Study and Optimal Design of a Direct-Driven Stator Coreless Axial Flux Permanent Magnet Synchronous Generator with Improved Dynamic Performance

Abstract

:1. Introduction

2. AFPMSG and Dynamic Analytical Model

2.1. AFPMSG

2.2. Dynamic Analytical Model

2.2.1. Dynamic Model of AFPMSG

2.2.2. AFPMSG Swing Equation

2.2.3. Dynamic Analytical Model of AFPMSG

3. Dynamic Performance and Key Factor Analysis

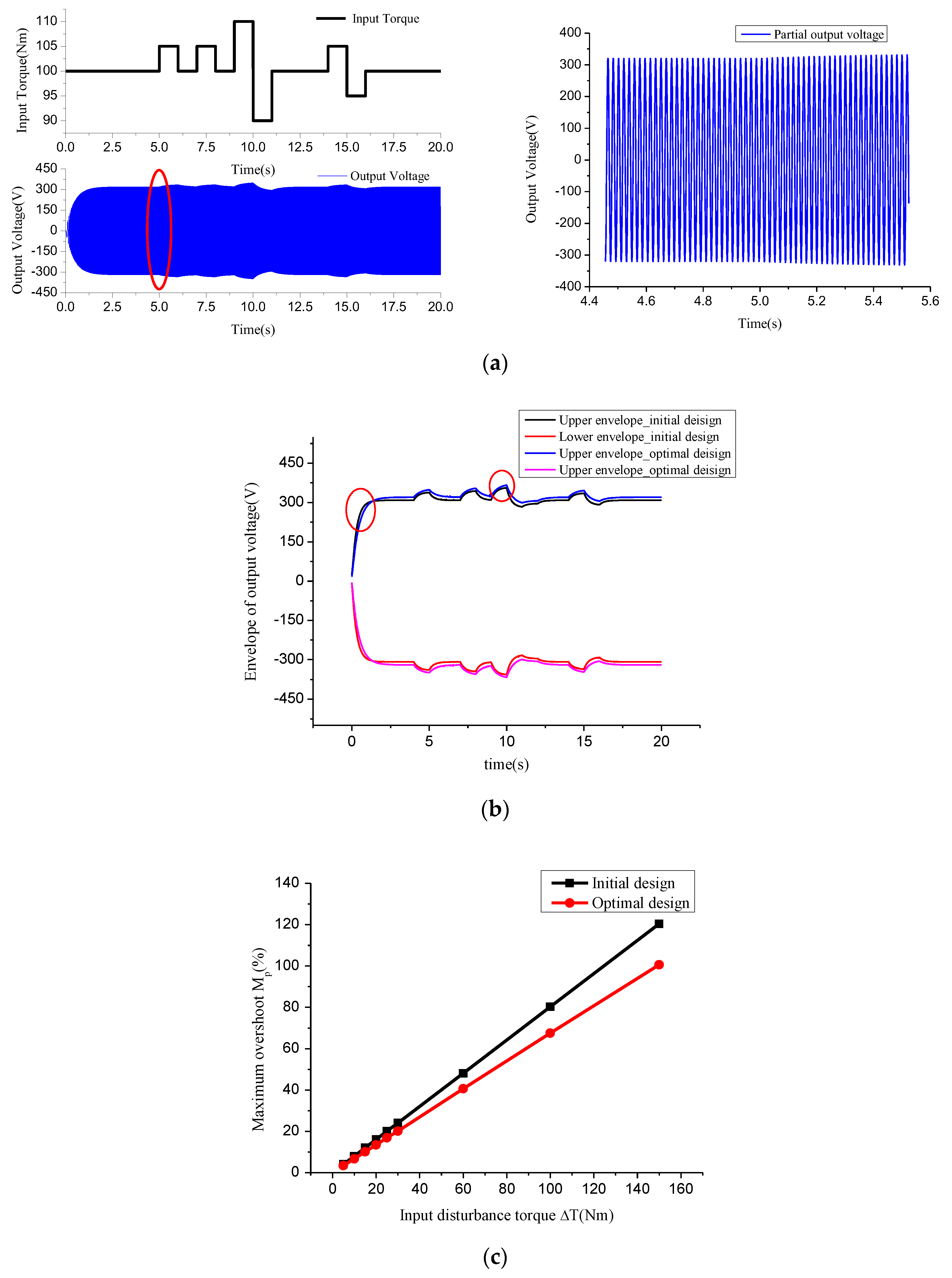

3.1. Dynamic Performance Analysis

3.2. Key Parameter Analysis

3.2.1. Ratio of Main Dimensions

3.2.2. Thickness of the Permanent Magnet

3.2.3. Thickness of Rotor Yoke

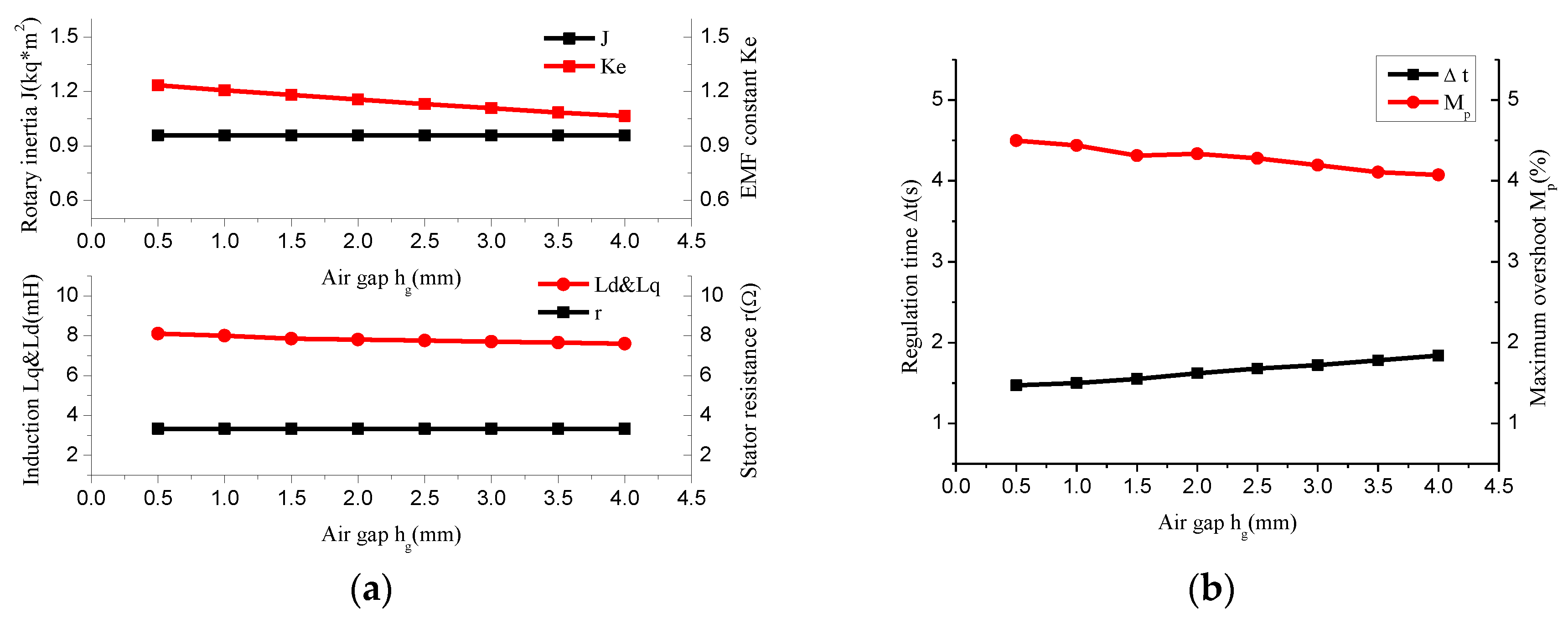

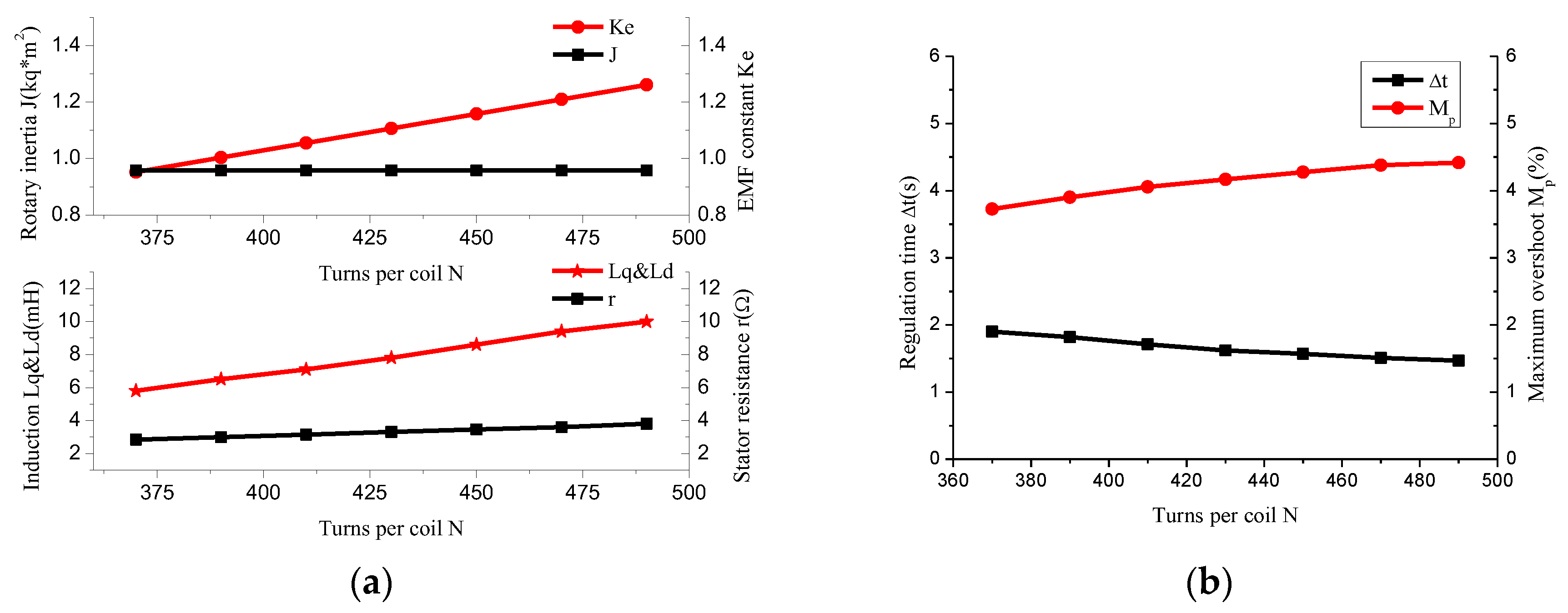

3.2.4. Length of the Air Gap

3.2.5. Turns of Coil

4. Integrated Optimization Design

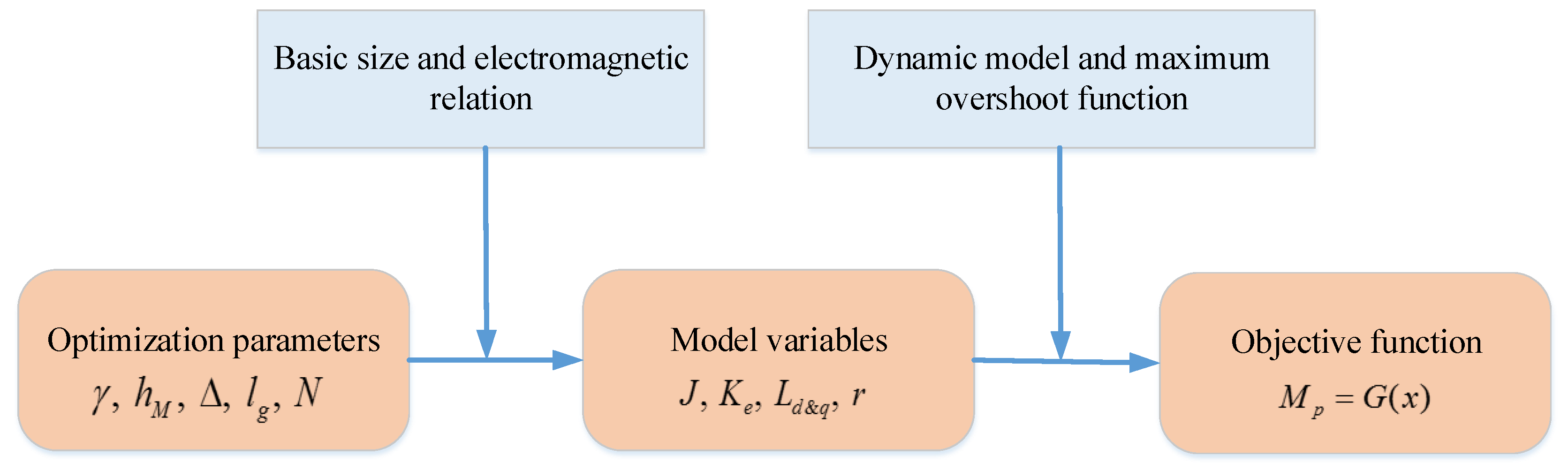

4.1. Optimization Model

4.2. Optimization Design

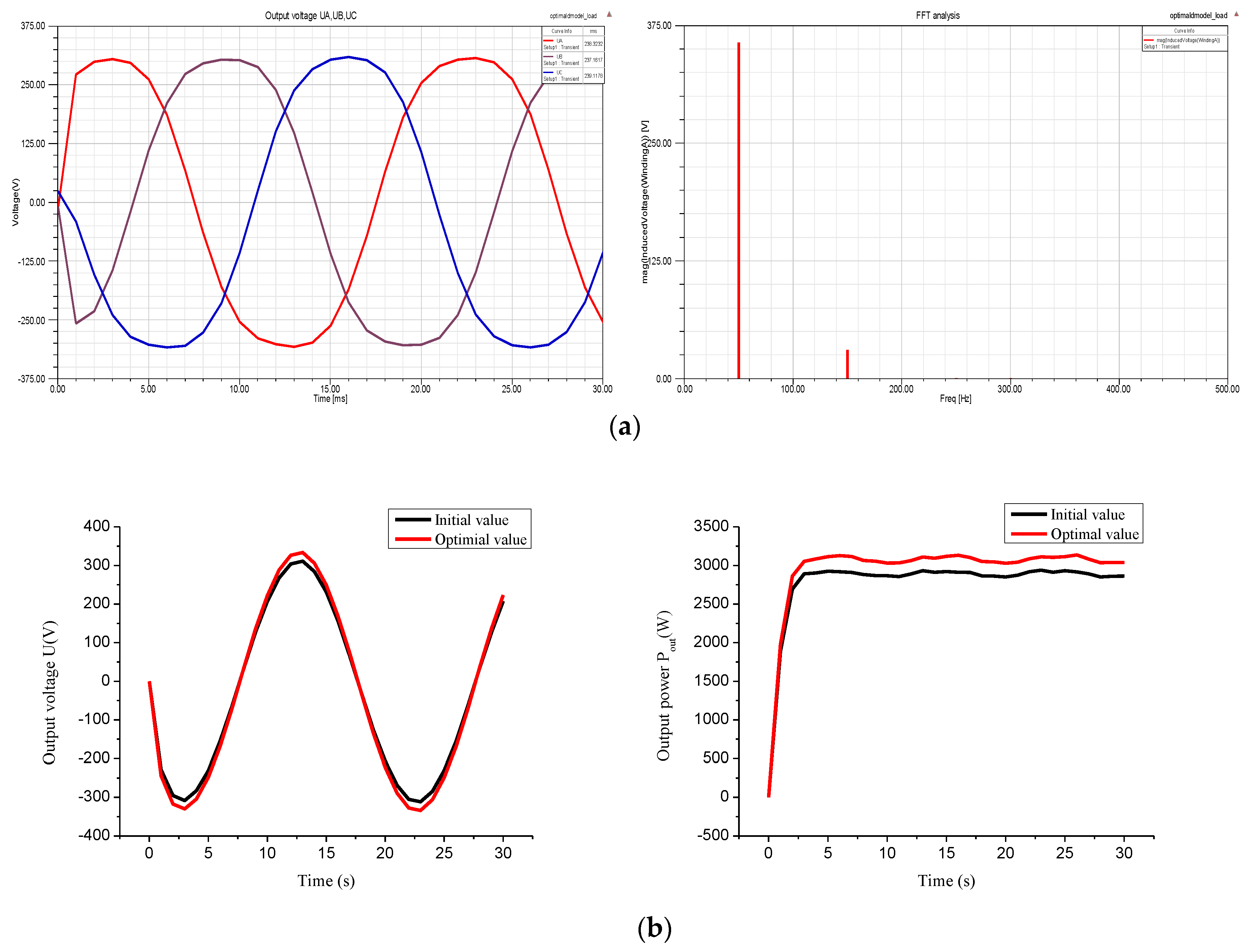

5. 3D Finite Element Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lampola, P. Directly Driven, Low-Speed Permanent-Magnet Generators for Wind Power Applications; Helsinki University of Technology: Espoo, Finland, 2000. [Google Scholar]

- Chan, T.F.; Lai, L.L. An Axial-Flux Permanent-Magnet synchronous generator for a Direct-Coupled Wind-Turbine system. IEEE Trans. Energy Convers. 2007, 22, 86–94. [Google Scholar] [CrossRef]

- Gieras, J.F.; Wing, M. Permanent Magnet Motor Technology: Design and Applications; Marcel Dekker: New York, NY, USA, 2009. [Google Scholar]

- Gieras, J.F.; Wang, R.J.; Kamper, M.J. Axial FLUX Permanent Magnet Brushless Machines; Springer: Dordrecht, The Netherlands, 2005. [Google Scholar]

- Capponi, F.G.; Donato, G.D.; Caricchi, F. Recent advances in Axial-Flux Permanent-Magnet machine technology. IEEE Trans. Ind. Appl. 2012, 48, 2190–2205. [Google Scholar] [CrossRef]

- Kamper, M.J.; Wang, R.J.; Rossouw, F.G. Analysis and performance evaluation of axial FLUX Air-Cored stator permanent magnet machine with concentrated coils. In Proceedings of the IEEE International Electric Machines & Drives Conference, Antalya, Turkey, 3–5 May 2007; pp. 13–20. [Google Scholar]

- Kamper, M.J.; Wang, R.J.; Rossouw, F.G. Analysis and performance of axial FLUX Permanent-Magnet machine with Air-Cored nonoverlapping concentrated stator windings. IEEE Trans. Ind. Appl. 2008, 44, 1495–1504. [Google Scholar] [CrossRef]

- Laxminarayan, S.S.; Singh, M.; Saifee, A.H.; Mittal, A. Design, modeling and simulation of variable speed Axial Flux Permanent Magnet Wind Generator. Sustain. Energy Technol. Assess. 2017, 19, 114–124. [Google Scholar] [CrossRef]

- Wang, R.J.; Kamper, M.J.; Westhuizen, K.D.; Gieras, J.F. Optimal design of a coreless stator axial flux permanent-magnet generator. IEEE Trans. Magn. 2005, 41, 55–64. [Google Scholar] [CrossRef]

- Cavagnino, A.; Lazzari, M.; Profumo, F.; Tenconi, A. A comparison between the axial flux and the radial flux structures for PM synchronous motors. IEEE Trans. Ind. Appl. 2002, 38, 1517–1524. [Google Scholar] [CrossRef]

- Park, Y.S.; Koo, M.M.; Jang, S.M.; Choi, J.-Y.; You, D.-J. Performance evaluation of Radial- and Axial-Flux PM wind power generators with mechanical energy storage system. IEEE Trans. Energy Convers. 2015, 30, 237–245. [Google Scholar] [CrossRef]

- Sitapati, K.; Krishnan, R. Performance comparisons of radial and axial field, permanent-magnet, brushless machines. IEEE Trans. Industry Appl. 2001, 37, 1219–1226. [Google Scholar] [CrossRef]

- Pop, A.A.; Jurca, F.; Oprea, C.; Chirca, M.; Breban, S.; Radulescu, M.M. Axial-flux vs. radial-flux permanent-magnet synchronous generators for micro-wind turbine application. In Proceedings of the European Conference on Power Electronics and Applications, Lille, France, 2–6 September 2013; pp. 1–10. [Google Scholar]

- Daghigh, A.; Javadi, H.; Torkaman, H. Design optimization of Direct-Coupled ironless axial FLUX permanent magnet synchronous wind generator with low cost and high annual energy yield. IEEE Trans. Magn. 2016, 52, 1–11. [Google Scholar] [CrossRef]

- Zhang, X.W.; Wang, X.Y.; Du, J.; Tang, R. Amelioration of coreless Permanent-Magnet disk synchronous motor based on fem: Motor with wedge airgap. J. Iron Steel Res. Int. 2006, 13, 427–432. [Google Scholar] [CrossRef]

- Barba, P.D.; Savini, A.; Wiak, S. Field Models in Electricity and Magnetism; Springer: Dordrecht, The Netherlands, 2008. [Google Scholar]

- Barba, P.D. Multiobjective Shape Design in Electricity and Magnetism; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Hawe, G.I.; Sykulski, J.K. A scalarizing One-Stage algorithm for efficient Multi-Objective optimization. IEEE Trans. Magn. 2008, 44, 1094–1097. [Google Scholar] [CrossRef]

- Lok, C.L.; Vengadaesvaran, B.; Ramesh, S. Implementation of hybrid pattern search–genetic algorithm into optimizing axial-flux permanent magnet coreless generator (AFPMG). Electr. Eng. 2016, 1–11. [Google Scholar] [CrossRef]

- Ahn, Y.; Park, J.; Lee, C.G.; Jeong, Y.-S.; Kim, Y.-J.; Jung, S.-Y. Optimal design of direct-driven PM wind generator using memetic algorithm coupled with FEM. In Proceedings of the International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2010; pp. 1–6. [Google Scholar]

- Jin, H.L.; Song, J.Y.; Kim, D.W.; Kim, J.-W.; Kim, T.-J.; Jung, S.-Y. Particle swarm optimization algorithm with intelligent particle number control for optimal design of electric machines. IEEE Trans. Ind. Electron. 2017, 65, 1791–1798. [Google Scholar]

- Meng, D.W.; Zhou, M.L. The application of Simulated Annealing Algorithm to electric machine design. Electr. Mach. Control 2001, 5, 154–158. [Google Scholar]

- Rostami, N.; Feyzi, M.R.; Pyrhonen, J.; Parviainen, A.; Behjat, V. Genetic algorithm approach for improved design of a variable speed Axial-Flux Permanent-Magnet synchronous generator. IEEE Trans. Magn. 2012, 48, 4860–4865. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Kahourzade, S.; Rahim, N.A.; Hew, W.P. Design, analysis, and prototyping of an Axial-Flux permanent magnet motor based on genetic algorithm and Finite-Element analysis. IEEE Trans. Magn. 2013, 49, 1479–1492. [Google Scholar] [CrossRef]

- Benlamine, R.; Dubas, F.; Randi, S.A.; Lhotellier, D.; Espanet, C. Design by optimization of an axial-flux permanent-magnet synchronous motor using genetic algorithms. In Proceedings of the International Conference on Electrical Machines and Systems, Busan, Korea, 26–29 October 2013; pp. 13–17. [Google Scholar]

- Taran, N.; Ardebili, M. A novel approach for efficiency and power density optimization of an Axial Flux Permanent Magnet generator through genetic algorithm and finite element analysis. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics, Istanbul, Turkey, 1–4 June 2014; pp. 709–714. [Google Scholar]

- Virtič, P.; Vražić, M.; Papa, G. Design of an axial FLUX permanent magnet synchronous machine using analytical method and evolutionary optimization. IEEE Trans. Energy. 2016, 31, 150–158. [Google Scholar] [CrossRef]

- Gary, S. Two-reaction theory of synchronous machines. Electr. Eng. 2013, 56, 905–906. [Google Scholar] [CrossRef]

- Behjat, V.; Hamrahi, M. Dynamic modeling and performance evaluation of axial flux PMSG based wind turbine system with MPPT control. AIN Shams Eng. J. 2014, 5, 1157–1166. [Google Scholar] [CrossRef]

- Bang, D.; Polinder, H.; Shrestha, G.; Ferreira, J.A. Review of generator system for direct- drive wind turbines. In Proceedings of the European Wind Energy Conference & Exhibition, Brussels, Belgium, 31 March–3 April 2008; pp. 1–11. [Google Scholar]

- Patil, K.; Mehta, B. Modeling and control of variable speed wind turbine with permanent magnet synchronous generator. In Proceedings of the International Conference on Advances in Green Energy, Thiruvananthapuram, India, 17–18 December 2015; pp. 258–264. [Google Scholar]

- Yin, M.; Li, G.; Zhou, M.; Zhao, C. Modeling of the Wind Turbine with a Permanent Magnet Synchronous Generator for Integration. In Proceedings of the Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007; pp. 1–6. [Google Scholar]

- Demello, F.P.; Hannett, L.N. Determination of synchronous machine stability study constants. Final Rep. Power Technol. 1980, 110, 268–280. [Google Scholar]

- Cao, X.; Kurita, A.; Mitsuma, H.; Tada, Y.; Okamoto, H. Improvements of numerical stability of electromagnetic transient simulation by use of phase-domain synchronous machine models. Electr. Eng. Jpn. 2015, 128, 53–62. [Google Scholar] [CrossRef]

- D’arco, S.; Suul, J.A.; Fosso, O.B. Control system tuning and stability analysis of Virtual Synchronous Machines. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 2664–2671. [Google Scholar]

- Gao, J.; Wang, X.; Zhang, L. Oscillation, Stability and Excitation Regulation of Synchronous Machine Systems. In AC Machine Systems; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Chapman, S.J. Electric Machinery Fundamentals; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Nezhadhosein, S.; Heydari, A.; Ghanbari, R. A modified hybrid genetic algorithm for solving nonlinear optimal control problems. Math. Probl. Eng. 2015, 2015, 1–21. [Google Scholar] [CrossRef]

- Mitchell, M. An Introduction to Genetic Algorithms; MIT Press: Cambridge, MA, USA, 1996. [Google Scholar]

- You, Y.M.; Hwang, K.Y.; Kwon, B.I. Optimal design of distributed winding axial flux permanent magnet synchronous generator for wind turbine systems. In Proceedings of the Digests of the 2010 14th Biennial IEEE Conference on Electromagnetic Field Computation, Chicago, IL, USA, 9–12 May 2010. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Rated output power | 3 kW | Outer diameter | 0.418 m |

| Rated RMS voltage at rated 300 rpm: | 220 V | Out-in diameter ratio: | 1.8 |

| Number of phase: | 3 | Magnet thickness: | 15 mm |

| Frequency: | 50 Hz | Winding turns per phase: | 434 |

| Number of pole pairs: | 10 | Air gap length: | 1 mm |

| Pole-arc coefficient: | 0.8 | Rotor yoke thickness: | 10 mm |

| Design Variable | Initial Value | Optimal Value |

|---|---|---|

| Outer diameter: | 418 mm | 420 mm |

| Out-in diameter ratio: | 1.8 | 1.75 |

| Magnet thickness: | 15 mm | 13 mm |

| Winding turns per phase: | 434 | 420 |

| Air gap length: | 1 mm | 0.6 mm |

| Rotor yoke thickness: | 10 mm | 15 mm |

| Axial length: | 62.1 mm | 67.5 mm |

| Parameters | Initial Value | Optimal Value | |

|---|---|---|---|

| Output performance | Rated output power: | 2893 W | 3078 W |

| Rated RMS voltage at rated 300 rpm: | 220 V | 237 V | |

| Total loss: | 325.8 W | 298.6 W | |

| Maximum efficiency: | 0.9 | 0.912 | |

| PM material volume: | 0.0024 m3 | 0.002 m3 | |

| Dynamic performance | Regulating time: | 1.5 s | 1.9 s |

| Maximum voltage overshoot: | 4.45% | 3.37% | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Wang, W.; Mi, H.; Mao, L.; Zhang, G.; Liu, H.; Wen, Y. Study and Optimal Design of a Direct-Driven Stator Coreless Axial Flux Permanent Magnet Synchronous Generator with Improved Dynamic Performance. Energies 2018, 11, 3162. https://doi.org/10.3390/en11113162

Wang W, Wang W, Mi H, Mao L, Zhang G, Liu H, Wen Y. Study and Optimal Design of a Direct-Driven Stator Coreless Axial Flux Permanent Magnet Synchronous Generator with Improved Dynamic Performance. Energies. 2018; 11(11):3162. https://doi.org/10.3390/en11113162

Chicago/Turabian StyleWang, Wenqiang, Weijun Wang, Hongju Mi, Longbo Mao, Guoping Zhang, Hua Liu, and Yadong Wen. 2018. "Study and Optimal Design of a Direct-Driven Stator Coreless Axial Flux Permanent Magnet Synchronous Generator with Improved Dynamic Performance" Energies 11, no. 11: 3162. https://doi.org/10.3390/en11113162