Analysis on Thermal Performance of Ground Heat Exchanger According to Design Type Based on Thermal Response Test

Abstract

:1. Introduction

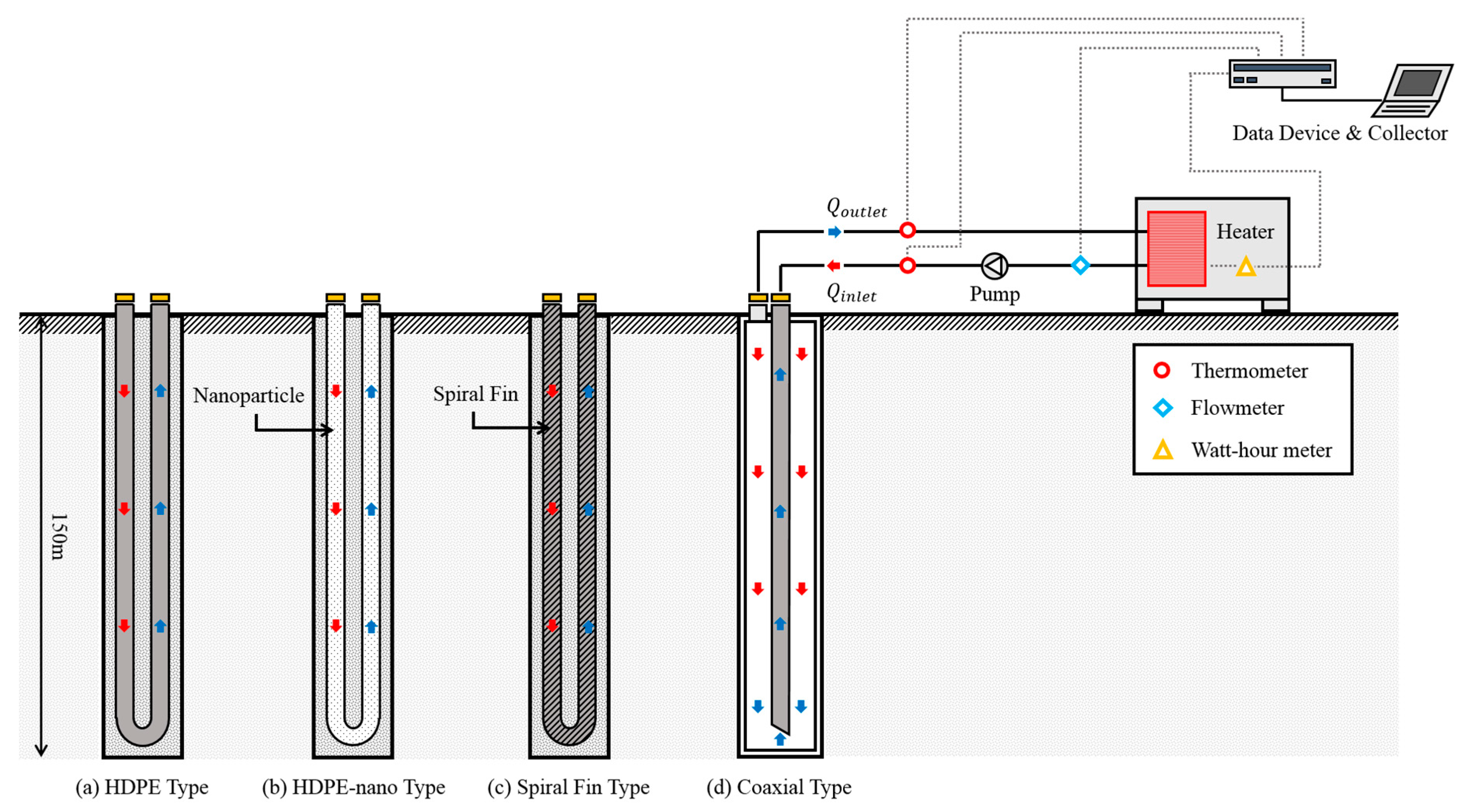

2. Field Experiment

2.1. Overview of Thermal Response Test

2.2. Assembly Procedure of the TRT

3. Thermal Response Test

3.1. Standards of Thermal Response Test

3.2. Thermal Response Test Theory

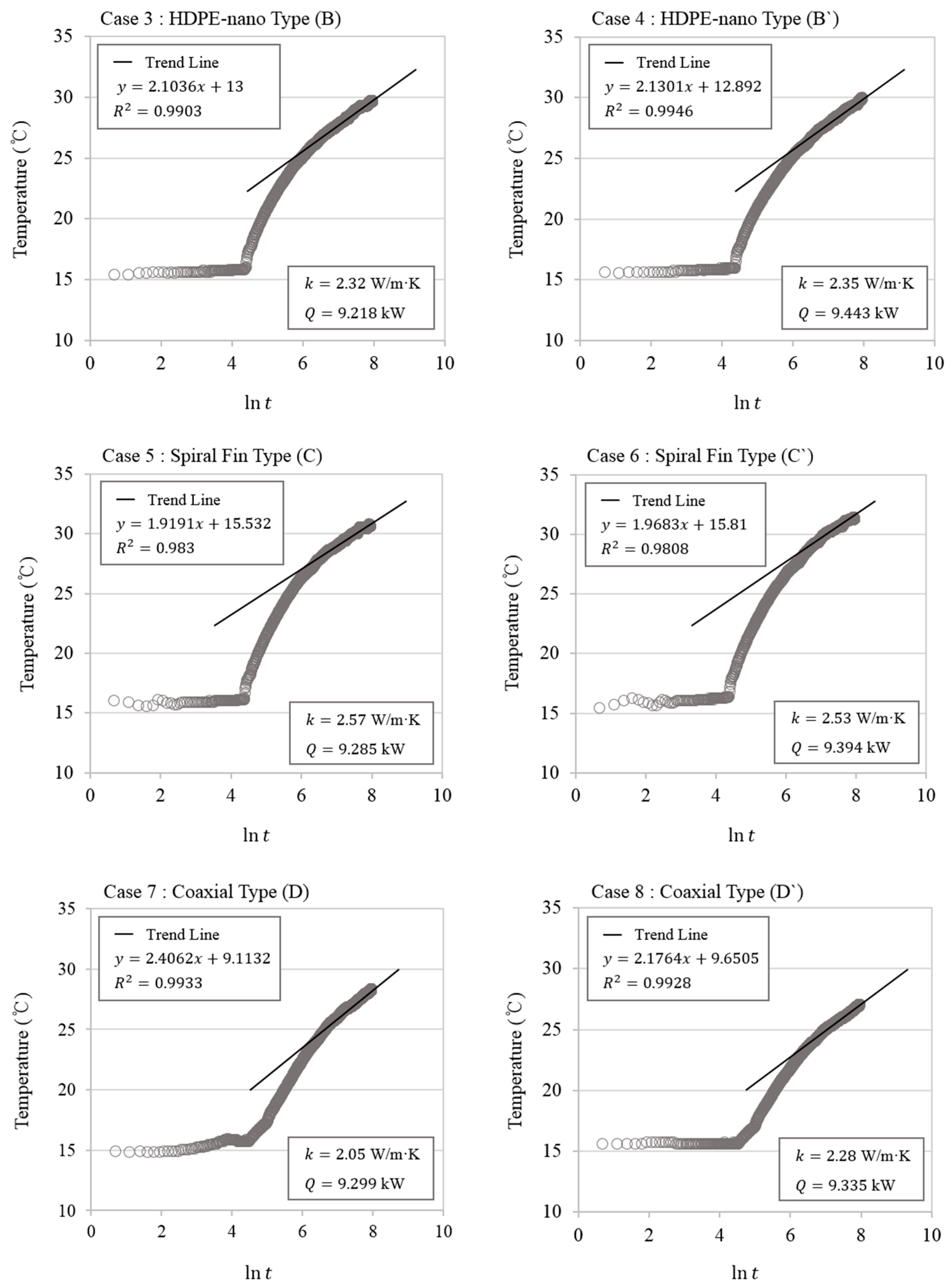

4. Results of Thermal Response Test

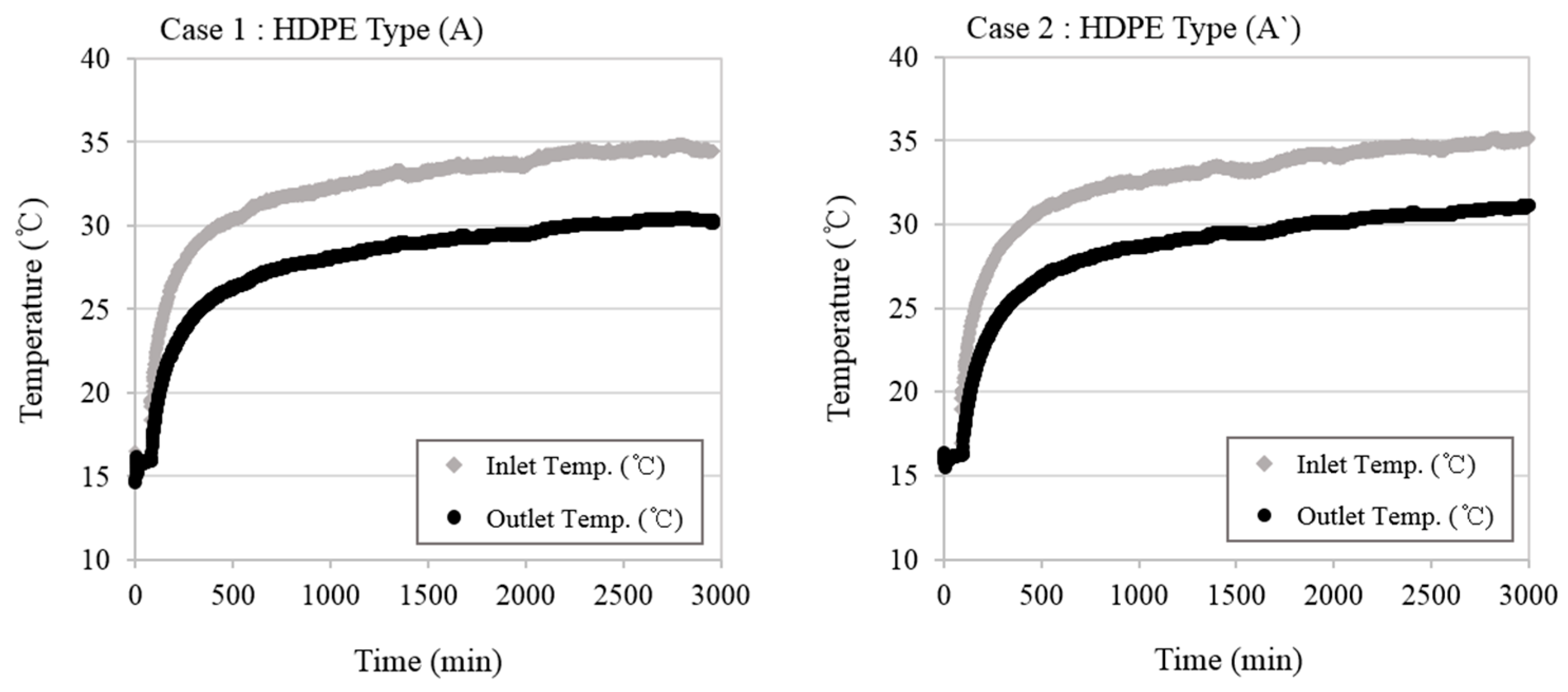

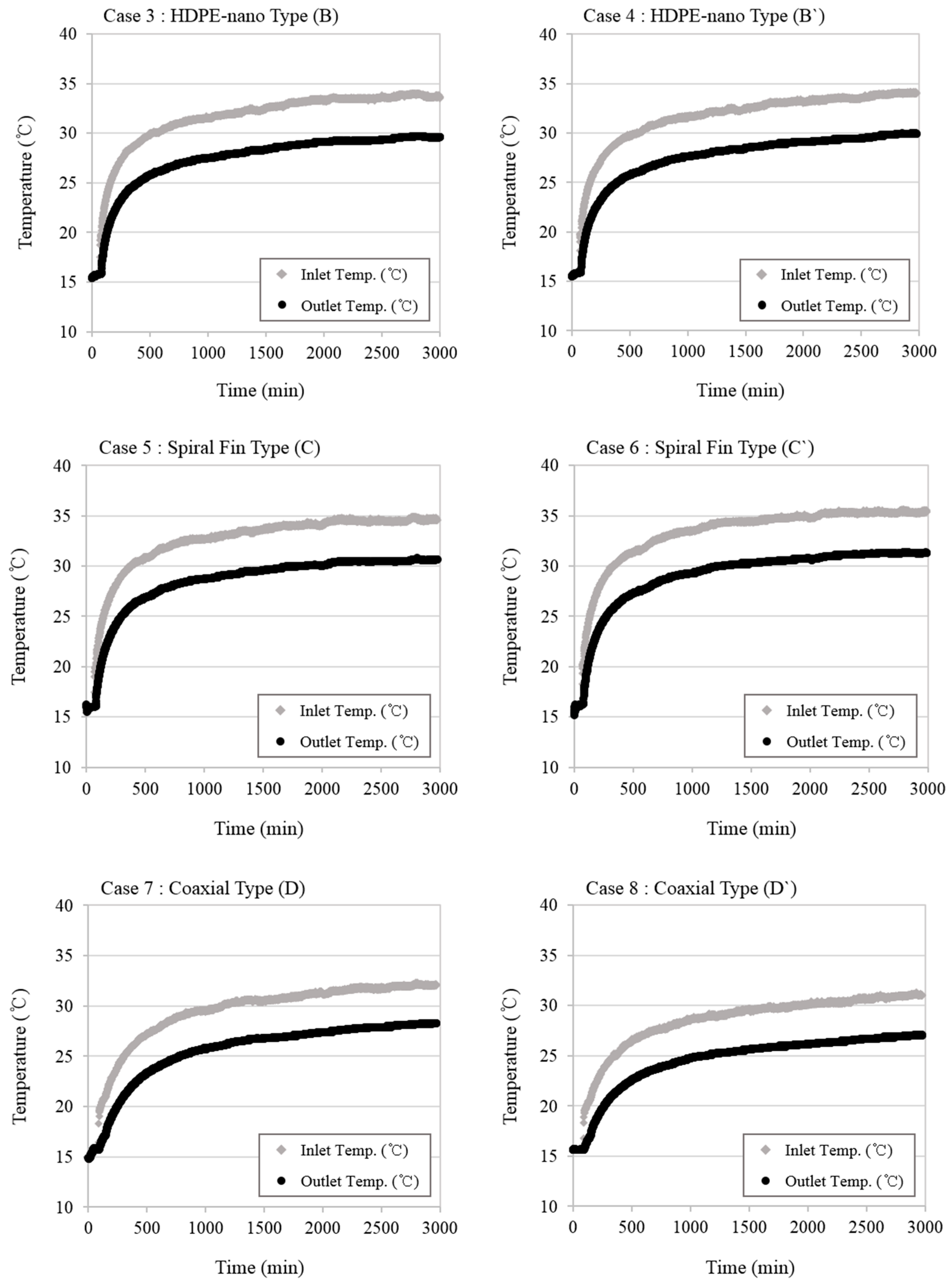

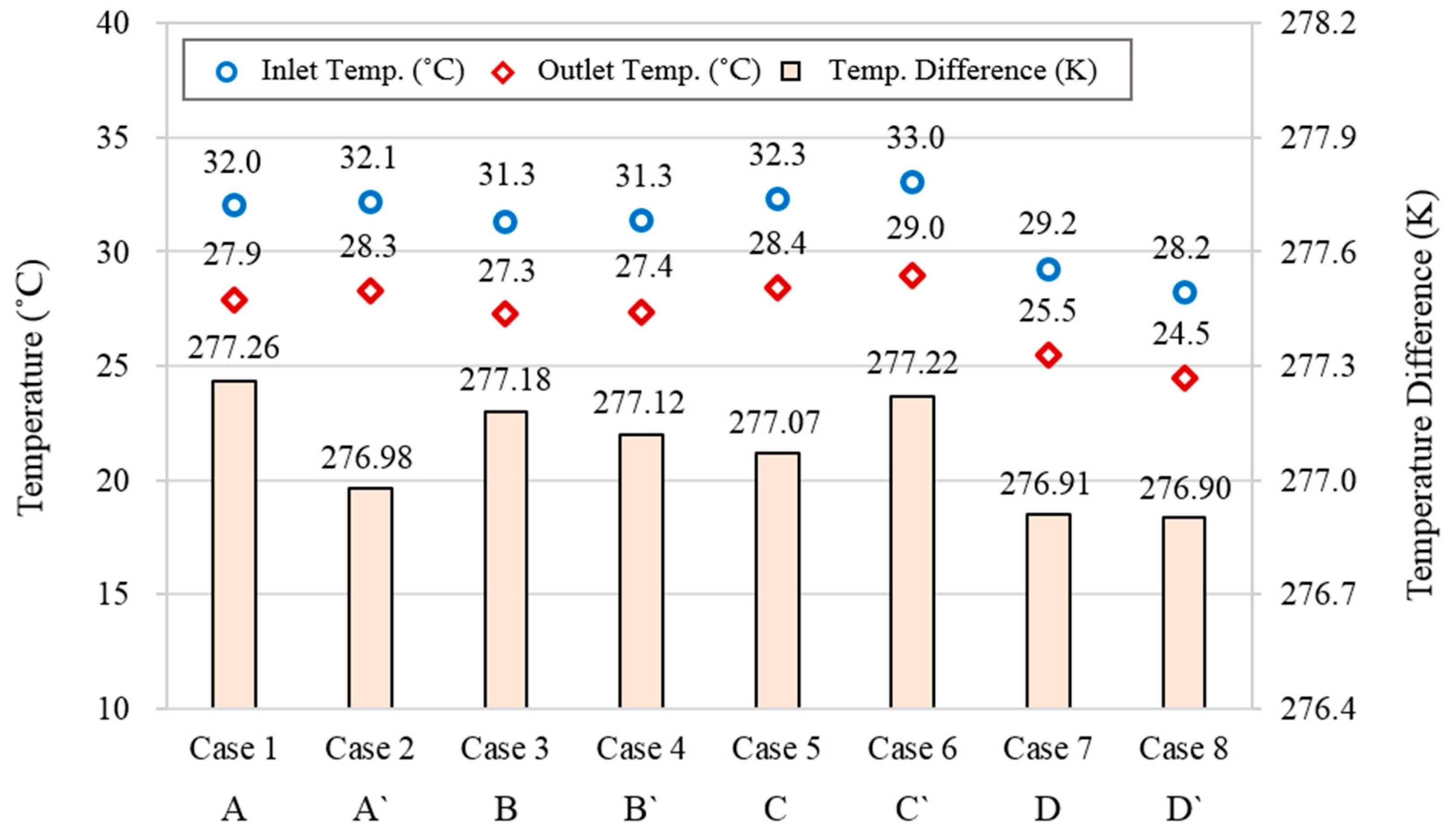

4.1. Temperature

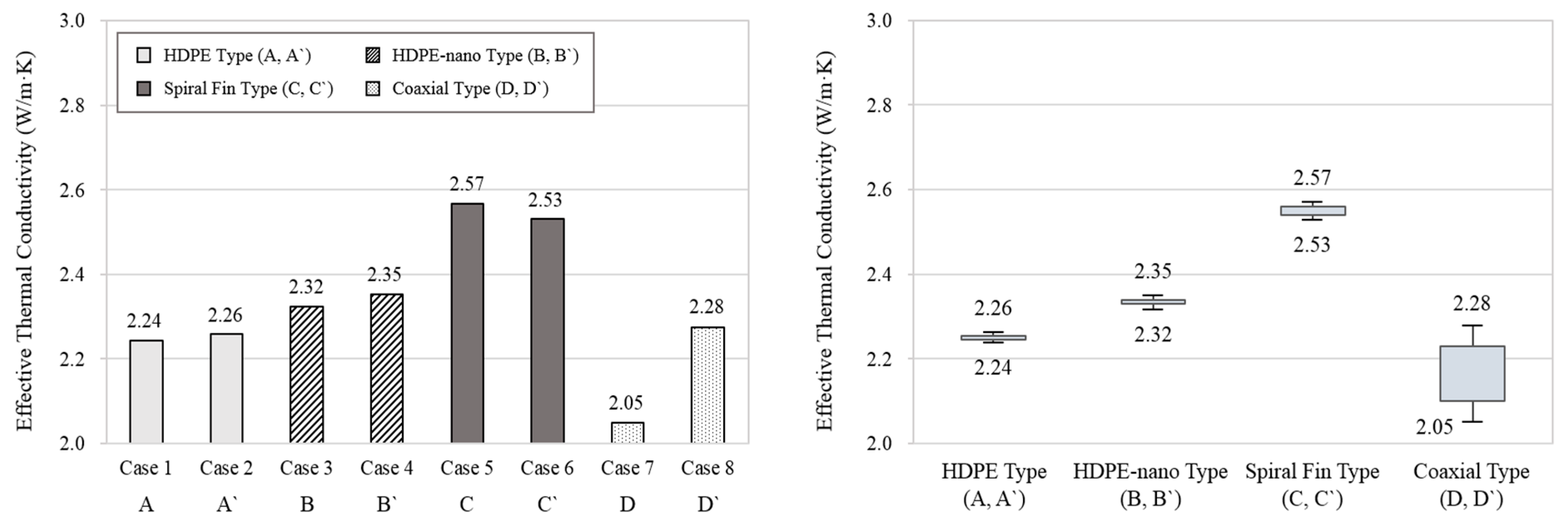

4.2. Effective Thermal Conductivity

5. Discussion of Thermal Response Test

5.1. Temperature and Effective Thermal Conductivity

5.2. Borehole Thermal Resistance

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ji, W.T.; Zhang, D.C.; He, Y.L.; Tao, W.Q. Prediction of fully developed turbulent heat transfer of international helically ribbed tubes—An extension of Gnielinski equation. Int. J. Heat Mass Transf. 2012, 55, 1375–1384. [Google Scholar] [CrossRef]

- Mensah, K.; Choi, J.M. Numerical analysis on the heat transfer characteristics of HDPE pipe with the variation of geometries for ground loop heat exchanger. Trans. Korea Soc. Geotherm. Energy Eng. 2016, 12, 33–39. [Google Scholar] [CrossRef]

- Saeidi, R.; Noorollahi, Y.; Esfahanian, V. Numerical simulation of a novel spiral type ground heat exchanger for enhancing heat transfer performance of geothermal heat pump. Energy Convers. Manag. 2018, 168, 296–307. [Google Scholar] [CrossRef]

- Oh, K.; Lee, S.; Park, S.; Han, S.I.; Choi, H. Field experiment on heat exchange performance of various coaxial-type ground heat exchangers considering construction conditions. Renew. Energy 2018. [Google Scholar] [CrossRef]

- Holmberg, H.; Acuña, J.; Næss, E.; Sønju, O.K. Thermal evaluation of coaxial deep borehole heat exchangers. Renew. Energy 2016, 97, 65–76. [Google Scholar] [CrossRef]

- Chen, S.; Mao, J.; Han, X. Heat transfer analysis of a vertical ground heat exchanger using numerical simulation and multiple regression model. Energy Build. 2016, 129, 81–91. [Google Scholar] [CrossRef]

- Pu, L.; Qi, D.; Li, K.; Tan, H.; Li, Y. Simulation study on the thermal performance of vertical U-tube heat exchangers for ground source heat pump system. Appl. Therm. Eng. 2015, 79, 202–213. [Google Scholar] [CrossRef]

- Li, M.; Zhang, L.; Liu, G. Estimation of thermal properties of soil and backfilling material from thermal response tests (TRTs) for exploiting shallow geothermal energy: Sensitivity, identifiability, and uncertainty. Renew. Energy 2019, 132, 1263–1270. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M. In-situ thermal response test for ground source heat pump system in Elazig, Turkey. Energy Build. 2009, 41, 395–401. [Google Scholar] [CrossRef]

- Franco, A.; Moffat, R.; Toledo, M.; Herrera, P. Numerical sensitivity analysis of thermal response tests (TRT) in energy piles. Renew. Energy 2016, 86, 985–992. [Google Scholar] [CrossRef]

- Lee, C.; Park, M.; Nguyen, T.B.; Sohn, B.; Choi, J.M.; Choi, H. Performance evaluation of closed-loop vertical ground heat exchangers by conducting in-situ thermal response tests. Renew. Energy 2012, 42, 77–83. [Google Scholar] [CrossRef]

- Miyara, A. Thermal performance and pressure drop of spiral-tube ground heat exchangers for ground-source heat pump. Appl. Therm. Eng. 2015, 90, 630–637. [Google Scholar] [CrossRef]

- Korea Institute of Geoscience and Mineral Resources. Geoscience Information System; Korea Institute of Geoscience and Mineral Resources: Daejeon, Korea, 2014. [Google Scholar]

- Bouhachina, B.; Saim, R.; Oztop, H.F. Numerical investigation of a novel tube design for the geothermal borehole heat exchanger. Appl. Therm. Eng. 2015, 79, 153–162. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 4427-1: Plastics Piping Systems—Polyethylene (PE) Pipes and Fittings for Water Supply; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- Kavanuagh, S.; Rafferty, K. Ground-Source Heat Pumps: Design of Geothermal Systems for Commercial and Institutional Buildings; ASHRAE: Atlanta, GA, USA, 1997. [Google Scholar]

- ASHRAE. ASHRAE Handbook: HVAC Applications; ASHRAE: Atlanta, GA, USA, 2007. [Google Scholar]

- Korea Energy Agency. Construction Standards for New and Renewable Energy Equipment; Korea Energy Agency: Kyeonggi-do, Korea, 2017. [Google Scholar]

- Austin, W.A. Development of an In Situ System for Measuring Ground Thermal Properties. Master’s Thesis, Oklahoma State University, Stillwater, OK, USA, 1998. [Google Scholar]

- Gehlin, S. Thermal Response Test Method Development and Evaluation. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2002. [Google Scholar]

- Bujok, P.; Grycz, D.; Klempa, M.; Kunz, A.; Prozer, M.; Pytlik, A.; Rozehnal, Z.; Vojcinák, P. Assessment of the influence of shortening the duration of TRT(thermal response test) on the precision of measured values. Energy 2014, 64, 120–129. [Google Scholar] [CrossRef]

- Ingersoll, L.R.; Plass, H.J. Theory of the ground pipe heat source for the heat pump. ASHVE Trans. 1948, 54, 339–348. [Google Scholar]

- Mogensen, P. Fluid to duct wall heat transfer in duct system heat storages. In Proceedings of the International Conference on Subsurface Heat Storage in Theory and Practice, Stockholm, Sweden, 6–8 June 1983; pp. 652–657. [Google Scholar]

- Sharqawy, M.H.; Mokheimer, E.M.; Habib, M.A.; Badr, H.M.; Said, S.A.; Al-Shayea, N.A. Energy, exergy and uncertainty analyses of the thermal response test for a ground heat exchanger. Int. J. Energy Res. 2008, 33, 582–592. [Google Scholar] [CrossRef]

- Wanger, R.; Clauser, C. Evaluating thermal response tests using parameter estimation for thermal conductivity and thermal capacity. J. Geophys. Eng. 2005, 2, 349–356. [Google Scholar]

- Chang, G.S.; Kim, M.J.; Kim, Y.J. A study on the thermal characteristics of horizontal ground heat exchanger using thermal response test. J. Korea Acad.-Ind. Cooper. Soc. 2016, 17, 24–30. [Google Scholar]

- Hwang, S.; Ooka, R.; Nam, Y. Evaluation of estimation method of ground properties for the ground source heat pump system. Renew. Energy 2010, 35, 2123–2130. [Google Scholar] [CrossRef]

- Signorelli, S.; Bassetti, S.; Pahud, D.; Kohl, T. Numerical evaluation of thermal response test. Geothermics 2007, 36, 141–166. [Google Scholar] [CrossRef]

- Lee, S.K.; Woo, J.S.; Kim, D.K. A study of determining initial ignoring time of line source model used in estimating the effective soil formation thermal conductivities. J. Energy Eng. 2008, 17, 167–174. [Google Scholar]

- Chang, G.S.; Kim, M.J.; Kim, Y.J. A study on the determining initial ignoring time for the analysis of ground thermal conductivity of SCW Type ground heat exchanger. Korean J. Air-Cond. Refrig. Eng. 2014, 26, 453–459. [Google Scholar]

- Sohn, B. Evaluation of ground effective thermal conductivity and borehole effective thermal resistance from simple line-source model. Korean J. Air-Cond. Refrig. Eng. 2007, 19, 512–520. [Google Scholar]

- Sohn, B. Evaluation of ground effective thermal properties and effect of borehole thermal resistance on performance of ground heat exchanger. Trans. Korea Soc. Geotherm. Energy Eng. 2012, 8, 32–40. [Google Scholar]

- Remmund, C. Borehole Thermal Resistance: Laboratory and Field Studies. In Proceedings of the ASHRAE Transactions, Seattle, WA, USA; 1999; Volume 105. [Google Scholar]

- Kavanaugh, S.; Rafferty, K. Geothermal heating and cooling: Design of ground-source heat pump systems. In Proceedings of the ASHRAE Transactions, New York, NY, USA; 2014; Volume 120. [Google Scholar]

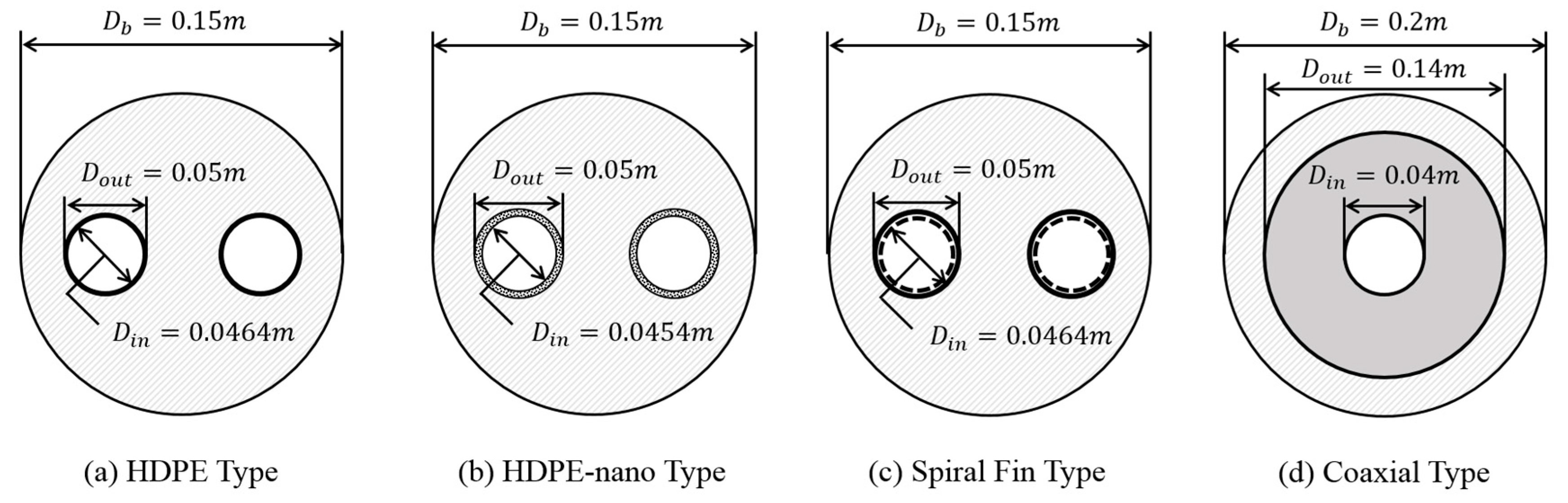

| Type of GHXs | Borehole Diameter (m) | Pipe Diameter (m) | Thermal Conductivity (W/m·K) |

|---|---|---|---|

| HDPE Type | 0.15 | = 0.05, = 0.0464 | 0.4 |

| HDPE-Nano Type | 0.15 | = 0.05, = 0.0454 | 0.55 |

| Spiral Fin Type | 0.15 | = 0.05, = 0.0464 | 0.4 |

| Coaxial Type | 0.2 | = 0.14, = 0.04 | 0.4 |

| Item | Measuring Equipment | Measurement Error |

|---|---|---|

| Flow Rate | Flowmeter (FLOW-300-25A) | ± 0.28% |

| Power Consumption | AC Ammeter (MT4Y-AA-43) | ± 0.02 A |

| AC Voltmeter (MT4Y-AV-34) | ± 0.3 V | |

| DC Ammeter (CM1-AD04VI) | ± 0.2 mA | |

| Wattmeter (DPM-TWAT-S1B1B1) | ± 0.01 kW | |

| Temperature | Thermometer (PT100) | ± 0.1 °C |

| Data Collector | Data Logger (CM1-RD04A) | ± 0.2 °C |

| Test Conditions | Value |

|---|---|

| Measurement Time | 2880 min |

| Time Step | 1 min |

| Fluid Type | Water |

| Average Flow Rate | 33.6 l/min |

| Average Initial Ground Temp. | 15.8 °C |

| Average Amount of Heat Injection | 9342 W |

| Grout Thermal Resistance (m·K/W) | Fluid Thermal Resistance (m·K/W) | Pipe Thermal Resistance (m·K/W) | Borehole Thermal Resistance (m·K/W) | |

|---|---|---|---|---|

| Case 1 | 0.1507 | 0.0025 | 0.0297 | 0.1829 |

| Case 2 | 0.1507 | 0.0024 | 0.0297 | 0.1828 |

| Case 3 | 0.1507 | 0.0025 | 0.0279 | 0.1811 |

| Case 4 | 0.1507 | 0.0024 | 0.0279 | 0.1810 |

| Case 5 | 0.1507 | 0.0004 | 0.0297 | 0.1808 |

| Case 6 | 0.1507 | 0.0004 | 0.0297 | 0.1808 |

| Case 7 | 0.0767 | 0.0065 | 0.2227 | 0.3059 |

| Case 8 | 0.0767 | 0.0065 | 0.2227 | 0.3059 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, S.M.; Nam, Y.; Choi, J.M.; Lee, K.H.; Choi, J.S. Analysis on Thermal Performance of Ground Heat Exchanger According to Design Type Based on Thermal Response Test. Energies 2019, 12, 651. https://doi.org/10.3390/en12040651

Bae SM, Nam Y, Choi JM, Lee KH, Choi JS. Analysis on Thermal Performance of Ground Heat Exchanger According to Design Type Based on Thermal Response Test. Energies. 2019; 12(4):651. https://doi.org/10.3390/en12040651

Chicago/Turabian StyleBae, Sang Mu, Yujin Nam, Jong Min Choi, Kwang Ho Lee, and Jae Sang Choi. 2019. "Analysis on Thermal Performance of Ground Heat Exchanger According to Design Type Based on Thermal Response Test" Energies 12, no. 4: 651. https://doi.org/10.3390/en12040651