Sequential Extraction of Valuable Bio-Products from Snow Crab (Chionoecetes opilio) Processing Discards Using Eco-Friendly Methods

Abstract

:1. Introduction

2. Results

2.1. Characterization of Raw Material (Crab Processing Discards)

2.2. Characterization of Extracted Crab Bio-Products

2.2.1. Extraction of Carotenoids with Vegetable Oil

2.2.2. Pigmented Protein Powder

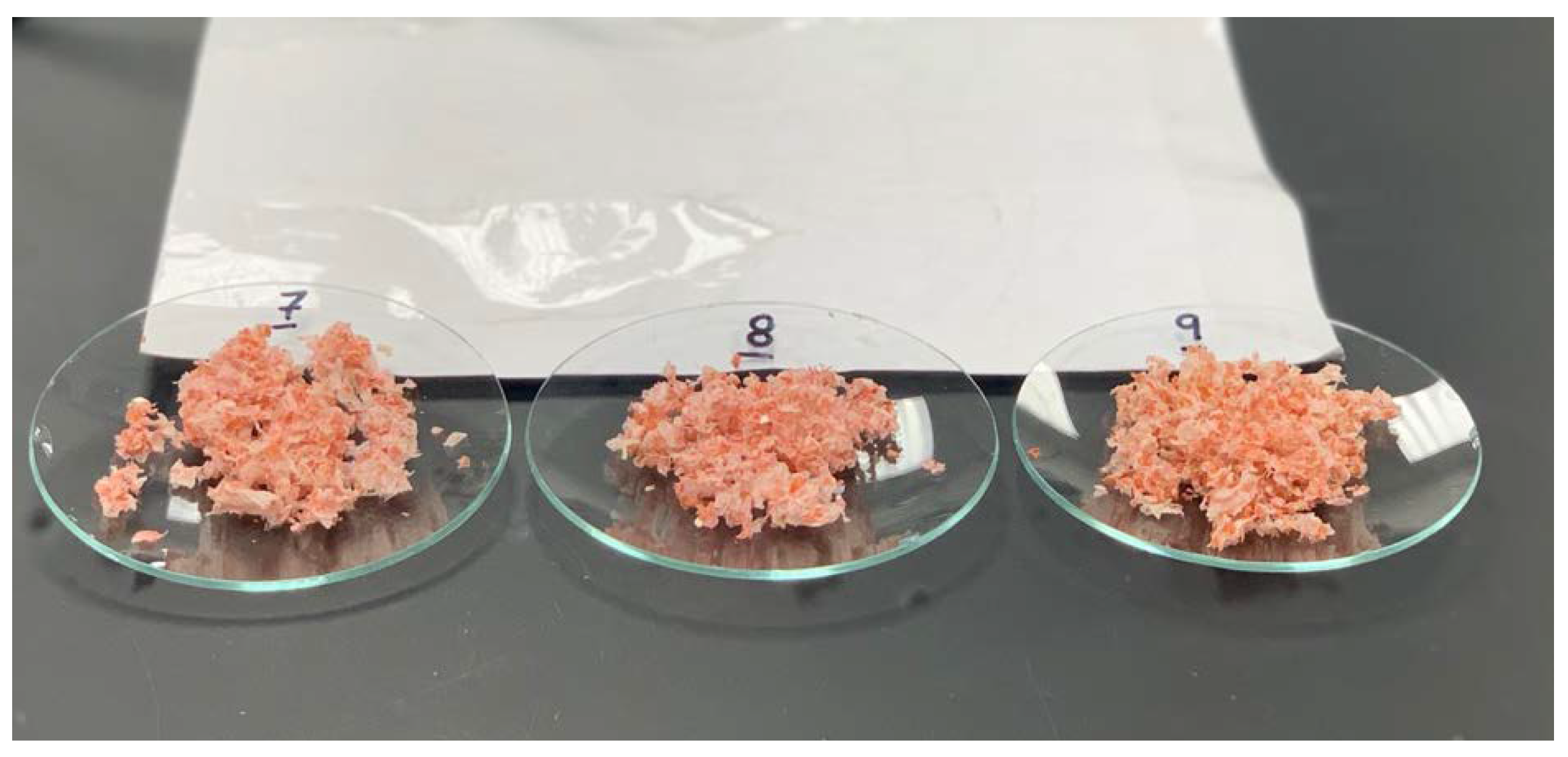

2.2.3. Chitin

Ash Content

Total Nitrogen Content

Residual Protein Content

Chitin Nitrogen Content

Color Characteristics

X-ray Diffraction Pattern and Crystallinity Index

3. Discussion

4. Materials and Methods

4.1. Characterization of Raw Material

4.1.1. Proximate Composition of Raw Material

4.1.2. Chitin Content

4.1.3. Characterization of Chitin

4.1.4. Total Astaxanthin Content

4.2. Extraction of Crab Bio-Products

4.2.1. Astaxanthin Extraction in Vegetable Oil

4.2.2. Demineralization with Citric Acid

4.2.3. Enzymatic Deproteination

4.2.4. Decolorization with Hydrogen Peroxide

4.3. Characterization of Snow Crab Bio-Products

4.3.1. Tristimulus Color Parameters

4.3.2. Powder X-ray Diffraction

4.3.3. Chitin Yield

4.4. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| AXT | L | a | b | |

|---|---|---|---|---|

| AXT | 1 | |||

| L | −0.19 | 1 | ||

| A | 0.60 | −0.64 | 1 | |

| B | −0.29 | 0.06 | −0.48 | 1 |

References

- Fisheries and Oceans Canada Seafisheries Landings. Available online: https://www.dfo-mpo.gc.ca/stats/commercial/sea-maritimes-eng.htm (accessed on 2 April 2023).

- Manuel, H. Innovations in crustacean processing: Bioproduction of chitin and its derivatives. In Fuels, Chemicals and Materials from the Oceans and Aquatic Sources; Kerton, F.M., Yan, N., Eds.; John Wiley and Sons Ltd.: Oxford, UK, 2017; pp. 113–149. [Google Scholar]

- Prakash, D.; Nawani, N.N.; Kapadnis, B.P. Microbial mining of value added products from seafood waste and their applications. In Microorganisms in Environmental Management: Microbes and Environment; Prakash, A., Satyanarayana, T., Johri, B.N., Eds.; Springer Science + Business Media B.V.: Dordrecht, The Netherlands, 2012; pp. 315–333. [Google Scholar]

- Burke, H.J. Green Chemistry and an Ocean Based Biorefinery Approach for the Valorization of Newfoundland and Labrador Snow Crab (Chionoecetes opilio) Processing Discards. Ph.D. Thesis, Memorial University of Newfoundland, St. Johns, NL, Canada, September 2022. Available online: https://research.library.mun.ca/15774/1/thesis.pdf (accessed on 16 April 2023).

- Nanda, P.K.; Das, A.K.; Dandapat, P.; Dhar, P.; Bandyopadhyay, S.; Dib, A.L.; Lorenzo, J.M.; Gagaoua, M. Nutritional aspects, flavour profile and health benefits of crab meat based novel food products and valorisation of processing waste to wealth: A review. Trends Food Sci. Technol. 2021, 112, 252–267. [Google Scholar] [CrossRef]

- Pohling, J.; Dave, D.; Liu, Y.; Murphy, W.; Trenholm, S. Two-step demineralization of shrimp (Pandalus borealis) shells using citric acid: An environmentally friendly, safe and cost-effective alternative to the traditional approach. Green Chem. 2021, 24, 1141–1151. [Google Scholar] [CrossRef]

- Shahidi, F.; Synowiecki, J. Isolation and characterization of nutrients and value-added products from snow crab (Chinoecetes opilio) and shrimp (Pandalus borealis) processing discards. J. Agric. Food Chem. 1991, 39, 1527–1532. [Google Scholar] [CrossRef]

- Percot, A.; Viton, C.; Domard, A. Optimization of Chitin Extraction from Shrimp Shells. Biomacromolecules 2003, 4, 12–18. [Google Scholar] [CrossRef]

- Lage-Yusty, M.-A.; Vilasoa-Martínez, M.; Álvarez-Pérez, S.; López-Hernández, J. Chemical composition of snow crab shells (Chionoecetes opilio). J. Food 2011, 9, 265–270. [Google Scholar] [CrossRef]

- Manu-Tawiah, W.; Haard, N. Recovery of Carotenoprotein from the Exoskeleton of Snow Crab Chionocetes opilio. Can. Inst. Food Sci. Technol. J. 1987, 20, 31–33. [Google Scholar] [CrossRef]

- Lindberg, D.; Solstad, R.G.; Arnesen, J.A.; Helmers, A.K.; Whitaker, R.D. Lab scale sustainable extraction of components from snow crab (Chionoecetes opilio) co-products, and estimation of processing costs based on a small-scale demonstration plant (Biotep). Econ. Fish. Res. 2021, 31, 42–57. [Google Scholar]

- Beaulieu, L.; Thibodeau, J.; Bryl, P.; Carbonneau, M. Characterization of enzymatic hydrolyzed snow crab (Chionoecetes opilio) by-product fractions: A source of high-valued biomolecules. Bioresour. Technol. 2009, 100, 3332–3342. [Google Scholar] [CrossRef]

- Higuera-Ciapara, I.; Félix-Valenzuela, L.; Goycoolea, F.M. Astaxanthin: A Review of its Chemistry and Applications. Crit. Rev. Food Sci. Nutr. 2006, 46, 185–196. [Google Scholar] [CrossRef]

- Chen, H.-M.; Meyers, S.P. Extraction of Astaxanthin Pigment from Crawfish Waste Using a Soy Oil Process. J. Food Sci. 1982, 47, 892–896. [Google Scholar] [CrossRef]

- Sachindra, N.; Mahendrakar, N. Process optimization for extraction of carotenoids from shrimp waste with vegetable oils. Bioresour. Technol. 2005, 96, 1195–1200. [Google Scholar] [CrossRef]

- Hooshmand, H.; Shabanpour, B.; Moosavi-Nasab, M.; Golmakani, M.T. Optimization of carotenoids extraction from blue crab (Portunus pelagicus) and shrimp (Penaeus semisulcatus) wastes using organic solvents and vegetable oils. J. Food Process. Preserv. 2017, 41, e13171. [Google Scholar] [CrossRef]

- Parjikolaei, B.R.; El-Houri, R.B.; Fretté, X.C.; Christensen, K.V. Influence of green solvent extraction on carotenoid yield from shrimp (Pandalus borealis) processing waste. J. Food Eng. 2015, 155, 22–28. [Google Scholar] [CrossRef]

- Chen, D.-W.; Zhang, M. Determination of odour-active compounds in the cooked meat of Chinese mitten crab (Eriocheir Sinensis) by solid phase microextraction, gas chromatography-olfactometry and gas chromatography-mass spectrometry. J. Food Drug Anal. 2010, 18, 4. [Google Scholar] [CrossRef]

- Ya, T. Recovery, Drying and Characterization of Carotenoproteins from Industrial Lobster Waste. Master’s Thesis, MacDonald College of McGill University, Montreal, QC, Canada, November 1990. Available online: https://escholarship.mcgill.ca/concern/theses/g158bj359 (accessed on 19 February 2022).

- Goodwin, T.W. Marine Invertebrates. In Carotenoids, Their Comparative Biochemistry; Chemical Publishing Co., Inc.: New York, NY, USA, 1954; pp. 155–188. [Google Scholar] [CrossRef] [Green Version]

- Meléndez-Martínez, A.J.; Mapelli-Brahm, P.; Hornero-Méndez, D.; Vicario, I.M. Chapter 1. Structures, Nomenclature and General Chemistry of Carotenoids and Their Esters. In Carotenoid Esters in Foods: Physical, Chemical and Biological Properties; Mercadante, A.Z., Ed.; Royal Society of Chemistry (RSC): London, UK, 2019; pp. 1–50. [Google Scholar]

- Goodwin, T.W. Carotenoid—Protein Complexes. In The Biochemistry of the Carotenoids; Springer: Dordrecht, The Netherlands, 1984; pp. 1–21. [Google Scholar] [CrossRef]

- Bhosale, P.; Bernstein, P.S. Vertebrate and invertebrate carotenoid-binding proteins. Arch. Biochem. Biophys. 2007, 458, 121–127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheesman, D.F.; Lee, W.L.; Zagalsky, P.F. Carotenoproteins in invertebrates. Biol. Rev. 1967, 42, 131–160. [Google Scholar] [CrossRef]

- Chessman, D.F.; Zagalsky, P.F.; Ceccaldi, H.J. Purification and properties of crustacyanin. Proc. R. Soc. 1966, 164, 130–151. [Google Scholar] [CrossRef]

- Maoka, T. Carotenoids in Marine Animals. Mar. Drugs 2011, 9, 278–293. [Google Scholar] [CrossRef]

- Kumirska, J.; Czerwicka, M.; Kaczyński, Z.; Bychowska, A.; Brzozowski, K.; Thöming, J.; Stepnowski, P. Application of Spectroscopic Methods for Structural Analysis of Chitin and Chitosan. Mar. Drugs 2010, 8, 1567–1636. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Xue, C.; Xue, Y.; Gao, R.; Zhang, X. Determination of the degree of deacetylation of chitin and chitosan by X-ray powder diffraction. Carbohydr. Res. 2005, 340, 1914–1917. [Google Scholar] [CrossRef]

- Maniukiewicz, W. Chapter 8: X-ray diffraction studies, chitin, chitosan, and their derivatives. In Chitin, Chitosan, Oligosaccharides and Their Derivatives. Biological Activities and Applications; Kim, S.-K., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2011; pp. 83–94. [Google Scholar]

- Abdou, E.S.; Nagy, K.S.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from local sources. Bioresour. Technol. 2008, 99, 1359–1367. [Google Scholar] [CrossRef]

- Fan, Y.; Saito, T.; Isogai, A. Preparation of Chitin Nanofibers from Squid Pen β-Chitin by Simple Mechanical Treatment under Acid Conditions. Biomacromolecules 2008, 9, 1919–1923. [Google Scholar] [CrossRef]

- Ofoedu, C.E.; You, L.; Osuji, C.M.; Iwouno, J.O.; Kabuo, N.O.; Ojukwu, M.; Agunwah, I.M.; Chacha, J.S.; Muobike, O.P.; Agunbiade, A.O.; et al. Hydrogen Peroxide Effects on Natural-Sourced Polysacchrides: Free Radical Formation/Production, Degradation Process, and Reaction Mechanism—A Critical Synopsis. Foods 2021, 10, 699. [Google Scholar] [CrossRef] [PubMed]

- Macías-Sánchez, M.; Mantell, C.; Rodríguez, M.; de la Ossa, E.M.; Lubián, L.; Montero, O. Comparison of supercritical fluid and ultrasound-assisted extraction of carotenoids and chlorophyll a from Dunaliella salina. Talanta 2009, 77, 948–952. [Google Scholar] [CrossRef] [PubMed]

- Yvonne, V.Y. Marine Algal Constituents. In Marine Nutraceuticals and Functional Foods; Barrow, C.B., Shahidi, F., Eds.; CRC Press: Boca Raton, FL, USA, 2007; pp. 259–296. [Google Scholar] [CrossRef]

- Pu, J.; Bechtel, P.J.; Sathivel, S. Extraction of shrimp astaxanthin with flaxseed oil: Effects on lipid oxidation and astaxanthin degradation rates. Biosyst. Eng. 2010, 107, 364–371. [Google Scholar] [CrossRef]

- Burke, H.; Kerton, F. Heavy metals in Snow crab (Chionoecetes opilio) Bio-products. J. Ocean Technol. 2022, 17, 102–126. [Google Scholar]

- Hajiali, F.; Vidal, J.; Jin, T.; de la Garza, L.C.; Santos, M.; Yang, G.; Moores, A. Extraction of Chitin from Green Crab Shells by Mechanochemistry and Aging. ACS Sustain. Chem. Eng. 2022, 10, 11348–11357. [Google Scholar] [CrossRef]

- Minke, R.; Blackwell, J. The structure of α-chitin. J. Mol. Biol. 1978, 120, 167–181. [Google Scholar] [CrossRef] [PubMed]

- Jang, M.-K.; Kong, B.-G.; Jeong, Y.-I.; Lee, C.H.; Nah, J.-W. Physicochemical characterization of alpha-chitin, beta-chitin, and gamma-chitin separated from natural resources. J. Polym. Sci. Part A Polym. Chem. 2004, 42, 3423–3432. [Google Scholar] [CrossRef]

- Salo-Väänänen, P.P.; Koivistoinen, P.E. Determination of protein in foods: Comparison of net protein and crude protein (N × 6.25) values. Food Chem. 1996, 57, 27–31. [Google Scholar] [CrossRef]

- Sindhu, S.; Sherief, P.M. Extraction, Characterization, Antioxidant and Anti-Inflammatory Properties of Carotenoids from the Shell Waste of Arabian Red Shrimp Aristeus alcocki, Ramadan 1938. Open Conf. Proc. J. 2011, 2, 95–103. [Google Scholar] [CrossRef]

- Focher, B.; Beltrame, P.; Naggi, A.; Torri, G. Alkaline N-deacetylation of chitin enhanced by flash treatments. Reaction kinetics and structure modifications. Carbohydr. Polym. 1990, 12, 405–418. [Google Scholar] [CrossRef]

- Struszczyk, H. Microcrystalline chitosan. I. Preparation and properties of microcrystalline chitosan. J. Appl. Polym. Sci. 1987, 33, 177–189. [Google Scholar] [CrossRef]

| Parameter | May 2018 5 | May 2021 #1 5 | May 2021 #2 5 | F Value | p Value |

|---|---|---|---|---|---|

| %Moisture Original Sample 1 | 65.60 ± 0.41 a | 65.23 ± 0.85 a | 65.12 ± 0.34 a | F2,6 = 4.36 | 0.07 |

| % Ash (db) 2 | 34.40 ± 0.45 a | 37.06 ± 1.10 b | 38.06 ± 1.60 b | F2,6 = 8.13 | 0.019 |

| % Nitrogen (db) 2 | 5.93 ± 0.08 a | 5.30 ± 0.16 b | 5.40 ± 0.23 b | F2,6 = 12.60 | 0.007 |

| % Lipid (db) 2 | 3.22 ± 0.63 a | 2.04 ± 0.002 a | 2.19 ± 0.23 a | F2,4 = 6.96 | 0.05 |

| % Chitin (db) 3 | 17.95 ± 1.89 a | 24.57 ± 1.90 a | 24.94 ± 2.64 a | F2,3 = 6.59 | 0.08 |

| Astaxanthin (µg/g) (db) 4 | 58.45 ± 0.38 a | 59.32 ± 3.25 a | 60.78 ± 2.36 a | F2,6 = 1.12 | 0.38 |

| % Astaxanthin in Vegetable Oil Solvents | ||

|---|---|---|

| Sunflower Oil | Corn Oil | Canola Oil |

| 24.85 ± 0.01 a | 37.93 ± 0.04 b | 31.23 ± 0.03 c |

| Composition | Sunflower Oil 3 | Corn Oil 3 | Canola Oil 3 |

|---|---|---|---|

| % Protein 1 (db) | 51.69 ± 0.53 a | 51.53 ± 1.23 a | 51.05 ± 0.52 a |

| % Lipid 2 (db) | 24.58 | 19.72 | 16.08 |

| % Ash 2 (db) | 0.86 | 0.72 | 0.76 |

| Total Astaxanthin 1 (µg/g) (db) | 39.56 ± 1.04 a | 33.77 ± 0.35 b | 37.67 ± 0.64 c |

| Parameter | Sunflower Oil | Corn Oil | Canola Oil | ||||||

|---|---|---|---|---|---|---|---|---|---|

| FAP | Sea-B-Zyme | Weifang | FAP | Sea-B-Zyme | Weifang | FAP | Sea-B-Zyme | Weifang | |

| % Chitin Yield a (db) | 17.06 | 17.09 | 18.57 | 18.02 | 18.20 | 20.08 | 17.53 | 17.46 | 19.15 |

| % Moisture b | 2.24 ± 0.68 | 1.65 ± 0.75 | 1.46 ± 0.50 | 1.10 ± 0.65 | 1.14 ± 0.37 | 1.26 ± 0.42 | 1.05 ± 0.55 | 1.26 ± 0.55 | 1.42 ± 0.42 |

| % Ash c (db) | 2.16 | 1.8 | 1.05 | 1.17 | 1.24 | 1.44 | 0.75 | 1.06 | 1.92 |

| % Total Nitrogen b (db) | 6.31 ± 0.10 | 6.34 ± 0.01 | 6.35 ± 0.03 | 6.38 ± 0.15 | 6.19 ± 0.01 | 6.61 ± 0.12 | 6.43 ± 0.07 | 6.24 ± 0.001 | 6.55 ± 0.21 |

| % Residual protein d (db) | 0.26 ± 0.17 | 0.39 ± 0.14 | 0.63 ± 0.21 | 0.28 ± 0.22 | 0.77 ± 0.37 | 0.95 ± 0.15 | 0.45 ± 0.28 | 0.76 ± 0.46 | 0.92 ± 0.15 |

| % Chitin Nitrogen e (db) | 6.27 | 6.28 | 6.25 | 6.34 | 6.07 | 6.46 | 6.30 | 6.12 | 6.40 |

| Astaxanthin f (μg/g) (db) | 17.61 ± 0.09 | 18.59 ± 0.57 | 9.91 ± 0.14 | 14.76 ± 0.77 | 20.70 ± 0.28 | 13.12 ± 0.10 | 15.64 ± 0.12 | 20.44 ± 0.21 | 12.36 ± 0.16 |

| Hunter Color Parameters g | FAP | Sea-B-Zyme | Weifang | FAP | Sea-B-Zyme | Weifang | FAP | Sea-B-Zyme | Weifang |

| L | 65.76 ± 0.54 | 70.25 ± 0.51 | 67.08 ± 0.15 | 69.87 ± 0.26 | 68.89 ± 0.34 | 70.82 ± 0.47 | 66.35 ± 1.45 | 63.45 ± 1.06 | 66.76 ± 0.58 |

| a | 23.64 ± 0.11 | 23.58 ± 0.13 | 23.46 ± 0.04 | 23.48 ± 0.12 | 23.85 ± 0.10 | 22.45 ± 0.14 | 24.28 ± 0.37 | 24.35 ± 0.26 | 23.12 ± 0.23 |

| b | 3.44 ± 0.23 | 0.36 ± 0.79 | 1.28 ± 0.27 | 0.84 ± 0.31 | 0.26 ± 0.15 | 1.09 ± 0.29 | −0.71 ± 0.39 | −0.66 ± 0.64 | 1.25 ± 0.71 |

| ANOVA | |||||

|---|---|---|---|---|---|

| Composition | May 2018 3 | June 2018 3 | July 2018 3 | F2,3 | p-Value |

| % Chitin Yield 1 (db) | 17.93 ± 1.89 a | 16.16 ± 5.65 a | 16.81 ± 0.31 a | 0.135 | 0.88 |

| % Ash 1 (db) | 0.68 ± 0.64 a | 0.46 ± 0.25 a | 0.26 ± 0.24 a | 0.48 | 0.66 |

| % Total Nitrogen 1 (db) | 6.30 ± 0.064 a | 6.38 ± 0.04 a | 6.43 ± 0.03 a | 4.53 | 0.12 |

| % Residual protein 1 (db) | 0.34 ± 0.36 a | 0.23 ± 0.25 a | 0.12 ± 0.02 a | 0.37 | 0.72 |

| % Chitin Nitrogen 1,2 (db) | 6.23 ± 0.014 a | 6.33 ± 0.014 a,b | 6.43 ± 0.049 b | 20.02 | 0.018 |

| Sample Description | Iam 2 | I110 3 | % CI |

|---|---|---|---|

| Crab Shell Backs 2021 (Chemical Process) | 500 | 3291.7 | 84.81 |

| May 2021 (Chemical Process) | 527.78 | 3097.2 | 82.96 |

| May 2021 (Green Process: Corn Oil + FAP + H2O2) | 611.11 | 3083.33 | 80.18 |

| May 2018 (Chemical Process) | 541.67 | 3000 | 81.94 |

| June 2018 (Chemical Process) | 333.33 | 4888.89 | 93.18 |

| July 2018 (Chemical Process) | 555.56 | 3555.56 | 84.37 |

| Parameter | Fungal Acid Protease (Aspergillus oryzae) | Sea-B-Zyme L200 | Weifang Acid Protease |

|---|---|---|---|

| Type of Protease | Endo and Exo | Acid Protease | Acid Protease |

| Enzyme Activity | >500 U/g | Not specified | >100,000 U/g |

| % Enzyme 1 | 2% | 2% | 2% |

| pH | 7.0 | 5.0 | 3.0 |

| Optimum Temp Range | 30–55 °C | 40–55 °C | 45 °C |

| Reaction Temp | 45 °C | 45 °C | 45 °C |

| Shell:Water | 1:10 | 1:10 | 1:10 |

| Bulk Cost (USD/kg) 2 | 80.00 | 32.50 | 12.00 |

| Crab Bio-Product | Parameters Analyzed | Method |

|---|---|---|

| Pigmented Oils | Total Astaxanthin | hexane:isopropanol [41], Equation (4) |

| Protein-Pigment Powder | Moisture | AOAC Method 930.14 |

| Total Nitrogen | AOAC Method 954.01/988.05 | |

| Ash Content | AOAC Method 938.08 Ash of Seafood | |

| Total Astaxanthin | hexane:isopropanol [41], Equation (4) | |

| Chitin | Moisture | AOAC Method 930.14 |

| Total Nitrogen | AOAC Method 954.01/988.05 | |

| Protein Nitrogen | Lowry method, Equation (3) | |

| Ash Content | AOAC Method 938.08 Ash of Seafood | |

| Total Astaxanthin | hexane:isopropanol [41], Equation (4) | |

| Chitin Yield | Equation (6) | |

| Chitin Nitrogen | Equation (2) | |

| Tristimulus Color Parameters | ColorTec PCM Colorimeter | |

| Powder X-ray Diffraction | Rigaku Ultima IV X-ray diffractometer, Equation (5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burke, H.J.; Kerton, F. Sequential Extraction of Valuable Bio-Products from Snow Crab (Chionoecetes opilio) Processing Discards Using Eco-Friendly Methods. Mar. Drugs 2023, 21, 366. https://doi.org/10.3390/md21060366

Burke HJ, Kerton F. Sequential Extraction of Valuable Bio-Products from Snow Crab (Chionoecetes opilio) Processing Discards Using Eco-Friendly Methods. Marine Drugs. 2023; 21(6):366. https://doi.org/10.3390/md21060366

Chicago/Turabian StyleBurke, Heather J., and Francesca Kerton. 2023. "Sequential Extraction of Valuable Bio-Products from Snow Crab (Chionoecetes opilio) Processing Discards Using Eco-Friendly Methods" Marine Drugs 21, no. 6: 366. https://doi.org/10.3390/md21060366

APA StyleBurke, H. J., & Kerton, F. (2023). Sequential Extraction of Valuable Bio-Products from Snow Crab (Chionoecetes opilio) Processing Discards Using Eco-Friendly Methods. Marine Drugs, 21(6), 366. https://doi.org/10.3390/md21060366