An Evaluation of the Acoustic Activity Emitted in Fiber-Reinforced Concrete Under Flexure at Low Temperature

Abstract

:1. Introduction

2. Research Significance

3. Experimental Program

3.1. Concrete Mixture Development

- M500-0.55 w/b means a concrete mixture with a binder content of 500 kg/m3 and 0.55 water–binder ratio.

- M550-SynF38 means a concrete mixture with a binder content of 550 kg/m3 and reinforced with synthetic fibers 38 mm in length.

3.2. Material Properties

3.3. Specimen Details and Preparation

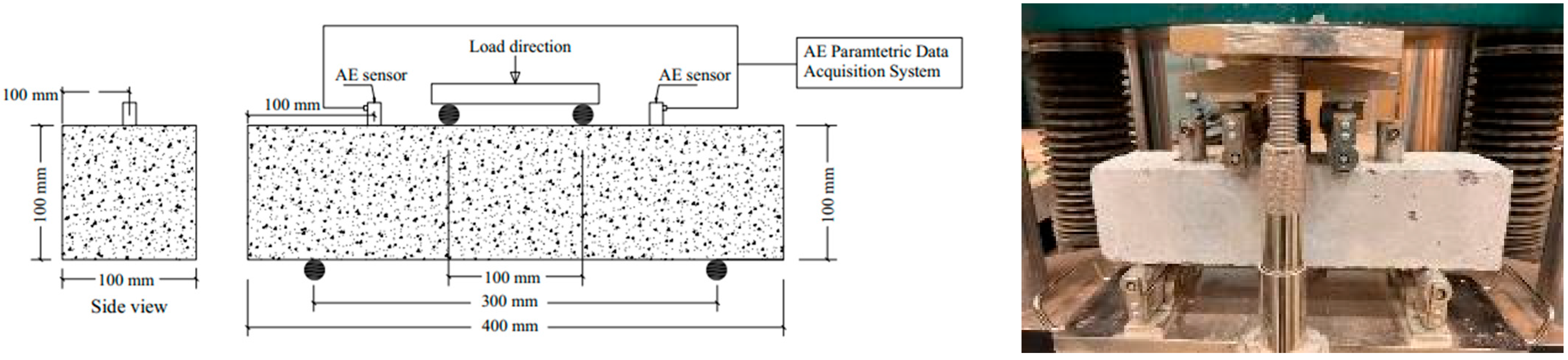

3.4. Four-Point Flexure Load Setup

3.5. AE Monitoring Setup

4. AE Data Filtering

4.1. Amplitude-Duration AE Data Filtering

4.2. Post-Testing Amplitude-Duration AE Data Filters

5. AE Analysis Methods

5.1. b-Value Method

5.2. Ib-Value Method

5.3. AE Signal Intensity Analysis

5.4. Average Frequency (AF) Versus Rise Time/Amplitude (RA) Analysis

6. Results and Discussion

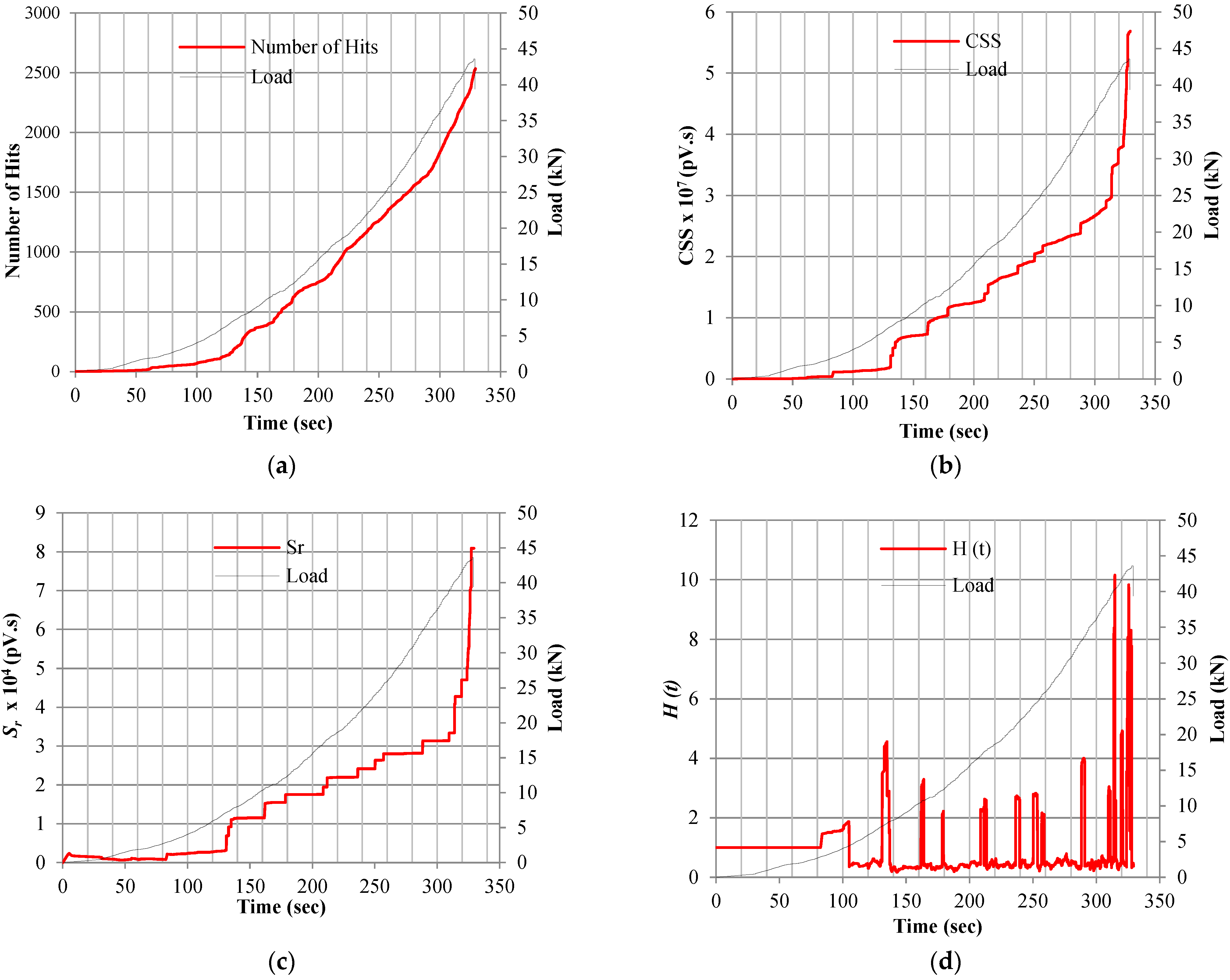

6.1. Micro- and Macro-Crack Stages’ Onset Indicators in Terms of AE Analysis Parameters

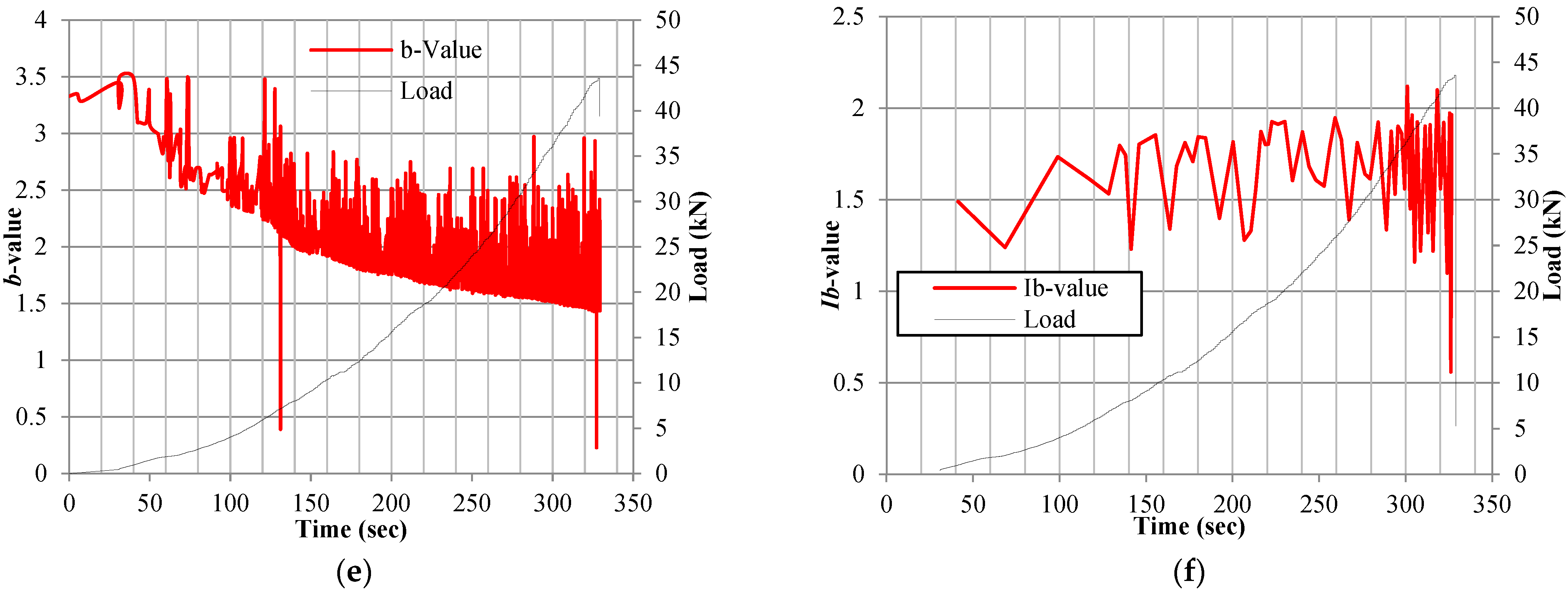

6.2. Cold Temperature Effect on AE Activity Parameters

6.3. Effect of W/C Ratio on the Behavior of AE Waves Emitted at −20 °C

6.4. Effect of Adding Fibers on the Behavior of AE Waves Emitted at −20 °C

6.5. Effect of Fiber Type on the Flexural Performance and Behavior of AE Waves at −20 °C

6.6. Effect of Fiber Content on the Behavior of AE Waves Emitted at −20 °C

6.7. Effect of Fiber Length on the Behavior of AE Waves Emitted at −20 °C

6.8. Classifying Micro- or Macro-Cracking Levels

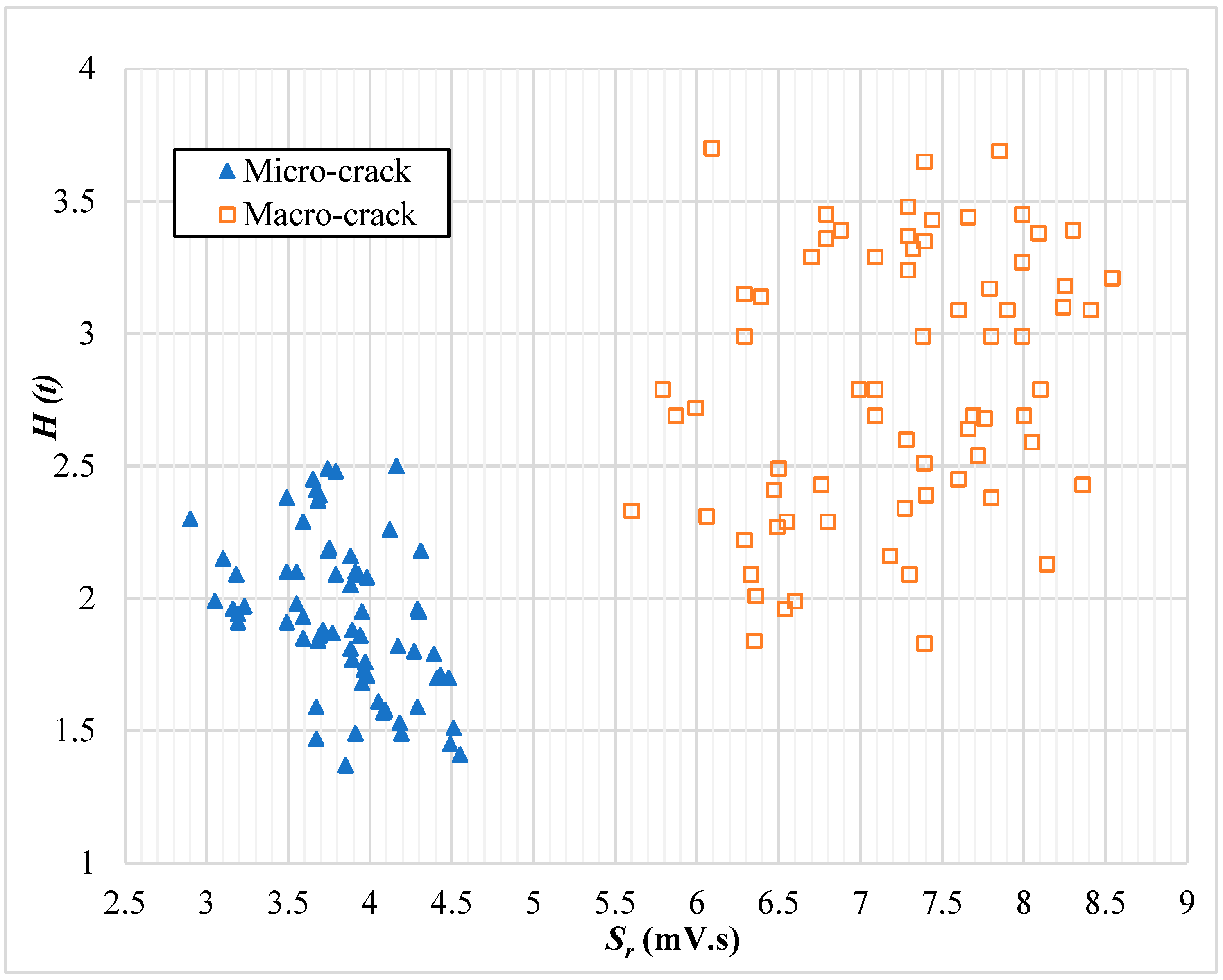

6.8.1. AE Intensity Analysis Parameter-Based Chart

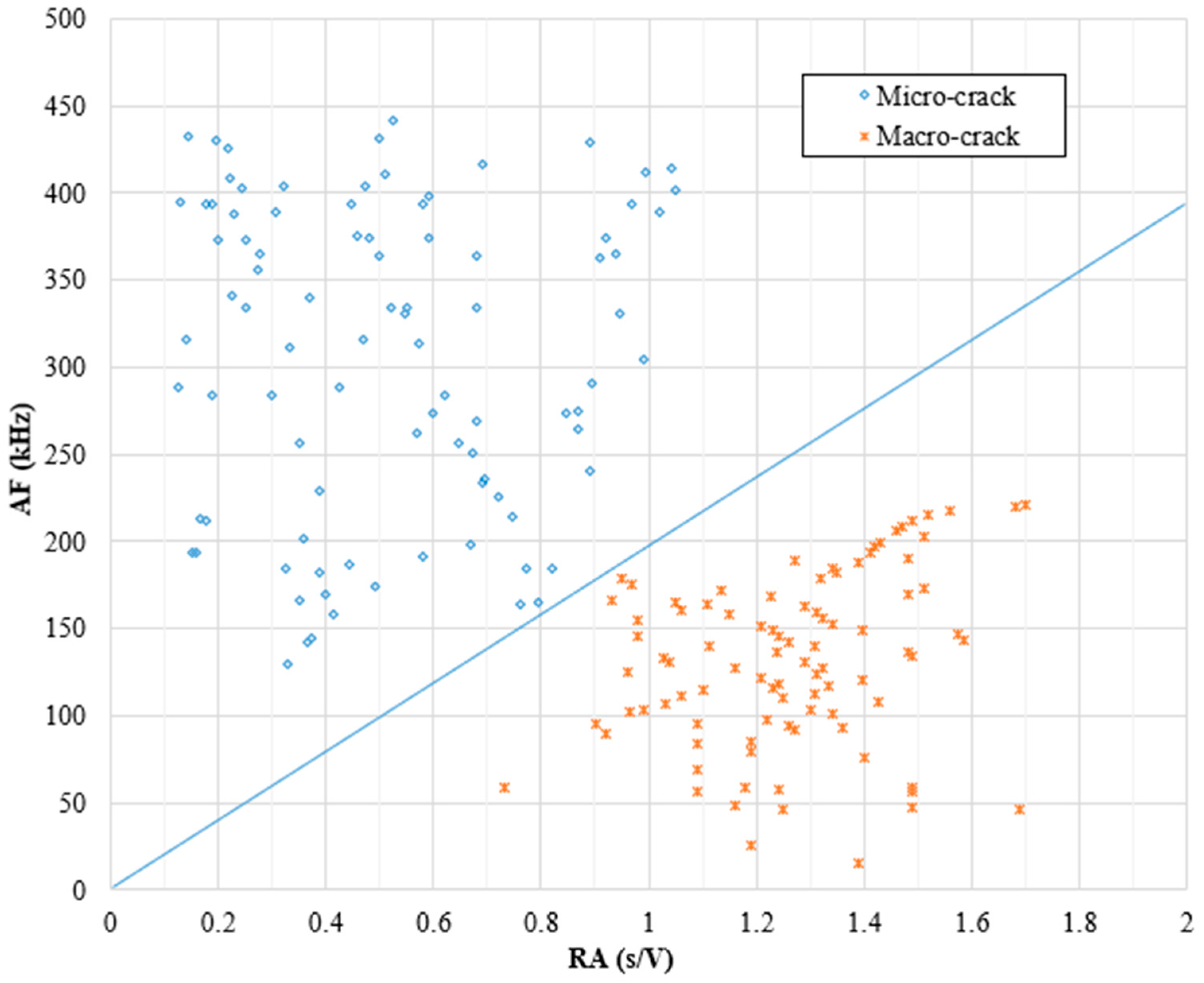

6.8.2. RA Analysis-Based Chart

7. Conclusions

- The initiation of micro- and macro-cracking coincided with a significant jump in the CSS, H (t), and Sr curves and an extreme dip in the b-value curve, while the bellows of the Ib-value curve fluctuation became noticeably concentrated only prior to macro-crack onset with no specific pattern change prior to micro-crack initiation.

- Flexural performance was enhanced, and time and load thresholds of micro- and macro-cracks increased when the samples were cooled down and tested at −20 °C, significantly in mixtures with higher W/B, longer fibers, and lower fiber content. This improvement was also associated with higher AE activity in the form of increased CSS, Sr, and H (t) values and lower b-values.

- The AE activity monitoring and analysis detected the onset of micro-cracks when the loads reached approximately 27–36% and 33–41% of the failure loads when samples were tested at 25 °C and −20 °C, respectively.

- Changing the concrete mixture design parameters, including the w/b ratio as well as fiber type, content, and length, resulted in a noticeable effect on the flexural behavior and the AE activity of the tested mixtures at both temperatures (25 °C and −20 °C).

- The intensity analysis parameters (H (t), and Sr) were found to have specific ranges according to the associated crack type. Subsequently, a micro- and macro-crack classification chart was developed and presented to characterize the crack type based on the values of the H (t) and Sr for the accompanying AE event.

- Micro-crack events were found to have relatively higher AF values and lower RA values. Meanwhile, macro-crack events have relatively higher RA values and lower AF values. Consequently, an RA analysis-based chart was developed and presented to classify the recorded AE events whether correlated with micro- or macro-crack activity in the tested specimens. A diagonal line with a slope M = 194.44 × 10 −3 kHz/s/V was found to split the AE events based on the values of RA and AF.

- The micro- and macro-crack classification charts developed can be used to evaluate the flexural behavior of FRC at low temperatures within the range of the studied parameters in this study. Future research is needed to refine and assess the effectiveness of the developed charts in the assessment of actual concrete structures exposed to cold temperatures and monitored with AE sensors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, G.; Shih, T.; Chang, K.-C. Mechanical properties of concrete at low temperature. J. Cold Reg. Eng. 1988, 2, 13–24. [Google Scholar] [CrossRef]

- Gardner, D.R.; Lark, R.J.; Barr, B. Effect of conditioning temperature on the strength and permeability of normal-and high-strength concrete. Cem. Concr. Res. 2005, 35, 1400–1406. [Google Scholar] [CrossRef]

- Yap, S.P.; Bu, C.H.; Alengaram, U.J.; Mo, K.H.; Jumaat, M.Z. Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete. Mater. Des. 2014, 57, 652–659. [Google Scholar] [CrossRef]

- Kim, M.-J.; Kim, S.; Lee, S.K.; Kim, J.H.; Lee, K.; Yoo, D.Y. Mechanical properties of ultra-high-performance fiber-reinforced concrete at cryogenic temperatures. Constr. Build. Mater. 2017, 157, 498–508. [Google Scholar] [CrossRef]

- Rostasy, F.; Wiedemann, G. Strength, deformation and thermal strains of concrete at cryogenic conditions. In Proceedings of the First International Conference on Cryogenic Concrete, Newcastle upon Tyne, UK, 27–31 March 1981. [Google Scholar]

- Sloan, J.E. The Seismic Behavior of Reinforced Concrete Members at Low Temperatures. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2005. [Google Scholar]

- Bandelt, M.J.; Billington, S.L. Bond behavior of steel reinforcement in high-performance fiber-reinforced cementitious composite flexural members. Mater. Struct. 2016, 49, 71–86. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Muhyaddin, G.F.; Asaad, D.S. Strain hardening ultra-high performance fiber reinforced cementitious composites: Effect of fiber type and concentration. Compos. Part B Eng. 2016, 103, 74–83. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Soufeiani, L.; Raman, S.N.; Jumaat, M.Z.B.; Alengaram, U.J.; Ghadyani, G.; Mendis, P. Influences of the volume fraction and shape of steel fibers on fiber-reinforced concrete subjected to dynamic loading—A review. Eng. Struct. 2016, 124, 405–417. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Farhat, F.A.; Nicolaides, D.; Kanellopoulos, A.; Karihaloo, B.L. High performance fibre-reinforced cementitious composite (CARDIFRC)—Performance and application to retrofitting. Eng. Fract. Mech. 2007, 74, 151–167. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, D.J.; An, Y.-K. Electro-mechanical self-sensing response of ultra-high-performance fiber-reinforced concrete in tension. Compos. Part B Eng. 2018, 134, 254–264. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A. Impact resistance and mechanical properties of self-consolidating rubberized concrete reinforced with steel fibers. J. Mater. Civ. Eng. 2017, 29, 04016193. [Google Scholar] [CrossRef]

- Choumanidis, D.; Badogiannis, E.; Nomikos, P.; Sofianos, A. The effect of different fibres on the flexural behaviour of concrete exposed to normal and elevated temperatures. Constr. Build. Mater. 2016, 129, 266–277. [Google Scholar] [CrossRef]

- Swamy, R.N.; Mangat, P.S. Influence of fiber geometry on the properties of steel fiber reinforced concrete. Cem. Concr. Res. 1974, 4, 451–465. [Google Scholar] [CrossRef]

- Lee, J.-H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Abouhussien, A.A.; Hassan, A.A. Crack Growth Monitoring in Fiber-Reinforced Self-Consolidating Concrete via Acoustic Emission. ACI Mater. J. 2019, 116, 181–191. [Google Scholar] [CrossRef]

- Abouhussien, A.A.; Hassan, A.A.A. Assessment of Crack Development in Engineered Cementitious Composites Based on Analysis of Acoustic Emissions. J. Mater. Civ. Eng. 2019, 31, 04019078. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Soulioti, D.V.; Barkoula, N.M.; Paipetis, A.S.; Matikas, T.E. Influence of fiber chemical coating on the acoustic emission behavior of steel fiber reinforced concrete. Cem. Concr. Compos. 2012, 34, 62–67. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Soulioti, D.V.; Gatselou, E.A.; Barkoula, N.M.; Matikas, T.E. Monitoring of the mechanical behavior of concrete with chemically treated steel fibers by acoustic emission. Constr. Build. Mater. 2013, 48, 1255–1260. [Google Scholar] [CrossRef]

- Li, G.; Zhang, L.; Zhao, F.; Tang, J. Acoustic Emission Characteristics and Damage Mechanisms Investigation of Basalt Fiber Concrete with Recycled Aggregate. Materials 2020, 13, 4009. [Google Scholar] [CrossRef]

- Ridgley, K.E.; Abouhussien, A.A.; Hassan, A.A.; Colbourne, B. Assessing abrasion performance of self-consolidating concrete containing synthetic fibers using acoustic emission analysis. Mater. Struct. 2018, 51, 119. [Google Scholar] [CrossRef]

- Ohtsu, M. Acoustic emission characteristics in concrete and diagnostic applications. J. Acoust. Emiss. 1987, 6, 99–108. [Google Scholar]

- Colombo, I.S.; Main, I.; Forde, M. Assessing damage of reinforced concrete beam using "b-value" analysis of acoustic emission signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Rao, M.V.; Lakshmi, K.P.; Rao, G.N.; Vijayakumar, K.; Udayakumar, S. Precursory microcracking and brittle failure of Latur basalt and migmatite gneiss under compressive loading. Curr. Sci. 2011, 101, 1053–1059. [Google Scholar]

- Abouhussien, A.A.; Hassan, A.A.A. Acoustic emission monitoring for bond integrity evaluation of reinforced concrete under pull-out tests. Adv. Struct. Eng. 2017, 20, 1390–1405. [Google Scholar] [CrossRef]

- Liu, H.; Li, W.; Luo, G.; Liu, S.; Lyu, X. Mechanical properties and fracture behavior of crumb rubber basalt fiber concrete based on acoustic emission technology. Sensors 2020, 20, 3513. [Google Scholar] [CrossRef]

- Pollock, A.A. Material Brittleness and the energetics of acoustic emission. In Experimental Mechanics on Emerging Energy Systems and Materials, Proceedings of the 2010 Annual Conference on Experimental and Applied Mechanics, Indianapolis, IN, USA, 7–10 June 2010; Springer: Berlin/Heidelberg, Germany, 2011; Volume 5. [Google Scholar]

- BIBM; CEMBUREAU; ERMCO; EFCA; EFNARC. The European Guidelines for Self-Compacting Concrete; International Bureau for Precast Concrete (BIBM): Brussels, Belgium, 2005. [Google Scholar]

- AbdelAleem, B.H.; Ismail, M.K.; Hassan, A.A. Properties of self-consolidating rubberised concrete reinforced with synthetic fibres. Mag. Concr. Res. 2017, 69, 526–540. [Google Scholar] [CrossRef]

- C150, A; Standard Specification for Portland Cement. ASTM international: Conshohocken, PA, USA, 2012.

- C1611/C1611M, A.; Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International: Conshohocken, PA, USA, 2009.

- C494-13, A; Standard Specification for Chemical Admixtures for Concrete. ASTM International: Conshohocken, PA, USA, 2013.

- Han, Q.; Carpinteri, A.; Lacidogna, G.; Xu, J. Fractal analysis and yule statistics for seismic prediction based on 2009 L’Aquila earthquake in Italy. Arab. J. Geosci. 2015, 8, 2457–2465. [Google Scholar] [CrossRef]

- Smith, W.D. The b-value as an earthquake precursor. Nature 1981, 289, 136–139. [Google Scholar] [CrossRef]

- Gutenberg, B.; Richter, C.F. Frequency of earthquakes in California. Bull. Seismol. Soc. Am. 1944, 34, 185–188. [Google Scholar] [CrossRef]

- Shiotani, T. Application of the AE Improved b-Value to Quantiative Evaluation of Fracture Process in Concrete-Materials. J. Acoust. Emiss. 2001, 19, 118–133. [Google Scholar]

- Shiotani, T. Evaluation of progressive failure using AE sources and improved b-value on slope model tests. Prog. Acoust. Emiss. VII JSNDI 1994, 529–534. [Google Scholar]

- Shiotani, T.; Ohtsu, M. Prediction of Slope Failure Based on AE Activity; ASTM Special Technical Publication; ASTM International: Conshohocken, PA, USA, 1999; Volume 1353, pp. 156–174. [Google Scholar]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridis, N.; Barkoula, N.M.; Paipetis, A.S.; Matikas, T.E. Acoustic emission characterization of steel fibre reinforced concrete during bending. In Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security 2010; SPIE: Bellingham, WA, USA, 2010. [Google Scholar]

- Chotickai, P. Acoustic Emission Monitoring of Prestressed Bridge Girders with Premature Concrete Deterioration. Master’s Thesis, University of Texas at Austin, Austin, TX, USA, 2001. [Google Scholar]

- Noorsuhada, M. An overview on fatigue damage assessment of reinforced concrete structures with the aid of acoustic emission technique. Constr. Build. Mater. 2016, 112, 424–439. [Google Scholar] [CrossRef]

- Di Benedetti, M.; Nanni, A. Acoustic emission intensity analysis for in situ evaluation of reinforced concrete slabs. J. Mater. Civ. Eng. 2014, 26, 6–13. [Google Scholar] [CrossRef]

- Fowler, T.J.; Blessing, J.A.; Conlisk, P.J.; Swanson, T.L. The MONPAC system. J. Acoust. Emiss. 1989, 8, 1–8. [Google Scholar]

- Ohtsu, M. Recommendation of RILEM TC 212-ACD: Acoustic emission and related NDE techniques for crack detection and damage evaluation in concrete: Measurement method for acoustic emission signals in concrete. Mater. Struct. 2010, 43, 1177–1181. [Google Scholar]

- Ohtsu, M.; Isoda, T.; Tomoda, Y. Acoustic emission techniques standardized for concrete structures. J. Acoust. Emiss. 2007, 25, 21–32. [Google Scholar]

- Soulioti, D.; Barkoula, N.M.; Paipetis, A.; Matikas, T.E.; Shiotani, T.; Aggelis, D.G. Acoustic emission behavior of steel fibre reinforced concrete under bending. Constr. Build. Mater. 2009, 23, 3532–3536. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Shahidan, S.; Bunnori, N.M.; Mohd, S.; Nor, N.M.; Johari, M.A.M. Analysis of the AE signals parameter at the critical area on the concrete beam. In Proceedings of the 2012 IEEE Symposium on Industrial Electronics and Applications, Bandung, Indonesia, 23–26 September 2012. [Google Scholar]

- Behnia, A.; Chai, H.K.; Yorikawa, M.; Momoki, S.; Terazawa, M.; Shiotani, T. Integrated non-destructive assessment of concrete structures under flexure by acoustic emission and travel time tomography. Constr. Build. Mater. 2014, 67, 202–215. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R. Acoustic emission and flexural behaviour of RC beams strengthened with UHPC overlay. Constr. Build. Mater. 2016, 123, 481–492. [Google Scholar] [CrossRef]

| Mixture No. | Mixture Type | Cement (kg/m3) | MK (kg/m3) | FA (kg/m3) | C/F | W/B | C.A. (kg/m3) | F.A. (kg/m3) | Water Content (kg/m3) | Vf % | HRWRA (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | M500-0.55w/b | 500 | - | - | 0.7 | 0.55 | 606.15 | 865.83 | 275 | - | 1.43 |

| M2 | M500-0.4w/b | 500 | - | - | 0.7 | 0.4 | 686.57 | 981.21 | 200 | - | 2.17 |

| M3 | M550-control | 275 | 110 | 165 | 0.7 | 0.4 | 619.67 | 885.84 | 220 | - | 3.51 |

| M4 | M550-SynF19 | 275 | 110 | 165 | 0.7 | 0.4 | 619.67 | 885.84 | 220 | 0.2 | 4.42 |

| M5 | M550-SynF38 | 275 | 110 | 165 | 0.7 | 0.4 | 619.67 | 885.84 | 220 | 0.2 | 4.69 |

| M6 | M550-1%SynF38 | 275 | 110 | 165 | 0.7 | 0.4 | 619.67 | 885.84 | 220 | 1 | 5.76 |

| M7 | M550-SF35 | 275 | 110 | 165 | 0.7 | 0.4 | 619.67 | 885.84 | 220 | 0.2 | 4.66 |

| Fiber Type | Material | Length (mm) | Diameter (mm) | Specific Gravity | Tensile Strength (MPa) | Fiber’s Shape |

|---|---|---|---|---|---|---|

| SF-35 | Steel | 35 | 0.55 | 7.85 | 1150 | single hooked-end |

| SynF-19 | polypropylene | 19 | 0.66 | 0.91 | 300 | straight |

| SynF-38 | polypropylene | 38 | 0.64 | 0.91 | 515 | straight |

| Chemical Properties F% | Cement | MK | Fly Ash |

|---|---|---|---|

| SiO2 | 19.63 | 51–53 | 51 |

| Al2O3 | 5.48 | 42–44 | 23 |

| Fe2O3 | 2.37 | <2.2 | 12 |

| FeO | -- | -- | -- |

| TiO2 | -- | <3.0 | -- |

| C | -- | -- | -- |

| Cr2O3 | -- | -- | -- |

| MnO | -- | -- | -- |

| P2O5 | -- | <0.21 | -- |

| SrO | -- | -- | -- |

| BaO | -- | -- | -- |

| SO4 | -- | <0.5 | -- |

| CaO | 62.43 | <0.2 | 5 |

| MgO | 2.47 | <0.1 | -- |

| Na2O | -- | <0.05 | -- |

| C3S | 52.33 | -- | -- |

| C2S | 16.82 | -- | -- |

| C3A | 10.51 | -- | -- |

| C4AF | 7.23 | -- | -- |

| K2O | -- | <0.40 | -- |

| L.O.I | 2.04 | <0.50 | -- |

| Cement | MK | Fly Ash | |

|---|---|---|---|

| Specific Gravity | 3.15 | 2.5 | 2.38 |

| Blaine Fineness (m2/kg) | 410 | 19,000 | 420 |

| AE Setup Parameters | Values |

|---|---|

| Threshold | 40 dBAE |

| Sample rate | 1 MSPS |

| Pre-trigger | 256 µs |

| Length | 1k points |

| Preamp gain | 40 dB |

| Preamp voltage | 28 |

| Analog filter | 1–50 kHz |

| Digital filter | 100–400 kHz |

| Peak definition | 200 µs |

| Hit definition time | 800 µs |

| Hit lockout time | 1000 µs |

| Maximum duration | 1000 µs |

| Amplitude Range (dB) | Duration (µs) | Amplitude Range (dB) | Duration (µs) | ||

|---|---|---|---|---|---|

| Lower | Upper | Lower | Upper | ||

| 40 ≤ A < 45 | 0 | 400 | 60 ≤ A < 65 | 300 | 1000 |

| 45 ≤ A < 48 | 0 | 500 | 65 ≤ A < 70 | 500 | 2000 |

| 48 ≤ A < 52 | 0 | 600 | 70 ≤ A < 80 | 1000 | 4000 |

| 52 ≤ A < 56 | 0 | 700 | 80 ≤ A < 90 | 2000 | 7000 |

| 56 ≤ A < 60 | 100 | 800 | 90 ≤ A < 100 | 3000 | 10,000 |

| Number of Hits, N | ≤50 | 51–200 | 201–500 | ≥501 |

|---|---|---|---|---|

| K | 0 | N-30 | 0.85N | N-75 |

| J | 0 | 50 | 50 | 50 |

| Authors | Mixture Type | Dimensions (mm) | Loading Type | Max RA (ms/V) | Max A-FRQ (kHz) | M (s/V/kHz) |

|---|---|---|---|---|---|---|

| Soulioti, Barkoula [48] | Steel-fiber-reinforced concrete (SFRC) | 100 × 100 × 100 | Monotonic | 6 | 65 | 0.09 |

| Aggelis [49] | Plain concrete | 100 × 100 × 400 | Monotonic | 15 | 550 | 0.027 |

| Shahidan, Bunnori [50] | Steel-reinforced concrete (RC) | 150 × 250 × 1900 | Cyclic | 150 | 150 | 1 |

| Behnia, Chai [51] | RC, SFRC, polypropylene FRC | 200 × 250 × 2500 | Cyclic | 5 × 10−3 | 400 | 12.5 × 10−6 |

| Prem and Murthy [52] | RC | 100 × 200 × 1500 | Monotonic | 200 | 200 | 1 |

| Mixture No. | Mixture Type | Testing Temperature | Compressive Strength (MPa) | Maximum Flexure Load (KN) | Flexure Strength (MPa) |

|---|---|---|---|---|---|

| M1 | M500-0.55w/b | 25 °C | 61.16 | 23.64 | 10.64 |

| −20 °C | 76.68 | 32.75 | 14.74 | ||

| M2 | M500-0.4w/b | 25 °C | 66.79 | 27.35 | 12.31 |

| −20 °C | 79.18 | 34.61 | 15.57 | ||

| M3 | M550-control | 25 °C | 74.12 | 31.14 | 14.01 |

| −20 °C | 89.91 | 39.85 | 17.93 | ||

| M4 | M550-SynF19 | 25 °C | 78.63 | 32.97 | 14.84 |

| −20 °C | 90.77 | 43.19 | 18.54 | ||

| M5 | M550-SynF38 | 25 °C | 76.16 | 33.76 | 15.19 |

| −20 °C | 88.28 | 43.34 | 19.05 | ||

| M6 | M550-1%SynF38 | 25 °C | 51.75 | 30.89 | 13.90 |

| −20 °C | 63.67 | 37.19 | 16.74 | ||

| M7 | M550-SF35 | 25 °C | 78.74 | 35.64 | 16.04 |

| −20 °C | 89.59 | 44.73 | 19.68 |

| Mixture No. | Mixture Type | Testing Temperature | Signal Amplitude (dB) | Number of Hits | CSS (pV.s) × 106 | H (t) | Sr × 104 (mV.s) | B-Value | First Micro-Crack Load (KN) | First Micro-Crack Time (s) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | AE Analysis | Visually Noticed | ||||

| M1 | M500-0.55w/b | 25 °C | 81 | 83 | 89 | 76 | 1.77 | 1.69 | 1.77 | 1.66 | 4.32 | 4.22 | 3.43 | 3.64 | 3.76 | 61 | 63 |

| −20 °C | 80 | 81 | 106 | 98 | 1.98 | 1.83 | 1.93 | 1.84 | 4.53 | 4.36 | 2.86 | 2.97 | 4.11 | 79 | 80 | ||

| M2 | M500-0.4w/b | 25 °C | 79 | 81 | 112 | 121 | 2.05 | 1.99 | 2.05 | 1.98 | 4.59 | 4.65 | 3.23 | 3.08 | 4.26 | 84 | 86 |

| −20 °C | 80 | 82 | 124 | 132 | 2.16 | 2.24 | 2.19 | 2.13 | 4.72 | 4.76 | 2.57 | 2.75 | 4.89 | 94 | 94 | ||

| M3 | M550-control | 25 °C | 79 | 80 | 132 | 139 | 2.28 | 2.21 | 2.25 | 2.32 | 4.81 | 4.79 | 2.32 | 2.19 | 5.33 | 89 | 90 |

| −20 °C | 81 | 79 | 146 | 163 | 2.49 | 2.55 | 2.36 | 2.77 | 4.96 | 4.88 | 2.04 | 2.13 | 5.81 | 103 | 105 | ||

| M4 | M550-SynF19 | 25 °C | 83 | 81 | 178 | 183 | 2.76 | 2.83 | 2.47 | 2.41 | 5.07 | 5.13 | 0.71 | 0.80 | 6.92 | 114 | 121 |

| −20 °C | 84 | 82 | 191 | 203 | 2.99 | 3.01 | 2.57 | 3.04 | 5.25 | 5.41 | 0.46 | 0.51 | 7.21 | 131 | 135 | ||

| M5 | M550-SynF38 | 25 °C | 80 | 81 | 155 | 163 | 2.48 | 2.55 | 2.29 | 2.39 | 4.81 | 4.91 | 1.49 | 1.56 | 5.89 | 97 | 104 |

| −20 °C | 82 | 79 | 169 | 174 | 2.63 | 2.51 | 2.43 | 2.66 | 4.96 | 5.05 | 1.84 | 1.71 | 6.23 | 112 | 117 | ||

| M6 | M550-1%SynF38 | 25 °C | 84 | 83 | 184 | 192 | 2.69 | 2.73 | 2.59 | 2.65 | 4.97 | 5.03 | 1.55 | 1.63 | 6.34 | 109 | 118 |

| −20 °C | 81 | 80 | 183 | 201 | 2.81 | 2.88 | 2.77 | 2.89 | 5.07 | 5.18 | 1.31 | 1.22 | 6.69 | 123 | 131 | ||

| M7 | M550-SF35 | 25 °C | 80 | 81 | 203 | 209 | 3.09 | 3.16 | 2.94 | 3.03 | 5.29 | 5.33 | 0.53 | 0.67 | 7.64 | 179 | 187 |

| −20 °C | 82 | 80 | 217 | 226 | 3.21 | 3.24 | 3.07 | 3.21 | 5.41 | 5.52 | 0.31 | 0.44 | 8.13 | 207 | 212 | ||

| Mixture No. | Mixture Type | Testing Temperature | Signal Amplitude (dB) | Number of Hits | CSS (pV.s) × 104 | H (t) | Sr (mV.s) | B-Value | Macro Crack Load (KN) | Macro Crack Time (s) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | CH-1 | CH-2 | |||||

| M1 | M500-0.55w/b | 25 °C | 79 | 81 | 1424 | 1389 | 3.95 × 107 | 3.73 × 107 | 4.51 | 4.22 | 5.91 × 105 | 5.85 × 105 | 3.92 | 2.17 | 23.64 | 206 |

| −20 °C | 81 | 83 | 1651 | 1589 | 4.19 × 107 | 4.02 × 107 | 5.03 | 4.89 | 6.27 × 105 | 6.13 × 105 | 3.19 | 3.31 | 32.75 | 248 | ||

| M2 | M500-0.4w/b | 25 °C | 80 | 79 | 1756 | 1813 | 4.56 × 107 | 4.37 × 107 | 5.24 | 5.33 | 6.68 × 105 | 6.51 × 105 | 2.97 | 3.04 | 27.35 | 251 |

| −20 °C | 82 | 83 | 1844 | 1901 | 4.78 × 107 | 4.69 × 107 | 5.76 | 5.83 | 7.29 × 105 | 7.18 × 105 | 2.72 | 2.81 | 34.61 | 263 | ||

| M3 | M550-control | 25 °C | 81 | 84 | 1969 | 2006 | 4.88 × 107 | 4.93 × 107 | 5.91 | 5.79 | 7.46 × 105 | 7.39 × 105 | 2.46 | 2.55 | 31.14 | 277 |

| −20 °C | 79 | 82 | 2034 | 2103 | 5.16 × 107 | 5.27 × 107 | 6.15 | 6.37 | 7.67 × 105 | 7.55 × 105 | 1.94 | 2.03 | 39.85 | 286 | ||

| M4 | M550-SynF19 | 25 °C | 81 | 83 | 2307 | 2341 | 5.39 × 107 | 5.46 × 107 | 8.04 | 8.33 | 7.88 × 105 | 7.73 × 105 | 0.86 | 0.99 | 32.97 | 306 |

| −20 °C | 83 | 81 | 2463 | 2391 | 5.62 × 107 | 5.68 × 107 | 8.38 | 9.12 | 8.09 × 105 | 7.91 × 105 | 0.23 | 0.29 | 43.19 | 327 | ||

| M5 | M550-SynF38 | 25 °C | 79 | 81 | 2068 | 2034 | 4.96 × 107 | 4.88 × 107 | 6.89 | 7.04 | 7.13 × 105 | 7.34 × 105 | 1.76 | 1.86 | 33.76 | 281 |

| −20 °C | 82 | 79 | 2109 | 2141 | 5.29 × 107 | 5.41 × 107 | 7.46 | 7.66 | 7.72 × 105 | 8.03 × 105 | 1.13 | 1.08 | 42.34 | 309 | ||

| M6 | M550-1%SynF38 | 25 °C | 81 | 82 | 2237 | 2209 | 5.16 × 107 | 5.09 × 107 | 7.32 | 7.68 | 8.65 × 105 | 8.86 × 105 | 0.89 | 0.94 | 30.89 | 266 |

| −20 °C | 80 | 83 | 2343 | 2296 | 5.33 × 107 | 5.43 × 107 | 7.91 | 8.12 | 9.23 × 105 | 9.41 × 105 | 0.66 | 0.59 | 37.19 | 294 | ||

| M7 | M550-SF35 | 25 °C | 79 | 81 | 2591 | 2678 | 5.89 × 107 | 5.77 × 107 | 9.11 | 9.73 | 11.21 × 105 | 11.37 × 105 | 0.37 | 0.41 | 35.64 | 394 |

| −20 °C | 83 | 81 | 2719 | 2788 | 6.13 × 107 | 6.33 × 107 | 9.87 | 10.13 | 12.05 × 105 | 11.86 × 105 | 0.18 | 0.23 | 44.73 | 434 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamel, O.A.; Abouhussien, A.A.; Hassan, A.A.A.; AbdelAleem, B.H. An Evaluation of the Acoustic Activity Emitted in Fiber-Reinforced Concrete Under Flexure at Low Temperature. Sensors 2025, 25, 2703. https://doi.org/10.3390/s25092703

Kamel OA, Abouhussien AA, Hassan AAA, AbdelAleem BH. An Evaluation of the Acoustic Activity Emitted in Fiber-Reinforced Concrete Under Flexure at Low Temperature. Sensors. 2025; 25(9):2703. https://doi.org/10.3390/s25092703

Chicago/Turabian StyleKamel, Omar A., Ahmed A. Abouhussien, Assem A. A. Hassan, and Basem H. AbdelAleem. 2025. "An Evaluation of the Acoustic Activity Emitted in Fiber-Reinforced Concrete Under Flexure at Low Temperature" Sensors 25, no. 9: 2703. https://doi.org/10.3390/s25092703

APA StyleKamel, O. A., Abouhussien, A. A., Hassan, A. A. A., & AbdelAleem, B. H. (2025). An Evaluation of the Acoustic Activity Emitted in Fiber-Reinforced Concrete Under Flexure at Low Temperature. Sensors, 25(9), 2703. https://doi.org/10.3390/s25092703