Thermoelectric Energy Recovery in a Light-Duty Diesel Vehicle under Real-World Driving Conditions at Different Altitudes with Diesel, Biodiesel and GTL Fuels

Abstract

:1. Introduction

2. Experimental Work

2.1. Vehicle and Experimental Equipment

2.2. Thermoelectric Generator

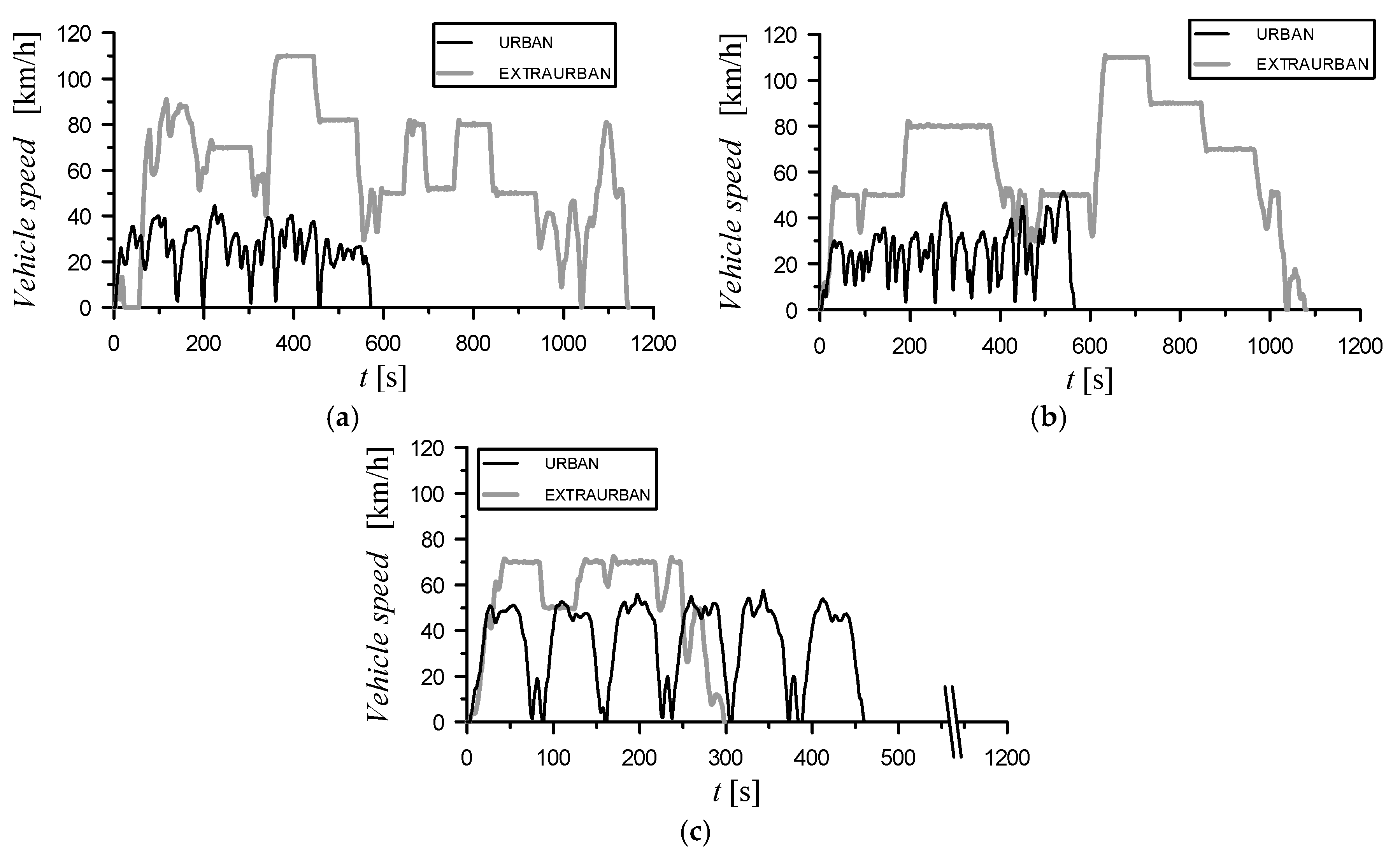

2.3. Locations and Description of the Circuits for Testing

- The maximum grade (slope) between any points of the circuit will not be more than 2% in order to avoid negative or positive steep grades.

- The test circuit must be defined inside an urban part of a city and should have different types of signals in its streets (stops, traffic lights, yields, etc.).

- The test circuit should have parts with traffic congestion, typical of the city center (velocity normally below the limits) and parts without congestion (velocity normally near the limits).

- The length of the test circuit must have an equivalent distance traveled by a light-duty vehicle under Urban Driving Cycle (UDC) of the NEDC (approximately 4 ± 1 km).

- The combination of criteria 3 and 4 must provide a test time of around 10 min.

- The maximum grade (slope) between any points of the circuit will not be more than 5% in order to avoid negative or positive steep grades.

- The test circuit should include segments oriented to all directions (north, south, east and west) and with the possibility to be run in both directions. This criterion allows the vehicle to be driven against dominant winds on the different parts of the test circuit.

- Length of the test circuit must be approximately 3 times the equivalent distance traveled by a light-duty vehicle under the Extra Urban Driving Cycle (EUDC) of the NEDC (3 × 7 km of EUDC ± 3 km = 21 ± 3 km). This criterion allows the vehicle to meet criterion 4.

- The selected circuit must allow for the testing of the vehicle at different constant velocities (for example 50, 70, 80, 90 and 110 or 120 km/h) fixed by means of the cruise control during at least 1.5–2 km for each velocity.

- The combination of criteria 3 and 4 must provide a test time of between 1520 min.

2.4. Vehicle Pre-Conditioning

2.5. Data Sampling and Processing

2.6. Tested Fuels

3. Methodology for Determining the Energy Recovery Potential

4. Thermoelectric Fuel Savings Calculation

5. Results and Discussion

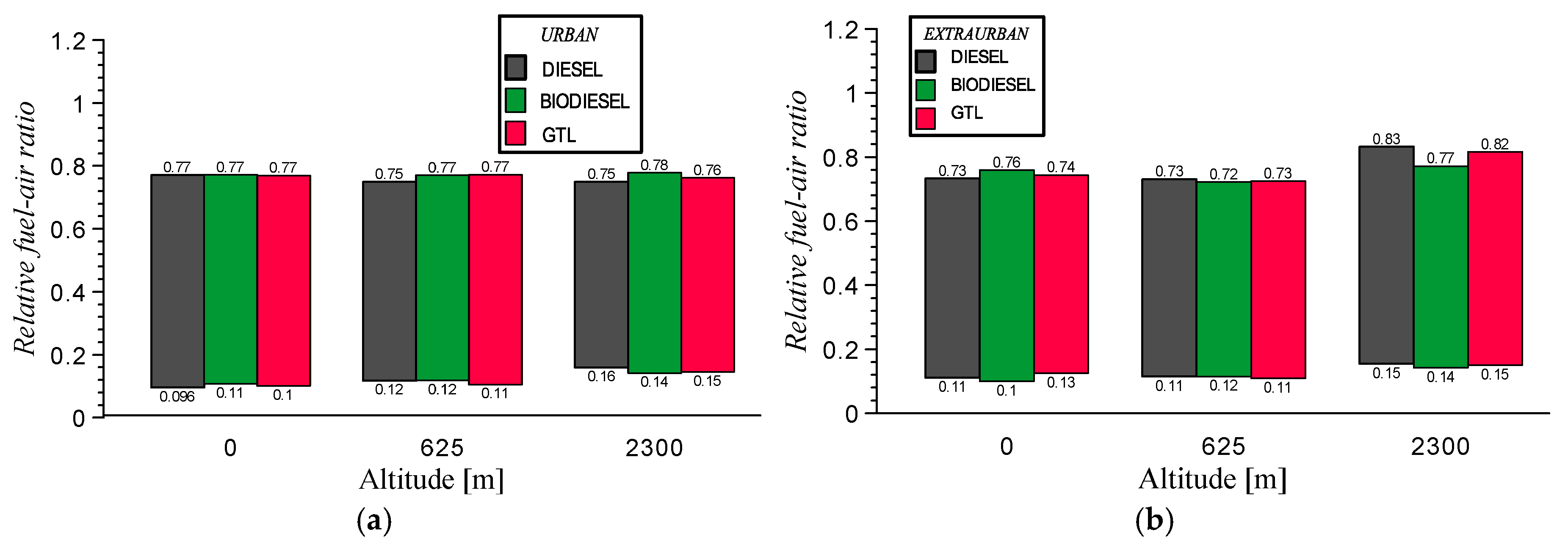

5.1. Exhaust Gas Characterization

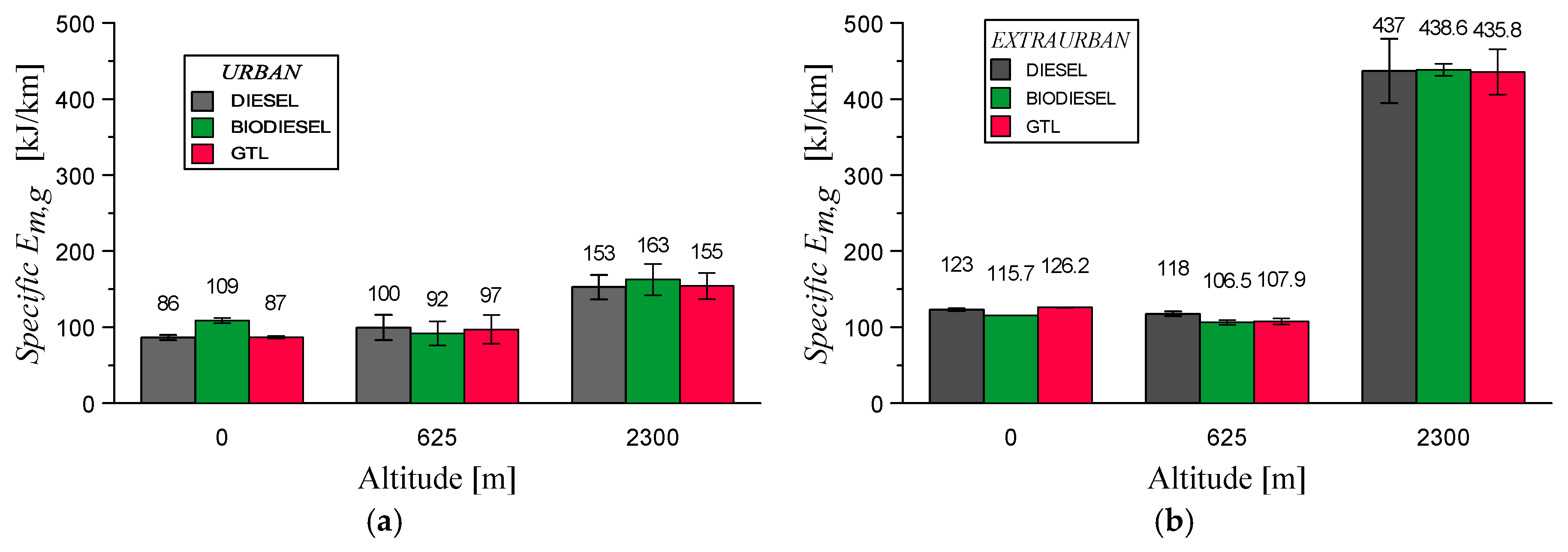

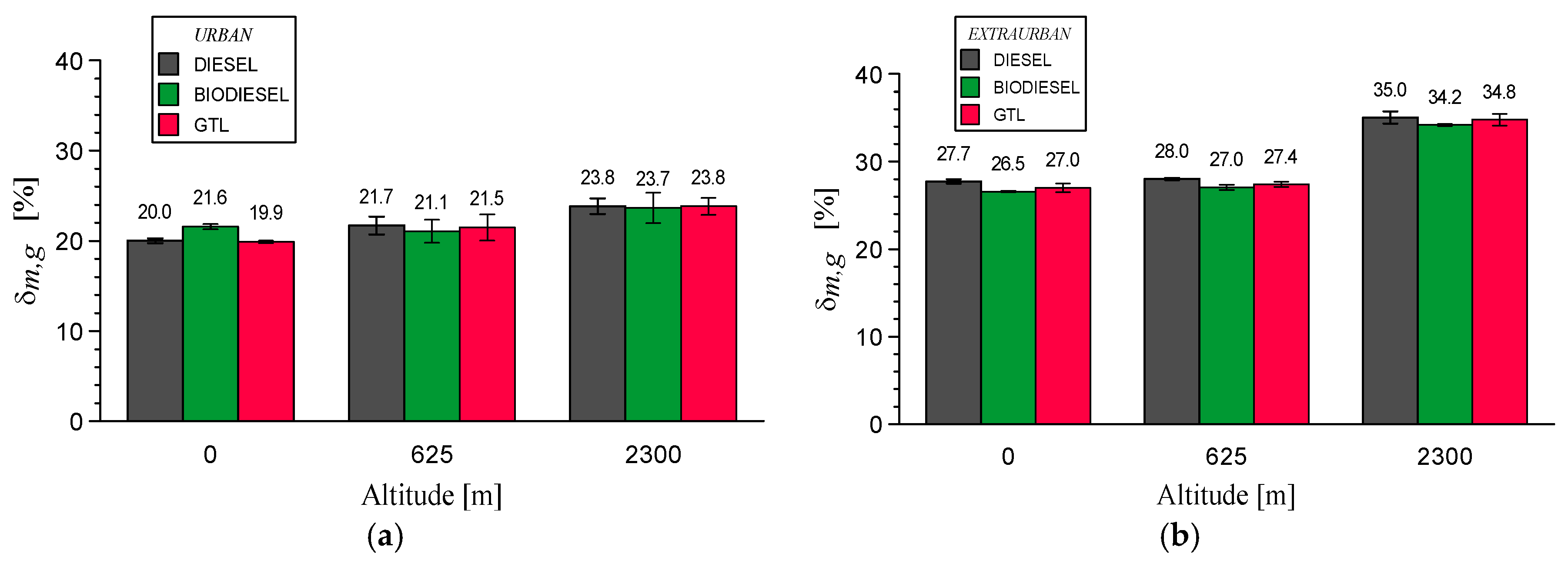

5.2. Exhaust Gas Exergy

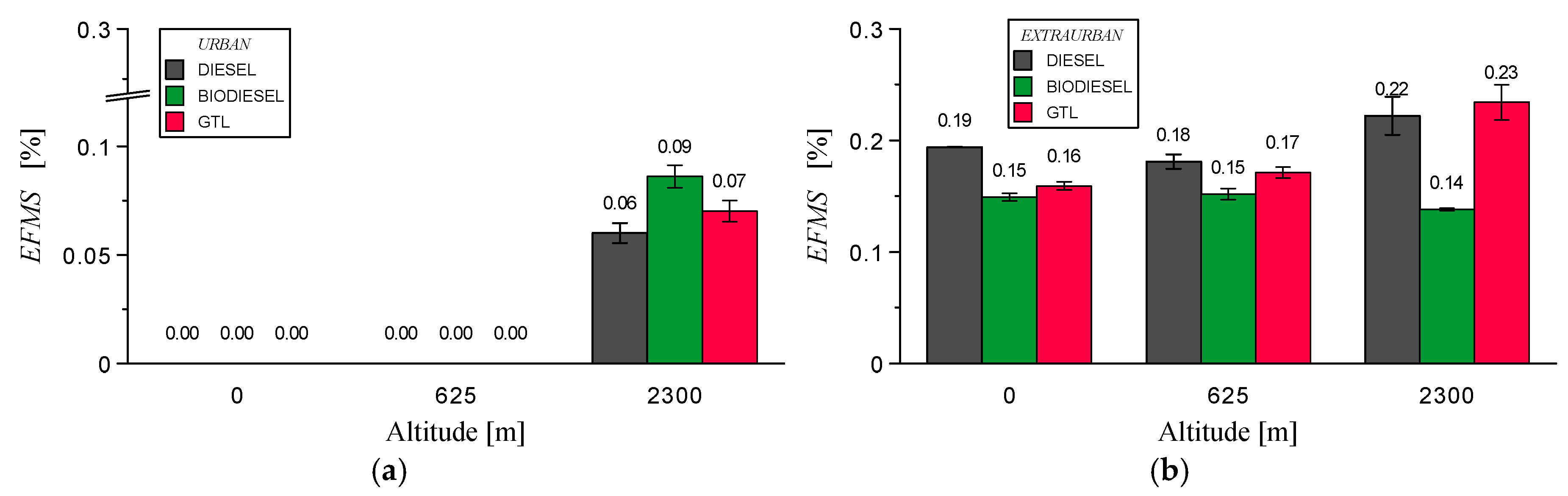

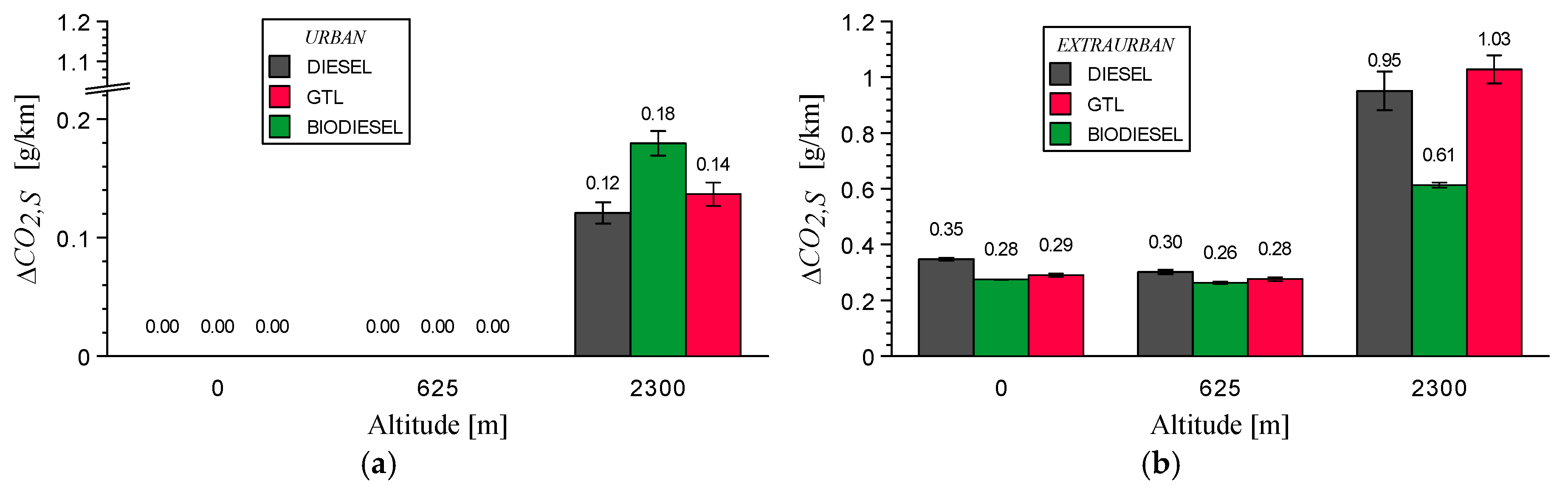

5.3. Fuel Savings

6. Conclusions

- (i)

- Up to 2300 masl, the expected exhaust gas temperature, downstream of the post-treatment devices (in this case, DPF), varies within the range 140–400 °C independently of the fuel tested (diesel, biodiesel and GTL fuels).

- (ii)

- The potential for energy recovery is always higher under extra-urban driving conditions at all altitudes tested due to the higher engine load and, consequently, higher temperatures and gas mass flow rates reached. This result is particularly important at high altitudes when the EGR valve is closed.

- (iii)

- Similar results were obtained between 0 and 625 masl for total exergy, exergy to energy ratio of gases, and fuel mass savings. This indicates that this altitude range, which corresponds to most European capital cities, does not have a significant effect on the potential for energy recovery.

- (iv)

- A total of 20–30% is the proportion of the energy of exhaust gases that could be converted into useful work in a recovery system coupled to the exhaust system of a current light-duty diesel vehicle.

- (v)

- Independently of the altitude, fuel mass savings can reach up to 0.2% in extra-urban driving conditions, while under urban driving conditions, the mean fuel savings are close to zero. Although these values are low, the use of TEG does not penalize fuel consumption. This result is valid for the TEG material and heat exchanger used in this work.

- (vi)

- The low efficiency of current commercial thermoelectric materials causes low values of recovered energy in real driving conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Increase in the total fuel mass-flow to provide electric energy (alternator) (g/s) | |

| Increase in the total fuel mass-flow to provide electric energy (thermoelectric generator) (g/s) | |

| Fuel mass saving (g) | |

| Dcycle | Distance traveled (km) |

| Exergy (J) | |

| Exergy rate (W) | |

| Specific enthalpy (J/kg) | |

| Enthalpy - Energy (J) | |

| Lower heating value (J/kg) | |

| Total fuel mass-flow rate of the engine using an alternator (baseline conditions) (g/s) | |

| Electric power output (W) | |

| Engine pumping losses (W) | |

| Net power output (W) | |

| SECO2,F | Specific emissions of CO2 (g CO2/g fuel) |

| Exergy to energy ratio | |

| η | Efficiency |

| alt | Alternator |

| eng | Engine |

| Dead state conditions, initial conditions | |

| Exhaust gases | |

| Losses in the components | |

| Mean (time average) | |

| s | Saving |

Abbreviations

| DOC | Diesel oxidation catalyst |

| DPF | Diesel particle filter |

| EFMS | Estimated fuel mass saving |

| EFVS | Estimated fuel volume saving |

| EGR | Exhaust gas recirculation |

| ETG | Electrical turbo-generation (or generator) |

| masl | Meters above sea level |

| NEDC | New European Driving Cycle |

| ORC | Organic Rankine Cycle |

| TEG | Thermoelectric generator |

References

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2009, 5, 2009.

- Wakode, V.R.; Kanase-Patil, A.B. Regression analysis and optimization of diesel engine performance for change in fuel injection pressure and compression ratio. Appl. Therm. Eng. 2017, 113, 322–333. [Google Scholar] [CrossRef]

- Li, X.; Zhou, H.; Zhao, L.M.; Su, L.; Xu, H.; Liu, F. Effect of split injections coupled with swirl on combustion performance in DI diesel engines. Energy Convers. Manag. 2016, 129, 180–188. [Google Scholar] [CrossRef]

- Ramos, Á.; García-Contreras, R.; Armas, O. Performance, combustion timing and emissions from a light duty vehicle at different altitudes fueled with animal fat biodiesel, GTL and diesel fuels. Appl. Energy 2016, 182, 507–517. [Google Scholar] [CrossRef]

- Guarieiro, L.L.N.; de Almeida Guerreiro, E.T.; dos Santos Amparo, K.K.; Manera, V.B.; Regis, A.C.D.; et al. Assessment of the use of oxygenated fuels on emissions and performance of a diesel engine. Microchem. J. 2014, 117, 94–99. [Google Scholar] [CrossRef]

- Liu, S.; Shen, L.; Bi, Y.; Lei, J. Effects of altitude and fuel oxygen content on the performance of a high pressure common rail diesel engine. Fuel 2014, 118, 243–249. [Google Scholar] [CrossRef]

- Battista, D.D.; Mauriello, M.; Cipollone, R. Waste heat recovery of an ORC-based power unit in a turbocharged diesel engine propelling a light duty vehicle. Appl. Energy 2015, 152, 109–120. [Google Scholar] [CrossRef]

- Formula One Power Unit Regulations 2014. Available online: https://www.fia.com/sites/default/files/publication/file/FIA%20F1%20Power%20Unit%20leaflet.pdf (accessed on 20 March 2019).

- Zheng, A.X.F.; Liu, C.X.; Yan, Y.Y.; Wang, Q. Review of thermoelectrics research—Recent developments and potentials for sustainable and renewable energy applications. Renew. Sustain. Energy Rev. 2014, 32, 486–503. [Google Scholar] [CrossRef]

- Wei, D.; Lu, X.; Lu, Z.; Gu, J. Performance analysis and optimization of organic Rankine cycle (ORC) for waste heat recovery. Energy Convers. Manag. 2007, 48, 1113–1119. [Google Scholar] [CrossRef]

- Comamala, M.; Cózar, I.R.; Massaguer, A.; Massaguer, E.; Pujol, T. Effects of Design Parameters on Fuel Economy and Output Power in an Automotive Thermoelectric Generator. Energies 2018, 11, 3274. [Google Scholar] [CrossRef]

- Thacher, E.F.; Helenbrook, B.T.; Karri, M.A.; Richter, C.J. Testing of an automobile exhaust thermoelectric generator in a light truck. Proc. Inst. Mech. Eng. 2007, 221, 95–107. [Google Scholar] [CrossRef]

- Bell, LE. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef]

- Legros, A.; Guillaume, L.; Diny, M.; Zaïdi, H.; Lemort, V. Comparison and impact of waste heat recovery technologies on passenger car fuel consumption in a normalized driving cycle. Energies 2014, 7, 5273–5290. [Google Scholar] [CrossRef]

- Ando Junior, O.; Calderon, N.; de Souza, S. Characterization of a thermoelectric generator (TEG) system for waste heat recovery. Energies 2018, 11, 1555. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Armas, O.; Kiwan, R.; Stefanopoulou, A.G.; Boehman, A.L. A thermoelectric generator in exhaust systems of spark-ignition and compression-ignition engines. A comparison with an electric turbo-generator. Appl. Energy 2018, 229, 80–87. [Google Scholar] [CrossRef]

- Shu, G.; Zhao, J.; Tian, H.; Liang, X.; Wei, H. Parametric and exergetic analysis of waste heat recovery system based on thermoelectric generator and organic rankine cycle utilizing R123. Energy 2012, 45, 806–816. [Google Scholar] [CrossRef]

- Kishita, Y.; Ohishi, Y.; Uwasu, M.; Kuroda, M. Evaluating the life cycle CO2 emissions and costs of thermoelectric generators for passenger automobiles: A scenario analysis. J. Clean. Prod. 2016, 126, 607–619. [Google Scholar] [CrossRef]

- Yu, R.; De Vaulx, C.; Aixala, L. Waste heat recovery by thermoelectricity on passenger car and heavy-duty truck diesel engine: The RENOTER project. In Diesel Powertrain Innovative Technologies for Future Emissions. France. 2012, pp. 1–8. Available online: https://www.researchgate.net/publication/295490897_Waste_heat_recovery_by_thermoelectricity_on_passenger_car_and_heavy-duty_truck_diesel_engine_the_RENOTER_project (accessed on 20 March 2019).

- Twaha, S.; Zhu, J.; Yan, Y.; Li, B. A comprehensive review of thermoelectric technology: Materials, applications, modelling and performance improvement. Renew. Sustain. Energy Rev. 2016, 65, 698–726. [Google Scholar] [CrossRef] [Green Version]

- Demir, M.E.; Dincer, I. Performance assessment of a thermoelectric generator applied to exhaust waste heat recovery. Appl. Therm. Eng. 2017, 120, 694–707. [Google Scholar] [CrossRef]

- Kempf, N.; Zhang, Y. Design and optimization of automotive thermoelectric generators for maximum fuel efficiency improvement. Energy Convers. Manag. 2016, 121, 224–231. [Google Scholar] [CrossRef] [Green Version]

- Massaguer, A.; Massaguer, E.; Comamala, M.; Pujol, T.; González, J.R.; Cárdenas, M.D.; Carbonell, D.; Bueno, A.J. A method to assess the fuel economy of automotive thermoelectric generators. Appl. Energy 2018, 222, 42–58. [Google Scholar]

- Fernández-Yañez, P.; Armas, O.; Capetillo, A.; Martínez-Martínez, S. Thermal analysis of a thermoelectric generator for light-duty diesel engines. Appl. Energy 2018, 226, 690–702. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Second-law analyses applied to internal combustion engines operation. Prog. Energy Combust. Sci. 2006, 32, 2–47. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Akram, A.; Karimi, M.; Najafi, G. Exergy and Energy Analysis of Combustion of Blended Levels of Biodiesel, Ethanol and Diesel Fuel in a DI Diesel Engine. Appl. Therm. Eng. 2016, 99, 720–729. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Gómez, A.; García-Contreras, R.; Armas, O. Evaluating thermoelectric modules in diesel exhaust systems: Potential in urban and extra-urban driving conditions. J. Clean. Prod. 2018, 182, 1070–1079. [Google Scholar] [CrossRef]

- Boretti, A.A. Transient operation of internal combustion engines with Rankine waste heat recovery systems. Appl. Therm. Eng. 2012, 48, 18–23. [Google Scholar] [CrossRef]

- Agudelo, A.F.; García-Contreras, R.; Agudelo, J.R.; Armas, O. Potential for exhaust gas energy recovery in a diesel passenger car under European driving cycle. Appl. Energy 2016, 174, 201–212. [Google Scholar] [CrossRef]

- Caliskan, H.; Tat, M.E.; Hepbasli, A. Performance assessment of an internal combustion engine at varying dead (reference) state temperatures. Appl. Therm. Eng. 2009, 29, 3431–3436. [Google Scholar] [CrossRef]

- Perez, P.L.; Boehman, A.L. Performance of a single-cylinder diesel engine using oxygen-enriched intake air at simulated high-altitude conditions. Aerosp. Sci. Technol. 2010, 14, 83–94. [Google Scholar] [CrossRef]

- Agudelo, J.; Agudelo, A.; Pérez, J. Energy and exergy analysis of a light duty diesel engine operating at different altitudes. Rev. Facult. Ing. Univ. Antioq. 2009, 48, 45–54. [Google Scholar]

- Wang, X.; Ge, Y.; Yu, L.; Feng, X. Effects of altitude on the thermal efficiency of a heavy-duty diesel engine. Energy 2013, 59, 543–548. [Google Scholar] [CrossRef]

- Çakmak, A.; Bilgin, A. Exergy and energy analysis with economic aspects of a diesel engine running on biodiesel-diesel fuel blends. Int. J. Exergy 2017, 24, 151–172. [Google Scholar] [CrossRef]

- Paul, A.; Panua, R.; Debroy, D. An experimental study of combustion, performance, exergy and emission characteristics of a CI engine fueled by Diesel-ethanol-biodiesel blends. Energy 2017, 141, 839–852. [Google Scholar] [CrossRef]

- López, I.; Quintana, C.E.; Ruiz, J.J.; Cruz-Peragón, F.; Dorado, M.P. Effect of the use of olive–pomace oil biodiesel/diesel fuel blends in a compression ignition engine: Preliminary exergy analysis. Energy Convers. Manag. 2014, 25, 227–233. [Google Scholar] [CrossRef]

- Nabi, M.N.; Rasul, M.G. Influence of second generation biodiesel on engine performance, emissions, energy and exergy parameters. Energy Convers. Manag. 2018, 169, 326–333. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Khalife, E.; Shojaei, T.R.; Dadak, A. Exergoeconomic analysis of a DI diesel engine fueled with diesel/biodiesel (B5) emulsions containing aqueous nano cerium oxide. Energy 2018, 149, 967–978. [Google Scholar] [CrossRef]

- Benjumea, P.; Agudelo, J.; Agudelo, A. Effect of altitude and palm oil biodiesel fuelling on the performance and combustion characteristics of a HSDI diesel engine. Fuel 2009, 88, 725–731. [Google Scholar] [CrossRef]

- Tat, M.E. Cetane number effect on the energetic and exergetic efficiency of a diesel engine fuelled with biodiesel. Fuel Process. Technol. 2011, 92, 1311–1321. [Google Scholar] [CrossRef]

- Ramos, A.; Muñoz, J.; Armas, O.; Andrés, F. NOx emissions from diesel light duty vehicle tested under NEDC and real-world driving conditions. Transp. Res. D Transp. Environ. 2018, 63, 37–48. [Google Scholar] [CrossRef]

- Fairbanks, J. Automotive Thermoelectric Generators and HVAC. In 2013 Annual Merit Review and Peer Evaluation Meeting; DOE Vehicle Technologies Office: Washington, DC, USA, 2013. [Google Scholar]

- Armas, O.; García-Contreras, R.; Ramos, A. On-line thermodynamic diagnosis of diesel combustion process with paraffinic fuels in a vehicle tested under NEDC. J. Clean. Prod. 2016, 138, 94–102. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, A. Emissions of Light Duty Vehicle Tested under Urban and Extraurban Real-World Driving Conditions with Diesel, Animal Fat Biodiesel and GTL fuels. SAE Tech. Paper 2013. [Google Scholar] [CrossRef]

- Karri, M.A.; Thacher, E.F.; Helenbrook, B.T. Exhaust energy conversion by thermoelectric generator: Two case studies. Energy Convers. Manag. 2011, 52, 1596–1611. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, A.; López, A.F. Impact of animal fat biodiesel, GTL and HVO fuel son combustion, performance and pollutant emissions of a light-duty diesel vehicle tested under the NEDC. J. Energy Eng.-ASCE 2015, 141, C4014009. [Google Scholar] [CrossRef]

- Al-Najem, N.; Diab, J. Energy-exergy analysis of a diesel engine. Heat Recover. Syst. CHP 1992, 12, 525–529. [Google Scholar] [CrossRef]

- Diesel Prices in Europe, l. Global Petrol Prices. Available online: http://www.globalpetrolprices.com/diesel_prices/Europe/ (accessed on 14 February 2019).

| Vehicle | |

| Effective frontal area (Cd × A) | 0.83 m2 |

| Weight (including devices and operators) | 2025 kg |

| Engine | |

| Cylinders | 4 |

| Displacement | 1994 cm3 |

| Bore | 84 mm |

| Stroke | 90 mm |

| Power max. | 110 kW at 4000 min−1 |

| Torque max. | 323 Nm at 2000 min−1 |

| Transmission | |

| Type | Manual, 6 gears |

| 1st gear ratio | 3.727 |

| 2nd gear ratio | 2.043 |

| 3rd gear ratio | 1.322 |

| 4th gear ratio | 0.947 |

| 5th gear ratio | 0.723 |

| 6th gear ratio | 0.596 |

| Differential ratio | 4.266 |

| Tyres | |

| Code | 215/65R16 |

| Injection system | |

| Injection pressure | 1600 bar (Maximum) |

| Number of nozzle holes | 5 |

| Properties | DIESEL | BIODIESEL | GTL |

|---|---|---|---|

| Molecular Formula | C14.62H26.87O0.08 | C18.41H37.23O2 | C16.89H35.77 |

| Molecular Weight (g/mol) | 203.7 | 290.7 | 238.9 |

| H/C Ratio | 1.84 | 2.02 | 2.12 |

| Stoichiometric Fuel/Air Ratio | 1/14.45 | 1/12.70 | 1/14.95 |

| C (% w/w) | 86.14 | 76.14 | 84.82 |

| H (% w/w) | 13.2 | 12.83 | 15.18 |

| O (% w/w) | 0.66 | 11.03 | 0 |

| Density at 15 °C (kg/m3) (EN ISO 12185) | 845 | 877 | 774 |

| Viscosity at 40 °C (cSt) (EN ISO 3104) | 2.51 | 4.03 | 2.34 |

| Lower Mass Heating Value (MJ/Kg) | 42.43 | 36.83 | 44.03 |

| Lower Volumetric Heating Value (MJ/L) | 35.85 | 32.29 | 34.08 |

| CFPP (°C) (EN 116) | −16 | 3 | −7 |

| Derived Cetane Number | 54.2 | 65.6 | 89.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Contreras, R.; Agudelo, A.; Gómez, A.; Fernández-Yáñez, P.; Armas, O.; Ramos, Á. Thermoelectric Energy Recovery in a Light-Duty Diesel Vehicle under Real-World Driving Conditions at Different Altitudes with Diesel, Biodiesel and GTL Fuels. Energies 2019, 12, 1105. https://doi.org/10.3390/en12061105

García-Contreras R, Agudelo A, Gómez A, Fernández-Yáñez P, Armas O, Ramos Á. Thermoelectric Energy Recovery in a Light-Duty Diesel Vehicle under Real-World Driving Conditions at Different Altitudes with Diesel, Biodiesel and GTL Fuels. Energies. 2019; 12(6):1105. https://doi.org/10.3390/en12061105

Chicago/Turabian StyleGarcía-Contreras, Reyes, Andrés Agudelo, Arántzazu Gómez, Pablo Fernández-Yáñez, Octavio Armas, and Ángel Ramos. 2019. "Thermoelectric Energy Recovery in a Light-Duty Diesel Vehicle under Real-World Driving Conditions at Different Altitudes with Diesel, Biodiesel and GTL Fuels" Energies 12, no. 6: 1105. https://doi.org/10.3390/en12061105

APA StyleGarcía-Contreras, R., Agudelo, A., Gómez, A., Fernández-Yáñez, P., Armas, O., & Ramos, Á. (2019). Thermoelectric Energy Recovery in a Light-Duty Diesel Vehicle under Real-World Driving Conditions at Different Altitudes with Diesel, Biodiesel and GTL Fuels. Energies, 12(6), 1105. https://doi.org/10.3390/en12061105