Design and Experiment of a Power Sharing Control Circuit for Parallel Fuel Cell Modules

Abstract

1. Introduction

2. Designing Parallel Operation of the Fuel Cell Modules

2.1. Conventional Parallel-Connected Fuel Cell Modules

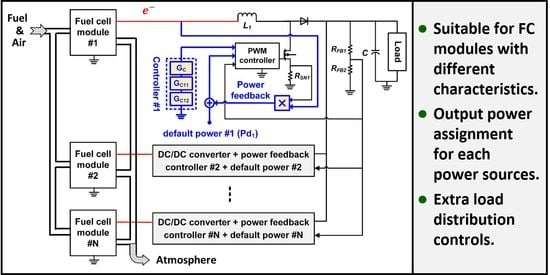

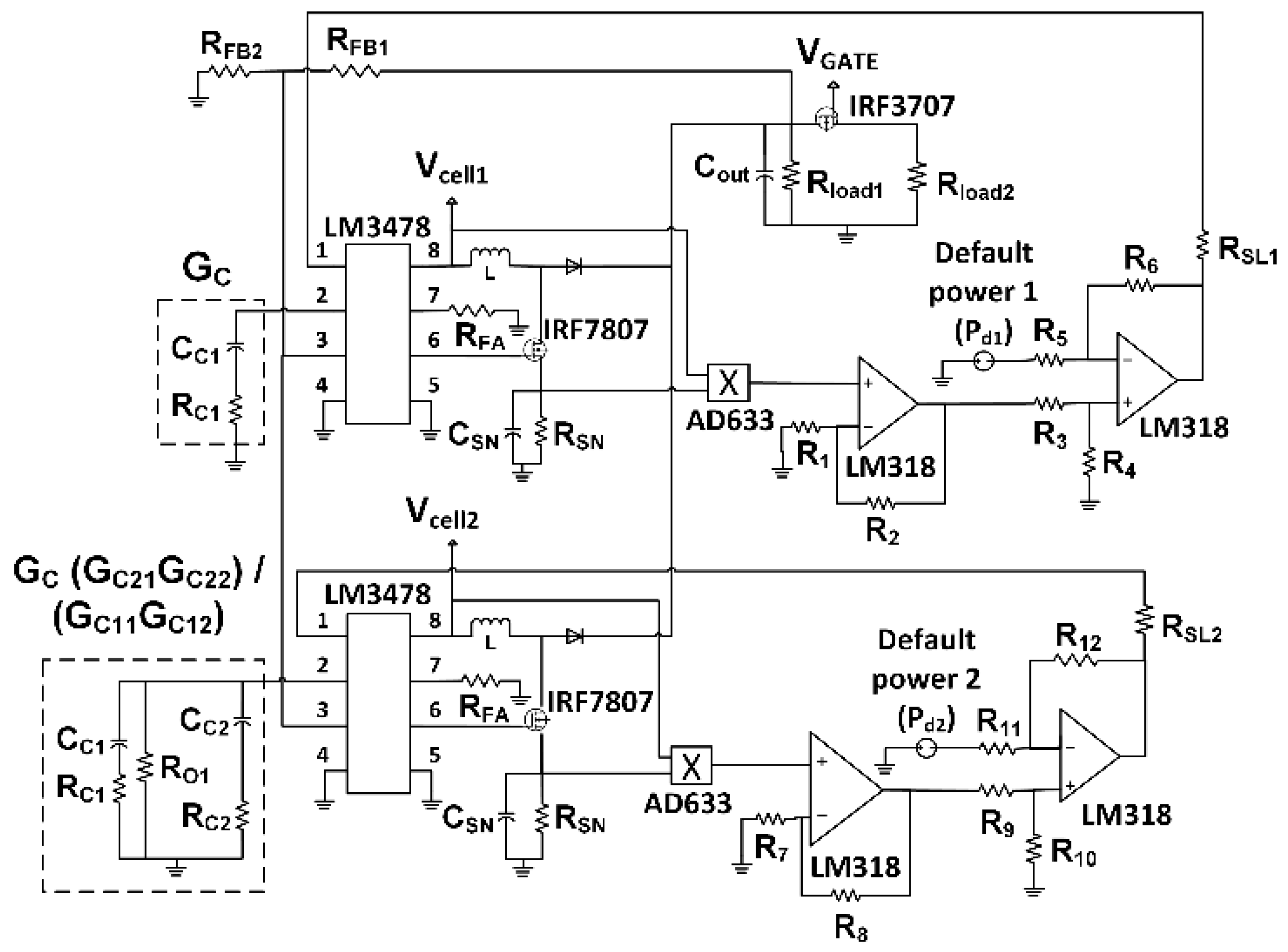

2.2. Proposed Power Sharing Control Configuration

3. Dynamics Modeling

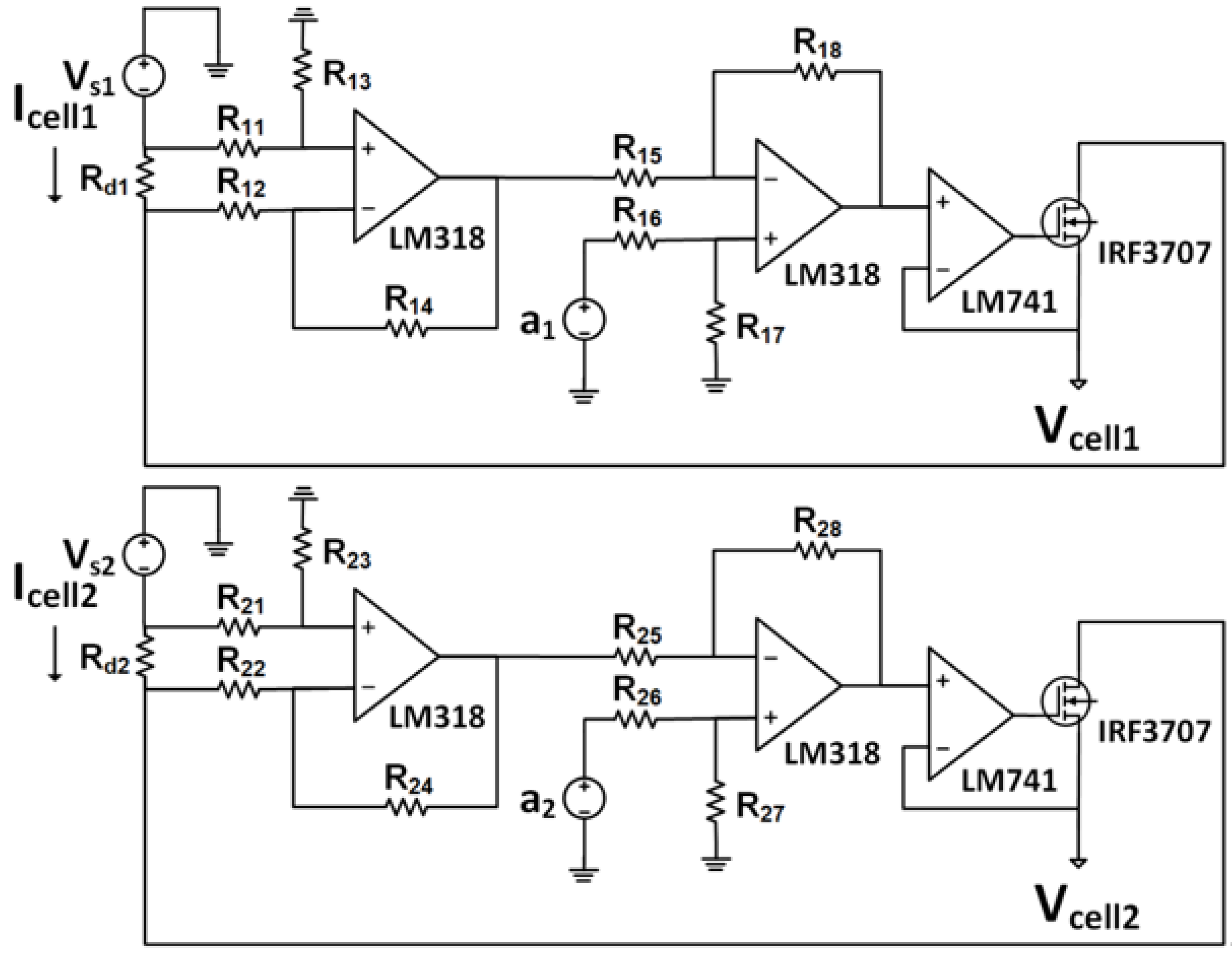

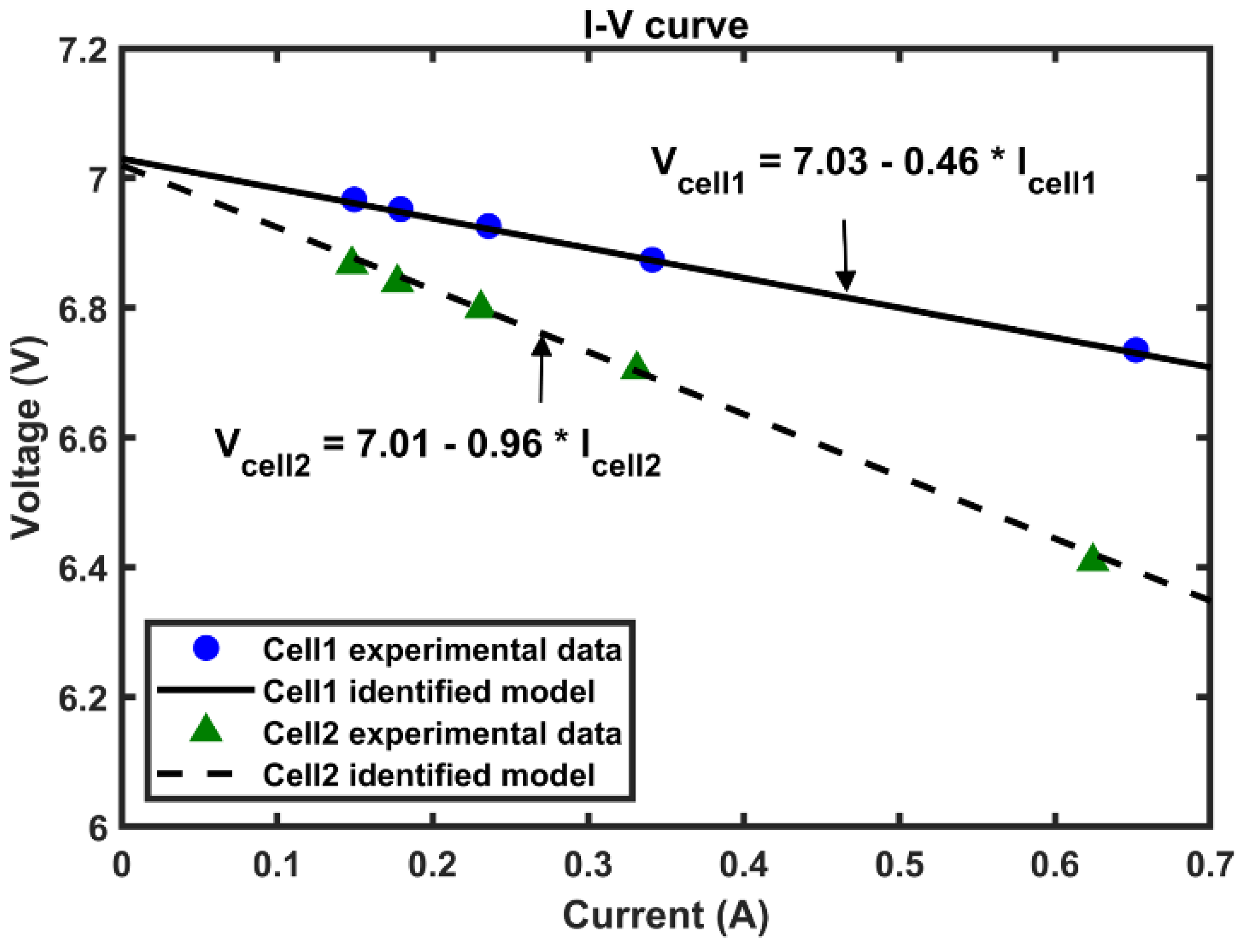

3.1. Fuel Cell

3.1.1. Dynamic Characteristics Modeling

3.1.2. Electrochemical Reaction Modeling

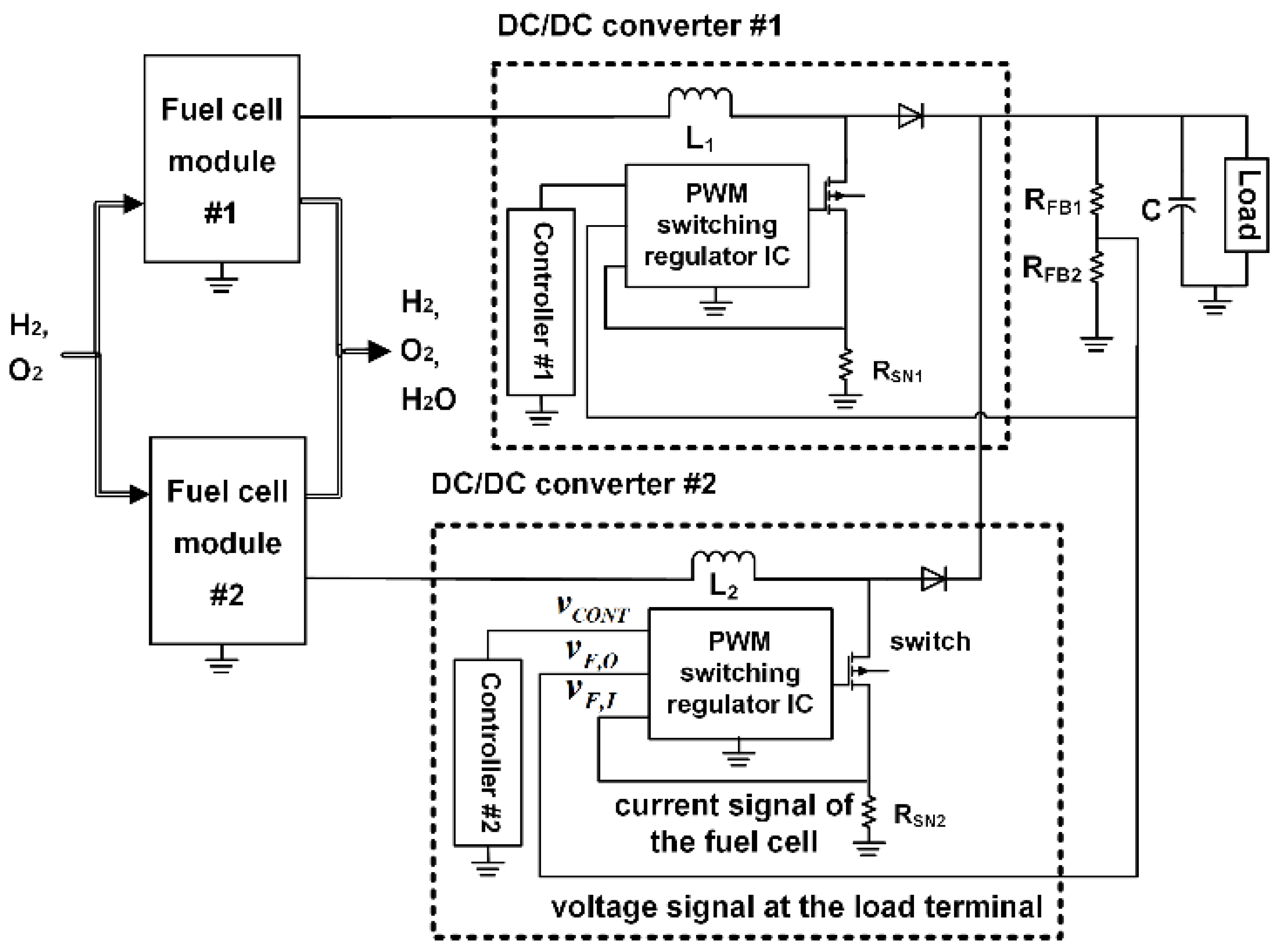

3.2. DC/DC Converters in Parallel

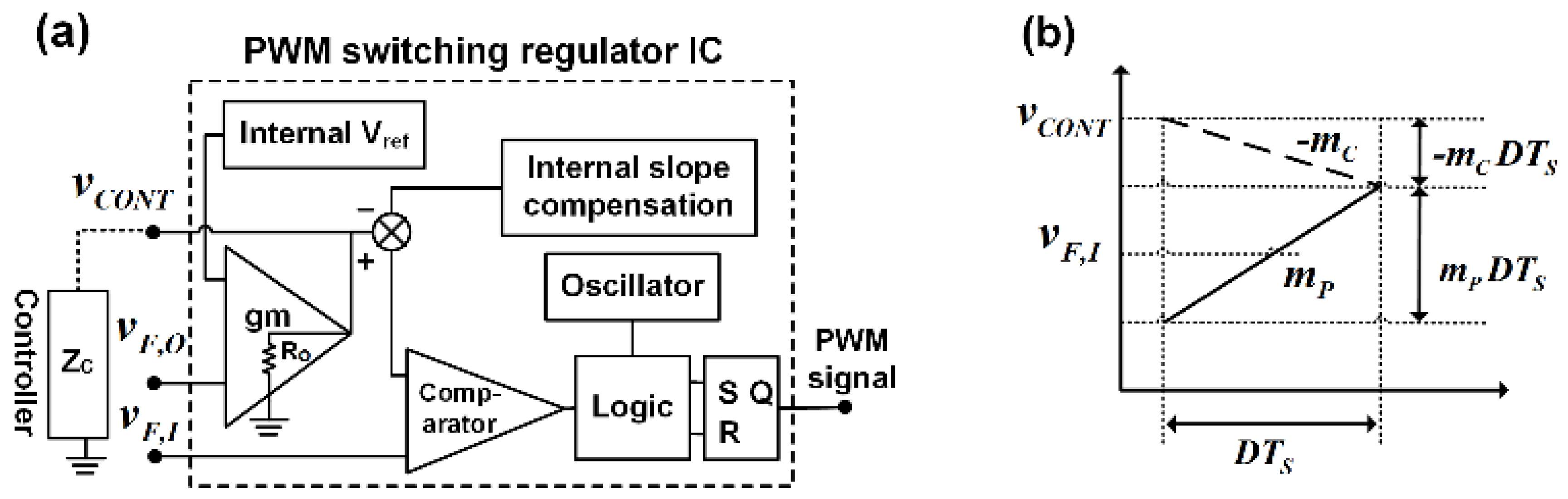

3.3. PWM Regulator with Power Feedback

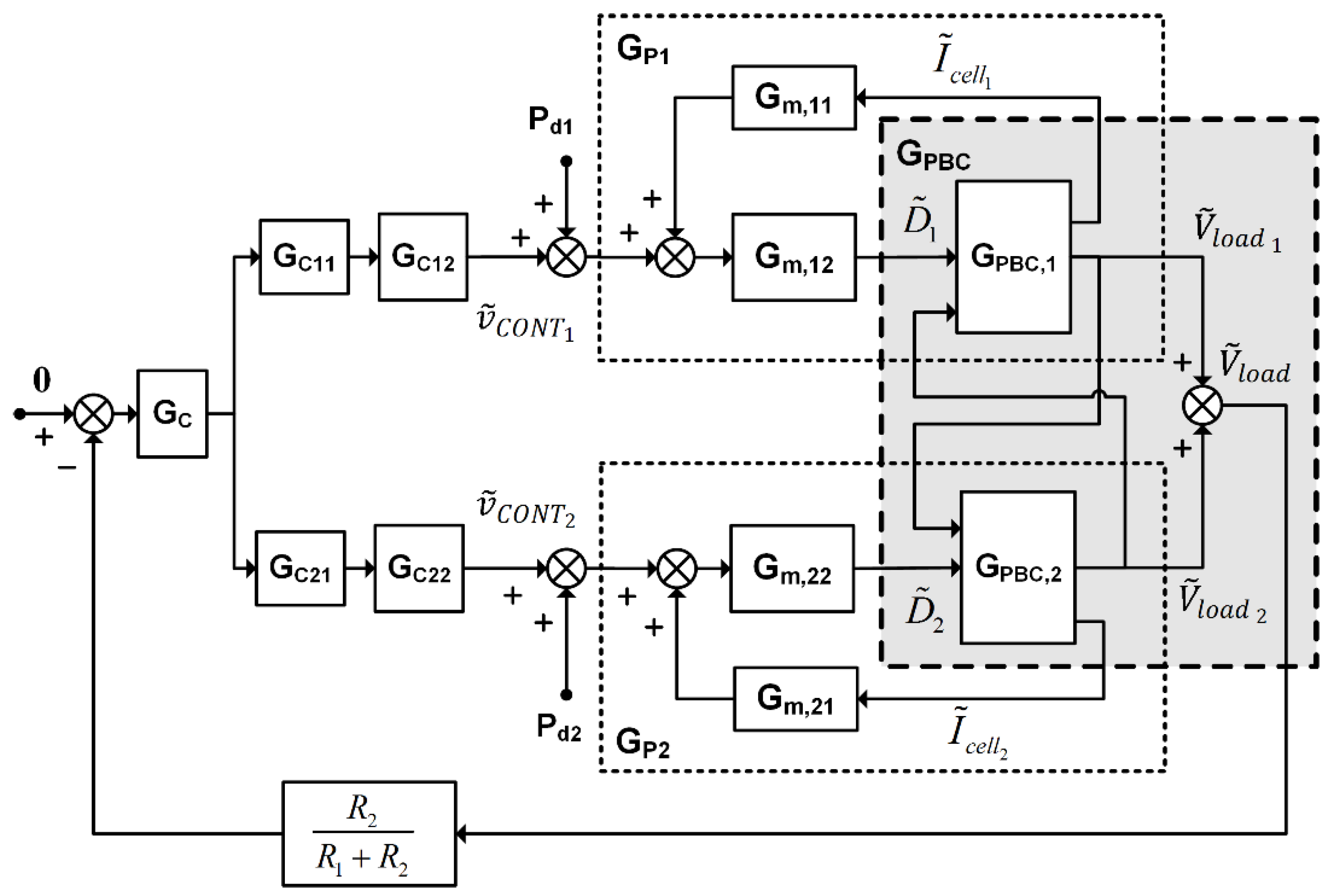

3.4. Modeling of Two Fuel Cells and DC/DC Converters in Parallel

4. Controller Design

5. Simulation Results

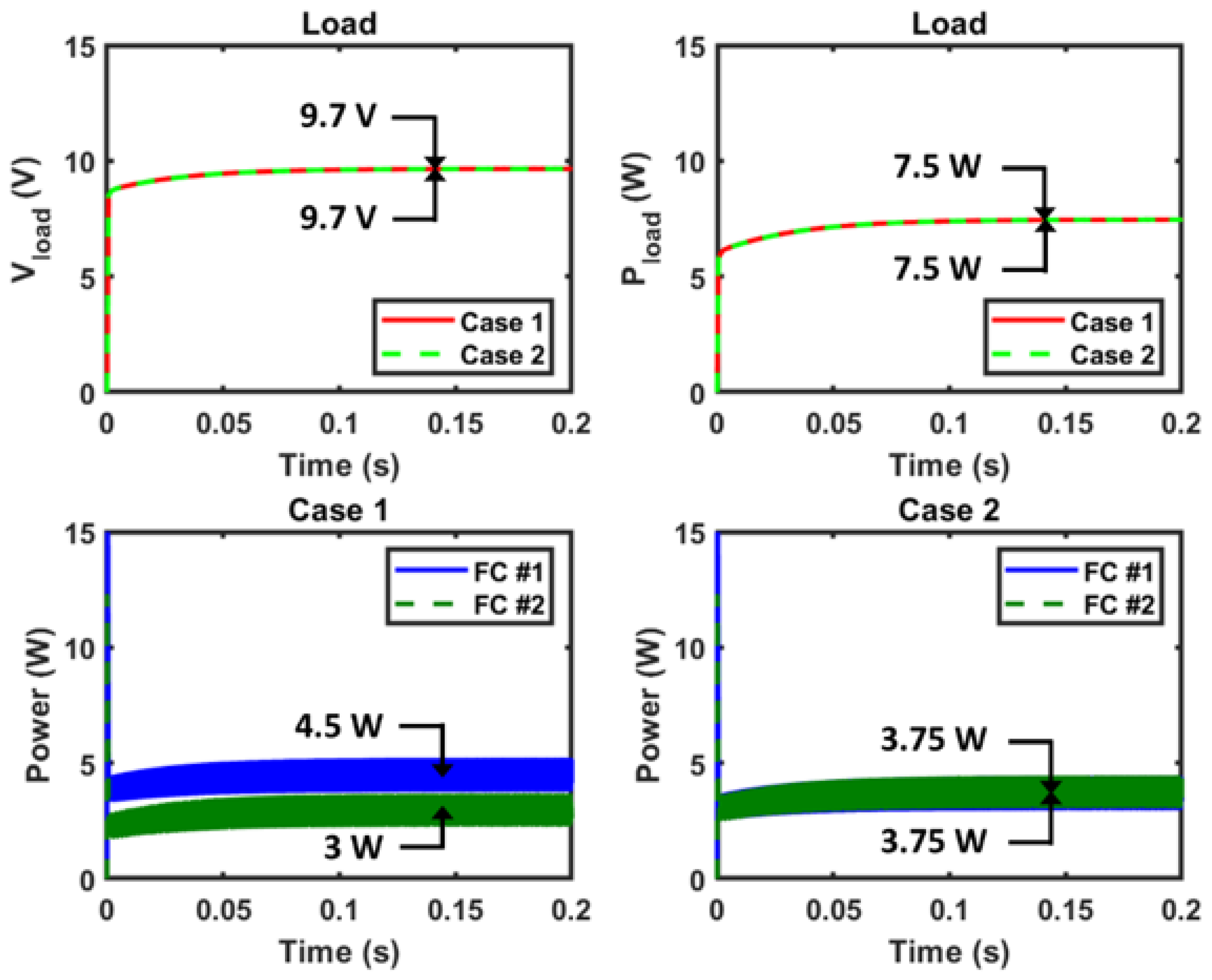

5.1. Parallel Performance of Fuel Cells with Different Cell Characteristics

5.2. Performance of Proposed Control Method

5.2.1. Controller Design

5.2.2. Power Assignment

5.2.3. Extra Load Distribution

6. Experimental Results

6.1. Layout of the Experimental Circuit

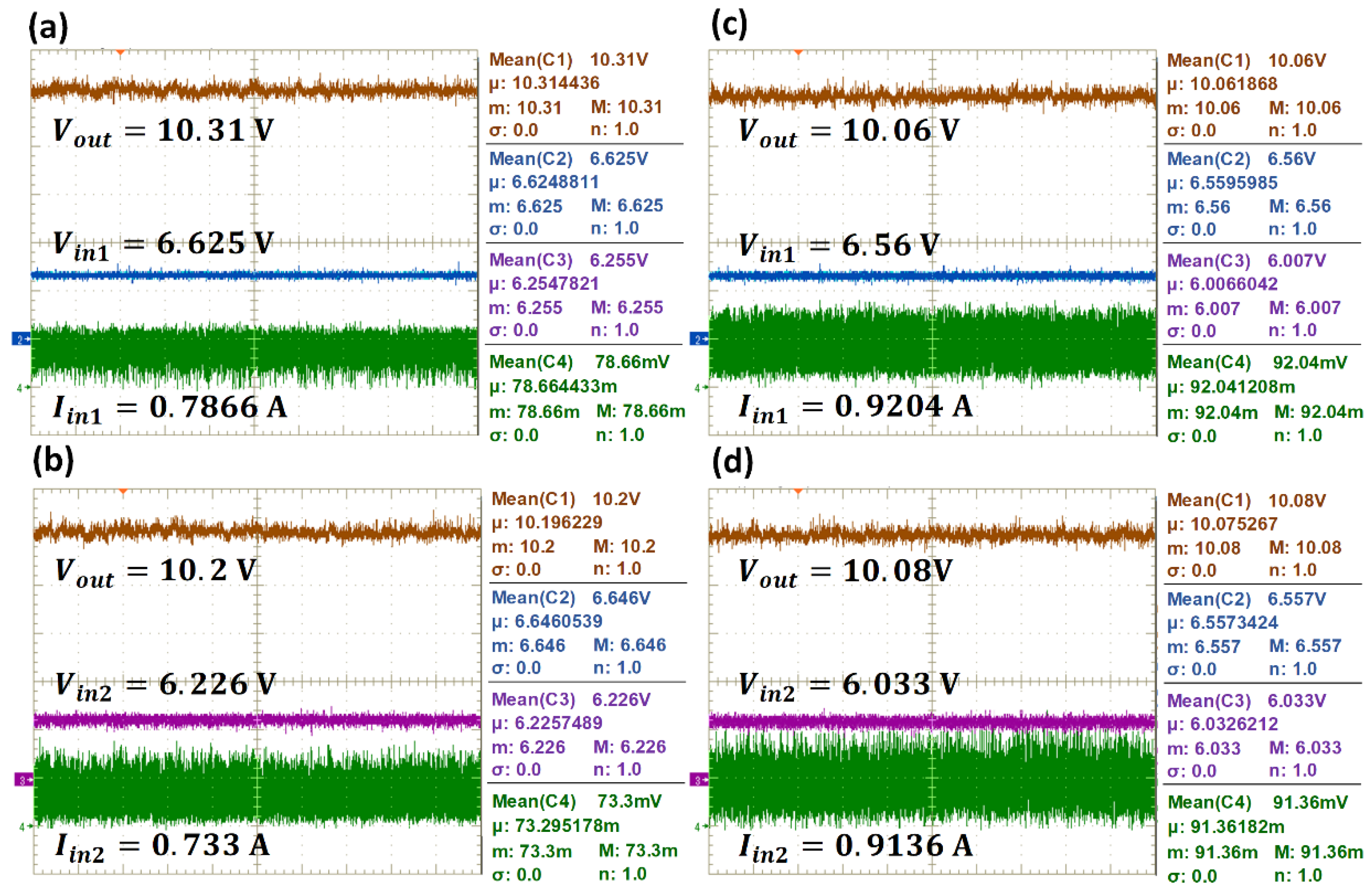

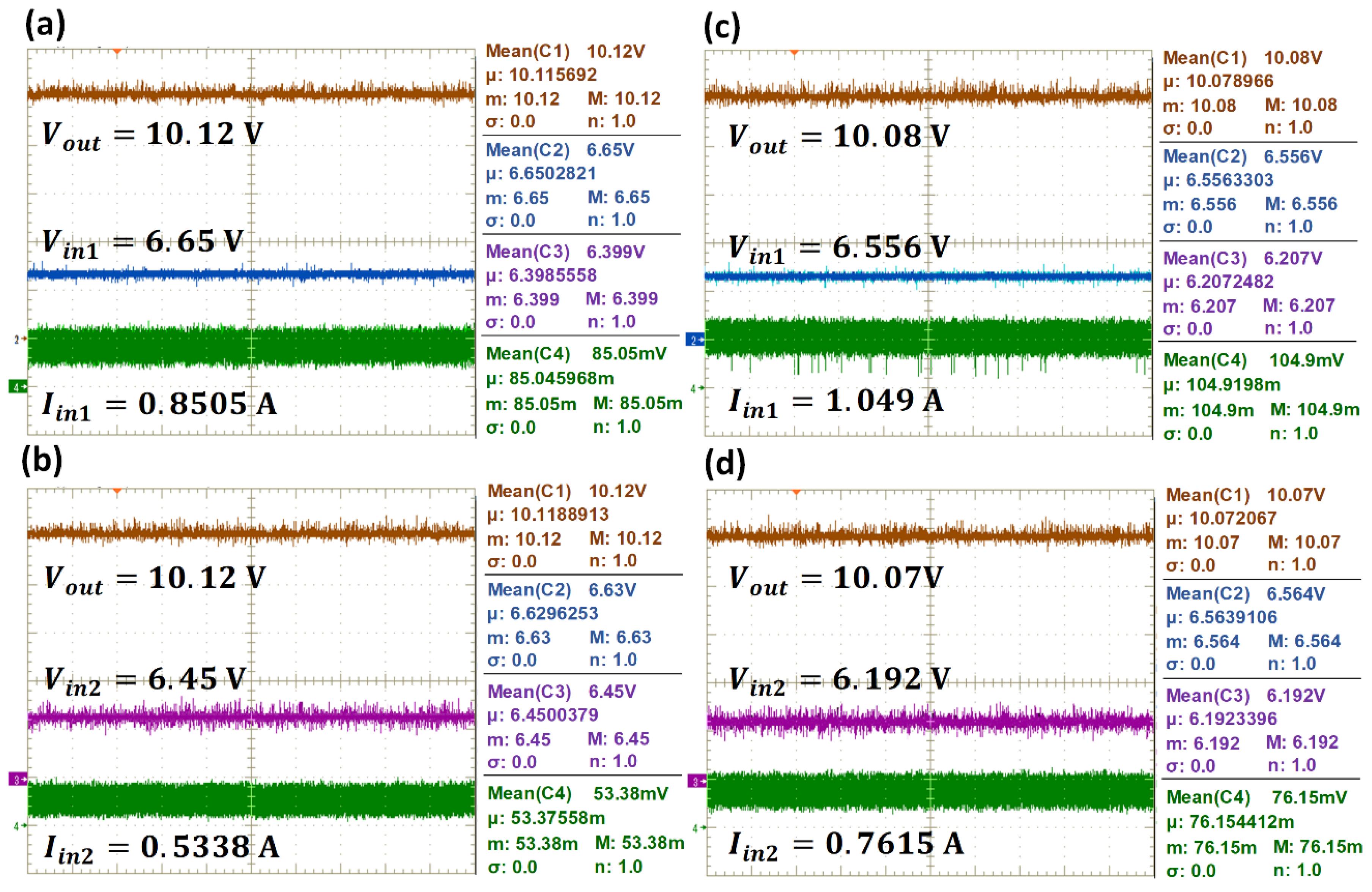

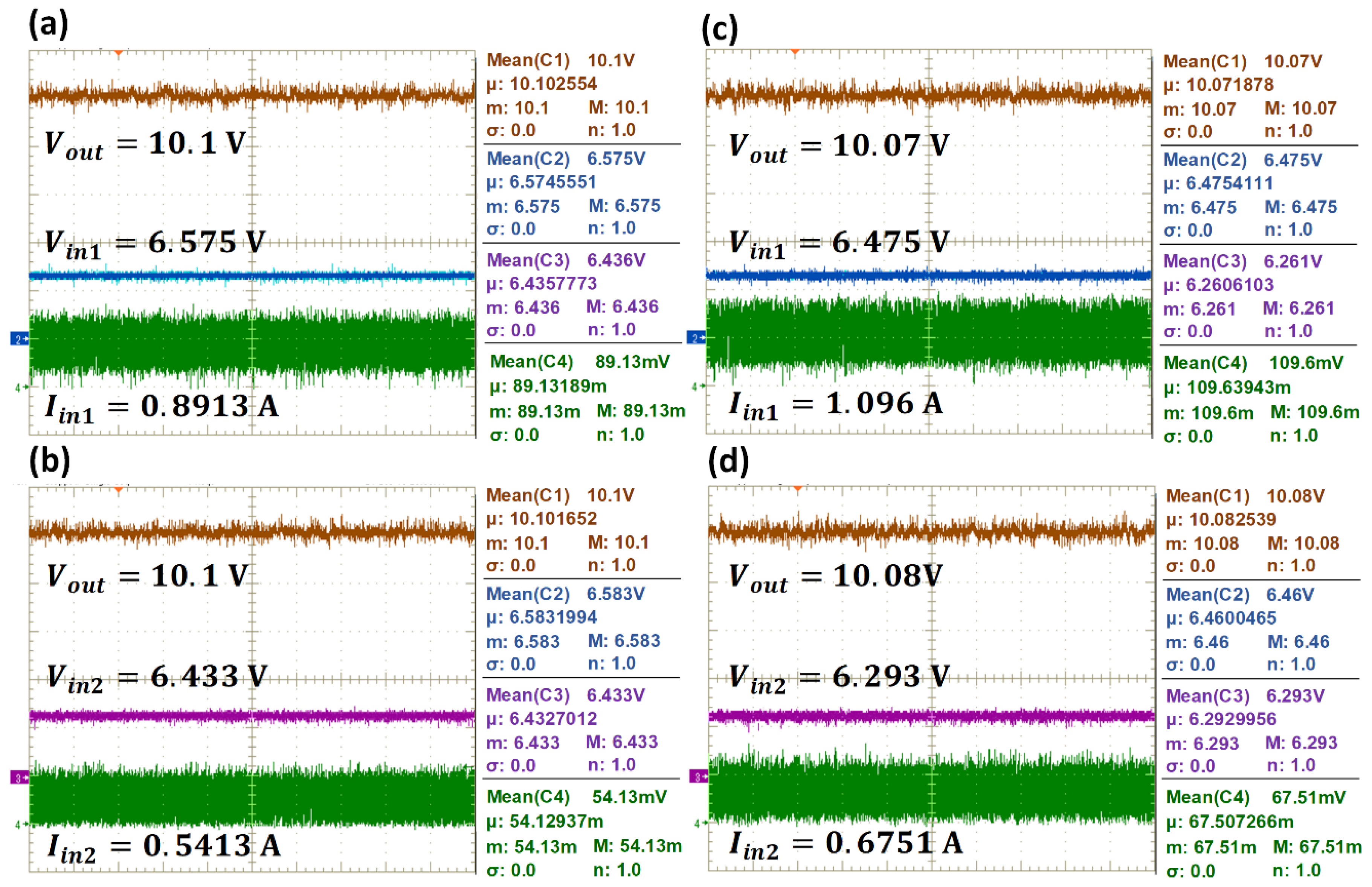

6.2. Power Assignment and Extra Load Distribution

6.3. MPVR Distribution

7. Discussion

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, H.; Lee, I.H. Environmental and efficiency analysis of simulated application of the solid oxide fuel cell co-generation system in a dormitory building. Energies 2019, 12, 3893. [Google Scholar] [CrossRef]

- Chatillon, Y.; Bonnet, C.; Lapicque, F. Heterogeneous aging within PEMFC stacks. Fuel Cells 2014, 14, 581–589. [Google Scholar] [CrossRef]

- Wu, C.C.; Chen, T.L. Dynamic modeling of a parallel-connected solid oxide fuel cell stack system. Energies 2020, 13, 501. [Google Scholar] [CrossRef]

- Chippar, P.; Ko, J.; Ju, H. A global transient, one-dimensional, two-phase model for direct methanol fuel cells (DMFCs)–part II: Analysis of the time-dependent thermal behavior of DMFCs. Energy 2010, 35, 2301–2308. [Google Scholar] [CrossRef]

- Kolli, A.; Gaillard, A.; De Bernardinis, A.; Bethoux, O.; Hissel, D.; Khatir, Z. A review on DC/DC converter architectures for power fuel cell applications. Energy Convers. Manag. 2015, 105, 716–730. [Google Scholar] [CrossRef]

- Marx, N.; Boulon, L.; Gustin, F.; Hissel, D.; Agbossou, K. A review of multi-stack and modular fuel cell systems: Interests, application areas and on-going research activities. Int. J. Hydrogen Energy 2014, 39, 12101–12111. [Google Scholar] [CrossRef]

- Bahrami, M.; Martin, J.P.; Maranzana, G.; Pierfederici, S.; Weber, M.; Meibody-Tabar, F.; Zandi, M. Multi-stack lifetime improvement through adapted power electronic architecture in a fuel cell hybrid system. Mathematics 2020, 8, 739. [Google Scholar] [CrossRef]

- Daud, W.R.W.; Rosli, R.E.; Majlan, E.H.; Hamid, S.A.A.; Mohamed, R.; Husaini, T. PEM fuel cell system control: A review. Renew. Energy 2017, 113, 620–638. [Google Scholar] [CrossRef]

- Nomnqa, M.; Ikhu-Omoregbe, D.; Rabiu, A. Performance evaluation of a HT-PEM fuel cell micro-cogeneration system for domestic application. Energy Syst. 2019, 10, 185–210. [Google Scholar] [CrossRef]

- Watzenig, D.; Brandstätter, B. Comprehensive Energy Management-Safe Adaptation, Predictive Control and Thermal Management; Springer: Berlin, Germany, 2018; pp. 95–101. [Google Scholar]

- Hawkes, A.; Staffell, I.; Brett, D.; Brandon, N. Fuel cells for micro-combined heat and power generation. Energy Environ. Sci. 2009, 2, 729–744. [Google Scholar] [CrossRef]

- Ozpineci, B.; Tolbert, L.M. Comparison of Wide-Bandgap Semiconductors for Power Electronics Applications; Department of Energy: Washington, DC, USA, 2004. [Google Scholar]

- Wang, J. System integration, durability and reliability of fuel cells: Challenges and solutions. Appl. Energy 2017, 189, 460–479. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, P.H.; Lee, F.C. Small signal analysis and design of active droop control using current mode equivalent circuit model. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition-APEC 2014, Fort Worth, TX, USA, 16–20 March 2014; pp. 2809–2816. [Google Scholar]

- Paspatis, A.G.; Konstantopoulos, G.C. Voltage support under grid faults with inherent current limitation for three-phase droop-controlled inverters. Energies 2019, 12, 997. [Google Scholar] [CrossRef]

- Shebani, M.M.; Iqbal, T.; Quaicoe, J.E. Modified droop method based on master current control for parallel-connected DC-DC boost converters. J. Electr. Comput. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Braitor, A.C.; Konstantopoulos, G.C.; Kadirkamanathan, V. Power sharing of parallel operated DC-DC converters using current-limiting droop control. In Proceedings of the 2017 25th Mediterranean Conference on Control and Automation (MED), Valletta, Malta, 3–6 July 2017; pp. 528–533. [Google Scholar]

- Anand, S.; Fernandes, B.G.; Guerrero, J. Distributed control to ensure proportional load sharing and improve voltage regulation in low-voltage DC microgrids. IEEE Trans. Power Electron. 2013, 28, 1900–1913. [Google Scholar] [CrossRef]

- Lu, X.; Guerrero, J.M.; Sun, K.; Vasquez, J.C. An improved droop control method for dc microgrids based on low bandwidth communication with dc bus voltage restoration and enhanced current sharing accuracy. IEEE Trans. Power Electron. 2014, 29, 1800–1812. [Google Scholar] [CrossRef]

- Choe, G.Y.; Kang, H.S.; Lee, B.K. A parallel operation algorithm with power-sharing technique for FC generation systems. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Washington, DC, USA, 15–19 February 2009; pp. 725–731. [Google Scholar]

- Grover, R.; Fredette, S.J.; Vartanian, G. Control of Paralleled Fuel Cell Assembles. U.S. Patent 20090325007, 31 December 2009. [Google Scholar]

- Tofoli, F.L.; de Castro Pereira, D.; de Paula, W.J.; Júnior, D.D.S.O. Survey on non-isolated high-voltage step-up dc–dc topologies based on the boost converter. IET Power Electron. 2015, 8, 2044–2057. [Google Scholar] [CrossRef]

- Texas Instruments. LM3478 High-Efficiency Low-Side N-Channel Controller for Switching Regulator; Application Note; Texas Instruments: Dallas, TX, USA, 2008. [Google Scholar]

- Wu, C.C.; Chen, T.L. Design and dynamics simulations of small scale solid oxide fuel cell tri-generation system. Energy Convers. Manag. X 2019, 1, 100001. [Google Scholar] [CrossRef]

- Yang, C.H.; Chang, S.C.; Chan, Y.H.; Chang, W.S. A dynamic analysis of the multi-stack SOFC-CHP system for power modulation. Energies 2019, 12, 3686. [Google Scholar]

- Soriano-Sánchez, A.G.; Rodríguez-Licea, M.A.; Pérez-Pinal, F.J.; Vázquez-López, J.A. Fractional-order approximation and synthesis of a PID controller for a buck converter. Energies 2020, 13, 629. [Google Scholar] [CrossRef]

- Muñoz, J.G.; Gallo, G.; Angulo, F.; Osorio, G. Slope compensation design for a peak current-mode controlled boost-flyback converter. Energies 2018, 11, 3000. [Google Scholar] [CrossRef]

- Oh, S.M.; Ko, J.H.; Kim, H.W.; Cho, K.Y. A hybrid current mode controller with fast response characteristics for super capacitor applications. Electronics 2019, 8, 112. [Google Scholar] [CrossRef]

- Humaira, H.; Baek, S.W.; Kim, H.W.; Cho, K.Y. Circuit topology and small signal modeling of variable duty cycle controlled three-level LLC converter. Energies 2019, 12, 3833. [Google Scholar] [CrossRef]

| Symbol | Value | Symbol | Value |

|---|---|---|---|

| Symbol | Value | Symbol | Value |

|---|---|---|---|

| Power Assignment (Output/Assignment) | Extra Load Dist. Ratio (Output/Assignment) | Power Assignment Error | Extra Load Dist. Error | ||

|---|---|---|---|---|---|

| Sim. 1 | FC #1 | 4.5/4.8 | 0.4615/0.5 | 0% | 3.85% |

| FC #2 | 3/3.2 | 0.5385/0.5 | 0% | ||

| Sim. 2 | FC #1 | 4.8/4.8 | 0.6923/0.6923 | 6.67% | 0% |

| FC #2 | 2.7/3.2 | 0.3077/0.3077 | −10% | ||

| Exp. 1 | FC #1 | 5.21/4 | 0.466/0.5 | 6.62% | 3.4% |

| FC #2 | 4.56/4 | 0.534/0.5 | −6.62% | ||

| Exp. 2 | FC #1 | 5.66/4.8 | 0.49/0.5 | 3.69% | 1% |

| FC #2 | 3.44/3.2 | 0.51/0.5 | −5.32% | ||

| Exp. 3 | FC #1 | 5.86/4.8 | 0.618/0.692 | 4.99% | 7.43% |

| FC #2 | 3.48/3.2 | 0.382/0.308 | −6.42% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.-C.; Chen, T.-L. Design and Experiment of a Power Sharing Control Circuit for Parallel Fuel Cell Modules. Energies 2020, 13, 2838. https://doi.org/10.3390/en13112838

Wu C-C, Chen T-L. Design and Experiment of a Power Sharing Control Circuit for Parallel Fuel Cell Modules. Energies. 2020; 13(11):2838. https://doi.org/10.3390/en13112838

Chicago/Turabian StyleWu, Chien-Chang, and Tsung-Lin Chen. 2020. "Design and Experiment of a Power Sharing Control Circuit for Parallel Fuel Cell Modules" Energies 13, no. 11: 2838. https://doi.org/10.3390/en13112838

APA StyleWu, C.-C., & Chen, T.-L. (2020). Design and Experiment of a Power Sharing Control Circuit for Parallel Fuel Cell Modules. Energies, 13(11), 2838. https://doi.org/10.3390/en13112838