Modular and Cost-Effective Computed Tomography Design

Abstract

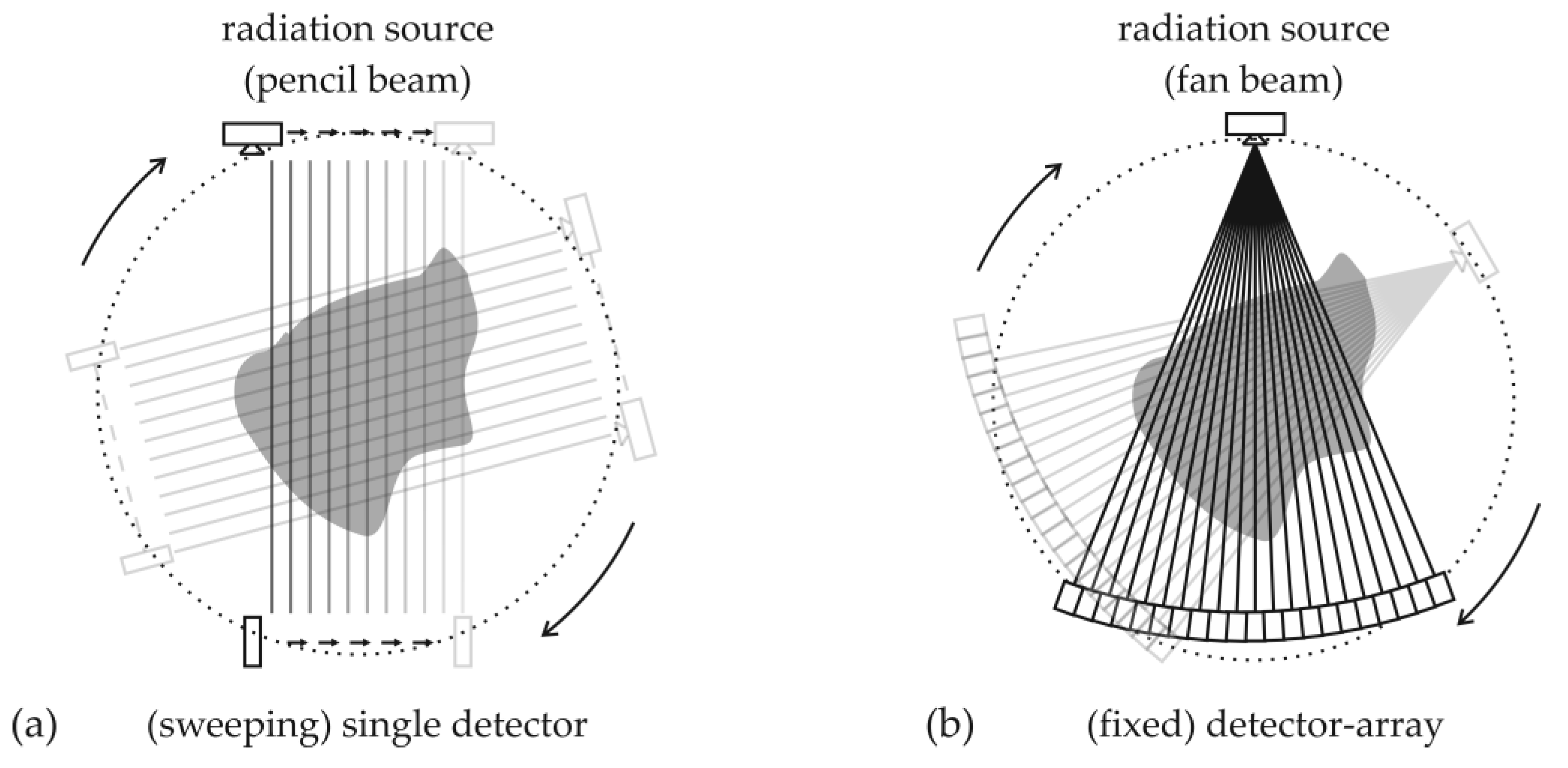

1. Introduction

2. Materials and Methods

2.1. Object-Adaptable CT Scanning Procedure

2.2. The Gamma Ray Detector Arc

- -

- Maximal compatibility with the pencil beam CT infrastructure, e.g., using their existing rotating, lifting and traverse units;

- -

- High gamma photon flux and detector interaction efficiency to optimal gamma photon statistics in the shortest scanning interval;

- -

- Pulse count operation with sufficient energy resolution to perform energy discrimination for each detected gamma photon;

- -

- Insensitivity to electromagnetic fields;

- -

- Long-term stability over many hours/days/weeks;

- -

- Data transfer/detector control over long distances up to 50 m;

- -

- Power supply must be exclusively provided over the data/control interface.

- -

- Split power over Ethernet (PoE) into (a) power supply for the detector electronic and temperature control unit and (b) standard 10/100 MBit Ethernet interface [38];

- -

- Operate the temperature control unit of the detector line.

2.3. ATEX Test Rig

- -

- All the moving parts are inside the acrylic glass housing. Therefore, there is no risk of becoming trapped.

- -

- The radiation that passes the detector arc is contained by a lead shield behind the detector arc that moves together with the assembly. The acryl glass housing ensures that no one can access the area between the gamma ray source and lead shield, so there is no danger of radiation exposure.

3. Results

3.1. Detector Evaluation

3.2. Demonstration of Attenuation Value Evaluation

3.3. Scanning Evaluation

3.4. CT Scans at the Test Rig with Iso-Hexane

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Value |

|---|---|

| Isotopic source | |

| Isotope | 137Cs |

| Photon energy | ≈662 keV |

| Half-life | ≈30.2 a |

| Dimension | Ø 6.4 mm × 16 mm |

| Activity | ≈200 mCi (7.4 GBq) |

| Radiation angle/height | ≈19°/25 mm |

| Detector arc | |

| Number of elements | 4 × 4 |

| Active area per element | 10 × 10 mm2 |

| Scintillation material | LYSO |

| Photon stopping efficiency | ≈75% |

| Detection angle/height | ≈16.36°/10 mm |

| Focus point | ≈1100 mm |

| Photonic converter | APD (S8664-1010, Hamamatsu) |

| Energy resolution | ≈13.5% (at 25 °C) |

| Dark counting rate | ≈120 cps (at 25 °C) |

| Temperature control system | Peltier + liquid |

| Temperature stabilization | ±0.5 K |

| Detector operating mode | Pulse mode/Energy discrimination |

| Data interface | 10/100 MBit |

| Power supply | PoE: IEEE 802.3bt-2018 |

| Temperature measuring points | 4 × 4 = 16 |

| Driving unit | |

| Positioning accuracy | ±0.2°, ±0.5 mm |

| Maximum object diameter | 770 mm |

References

- Bender, P.; Moll, A. Modifications to structured packings to increase their capacity. Chem. Eng. Res. Des. 2002, 81, 58–67. [Google Scholar] [CrossRef][Green Version]

- Moll, A. Air distillation. In Distillation: Operation and Applications; Gorak, A., Schoenmakers, H., Eds.; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Petrova, T.; Darakchiev, R.; Semkov, K.; Darakchiev, S. Estimations of Gas Flow Maldistribution in Packed-Bed Columns. Chem. Eng. Technol. 2008, 31, 1723–1729. [Google Scholar] [CrossRef]

- Stoter, F.; Olujić, Ž.; de Graauw, J. Modelling and measurement of gas flow distribution in corrugated sheet structured packings. Chem. Eng. J. Biochem. Eng. J. 1993, 53, 55–66. [Google Scholar] [CrossRef]

- Billingham, J.F.; Lockett, M.J. A Simple Method to Assess the Sensitivity of Packed Distillation Columns to Maldistribution. Chem. Eng. Res. Des. 2002, 80, 373–382. [Google Scholar] [CrossRef]

- Olujić, Ž. Development of a complete simulation model for predicting the hydraulic and separation performance of distillation columns equipped with structured packings. Chem. Biochem. Eng. Q. 1997, 11, 31–46. [Google Scholar]

- Pavlenko, A.N.; Pecherkin, N.; Chekhovich, V.; Zhukov, V.E.; Sunder, S.; Houghton, P.; Nazarov, A. Separation of mixtures and distribution of a liquid on a structured packing in a large-scale model of a distillation column. Theor. Found. Chem. Eng. 2006, 40, 329–338. [Google Scholar] [CrossRef]

- Pavlenko, A.N.; Pecherkin, N.; Chekhovich, V.; Zhukov, V.E.; Sunder, S.; Houghton, P. Experimental study of the effect of maldistribution at the structured packing inlet on the freon mixture separation efficiency. Theor. Found. Chem. Eng. 2009, 43, 1–11. [Google Scholar] [CrossRef]

- Pavlenko, A.N.; Zhukov, V.E.; Pecherkin, N.; Chekhovich, V.; Volodin, O.A.; Shilkin, A.; Großmann, C. Investigation of flow parameters and efficiency of mixture separation on a structured packing. AIChE J. 2014, 60, 690–705. [Google Scholar] [CrossRef]

- Toye, D.; Marchot, P.; Crine, M.; Pelsser, A.-M.; L’Homme, G. Local measurements of void fraction and liquid holdup in packed columns using X-ray computed tomography. Chem. Eng. Process. 1998, 37, 511–520. [Google Scholar] [CrossRef]

- Aferka, S.; Crine, M.; Saroha, A.-K.; Toye, D.; Marchot, P. In situ measurements of the static liquid holdup in Katapak-SP 12TM packed column using X-ray tomography. Chem. Eng. Sci. 2007, 62, 6076–6080. [Google Scholar] [CrossRef]

- Schug, S.; Arlt, W. Imaging of Fluid Dynamics in a Structured Packing Using X-ray Computed Tomography. Chem. Eng. Technol. 2016, 39, 1561–1569. [Google Scholar] [CrossRef]

- De Vuono, A.C.; Schlosser, P.A.; Kulacki, F.A.; Munshi, P. Design of an Isotopic CT Scanner for Two Phase Flow Measurements. IEEE Trans. Nucl. Sci. 1980, 27, 814–820. [Google Scholar] [CrossRef]

- Kumar, S.B.; Moslemian, D.; Dudukovic, M.P. Gas Holdup Measurements in Bubble Columns using Computed Tomography. AIChE J. 1995, 43, 1414–1425. [Google Scholar] [CrossRef]

- Kumar, S.B.; Moslemian, D.; Dudukovic, M.P. A gamma-ray Tomographic Scanner for Imaging Voidage Distribution in Two-Phase Flow Systems. Flow Meas. Instrum. 1995, 6, 61–73. [Google Scholar] [CrossRef]

- Johansen, G.A.; Froystein, T.; Hjertaker, B.T.; Olsen, O. A Dual Sensor Flow Imaging Tomographic System. Meas. Sci. Technol. 1996, 7, 297–307. [Google Scholar] [CrossRef]

- Shollenberger, K.A.; Torczynski, J.R.; Adkins, D.R.; O’Hern, T.J.; Jackson, N.B. Gamma-Densitometriy Tomography of Gas Holdup Spatial Distribution in Industral-Scale Bubble Columns. Chem. Eng. Sci. 1997, 52, 2037–2048. [Google Scholar] [CrossRef]

- Kemoun, A.; Ong, B.C.; Gupta, P.; Al-Dahan, M.H.; Dudukovic, M.P. Gas Holdup in Bubble Columns at Elevated Pressure via Computed Tomography. Int. J. Multiph. Flow 2001, 27, 929–946. [Google Scholar] [CrossRef]

- Kok, H.V.; van der Hagen, T.H.J.J.; Mudde, R.F. Subchannel Void-Fraction Measurements in a 6 × 6 Rod Bundle using a single gamma-transmission Methode. Int. J. Multiph. Flow 2001, 27, 147–170. [Google Scholar] [CrossRef]

- Veera, U.P. Gamma Ray Tomography Design for the Measurement of Hold-Up Profiles in Two-Phase Bubble Columns. Chem. Eng. J. 2001, 81, 251–260. [Google Scholar] [CrossRef]

- Thorn, R.; Johansen, G.A.; Hjertaker, B.T. Three-phase flow measurement in the petroleum industry. Meas. Sci. Technol. 2013, 24, 012003. [Google Scholar] [CrossRef]

- Boyer, C.; Fanget, B. Measurement of liquid flow distribution in trickle bed reactor of large diameter with a new gamma-ray tomographic system. Chem. Eng. Sci. 2002, 57, 1079–1089. [Google Scholar] [CrossRef]

- Bradtmöller, C.; Janzen, A.; Crine, M.; Toye, D.; Kenig, E.; Scholl, S. Influence of Viscosity on Liquid Flow Inside Structured Packings. Ind. Eng. Chem. Res. 2015, 54, 2803–2815. [Google Scholar] [CrossRef]

- Fourati, M.; Roig, V.; Raynal, L. Experimental study of liquid spreading in structured packings. Chem. Eng. Sci. 2012, 80, 1–15. [Google Scholar] [CrossRef]

- Olujić, Ž.; Jansen, H. Large-diameter experimental evidence on liquid (mal)distribution properties of structured packings. Chem. Eng. Res. Des. 2015, 99, 2–13. [Google Scholar] [CrossRef]

- Rollbusch, P.; Becker, M.; Ludwig, M.; Bieberle, A.; Grünewald, M.; Hampel, U.; Franke, R. Experimental investigation of the influence of column scale, gas density and liquid properties on gas holdup in bubble columns. Int. J. Multiph. Flow 2015, 75, 88–106. [Google Scholar] [CrossRef]

- Sidi-Boumedine, R.; Raynal, L. Influence of the viscosity on the liquid hold-up in trickle-bed reactors with structured packings. Catal. Today 2005, 105, 673–679. [Google Scholar] [CrossRef]

- Wehrli, M.; Kögl, T.; Linder, T.; Arlt, W. An unobstructed view of liquid flow in structured packing. Chem. Eng. Trans. 2018, 69, 775–780. [Google Scholar] [CrossRef]

- Yin, F.; Afacan, A.; Nandakumar, K.; Chuang, K.T. Liquid holdup distribution in packed columns: Gamma ray tomography and CFD simulation. Chem. Eng. Process. 2002, 41, 473–483. [Google Scholar] [CrossRef]

- Kak, A.C.; Slaney, M. Principles of Computerized Tomographic Imaging; IEEE Press: New York, NY, USA, 1988. [Google Scholar] [CrossRef]

- Wang, M. (Ed.) Industrial Tomography; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Hampel, U.; Bieberle, A.; Hoppe, D.; Kronenberg, J.; Schleicher, E.; Sühnel, T.; Zimmermann, F.; Zippe, C. High resolution gamma ray tomography scanner for flow measurement and non-destructive testing applications. Rev. Sci. Instrum. 2007, 78, 103704. [Google Scholar] [CrossRef]

- Hoffmann, R.; Kögl, T. An ATEX-proof gamma tomography setup for measuring liquid distribution in process equipment. Flow Meas. Instrum. 2017, 53, 147–153. [Google Scholar] [CrossRef]

- Saint-Gobain Ceramics & Plastics. Datasheet: LYSO Scintillation Material. 2018. Available online: https://www.crystals.saint-gobain.com/sites/imdf.crystals.com/files/documents/lyso-material-data-sheet.pdf (accessed on 11 February 2020).

- Ikagawa, T.; Kataoka, J.; Yatsu, Y.; Saito, T.; Kuramoto, Y.; Kawai, N.; Kawabata, N. Study of large area Hamamatsu avalanche photodiode in a ray scintillation detector. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2005, 538, 640–650. [Google Scholar] [CrossRef]

- Bieberle, A.; Schleicher, E.; Hampel, U. Temperature control design for a high-resolution gamma-ray tomography detector. Rev. Sci. Instrum. 2010, 81, 014702. [Google Scholar] [CrossRef] [PubMed]

- Knoll, G.F. Radiation Detection and Measurement; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-13148-0. [Google Scholar]

- Law, D. IEEE 802.3 Ethernet (January 2010). Available online: https://www.ieee802.org/misc-docs/GlobeCom2009/IEEE_802d3_Law.pdf (accessed on 11 April 2024).

- IEEE Std 802.3bt-2018; IEEE Standard for Ethernet Amendment 2: Physical Layer and Management Parameters for Power over Ethernet over 4 Pairs. IEEE: New York, NY, USA, 2019. [CrossRef]

- EU. Directive 2014/34/EU. 2014. Available online: https://eur-lex.europa.eu/eli/dir/2014/34/oj?locale=de (accessed on 11 April 2024).

- Versloot, N.H.A.; Klein, A.J.J.; De Maaijer, M. The ATEX Directives: Explosion Safety and Regulation, the European Approach. In Emergency Planning Preparedness, Prevention & Response; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 389–404. [Google Scholar] [CrossRef]

- Gregor, J.; Benson, T. Computational Analysis and Improvement of SIRT. IEEE Trans. Med. Imaging 2008, 27, 918–924. [Google Scholar] [CrossRef] [PubMed]

- Van Aarle, W.; Palenstijn, W.J.; De Beenhouwer, J.; Altantzis, T.; Bals, S.; Batenburg, K.J.; Sijbers, J. The ASTRA Toolbox: A platform for advanced algorithm development in electron tomography. Ultramicroscopy 2015, 157, 35–47. [Google Scholar] [CrossRef]

| Medium | Temperature (°C) | Density (kg/m3) | Surface Tension (mNs/m2) | Dynamic Viscosity (mNs/m2) |

|---|---|---|---|---|

| Liquid Argon | −185 | 1388 | 12.3 | 0.25 |

| Iso-Hexane | 20 | 653 | 17.6 | 0.31 |

| Water | 20 | 997 | 72.3 | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bieberle, A.; Hoffmann, R.; Döß, A.; Schleicher, E.; Hampel, U. Modular and Cost-Effective Computed Tomography Design. Sensors 2024, 24, 2568. https://doi.org/10.3390/s24082568

Bieberle A, Hoffmann R, Döß A, Schleicher E, Hampel U. Modular and Cost-Effective Computed Tomography Design. Sensors. 2024; 24(8):2568. https://doi.org/10.3390/s24082568

Chicago/Turabian StyleBieberle, André, Rainer Hoffmann, Alexander Döß, Eckhard Schleicher, and Uwe Hampel. 2024. "Modular and Cost-Effective Computed Tomography Design" Sensors 24, no. 8: 2568. https://doi.org/10.3390/s24082568

APA StyleBieberle, A., Hoffmann, R., Döß, A., Schleicher, E., & Hampel, U. (2024). Modular and Cost-Effective Computed Tomography Design. Sensors, 24(8), 2568. https://doi.org/10.3390/s24082568