1. Introduction

The history of hard coal mining in Poland goes back to the end of the 18th century. At that time, first mines were opened in the Upper Silesian Basin. It is a region rich in hard coal deposits, where its mining continues to this day. Until the mid-20th century, coal was mined from non-methane deposits. There are known cases when, after encountering a methane hazard, further mining (or even construction of mines) was abandoned. Due to its explosiveness, methane accompanying hard coal mining in mines poses a serious threat to the safety of mining crews and production of mining plants. The detailed characteristics of the existing methane deposits and the description of parameters influencing its secretion can be found in this article [

1]. Methods for safe coal mining and simultaneous methane emission reduction are being sought all over the world. The relationships between coal production, methane emission, methane drainage, and utilisation are analysed so that both coal mining and methane extraction are possible at the same time (co-exploitation) [

2]. The problem with methane emission to the atmosphere and with the use of this gas concerns closed mines as well [

3]. In mines, the basic methods of controlling methane hazard include ventilation of mine workings and methane drainage from coal seams. Methane from coal seams in mines—coal mine methane (CMM)—is extracted to the surface using ventilation of underground excavations and installations used for methane drainage [

4,

5].

According to a previous study [

6], the potential to create a greenhouse effect due to methane is estimated to be 28–34 times higher than for carbon dioxide. Additionally, recent studies [

7] may indicate that methane emission due to industrial use of fossil fuels is much higher than previously estimated. Regardless of the division into sources of emission, the concentrations of atmospheric methane are ever-increasing and, according to the data as of February 2020, is 1873.7 ppb (CH

4 mole fraction) against 1864.9 ppb in February 2019 and 1625.9 ppb in July 1983—the beginning of measurements [

8]. It follows that methane is the most important greenhouse gas (GHG) in the atmosphere except for CO

2 (non-CO

2 GHG) [

9]. Its atmospheric lifetime is relatively short (approximately 9–15 years [

10]), but it is responsible for about 14% of the total GHG emission [

11]. Of the three main greenhouse gases (CO

2, CH

4, and N

2O), from the time of rapid development of industrial activity (since 1750), the greatest percentage increase in concentrations in the atmosphere has been observed in methane [

12].

In 2019 in Poland, the annual coal extraction from hard coal seams was 61.6 million Mg, with approximately 80% of production coming from coal seams containing methane [

13].

Figure 1 shows how the total emission of methane into the atmosphere is formed and (broken down into methane) removed by the mine’s ventilation system (ventilation air methane—VAM) and by the installations used for methane drainage (coal mine methane—CMM) in the Polish hard coal mining industry in the last 13 years.

As the concentrations of methane from the installations used for methane drainage most often exceed 40%, this gas can be used as a low-methane fuel in various types of heat and power installations, e.g., in boilers with gas burners, engines, and gas turbines. In Poland, low-methane gas is used as fuel in many power installations, e.g., in Jastrzębska Spółka Węglowa S.A. (JSW S.A.). Nevertheless, the total rate of economic use of methane captured by methane drainage from coal seams of Polish mines remains at the level 50%.

Drained methane, depending on its quality and volume flow, can be used in various ways. The methods of methane utilisation are described in detail in numerous articles, e.g., [

4,

14,

15,

16]. The basic methods of methane utilisation include

power generation in gas engines or turbines;

fuel used in ovens, boilers and burners;

VAM oxidation processes;

injection into gas pipelines;

vehicle fuel;

production of fertilizers;

flaring.

Combustion of captured methane is the simplest method to reduce CH

4 emissions. The result is CO

2 and water. In this case, CO

2 emissions are less hazardous to the environment than CH

4 emissions. Direct methane combustion should only be used when there is no other option or in case of a failure. The problem with using VAM is mainly related to low methane concentrations at very high airflows. The limitation of most technologies is methane concentration at the level of 0.5% [

17]. The methods of VAM utilisation are described in numerous articles, e.g., references [

12,

18,

19,

20]. The injection of captured methane directly into natural gas pipelines is a very costly solution due to the high purity and, above all, concentration requirements. By far the most developed method of methane utilisation is conversion to electricity and heat. The database of projects concerning the methane use, developed by the US Environmental Protection Agency (US EPA) [

21], contains a list of over 200 projects. More than half of installations concerns the electricity generation, directly and in cogeneration with heat (

Figure 2).

The distribution of projects using drained methane differs in Poland. In 2019, using methane drainage, 340 million cubic metres of methane was obtained, out of which around 200 million cubic metres (58.8%) was used as fuel. Almost half of the methane captured (47%) (

Figure 3) was used as fuel in gas burners in gas-fired boilers. This is due to the relatively low cost of such a solution compared to other options. Twenty-five percent of methane was burnt in gas engines to generate electricity and heat.

Methods of drained methane utilisation in one of the coal companies in Poland—JSW S.A.—and recorded gas parameters are shown in

Figure 4. Captured methane is used both for own needs of individual mines (e.g., hot-water boilers, dryers) and, above all, to generate power and/or heat in gas engines. The 2017 detailed data on the use of drained methane in JSW S.A. have been presented in

Table 1. A total of 103,648.8 thousand cubic metres of drained methane was used, and more than half (55%) was used in gas engines—57,248.8 thousand cubic metres. The percentage share of methane use in individual mines is notable. It ranges from 95% (Zofiówka coal mine, Zofiówka section), through 92% (Pniówek coal mine), and 91% (Borynia coal mine, Borynia section) to 59% (Budryk coal mine). On average, JSW S.A. uses 79% of captured methane. More than 27 thousand cubic metres remain to be used.

In order to increase the efficiency of drained gas use, the composition of the methane–air mixture used in power and heat installations should be stable [

23]. The stabilisation of the quantitative and qualitative parameters of drained gas can be obtained as a result of

controlling and regulating the process of methane drainage from coal seams in the mine;

the use of installations for stabilisation, such as underground tanks for storing drained gas and surface gas tanks;

supplying high-methane gas from an external source;

removal of inert gases from the methane–air mixture (mine gas purification).

3. Results

3.1. Preliminary Analysis of the Collected Data

Based on the results from a methane drainage station, an analysis of gas captured from methane drainage in the research period was carried out. The first stage was the statistical analysis of the collected data, including looking for any correlation between data.

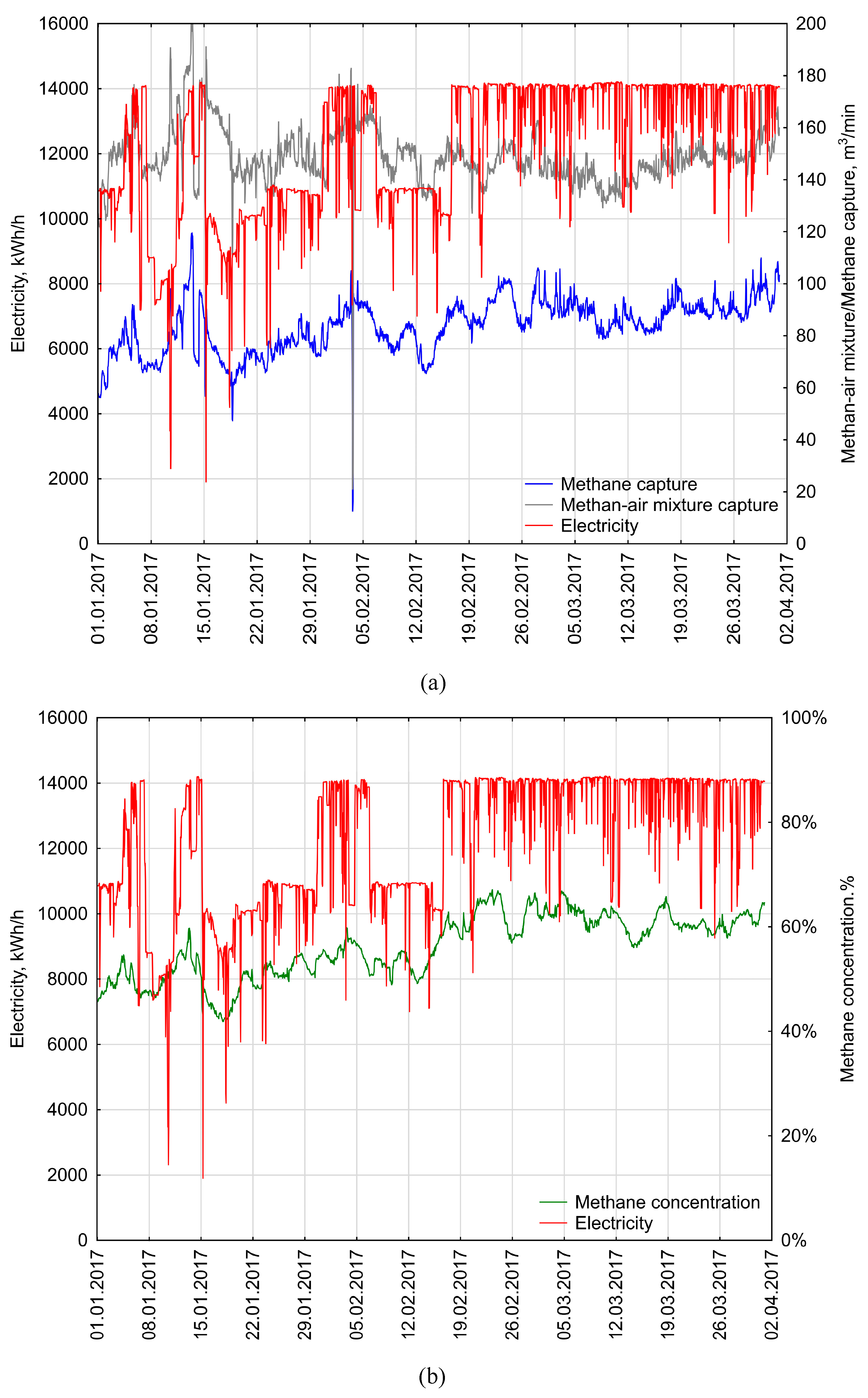

Figure 9 shows the changes in electricity production, the mixture and methane capture, and concentration of methane in the methane–air mixture in the first quarter of 2017.

The energy production marked in red on the figure varies from 2000 kWh/h to over 14,000 kWh/h. The coverage of pure methane in this period varies from 10 to 120 m

3/min, while the concentration of methane is the most stable of the presented parameters and varies from 41% to 67%. Detailed statistical data on all variables included in the analysis are presented in

Table 5.

An important aspect of the analysis was the total methane capture and the amount of electricity that was produced in the context of reducing direct methane emissions to the atmosphere. As mentioned at the beginning of the article, methane is characterized by a high GWP, hence its capture is particularly important, and the production of electricity is an additional benefit.

Figure 10 shows the variability of the methane capture and electricity production in the analysed period, both in a daily and monthly cycle.

The monthly methane capture in the first quarter of 2017 varies from 3,384,315 m3 to 4,009,869 m3 per month, which translates into electricity production from 7790 MWh to 10,190 MWh per month. The emission of methane in this amount corresponds to approx. 66,700–79,035 tonnes of CO2eq, assuming a GWP equal to 30. As a result of methane combustion, more carbon dioxide is released into the atmosphere than the methane supplied to the process. For every tonne of methane burned, 2.75 tonnes of carbon dioxide are emitted. Due to the much lower greenhouse effect of this gas, despite the higher emissions, this process has a much lower environmental impact compared to the emission of pure methane. With such a significant emission of methane to the atmosphere during extraction, methane combustion plays a key role in reducing the greenhouse effect.

The next step in the statistical analysis of the collected data was to determine the relationship between electricity production and selected parameters. For this purpose, the dependence of electric energy on methane concentration and pure methane capture were presented, where the independent variables were divided into specific value ranges.

Figure 11 presents the described dependencies in the form of box plots and also contains a surface chart showing the dependence of electricity production as a function of methane concentration and pure methane consumption in the analysed period.

Electricity production depends on many factors, therefore, for further analysis, a correlation matrix was used that shows relations between both the sought value and the identified parameters, and between individual variables. The matrix is presented in

Table 6.

On the basis of the correlation analysis, it was noticed that the parameter characterizing the methane-air mixture and the time of measurement showed the lowest impact on energy production. For further analysis, all factors were adopted, except for the mixture capture, due to the partial inclusion of this value in the parameter describing the concentration of methane in the mixture, which shows a much higher correlation coefficient. In summary, the predictive model was built on the basis of five variables: one qualitative parameter (day of the week) and four quantitative parameters (hour, pressure, methane capture, and methane concentration).

3.2. Neural Network Models

In this section, models with the best fit according to the correlation coefficient are presented. During the preparation of the models, the number of hidden neurons varied from 5 to 500. The research also considered the different activation functions of both the input and output layers. The error function was chosen as the sum of the squares. Five networks were selected that showed the best model fit in each of the following groups: the training, test, and validation groups. Detailed data on the network are presented in

Table 7.

3.3. Prediction Results—Evaluation

Based on the evaluation factors described above, the selected networks were compared with each other. The results are shown in

Table 8.

As one can see, the best results were achieved by the MLP 4 model, which has a correlation coefficient of 0.94, an average error of 441.58 kWh/h, which translates into an average error percentage of 4%.

Based on the proposed models,

Table 9 compares the sensitivity analysis. As can be seen, despite the initially low values of the correlation coefficients for the hour of observation, the sensitivity coefficient is noticeably high for each of the models. Each of the models showed the greatest sensitivity in terms of methane concentration, which indicates the importance of this parameter.

Due to the best results of the above-mentioned MLP 4 network, further analysis of the results was performed for this model only. Based on the obtained values, predicted according to the model, relationship between the actual and predicted values is presented, and the values as a function of time are compared in

Figure 12. As one can see, the biggest problem in the presented model are the extreme values that are the worst mapped by the proposed model.

4. Discussion

The article discusses issues related to the capture of methane from hard coal mine on the example of the Pniówek mine in Poland. The analysis includes the study of methane capture and electricity production from mine’s firedamp drainage system. The study takes into account both the environmental impact and the economic justification for such solution. Monthly methane capture from the analysed firedamp drainage installation in the analysed period ranges from 3,384,315 m3 to 4,009,869 m3, which corresponds to monthly electricity production from 7790 MWh to 10,190 MWh. Taking into account the high GWP coefficient of methane, such methane emission as CO2 equivalent amounts to approx. 66,700–79,035 tonnes of CO2eq. Analysing the electricity production with the use of such amount of methane and assuming the calorific value of hard coal at the level of 30 MJ/kg and 100% boiler efficiency, the monthly methane capture in the analysed period corresponds to the production of electricity which would be possible with the combustion of 960 tonnes to 1270 tonnes of hard coal. As mentioned above, as a result of methane combustion, carbon dioxide is released into the atmosphere, the amount of which is 2.75 times the amount of fuel supplied. Based on the results obtained for March, the amount of methane captured that was subsequently combusted was 4,009,869 m3, which corresponds to 79,035 t CO2eq. When methane is combusted, 7245 t of CO2 is released into the atmosphere, which means a reduction in emissions expressed in CO2 units by over 90%.

Considering the energy consumption of the mining industry and the costs associated with electricity consumption during operation, proper management of energy resources is essential to maintain the profitability of mining. Currently, the share of electricity costs ensuring safe conditions for underground work in hard coal mines is significant. Therefore, the energy efficiency of underground hard coal mining depends, inter alia, on the electricity cost of the main technological processes. An important direction of increasing the energy efficiency of hard coal mining is forecasting power consumption and monitoring electricity consumption, as well as appropriate management of the electricity produced. This article presents models of artificial neural networks for the energy system using methane from the hard-coal mine’s firedamp drainage system. The models presented are characterized by a correlation coefficient ranging from 0.918 to 0.940. The mean prediction error for the proposed networks varies from 441.58 to 545.64, and the mean percentage error from 4.05% to 5.14%. The evaluation indicators made it possible to select the most precise network—MLP 4, whose MAPE was 4.05%. The proposed model was characterized by the activation function of the hyperbolic tangent hidden layer and the logistic output layer, with the total number of hidden units: 290. Analysing the sensitivity coefficients for each of the input variables, it can be noticed that, among the proposed inputs, in each of the presented models, the methane concentration has the greatest impact on the predicted value. What is more, the time and day of observation are also significant. Preliminary statistical analysis showed that there is no significant correlation between electricity production and the hour of measurements, however, in the neural network model this parameter plays an important role.

As the analysis showed, the production of electricity fuelled by hard-coal-bed methane strongly depends on many factors. The most important parameter turned out to be the concentration of methane in the air-methane mixture discharged by the ventilation system. The proposed model allows for the determination of electricity production with high accuracy, which enables proper management of the mine’s energy system.

5. Conclusions

In addition to the properties of coal deposits, there are many factors that influence CMM emissions during mining. Moreover, the gas produced by CMM activities can be high quality gas such as pre-extraction methane or gas with a low methane concentration, e.g., VAM. Poland is one of the countries with significant CMM emissions. Other leading global emitters include the United States, Russia, Australia, Ukraine, Kazakhstan, and India. Recognising the importance of the capture and use of coordinate measuring machines for mine safety, power generation, and greenhouse gas reduction, these countries implement various CMM projects. Depending on economic, social, and regulatory conditions, the implementation of CMM projects involves a number of challenges which may slow down or limit their progress. These challenges must be addressed and solved in cooperation with both government agencies and the private sector in each country, as well as through cooperation at international level by financing and demonstrating the importance of the capture and use of CMM in improving mine safety, power generation, and in reducing greenhouse gases.

Methane emissions from the mines have been of great interest for years. This is a very important topic, not only for environmental reasons, but also because of its energy benefits and resulting financial benefits. Methane is associated with great danger, both for employees and the environment, but when used properly, it can become a valuable energy resource. The conducted analysis showed that it is possible to estimate in detail the energy benefits on the basis of parameters defining the captured ventilation air from mines. Proper prediction of electricity production is very important for the efficient management of energy resources. The artificial neural network models allow for the estimation of electricity production for specific input parameters. It also makes it possible to distinguish the parameters that determine the amount of electricity produced. Coal companies are constantly making technical and economic efforts to intensify the use of released and captured methane. Investments implemented in this regard are capital intensive and time-consuming. Due to the gas network infrastructure in the vicinity of the mine and the related limitations of methane transport from coal seams, most of the power systems are located in the mines or in close proximity. Proper determination of electricity production in installations in the mine will allow mine operators to determine how much electricity obtained from other sources, including the transmission network, is necessary for the proper functioning of the mine. In the case of large installations and possible surpluses of electricity production related to the variability of electricity consumption by mines over time, it allows mine operators to determine the amount of electricity transferred to the grid.