3.1. Processes for Restoring the Missing Pressures

Because the reservoir pressure decreased throughout the production period in

Figure 2, it is important to estimate the future productivity of the well. To understand the future performance and estimate the reserves, it is necessary to restore the missing or erroneous BHP and THP data. In this study, data restoration was performed using the RNN-LSTM method through the following three processes:

Process 1: THP prediction in Period B,

Process 2: THP prediction in Period F,

Process 3: BHP prediction in Periods D, E, F, and G.

Process 1 has been performed by a previous study [

25] using the RNN-LSTM methodology, where an RNN model was constructed to predict the THP for Period B. After THP, BHP, and gas production data from Period A were used to train the RNN-LSTM model, the THP for Period B was estimated. The results are summarized in the following section.

Process 2 predicts the THP for the buildup in Period F. Because there are no BHP data for Periods D to G, only the THP and gas production data were used for training the RNN-LSTM model. In this case, the restored THP data for Period B obtained in Process 1 are used as input data. In Process 3, data restored from Processes 1 and 2 were used to train the RNN-LSTM model to predict the BHP data for Periods D to G.

The prediction processes for the THP of Period B (Process 1) and BHP of Periods D to G (Process 3) seem to be similar, but there are some differences. To predict the THP of Period B, the BHP and THP data of Period A were learned by the RNN-LSTM model. Period B is composed of two sets of the long-term shut-in and flowing sequences, and except for the last flowing period, the BHP pressures in Period B are within the range of BHP values obtained in Period A. The THP seems to have the same situation. Therefore, the RNN-LSTM model trained using the data from Period A can be expected to have a good predictive performance for the pressure in Period B.

On the other hand, we consider the case where the RNN-LSTM is trained using the pressure data from Periods A to C to predict the BHP of Periods D to G (Process 3). Periods D to G consist of lower THP values than those in Periods A and B. In other words, the RNN-LSTM model trained using the data from Periods A to C needs to predict BHP values beyond the range of the data used for the training. Thus, it is very possible that the predictive performance will deteriorate. Process 2 has a similar situation, in that the THP prediction in Period F uses production data obtained for a very long time before Period F. Thus, long-term decreasing pressure data should be used as the input feature, which may also degrade the performance of the RNN-LSTM model. To compensate for these degradations in Processes 2 and 3, the RNN-LSTM models require different input variables from those used in Process 1. Thus, Process 2 introduces the pressure difference between two adjacent values in THP data, and Process 3 introduces the pressure difference between the THP and BHP values of the same time. In this way, the values of the pressure difference in the prediction periods are expected to be within the range of those in the training data, which can circumvent the aforementioned degradation problems. In addition, Processes 2 and 3 introduce the cumulative gas production as an input feature to partially consider the effect of the long-term decrease in reservoir pressure due to gas production.

3.2. Setup of the RNN-LSTM Model

Figure 6 shows an example of the RNN-LSTM models constructed in this study. The system predicts the output variable at the (

t + 1) th time step using an input sequence with a length of

τ backward from the

tth time step. The output variable at the (

t + 1) th time step may be directly affected by the input variable at the same time step. Therefore, any input variables other than the target variable, if available, at the (

t + 1) th time step can also be used as input features. For example, consider that an RNN-LSTM model predicts the THP at the (

t + 1) th time step using a sequence with a length of

τ composed of THP, BHP, and Qg data. Then, it can be conjectured that the THP at the (

t + 1) th time step will be affected by the BHP and gas rate at the same time step, and thus the input data can be constructed in the form of {(THP

t-τ+1, BHP

t-τ+2, Qg

t-τ+2), (THP

t-τ+2, BHP

t-τ+3, Qg

t-τ+3), …, (THP

t, BHP

t+1, Qg

t +1)} to predict THP

t+1.

Table 2 lists the hyperparameters applied in Processes 1 to 3. Different types of available data and validation schemes for each process allow the hyperparameters to be customized, as presented in

Table 2. Process 1 has three input features, i.e., THP, BHP, and Qg, and one output variable, while Process 2 has four input features, i.e., THP, the pressure difference between adjacent THPs, Qg, and the cumulative gas production. Process 3 has different input features from Process 1 because the pressures are beyond the range of the training data from Periods A to C. Therefore, the input features in Process 3 are composed of THP, Qg, the cumulative gas production, and the difference between THP and BHP. Moreover, rather than BHP, the output variable was also set to the pressure difference between THP and BHP.

All of the available data were normalized using Equation (9). Thus, all of the data have values between 0 and 1.

where

is the original value, and

represents the normalized value of

;

and

indicate the maximum and minimum values, respectively.

As loss functions, which are a measure of optimization, the mean absolute error (MAE) and mean absolute percentage error (MAPE) shown in Equations (10) and (11) are used. After a sufficient number of epochs is applied for training, the optimized model that can estimate the missing variables with the lowest error based on the validation data during the training process is selected.

where

and

represent the true and predicted values from the model, respectively, and

n is the number of training data. One hidden layer with 100 LSTM cells was employed, and Adam was used as an optimization algorithm. Python with Tensorflow-Keras [

30] was used to implement the RNN-LSTM method.

3.3. Process 1: THP Prediction during Period B

As mentioned in the previous section, Process 1 was carried out in the previous study [

25], and the main results are summarized as follows. The input data are composed of a set of THP, BHP, and Qg from Period A using Equation (12), and the output is the THP at the

th time step given in Equation (13). The number of time steps in the input data sequence is

: BHP and Qg use data from the (

th to (

th time steps, while THP uses data from the (

)th to

th time steps. Note that the BHP and Qg at the (

)th time step are used to predict the THP value at the (

)th time step, which results in a more accurate and reliable model.

The number of production data points in Period A is 575, which is used to generate 275 datasets with an input sequence length (

τ) of 300. The datasets were split such that 125 were used for training, 100 were used for validation, and 50 were used as the test dataset.

Figure 7 shows the results of the RNN-LSTM training:

Figure 7a shows the loss function versus the epoch, and

Figure 7b shows a comparison of the trained results and field pressure data. It can be confirmed that the training was successfully accomplished without overfitting, and the trained RNN model can effectively predict the measured THP behavior in Period A. The MAE values of the training, validation, and test data were estimated as 0.00787, 0.0059, and 0.01586, respectively.

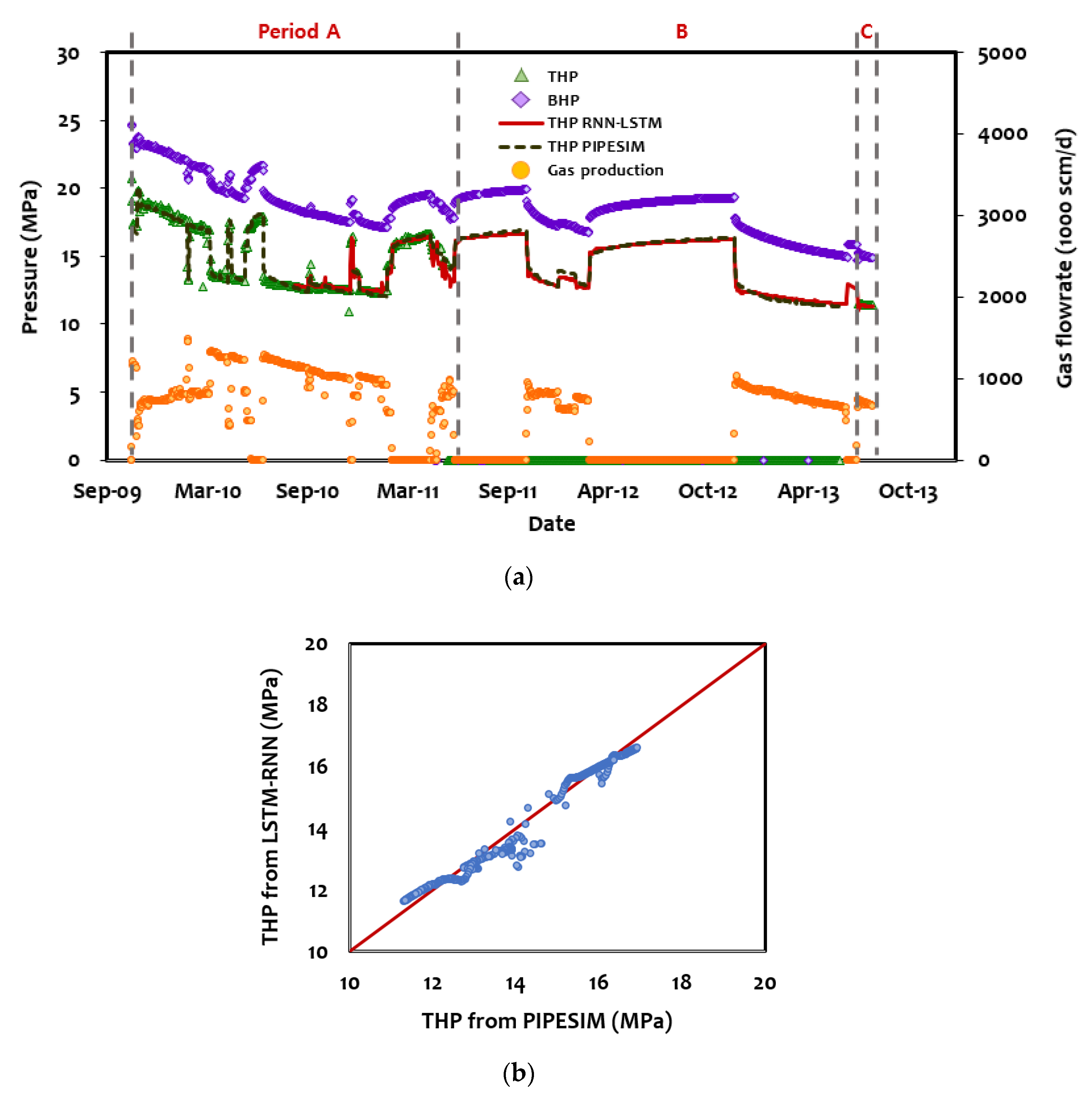

The trained RNN model was used to predict the THP in Periods B and C, as shown in

Figure 8. These predictions were also compared with the estimation obtained using PIPESIM software. The differences in the THP during Period B obtained with the RNN model and PIPESIM software are compared in

Figure 8b; the MAPE is only 1.53% with a standard deviation of 1.37%. In addition, the difference between the predicted and measured THP in Period C is negligible, thereby verifying that the developed RNN-LSTM model is a highly reliable predictive model. Therefore, it can be concluded that the missing THP data were successfully restored.

3.4. Process 2: THP Prediction during Period F

Period F in

Figure 2 is the only long-term buildup interval in more than four years of production operation after Period C, except for the very short shut-ins in Periods D and E. The THP measurements were not performed properly owing to the malfunctioning of the gauge during the entirety of Period F; however, the THP values were measured correctly in the subsequent Period G. In Process 2, an RNN-LSTM model was constructed to predict the THP values in Period F by employing the THP data restored in Process 1; the THPs in Periods A to E were used as the training, validation, and test datasets for Process 2.

It should be carefully considered that the formation water production commenced during Period E. Water production affects the pressure drop through the well system, and thus the effect of water production should be reflected in some of the input features of the RNN-LSTM model. One simple method to accomplish this is to introduce the equivalent gas rate concept, which describes the pressure drop due to the water production in addition to the gas flow rate. In other words, the equivalent gas flow rate has the same pressure drop as that caused by the multiphase flow of gas and water in the tubing.

Figure 9 shows the preprocess for establishing the equivalent gas rate.

Figure 9a shows the water and gas production profiles after water breakthrough; there are three buildup periods, as indicated by the shaded areas. It is also notable that there are some missing values in the water production record around the 15 July, which is attributed to missed recordings in the operation field.

When the well was reopened after each buildup, water production started with a peak rate followed by a rapid decline, while the gas rate exhibited the opposite behavior. As explained in the previous section, this phenomenon is attributed to water invasion into the reservoir from the wellbore after a shut-in. The water–gas ratio (WGR) was used to model the water production trend, as shown in

Figure 9b, in which a second-order polynomial fitting was adopted. If the trend of rapid decline in the water production after buildup is ignored, the fitting is sufficient to model the overall water production trend during the flowing periods.

To calculate the equivalent gas flow rate, a sensitivity analysis of the pressure drop was conducted using PIPESIM with controllable parameters: gas flow rates of 100, 200, 400, 550, and 700

10

3 scm/d; WGRs of 0, 0.05, 0.1, 0.15, and 0.22 scm water/1000 scm gas; THPs of 4.5, 6.0, and 7.5 MPa, which cover the actual range of the observed production. A proxy model based on the sensitivity data was generated to estimate the gas flow rate based on various pressure drop, WGR, and THP values. Then, the model was used to determine the equivalent gas flow rate under the condition of WGR = 0, which reproduces the observed pressure drop.

Figure 9c shows the resulting equivalent gas flow rate.

Figure 9d shows the original THP profile and its preprocessed profile during the water production period. Outliers in the gas rate and THP data, such as high fluctuations during shut-ins and re-openings of the well, were excluded from the entire dataset for simplicity and consistency with the dataset before the water breakthrough. The two early shut-ins in

Figure 9a were removed from the preprocessed data because the intervals were too short to be considered, and those intervals were replaced with interpolated data using the flow data in the vicinity of the shut-ins.

Figure 10 shows the datasets used for the model training and prediction in Process 2. The dataset for the model training includes the training, validation, and testing data. After the RNN-LSTM model is trained, the THP prediction is performed for the prediction interval. There are four input features: THP, the difference between the THP values at adjacent time steps, the equivalent gas rate, and the cumulative gas production in Equation (14). The output target is the difference between the THP at the

th and (

)th time steps in Equation (15). It should be noted that the Qg and cumulative gas data at the (

)th time step were also included in the input data to improve the training efficiency and accuracy.

The datasets were resampled with weekly data for training simplicity, and split into training, validation, and test datasets at ratios of 80%, 10%, and 10%, respectively. The datasets were normalized according to Equation (9). The length of the input sequence is 180, which seems sufficiently long to reflect the effect of previous long-term shut-ins on the later pressure and flow rate behaviors. The hyperparameters for the model structure and its training are listed in

Table 2.

Figure 11 shows the training and validation errors with respect to the epochs. The training results show a fairly good match, as the MAE values are 0.00504, 0.00484, and 0.00799 for the normalized training, validation, and test data, respectively, as summarized in

Table 3.

Figure 12 shows a comparison between the predicted THP values and the measured data. It is clear that the RNN-LSTM model has been fairly well trained in terms of the matches in the training, validation, and test datasets. The trained model generated THPs for the prediction interval, which included long shut-in and subsequent production periods. The shapes of the pressure buildups appear very similar to those of the shut-ins in the early part of the training data. There are, however, some large deviations at early flowing times after the long shut-in period (see the dotted circle in

Figure 12). This seems to be attributable to the unstable behavior of the multiphase flow after the shut-in. As mentioned above, a shut-in can cause gravity segregation of the multiphase mixture in the wellbore, which can result in productivity loss with water intrusion into the reservoir. Therefore, the measured data in the dotted circle are regarded as less reliable than that in the rest of Period G in

Figure 2. The data for the later part of Period G are preferable for use when evaluating the predicted results because this data appears to represent an operation condition in which the productivity has been recovered through long-term and stable production. The similarity between the measured and predicted THPs in the later part of Period G validates the applicability of the procedure in Process 2.

Figure 13 shows a comparison of the predicted and measured THPs. The matches of the training, validation, and test datasets are very good, with an MAE of 0.09 MPa and an MAPE of 1.04%, as summarized in

Table 4. This means that the predicted THP is accurate within an error of 1.04%. The MAE for the prediction interval is 0.27 MPa, which corresponds to an MAPE of 5.18%. The dotted circle in

Figure 13 corresponds to the dotted circle in

Figure 12. When the data in the dotted circle are excluded, the MAE is reduced to 0.05 MPa and the MAPE is 0.96%. In other words, the prediction is very accurate in the later part of the production period (Period G in

Figure 2). It is also notable that the concept of the equivalent gas flow rate is shown to be an efficient way to handle multiphase flow data, especially in the case of water production in the middle or later part of the operation period.

3.5. Process 3: BHP Prediction during Periods D to G

In this process, the BHPs in Periods D to G in

Figure 2 are predicted based on the results of Processes 1 and 2. Reliable BHP predictions are helpful to inform the decision-making process for future operations utilizing traditional analysis techniques such as reservoir simulations, material balance calculations, and rate transient analyses. In particular, Period F is the last shut-in data in the given dataset, and thus the shut-in information is directly related to the average reservoir pressure, which is essential for forecasting the future performance of the reservoir.

The input data are composed of four features: the THP, the difference between the THP and BHP at the same time step, the equivalent gas rate, and the cumulative gas production in Equation (16); the output target is the difference between the THP and BHP at the (

)th time step given in Equation (17). It should be noted that the THP, Qg, and cumulative gas data at the (

)th time step are also included in the input data to improve the training efficiency.

To ensure the RNN-LSTM model runs efficiently, the data were resampled with an interval of 7 days while preserving the characteristics of the production profile.

Figure 14 shows the revised data. The datasets are split into two parts: one for training the RNN-LSTM model and the other for predicting the missing BHP data, as shown in

Figure 14. The dataset for the model training includes training, validation, and testing data. After the RNN-LSTM model was trained, the BHP prediction was performed for the prediction interval.

The datasets were split into training, validation, and test datasets with ratios of 80%, 10%, and 10%, respectively; the length of one input sequence is 100. The hyperparameters for the RNN-LSTM training are listed in

Table 2.

Figure 15 shows the training and validation errors with respect to the epoch. The MAEs of the final model are 0.00206, 0.00011, and 0.00052 for the normalized training, validation, and test data, respectively (

Table 5). The fact that the validation error is much smaller than the training error indicates that the optimized model ensures the minimum validation error among the trained models. The error trends in

Figure 15 indicate that the RNN-LSTM model was trained with high stability, although there are many scattered points in the training data as shown in

Figure 14.

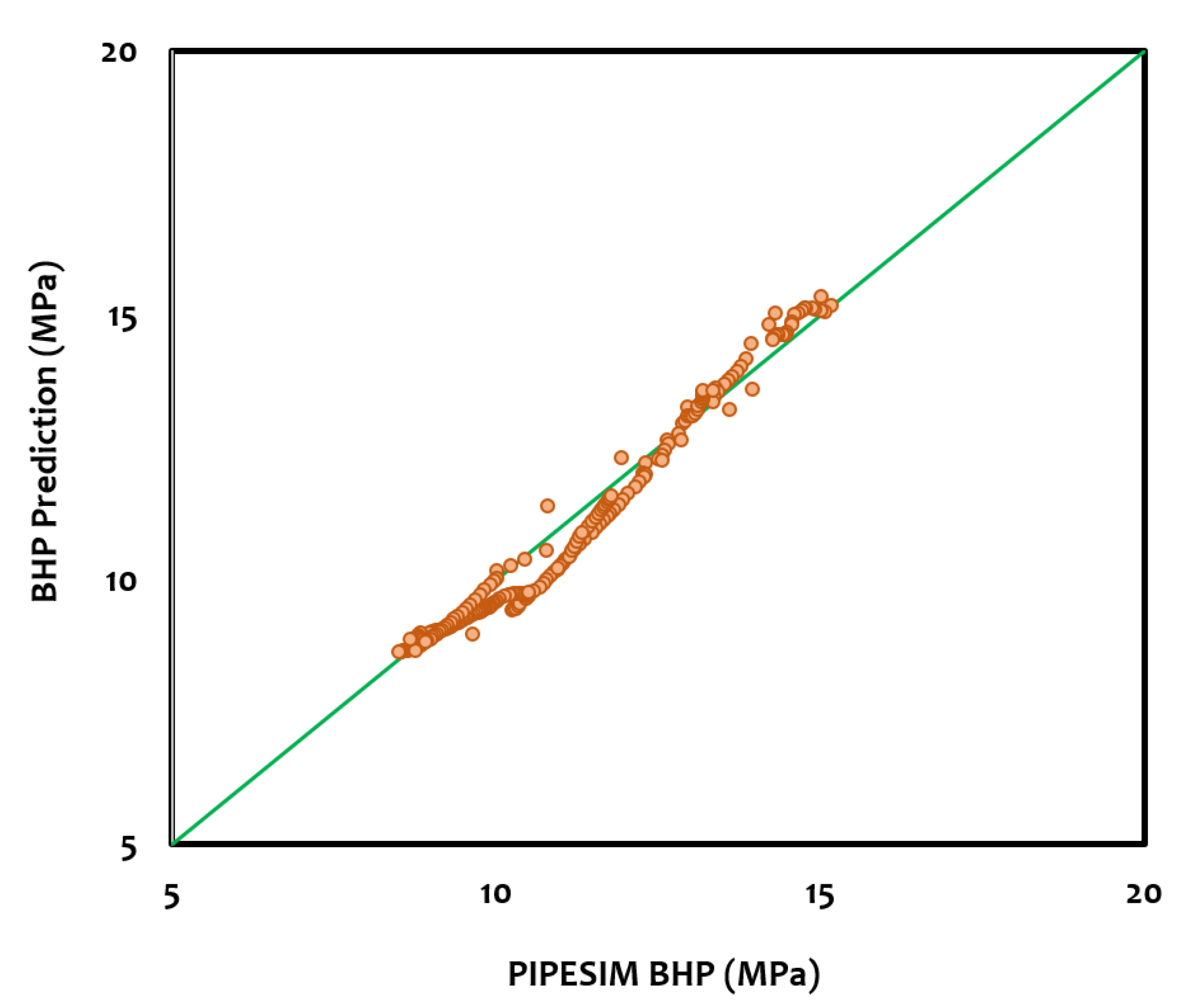

Figure 16 shows the predicted BHPs compared with the results calculated using PIPESIM. The comparison shows similarity in the trends of the results between the RNN-LSTM model and PIPESIM, although there are larger deviations between July 2014 and July 2015 and small deviations in the buildup period around July 2016. The difference between the BHPs obtained with the RNN-LSTM model and those obtained with PIPESIM in the prediction interval are compared in

Figure 17, and

Table 6 summarizes the corresponding absolute and relative errors. The MAE is 0.31 MPa with a maximum error of 0.84 MPa, which corresponds to an MAPE of 2.77% and a maximum relative error of 8.11%. Considering that the prediction interval is quite long, the RNN-LSTM model performs well in predicting the missing part of the BHP data.