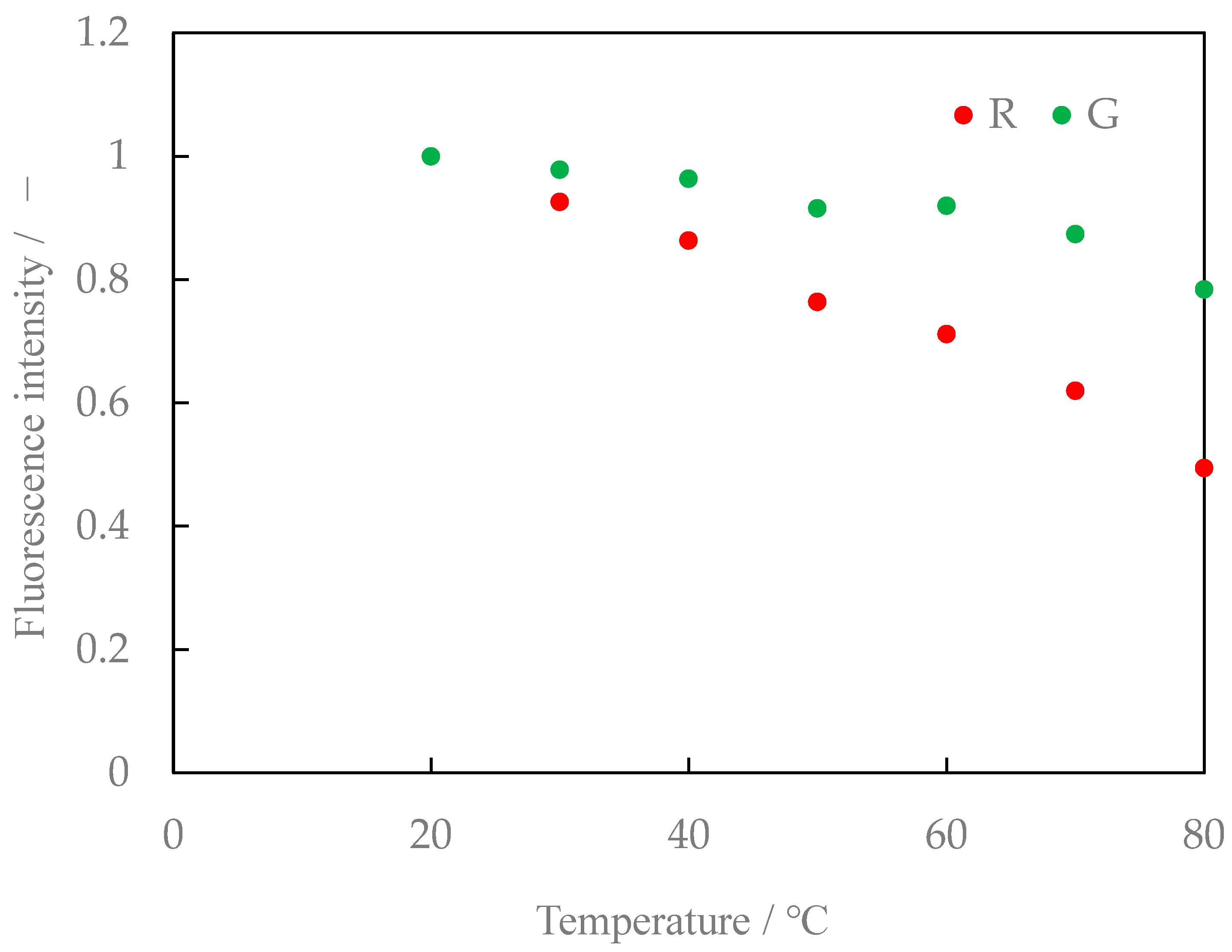

3.1. Characteristics of Lumisis Phosphor

3.2. Characteristics of Mixed Aqueous Solution of Lumisis Red and Green

3.3. Uncertainty Analysis

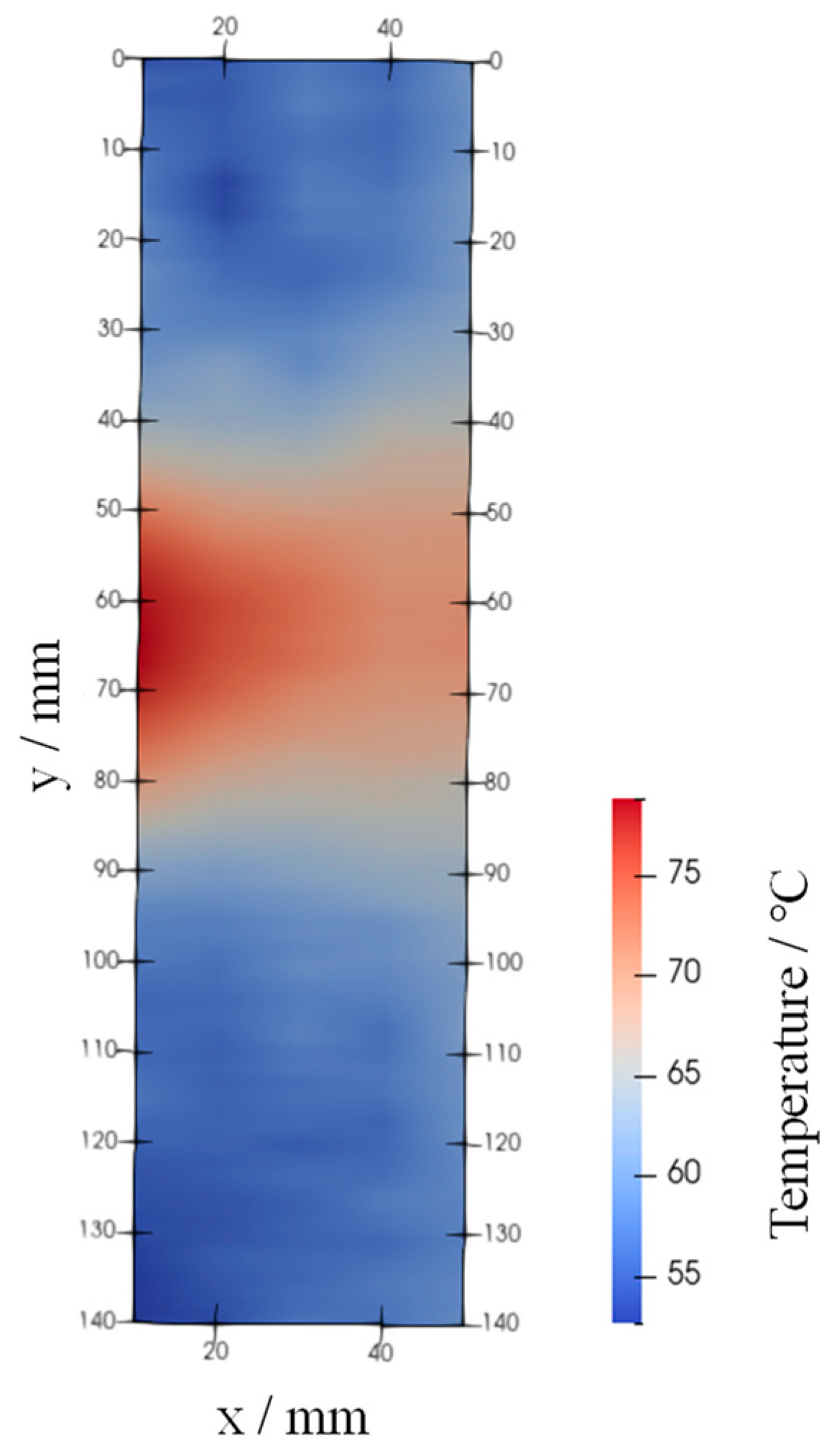

4. Application to Flow Fields

5. Conclusions

- (1)

- The difference in the percentage decrease in the intensity of the Red and Green fluorescence of Lumisis phosphors shows that two-color LIF using Lumisis phosphors is possible.

- (2)

- A Red/Green ratio of 1:1.25 of Lumisis phosphor enabled the highly accurate measurement of temperature changes as well as strong luminescence.

- (3)

- The average measurement error of the fluorescent wire was improved to 0.20 K, compared to the previous studies coating rhodamine B, thereby proving that the temperature measurement accuracy of the proposed method is high.

- (4)

- The results of the application of the proposed measurement method to hot air jet phenomena show that the temperature changes in hot air are accurately captured, thereby proving its validity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wade, S.A.; Collins, S.F.; Baxter, G.W. Fluorescence intensity ratio technique for optical fiber point temperature sensing. J. Appl. Phys. 2003, 94, 4743–4756. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Q.; Zhu, W.; Yang, M.; Lewis, E. Novel optical fiber SPR temperature sensor based on MMF-PCF-MMF structure and gold-PDMS film. Opt. Express 2018, 26, 1910–1917. [Google Scholar] [CrossRef] [PubMed]

- Sakakibara, J.; Adrian, R.J. Whole field measurement of temperature in water using two-color laser induced fluorescence. Exp. Fluids 1999, 26, 7–15. [Google Scholar] [CrossRef]

- Hishida, K.; Sakakibara, J. Combined planar laser-induced fluorescence-particle image velocimetry technique for velocity and temperature fields. Exp. Fluids 2000, 29, 129–140. [Google Scholar] [CrossRef]

- Sakakibara, J.; Adrian, R.J. Measurement of temperature field of a Rayleigh-Bénard convection using two-color laser-induced fluorescence. Exp. Fluids 2004, 37, 331–340. [Google Scholar] [CrossRef]

- Kashanj, S.; Nobes, D.S. Application of 4D two-colour LIF to explore the temperature field of laterally confined turbulent Rayleigh–Bénard convection. Exp. Fluids 2023, 64, 46. [Google Scholar] [CrossRef]

- Abdelghany, A.; Kuribayashi, K.; Tange, M. Ratiometric laser-induced fluorescence for liquid-phase thermometry around boiling bubbles at extended temperatures above 70 °C. Exp. Fluids 2022, 63, 52. [Google Scholar] [CrossRef]

- Abram, C.; Pougin, M.; Beyrau, F. Temperature field measurements in liquids using ZnO thermographic phosphor tracer particles. Exp. Fluids 2016, 57, 115. [Google Scholar] [CrossRef]

- Vogt, J.; Stephan, P. Using microencapsulated fluorescent dyes for simultaneous measurement of temperature and velocity fields. Meas. Sci. Technol. 2012, 23, 105306. [Google Scholar] [CrossRef]

- Massing, J.; Kaden, D.; Kähler, C.J.; Cierpka, C. Luminescent two-color tracer particles for simultaneous velocity and temperature measurements in microfluidics. Meas. Sci. Technol. 2016, 27, 115301. [Google Scholar] [CrossRef]

- Cellini, F.; Peterson, S.D.; Porfiri, M. Flow velocity and temperature sensing using thermosensitive fluorescent polymer seed particles in water. Int. J. Smart Nano Mater. 2017, 8, 232–252. [Google Scholar] [CrossRef]

- Dabiri, D. Digital particle image thermometry/velocimetry: A review. Exp. Fluids 2009, 46, 191–241. [Google Scholar] [CrossRef]

- Kowalewski, T.A.; Ligrani, P.; Dreizler, A.; Schulz, C.; Fey, U. Temperature and Heat Flux: Thermochromic Liquid Crystals. In Springer Handbook of Experimental Fluid Mechanics; Tropea, C., Yarin, A.L., Foss, J.F., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 487–500. [Google Scholar] [CrossRef]

- Nobuyuki, F.; Watanabe, M.; Hashizume, Y. Visualization of turbulence structure in unsteady non-penetrative thermal convection using liquid crystal thermometry and stereo velocimetry. J. Vis. 2008, 11, 173–180. [Google Scholar] [CrossRef]

- Jan, S.; Jewartowski, M. LCT, PIV and IR Imaging Detection in Selected Technical and Biomedical Applications. J. Phys. Conf. Ser. 2019, 1224, 012029. [Google Scholar] [CrossRef]

- Funatani, S.; Toriyama, K.; Takeda, T. Temperature Measurement of Air Flow Using Fluorescent Mists Combined with Two-Color LIF. J. Flow Control Meas. Vis. 2013, 1, 20–23. [Google Scholar] [CrossRef]

- Funatani, S.; Tsukamoto, Y.; Toriyama, K. Temperature measurement of hot airflow using ultra-fine thermo-sensitive fluorescent wires. Sensors 2022, 22, 3175. [Google Scholar] [CrossRef]

- Allison, S.W.; Gillies, G.T. Remote thermometry with thermographic phosphors: Instrumentation and applications. Rev. Sci. Instrum. 1997, 68, 2615–2650. [Google Scholar] [CrossRef]

- Shumpei, F.; Takei, R.; Tsukamoto, Y. Development of a Temperature Distribution Measurement System for Transmission Oil for Transportation Equipment. Sensors 2023, 23, 5499. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, Y.; Ohkubo, T.; Nakanishi, T.; Kobayashi, A.; Kato, M.; Seki, T.; Ito, H.; Fushimi, K. Effect of ligand polarization on asymmetric structural formation for strongly luminescent lanthanide complexes. Eur. J. Inorg. Chem. 2013, 34, 5911–5918. [Google Scholar] [CrossRef]

- Lumisis Phosphor (Central Techno Co., Ltd.). Available online: https://www.central-techno.co.jp/lumisis.html (accessed on 1 January 2024).

| Temperature, °C | 30 | 40 | 50 |

| Measurement error, K | ±0.08 | ±0.10 | ±0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Funatani, S.; Tsukamoto, Y. Improvement of Temperature Measurement Accuracy of Hot Airflow Using Ultrafine Thermo-Sensitive Fluorescent Wires of Lumisis Phosphor. Sensors 2024, 24, 2510. https://doi.org/10.3390/s24082510

Funatani S, Tsukamoto Y. Improvement of Temperature Measurement Accuracy of Hot Airflow Using Ultrafine Thermo-Sensitive Fluorescent Wires of Lumisis Phosphor. Sensors. 2024; 24(8):2510. https://doi.org/10.3390/s24082510

Chicago/Turabian StyleFunatani, Shumpei, and Yusaku Tsukamoto. 2024. "Improvement of Temperature Measurement Accuracy of Hot Airflow Using Ultrafine Thermo-Sensitive Fluorescent Wires of Lumisis Phosphor" Sensors 24, no. 8: 2510. https://doi.org/10.3390/s24082510