Conducting Polymers-Based Gas Sensors: Principles, Materials, and Applications

Abstract

:1. Introduction

2. Conductive Polymer-Based Gas Phase Sensors

2.1. Detection Principle

2.1.1. Electrochemical Sensing

2.1.2. Chemiresistive Sensing

2.1.3. Piezoelectric Sensing

2.1.4. Mechanical Sensing

2.1.5. Optical Sensing

2.1.6. Field-Effect Transistor (FET) Sensing

2.2. Sensitive Material

2.2.1. PANi

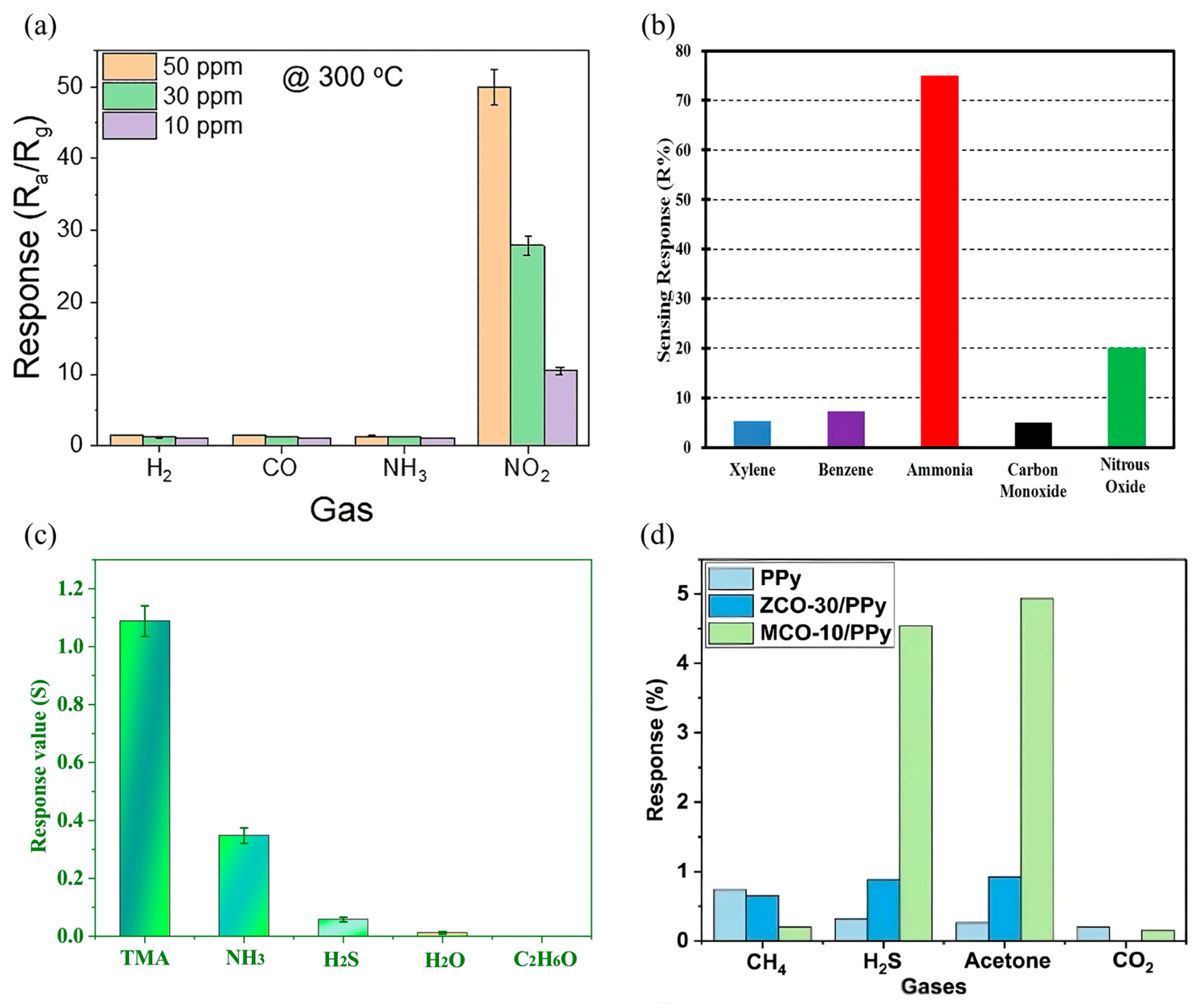

2.2.2. PPy

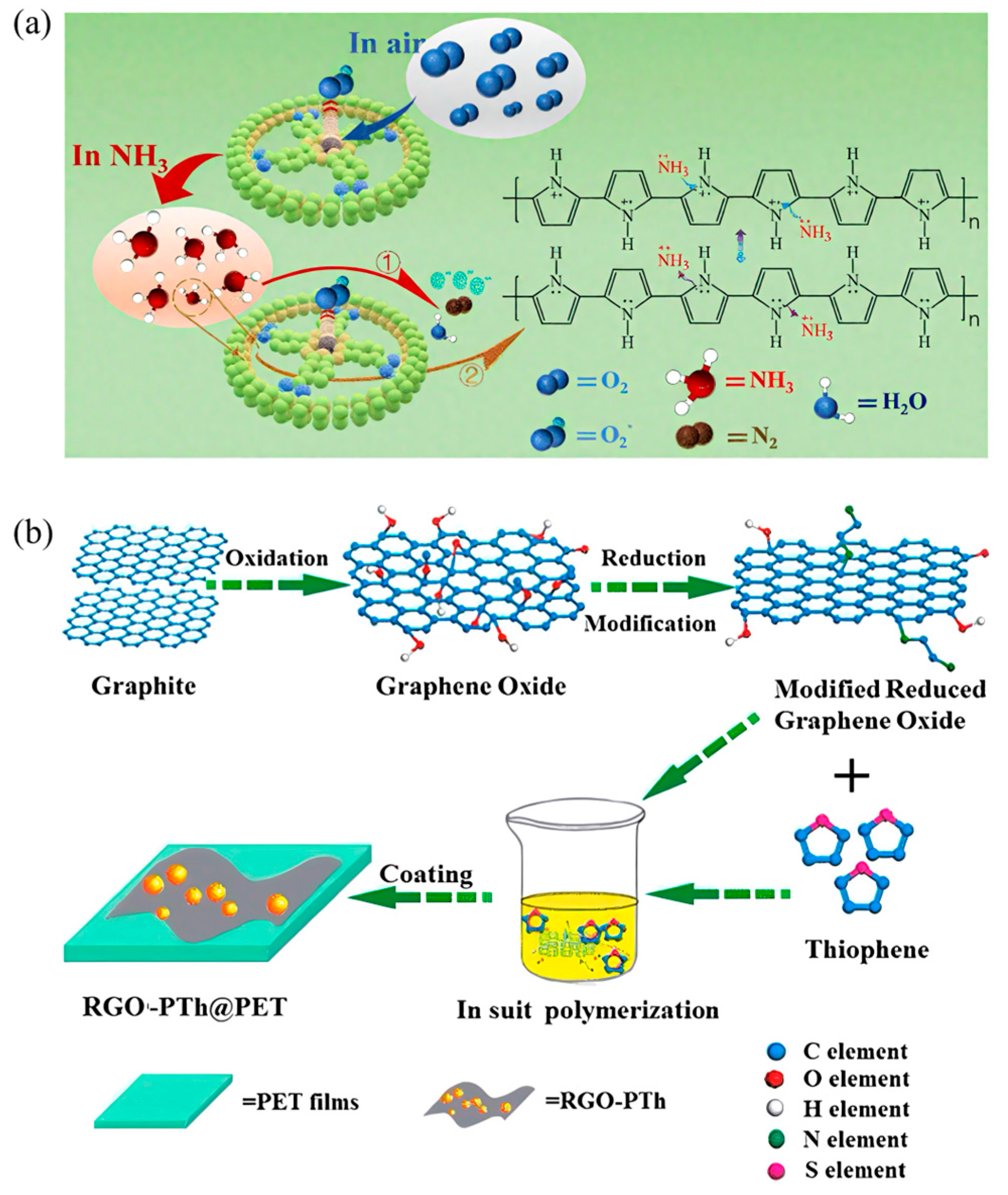

2.2.3. PTh

2.2.4. PEDOT

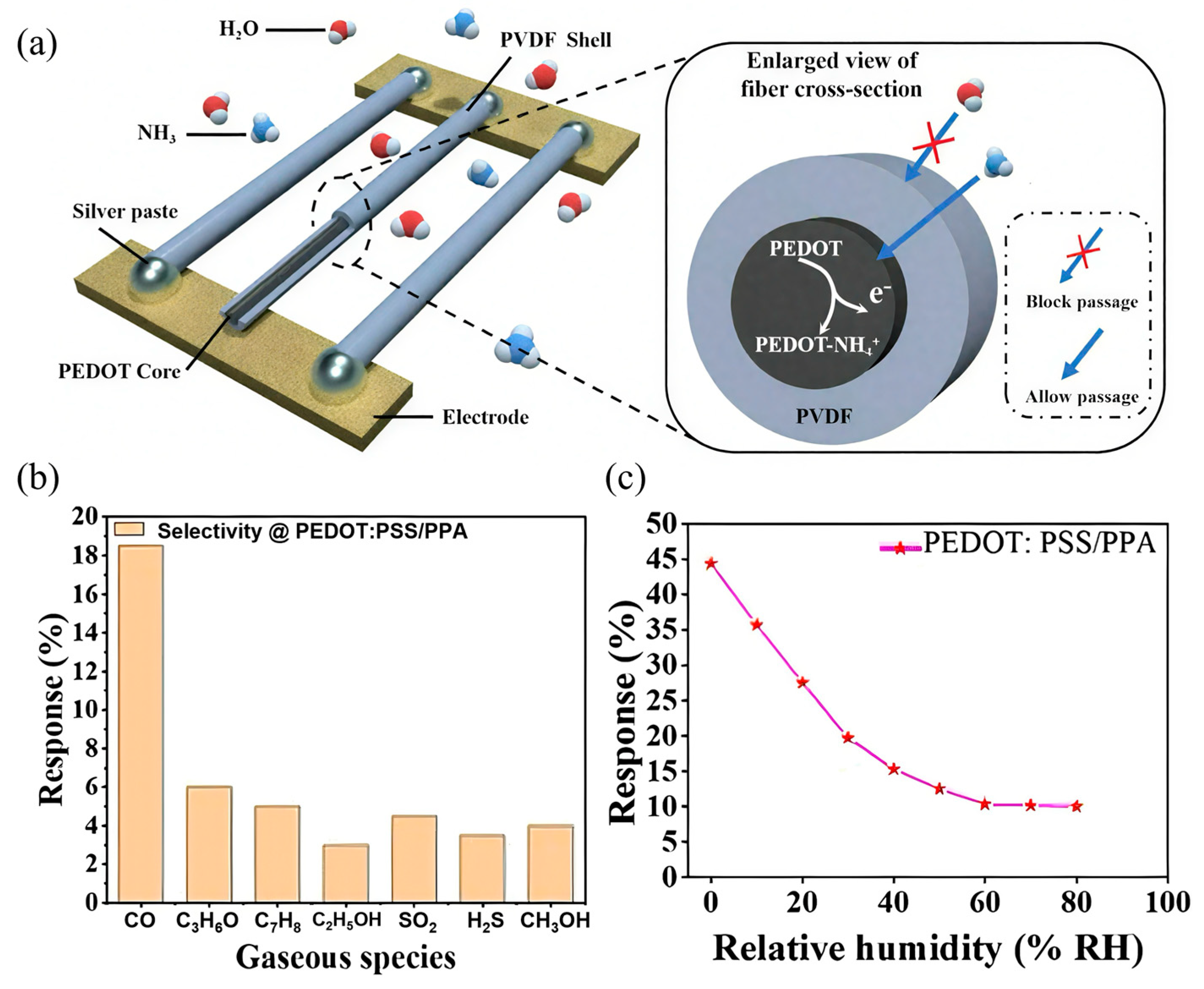

2.2.5. PEDOT:PSS

| Mechanism | Sensor Materials | Target | LOD | Responce | Ref. |

|---|---|---|---|---|---|

| Chemiresistive | PEDOT:PSS/PPA | CO | 50 ppm | 58 s | [104] |

| Chemiresistive | PANI/SnO2 | C6H6 | 0.4 ppm | 33 s | [105] |

| Mechanical | poly(DTCPA-co-BHTBT)-CB | C7H8 | 4 ppm | 36.47 s | [48] |

| Chemiresistive | TSP-nAu-PANi | CHCl3 | – | 360 s | [106] |

| Chemiresistive | GO:PEDOT:PSS | CH3OH | – | 24.47 s | [103] |

| Optical | POF/PPy | C2H5OH | 140 ppm | 5 s | [61] |

| Chemiresistive | SWCNT/C4F-PPy | C3H6O | 1 ppm | 750 s | [107] |

| Chemiresistive | SnO2/PTh | C3H6O | 0.5 ppm | 10 s | [35] |

| Chemiresistive | PANi/AgNWs/Silk | TMA | 1.38 ppm | 90 s | [24] |

| Chemiresistive | PANi | H2 | 1 ppm | 15 s/17 s | [78] |

| Chemiresistive | CA-PANi | H2S | 1 ppm | 1 s | [16] |

| Chemiresistive | PANi/MOX | H2S | <100 ppm | 10 s | [88] |

| FET | Si/PANI:DBSA | NH3 | – | 2 s | [66] |

| Chemiresistive | PEDOT-PVDF | NH3 | 10 ppm | 80 s | [99] |

| Chemiresistive | PA-PANI/GO | NH3 | 25 ppm | – | [73] |

| Chemiresistive | f-MWCNT-PEDOT:PSS | NH3 | <10 ppm | 228 s | [108] |

| Chemiresistive | PPy-TcCoPc | NH3 | 50 ppm | 8 s | [84] |

| Chemiresistive | CdS QDs-PTh | NH3 | 10 ppm | 0.6 s | [36] |

| Electrochemical | PEDOT:PSS/IrOx Ps | NH3 | 8 ppm | 87 ± 9 s | [30] |

| Chemiresistive | PANi | NH3 | 2.5 ppm | 110 s | [22] |

| Chemiresistive | PPy@LIG | NH3 | 1 ppm | 450 s | [86] |

| Chemiresistive | PANi/FMWCNT | NH3 | 1 ppm | 15 s | [77] |

| Chemiresistive | PANi-MWCNTs/PDMS | NH3 | 10 ppb | – | [109] |

| Chemiresistive | RGO-PTh | NO2 | 0.52 ppm | 498 s | [95] |

| Chemiresistive | MWCNTs/PANi | NH3 | 0.3 ppm | 21 s | [76] |

| Piezoelectric | GO:PEDOT:PSS | NO2 | 175 ppb | 35 s | [43] |

| Chemiresistive | PTh | NO2 | 0.25 ppm | 4980 s | [110] |

| Chemiresistive | PANi/BP | NO2 | <2 ppm | 98 s | [111] |

| Chemiresistive | Au-ZnO-PANi | NO2 | <10 ppm | 600 s | [112] |

2.3. Main Constituent Materials of the Sensor Device

2.3.1. Substrate

2.3.2. Electrode Material

2.3.3. Packaging Material

3. Application of CPs-Based Gas Sensors

3.1. Promising and Broad Applications

3.1.1. Environmental Monitoring Field

3.1.2. Industrial Production Field

3.1.3. Food Safety Field

3.1.4. Medical Diagnostic Field

3.2. Critical Issues in Real Applications

3.2.1. Long-Term Stability and Humidity Drift: Mechanisms and Quantitative Evaluations

3.2.2. Biocompatibility, Toxicology, and Regulatory Considerations for CP-Based Wearable and Biomedical Sensors

Biocompatibility and Toxicological Assessment

Relevant Standards and Regulatory Framework

- (1)

- ISO 10993-5 (in vitro cytotoxicity);

- (2)

- ISO 10993-10 (skin irritation and sensitization);

- (3)

- ISO 10993-11 (systemic toxicity);

- (4)

- ISO 10993-6 (implantation effects) if the device is implanted.

Design Considerations for Clinical Translation

- (1)

- Encapsulation strategies using biocompatible elastomers (e.g., PDMS, TPU) are essential to isolate CPs from direct tissue exposure while maintaining sensing functionality [125];

- (2)

- Incorporation of bioinert and hydrophobic coatings also helps prevent ion leaching and immune response [156];

- (3)

- Long-term implantation trials (animal models >30 days) are necessary to assess chronic inflammation and fibrotic encapsulation [157].

| Conducting Polymer | Biocompatibility | Toxicity Concerns | Regulatory Standard | Ref. |

|---|---|---|---|---|

| PANi | Variable; can release toxic aniline, modified forms, or composites safer | Aniline toxicity, residual dopants, and degradation products are concerns | ISO 10993-5, -10; FDA Class I/11 depending on application | [145,146] |

| PPy | Generally good; supports cell adhesion and proliferation | Low toxicity if properly synthesized | ISO 10993-5, -10, -11; preclinical animal studies needed for implants | [147,148] |

| PTh | General, modification or compounding for improvement | The toxicity of degradation products is unknown; residual monomers may be toxic | ISO 10993-5, -10; in some cases, additional in vitro and in vivo testing may be required based on application | [149,150] |

| PEDOT | Excellent; used in neural and cardiac interfaces | Minimal; depends on dopants and processing additives | ISO 10993-1, -5, -6, -10, -11; used in FDA-cleared implants | [151] |

| PEDOT:PSS | Good after PSS removal or treatment (DMSO/EG); low cytotoxicity | Excess PSS may irritate; removal improves safety | ISO 10993-5, -10; reviewed under FDA Class 11 submissions (e.g., neural devices) | [152,153] |

4. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Ding, C.Q.; Ren, Y.; Liu, X.Y.; Zeng, J.J.; Yu, X.P.; Zhou, D.X.; Li, Y.J. Detection and discrimination of sulfur dioxide using a colorimetric sensor array. RSC Adv. 2022, 12, 25852–25859. [Google Scholar] [CrossRef]

- Li, X.; Feng, Y.; Long, J.Y.; Lv, H.F.; Guo, Y.J.; Zu, X.T. MXene-activated graphene oxide enhancing NO2 capture and detection of surface acoustic wave sensors. Sens. Actuators B Chem. 2024, 401, 135006. [Google Scholar] [CrossRef]

- Teixeira, G.D.G.; Esteves, C.; Moro, A.J.; Lima, J.C.; Barbosa, A.J.M.; Roque, A.C.A. An odorant-binding protein based electrical sensor to detect volatile organic compounds. Sens. Actuators B Chem. 2024, 411, 135726. [Google Scholar] [CrossRef]

- Ku, W.; Lee, G.; Lee, J.Y.; Kim, D.H.; Park, K.H.; Lim, J.; Cho, D.; Ha, S.C.; Jung, B.G.; Hwang, H.; et al. Rational design of hybrid sensor arrays combined synergistically with machine learning for rapid response to a hazardous gas leak environment in chemical plants. J. Hazard. Mater. 2024, 466, 133649. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.Z.; Yang, X.T.; Ying, X.G.; Shi, C.; Jia, Z.X.; Jia, B.C. Applications of gas sensing in food quality detection: A review. Foods 2023, 12, 3966. [Google Scholar] [CrossRef]

- Hu, W.W.; Wu, W.W.; Jian, Y.Y.; Haick, H.; Zhang, G.J.; Qian, Y.; Yuan, M.M.; Yao, M.S. Volatolomics in healthcare and its advanced detection technology. Nano Res. 2022, 15, 8185–8213. [Google Scholar] [CrossRef]

- Tao, B.R.; Bai, J.N.; Miao, F.J.; Zhao, M. Passive RFID integrated acetone sensor and ammonia sensor based on LaFeO3/ZnO/rGO composites. Microchem. J. 2024, 207, 112122. [Google Scholar] [CrossRef]

- Zheng, Q.Y.; Yang, M.; Dong, X.; Zhang, X.F.; Cheng, X.L.; Huo, L.H.; Major, Z.; Xu, Y.M. ZnO/PANi nanoflake arrays sensor for ultra-low concentration and rapid detection of NO2 at room temperature. Rare Met. 2023, 42, 536–544. [Google Scholar] [CrossRef]

- Ampong, I.; Zimmerman, K.D.; Nathanielsz, P.W.; Cox, L.A.; Olivier, M. Optimization of imputation strategies for high-resolution gas chromatography-mass spectrometry (HR GC–MS) metabolomics data. Metabolites 2022, 12, 429. [Google Scholar] [CrossRef]

- Alenzy, E.K.; Kandjani, A.E.; Shaibani, M.; Trinchi, A.; Bhargava, S.K.; Ippolito, S.J.; Sabri, Y. Human breath analysis; clinical application and measurement: An overview. Biosens. Bioelectron. 2024, 278, 117094. [Google Scholar] [CrossRef]

- Ziani, I.; Bouakline, H.; El Guerraf, A.; El Bachiri, A.; Fauconnier, M.L.; Sher, F. Integrating AI and advanced spectroscopic techniques for precision food safety and quality control. Trends Food Sci. Techol. 2024, 156, 104850. [Google Scholar] [CrossRef]

- Lou, C.G.; Liu, X.; Wang, Y.; Li, R.K.; Huang, L.; Liu, X.L. Miniature quartz tuning fork-based broad spectral coverage and high detectivity infrared spectroscopy. Infrared Phys. Technol. 2022, 126, 104322. [Google Scholar] [CrossRef]

- Pavel, I.A.; Lakard, S.; Lakard, B. Flexible sensors based on conductive polymers. Chemosensors 2022, 10, 97. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Wang, Y.L.; Li, Y.Y.; Sui, C.M.; Liu, Y.Z.; Liu, Y.Y.; Zhao, Y.D.; Liang, X.S.; Liu, F.M.; Lu, G.Y. Bimetallic MOF derived mesoporous structure of Ru doped SnO2 enable high-sensitivity gas sensors for triethylamine in high humidity. Sens. Actuators B Chem. 2024, 405, 135275. [Google Scholar] [CrossRef]

- Zhao, J.Y.; Li, P.; Zhang, Q.; Ye, Z.L.; Wang, Y.J.; Tian, J.Y.; Xu, Z.; Peng, N.C.; Ren, H.; Zhang, X.H. MOF nanoflowers-based flexible portable NO sensors for human airway inflammation detection. Chem. Eng. J. 2024, 499, 156184. [Google Scholar] [CrossRef]

- Bibi, A.; Rubio, Y.R.M.; Santiago, K.S.; Jia, H.W.; Ahmed, M.M.M.; Lin, Y.F.; Yeh, J.M. H2S-sensing studies using interdigitated electrode with spin-coated carbon aerogel-polyaniline composites. Polymers 2021, 13, 1457. [Google Scholar] [CrossRef]

- Lawaniya, S.D.; Kumar, S.; Yu, Y.; Awasthi, K. Ammonia sensing properties of PPy nanostructures (urchins/flowers) toward low-cost and flexible gas sensors at room temperature. Sens. Actuators B Chem. 2023, 382, 133566. [Google Scholar] [CrossRef]

- Belhousse, S.; Tıghılt, F.Z.; Bennıa, S.; Adjtoutah, S.; Sam, S.; Lasmı, K.; Hamdanı, K. Effect of polythiophene thickness on hybrid sensor sensitivity. Rev. Adv. Mater. Sci. 2021, 60, 839–845. [Google Scholar] [CrossRef]

- Hui, Y.; Bian, C.; Xia, S.H.; Tong, J.H.; Wang, J.F. Synthesis and electrochemical sensing application of poly(3, 4-ethylenedioxythiophene)-based materials: A review. Anal. Chim. Acta 2018, 1022, 1–19. [Google Scholar] [CrossRef]

- Lv, C.H.; Zhou, X.; Chen, C.; Liu, X.H.; Qian, J. Highly sensitive and flexible ammonia sensor based on PEDOT:PSS doped with lewis acid for wireless food monitoring. Chem. Eng. J. 2024, 493, 152652. [Google Scholar] [CrossRef]

- Deller, A.E.; Hryniewicz, B.M.; Pesqueira, C.; Horta, R.P.; Silva, B.J.G.; Weheabby, S.; Al-Hamry, A.; Kanoun, O.; Vidotti, M. PEDOT:PSS/AuNPs-based composite as voltammetric sensor for the detection of pirimicarb. Polymers 2023, 15, 739. [Google Scholar] [CrossRef] [PubMed]

- Dipak, P.; Tiwari, D.C.; Samadhiya, A.; Kumar, N.; Biswajit, T.; Singh, P.A.; Tiwari, R.K. Synthesis of polyaniline (printable nanoink) gas sensor for the detection of ammonia gas. J. Mater. Sci. Mater. Electron. 2020, 31, 22512–22521. [Google Scholar] [CrossRef]

- Byeon, J.H.; Kim, J.S.; Kang, H.K.; Kang, S.; Kim, J.Y. Acetone gas sensor based on SWCNT/polypyrrole/phenyllactic acid nanocomposite with high sensitivity and humidity stability. Biosensors 2022, 12, 354. [Google Scholar] [CrossRef]

- Li, Y.H.; Li, Y.X.; Shi, J.Y.; Li, Z.H.; Wang, X.; Hu, X.T.; Gong, Y.Y.; Zou, X.B. A novel gas sensor for detecting pork freshness based on PANi/AgNWs/silk. Foods 2022, 11, 2372. [Google Scholar] [CrossRef]

- Zeng, L.H.; He, M.; Yu, H.H.; Li, D.L. An H2S sensor based on electrochemistry for chicken coops. Sensors 2016, 16, 1398. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Meng, W.W.; He, Z.X.; Meng, W.; Li, Y.H.; Dai, L. Enhanced selective performance of mixed potential ammonia gas sensor by Au nanoparticles decorated CeVO4 sensing electrode. Sens. Actuators B Chem. 2018, 272, 219–228. [Google Scholar] [CrossRef]

- Pereira, J.D.; Monge, J.; Postolache, O. Measurement and applications: Electrochemical sensors and instruments: Main characteristics and applications. IEEE Instrum. Meas. Mag. 2024, 27, 18–25. [Google Scholar] [CrossRef]

- Wu, Z.X.; Rong, L.M.; Yang, J.L.; Wei, Y.M.; Tao, K.; Zhou, Y.B.; Yang, B.R.; Xie, X.; Wu, J. Ion-conductive hydrogel-based stretchable, self-healing, and transparent NO2 sensor with high sensitivity and selectivity at room temperature. Small 2021, 17, 2104997. [Google Scholar] [CrossRef]

- Ghazanfar, E.; Zahoor, H.; Awwad, N.S.; Ibrahium, H.A.; Mir, S.; Ahmed, I. Ternary composites based next-generation supercapacitors electrode material: Emerging trends. Electrochem. Commun. 2025, 20, 107893. [Google Scholar] [CrossRef]

- Serafini, M.; Mariani, F.; Gualandi, I.; Decataldo, F.; Possanzini, L.; Tessarolo, M.; Fraboni, B.; Tonelli, D.; Scavetta, E. A wearable electrochemical gas sensor for ammonia detection. Sensors 2021, 21, 7905. [Google Scholar] [CrossRef]

- Williams, D.E. Electrochemical sensors for environmental gas analysis. Curr. Opin. Electrochem. 2020, 22, 145–153. [Google Scholar] [CrossRef]

- Ghorbani, G.; Taghipour, F. UV-activated chemiresistive gas sensor response curve analysis for the fast measurement of toxic gases. Sens. Actuators B Chem. 2024, 419, 136396. [Google Scholar] [CrossRef]

- Gao, C.S.; Zhang, Y.Y.; Yang, H.R.; Liu, Y.; Liu, Y.F.; Du, J.H.; Ye, H.Y.; Zhang, G.Q. A DFT study of in doped TI2O: A superior NO2 gas sensor with selective adsorption and distinct optical response. Appl. Surf. Sci. 2019, 494, 162–169. [Google Scholar] [CrossRef]

- Barkade, S.S.; Pinjari, D.V.; Nakate, U.T.; Singh, A.K.; Gogate, P.R.; Naik, J.B.; Sonawane, S.H.; Pandit, A.B. Ultrasound assisted synthesis of polythiophene/SnO2 hybrid nanolatex particles for LPG sensing. Chem. Eng. Process. Process Intensif. 2013, 74, 115–123. [Google Scholar] [CrossRef]

- Beniwal, A. Room temperature operated electrospun nanofibers-based SnO2/PTh sensor for acetone sensing applications. IEEE Trans. Elect. Dev. 2021, 68, 4084–4089. [Google Scholar] [CrossRef]

- Chaudhary, P.L.; Adhyapak, P.V. Cadmium sulfide quantum dots-polythiophene nanocomposite for electrical ammonia sensing. J. Mater. Sci. Mater. Electron. 2024, 35, 1659. [Google Scholar] [CrossRef]

- Sharma, A.; Rawal, I.; Rajpal, A.; Khokhar, A.; Kumar, V.; Goyal, P.K. Highly sensitive and selective room temperature ammonia sensor based on polyaniline thin film: In situ dip-coating polymerization. J. Mater. Sci. Mater. Electron. 2022, 33, 14071–14085. [Google Scholar] [CrossRef]

- Kim, K.J.; Culp, J.T.; Ohodnicki, P.R.; Cvetic, P.C.; Sanguinito, S.; Goodman, A.L.; Kwon, H.T. Alkylamine-integrated metal–organic framework-based waveguide sensors for efficient detection of carbon dioxide from humid gas streams. ACS Appl. Mater. Interfaces 2019, 11, 33489–33496. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Jiang, X.; Kim, T. Static force measurement using piezoelectric sensors. J. Sens. 2021, 2021, 6664200. [Google Scholar] [CrossRef]

- Wang, Z.L. Piezotronic and piezophototronic effects. J. Phys. Chem. Lett. 2010, 1, 1388–1393. [Google Scholar] [CrossRef]

- Bader, N.; Yempally, S.; Al-Ashker, F.; Al-Ejji, M.; Ponnamma, D. Cerium oxide decorated graphene nanolayers filled polyvinylidene fluoride nanofibers as optical piezoelectric sensors. Macromol. Mater. Eng. 2024, 3, 2400350. [Google Scholar] [CrossRef]

- Adjaoud, A.; Nguyen, G.T.; Chikh, L.; Péralta, S.; Trouillet-Fonti, L.; Uguen, N.; Braida, M.D.; Plesse, C. Piezoionic sensors based on formulated PEDOT:PSS and Aquivion for ionic polymer-polymer composites. Smart Mater. Struct. 2021, 30, 105027. [Google Scholar] [CrossRef]

- Pasupuleti, K.S.; Reddeppa, M.; Nam, D.J.; Bak, N.H.; Peta, K.R.; Cho, H.D.; Kim, S.G.; Kim, M.D. Boosting of NO2 gas sensing performances using GO-PEDOT:PSS nanocomposite chemical interface coated on langasite-based surface acoustic wave sensor. Sens. Actuators B Chem. 2021, 344, 130267. [Google Scholar] [CrossRef]

- Yang, L.Y.; Liu, Q.; Li, M.F.; Liu, Y.P.; Li, X.F.; Liu, Q.Z.; Zhu, T.; Lu, Y.; Liu, X.; Wang, D. A high-performance, flexible, and dual-modal humidity-piezoelectric sensor without mutual interference. Sens. Actuators B Chem. 2025, 423, 136778. [Google Scholar] [CrossRef]

- Joshi, V.; Strege, P.R.; Farrugia, G.; Beyder, A. Mechanotransduction in gastrointestinal smooth muscle cells: Role of mechanosensitive ion channels. J. Appl. Physiol. Gastrointest. Liver Physiol. 2021, 320, G897–G906. [Google Scholar] [CrossRef]

- Yi, H.K.; Wang, S.J.; Mei, S.X.; Li, Z. Conductive polymer composites for resistive flexible strain sensors. Polymer 2024, 307, 127286. [Google Scholar] [CrossRef]

- Budiman, B.A.; Adziman, F.; Sambegoro, P.L.; Nurprasetio, I.P.; Ilhamsyah, R.; Aziz, M. The role of interfacial rigidity to crack propagation path in fiber reinforced polymer composite. Fibers Polym. 2018, 19, 1980–1988. [Google Scholar] [CrossRef]

- Mallya, A.N.; Ramamurthy, P.C. Mechanical actuation of conducting polymer in the presence of organic vapor stimulus. IEEE Sens. J. 2017, 17, 3391–3397. [Google Scholar] [CrossRef]

- Wang, D.; Li, X.; Tian, H.; Chen, X.; Nie, B.; Luo, Y.; Shao, J. Flexible strain sensor based on embedded three-dimensional annular cracks with high mechanical robustness and high sensitivity. Appl. Mater. Today 2021, 25, 101247. [Google Scholar] [CrossRef]

- Afsari, A.; Sarraf, M.J. Design of a hydrogen sulfide gas sensor based on a photonic crystal cavity using graphene. Micro Nanostruct. 2020, 138, 106362. [Google Scholar] [CrossRef]

- Liu, W.; Shi, Y.; Yi, Z.; Liu, C.; Wang, F.M.; Li, X.L.; Lv, J.W.; Yang, L.; Chu, P.K. Surface plasmon resonance chemical sensor composed of a microstructured optical fiber for the detection of an ultra-wide refractive index range and gas-liquid pollutants. Opt. Express 2021, 29, 40734–40747. [Google Scholar] [CrossRef]

- Nimbekar, A.A.; Bhatia, P.G.; Deshmukh, R.R. Ammonia sensors manufactured by plasma enhanced grafting of conducting polymers on nylon-6 fabrics. Synth. Met. 2021, 279, 116840. [Google Scholar] [CrossRef]

- Mumtaz, F.; Zhang, B.H.; Subramaniyam, N.; Roman, M.; Holtmann, P.; Hungund, A.P.; Hungund, A.P.; O’Malley, R.; Spudich, T.M.; Davis, M.; et al. Miniature optical fiber Fabry–Perot interferometer based on a Single-Crystal Metal–Organic framework for the detection and quantification of benzene and ethanol at low concentrations in nitrogen gas. ACS Appl. Mater. Interfaces 2024, 16, 13071–13081. [Google Scholar] [CrossRef]

- Rossi, S.; Olsson, O.; Chen, S.Z.; Shanker, R.; Banerjee, D.; Dahlin, A.; Jonsson, M.P. Dynamically tuneable reflective structural coloration with electroactive conducting polymer nanocavities. Adv. Mater. 2021, 33, 2105004. [Google Scholar] [CrossRef]

- Zandi, A.; Amjadi, M.; Hallaj, T. Plasmon-enhanced fluorimetric and colorimetric dual sensor based on fluorescein/Ag nanoprisms for sensitive determination of mancozeb. Food Chem. 2022, 369, 130967. [Google Scholar] [CrossRef]

- Li, M.; Zhou, Q.W.; Wu, Y.Q.; Gao, J.; Zhu, R.; Gao, Q.; Wu, X.J.; Zhang, Y.G. An ultrafast optical sensor for simultaneous detection of NH3 temperature and concentration based on ultraviolet absorption spectral redshift combined with spectral reconstruction. Sens. Actuators B Chem. 2025, 422, 136631. [Google Scholar] [CrossRef]

- Njegovec, M.; Donlagic, D. A fiber-optic gas sensor and method for the measurement of refractive index dispersion in NIR. Sensors 2020, 20, 3717. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.C.; Liou, C.S.; Chien, T.L.; Tsou, C.; Fang, W. Integration and encapsulation of light-emitting diode and CMOS-MEMS chips for fluorescence quenching gas sensor. Front. Mech. Eng. 2022, 8, 894060. [Google Scholar] [CrossRef]

- Lotfiani, A.; Mohseni, S.M.; Ghanaatshoar, M. High-sensitive optoelectronic SPR biosensor based on fano resonance in the integrated MIM junction and optical layers. Opt. Commun. 2020, 477, 126323. [Google Scholar] [CrossRef]

- Zhao, L.L.; Chen, H.Y.; Tang, Y.; Li, P.P.; Zhu, X.H.; Liu, J.Y.; Liu, M.L.; Zhang, Y.Y.; Yao, S.Z. Ag2S QDs integration with MnO2 nanosheets for the sensitive detection of Cr (VI) via the redox reaction induced photoelectrochemical variation. Anal. Chim. Acta 2023, 22, 341471. [Google Scholar] [CrossRef]

- Liu, W.Y.; Hu, Y.J.; Hou, Y.L. Ethanol gas sensitivity sensor based on roughened POF taper of modified polypyrrole films. Sensors 2020, 20, 989. [Google Scholar] [CrossRef]

- Wang, H.L.; Chen, D.; Chen, Y.; Liu, J.Y.; Xu, J.X.; Zhu, A.N.; Long, F. Development of novel handheld optical fiber dissolved oxygen sensor and its applications. Anal. Chim. Acta 2022, 1200, 339587. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.S.; Long, W.B.; Hu, Z.X.; Wang, P.; Li, H.Y.; Liu, H. Field effect transistors with semiconductor-sensitized gate for high-sensitivity hydrogen detection. IEEE Sens. J. 2023, 23, 22651–22659. [Google Scholar] [CrossRef]

- Yin, W.J.; Sun, J.; Zhang, Y.; Zhang, Y.; Li, S.S.; Zhu, M.Q.; Hong, H.; Ba, Y.T.; Deng, T. A novel three-dimensional Ag nanoparticles/reduced graphene oxide microtubular field effect transistor sensor for NO2 detections. Nanotechnology 2020, 32, 025304. [Google Scholar] [CrossRef]

- Suh, Y.; Lim, D. Doping-and capacitor-less 1T-DRAM cell using reconfigurable feedback mechanism. Nanotechnology 2024, 36, 065203. [Google Scholar] [CrossRef] [PubMed]

- Amer, K.; Elshaer, A.M.; Anas, M.; Ebrahim, S. Fabrication, characterization, and electrical measurements of gas ammonia sensor based on organic field effect transistor. J. Mater. Sci. Mater. Electron. 2019, 30, 391–400. [Google Scholar] [CrossRef]

- Kumar, A.; Tripathi, D.; Rawat, R.K.; Chauhan, P. Hybrid MoS2/PEDOT:PSS sensor for volatile organic compounds detection at room temperature: Experimental and DFT insights. ACS Appl. Nano Mater. 2024, 7, 27599–27611. [Google Scholar] [CrossRef]

- Yuvaraja, S.; Bhyranalyar, V.N.; Bhat, S.A.; Surya, S.G.; Yelamaggad, C.V.; Salama, K.N. A highly selective electron affinity facilitated H2S sensor: The marriage of tris (keto-hydrazone) and an organic field-effect transistor. Mater. Horiz. 2021, 8, 525–537. [Google Scholar] [CrossRef]

- Park, C.S.; Lee, C.; Kwon, O.S. Conducting polymer based nanobiosensors. Polymers 2016, 8, 249. [Google Scholar] [CrossRef]

- Ali, S.S.; Pauly, A.; Brunet, J.; Varenne, C.; Ndiaye, A.L. MWCNTs/PMMA/PS composites functionalized PANi: Electrical characterization and sensing performance for ammonia detection in a humid environment. Sens. Actuators B Chem. 2020, 320, 128364. [Google Scholar]

- Alaş, M.Ö.; Güngör, A.; Genç, R.; Erdem, E. Feeling the power: Robust supercapacitors from nanostructured conductive polymers fostered with Mn2+ and carbon dots. Nanoscale 2019, 11, 12804–12816. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.Y.; Xu, X.R.; Liu, M.D.; Chen, C.; Cui, J.; Chen, X.; Wu, K.; Sun, D.P. Wearable and flexible bacterial cellulose/polyaniline ammonia sensor based on a synergistic doping strategy. Sens. Actuators B Chem. 2021, 334, 129647. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, H.Y.; Bu, X.R.; Wu, Q.; Wang, X.M.; Han, C.Y.; Li, X.; Wang, X.L.; Liu, W.H. Improving ammonia detecting performance of polyaniline decorated rGO composite membrane with GO doping. Materials 2021, 14, 2829. [Google Scholar] [CrossRef] [PubMed]

- Beygisangchin, M.; Abdul, R.S.A.; Shafie, S.; Sadrolhosseini, A.R.; Lim, H.N. Preparations, properties, and applications of polyaniline and polyaniline thin films—A review. Polymers 2021, 13, 2003. [Google Scholar] [CrossRef]

- Wan, P.B.; Wen, X.M.; Sun, C.Z.; Chandran, B.K.; Zhang, H.; Sun, X.M.; Chen, X.D. Flexible transparent films based on nanocomposite networks of polyaniline and carbon nanotubes for high-performance gas sensing. Small 2015, 11, 5409–5415. [Google Scholar] [CrossRef]

- Zhuang, Y.; Wang, X.; Lai, P.f.; Li, J.; Chen, L.; Lin, Y.J.; Wang, F. Wireless flexible system for highly sensitive ammonia detection based on polyaniline/carbon nanotubes. Biosensors 2024, 14, 191. [Google Scholar] [CrossRef]

- Askar, P.; Kanzhigitova, D.; Ospanova, A.; Tapkharov, A.; Duisenbekov, S.; Abutalip, M.; Soltabayev, B.; Turlybekuly, A.; Adilov, S.; Nuraje, N. 1 ppm-detectable hydrogen gas sensor based on nanostructured polyaniline. Sci. Rep. 2024, 14, 26984. [Google Scholar] [CrossRef] [PubMed]

- Rahman Khan, M.M.; Rumon, M.M.H. Recent progress on the synthesis, morphological topography, and battery applications of polypyrrole-based nanocomposites. Polymers 2024, 16, 3277. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, Y.J.; Chen, Z.H.; Zhong, L.X. Cellulose carbon aerogel/PPy composites for high-performance supercapacitor. Carbohydr. Polym. 2019, 215, 322–329. [Google Scholar] [CrossRef]

- Wang, Y.M.; Liu, A.P.; Han, Y.Q.; Li, T.X. Sensors based on conductive polymers and their composites: A review. Polym. Int. 2020, 69, 7–17. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Zaborski, M. Polymer-based sensors: A review. Polym. Test. 2018, 67, 342–348. [Google Scholar] [CrossRef]

- Antony, N.; Mohanty, S.; Nayak, S.K. Electrochemical inspection of polypyrrole/chitosan/zinc oxide hybrid composites. J. Appl. Polym. Sci. 2020, 137, 49561. [Google Scholar] [CrossRef]

- Kurian, A.S.; Souri, H.; Mohan, V.B.; Bhattacharyya, D. Highly stretchable strain sensors based on polypyrrole-silicone rubber composites for human motion detection. Sens. Actuators A Phys. 2020, 312, 112131. [Google Scholar] [CrossRef]

- Gai, S.J.; Wang, X.L.; Zhang, R.Z.; Zeng, K.; Miao, S.L.; Wu, Y.Q.; Wang, B. A controllably fabricated polypyrrole nanorods network by doping a tetra-β-carboxylate cobalt phthalocyanine tetrasodium salt for enhanced ammonia sensing at room temperature. RSC Adv. 2023, 13, 13725–13734. [Google Scholar] [CrossRef] [PubMed]

- Dimple; Madan, R.; Kumar, V.; Mohan, D.; Garg, R. Acetone gas sensing behavior of polypyrrole/ZnO nanocomposites synthesized via chemical oxidation method. J. Mater. Sci. Mater. Electron. 2024, 35, 130. [Google Scholar] [CrossRef]

- Santos-Ceballos, J.C.; Salehnia, F.; Romero, A.; Vilanova, X.; Llobet, E. Low cost, flexible, room temperature gas sensor: Polypyrrole-modified laser-induced graphene for ammonia detection. IEEE Sens. J. 2024, 24, 9366–9374. [Google Scholar] [CrossRef]

- Luo, K.H.; Yan, M.; Hung, Y.H.; Kuang, J.Y.; Chang, H.C.; Lai, Y.J.; Yeh, J.M. Polyaniline composites containing eco-friendly biomass carbon from agricultural-waste coconut husk for enhancing gas sensor performance in hydrogen sulfide detection. Polymers 2023, 15, 4554. [Google Scholar] [CrossRef]

- Kabel, K.; Al-Sabagh, A.; Sharara, T.; Badawi, A.M.; Abdel-Rahman, A.; Gado, W. Fabrication of H2S gas sensor based on PPy/CuO and PPy/SnO2 nanocomposites at room temperature. Egypt. J. Chem. 2020, 63, 2763–2774. [Google Scholar] [CrossRef]

- Xiong, S.; Zhou, J.; Wu, J.H.; Li, H.L.; Zhao, W.; He, C.G.; Liu, Y.; Chen, Y.Q.; Fu, Y.Q.; Duan, H.G. High performance acoustic wave nitrogen dioxide sensor with ultraviolet activated 3D porous architecture of Ag-decorated reduced graphene oxide and polypyrrole aerogel. ACS Appl. Mater. Interfaces 2021, 13, 42094–42103. [Google Scholar] [CrossRef]

- Farea, M.A.; Bhanuse, G.B.; Mohammed, H.Y.; Farea, M.O.; Sallam, M.; Shirsat, S.M.; Tsai, M.L.; Shirsat, M.D. Ultrahigh sensitive and selective room-temperature carbon monoxide gas sensor based on polypyrrole/titanium dioxide nanocomposite. J. Alloys Compd. 2022, 917, 165397. [Google Scholar] [CrossRef]

- Chen, R.; Chen, S.S.; Zhou, Y.L.; Wei, Z.Y.; Wang, H.Y.; Zheng, Y.J.; Li, M.; Sun, K.; Li, Y.F. Unsubstituted polythiophene film deposited via in-situ sequential solution polymerization for chemo-/electrochromism. Macromolecules 2020, 53, 4247–4254. [Google Scholar] [CrossRef]

- Husain, A.; Ahmad, S.; Mohammad, F. Thermally stable and highly sensitive ethene gas sensor based on polythiophene/zirconium oxide nanocomposites. Mater. Today Commun. 2019, 20, 100574. [Google Scholar] [CrossRef]

- Haldar, U.; Mondal, S.; Hazra, S.; Guin, S.; Yeasmin, L.; Chatterjee, D.P.; Nandi, A.K. Tailor made synthesis of water-soluble polythiophene-graft-poly(caprolactone-block-dimethylaminoethyl methacrylate) copolymer and their pH tunable self-assembly and optoelectronic properties. Eur. Polym. J. 2022, 168, 111124. [Google Scholar] [CrossRef]

- Du, Y.N.; Wang, M.Y.; Ye, X.L.; Liu, B.Q.; Han, L.; Jafri, S.H.M.; Liu, W.C.; Zheng, X.X.; Ning, Y.F.; Li, H. Advances in the field of graphene-based composites for energy-storage applications. Crystals 2023, 13, 912. [Google Scholar] [CrossRef]

- Bai, S.L.; Guo, J.; Sun, J.H.; Tang, P.G.; Chen, A.; Luo, R.X.; Li, D.Q. Enhancement of NO2-sensing performance at room temperature by graphene-modified polythiophene. Ind. Eng. Chem. Res. 2016, 55, 5788–5794. [Google Scholar] [CrossRef]

- Brodský, J.; Migliaccio, L.; Sahalianov, I.; Zítka, O.; Neužil, P.; Gablech, I. Advancements in PEDOT-based electrochemical sensors for water quality monitoring: From synthesis to applications. Trends Anal. Chem. 2024, 183, 118115. [Google Scholar] [CrossRef]

- Groenendaal, L.; Jonas, F.; Freitag, D.; Pielartzik, H.; Reynolds, J.R. Poly(3,4-ethylenedioxythiophene) and its derivatives: Past, present, and future. Adv. Mater. 2000, 12, 481–494. [Google Scholar] [CrossRef]

- Jang, C.; Park, J.K.; Yun, G.H.; Choi, H.H.; Lee, H.J.; Yook, J.G. Radio-frequency/microwave gas sensors using conducting polymer. Materials 2020, 13, 2859. [Google Scholar] [CrossRef]

- Xiao, S.H.; Hu, M.J.; Hong, Y.H.; Hu, M.J.; Sun, T.T.; Chen, D.J. Core-shell PEDOT-PVDF nanofiber-based ammonia gas sensor with robust humidity resistance. Biosensors 2024, 14, 411. [Google Scholar] [CrossRef]

- Yang, L.F.; Zhou, Y.; Xu, X.; Shen, Y.Y.; Yan, H.F.; Qin, Z.Y. Interior design of hierarchical micro/nanostructures for enhancing energy storage ability of polyanilines through frozen interfacial polymerization. Electrochim. Acta 2021, 386, 138448. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.X.; Shu, Z.; Wang, M.; Wang, Y.; Yao, Y. Photoelectrochemical sensor for hypochlorous acid detection based on the MWNTs doped PEDOT loaded with BP5 functionalized gold nanoparticles. Mater. Today Chem. 2024, 40, 102230. [Google Scholar] [CrossRef]

- Zhang, X.S.; Yang, W.T.; Zhang, H.N.; Xie, M.Y.; Duan, X.X. PEDOT:PSS: From conductive polymers to sensors. Nanotechnol. Precis. Eng. 2021, 4, 045004. [Google Scholar] [CrossRef]

- Alves, L.S.M.; das Neves, M.F.F.; Benatto, L.; Ramos, M.K.; Eising, M.; de Oliveira, C.K.B.Q.M.; Zarbin, A.J.; Roman, L.S. Influence of nanostructuring sensors based on graphene oxide and PEDOT:PSS for methanol detection. IEEE Sens. J. 2022, 23, 1845–1853. [Google Scholar] [CrossRef]

- Farea, M.O.; Alhadlaq, H.A.; Alaizeri, Z.M.; Ahmed, A.A.; Sallam, M.O.; Ahamed, M. High performance of carbon monoxide gas sensor based on a novel PEDOT:PSS/PPA nanocomposite. ACS Omega 2022, 7, 22492–22499. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.H.; Zhang, H.H.; Shi, Y.B.; Yu, X.Y.; Lan, G.D. Preparation and gas sensing properties of PANi/SnO2 hybrid material. Polymers 2021, 13, 1360. [Google Scholar] [CrossRef]

- Selvanayakam, S.; Esakkidurai, S.P.; Kalaiyar, S. Conductivity-based gas sensors using tamarindus indica polysaccharide-capped gold nanoparticles for the detection of volatile gases. ACS Omega 2024, 9, 10640–10649. [Google Scholar] [CrossRef]

- Kang, H.K.; Byeon, J.H.; Hwang, H.J.; Jang, Y.H.; Kim, J.Y. Flexible sensor film based on rod-shaped SWCNT-polypyrrole nanocomposite for acetone gas detection. Polymers 2023, 15, 3416. [Google Scholar] [CrossRef]

- Boonthum, D.; Oopathump, C.; Fuengfung, S.; Phunudom, P.; Thaibunnak, A.; Juntong, N.; Rungruang, S.; Pakdee, U. Screen-printing of functionalized MWCNT-PEDOT:PSS based solutions on bendable substrate for ammonia gas sensing. Micromachines 2022, 13, 462. [Google Scholar] [CrossRef]

- Zhu, C.H.; Zhou, T.T.; Xia, H.; Zhang, T. Flexible room-temperature ammonia gas sensors based on PANi-MWCNTs/PDMS film for breathing analysis and food safety. Nanomaterials 2023, 13, 1158. [Google Scholar] [CrossRef]

- Park, C.S.; Kim, D.Y.; Jung, E.Y.; Jang, H.J.; Bae, G.T.; Kim, J.Y.; Shin, B.J.; Lee, H.K.; Tae, H.S. Ultrafast room temperature synthesis of porous polythiophene via atmospheric pressure plasma polymerization technique and its application to NO2 gas sensors. Polymers 2021, 13, 1783. [Google Scholar] [CrossRef]

- Tang, B.L.; Shi, Y.B.; Liu, J.J.; Zheng, C.D.; Zhao, K.; Zhang, J.H.; Feng, Q.H. Low-drift NO2 sensor based on polyaniline/black phosphorus composites at room temperature. Chemosensors 2024, 12, 181. [Google Scholar] [CrossRef]

- Bonyani, M.; Zebarjad, S.M.; Janghorban, K.; Kim, J.Y.; Kim, H.W. Au-decorated polyaniline-ZnO electrospun composite nanofiber gas sensors with enhanced response to NO2 gas. Chemosensors 2022, 10, 388. [Google Scholar] [CrossRef]

- Sun, B.C.; Xu, G.B.; Guan, C.H.; Ji, X.; Yang, Z.H.; Chen, S.R.; Chen, X.; Ma, Y.M.; Yu, Y.Q.; Feng, J.G. Nacre-inspired hierarchical bionic substrate for enhanced thermal and mechanical stability in flexible applications. Sens. Actuators A Phys. 2024, 378, 115832. [Google Scholar] [CrossRef]

- Peng, X.Y.; Zhang, X.Q.; Wang, R.; Chen, Y.K.; Chu, X.M.; Kong, L.; Yan, X.; Kuang, M.X. Printing of carbon nanotube-based temperature and bending sensors for high-temperature-resistant intelligent textiles. ACS Appl. Electron. Mater. 2022, 4, 1949–1957. [Google Scholar] [CrossRef]

- Chen, Y.; Pu, X.; Xu, X.; Shi, M.; Li, H.J.; Wang, D. PET/ZnO@MXene-based flexible fabrics with dual piezoelectric functions of compression and tension. Sensors 2022, 23, 91. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Guo, J.P.; Bi, C.C.; Hao, Z.F.; Li, C.P.; Wang, Q.; Han, X.G. Sandwich-like polyimide nanofiber membrane of PEO-based solid-state electrolytes to promote mechanical properties and security for lithium metal batteries. Int. J. Hydrogen Energy 2025, 109, 1266–1273. [Google Scholar] [CrossRef]

- Chen, X.J.; Gao, X.X.; Nomoto, A.; Shi, K.; Lin, M.Y.; Hu, H.J.; Gu, Y.; Zhu, Y.Z.; Wu, Z.H.; Chen, X.; et al. Fabric-substrated capacitive biopotential sensors enhanced by dielectric nanoparticles. Nano Res. 2021, 14, 3248–3252. [Google Scholar] [CrossRef]

- Sawada, H.; Borisenko, K.B.; Ohnishi, I.; Jimbo, Y.; Okunishi, E.; Kirkland, A.I. STEM and elemental analysis by EDS and EELS for two-dimensional atomic structure containing Au and Cu. Microsc. Microanal. 2019, 25, 1776–1777. [Google Scholar] [CrossRef]

- Yu, X.T.; Hu, X.Q.; Ma, X.; Chen, G.Y.; Ling, Y.Q.; Jin, T.; Chen, Y.F. Carbon nanotubes for optimizing response stability and speed of acrylate hybrid copolymers humidity sensor. Polym. Compos. 2024, 45, 10516–10526. [Google Scholar] [CrossRef]

- Choi, C.; Schlenker, E.; Ha, H.; Cheong, J.Y.; Hwang, B. Versatile applications of silver nanowire-based electrodes and their impacts. Micromachines 2023, 14, 562. [Google Scholar] [CrossRef]

- Li, L.B.; Tang, X.N.; Wu, B.; Huang, B.Y.; Yuan, K.; Chen, Y.W. Advanced architectures of air electrodes in zinc–air batteries and hydrogen fuel cells. Adv. Mater. 2024, 36, 2308326. [Google Scholar] [CrossRef]

- Tay, Y.S.; Yang, L.; Zhang, H.; Kor, H.B.; Zhang, L.; Liu, H.; Gill, V.; Lambourne, A.; Li, K.H.; Chen, Z.; et al. Ruggedized sensor packaging with advanced die attach and encapsulation material for harsh environment. Microelectron. Reliab. 2023, 150, 115115. [Google Scholar] [CrossRef]

- Maharshi, V.; Ahmad, I.; Agarwal, A.; Mitra, B. Wafer level hermetic bonding and packaging using recrystallized parylene. J. Micromech. Microeng. 2022, 33, 014004. [Google Scholar] [CrossRef]

- Duarah, R.; Aleksic, I.; Milivojevic, D.; Rameshkumar, S.; Nikodinovic-Runic, J.; Padamati, R.B. Development of nystatin-based antifungal, biodegradable polymer composite materials for food packaging via melt processing approach. J. Appl. Polym. Sci. 2023, 140, e54663. [Google Scholar] [CrossRef]

- Safaee, M.M.; Gravely, M.; Roxbury, D. A wearable optical microfibrous biomaterial with encapsulated nanosensors enables wireless monitoring of oxidative stress. Adv. Funct. Mater. 2021, 31, 2006254. [Google Scholar] [CrossRef]

- Da Silva, A.C.; Córdoba de Torresi, S.I. Advances in conducting, biodegradable and biocompatible copolymers for biomedical applications. Front. Mater. 2019, 6, 98. [Google Scholar] [CrossRef]

- Balaburov, E.; Kamaraj, M.; Doyle, S.E.; Ahmadi, Z.; Di Bella, C.; Nisbet, D.R.; Moulton, S.E.; Caballero Aguilar, L.M. Noninvasive biosensing 3D scaffold to monitor degradation: The potential of fluorescent PCL and PLGA for tissue engineering. J. Appl. Polym. Sci. 2024, 141, e54759. [Google Scholar] [CrossRef]

- Cai, X.X.; Wang, X.Q.; Bian, F.P.; Li, J.Y.; Zhou, R.X.; Hu, J.W.; Lin, S.D. Flexible sensor based on conformable, sticky, transparent elastomers for electronic skin. Chem. Eng. J. 2024, 498, 154934. [Google Scholar] [CrossRef]

- Lu, L.J.; Wei, X.D.; Zhang, Y.; Zheng, G.Q.; Dai, K.; Liu, C.T.; Shen, C.Y. A flexible and self-formed sandwich structure strain sensor based on AgNW decorated electrospun fibrous mats with excellent sensing capability and good oxidation inhibition properties. J. Mater. Chem. C 2017, 5, 7035–7042. [Google Scholar] [CrossRef]

- Seok, S. Polymer-based biocompatible packaging for implantable devices: Packaging method, materials, and reliability simulation. Micromachines 2021, 12, 1020. [Google Scholar] [CrossRef]

- Kim, T.G.; Ha, S.R.; Choi, H.; Uh, K.; Kundapur, U.; Park, S.; Lee, C.W.; Lee, S.H.; Kim, J.; Kim, J.M. Polymerizable supramolecular approach to highly conductive PEDOT:PSS patterns. ACS Appl. Mater. Interfaces 2017, 9, 19231–19237. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; You, S.X.; Li, G.J.; Li, X.X.; Fan, Z.C. Application of semiconductor metal oxide in chemiresistive methane gas sensor: Recent developments and future perspectives. Molecules 2023, 28, 6710. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.T.; Lv, X.; Hu, Z.N.; Xu, A.S.; Feng, C.H. Semiconductor metal oxides as chemoresistive sensors for detecting volatile organic compounds. Sensors 2019, 19, 233. [Google Scholar] [CrossRef] [PubMed]

- Mir, N.A.; Rafiq, A.; Kumar, F.; Singh, V.; Shukla, V. Determinants of broiler chicken meat quality and factors affecting them: A review. J. Food Sci. Technol. 2017, 54, 2997–3009. [Google Scholar] [CrossRef]

- Ruedt, C.; Gibis, M.; Weiss, J. Quantification of surface iridescence in meat products by digital image analysis. Meat Sci. 2020, 163, 108064. [Google Scholar] [CrossRef]

- Andre, R.S.; Facure, M.H.; Mercante, L.A.; Correa, D.S. Electronic nose based on hybrid free-standing nanofibrous mats for meat spoilage monitoring. Sens. Actuators B Chem. 2022, 353, 131114. [Google Scholar] [CrossRef]

- Tripathi, K.M.; Kim, T.; Losic, D.; Tung, T.T. Recent advances in engineered graphene and composites for detection of volatile organic compounds (VOCs) and non-invasive diseases diagnosis. Carbon 2016, 110, 97–129. [Google Scholar] [CrossRef]

- Zhou, T.T.; Zhang, P.; Yu, Z.Z.; Tao, M.; Zhou, D.L.; Yang, B.; Zhang, T. Light-driven, ultra-sensitive and multifunctional ammonia wireless sensing system by plasmonic-functionalized Nb2CTX MXenes toward smart agriculture. Nano Energy 2023, 108, 108216. [Google Scholar] [CrossRef]

- Cox, L.A., Jr. Re-assessing human mortality risks attributed to PM2.5-mediated effects of agricultural ammonia. Environ. Res. 2023, 223, 115311. [Google Scholar] [CrossRef]

- Ananda, S.R.; Kumari, L.; MV, M. Studies on room-temperature acetone sensing properties of ZnCo2O4/PPy and MnCo2O4/PPy nanocomposites for diabetes diagnosis. Appl. Phys. A 2022, 128, 669. [Google Scholar] [CrossRef]

- Wang, B.; Jian, Y.Y.; Jiang, X.; Liu, T.Q.; Yang, D.Y.; Zhao, Z.H.; Liang, Y.P.; Feng, H.R.; Yao, M.S.; Xie, P.Y.; et al. Controlling response of polyaniline toward humidity by self-assembly fatty acids. ECS J. Solid State Sci. Technol. 2022, 11, 037001. [Google Scholar] [CrossRef]

- Ibanez, J.G.; Rincon, M.E.; Gutierrez-Granados, S.; Chahma, M.; Jaramillo-Quintero, O.A.; Frontana-Uribe, B.A. Conducting polymers in the fields of energy, environmental remediation, and chemical-chiral sensors. Chem. Rev. 2018, 118, 4731–4816. [Google Scholar] [CrossRef] [PubMed]

- Sezen-Edmonds, M.; Yeh, Y.W.; Yao, N.; Loo, Y.L. Humidity and strain rate determine the extent of phase shift in the piezoresistive response of PEDOT: PSS. ACS Appl. Mater. Interfaces 2019, 11, 16888–16895. [Google Scholar] [CrossRef]

- Liu, X.H.; Zheng, W.; Kumar, R.; Kumar, M.; Zhang, J. Conducting polymer-based nanostructures for gas sensors. Coord. Chem. Rev. 2022, 462, 214517. [Google Scholar] [CrossRef]

- Youssef, A.M.; Hasanin, M.S.; Abd El-Aziz, M.E.; Turky, G.M. Conducting chitosan/hydroxylethyl cellulose/polyaniline bionanocomposites hydrogel based on graphene oxide doped with Ag-NPs. Int. J. Biol. Macromol. 2020, 167, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Tran, N.P.; Okahisa, Y.; Okubayashi, S. Chitosan aerogel containing mechanically fibrillated fibroin and its model test for wound dressing. Polym. Eng. Sci. 2025, 65, 1340–1349. [Google Scholar] [CrossRef]

- Humpolíček, P.; Kašpárková, V.; Pacherník, J.; Stejskal, J.; Bober, P.; Capáková, Z.; Radaszkiewicz, K.A.; Junkar, I.; Lehocký, M. The biocompatibility of polyaniline and polypyrrole: A comparative study of their cytotoxicity, embryotoxicity and impurity profile. Biomater. Adv. 2018, 91, 303–310. [Google Scholar] [CrossRef]

- Li, Y.M.; Zhao, R.; Li, X.; Wang, C.Y.; Bao, H.W.; Wang, S.D.; Fang, J.; Huang, J.Q.; Wang, C. Blood-compatible polyaniline coated electrospun polyurethane fiber scaffolds for enhanced adhesion and proliferation of human umbilical vein endothelial cells. Fibers Polym. 2019, 20, 250–260. [Google Scholar] [CrossRef]

- Sarvari, R.; Massoumi, B.; Zareh, A.; Beygi-Khosrowshahi, Y.; Agbolaghi, S. Porous conductive and biocompatible scaffolds on the basis of polycaprolactone and polythiophene for scaffolding. Polym. Bull. 2020, 77, 1829–1846. [Google Scholar] [CrossRef]

- Molina, B.G.; Cianga, L.; Bendrea, A.D.; Cianga, I.; Alemán, C.; Armelin, E. An amphiphilic, heterografted polythiophene copolymer containing biocompatible/biodegradable side chains for use as an (electro) active surface in biomedical applications. Polym. Chem. 2019, 10, 5010–5022. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, G.; Duan, X.; Chen, H.L.; Kim Richie, D.H. Nanostructured PEDOT coatings for electrode–neuron integration. ACS Appl. Bio Mater. 2021, 4, 5556–5565. [Google Scholar] [CrossRef] [PubMed]

- Tan, F.; Li, X.R.; Li, X.; Xu, M.X.; Shahzad, K.A.; Hou, L. GelMA/PEDOT:PSS composite conductive hydrogel-based generation and protection of cochlear hair cells through multiple signaling pathways. Biomolecules 2024, 14, 95. [Google Scholar] [CrossRef]

- Gou, S.C.; Li, P.X.; Yang, S.; Bi, G.Q.; Du, Z.H. High-performance MXene/PEDOT-PSS microscale fiber electrodes for neural recording and stimulation. Adv. Funct. Mater. 2025, 2424236. [Google Scholar] [CrossRef]

- Thangaraju, P.; Varthya, S.B. ISO 10993: Biological evaluation of medical devices. In Medical Device Guidelines and Regulations Handbook; Springer International Publishing: Cham, Switzerland, 2022; pp. 163–187. [Google Scholar]

- Aronson, J.K.; Heneghan, C.; Ferner, R.E. Medical devices: Definition, classification, and regulatory implications. Drug Saf. 2020, 43, 83–93. [Google Scholar] [CrossRef] [PubMed]

- Qu, F.D.; Zhang, S.D.; Huang, C.Z.; Guo, X.Y.; Zhu, Y.; Thomas, T.; Guo, H.C.; Attfield, J.P.; Yang, M.H. Surface functionalized sensors for humidity-independent gas detection. Angew. Chem. Int. Ed. 2021, 133, 6635–6640. [Google Scholar] [CrossRef]

- Cai, Y.; Liang, B.; Chen, S.D.; Zhu, Q.; Tu, T.T.; Wu, K.; Cao, Q.P.; Fang, L.; Liang, X.; Ye, X.S. One-step modification of nano-polyaniline/glucose oxidase on double-side printed flexible electrode for continuous glucose monitoring: Characterization, cytotoxicity evaluation ametal oxidemetal oxidemetal oxidend in vivo experiment. Biosens. Bioelectron. 2020, 165, 112408. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Xuan, W.F.; Chen, S.; Yang, M.N.; Xing, H.K. The screening and diagnosis technologies toward pneumoconiosis: From imaging analysis to e-noses. Chemosensors 2025, 13, 102. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, R.; Yang, M.; Zuo, Y.; Liang, L.; Xing, H.; Duan, X.; Chen, S. Conducting Polymers-Based Gas Sensors: Principles, Materials, and Applications. Sensors 2025, 25, 2724. https://doi.org/10.3390/s25092724

Dong R, Yang M, Zuo Y, Liang L, Xing H, Duan X, Chen S. Conducting Polymers-Based Gas Sensors: Principles, Materials, and Applications. Sensors. 2025; 25(9):2724. https://doi.org/10.3390/s25092724

Chicago/Turabian StyleDong, Rongqing, Mingna Yang, Yinxiu Zuo, Lishan Liang, Huakun Xing, Xuemin Duan, and Shuai Chen. 2025. "Conducting Polymers-Based Gas Sensors: Principles, Materials, and Applications" Sensors 25, no. 9: 2724. https://doi.org/10.3390/s25092724

APA StyleDong, R., Yang, M., Zuo, Y., Liang, L., Xing, H., Duan, X., & Chen, S. (2025). Conducting Polymers-Based Gas Sensors: Principles, Materials, and Applications. Sensors, 25(9), 2724. https://doi.org/10.3390/s25092724