Research on the Causes of Gas Explosion Accidents Based on Safety Information Transmission

Abstract

:1. Introduction

2. Safety Information Transmission

2.1. Safety Information

2.2. Safety Information Loss

3. Coal Mine Gas Explosion Accidents

3.1. Mechanism of Gas Explosion Accidents

3.2. Causes of Gas Explosion Accidents

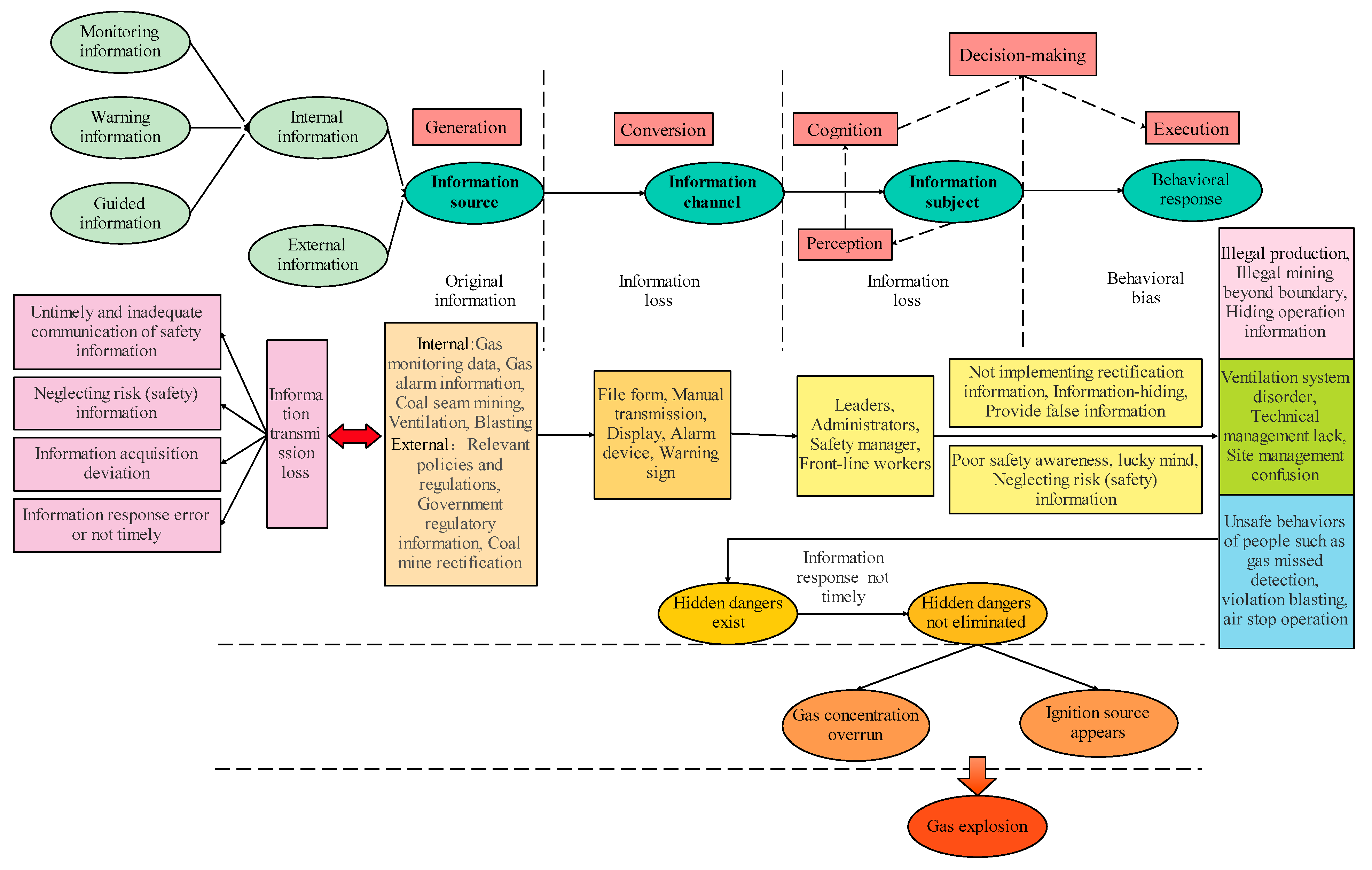

4. Accident-Causation Model of Coal Mine Gas Explosion

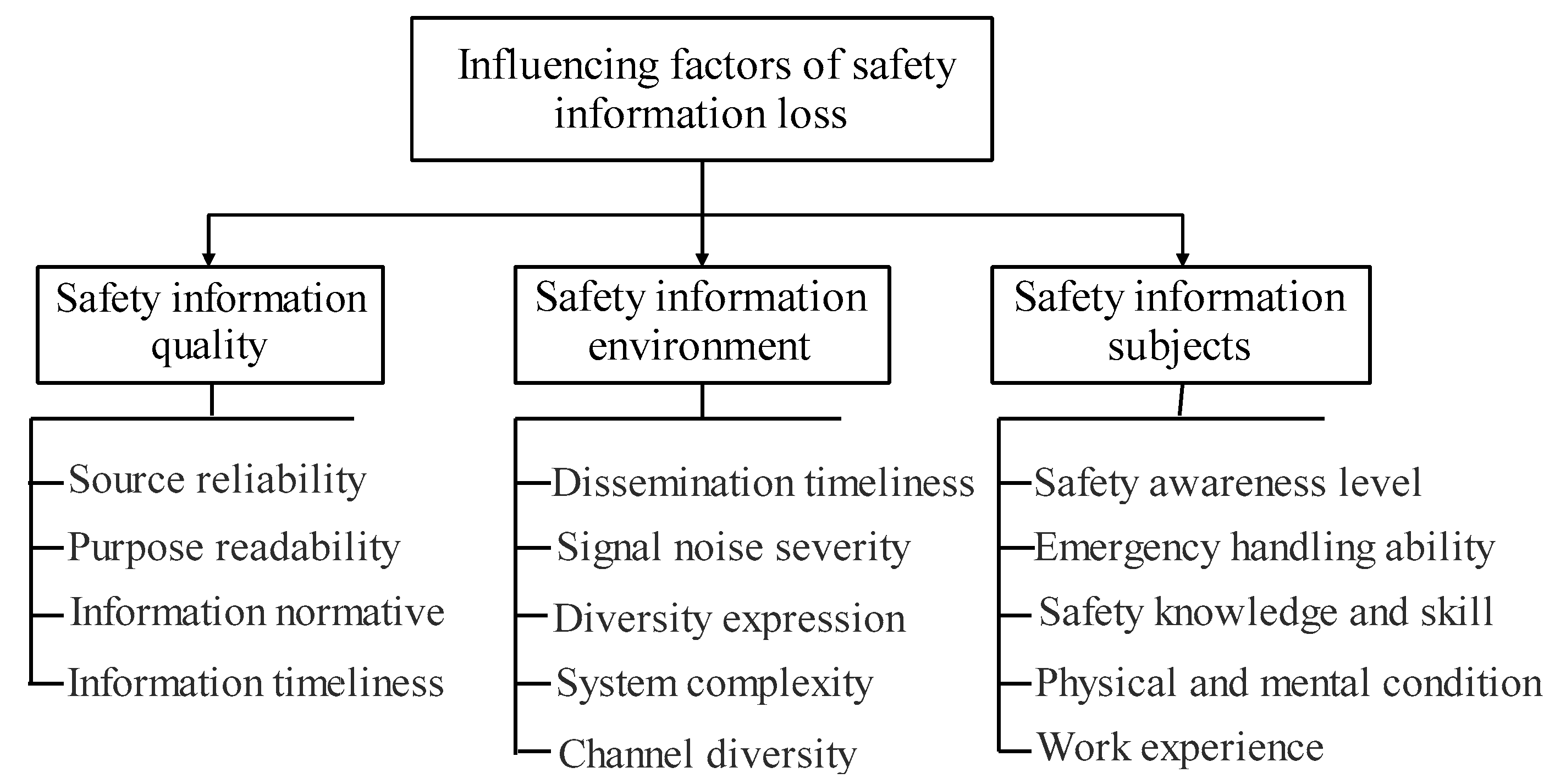

4.1. Analysis of Influencing Factors of Safety Information Loss

4.2. Construction of Accident-Causation Model

5. Quantitative Analysis Based on DEMATEL-ISM

5.1. Correlation Characteristic Analysis

5.1.1. Identification of Causal Factors in Gas Explosion Accidents

5.1.2. Establishment of Direct Influence Matrix K

5.1.3. Establishment of Comprehensive Influence Matrix T

5.1.4. Determination of Centrality and Causation Degree

5.2. Hierarchical Characteristic Analysis

5.2.1. Adjacency Matrix L and Accessibility Matrix Z

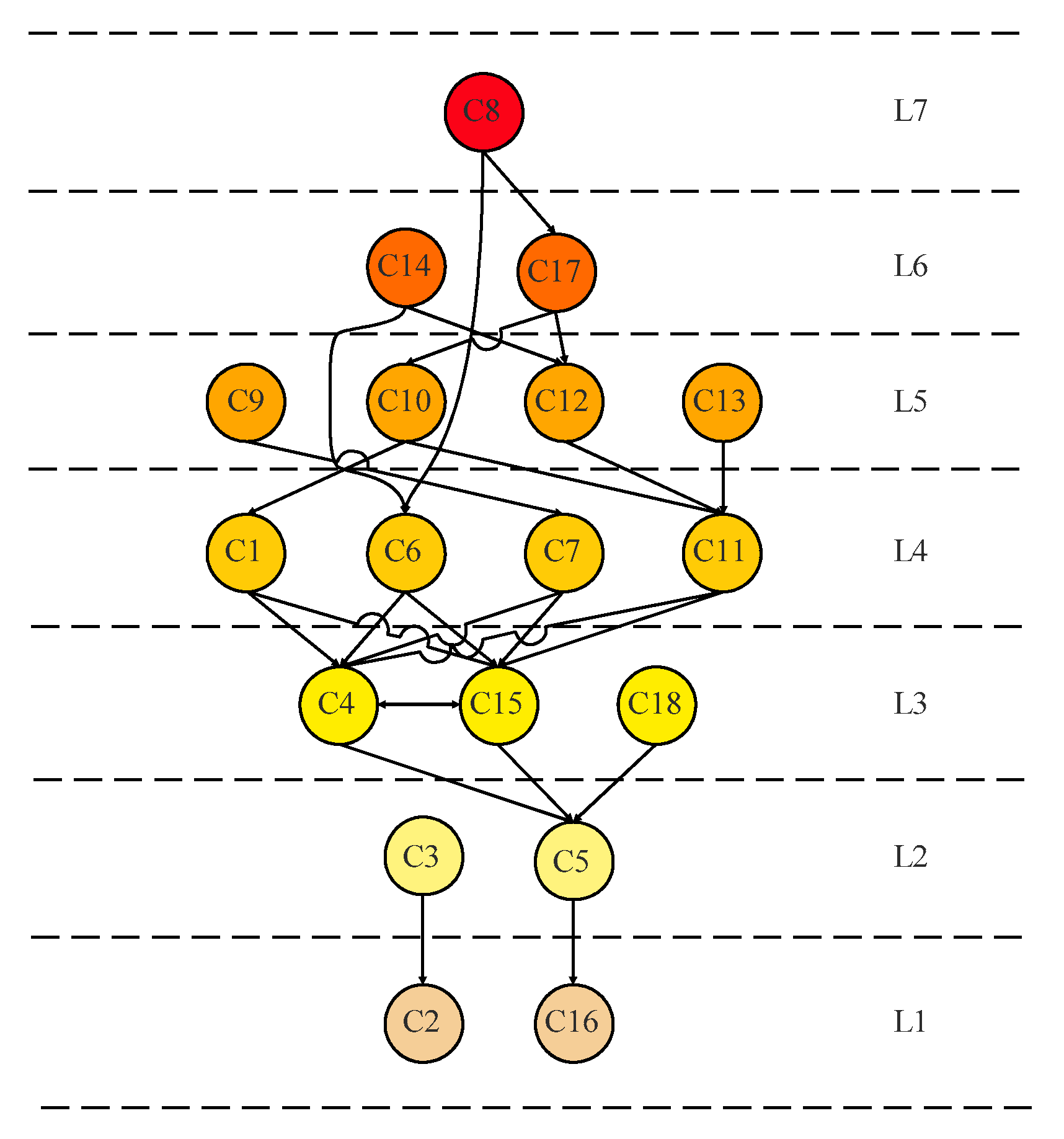

5.2.2. Multilevel Hierarchical ISM

6. Discussion

- (1)

- The information subject is not only the recipient of safety information, but also the transmitter of information. Work experience, safety awareness level, and the physical and mental state of information subjects have a significant impact on information transmission, which directly affects the accuracy and effectiveness of information transmission and use. Therefore, coal mining enterprises need to improve the safety awareness level, information cognition, and processing ability of their employees through daily safety training and assessment. In addition, signal noise, dissemination channels, and information expression forms in the information transmission process have a certain impact on information loss. It is necessary to consider the ways and manifestations of information transmission from the perspective of information types, the needs of the information subjects, and understanding. This can help avoid the homogenization of information transmission and further improve the effectiveness of information transmission.

- (2)

- Owing to the complexity of underground production systems, there are many types and structures of safety information in the coal mine production process. There are problems in the quality assurance of the source, the transmission environment is complex and changeable, and the comprehensive quality of the information recipients is uneven, which leads to problems in the process of information transmission. Different degrees of loss result in gas accumulation or the emergence of fire sources, which leads to gas explosion accidents. Therefore, in view of the complexity of the system, it is necessary to comprehensively analyse the information types, characteristics, attributes, and target states. Additionally, the safety information should be divided according to the urgency, manifestation, and response needs. The information transmission efficiency and information utilisation rate must be improved, and the role of safety information must assume full importance.

7. Conclusions

- (1)

- Loss of safety information is a key factor in gas explosion accidents. Based on the entire process of safety information transmission, the factors affecting safety information loss were extracted, including safety information quality, safety information environment, safety information subjects, three first-level indicators, and fourteen second-level indicators.

- (2)

- The three elements (source, channel, and information subject) and six stages (generation, conversion, perception, cognition, decision-making, and execution) of safety information transmission were analyzed. This was combined with the case of gas explosion accidents to develop an accident-causation model of a gas explosion accident based on safety information transmission, which has a certain guiding significance for the prevention of gas explosion accidents.

- (3)

- Eighteen causal factors were extracted according to the accident-causation model of a gas explosion, based on safety information transmission. The DEMATEL-ISM quantitative analysis method was used to determine ten cause factors and eight result factors. Among them, C8, C14, and C17 were the root factors affecting the occurrence of gas explosion accidents, and C2 and C16 were the surface factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Cheng, Y.P.; Liu, H.Y. An analysis of fatal gas accidents in Chinese coal mines. Saf. Sci. 2014, 62, 107–113. [Google Scholar] [CrossRef]

- Zhang, J.J.; Xu, K.L.; Genserik, R.; Greg, Y. Statistical analysis the characteristics of extraordinarily severe coal mine accidents (ESCMAs) in China from 1950 to 2018. Process Saf. Environ. Prot. 2020, 133, 332–340. [Google Scholar] [CrossRef]

- Meng, X.F.; Liu, Q.L.; Luo, X.X.; Zhou, X.X. Risk assessment of the unsafe behaviours of humans in fatal gas explosion accidents in China’s underground coal mines. J. Clean. Prod. 2019, 210, 970–976. [Google Scholar] [CrossRef]

- Cheng, L.H.; Guo, H.M. The operational mechanism of enterprise safety system based on CAS theory. J. Wuhan Univ. Technol. (Inf. Manag. Eng.) 2017, 39, 507–510, 520. [Google Scholar]

- Cheng, L.H.; Guo, H.M.; Lin, H.F. Evolutionary model of coal mine safety system based on multi-agent modeling. Process Saf. Environ. Prot. 2021, 147, 1193–1200. [Google Scholar] [CrossRef]

- Huang, L.; Wu, C.; Ma, J. An accident-causing model under the perspective of safety information flow. Manag. Rev. 2020, 32, 274–285. [Google Scholar]

- Luo, T.Y.; Wu, C. Construction and empirical of accident cause model under SIC thinking. China Saf. Sci. J. 2017, 27, 1–6. [Google Scholar]

- Wu, C.; Huang, L. A new accident causation model based on information flow and its application in Tianjin Port fire and explosion accident. Reliab. Eng. Syst. Saf. 2019, 182, 73–85. [Google Scholar] [CrossRef]

- Cheng, L.H.; Wang, C.H.; Li, S.G.; Xu, J. Analysis of the influential factors of the sharing process for the safety information within the enterprise system itself. J. Saf. Environ. 2019, 19, 65–70. [Google Scholar]

- Underwood, P.; Waterson, P. Systemic accident analysis: Examining the gap between research and practice. Accid. Anal. Prev. 2013, 55, 154–164. [Google Scholar] [CrossRef]

- Zhao, C.F.; Zhou, X.H. Preliminary Study on theory of accident-causing based on safety information missing. World SCI-Tech RD 2012, 34, 6–9. [Google Scholar]

- Li, S.X.; Wu, C.; Wang, B. Study on model for accident resulting from multilevel safety information asymmetry. China Saf. Sci. J. 2017, 27, 18–23. [Google Scholar]

- Liaw, H.J. Deficiencies frequently encountered in the management of process safety information. Process Saf. Environ. Prot. 2019, 132, 226–230. [Google Scholar] [CrossRef]

- Feng, W.; Chen, Y.J.; Wu, C.; Cheng, S.Y. Research on accident causation model based on safety information cognition. J. Intell. 2019, 38, 160–165. [Google Scholar]

- Lei, Y.; Wu, C.; Feng, Y.X.; Wang, B. Optimization of multi-level safety information cognition (SIC): A new approach to reducing the systematic safety risk. Reliab. Eng. Syst. Saf. 2019, 190, 106497.1–106497.11. [Google Scholar] [CrossRef]

- Guang, X.L.; Wu, C.; Wang, B. Construct and empirical study of PAR accident-causing model based on safety & security information thinking. J. Intell. 2020, 39, 179–187. [Google Scholar]

- Li, Y.H.; Chen, G.H. The foundation of safety management information system discipline and its connotation and extension. China Saf. Sci. J. 2007, 17, 129–134. [Google Scholar]

- Sun, D.G.; Hu, G.X. Safety Information Management; Shanghai Jiao Tong University Press: Shanghai, China, 2014; pp. 34–38. [Google Scholar]

- Wang, B.; Wu, C. An outline of the research of system safety science under the guidance of safety information. J. Intell. 2017, 36, 48–55. [Google Scholar]

- Luo, T.Y.; Wu, C. Basic issues of safety information science. Sci. Technol. Rev. 2018, 36, 65–76. [Google Scholar]

- Cheng, L.H.; Guo, H.M.; Wang, C.H.; Li, S.G. Research on multilevel information loss of the sharing process for safety Information. J. Loss Prev. Process Ind. 2020, 67, 104223. [Google Scholar] [CrossRef]

- Huang, L.; Wu, C.; Wang, B. Individual behavioral safety mechanism and its influence factors based on information cognition. J. Intell. 2018, 37, 121–127. [Google Scholar]

- Cheng, L.H.; Jiang, B.L.; Guo, H.M. Modeling the Causes of Accidental Gas Explosions from the Perspective of Safety Information Loss. Process Saf. Prog. 2022. [Google Scholar] [CrossRef]

- Si, S.L.; You, X.Y.; Liu, H.C.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Li, G.L.; Yan, Y.Z.; Liu, W.Q.; Chen, Y.G.; Wu, Z.Y. Research on formation factors of miners’ unsafe emotions based on DMATEL-ISM. China Saf. Sci. J. 2021, 31, 30–37. [Google Scholar]

| Causal Factors | Causal Factors | Causal Factors | |||

|---|---|---|---|---|---|

| Safety information quality | Source reliability C1 | Safety information environment | Dissemination timeliness C5 | Safety information subjects | Safety awareness level C10 |

| Purpose readability C2 | Signal noise severity C6 | Emergency handling ability C11 | |||

| Information normative C3 | Diversity expression C7 | Safety knowledge and skill C12 | |||

| Information timeliness C4 | System complexity C8 | Physical and mental condition C13 | |||

| Hidden dangers | Gas concentration overrun C15 | Channel diversity C9 | Work experience C14 | ||

| Ignition source appears C16 | External environment | Government regulation C17 | Social supervision C18 | ||

| Factors | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | C18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 3 | 1 | 0 | 0 |

| C2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 |

| C3 | 1 | 3 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 |

| C4 | 0 | 0 | 0 | 0 | 3 | 1 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 3 | 3 | 2 | 1 |

| C5 | 0 | 0 | 0 | 2 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 2 | 3 | 0 | 0 |

| C6 | 0 | 3 | 3 | 3 | 3 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 2 | 0 | 3 | 3 | 2 | 0 |

| C7 | 0 | 2 | 1 | 2 | 2 | 1 | 0 | 1 | 2 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 2 | 1 |

| C8 | 0 | 3 | 3 | 3 | 3 | 3 | 0 | 0 | 1 | 1 | 2 | 2 | 2 | 0 | 3 | 3 | 3 | 1 |

| C9 | 0 | 3 | 0 | 3 | 3 | 2 | 3 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 3 | 3 | 2 | 1 |

| C10 | 2 | 3 | 2 | 3 | 3 | 0 | 1 | 0 | 1 | 0 | 2 | 2 | 1 | 0 | 3 | 3 | 2 | 0 |

| C11 | 0 | 0 | 0 | 1 | 3 | 0 | 1 | 0 | 0 | 1 | 0 | 2 | 0 | 0 | 3 | 3 | 0 | 0 |

| C12 | 2 | 3 | 2 | 0 | 1 | 0 | 0 | 0 | 0 | 2 | 3 | 0 | 1 | 0 | 3 | 3 | 1 | 0 |

| C13 | 2 | 2 | 2 | 2 | 3 | 2 | 0 | 0 | 0 | 2 | 3 | 1 | 0 | 0 | 2 | 2 | 0 | 0 |

| C14 | 1 | 2 | 2 | 2 | 2 | 3 | 0 | 0 | 1 | 2 | 3 | 3 | 1 | 0 | 2 | 2 | 2 | 1 |

| C15 | 2 | 2 | 1 | 3 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 |

| C16 | 2 | 2 | 2 | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 |

| C17 | 3 | 3 | 3 | 3 | 2 | 0 | 1 | 0 | 2 | 3 | 3 | 3 | 1 | 0 | 1 | 1 | 0 | 1 |

| C18 | 1 | 2 | 1 | 1 | 2 | 0 | 2 | 0 | 2 | 2 | 1 | 1 | 2 | 0 | 0 | 0 | 2 | 0 |

| Factors | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | C18 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.01 | 0.06 | 0.07 | 0.03 | 0.02 | 0.01 | 0.01 | 0.03 | 0.03 | 0.00 | 0.01 | 0.01 | 0.01 | 0.00 | 0.11 | 0.05 | 0.01 | 0.00 | 1.42 | −0.48 |

| C2 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.03 | 0.03 | 0.01 | 0.00 | 0.04 | 0.04 | 0.00 | 0.00 | 2.02 | −1.60 |

| C3 | 0.04 | 0.11 | 0.01 | 0.05 | 0.05 | 0.00 | 0.03 | 0.00 | 0.01 | 0.00 | 0.04 | 0.04 | 0.01 | 0.00 | 0.05 | 0.02 | 0.01 | 0.00 | 1.70 | −0.76 |

| C4 | 0.03 | 0.04 | 0.03 | 0.05 | 0.13 | 0.04 | 0.02 | 0.00 | 0.08 | 0.01 | 0.02 | 0.01 | 0.02 | 0.00 | 0.13 | 0.13 | 0.07 | 0.04 | 2.58 | −0.90 |

| C5 | 0.01 | 0.02 | 0.01 | 0.08 | 0.03 | 0.01 | 0.04 | 0.00 | 0.04 | 0.00 | 0.01 | 0.00 | 0.01 | 0.00 | 0.08 | 0.11 | 0.01 | 0.01 | 2.42 | −1.46 |

| C6 | 0.04 | 0.14 | 0.12 | 0.15 | 0.15 | 0.01 | 0.02 | 0.00 | 0.05 | 0.02 | 0.06 | 0.02 | 0.08 | 0.00 | 0.15 | 0.14 | 0.08 | 0.01 | 1.76 | 0.70 |

| C7 | 0.02 | 0.10 | 0.06 | 0.11 | 0.11 | 0.04 | 0.02 | 0.03 | 0.08 | 0.01 | 0.05 | 0.02 | 0.02 | 0.00 | 0.08 | 0.08 | 0.08 | 0.04 | 1.53 | 0.41 |

| C8 | 0.05 | 0.18 | 0.15 | 0.18 | 0.19 | 0.11 | 0.03 | 0.00 | 0.06 | 0.06 | 0.11 | 0.10 | 0.10 | 0.00 | 0.18 | 0.18 | 0.12 | 0.04 | 1.93 | 1.71 |

| C9 | 0.03 | 0.14 | 0.04 | 0.15 | 0.16 | 0.07 | 0.11 | 0.00 | 0.03 | 0.01 | 0.06 | 0.02 | 0.03 | 0.00 | 0.15 | 0.15 | 0.09 | 0.04 | 2.03 | 0.53 |

| C10 | 0.10 | 0.15 | 0.10 | 0.15 | 0.16 | 0.01 | 0.05 | 0.00 | 0.06 | 0.02 | 0.09 | 0.08 | 0.06 | 0.00 | 0.16 | 0.16 | 0.08 | 0.01 | 2.06 | 0.84 |

| C11 | 0.02 | 0.03 | 0.02 | 0.07 | 0.12 | 0.01 | 0.04 | 0.00 | 0.01 | 0.04 | 0.01 | 0.07 | 0.02 | 0.00 | 0.12 | 0.12 | 0.01 | 0.00 | 1.80 | −0.34 |

| C12 | 0.09 | 0.14 | 0.09 | 0.05 | 0.08 | 0.01 | 0.01 | 0.00 | 0.01 | 0.07 | 0.11 | 0.02 | 0.05 | 0.00 | 0.14 | 0.13 | 0.04 | 0.00 | 1.85 | 0.27 |

| C13 | 0.09 | 0.11 | 0.09 | 0.11 | 0.15 | 0.07 | 0.02 | 0.00 | 0.02 | 0.07 | 0.11 | 0.05 | 0.02 | 0.00 | 0.12 | 0.12 | 0.02 | 0.01 | 1.95 | 0.41 |

| C14 | 0.08 | 0.14 | 0.11 | 0.14 | 0.15 | 0.10 | 0.02 | 0.00 | 0.06 | 0.09 | 0.13 | 0.12 | 0.07 | 0.00 | 0.15 | 0.15 | 0.09 | 0.04 | 1.64 | 1.64 |

| C15 | 0.07 | 0.08 | 0.04 | 0.11 | 0.09 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | 0.07 | 0.00 | 0.03 | 0.03 | 0.01 | 0.00 | 2.49 | −1.31 |

| C16 | 0.07 | 0.08 | 0.07 | 0.08 | 0.08 | 0.01 | 0.01 | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | 0.07 | 0.00 | 0.03 | 0.03 | 0.01 | 0.00 | 2.39 | −1.23 |

| C17 | 0.13 | 0.16 | 0.13 | 0.15 | 0.14 | 0.02 | 0.06 | 0.01 | 0.09 | 0.11 | 0.13 | 0.12 | 0.06 | 0.00 | 0.12 | 0.11 | 0.03 | 0.04 | 2.45 | 0.77 |

| C18 | 0.06 | 0.11 | 0.06 | 0.08 | 0.12 | 0.01 | 0.08 | 0.00 | 0.08 | 0.08 | 0.07 | 0.05 | 0.08 | 0.00 | 0.06 | 0.06 | 0.08 | 0.01 | 1.41 | 0.81 |

| Factors | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | C18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C3 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C4 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| C6 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C7 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C8 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 |

| C9 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C10 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C11 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C12 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 |

| C13 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 |

| C14 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 |

| C15 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| C17 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 |

| C18 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Li, S.; Cheng, L. Research on the Causes of Gas Explosion Accidents Based on Safety Information Transmission. Int. J. Environ. Res. Public Health 2022, 19, 10126. https://doi.org/10.3390/ijerph191610126

Guo H, Li S, Cheng L. Research on the Causes of Gas Explosion Accidents Based on Safety Information Transmission. International Journal of Environmental Research and Public Health. 2022; 19(16):10126. https://doi.org/10.3390/ijerph191610126

Chicago/Turabian StyleGuo, Huimin, Shugang Li, and Lianhua Cheng. 2022. "Research on the Causes of Gas Explosion Accidents Based on Safety Information Transmission" International Journal of Environmental Research and Public Health 19, no. 16: 10126. https://doi.org/10.3390/ijerph191610126