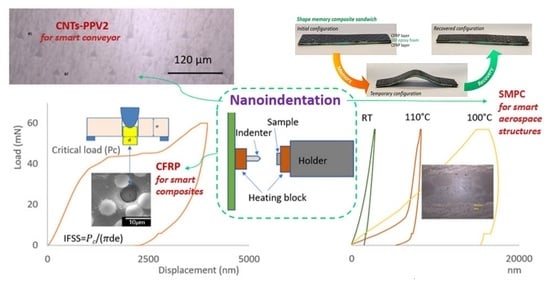

Nanoindentation of Multifunctional Smart Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. CNTs-Reinforced PPV-2 Nanocomposite (CNTs-PPV2)

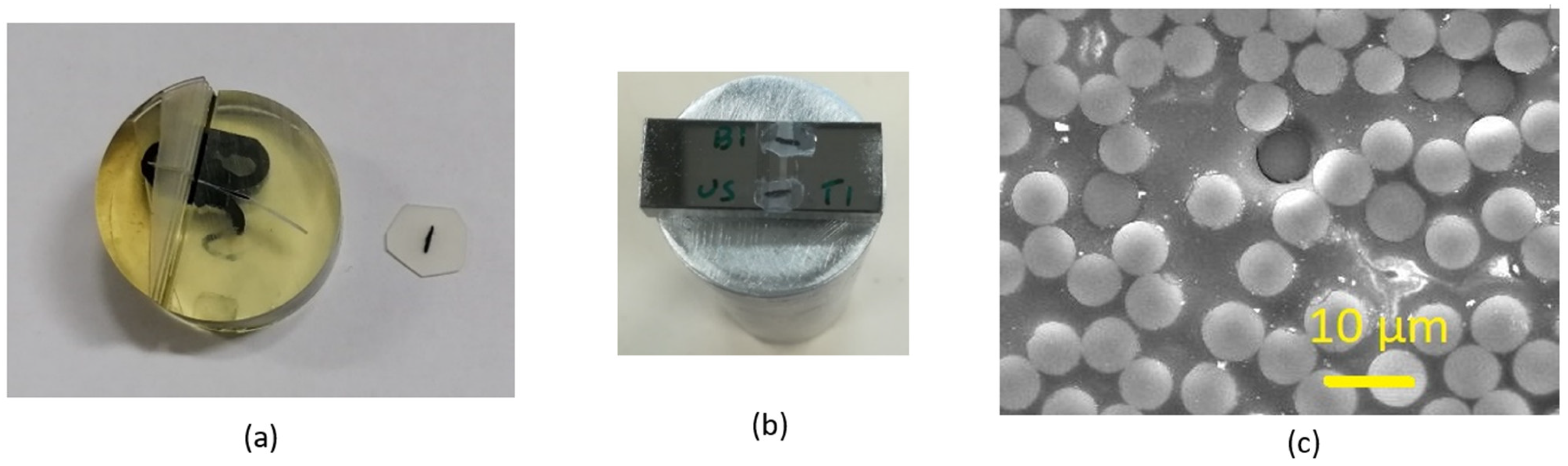

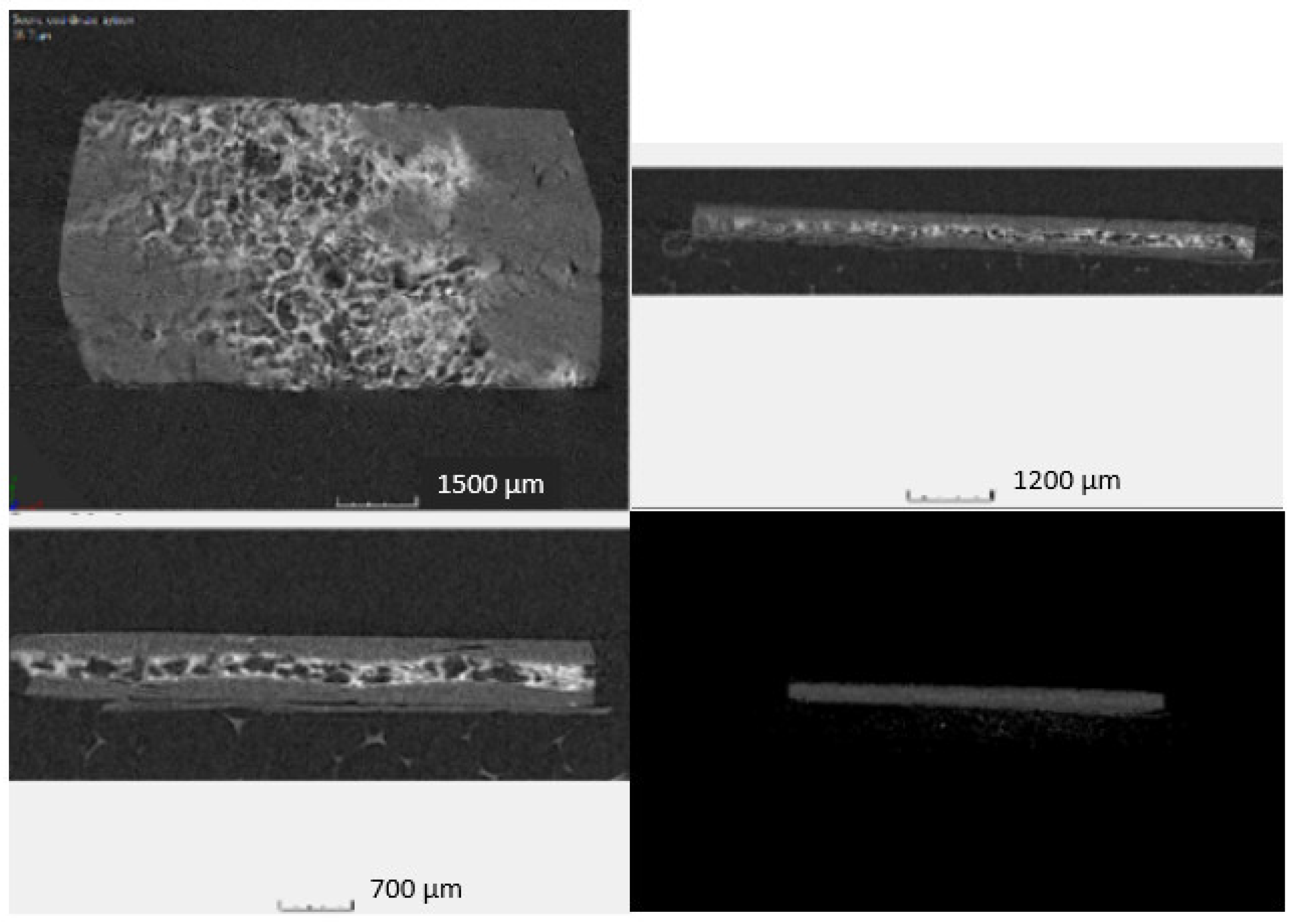

2.2. Nanomechanical Properties and Interfacial Properties of the CFRP

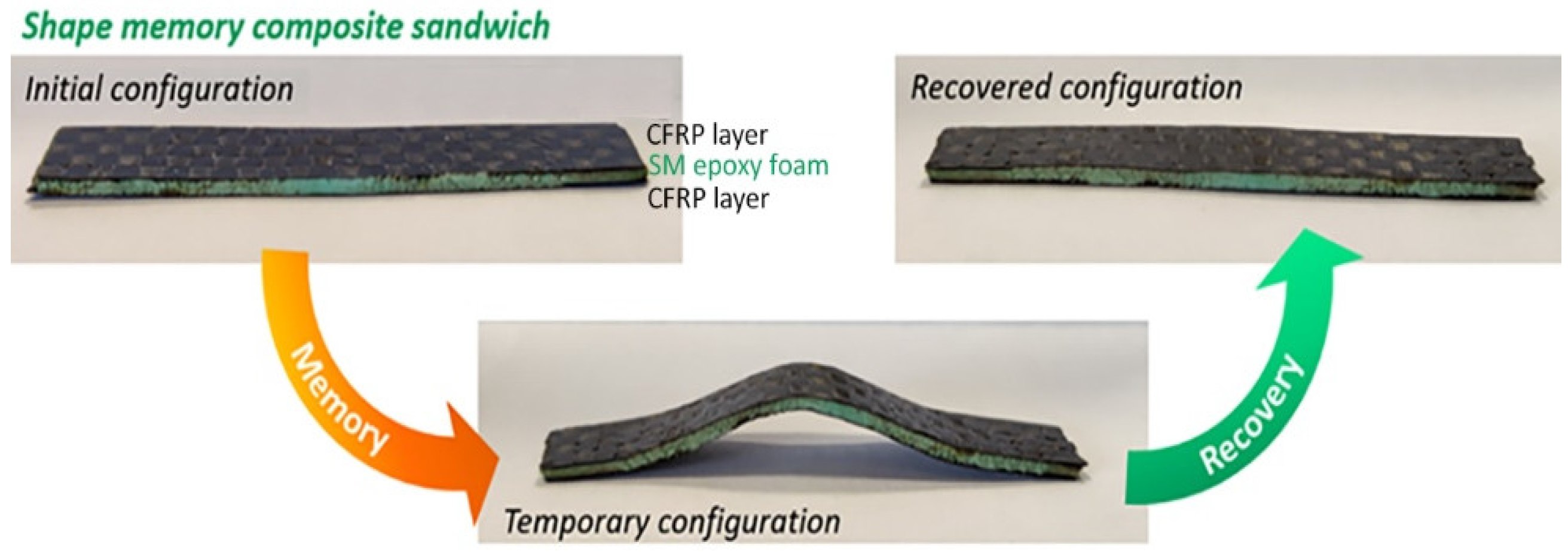

2.3. Shape Memory Polymer Composite (SMPC) Sandwich Structure

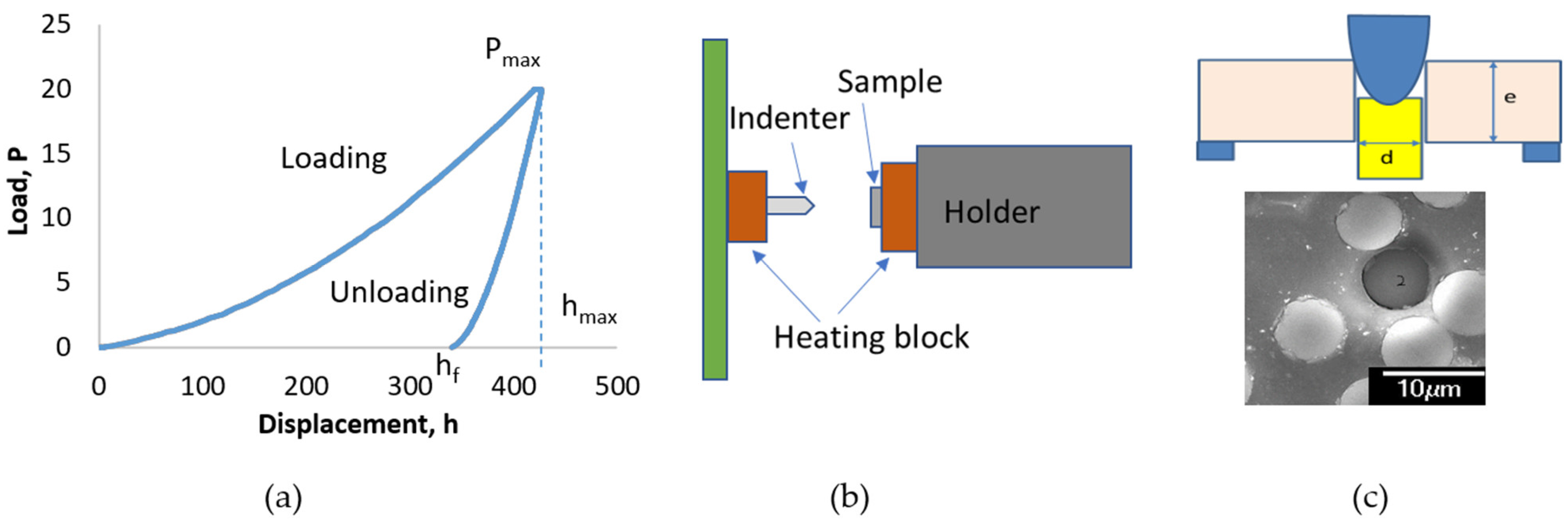

2.4. Nanoindentation and Push-Out Test

3. Results and Discussion

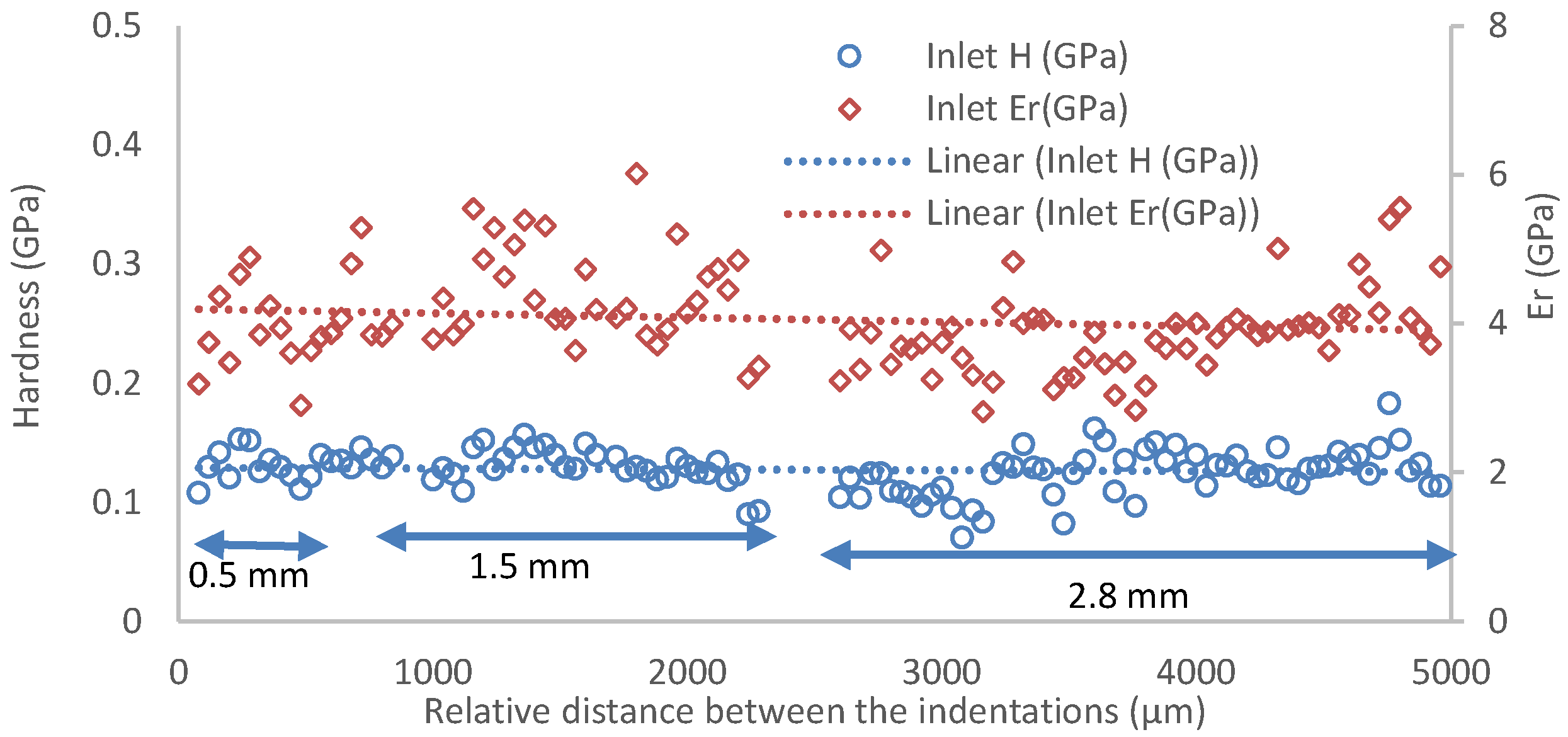

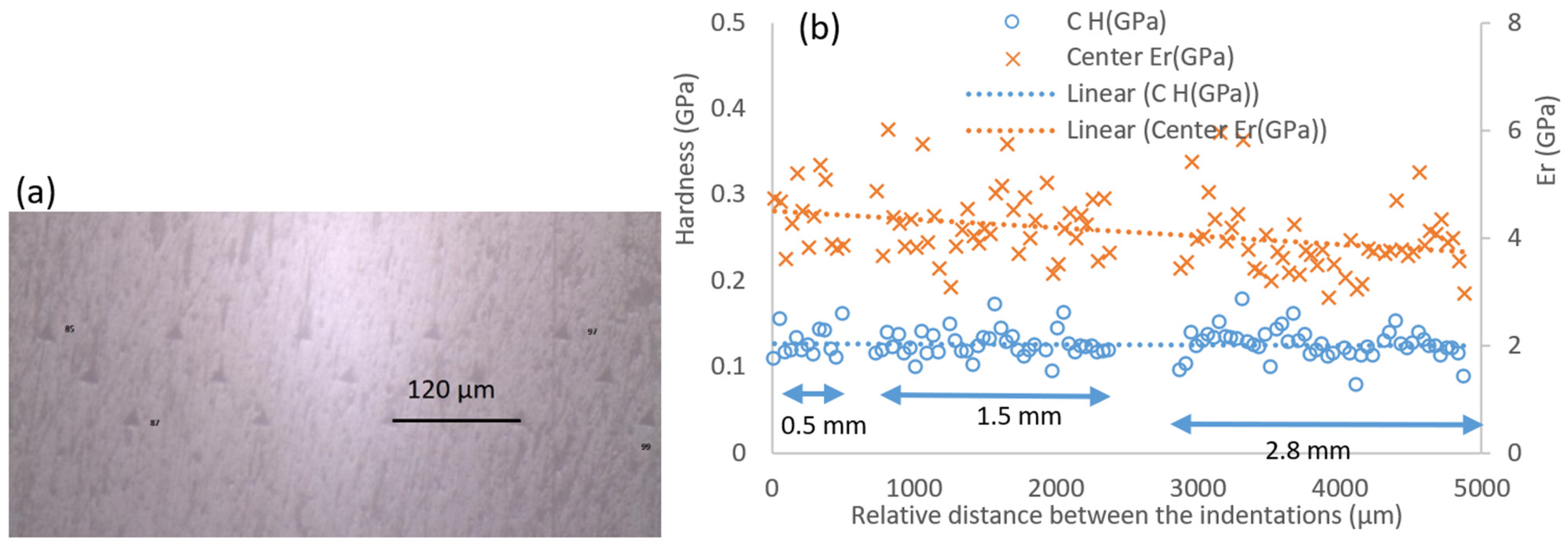

3.1. Nanomechanical Properties of the CNTs-PPV2 Nanocomposite

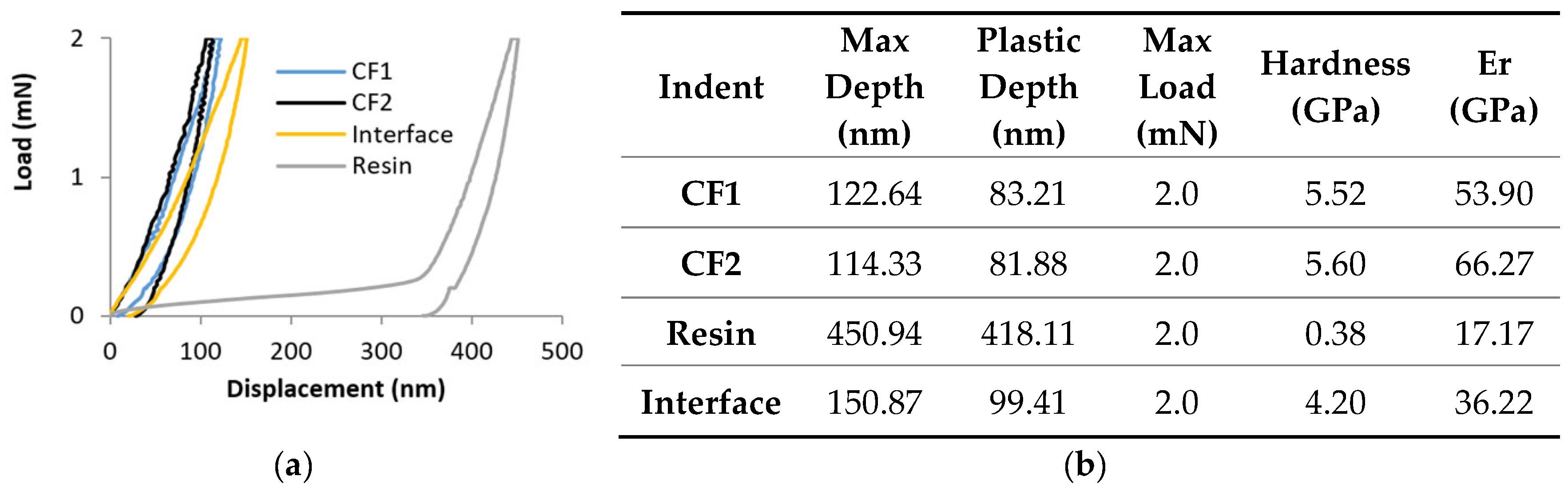

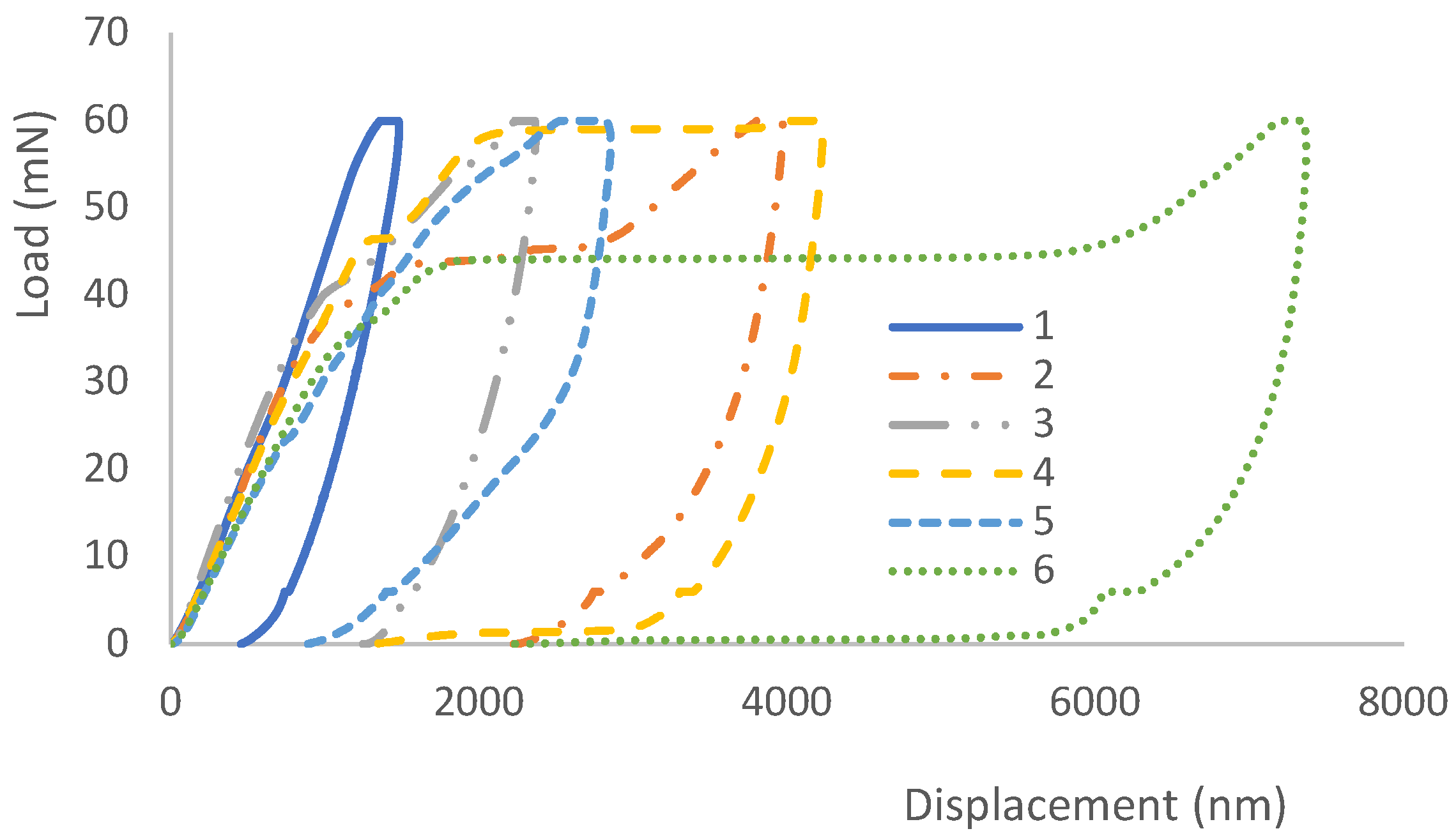

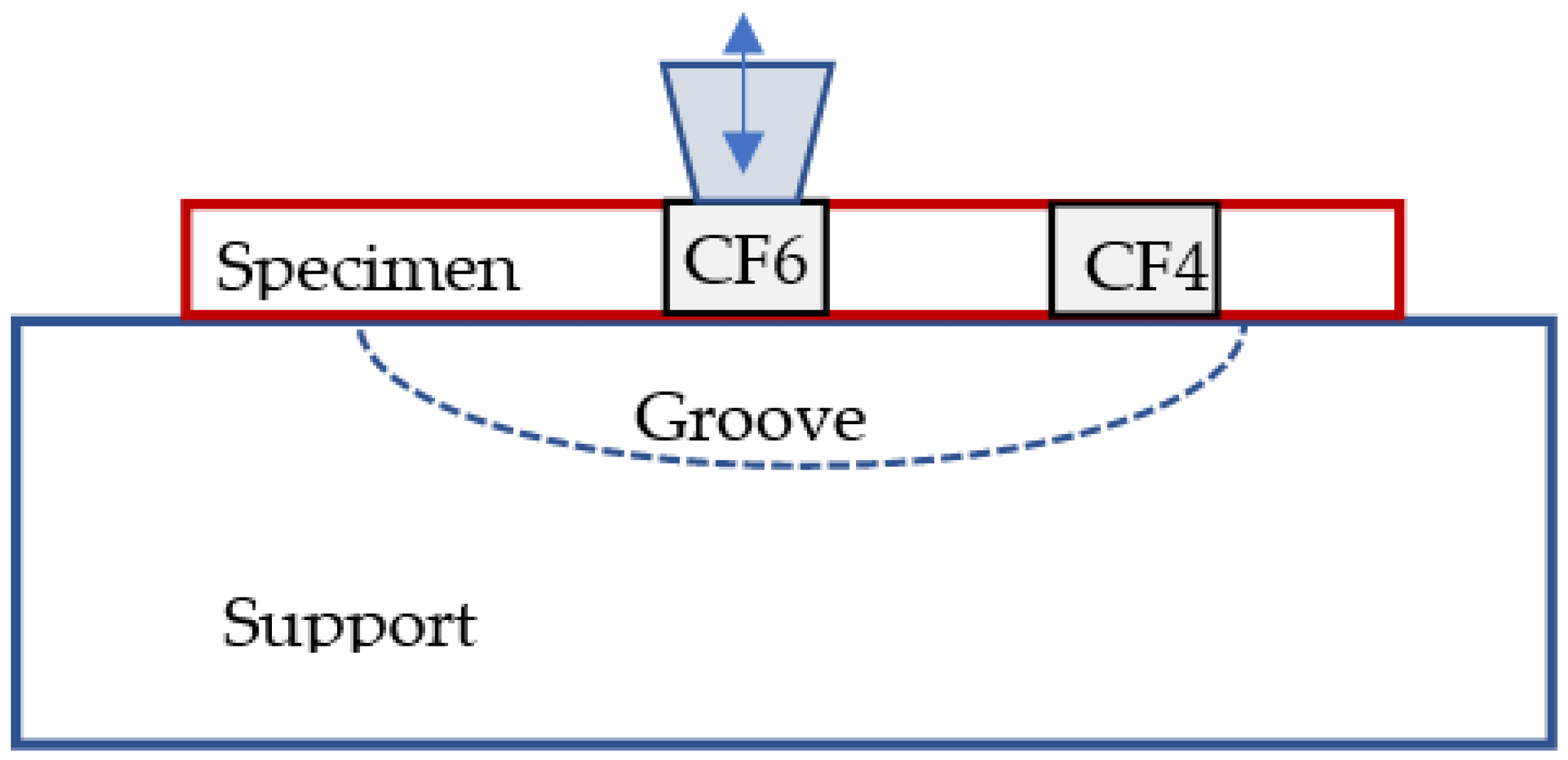

3.2. Evaluation of the Interfacial Properties of the CFRP Composite

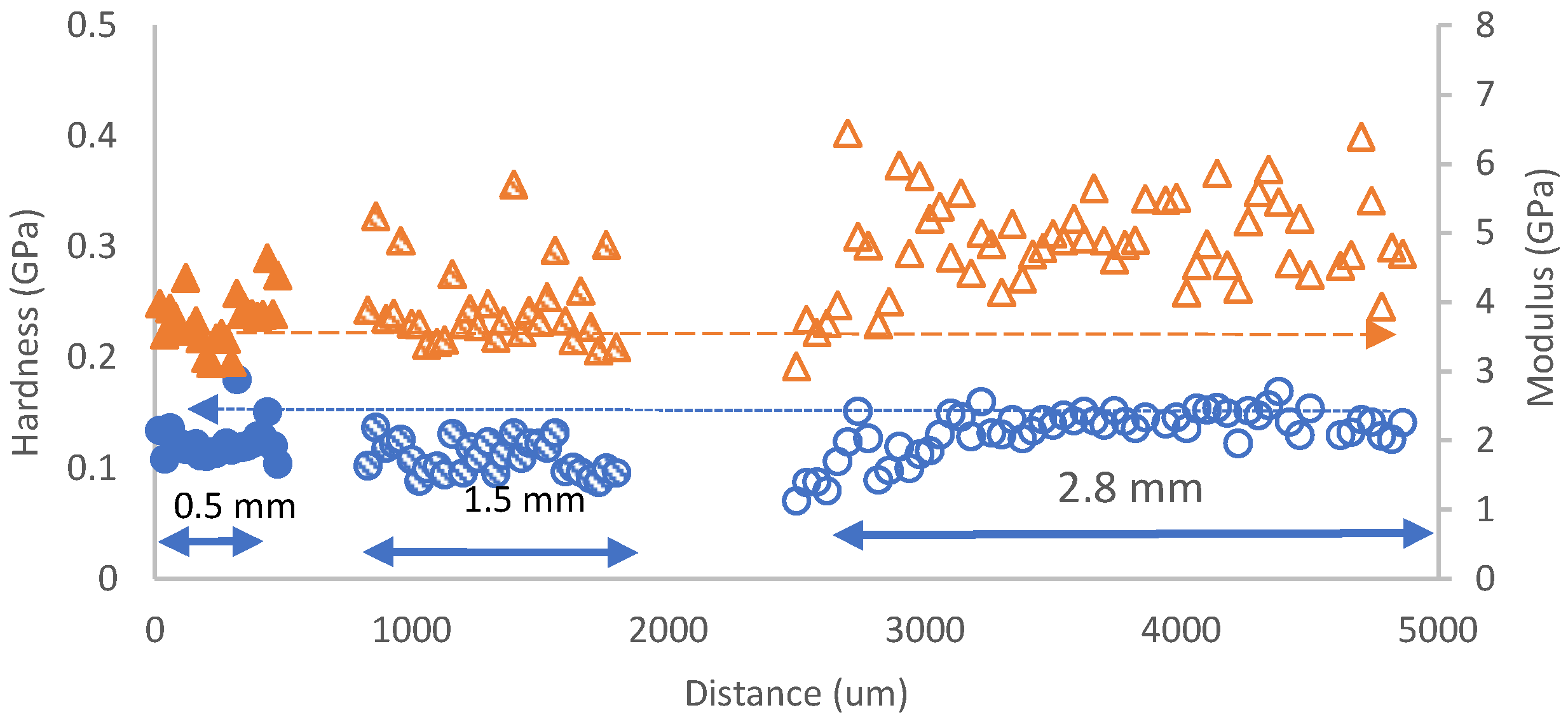

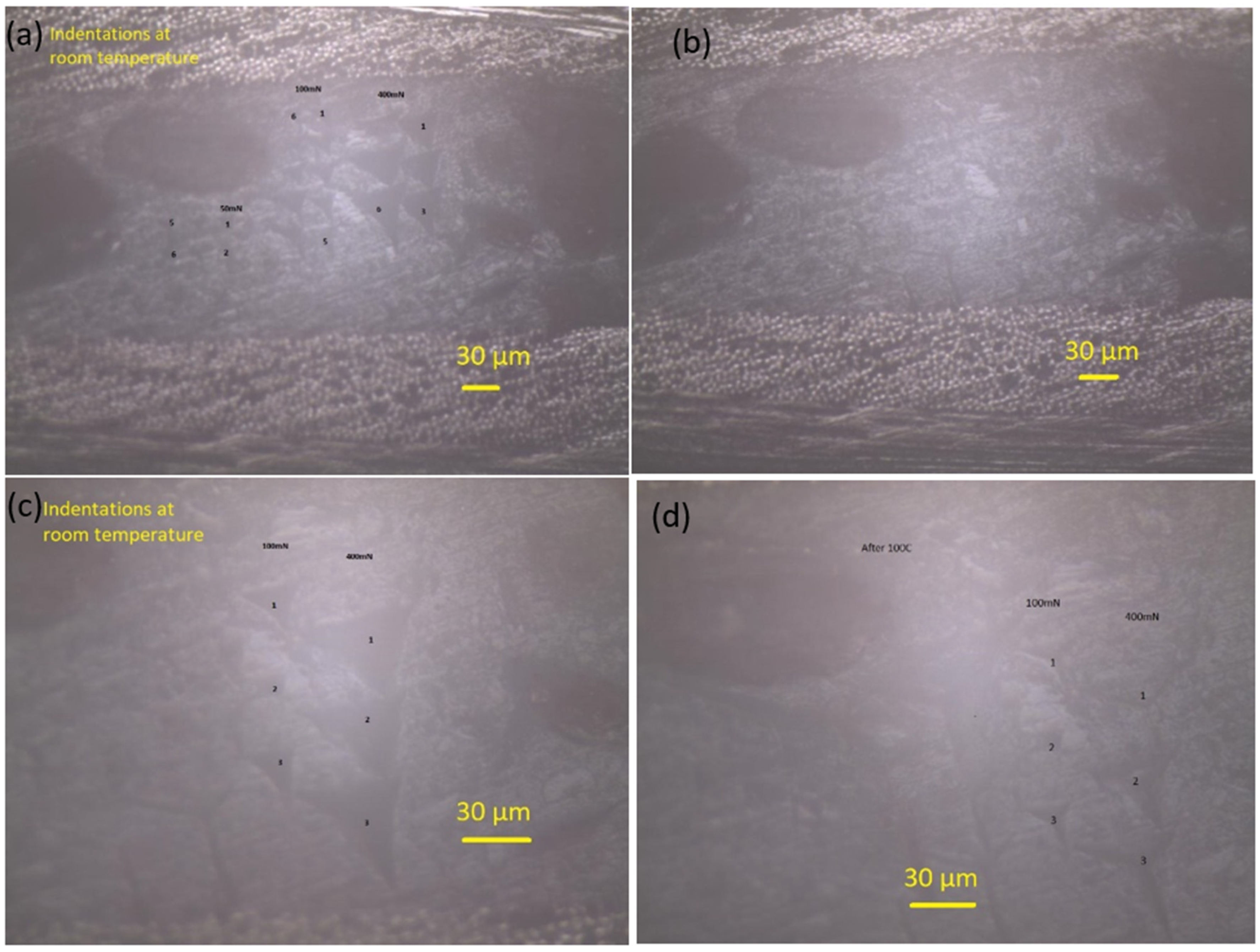

3.3. Response of Shape Memory Polymer

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, H.; Bilotti, E.; Peijs, T. The use of carbon nanotubes for damage sensing and structural health monitoring in laminated composites: A review. Nanocomposites 2015, 1, 167–184. [Google Scholar] [CrossRef] [Green Version]

- Esawi, A.M.K.; Farag, M.M. Carbon nanotube reinforced composites: Potential and current challenges. Mater. Des. 2007, 28, 2394–2401. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, X.; Jestin, S.; Termine, S.; Trompeta, A.F.; Araújo, A.; Santos, R.M.; Charitidis, C.; Dong, H. The Impact of Carbon Nanofibres on the Interfacial Properties of CFRPs Produced with Sized Carbon Fibres. Polymers 2021, 13, 3457. [Google Scholar] [CrossRef]

- Liang, Y.; Li, X.; Semitekolos, D.; Charitidis, C.A.; Dong, H. Enhanced properties of PAN-derived carbon fibres and resulting composites by active screen plasma surface functionalisation. Plasma Process. Polym. 2020, 17, 1900252. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Liu, Y.; Leng, J. Mechanical properties of shape memory polymer composites enhanced by elastic fibers and their application in variable stiffness morphing skins. J. Intell. Mater. Syst. Struct. 2014, 26, 2020–2027. [Google Scholar] [CrossRef]

- Herath, M.; Epaarachchi, J. Chapter 21—Shape memory polymer composites and their smart structural applications. In Composite Materials: Manufacturing, Properties and Applications; Low, I.-M., Dong, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 581–610. [Google Scholar] [CrossRef]

- Constantinides, G.; Ravi Chandran, K.S.; Ulm, F.J.; Van Vliet, K.J. Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Eng. A 2006, 430, 189–202. [Google Scholar] [CrossRef]

- Gibson, R.F. A review of recent research on nanoindentation of polymer composites and their constituents. Compos. Sci. Technol. 2014, 105, 51–65. [Google Scholar] [CrossRef]

- Gregory, J.R.; Spearing, S.M. Nanoindentation of neat and in situ polymers in polymer–matrix composites. Compos. Sci. Technol. 2005, 65, 595–607. [Google Scholar] [CrossRef]

- Bedi, H.S.; Agnihotri, P.K. Designing the interphase in carbon fiber polymer composites using carbon nanotubes. Procedia Struct. Integr. 2019, 14, 168–175. [Google Scholar] [CrossRef]

- Enrique-Jimenez, P.; Quiles-Díaz, S.; Salavagione, H.J.; Fernández-Blázquez, J.P.; Monclús, M.A.; Guzman de Villoria, R.; Gómez-Fatou, M.A.; Ania, F.; Flores, A. Nanoindentation mapping of multiscale composites of graphene-reinforced polypropylene and carbon fibres. Compos. Sci. Technol. 2019, 169, 151–157. [Google Scholar] [CrossRef]

- Genna, S.; Trovalusci, F.; Tagliaferri, V. Indentation test to study the moisture absorption effect on CFRP composite. Compos. Part B Eng. 2017, 124, 1–8. [Google Scholar] [CrossRef]

- Medina, M.C.; Molina-Aldareguía, J.M.; González, C.; Melendrez, M.F.; Flores, P.; LLorca, J. Comparison of push-in and push-out tests for measuring interfacial shear strength in nano-reinforced composite materials. J. Compos. Mater. 2016, 50, 1651–1659. [Google Scholar] [CrossRef] [Green Version]

- Csanádi, T.; Németh, D.; Zhang, C.; Dusza, J. Nanoindentation derived elastic constants of carbon fibres and their nanostructural based predictions. Carbon 2017, 119, 314–325. [Google Scholar] [CrossRef] [Green Version]

- Koumoulos, E.P.; Jagdale, P.; Kartsonakis, I.A.; Giorcelli, M.; Tagliaferro, A.; Charitidis, C.A. Carbon nanotube/polymer nanocomposites: A study on mechanical integrity through nanoindentation. Polym. Compos. 2014, 36, 1432–1446. [Google Scholar] [CrossRef]

- Zhang, Z.; Gallo, S.C.; Li, X.; Dong, H.; Dragatogiannis, D.; Charitidis, C.A. Evaluation of the creep behaviour of the carbon fibre in an unidirectional pultruded reinforced composite using nano-indentation technique. Polym. Test. 2019, 80, 106091. [Google Scholar] [CrossRef]

- Wornyo, E.; Gall, K.; Yang, F.; King, W. Nanoindentation of shape memory polymer networks. Polymer 2007, 48, 3213–3225. [Google Scholar] [CrossRef]

- Tian, M.; Venkatesh, T.A. Indentation of shape memory polymers: Characterization of thermomechanical and shape recovery properties. Polymer 2013, 54, 1405–1414. [Google Scholar] [CrossRef]

- Jin, C.; Ebenstein, D.M. Nanoindentation of compliant materials using Berkovich tips and flat tips. J. Mater. Res. 2017, 32, 435–450. [Google Scholar] [CrossRef] [Green Version]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. A review of key developments and pertinent issues in nanoindentation testing of fibre reinforced plastic microstructures. Compos. Struct. 2017, 180, 782–798. [Google Scholar] [CrossRef]

- Zhandarov, S.; Mäder, E. Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. Compos. Sci. Technol. 2005, 65, 149–160. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of interfacial properties between fibre and polymer matrix in composite materials—A critical review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Corujeira Gallo, S.; Li, X.; Zhang, Z.; Charitidis, C.; Dong, H. Viscoelastic response of carbon fibre reinforced polymer during push-out tests. Compos. Part A Appl. Sci. Manuf. 2018, 112, 178–185. [Google Scholar] [CrossRef]

- Yang, F.; Wornyo, E.; Gall, K.; King, W.P. Nanoscale indent formation in shape memory polymers using a heated probe tip. Nanotechnology 2007, 18, 285302. [Google Scholar] [CrossRef]

- Squeo, E.A.; Quadrini, F. Shape memory epoxy foams by solid-state foaming. Smart Mater. Struct. 2010, 19, 105002. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, X.; Dong, H.; Jestin, S.; Termine, S.; Trompeta, A.-F.; Araújo, A.; Santos, R.M.; Charitidis, C. Investigation on the interfacial properties of CNTs sized carbon fibres in epoxy resin using push-out method via nano-indentation technique. MATEC Web Conf. 2021, 349, 01007. [Google Scholar] [CrossRef]

| Composite Materials | Properties Characterization | Methods or Indentation | References |

|---|---|---|---|

| Homogeneous or heterogeneous composite, i.e., polymer nanotube composite | Evaluate nanomechanical properties including elastic modulus and nanohardness | Grid indentation or modulus mapping | [4,8,9] |

| Chemical modification of graphene-reinforced composite | Impact of the modified graphene on the resistance of the laminate under shear stress conditions | Push-in tests | [12] |

| An autoclave-cured CF-reinforced polymer plates | Effect of moisture absorption on the reduction of its stiffness due to the ageing in water | A flat-top cylinder indenter | [13]. |

| Glass fibre epoxy composites | Influence of the CNT content on the glass fibre/matrix interfacial shear strength | Push-in and push-out test by a diamond flat conical tip | [14] |

| CNFs sized CFs-modified composite | Effect of sizing with CNFs on the interfacial properties of CFs and resin | Cone-shaped indenter push-out | [3] |

| CFs-reinforced SiC composite | Properties of the transversal and longitudinal cross-sections of individual CFs | Berkovich indenter indentation | [15] |

| CNTs-reinforced polymer composites | Nanomechanical (hardness/elastic modulus) and nanotribological (coefficient of friction) properties | Berkovich indenter | [16] |

| Unidirectional CFs-reinforced composite | Creep behaviour of the carbon fibre in the composite using POT technique | Berkovich and cone-shaped diamond indenters | [17] |

| Shape memory polymer | Deformation of the polymer networks at ambient and elevated temperatures, and modelling the shape memory response | Indentation load–depth response using Berkovich indenter | [18,19] |

| Property | Unit | Value | STD Reference |

|---|---|---|---|

| Density | g/cm3 | 0.93 | ASTM D 1505 |

| Melt Index @ 230 °C 2.16/kg | g/10′ | 29 ± 2 | ASTM D 1238 |

| Flexural modulus | MPa | 1800 | ASTM D 790 |

| HDT @ 0.455 MPa | °C | 111 | ASTM D 648 |

| VICAT @ 10 N | °C | 152 | ASTM D 1525 |

| Flame Resistance | Class | V-2 starting from 1.4 mm | UL-94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Bellisario, D.; Quadrini, F.; Jestin, S.; Ravanelli, F.; Castello, M.; Li, X.; Dong, H. Nanoindentation of Multifunctional Smart Composites. Polymers 2022, 14, 2945. https://doi.org/10.3390/polym14142945

Zhang Z, Bellisario D, Quadrini F, Jestin S, Ravanelli F, Castello M, Li X, Dong H. Nanoindentation of Multifunctional Smart Composites. Polymers. 2022; 14(14):2945. https://doi.org/10.3390/polym14142945

Chicago/Turabian StyleZhang, Zhenxue, Denise Bellisario, Fabrizio Quadrini, Simon Jestin, Francesca Ravanelli, Mauro Castello, Xiaoying Li, and Hanshan Dong. 2022. "Nanoindentation of Multifunctional Smart Composites" Polymers 14, no. 14: 2945. https://doi.org/10.3390/polym14142945

APA StyleZhang, Z., Bellisario, D., Quadrini, F., Jestin, S., Ravanelli, F., Castello, M., Li, X., & Dong, H. (2022). Nanoindentation of Multifunctional Smart Composites. Polymers, 14(14), 2945. https://doi.org/10.3390/polym14142945