Environmental Performance of Emerging Photovoltaic Technologies: Assessment of the Status Quo and Future Prospects Based on a Meta-Analysis of Life-Cycle Assessment Studies

Abstract

1. Introduction

2. Methodology

2.1. Overview

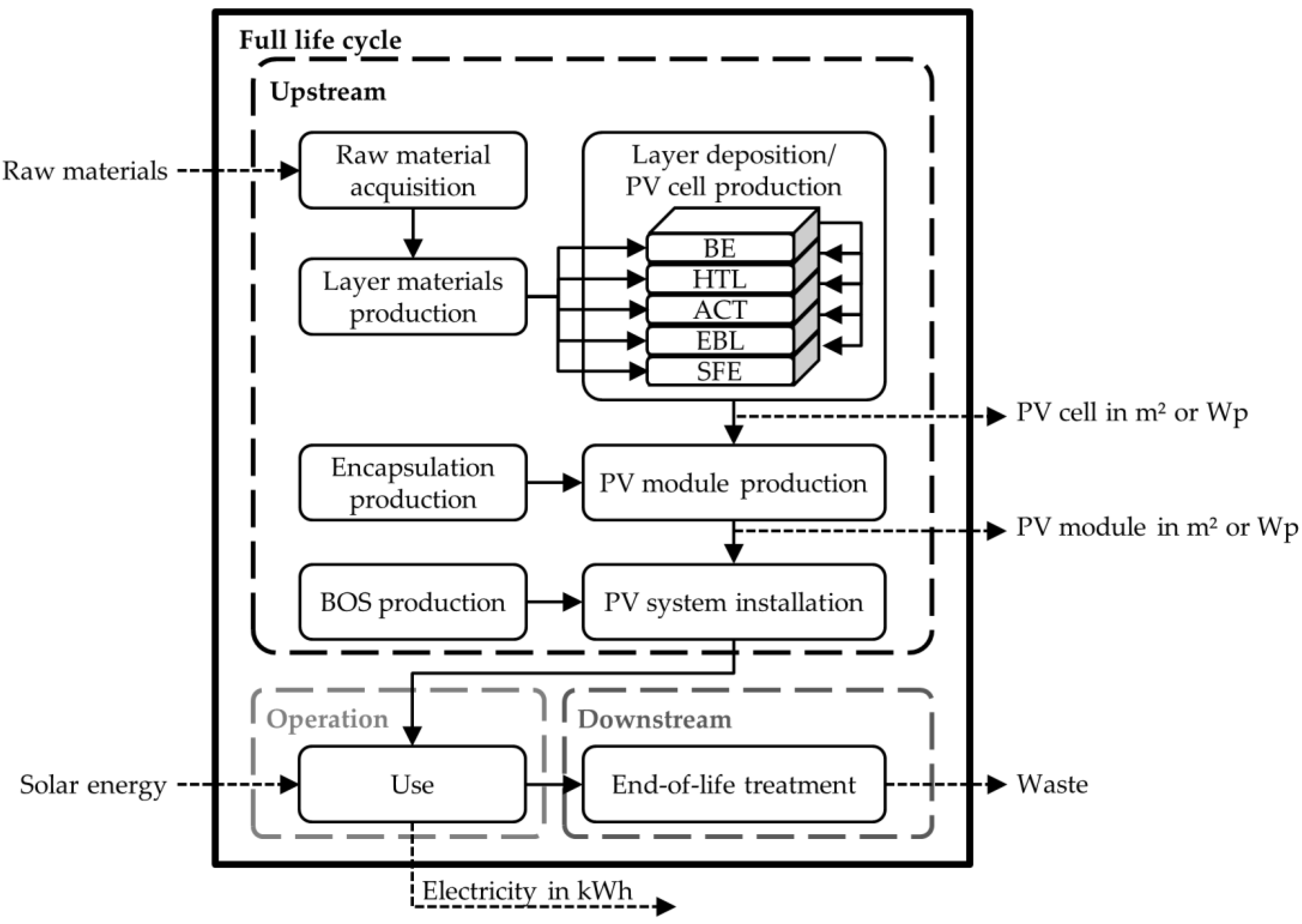

2.2. Conceptual Life Cycle of Emerging PVs

2.2.1. Description of the Technological Life Cycle of Emerging PVs

2.2.2. Methodological Elements of LCA of Emerging PVs

2.3. Systematic Review Approach of LCA Literature and Datasets

2.3.1. Literature and Dataset Search

2.3.2. Literature and Dataset Selection

- Relevance of the technologies: Only emerging PVs from the fields of DSSC, OPV, PSC, QDPV, and CTZSSe were considered in this meta-analysis.

- Completeness and transparency of the LCA study: In this meta-analysis, as a minimum requirement, the product system needed to consider at least the upstream impacts of PV cells (Figure 1). Transparency had to be ensured with respect to basic LCA elements, such as the defined goal with the corresponding information on the functional unit and assessed impact categories.

- (1)

- The LCA dataset was not published previously in another LCA study.

- (2)

- The LCA dataset included, as a minimum life cycle, impacts of the energy demand or the contributed GHG emissions of the production of PV cells.

- (3)

- The LCA dataset included information necessary for the conversion of the functional unit to m², Wp, or kWh.

2.4. Harmonization Approach for LCA Datasets

2.4.1. General Framework

2.4.2. Harmonization to Consistent Functional Units

2.4.3. Key Indicators (KEYIs)

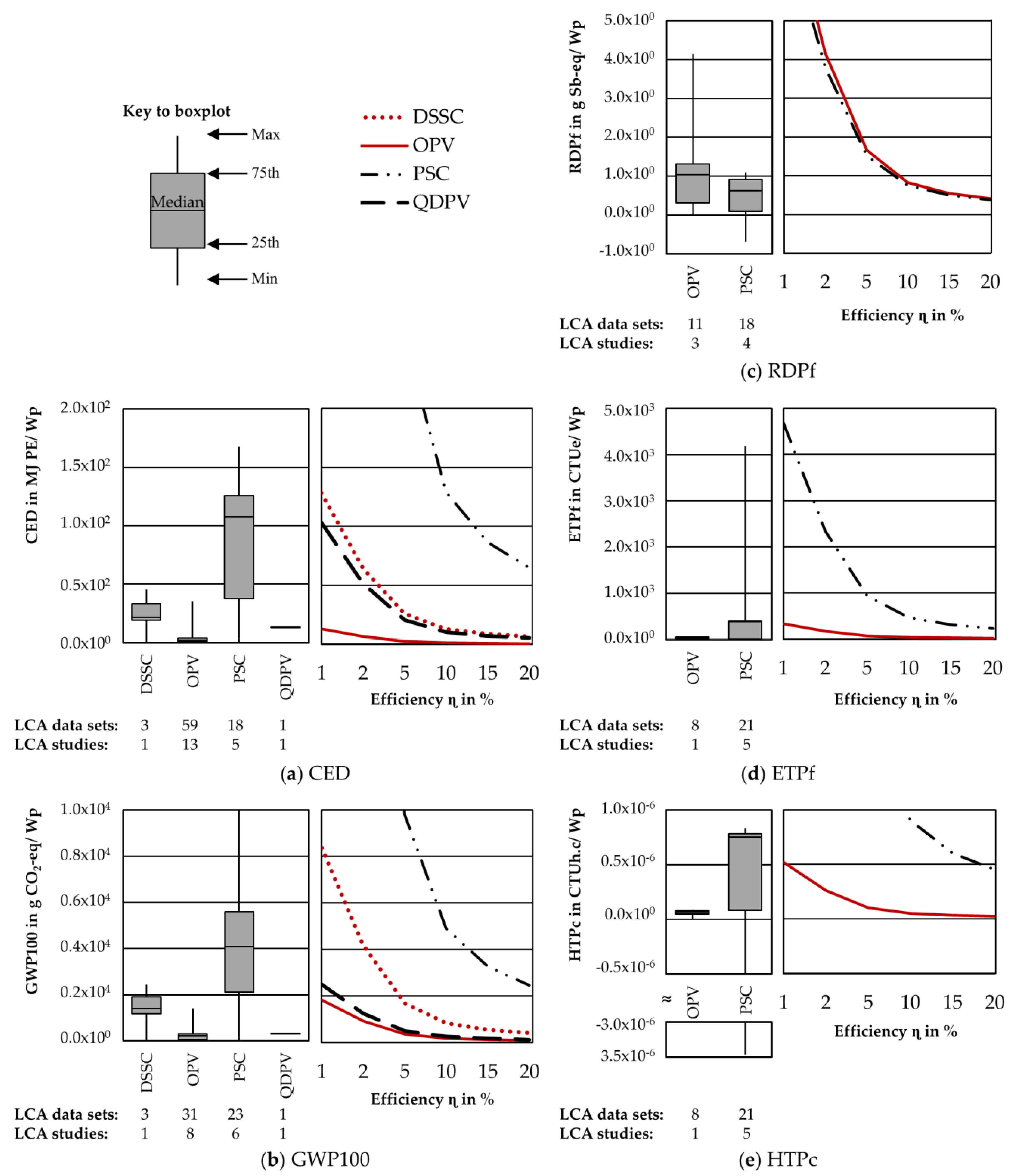

- Energy-related KEYIs:

- Cumulative energy demand (CED): The CED in MJ PE quantifies the primary energy (PE) inputs of the included life cycle stages.

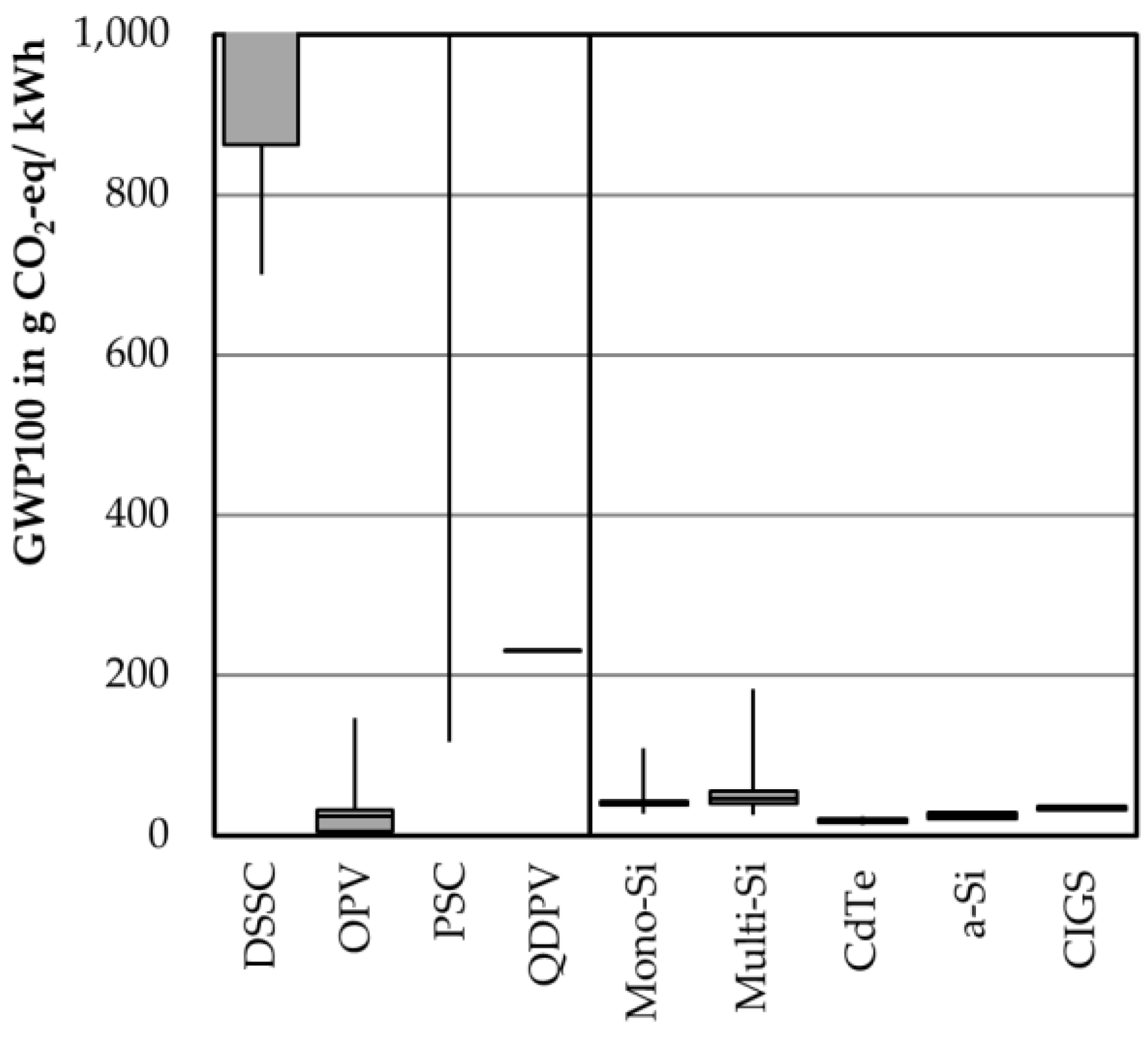

- Global warming potential (GWP): GWP quantifies the GHG emissions in g of carbon dioxide equivalents (g CO2-eq) resulting mostly from the energy demand.

- Material-related KEYIs:

- Resource depletion, mineral, fossil, and renewable resources (RDPf): The RDPf in g of antimony equivalents (g Sb-eq) considers the resource use and impacts on the resource availability.

- Toxicity indicators: These indicators are relevant in assessing the toxicity potential of the included layer materials to the ecosystem and human health, assessed by the following two indicators in this meta-analysis:

- Ecotoxicity potential for freshwater (ETPf) in comparative toxic units for ecosystems (CTUe);

- Human toxicity, cancer effects (HTPc) in comparative toxic units for human health impact equivalent to the incidence of cancer (CTUh).

2.4.4. Key Modeling Assumptions (KEYAs)

- LCA type, temporal coverage, and technology scale: These KEYAs were interrelated in LCA studies on emerging PVs. The term LCA type stands here for the modeling approach of the LCA study. It was differentiated into the following:

- Conventional LCA, representing the common approach of LCA studies, particularly commercial technologies which are established on the market and show sufficient primary data quantities for the assessment of the status quo;

Accordingly, the temporal coverage of a conventional LCA is based on present conditions of technologies, whereas prospective LCAs consider future scenarios and developments of technologies. Moreover, the technology scale of the assessed technology depends on the LCA type as well. The technology scale characterizes here the stage of development of the assessed emerging PV, and it is an important specification for the characterization and differentiation of emerging PVs in LCA studies. In conventional LCAs, technologies are assessed based on the current technology scale and stage of development. On the contrary, in prospective LCAs, the technology scale is upscaled by the consideration of likely future scenarios and, consequently, emerging technologies are assessed based on higher technology scales. In particular, for a fair comparison between emerging PVs and commercial technologies or technologies at higher or lower development stage, the technology scale of the assessed technology needs to be indicated. A common method for characterizing the technology scale is the concept of technology readiness levels (TRLs), consisting of nine TRLs established by National Aeronautics and Space Administration (NASA) [53]. However, none of the included LCA studies reported TRLs. Therefore, the following classification scheme based on the TRL concept was introduced and applied for the characterization of the technology scale of the LCA datasets on emerging PVs:- TRL 1 (“basic principles observed and reported”) was omitted since it may be relevant for LCA studies of new technology concepts but not for the included emerging PVs [53];

- Laboratory scale, referring to TRLs 2–4 (“research to prove feasibility”);

- Pilot scale, referring to TRLs 5–7 (“technology demonstration”);

- Industrial scale, referring to TRLs 8–9 (“system test, launch, and operations”).

- Product system: The considered product system of emerging PVs can be distinguished into the three options: (1) PV cell, (2) PV module, and (3) PV system. As shown in Figure 1, the PV system includes more components than the PV cell. Each component has its own impact and, consequently, the consideration of its contributions and tradeoffs is necessary.

- Layer components: The different layer options as components of the PV cell are relevant to the life-cycle impacts resulting from the energy requirements of the deposition and from possible hazardous elements or materials. Therefore, the further subdivision of the PV cell into the layer components is necessary to track and compare the life-cycle impacts and the contribution of the layer materials and deposition methods.

- System boundary: As mentioned above, the minimum requirement for the selection of a dataset was the inclusion of the upstream stage, i.e., the production of the PV cell. In addition, studies could also include also the operation stage or cover the full life cycle, including the downstream stage. While the inclusion of the operation stage yields electricity generation and, thus, is covered by the respective functional units of energy, the inclusion of the downstream stage is often omitted and hinders the comparison of results. However, since the LCA studies gave very limited information on end-of-life treatment, the contribution of the downstream stage could not be added to the overall result; thus, an important source of tradeoff was not fully considered. Therefore, the influence of the system boundary was taken into account as KEYAs.

2.4.5. Key Performance Parameters (KEYPs)

- Efficiency of the PV cell or PV module (ɳ);

- Performance ratio of the PV system (PR);

- Irradiation on the installed PV system (I);

- Lifetime of the PV system (τ) and its components.

3. Results

3.1. Systematic Review of LCA Datasets on Emerging PVs

3.2. Harmonization of LCA Datasets on Emerging PVs

3.2.1. Mathematical Procedure of the Harmonization

3.2.2. Standardization of the KEYPs

3.3. Status Quo of the Environmental Performance of Emerging PVs

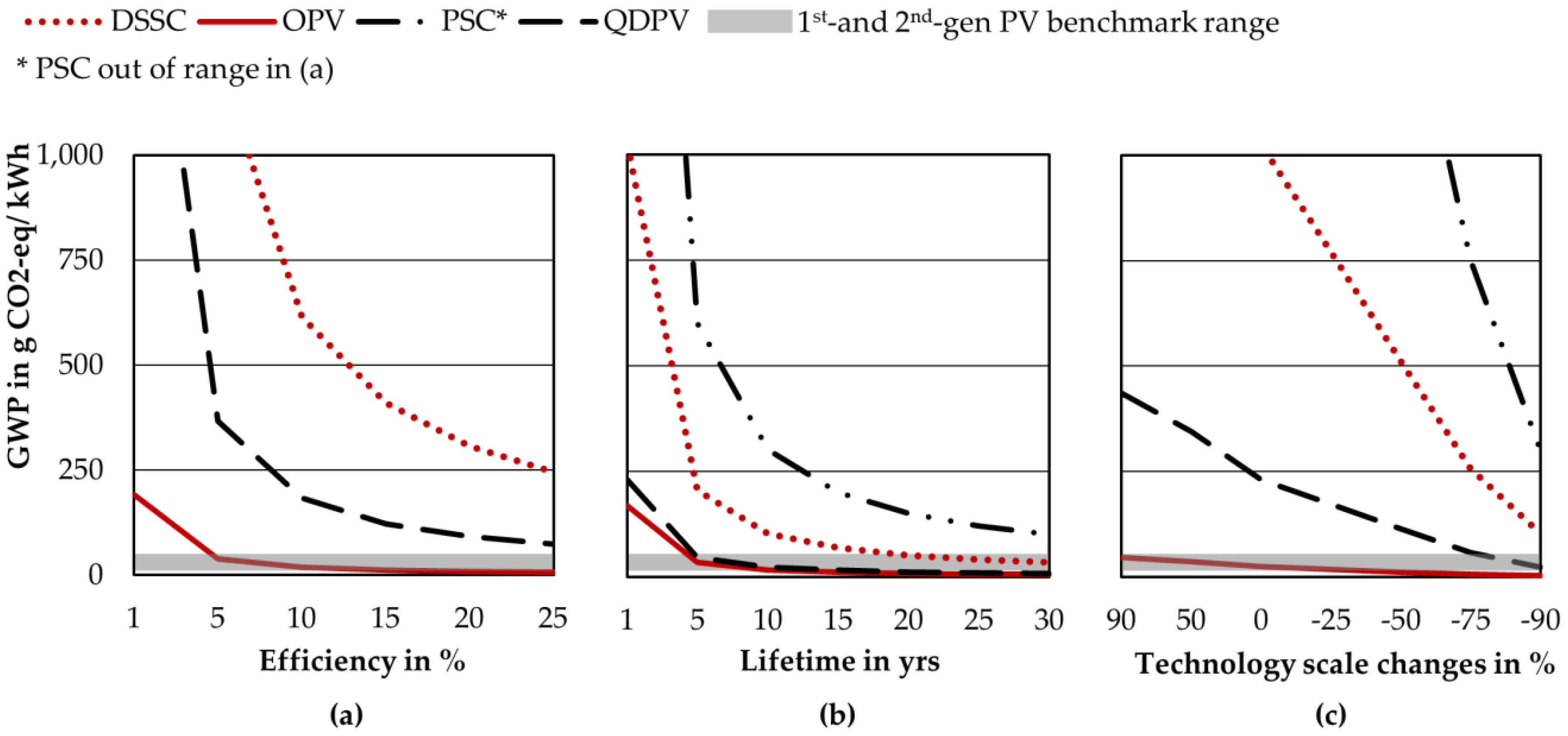

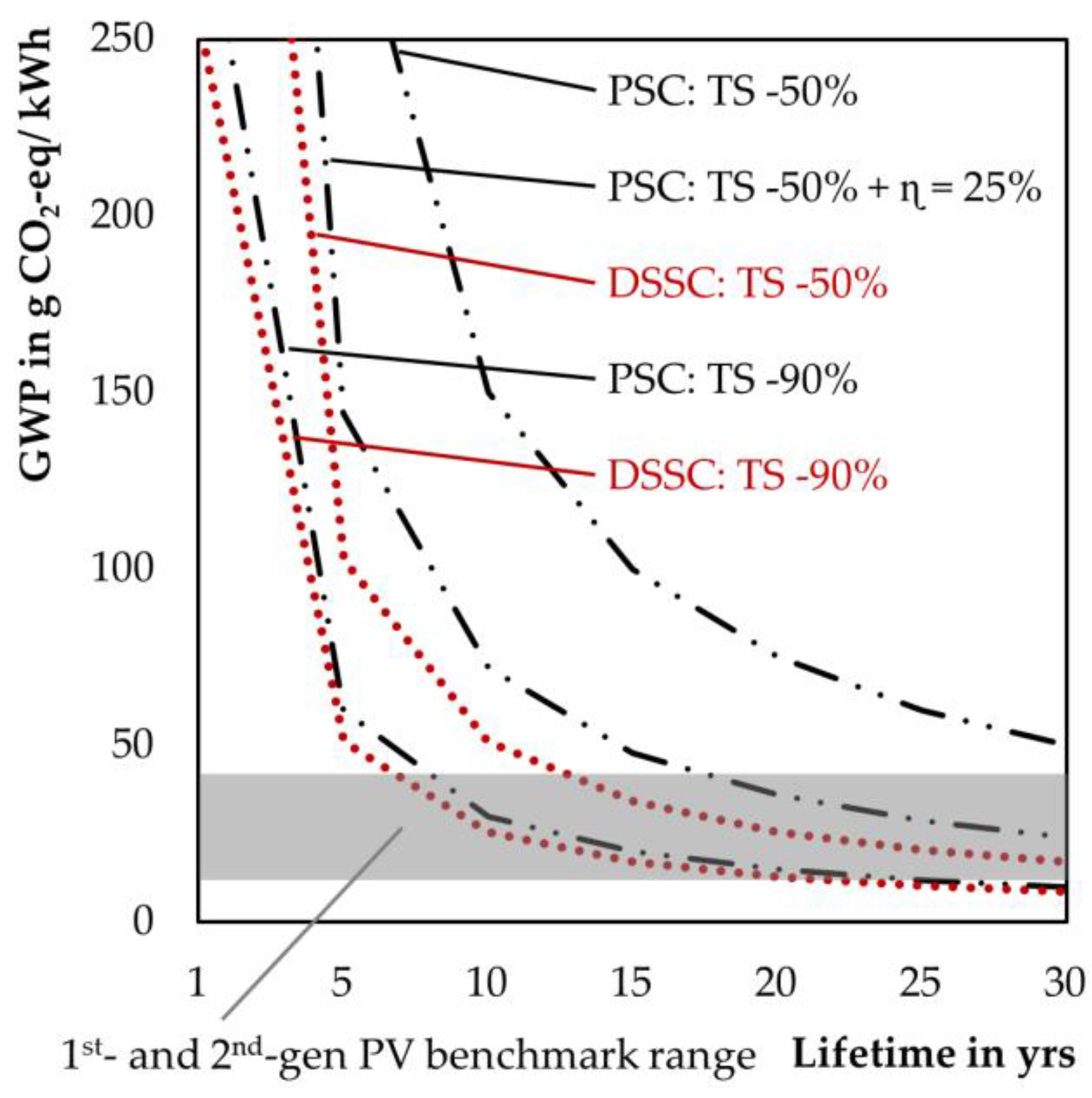

3.4. Future Prospects of Emerging PVs

- Efficiency increase from 1% to 25% (the latter value was set as the most optimistic assumption based on the maximum reported efficiency [3]);

- Lifetime increase from the minimum reported lifetime of one year to the most optimistic assumption of 30 years as the typical lifetime of first- and second-generation PVs;

- Upscaling of production from the laboratory to industrial scale was depicted as changes in the energy demand from −90% to 90% (as a proxy of the environmental impact in general) and, consequently, of the GWP impacts in the same range as a consequence of this technology scale leap.

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| PVs | Photovoltaic technologies |

| Mono-Si | Monocrystalline silicon |

| Multi-Si | Multicrystalline silicon |

| a-Si | Amorphous silicon |

| CdTe | Cadmium–telluride solar cells |

| CIGS | Copper–indium–gallium–diselenide solar cells |

| CZTSSe | Copper–zinc–tin–sulfur–selenide solar cell |

| DSSC | Dye-sensitized solar cell |

| OPV | Organic photovoltaic |

| PSC | Perovskite solar cell |

| QDPV | Quantum-dot photovoltaic |

| KEYIs | Key indicators |

| CED | Cumulative energy demand in MJ PE (primary energy) |

| ETPf | Ecotoxicity potential for freshwater in CTUe (comparative toxic units for ecosystems) |

| GHG/GWP | Greenhouse gas/global warming potential in g CO2-eq (carbon dioxide equivalents) |

| HTPc | Human toxicity, cancer effects in CTUh (comparative toxic units for human health impacts equivalent to incidence of cancer) |

| RDPf | Resource depletion, mineral, fossil, and renewable resources in g Sb-eq (antimony equivalents) |

| KEYAs | Key modeling assumptions |

| C | Conventional |

| P | Prospective |

| TS/TRL | Technology scale/technology readiness level |

| L | Laboratory scale |

| PI/IN | Pilot/industrial scale |

| KEYPs | Key performance parameters |

| ɳ | Efficiency |

| τ | Lifetime |

| I | Irradiation |

| PR | Performance ratio |

| Further | |

| BOS | Balance-of-system |

| LCA | Life-cycle assessment |

| Wp | Watt-peak |

References

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework; (DIN EN ISO 14040); The International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- ISO 14044. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; (DIN ISO 14044); The International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- National Renewable Energy Laboratory (NREL). Best Research-Cell Efficiencies [Internet], updated 03 January 2019. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 10 January 2019).

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photon 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Polman, A.; Knight, M.; Garnett, E.C.; Ehrler, B.; Sinke, W.C. Photovoltaic materials: Present efficiencies and future challenges. Science 2016, 352, aad4424. [Google Scholar] [CrossRef] [PubMed]

- Krebs, F.C.; Tromholt, T.; Jorgensen, M. Upscaling of polymer solar cell fabrication using full roll-to-roll processing. Nanoscale 2010, 2, 873–886. [Google Scholar] [CrossRef] [PubMed]

- Kalkman, J.; Merhaba, A.; Bose, S.; Bradley, H. Emerging Technologies in Solar PV: Identifying and Cultivating Potential Winners: Traversing the PV Lab-to-Fab “valleys of death” [Internet]. Arthur D Little. Available online: https://www.adlittle.com/sites/default/files/viewpoints/ADL-Renewable-Energy-Emerging-PV-Technology.pdf (accessed on 10 September 2018).

- Alsema, E.A. Energy pay-back time and CO2 emissions of PV systems. Prog. Photovolt. Res. Appl. 2000, 8, 17–25. [Google Scholar] [CrossRef]

- Bhandari, K.P.; Collier, J.M.; Ellingson, R.J.; Apul, D.S. Energy payback time (EPBT) and energy return on energy invested (EROI) of solar photovoltaic systems: A systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2015, 47, 133–141. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Alsema, E.A.; de Wild-Scholten, M.J. Life cycle assessment of photovoltaics: Perceptions, needs, and challenges. In Proceedings of the Conference Record of the Thirty-First IEEE Photovoltaic Specialists Conference, Lake buena Vista, FL, USA, 3–7 January 2005; pp. 1655–1658. [Google Scholar]

- Hsu, D.D.; O’Donoughue, P.; Fthenakis, V.; Heath, G.A.; Kim, H.C.; Sawyer, P.; Choi, J.-K.; Turney, D.E. Life cycle greenhouse gas emissions of crystalline silicon photovoltaic electricity generation. J. Ind. Ecol. 2012, 16, S122–S135. [Google Scholar] [CrossRef]

- Kim, H.C.; Fthenakis, V.; Choi, J.-K.; Turney, D.E. Life cycle greenhouse gas emissions of thin-film photovoltaic electricity generation. J. Ind. Ecol. 2012, 16, S110–S121. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- Gibon, T.; Arvesen, A.; Hertwich, E.G. Life cycle assessment demonstrates environmental co-benefits and trade-offs of low-carbon electricity supply options. Renew. Sustain. Energy Rev. 2017, 76, 1283–1290. [Google Scholar] [CrossRef]

- Frankl, P.; Menichetti, E.; Raugei, M. Deliverable n 11.2—RS Ia Final report on technical data, costs and life cycle inventories of PV applications. 2006. Available online: http://www.needs-project.org/RS1a/RS1a%20D11.2%20Final%20report%20on%20PV%20technology.pdf (accessed on 10 January 2019).

- Heath, G.A.; Mann, M.K. Background and reflections on the life cycle assessment harmonization project. J. Ind. Ecol. 2012, 16, S8–S11. [Google Scholar] [CrossRef]

- Burkhardt, J.J.; Heath, G.; Cohen, E. Life cycle greenhouse gas emissions of trough and tower concentrating solar power electricity generation. J. Ind. Ecol. 2012, 16, S93–S109. [Google Scholar] [CrossRef]

- Dolan, S.L.; Heath, G.A. Life cycle greenhouse gas emissions of utility-scale wind power. J. Ind. Ecol. 2012, 16, S136–S154. [Google Scholar] [CrossRef]

- Warner, E.S.; Heath, G.A. Life cycle greenhouse gas emissions of nuclear electricity generation. J. Ind. Ecol. 2012, 16, S73–S92. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G.A.; O’Donoughue, P.; Vorum, M. Life cycle greenhouse gas emissions of coal-fired electricity generation. J. Ind. Ecol. 2012, 16, S53–S72. [Google Scholar] [CrossRef]

- Parisi, M.L.; Maranghi, S.; Basosi, R. The evolution of the dye sensitized solar cells from Grätzel prototype to up-scaled solar applications: A life cycle assessment approach. Renew. Sustain. Energy Rev. 2014, 39, 124–138. [Google Scholar] [CrossRef]

- Anctil, A.; Babbitt, C.W.; Raffaelle, R.P.; Landi, B.J. Cumulative energy demand for small molecule and polymer photovoltaics. Prog. Photovolt. Res. Appl. 2013, 21, 1541–1554. [Google Scholar] [CrossRef]

- Espinosa, N.; García-Valverde, R.; Urbina, A.; Krebs, F.C. A life cycle analysis of polymer solar cell modules prepared using roll-to-roll methods under ambient conditions. Sol. Energy Mater. Sol. Cells 2011, 95, 1293–1302. [Google Scholar] [CrossRef]

- Espinosa, N.; García-Valverde, R.; Krebs, F.C. Life-cycle analysis of product integrated polymer solar cells. Energy Environ. Sci. 2011, 4, 1547. [Google Scholar] [CrossRef]

- Espinosa, N.; García-Valverde, R.; Urbina, A.; Lenzmann, F.; Manceau, M.; Angmo, D.; Krebs, F.C. Life cycle assessment of ITO-free flexible polymer solar cells prepared by roll-to-roll coating and printing. Sol. Energy Mater. Sol. Cells 2012, 97, 3–13. [Google Scholar] [CrossRef]

- Espinosa, N.; Hösel, M.; Angmo, D.; Krebs, F.C. Solar cells with one-day energy payback for the factories of the future. Energy Environ. Sci. 2012, 5, 5117–5132. [Google Scholar] [CrossRef]

- Espinosa, N.; Lenzmann, F.O.; Ryley, S.; Angmo, D.; Hösel, M.; Søndergaard, R.R.; Huss, D.; Dafinger, S.; Gritsch, S.; Kroon, J.M.; et al. OPV for mobile applications: An evaluation of roll-to-roll processed indium and silver free polymer solar cells through analysis of life cycle, cost and layer quality using inline optical and functional inspection tools. J. Mater. Chem. A 2013, 1, 7037. [Google Scholar] [CrossRef]

- Espinosa, N.; Hösel, M.; Jørgensen, M.; Krebs, F.C. Large scale deployment of polymer solar cells on land, on sea and in the air. Energy Environ. Sci. 2014, 7, 855. [Google Scholar] [CrossRef]

- Espinosa, N.; Laurent, A.; dos Reis Benatto, G.A.; Hösel, M.; Krebs, F.C. Which Electrode Materials to Select for More Environmentally Friendly Organic Photovoltaics? Adv. Eng. Mater. 2016, 18, 490–495. [Google Scholar] [CrossRef]

- García-Valverde, R.; Cherni, J.A.; Urbina, A. Life cycle analysis of organic photovoltaic technologies. Prog. Photovolt. Res. Appl. 2010, 18, 535–558. [Google Scholar] [CrossRef]

- Roes, A.L.; Alsema, E.A.; Blok, K.; Patel, M.K. Ex-ante environmental and economic evaluation of polymer photovoltaics. Prog. Photovolt Res. Appl. 2009, 17, 372–393. [Google Scholar] [CrossRef]

- Søndergaard, R.R.; Espinosa, N.; Jørgensen, M.; Krebs, F.C. Efficient decommissioning and recycling of polymer solar cells: Justification for use of silver. Energy Environ. Sci. 2014, 7, 1006. [Google Scholar] [CrossRef]

- Tsang, M.P.; Sonnemann, G.W.; Bassani, D.M. A comparative human health, ecotoxicity, and product environmental assessment on the production of organic and silicon solar cells. Prog. Photovolt Res. Appl. 2015, 24, 645–655. [Google Scholar] [CrossRef]

- Tsang, M.P.; Sonnemann, G.W.; Bassani, D.M. Life-cycle assessment of cradle-to-grave opportunities and environmental impacts of organic photovoltaic solar panels compared to conventional technologies. Sol. Energy Mater. Sol. Cells 2016, 156, 37–48. [Google Scholar] [CrossRef]

- Celik, I.; Song, Z.; Cimaroli, A.J.; Yan, Y.; Heben, M.J.; Apul, D. Life cycle assessment (LCA) of perovskite PV cells projected from lab to fab. Sol. Energy Mater. Sol. Cells 2016, 156, 157–169. [Google Scholar] [CrossRef]

- Espinosa, N.; Serrano-Luján, L.; Urbina, A.; Krebs, F.C. Solution and vapour deposited lead perovskite solar cells: Ecotoxicity from a life cycle assessment perspective. Sol. Energy Mater. Sol. Cells 2015, 137, 303–310. [Google Scholar] [CrossRef]

- Gong, J.; Darling, S.B.; You, F. Perovskite photovoltaics: Life-cycle assessment of energy and environmental impacts. Energy Environ. Sci. 2015, 8, 1953–1968. [Google Scholar] [CrossRef]

- Serrano-Lujan, L.; Espinosa, N.; Larsen-Olsen, T.T.; Abad, J.; Urbina, A.; Krebs, F.C. Tin- and lead-based perovskite solar cells under scrutiny: An environmental perspective. Adv. Energy Mater. 2015, 5, 1501119. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, X.; Deng, Y.; Li, B.; Yuan, C. Life cycle assessment of titania perovskite solar cell technology for sustainable design and manufacturing. ChemSusChem 2015, 8, 3882–3891. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Gao, X.; Deng, Y.; Zha, Y.; Yuan, C. Comparison of life cycle environmental impacts of different perovskite solar cell systems. Sol. Energy Mater. Sol. Cells 2017, 166, 9–17. [Google Scholar] [CrossRef]

- Şengül, H.; Theis, T.L. An environmental impact assessment of quantum dot photovoltaics (QDPV) from raw material acquisition through use. J. Clean. Prod. 2011, 19, 21–31. [Google Scholar] [CrossRef]

- Itten, R.; Stucki, M. Highly efficient 3rd generation multi-junction solar cells using silicon heterojunction and perovskite tandem: prospective life cycle environmental impacts. Energies 2017, 10, 841. [Google Scholar] [CrossRef]

- Maranghi, S.; Parisi, M.L.; Basosi, R.; Sinicropi, A. environmental profile of the manufacturing process of perovskite photovoltaics: harmonization of life cycle assessment studies. Energies 2019, 12, 3746. [Google Scholar] [CrossRef]

- Ahmad, Z.; Najeeb, M.A.; Shakoor, R.A.; Al-Muhtaseb, S.A.; Touati, F. Limits and possible solutions in quantum dot organic solar cells. Renew. Sustain. Energy Rev. 2018, 82, 1551–1564. [Google Scholar] [CrossRef]

- Elumalai, N.K.; Mahmud, M.A.; Wang, D.; Uddin, A. Perovskite solar cells: Progress and advancements. Energies 2016, 9, 861. [Google Scholar] [CrossRef]

- Peters, C.H.; Sachs-Quintana, I.T.; Kastrop, J.P.; Beaupré, S.; Leclerc, M.; McGehee, M.D. High efficiency polymer solar cells with long operating lifetimes. Adv. Energy Mater. 2011, 1, 491–494. [Google Scholar] [CrossRef]

- Office, P. Directive 2012/19/EU of The European Parliament and of The Council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off. J. Eur. Union L 2012, 197, 38–71. [Google Scholar]

- Frischknecht, R.; Heath, G.; Raugei, M.; Sinha, P.; de Wild-Scholten, M.J.; Fthenakis, V.; Kim, H.C.; Alsema, E.; Held, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity, 3rd ed.; IEA PVPS Task 12, Report IEA-PVPS T12-06; International Energy Agency Photovoltaic Power Systems Programme: St. Ursen, Switzerland, 2016; ISBN 978-3-906042-38-1. [Google Scholar]

- IEC 61215. Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval; International Electrotechnical Commission: Geneva, Switzerland, 2016; ISBN 978-2-8322-3206-4. [Google Scholar]

- Chatzisideris, M.D.; Laurent, A.; Hauschild, M.Z.; Krebs, F.C. Environmental impacts of electricity self-consumption from organic photovoltaic battery systems at industrial facilities in Denmark. CIRP Ann. Manuf. Technol. 2017, 66, 45–48. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.-M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental assessment of emerging technologies: recommendations for prospective LCA. J. Ind. Ecol. 2017, 80, 40. [Google Scholar] [CrossRef]

- Cucurachi, S.; van der Giesen, C.; Guinée, J. Ex-ante LCA of emerging technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- National Aeronautics and Space Administration. NASA Systems Engineering Handbook; NASA: Washington, DC, USA, 2007; ISBN 978-0-16-079747-7.

- Darling, S.B.; You, F. The case for organic photovoltaics. RSC Adv. 2013, 3, 17633–17648. [Google Scholar] [CrossRef]

- Green, M.A.; Hishikawa, Y.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (version 51). Prog. Photovolt. Res. Appl. 2018, 26, 3–12. [Google Scholar] [CrossRef]

- Fraunhofer ISE. Photovoltaics Report [Internet], updated 14 March 2019. Freiburg. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 30 March 2019).

- Poluektov, O.G.; Niklas, J.; Mardis, K.L.; Beaupré, S.; Leclerc, M.; Villegas, C.; Erten-Ela, S.; Delgado, J.L.; Martín, N.; Sperlich, A.; et al. Electronic structure of fullerene heterodimer in bulk-heterojunction blends. Adv. Energy Mater. 2014, 4, 1301517. [Google Scholar] [CrossRef]

- Collavini, S.; Delgado, J.L. Carbon nanoforms in perovskite-based solar cells. Adv. Energy Mater. 2017, 7, 1601000. [Google Scholar] [CrossRef]

- Pascual, J.; Delgado, J.L.; Tena-Zaera, R. Physicochemical phenomena and application in solar cells of perovskite: Fullerene films. J. Phys. Chem. Lett. 2018, 9, 2893–2902. [Google Scholar] [CrossRef]

- Yavari, M.; Mazloum-Ardakani, M.; Gholipour, S.; Marinova, N.; Delgado, J.L.; Turren-Cruz, S.-H.; Domanski, K.; Taghavinia, N.; Saliba, M.; Grätzel, M.; et al. Carbon nanoparticles in high-performance perovskite solar cells. Adv. Energy Mater. 2018, 8, 1702719. [Google Scholar] [CrossRef]

- Asghar, M.I.; Zhang, J.; Wang, H.; Lund, P.D. Device stability of perovskite solar cells—A review. Renew. Sustain. Energy Rev. 2017, 77, 131–146. [Google Scholar] [CrossRef]

- Werner, J.; Niesen, B.; Ballif, C. Perovskite/Silicon tandem solar cells: marriage of convenience or true love story?—An Overview. Adv. Mater. Interfaces 2018, 5, 1700731. [Google Scholar] [CrossRef]

- Oxford PV. Oxford PV—The Perovskite Company. Available online: https://www.oxfordpv.com (accessed on 15 June 2019).

- Glogic, E.; Weyand, S.; Tsang, M.P.; Young, S.B.; Schebek, L.; Sonnemann, G. Life cycle assessment of organic photovoltaic charger use in Europe: The role of product use intensity and irradiation. J. Clean. Prod. 2019, 233, 1088–1096. [Google Scholar] [CrossRef]

| Layer | DSSC | OPV | PSC | QDPV | DSSC | OPV | PSC | QDPV |

|---|---|---|---|---|---|---|---|---|

| Materials | Deposition Methods | |||||||

| BE | FTO + Ag (3) | Ag (40), Al, Al+Ca, Al+Cr, C | Au (12), Al or MoOx/Al, Pt, Ag, or C | ITO (1) | [21] | Screen printing, Gravure printing, N/A, Slot die coating, Evaporation, Sputtering | Evaporation, Dip coating, Sputtering | [41] |

| HTL | Electrolyt (porphyrin-Co- dye) (3) | PEDOT:PSS (37), -, MoO3,TiOx | Spiro-OMeTAD (14), PCBM, Electrolyt (LiI), CuSCN or - | Al2O3 (1) | [21] | N/A, Slot die coating, Screen printing, Gravure printing, Evaporation | Spray coating, Screen printing, Sputtering, N/A | [41] |

| ACT | Ru-dye (3) | P3HT:PCBM (45), combination of P3HT or PCBM and other acceptor or donator | CH3NH3PbI3,-ICl2, -I2Cl (16), CH3NH3SnI3-xBrx, CsPbBr3, FAPbI3 | CdSe (1) | [21] | Slot die coating, Gravure printing, Evaporation, N/A, Spin coating, Inkjet printing | Spin coating, Dip coating, Evaporation, Slot die coating, Spray coating | [41] |

| EBL | TiO2 (3) | ZnO (21), PEDOT:PSS, PEDOT:PSS + ZnO, MoO3, MeOH+ZnO, Ag | TiO2 (Comp., Meso.) (16), SnO2, PEDOT:PSS, ZnO | - | [21] | Slot die coating, Gravure printing, Screen printing, N/A, Inkjet printing, Spin coating | Spin coating, Spray coating/pyrolysi, Screen printing, -N/A, Sputtering | [41] |

| FE | Pt + Ag (3) | ITO (19), Ag, Ag + PEDOT:PSS, PEDOT:PSS, FTO, -, C, Al, Cu | FTO (19), ITO | - | [21] | Inkjet printing, Sputtering, Screen printing, Slot die coating, Patterning, N/A | N/A, Evaporation, Patterning, Anti- reflex-coating, Sputtering | [41] |

| S | Glass (2), PET | PET, PET + UV-Filter, Barrier (63), Filter, -, Glass | Glass (21), PET | Al (1) | [21] | N/A | N/A | [41] |

| LCA Studies with Number of Included LCA Data Sets | KEYIs a | KEYAs b | KEYPs c | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Author (Year) | DS | FU | CED | GWP | RDPf/Tox | LCA type/TS | PS | SB | ɳR | τR | IR | PRR | |

| in MJ PE | in g CO2- eq | in g Sb -eq or CTU | Down-stream | in % | in years | in kWh/ m²·year | in % | ||||||

| DSSC | |||||||||||||

| Parisi et al. (2014) [21] | 3 | 1 kWh | ✓ | ✓ | −/− | P | PI | S | □ | 8 | 20 | 1700 | 75 |

| OPV | |||||||||||||

| Anctil et al. (2013) [22] | 13 | 1 Wp | ✓ | − | −/− | C | L | M | □ | 3.0–7.7 | N/A | N/A | N/A |

| Darling and You (2013) [54] | 1 | 1 m² | ✓ | − | −/− | C | PI | M | □ | 1 | 2 | 1700 | 75 |

| Espinosa et al. (2011a) [23] | 1 | 1 m² | ✓ | ✓ | −/− | C | IN | M | □ | 2 | 15 | 1700 | 80 |

| Espinosa et al. (2011b) [24] | 1 | 104 cm² | ✓ | − | −/− | C | IN | S | □ | 2–3 | 2 | N/A | N/A |

| Espinosa et al. (2012a) [25] | 1 | 1 m² | ✓ | ✓ | −/− | P | PI | M | □ | 1 | 15 | 1700 | 80 |

| Espinosa et al. (2012b) [26] | 10 | 1 m² | ✓ | − | −/− | C | PI | M | □ | 1 | 15 | 1700 | N/A |

| Espinosa et al. (2013) [27] | 6 | 1 m² | ✓ | −✓ | −✓/− | C | PI | M | □ | 2 | N/A | 1700 | N/A |

| Espinosa et al. (2014) [28] | 5 | 1 m² | ✓ | − | −/− | C | IN | M/S | □ | 2.2/1.6 | 1 | 1700 | 80 |

| Espinosa et al. (2016) [29] | 8 | 1 kWh | − | ✓ | ✓/✓ | C | PI | M | ■ | 0.7–1 | 2 | - | N/A |

| García-Valverde et al. (2010) [30] | 1 | 1 m² | ✓ | ✓ | −/− | C | L | M | □ | 5 | 15 | 1700 | 80 |

| Roes et al. (2009) [31] | 2 | 1 Wp | ✓ | ✓ | ✓/− | C | L | S | □ | 5 | 25 | 1700 | 75 |

| Søndergaard et al. (2014) [32] | 3 | 1 m² | ✓ | − | −/− | C | PI | M | ■ | 2 | N/A | 1700 | 80 |

| Tsang et al. (2015) [33] | 3 | 1 Wp | ✓ | ✓ | −/− | P | PI | C | □ | 5 | N/A | 1700 | 75 |

| Tsang et al. (2016) [34] | 12 | 1 Wp/1 kWp | ✓ | ✓ | −/− | P | PI/IN | S | ■ | 5 | 25/5 | 1300 | 75 |

| PSC | |||||||||||||

| Celik et al. (2016) [35] | 3 | 1 kWh | ✓ | ✓ | −/✓ | P | IN | C | □ | 15 | 5 | 1700 | 75 |

| Espinosa et al. (2015) [36] | 2 | 1 kWh | ✓ | ✓ | ✓/✓ | C | L | C | □ | 11.5/15.4 | 1 | 1700 | N/A |

| Gong et al. (2015) [37] | 2 | 1 m² | ✓ | ✓ | −/− | P | PI/IN | M | ■ | 9.1/11 | 2 | 1960 | 80 |

| Serrano-Lujan et al. (2015) [38] | 3 | 1 kWh | ✓ | ✓ | ✓/✓ | C | L | C | □/■ | 6.4–9.2 | 1 | 1700 | 80 |

| Zhang et al. (2015) [39] | 3 | 1 cm² | − | ✓ | ✓/✓ | C | L | S | □ | 6.5 | N/A | N/A | N/A |

| Zhang et al. (2017) [40] | 10 | 1 cm² | ✓ | ✓ | ✓/✓ | C | L | S | ■ | 4.88–20.0 | 1 | 1700 | 75 |

| QDPV | |||||||||||||

| Şengül et Theis (2011) [41] | 1 | 1 m² | ✓ | ✓ | −/− | P | PI/IN | S | □ | 14 | 25 | 1700 | 80 |

| Harmonization Equations | Parameter/Units | Abbreviations | Standard Values | |

|---|---|---|---|---|

| Conversion of the reviewed KEYIs to W | ||||

| W = KEYIR · CF | (2) | Total life-cycle impacts of the LCA dataset in LCIA/m² | W | - |

| Reviewed key indicator in LCIA/FU | KEYIR | - | ||

| Conversion factor | CF | see Equations (3)–(5) | ||

| Conversion factors depending on the reviewed functional unit (FU) | ||||

| CF = 1 (FU = 1 m²) | (3) | |||

| CF = E · ɳR (FU = 1 Wp) | (4) | Light intensity in W/m² according to IEC 61215 [49] | E | 1000 |

| CF = ɳR· PRR · IR· τR (FU = 1 kWh) | (5) | Reviewed KEYPs | ɳR, PRR, IR, τR | - |

| Harmonization of the case "characterizing the status quo" | ||||

| (6) | Harmonized key indicator in Case “status quo“: LCIA/Wp Case “prospects”: LCIA/kWh | KEYIH | - | |

| Standard values of the KEYPs: • efficiency in % | ɳH | DSSC: 6 OPV/QDPV: 8 PSC: 12 | ||

| Harmonization of the case "possible future performance" | ||||

| (7) | • performance ratio in % | PRH | 80 | |

| • irradiation in kWh/(m²·year) | IH | 1700 | ||

| • lifetime in years | τH | - | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weyand, S.; Wittich, C.; Schebek, L. Environmental Performance of Emerging Photovoltaic Technologies: Assessment of the Status Quo and Future Prospects Based on a Meta-Analysis of Life-Cycle Assessment Studies. Energies 2019, 12, 4228. https://doi.org/10.3390/en12224228

Weyand S, Wittich C, Schebek L. Environmental Performance of Emerging Photovoltaic Technologies: Assessment of the Status Quo and Future Prospects Based on a Meta-Analysis of Life-Cycle Assessment Studies. Energies. 2019; 12(22):4228. https://doi.org/10.3390/en12224228

Chicago/Turabian StyleWeyand, Steffi, Carolin Wittich, and Liselotte Schebek. 2019. "Environmental Performance of Emerging Photovoltaic Technologies: Assessment of the Status Quo and Future Prospects Based on a Meta-Analysis of Life-Cycle Assessment Studies" Energies 12, no. 22: 4228. https://doi.org/10.3390/en12224228

APA StyleWeyand, S., Wittich, C., & Schebek, L. (2019). Environmental Performance of Emerging Photovoltaic Technologies: Assessment of the Status Quo and Future Prospects Based on a Meta-Analysis of Life-Cycle Assessment Studies. Energies, 12(22), 4228. https://doi.org/10.3390/en12224228