Heating Performance Enhancement of High Capacity PTC Heater with Modified Louver Fin for Electric Vehicles

Abstract

:1. Introduction

2. Experimental and Numerical Procedures

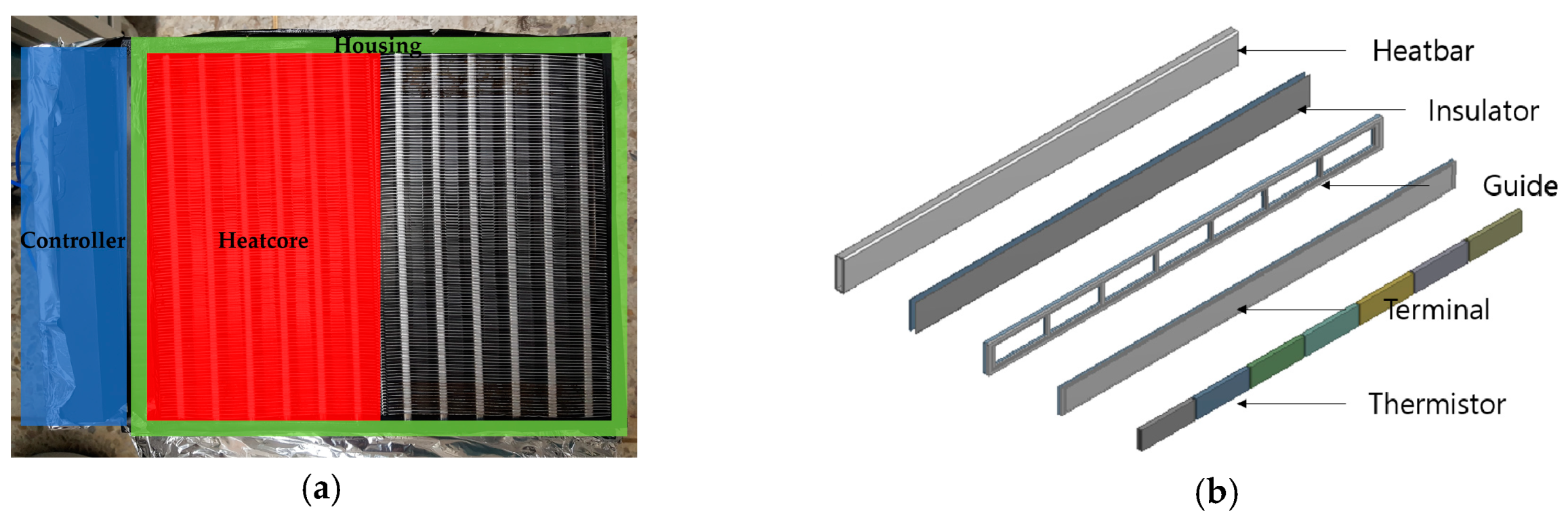

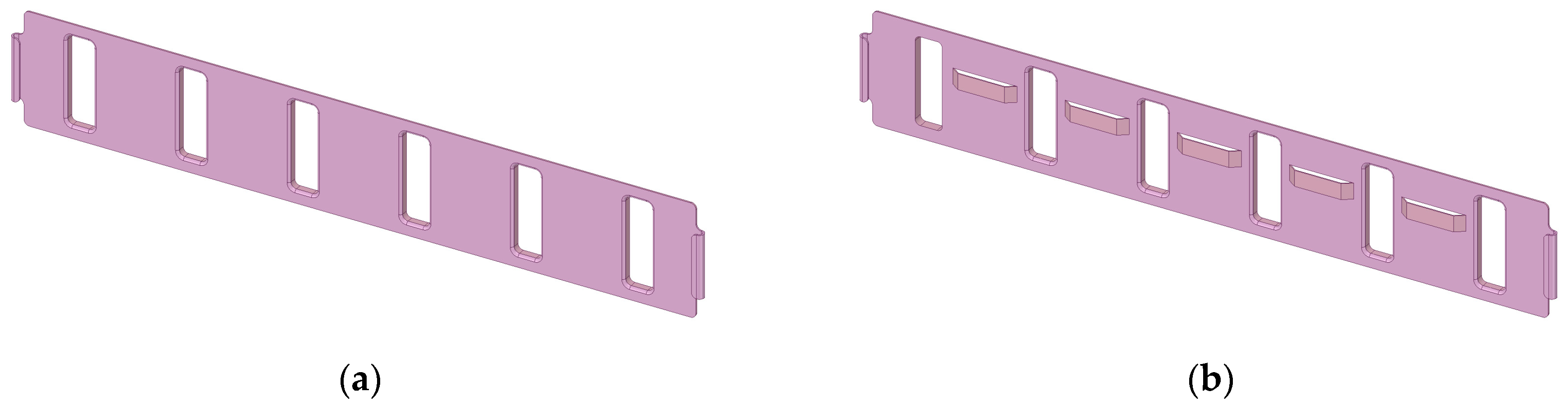

2.1. Heater Design

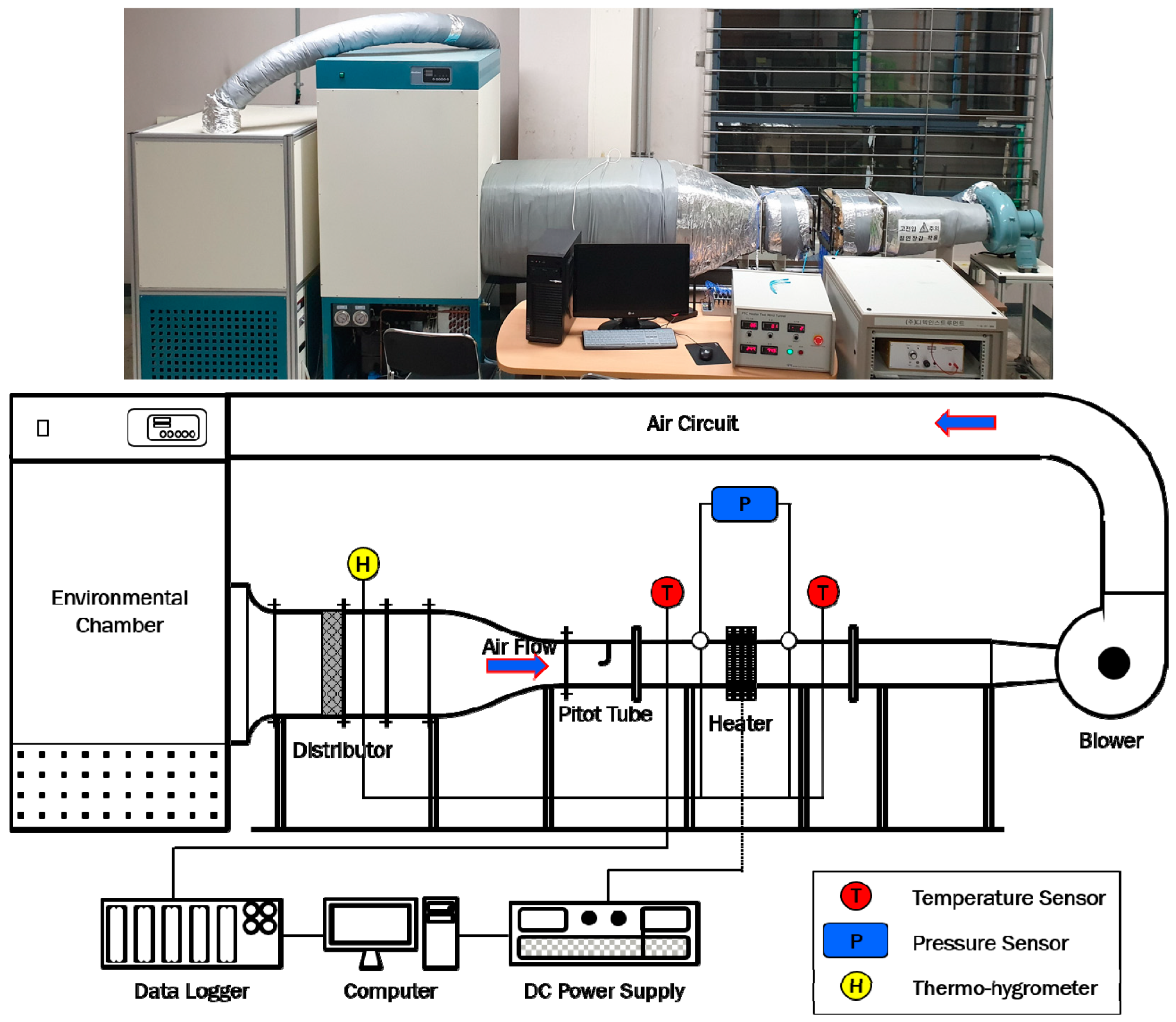

2.2. Experiment Setup and Method

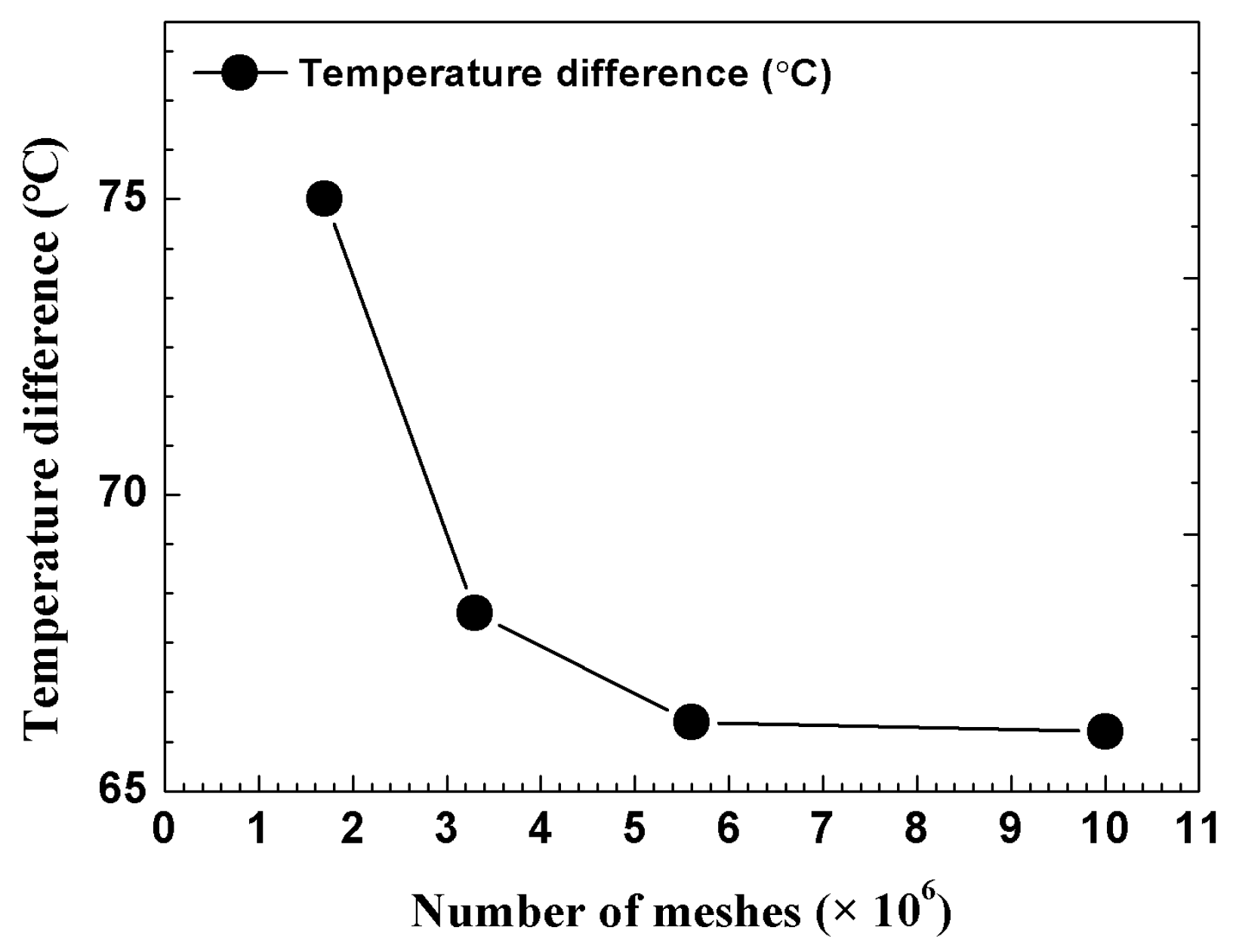

2.3. Physical Modeling

2.4. Mathematical Background and Boundary Condition

3. Results and Discussion

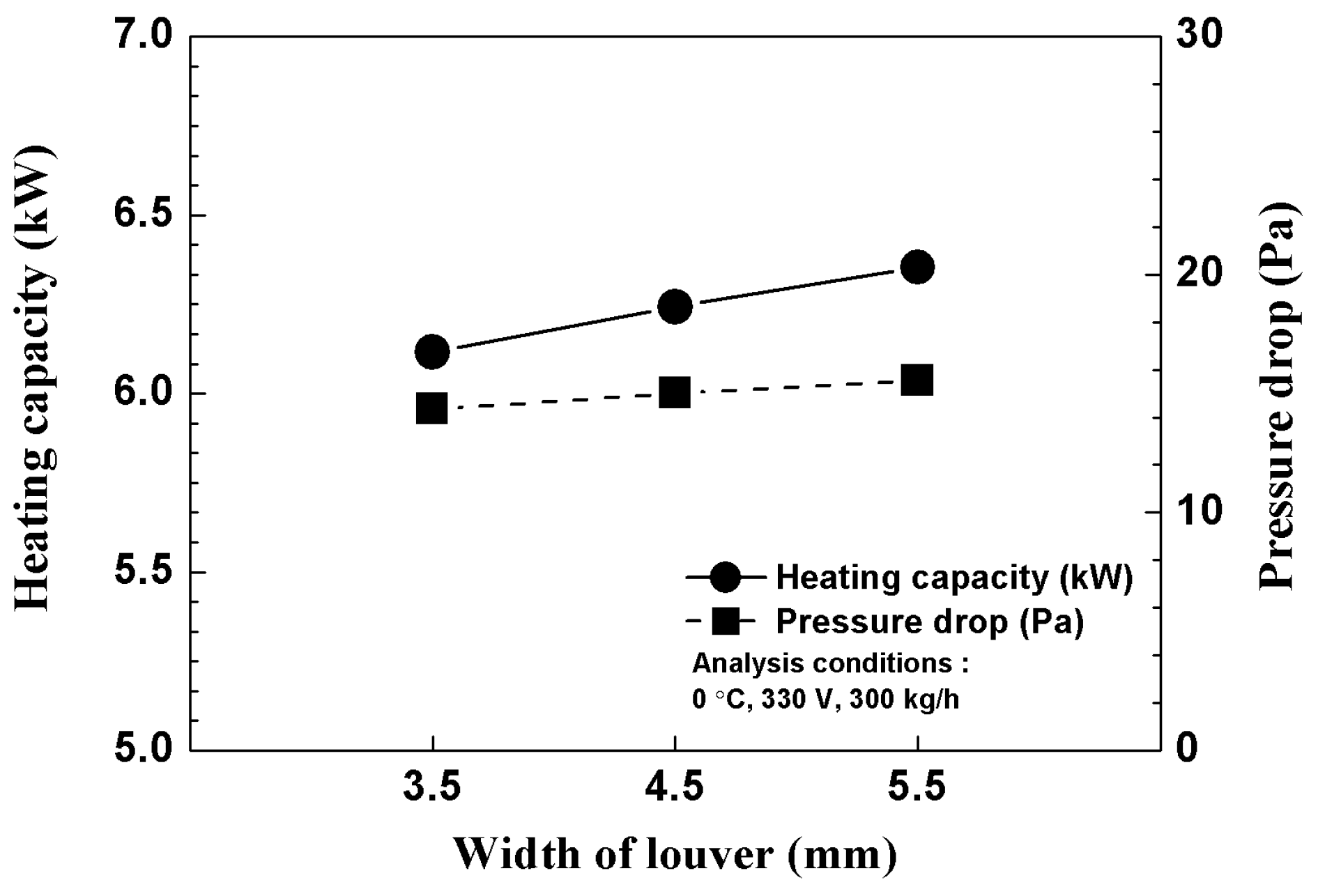

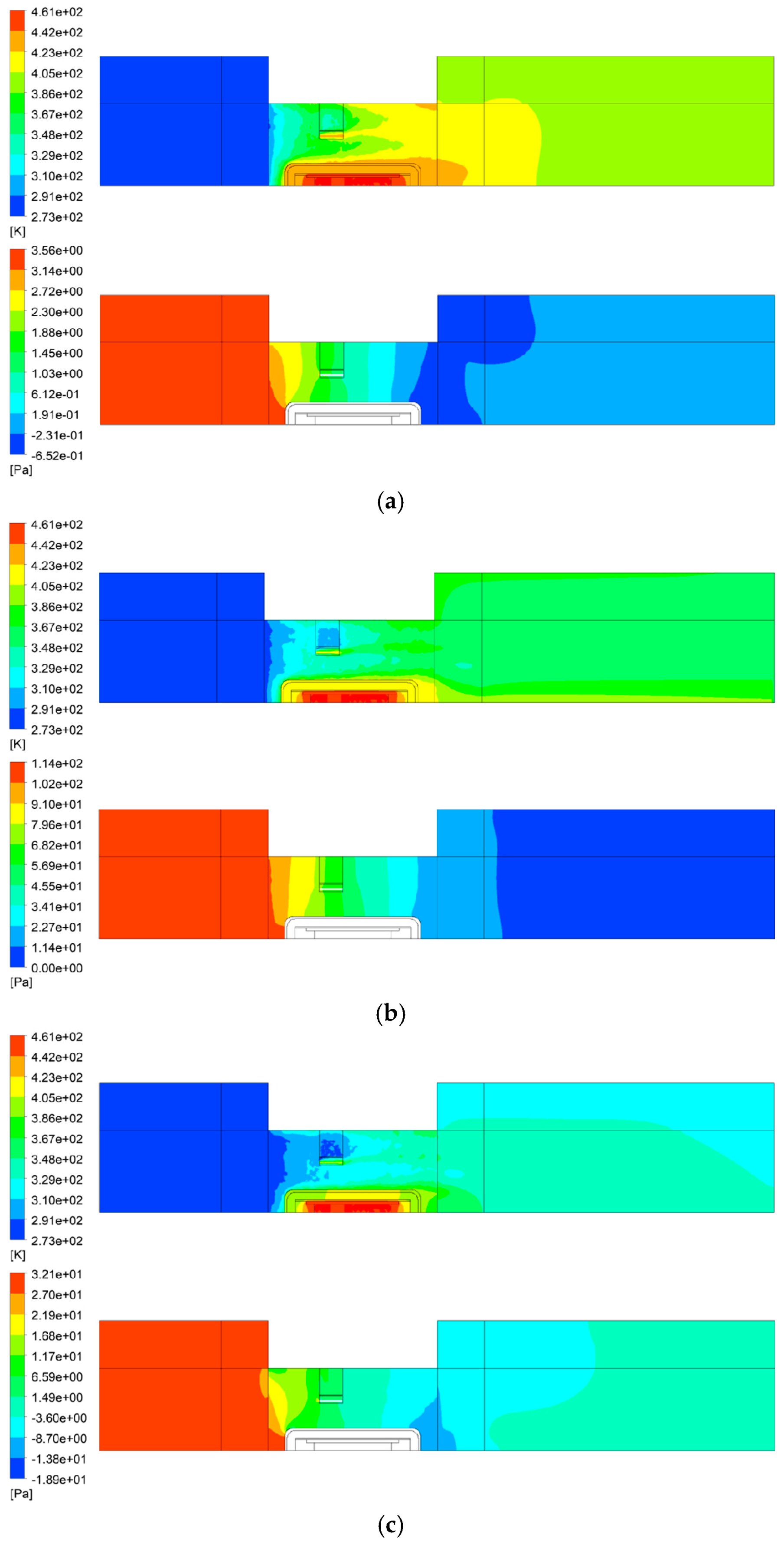

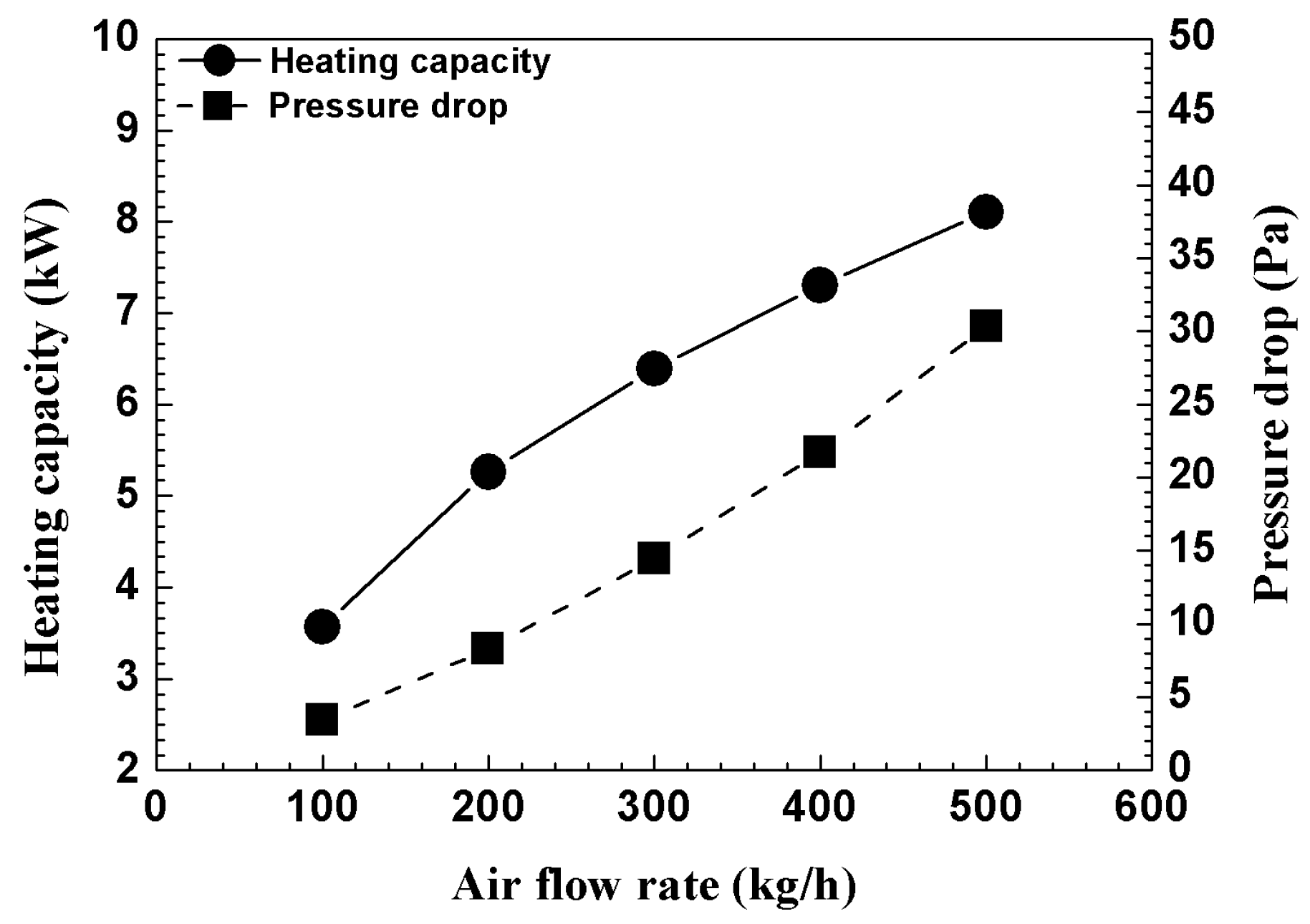

3.1. Heating Performance Enhancement of Various Geometric Parameters for the Modified Louver Fin

3.2. Numerical Analysis Results for Improved Prototype

3.3. Experimental Results and Discussion

5. Conclusions

- A reliable heat flow numerical analysis with a heating performance prediction error of 5.62% was used to perform comparative analysis on the heating capacity and pressure drop according to the geometric design variables (width, position, height, and angle) of the modified louver fin.

- The heat transfer and pressure drop characteristics of the modified louver fin were analyzed under changed flow rate conditions. As the flow rate increased, the heat transfer increased by an average of 23.5%, and the pressure drop increased by an average of 76.70%. At 100 kg/h, which corresponds to severe conditions for the heater, a high heating capacity of 3.57 kW was noted.

- Based on the numerical analysis results, an improved prototype was built, and its heating performance was tested. The results showed a heating performance of 6.05 kW, an efficiency of 98.0%, a pressure drop of 18.3 Pa, and a heating density of 3.81 kW/kg. The heating performance improved by 15.7% compared to the initial prototype.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Specific heat (J/kg∙K) | |

| Depth (mm) | |

| Height (mm) | |

| Current (A) | |

| Mass flow rate (kg/s) | |

| Heating capacity (W) | |

| Temperature (°C) | |

| Input voltage (V) | |

| Width (mm) | |

| Weight of heater (kg) | |

| Energy efficiency (%) | |

| Heating density (kW/kg) | |

| Subscripts | |

| a | Angle |

| d | Depth |

| h | Height |

| i | Inlet |

| o | Outlet |

| p | Position |

| w | Width |

References

- Kwon, C.K.; Kim, M.S.; Choi, Y.G.; Kim, M.S. Performance evaluation of a vapor injection heat pump system of electric vehicles. Int. J. Refrig. 2017, 74, 138–150. [Google Scholar] [CrossRef]

- Lee, D.Y.; Cho, C.W.; Won, J.P.; Park, Y.C.; Lee, M.Y. Performance characteristics of mobile heat pump for a Large passenger electric vehicle. Appl. Therm. Eng. 2013, 50, 660–669. [Google Scholar] [CrossRef]

- Cho, C.W.; Lee, H.S.; Won, J.P.; Lee, M.Y. Measurement and evaluation of heating performance of heat pump systems using wasted heat from electric devices for an electric bus. Energies 2012, 5, 658–669. [Google Scholar] [CrossRef]

- Kim, K.Y.; Kim, S.C.; Kim, M.S. Experimental studies on the heating performance of the PTC heater and heat pump combined system in fuel cells and electric vehicles. Int. J. Automot. Technol. 2012, 13, 971–977. [Google Scholar] [CrossRef]

- Lee, D. Experimental study on the heat pump system using R134a refrigerant for zero-emission vehicles. Int. J. Automot. Technol. 2015, 16, 923–928. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, M.; Guo, C.; Zhao, M. Enhance the heating performance of an electric vehicle AC/HP system under low temperature. Energy Procedia. 2017, 105, 2384–2389. [Google Scholar] [CrossRef]

- Shin, Y.H.; Sim, S.; Kim, S.C. Performance characteristics of a modularized and integrated PTC heating system for an electric vehicle. Energies 2016, 9, 18. [Google Scholar] [CrossRef]

- Shin, Y.H.; Ahn, S.K.; Kim, S.C. Performance characteristics of PTC elements for an electric vehicle heating system. Energies 2016, 9, 813. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, S.C. Heating performance characteristics of high-voltage PTC heater for an electric vehicle. Energies 2017, 10, 1494. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, S.C. Effects of geometric parameters and operating conditions on the performance of a high-voltage PTC heater for an electric vehicle. Appl. Therm. Eng. 2018, 143, 1023–1033. [Google Scholar] [CrossRef]

- Kang, H.S.; Sim, S.; Shin, Y.H. A numerical study on the light-weight design of PTC heater for an electric vehicle heating system. Energies 2018, 11, 1276. [Google Scholar] [CrossRef]

| Parameter | Heater A (Initial Prototype) | Heater B (Improved Prototype) |

|---|---|---|

| Total heater size (mm3) | 330.0 (W) × 230.0 (H) × 22.0 (D) | |

| Heater module size (mm3) | 265.5 (W) × 215.0 (H) × 22.0 (D) | |

| Weight (kg) | 1.59 | 1.59 |

| Input voltage (V) | 330 | 330 |

| Fin type | Plate | Modified louver |

| Fin pitch (mm) | 1.8 | 1.8 |

| Fin thickness (mm) | 0.3 | 0.3 |

| Number of fins | 112 | 112 |

| PTC thermistor temperature (°C) | 172 | 188 |

| Component | Specification |

|---|---|

| Thermocouple (K-type) | ± 0.1% (−60–200 °C), inlet 6 points, outlet 54 points |

| Diff. pressure gauge (Setra) | ± 0.14% (0–125 Pa) |

| Pitot tube (Samdukeng) | Φ3.2 × 150 mm |

| Thermo-hygrometer (Kimo) | ± 0.25% (0–50 °C), ± 1.5% (5%–95% RH) |

| Data acquisition system (NI) | 60 channels, 9–30 V @ 15 W |

| Blower (Dongkun) | Turbo fan, max volume flow rate: 5 m3/min |

| Model | Fin Type | Lw | Lp | Lh | La |

|---|---|---|---|---|---|

| P1 (initial prototype) | Plate | - | - | - | - |

| L1 | Modified louver | 4.5 | 11 | 0.9 | 50° |

| L2 | Modified louver | 3.5 | 11 | 0.9 | 50° |

| L3 | Modified louver | 5.5 | 11 | 0.9 | 50° |

| L4 | Modified louver | 4.5 | 8 | 0.9 | 50° |

| L5 | Modified louver | 4.5 | 14 | 0.9 | 50° |

| L6 | Modified louver | 4.5 | 11 | 0.6 | 50° |

| L7 | Modified louver | 4.5 | 11 | 1.2 | 50° |

| L8 | Modified louver | 4.5 | 11 | 0.9 | 30° |

| L9 | Modified louver | 4.5 | 11 | 0.9 | 70° |

| L10 (improved prototype) | Modified louver | 4.5 | 8 | 1.2 | 50° |

| Part | Density (kg/m3) | Specific Heat (J/kg∙°C) | Thermal Conductivity (W/m∙°C) |

|---|---|---|---|

| PTC thermistor | 3890 | 779 | 36 |

| Guide | 1200 | 1050 | 0.23 |

| Terminal | 8470 | 380 | 116 |

| Insulator | 0.0024 | 0.87 | 0.8 |

| Heatbar | 2700 | 900 | 218 |

| Fin | 2719 | 871 | 202.4 |

| Parameter | Heater B (Improved Prototype) |

|---|---|

| Input current (A) | 18.63 |

| Power consumption (kW) | 6.18 |

| Temperature difference (°C) | 72.3 |

| Heating capacity (kW) | 6.05 |

| Pressure drop (Pa) | 18.3 |

| Energy efficiency (%) | 98.0 |

| Heating density (kW/kg) | 3.81 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, M.H.; Kim, S.C. Heating Performance Enhancement of High Capacity PTC Heater with Modified Louver Fin for Electric Vehicles. Energies 2019, 12, 2900. https://doi.org/10.3390/en12152900

Park MH, Kim SC. Heating Performance Enhancement of High Capacity PTC Heater with Modified Louver Fin for Electric Vehicles. Energies. 2019; 12(15):2900. https://doi.org/10.3390/en12152900

Chicago/Turabian StylePark, Myeong Hyeon, and Sung Chul Kim. 2019. "Heating Performance Enhancement of High Capacity PTC Heater with Modified Louver Fin for Electric Vehicles" Energies 12, no. 15: 2900. https://doi.org/10.3390/en12152900

APA StylePark, M. H., & Kim, S. C. (2019). Heating Performance Enhancement of High Capacity PTC Heater with Modified Louver Fin for Electric Vehicles. Energies, 12(15), 2900. https://doi.org/10.3390/en12152900