Management of Radioactive Waste Containing Graphite: Overview of Methods

Abstract

:1. Introduction

2. Carbonaceous Components of Nuclear Power Plant Installations

Nuclear Graphite and Radioactive Isotopes in Graphite-Containing Waste

3. Management Strategies of Waste Containing Irradiated Graphite

3.1. Standard Methods of Radioactive Waste Management

- ✓

- waste pre-treatment and treatment involve waste collection, segregation, characterization, mass (or volume) reduction, drying (of wet or liquid waste), the separation of high-activity waste from waste with lower activity, combustion (e.g., of i-graphite-containing waste), solidification of liquid radioactive waste, etc.

- ✓

- conditioning operations include cementation, bituminization, immobilization using synthetic resins and polymers, vitrification or inclusion in SynRoc materials, followed by packaging.

- ✓

- temporary storage, sending some parts of the waste for recycling, transportation to a repository, and final disposal are often considered a single operation.

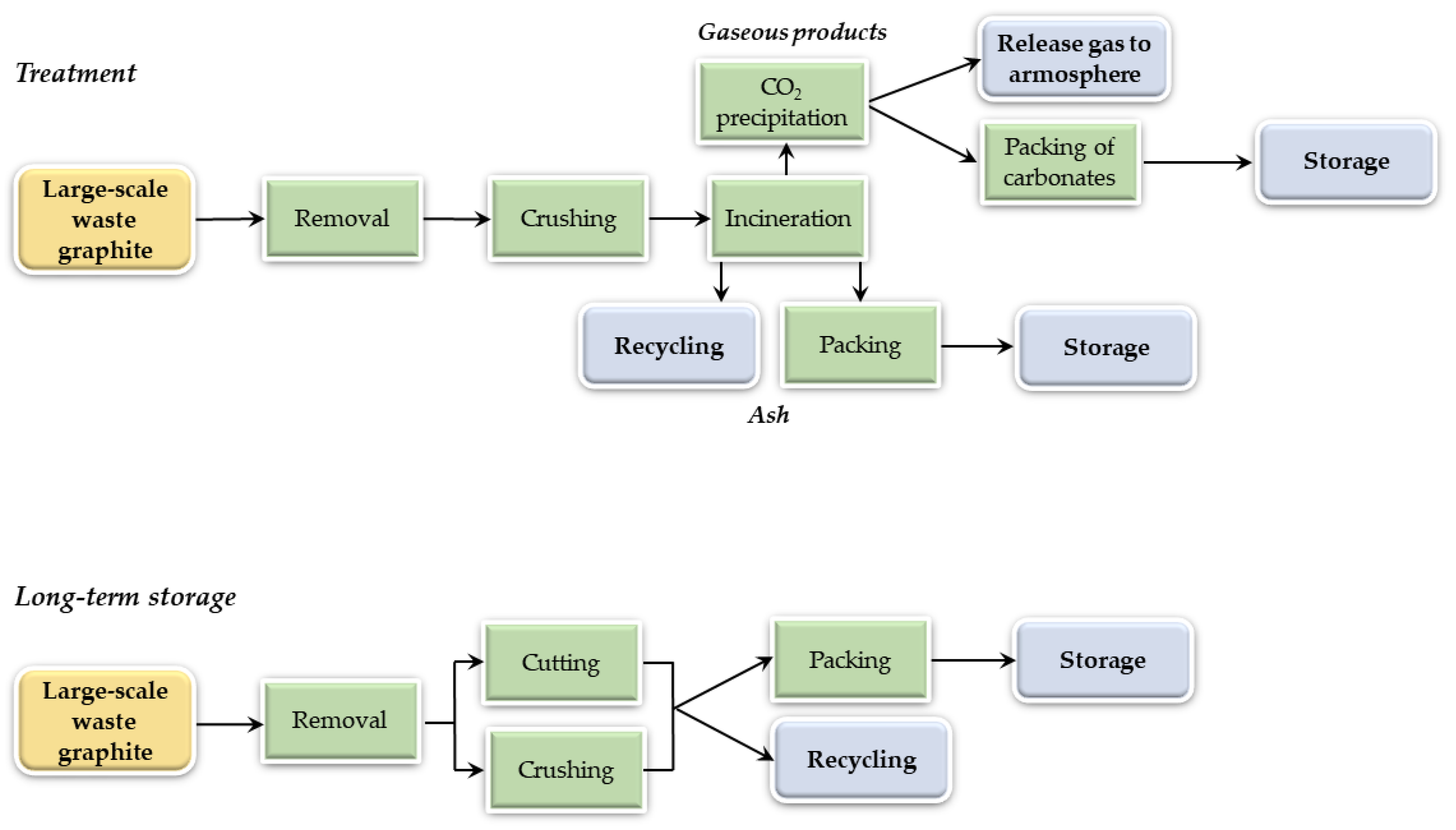

3.2. Management of Radioactive Waste Containing Graphite

- Long-term storage, e.g., removing i-graphite by breaking it up in situ and storing outside the reactor core for a sufficiently long time in special containers filled with a binder. The unit cost when a radiation-resistant polymeric matrix is used is approximately USD 2600 per ton of graphite. [3]. In turn, the cost of immobilizing graphite in an inorganic binder (e.g., cement) is only USD 1400 per ton. In the Russian Federation, piles of decommissioned reactors are planned to be decommissioned in reactor chambers [3].

- Disposal of i-graphite by thermochemical treatment, i.e., by combustion or incineration. In the UK, graphite is gasified to carbon dioxide to manage the resulting gas and residual secondary solid waste, which diminishes the graphite volume by 95% and saves up to GBP 2.4 bn in graphite management costs [30].

- ✓

- it considerably reduces the volume of the waste to be stored. Graphite, like any carbonaceous material, may be completely gasified. For example, according to Sugikawa, 99% or more of the graphite matrix can be gasified by soaking the graphite in a catalyst solution and gasifying the catalyst-impregnated graphite at temperatures below 900 °C [31]. The resulting residual solid secondary waste containing mainly 60Co, 137Cs and 55Fe and residual gamma particles have only about 1–2% of their initial volumes. Radioactive contaminants in the form of carbonates may be trapped in filters or in the scrubber solutions.

- ✓

- the gaseous radioactive products (beta emitters: 14C in the form of carbon dioxide and tritium in the form of water vapor), if their concentrations are not very high, may be diluted many times and dispersed in the atmosphere. If the concentrations of gaseous beta emitters are too high to be diluted, existing technologies offer their solidification as carbonates with the aim of protecting the environment.

4. Management of Graphite-Containing Waste—Special Cases

- (1).

- Removal of large elements from nuclear installations as solid graphite and prolonged (or permanent) storage with or without crushing.

- (2).

- Decomposition of graphite elements, e.g., by thermochemical methods (incineration).

- (3).

- Recovery of graphite (regeneration) for reuse, e.g., by decontamination.

4.1. Handling Large, Highly Radioactive Elements of Decommissioned Nuclear Installations Made of Graphite: Long-Term Storage

- (1).

- Immediately after dismantling, entire graphite items are carefully washed, roughly decontaminated, and securely placed for temporary storage. This first stage continues for 5–10 years, and during this period, all short-lived radionuclides decay.

- (2).

- After this phase, the resulting non-radioactive parts of the waste may be withdrawn and, if possible, re-used. The other remaining radioactive components remain stored in special “safes” for an additional thirty years. If needed, this phase is prolonged for 100 years. During this period, only routine radiometric inspections are carried out.

- (3).

- When the end of the second period arrives, i.e., after about 135 years, the stored graphite elements may be dismantled when their radioactivity is reduced to a relatively low and stable level.

4.2. Management of Low and Medium Level Radioactive Graphite-Containing Waste

- ✓

- graphite gasification,

- ✓

- direct removal without chemical processing,

- ✓

- decontamination of the carbon/graphite matrix with graphite recycling.

4.2.1. Conditioning/Disposal Associated with the Gasification of Graphite and Carbon Waste Constituents

- ✓

- it significantly reduces the amount of waste because only a small amount of solid ash is formed, along with some gaseous products,

- ✓

- it reduces issues with ensuring the safe storage of waste because inorganic ash formed is extremely resistant when in contact with the environment,

- ✓

- it also enables the recovery of many valuable heavy and rare metals, including uranium and plutonium.

4.2.2. Direct Disposal of Small Graphite Waste

5. Disposal of Spent Graphite-Containing HTGR Fuel

5.1. Storage of the Entire Graphite Blocks of Spent Fuel

- (1)

- what material the protective packaging should be made from,

- (2)

- the length of the preliminary storage time required before packing the waste into specially designed capsules,

- (3)

- whether the use of maxi packages is permitted, or the maximum mass of waste in each package.

5.2. Storage of Spent Fuel Blocks with Preceding Removal of Graphite

5.3. Disposal of Fuel Combined with Actinides Recovery

5.4. Decomposition of Spent Spherical Nuclear Fuels

5.4.1. Mechanical Graphite Crushing

5.4.2. Combustion of Graphite

5.4.3. Electrochemical Methods

6. Decontamination of Graphite Elements

- ✓

- fuel blocks,

- ✓

- solid neutron reflectors,

- ✓

- neutron moderators.

7. Conclusions

- ✓

- Currently, there is no universally accepted procedure that meets the criteria imposed for storing radioactive waste and for handling waste gases generated during graphite processing.

- ✓

- The most accepted, perhaps the most satisfying, and certainly the cheapest method is to withdraw entire blocks of spent fuel and store them for a sufficiently long time.

- ✓

- To obtain graphite that can be stored as LLW waste, the main task is to separate it from fuel elements.

- ✓

- To separate fuel from graphite by physical methods or the combustion of radioactive contaminated graphite, e.g., by 14C, the main problem is its precipitation as carbonates.

- ✓

- Waste treatment in connection with the dissolution of fuel elements may be performed when the recovery of some of the fuel components is expected.

- ✓

- Special attention should be given to the release of Wigner energy in the form of heat by graphite. This effect, if it is too intense, may cause the self-ignition of the waste.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Operating Experience with Nuclear Power Stations in Member States; International Atomic Energy Agency: Vienna, Austria, 2019.

- Status and Trends in Spent Fuel and Radioactive Waste Management; IAEA Nuclear Energy Series No. NW-T-1.14; International Atomic Energy Agency: Vienna, Austria, 2018; p. 1.

- Anfimov, S.S. Management of radioactive waste in nuclear power: Handling of irradiated graphite from water-cooled graphite reactors. In Proceedings of the International Youth Nuclear Congress 2000: Youth, Future, Nuclear Transactions, Bratislava, Slovakia, 9–14 April 2000; p. 278. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/32/015/32015333.pdf?r=1&r=1 (accessed on 7 July 2020).

- Dunzik-Gougar, M.L.; Smith, T.E. Removal of carbon-14 from irradiated graphite. J. Nucl. Mater. 2014, 451, 328–335. [Google Scholar] [CrossRef]

- LaBrier, D.; Dunzik-Gougar, M.L. Identification and location of 14C-bearing species in thermally treated neutron irradiated graphites NBG-18 and NBG-25: Pre- and Post-thermal treatment. J. Nucl. Mater. 2015, 460, 174–183. [Google Scholar] [CrossRef]

- Liu, J.; Wang, C.; Dong, L.; Liang, T. Study on the Recycling of Nuclear Graphite after Micro-Oxidation. Nucl. Eng. Technol. 2016, 48, 182–188. [Google Scholar] [CrossRef] [Green Version]

- Pavlyuk, A.O.; Kotlyarevsky, S.G.; Bespala, E.V.; Bespala, Y.R. Potential of application of IRT-T research reactor as the solution of the problem of graphite radwaste disposal. Nucl. Energy Technol. 2018, 4, 127–133. [Google Scholar] [CrossRef] [Green Version]

- Smith, S.W.; Bredell, P.J. Development of a strategy for the management of PBMR spent fuel in South Africa. Nucl. Eng. Des. 2010, 240, 2415–2420. [Google Scholar] [CrossRef]

- Progress in Radioactive Graphite Waste Management. In Report of IAEA Technical Committee Meeting on Progress in Radioactive Graphite Waste Management; IAEA-TECDOC-1647; International Atomic Energy Agency: Vienna, Austria, 2010.

- Junfeng, L. Treatment and Disposal of the Radioactive Graphite Waste of High-Temperature Gas-Cooled Reactor Spent Fuel; IAEA-TECDOC-1790 (COMPANION CD-ROM); International Atomic Energy Agency: Vienna, Austria, 2016; Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/48/076/48076815.pdf?r=1&r=1 (accessed on 9 July 2020).

- Processing of Irradiated Graphite to Meet Acceptance Criteria for Waste Disposal: Results of a Coordinated Research Project; IAEA-TECDOC-1790; International Atomic Energy Agency: Vienna, Austria, 2016; p. 105. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/47/091/47091257.pdf?r=1 (accessed on 26 August 2020).

- Wickham, A.; Steinmetz, H.-J.; O’Sullivan, P.; Ojovan, M.I. Updating irradiated graphite disposal: Project ‘GRAPA’ and the international decommissioning network. J. Environ. Radioact. 2017, 171, 34–40. [Google Scholar] [CrossRef]

- Wareing, A.; Abrahamsen, L.; Banford, A.; Metcalfe, M.; von Lensa, W. CARBOWASTE: Treatment and Disposal of Irradiated Graphite and Other Carbonaceous Waste. Final Publishable CARBOWASTE Report 2013. Available online: https://igdtp.eu/wp-content/uploads/2019/02/CARBOWASTE-2013-D0.3.12-FinalReport-g.pdf (accessed on 26 August 2020).

- Nuclear Grade Graphite. Available online: https://www.canadacarbon.com/nuclear-grade-graphite (accessed on 24 June 2020).

- Tang, C.H.; Tang, Y.P.; Zhu, J.G.; Zou, Y.W.; Li, J.H.; Ni, X.J. Design and Manufacture of the Fuel Element for the 10 Mw High Temperature Gas-Cooled Reactor. Nucl. Eng. Des. 2002, 218, 91–102. [Google Scholar] [CrossRef]

- Nightingale, R.E. Nuclear Graphite. Division of Technical Information, 1st ed.; Academic Press: New York, NY, USA, 1962. [Google Scholar]

- Canzone, G.; Lo Frano, R.; Sumini, M.; Troiani, F. Dismantling of the graphite pile of Latina NPP: Characterization and handling/removal equipment for single brick or multi-bricks. Prog. Nucl. Energy 2016, 93, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Jefferies, N.L. The Evolution of Carbon-14 and Tritium Containing Gases in a Radioactive Waste Repository; Nirex Report NSS/R198; United Kingdom Nirex: London, UK, 1990; p. 11. [Google Scholar]

- Wareing, A.; Abrahamsen-Mills, L.; Fowler, L.; Grave, M.; Banford, A.W. Development of integrated waste management options for irradiated graphite. Nucl. Eng. Technol. 2017, 49, 1010–1018. [Google Scholar] [CrossRef]

- Information Kit, AREVA, HTGR High Temperature Gas-cooled Reactor, March 2014. Available online: http://us.areva.com/home/liblocal/docs/Nuclear/HTGR/HTGR-InfoKit-2014-03.pdf (accessed on 7 July 2020).

- Gore, D. Decommissioning of Nuclear Power Stations; Research paper--96/83; House of Commons: London, UK, 1996. [Google Scholar]

- Remeikis, V.; Plukis, A.; Juodis, L.; Gudelis, A.; Lukauskas, D.; Druteikienė, R.; Lujanienė, G.; Lukšienė, B.; Plukienė, R.; Duškesas, G. Study of the nuclide inventory of operational radioactive waste for the RBMK1500 reactor. Nucl. Eng. Des. 2009, 239, 813–818. [Google Scholar] [CrossRef]

- Ancius, D.; Ridikas, D.; Remeikis, V.; Plukis, A.; Plukiene, R.; Cometto, M. Evaluation of the activity of irradiated graphite in the Ignalina Nuclear Power Plant RBMK-1500 reactor. Nukleonika 2004, 50, 113–120. [Google Scholar]

- Bushuev, A.V.; Zubarev, V.N.; Proshin, I.M. Composition and quantity of impurities in graphite of industrial reactors. At. Energiya 2002, 92, 331–335. [Google Scholar] [CrossRef]

- Radioactive Waste in Perspective; NEA Publication No. 6350; Nuclear Energy Agency of Organisation for Economic Co-Operation and Development, Nuclear Energy Agency of the OECD (NEA): Paris, France, 2010; p. 19. Available online: https://www.oecd-nea.org/ndd/pubs/2010/6350-waste-perspective.pdf (accessed on 9 July 2020).

- Classification of Radioactive Waste; Safety Series No. 111-G-1.1.; IAEA: Vienna, Austria, 1994.

- Valdovinos, V.; Monroy-Guzman, F.; Bustos, E. Treatment Methods for Radioactive Wastes and Its Electrochemical Applications. In Environmental Risk Assessment of Soil Contamination; Hernandez Soriano, M.C., Ed.; IntechOpen Limited: London, UK, 2014; p. 400. [Google Scholar]

- IAEA Safety Glossary: Terminology Used in Nuclear Safety and Radiation Protection, 2018 edition; International Atomic Energy Agency: Vienna, Austria, 2019; Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/PUB1830_web.pdf (accessed on 28 August 2020).

- Ojovan, M.; Lee, W. An Introduction to Nuclear Waste Immobilisation; Elselvier: Oxford, UK, 2014; p. 376. [Google Scholar]

- Goodwin, J.; Bradbury, D.; Black, S.; Tomlinson, T.; Livesey, B.; Robinson, J.; Lindberg, M.; Newton, C.; Jones, A.; Wickham, A. From Core to Capture: Graphite Management by Gasification and Carbon Capture & Storage (CCS); IAEA-TECDOC-1790 (COMPANION CD-ROM); International Atomic Energy Agency: Vienna, Austria, 2016. [Google Scholar]

- Sugikawa, S.; Maeda, M.; Tsujino, T. Process for a Gasification of Graphite. US/JP Patent US4228141A (1977/78).

- Fujii, S.; Shirakawa, M.; Murakami, T. Study on Efficient Methods for Removal and Treatment of Graphite Blocks in a Gas Cooled Reactor; IAEA-NGWM/CD--01; International Atomic Energy Agency: Vienna, Austria, 2001; p. 7. Available online: www-pub.iaea.org/MTCD/publications/PDF/ngwm-cd/PDFFiles/paper8(Fuji).pdf (accessed on 8 July 2020).

- Kim, S. Plan for Moata Reactor Decommissioning, ANSTO; (INIS-XA-C--030); International Atomic Energy Agency: Vienna, Austria, 2003; p. 5. [Google Scholar]

- Bolla, G.; Macci, E.; Craik, J.F.D.; Walkden, P. The decommissioning of the Latina nuclear power plant. In Proceedings of the WM’01 Conference, Tucson, AZ, USA, 25 February–1 March 2001; p. 3. Available online: http://online.anyflip.com/ejyf/mgrs/ (accessed on 9 June 2020).

- Wikham, A.J.; Marsden, B.J.; Pilkington, N.J.; Sellers, R.M. Graphite Core Stability during ‘Care and Maintenance’ and ‘Safestorage’. IAEA TEC-DOC-1043. In Proceedings of the IAEA Technical Committee Meeting on “Gas-Cooled Reactor Decommissioning, Fuel Storage and Waste Disposal”, Julich, Germany, 8–10 September 1997. [Google Scholar]

- The Principles of Radioactive Waste Management A Publication Within the RADWASS Programme; International Atomic Energy Agency: Vienna, Austria, 1995.

- Mason, J.B.; Bradbury, D. Pyrolysis and Its Potential Use in Nuclear Graphite Disposal. Nucl. Energy 2000, 39, 305–310. [Google Scholar]

- Luo, S.G. Incineration Treatment of Radioactive Wastes. Nucl. Tech. 1990, 13, 1–8. (In Chinese) [Google Scholar]

- Braun, H.; Gutowski, H.; Bonka, H.; Grundlen, D. Plant for Retention of 14C in Reprocessing Plants for LWR Fuel Elements. In Proceedings of the 17th DOE Nuclear Air Cleaning Conference, Denver, CO, USA, 1–6 August 1982; Harvard Air Cleaning Lab: Boston, MA, USA, 1983; Volume 1, pp. 381–399. [Google Scholar]

- Forsberg, C.W.; Del Cul, G.D.; Spencer, B.B.; Collins, E.D. A New Repository Waste Form: Graphite–Carbon High-Level Waste. In Proceedings of the International HLW Management Conference, Las Vegas, NV, USA, 30 March–2 April 2003. [Google Scholar]

- McEnaney, B.; Wickham, A.J.; Dubourg, M. Planning for Disposal of Irradiated Graphite: Issues for the New Generation of HTGRs, Basic Studies in the Field of High-Temperature Engineering; Nuclear Energy Agency of the OECD (NEA): Paris, France, 2002; pp. 281–291. [Google Scholar]

- Brinkmann, H.U.; Duwe, R.; Ganser, B.; Mehner, A.W.; Rebmann, A. Contributions Towards the Development of a Packaging Concept for the Final Disposal of Spent HTGR Pebble Bed Fuel. Nucl. Eng. Des. 1990, 118, 107–113. [Google Scholar] [CrossRef]

- Edwards, W.S.; Smith, R.J.; Wells, A.H. Packaging Design Criteria for the Type B Drum (WHC-SP--1168). United Statesm 1995. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/27/026/27026011.pdf?r=1 (accessed on 5 April 2020).

- Wise, M. Management of UKAEA graphite liablities. In Proceedings of the Technical Committee Meeting on Nuclear Graphite Waste Management, Manchester, UK, 18–20 October 1999; 2001 IAEA-NGWM/CD--01; International Atomic Energy Agency: Vienna, Austria, 2001. [Google Scholar]

- Pugliese, G.; Lo Frano, R.; Forasassi, G. Spent fuel transport cask thermal evaluation under normal and accident conditions. Nucl. Eng. Des. 2010, 240, 1699–1706. [Google Scholar] [CrossRef]

- Sudareva, N.A.; Aleksandrov, V.O.; Zaviyalova, I.M. Use of polymeric materials as the preservative agents for radioactive design components. In Proceedings of the SAFEWASTE 93: International Conference on Safe Management and Disposal of Nuclear Waste, Avignon, France, 13–18 June 1993; Societe Francaise d’Energie Nucleaire (SFEN): Paris, France, 1993; pp. 121–126. [Google Scholar]

- Radioactive Waste Management. Available online: https://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-wastes/radioactive-waste-management.aspx (accessed on 27 July 2020).

- Ringwood, A.E. Disposal of High-Level Nuclear Wastes: A Geological Perspective. Miner. Mag. 1985, 49, 159–176. [Google Scholar] [CrossRef] [Green Version]

- Young, D.T. Fluidized Combustion of Beds of Large, Dense Particles in Reprocessing HTGR Fuel. In Proceedings of the Intersociety Energy Conversion Engineering Conference, Washington, DC, USA, 28 August–2 September 1977; p. 12. [Google Scholar]

- Yuanhui, X. The HTR-10 project and its further development (INIS-XA--524). In Proceedings of the HTR-2002: Conference on High Temperature Reactors, Petten, The Netherlands, 22–24 April 2002; International Atomic Energy Agency: Vienna, Austria; European Nuclear Society: Bern, Switzerland, 2002; Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/33/033/33033030.pdf (accessed on 9 July 2020).

- Method 1310b: Extraction Procedure (EP) Toxicity Test Method and Structural Integrity Test. Available online: https://www.epa.gov/sites/production/files/2015-12/documents/1310b.pdf (accessed on 9 July 2020).

- TRISO Particles: The Most Robust Nuclear Fuel on Earth. Available online: https://www.energy.gov/ne/articles/triso-particles-tre-nuclear-fuel-earth (accessed on 28 August 2020).

- Method 1311: Toxicity Characteristic Leaching Procedure. Available online: https://www.epa.gov/sites/production/files/2015-12/documents/1311.pdf (accessed on 9 July 2020).

- Lamb, C.E.; Mitchell, A.D.; Vaughen, V.C.A.; Shannon, R.J. Thorex Solvent Extraction Studies with Irradiated HTGR Fuel: Series, I. ORNL/TM-7108. 1980. Available online: https://digital.library.unt.edu/ark:/67531/metadc708272/m2/1/high_res_d/711367.pdf (accessed on 9 July 2020).

- Del Cul, G.D.; Spencer, B.B.; Forsberg, C.W.; Collins, E.R.D.; Rickman, W.S. TRISO-Coated Fuel Processing to Support High Temperature Gas-Cooled Reactors, Report ORNL/TM-2002/156. 2002. Available online: https://info.ornl.gov/sites/publications/Files/Pub57144.pdf (accessed on 9 July 2020).

- Tian, L.F.; Wen, M.F.; Li, L.Y.; Chen, J. Disintegration of graphite matrix from the simulative high temperature gas-cooled reactor fuel element by electrochemical method. Electrochim. Acta 2009, 54, 7313–7317. [Google Scholar] [CrossRef]

- Tian, L.F.; Wen, M.F.; Chen, J. Analysis of electrochemical disintegration process of graphite matrix. Electrochim. Acta 2010, 56, 985. [Google Scholar] [CrossRef]

- Masson, M.; Grandjean, S.; Lacquement, J.; Bourg, S.; Delauzun, J.M.; Lacombe, J. Block-type HTGR spent fuel processing: CEA investigation program and initial results. Nucl. Eng. Des. 2006, 236, 516. [Google Scholar] [CrossRef]

- Merz, E. On the disintegration of graphite by the formation of electrolytic graphite intercalation compounds. Kerntechnik 1970, 12, 341–346. [Google Scholar]

- Terrani, K.A.; Kiggans, J.O.; Silva, C.M.; Shih, C.; Katoh, Y.; Snead, L.L. Progress on matrix SiC processing and properties for fully ceramic microencapsulated fuel form. J. Nucl. Mater. 2015, 457, 9–17. [Google Scholar] [CrossRef] [Green Version]

| Advantages | Disadvantages |

|---|---|

| Waste disposal cost is low. | Maintenance and surveillance must be regularly carried out to prevent environmental accidents. |

| More efficient and cost-effective dismantling techniques may be developed in the future. | The site cannot be re-used until the waste is dismantled. |

| Waste from dismantling can be handled safely due to lower activity levels. | Staff with first-hand knowledge of the reactor will not be available in the future. |

| Volume of highly radioactive waste is low. | Care and maintenance costs may accumulate. |

| Sufficiently long radioactive decay period decreases radiation exposure to operators during dismantling. | The reactor owner will be liable for its safety for a long time. |

| Advantages | Disadvantages |

|---|---|

| Simple operation | Carbonate precipitation is required for gases containing 14C-CO2 |

| Small amount of solid waste (ash) | Large volumes of solid waste containing radioactive corrosion products, actinides, and fission products are produced |

| Direct removal of non-radioactive gaseous products | Expensive installations are required for current gasification and solidification procedures |

| Advantages | Disadvantages |

|---|---|

| Simple method | Requires large-capacity storage sites to prevent overheating due to the Wigner effect |

| Resistance to leakage | Continuous inspection of graphite elements in nuclear installations to prevent their contamination |

| Near-surface landfill |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuks, L.; Herdzik-Koniecko, I.; Kiegiel, K.; Zakrzewska-Koltuniewicz, G. Management of Radioactive Waste Containing Graphite: Overview of Methods. Energies 2020, 13, 4638. https://doi.org/10.3390/en13184638

Fuks L, Herdzik-Koniecko I, Kiegiel K, Zakrzewska-Koltuniewicz G. Management of Radioactive Waste Containing Graphite: Overview of Methods. Energies. 2020; 13(18):4638. https://doi.org/10.3390/en13184638

Chicago/Turabian StyleFuks, Leon, Irena Herdzik-Koniecko, Katarzyna Kiegiel, and Grazyna Zakrzewska-Koltuniewicz. 2020. "Management of Radioactive Waste Containing Graphite: Overview of Methods" Energies 13, no. 18: 4638. https://doi.org/10.3390/en13184638

APA StyleFuks, L., Herdzik-Koniecko, I., Kiegiel, K., & Zakrzewska-Koltuniewicz, G. (2020). Management of Radioactive Waste Containing Graphite: Overview of Methods. Energies, 13(18), 4638. https://doi.org/10.3390/en13184638