State-of-Health Prediction for Lithium-Ion Batteries Based on a Novel Hybrid Approach

Abstract

1. Introduction

2. Dataset Analysis and Health Indicator Construction

3. The Signal Decomposition

3.1. Decomposition Method of EMD, EEMD, and CEEMDAN

- Step 1:

- Assuming that is the signal that needs to be decomposed, and is the Gaussian white noise added by the i-th experiment, then

- Step 2:

- Decompose each using EMD to get its mode , where and represents the serial number of the modes.

- Step 3:

- The -th mode of is written as , and the average value of is

- Step 1:

- Same as EEMD, CEEMDAN conducted times experiments on signal , and decompose the signal by EMD times to calculate the st mode , and calculate the st residual in the 1st stage.

- Step 2:

- Conduct times experiments to decompose the signal until the first EMD mode is calculated, and then calculate the nd mode:

- Step 3:

- For other stages , calculate the th residual signal and calculate the modal components, which is as follows:

- Step 4:

- Return to Step 4 until the residual cannot be decomposed (residual extreme point <= 2).

- Step 5:

- After calculating a total of modes, calculate the residual signal .

- Finally :

- The decomposition result of the original signal .

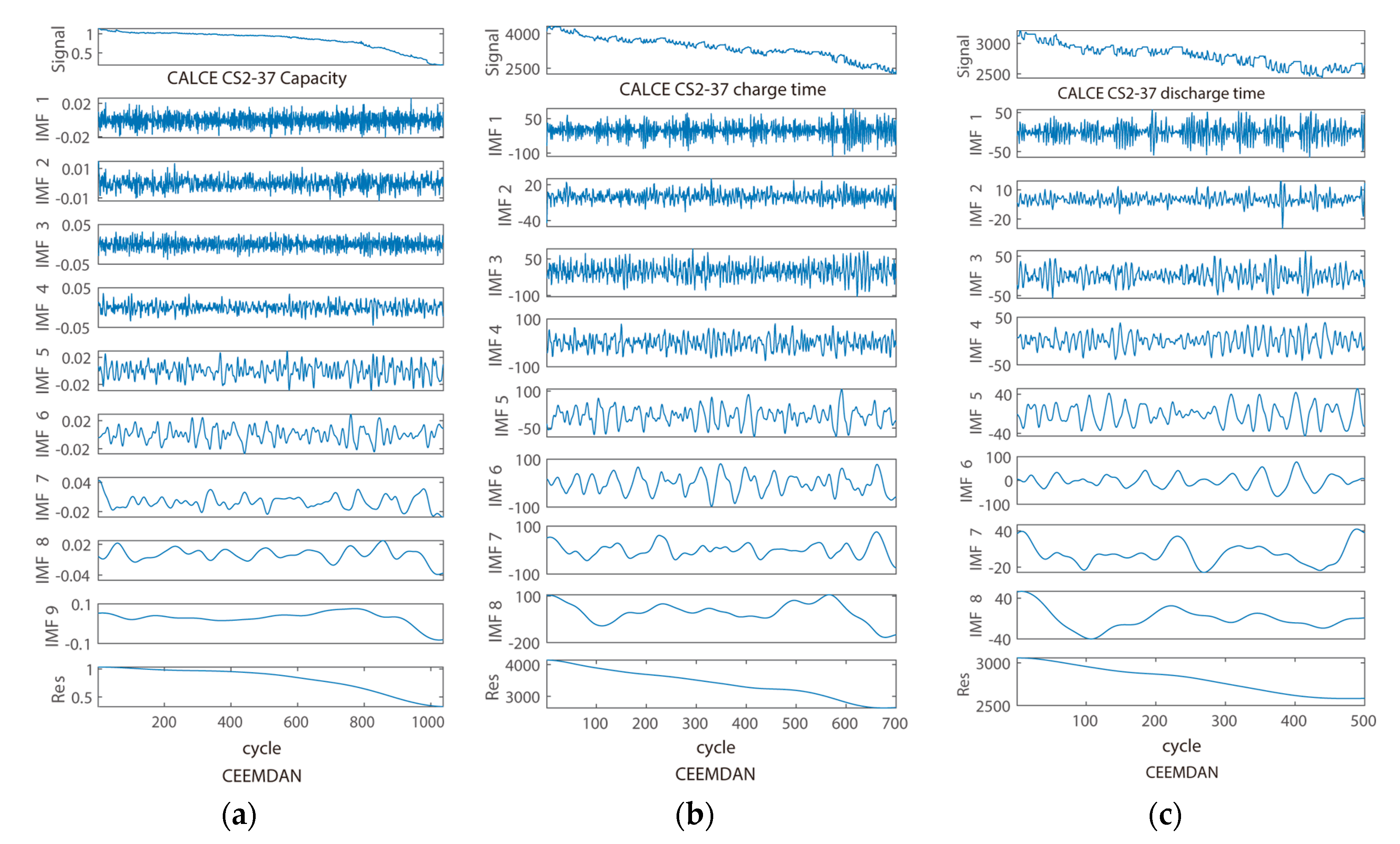

3.2. Result of the Signal Decomposition

- Step 1:

- Assuming trend item = , non-trend item =

- Step 2:

- Determine whether the trend item is appropriate (such as mean calculation, correlation analysis, or other standards that are considered set, etc.)

- Step 3:

- If the trend item and trend item are inappropriate, assuming the trend term = , non-trend item =

- Step 4:

- Continue until the two items are suitable.

4. The ARIMA Model

4.1. Principle of the ARIMA Model

4.2. ARIMA Prediction Experiment of Trend Terms

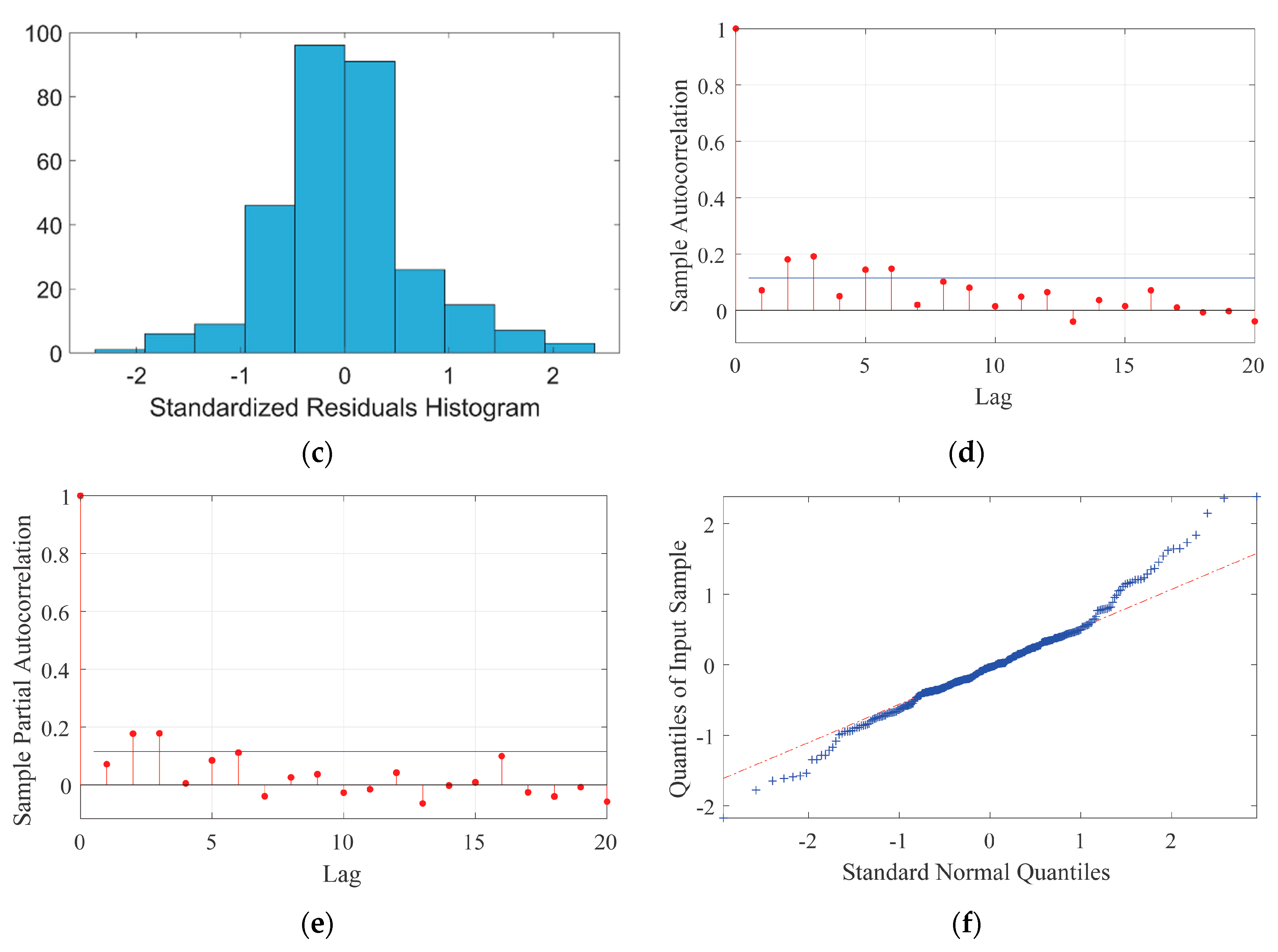

4.3. Residuals of Autoregressive Integrated Moving Average Model

5. Prediction Based on LSSVM

5.1. Phase Space Reconstruction Theory

- Step 1:

- Initialize, such as speed, position, inertia factor, acceleration constant, number of iterations cycles, etc.

- Step 2:

- Evaluate the initial fitness value of each particle and use it as the local optimal value of the particle, and its position as the location of the local optimal value of the particle.

- Step 3:

- Take the best initial adaptation value as the current global optimal value, and its position as the location of the global optimal value.

- Step 4:

- Update the flying speed of each particle according to Equation (17) and limit the amplitude, and update the current position of the particle. In the formula, , , is an inertia factor (non-negative number), is a non-negative constant acceleration factor, are random numbers in (0,1), is the constraint factor used to control the speed weight, is the number of particles, is the dimension of the target search space.

- Step 5:

- Compare the effect of the current particle fitness value. If satisfied, the current fitness value is regarded as the local optimum, and its position is regarded as the location of the particle’s local optimum.

- Step 6:

- Find the global optimal value in the current swarm and use it as the location of the global optimal value of the particle swarm.

- Step 7:

- Repeat steps 4–6 until the number of iterations is reached.

- Step 8:

- Output the global optimal value and position of the particle swarm, the local optimal value and the position of each particle.

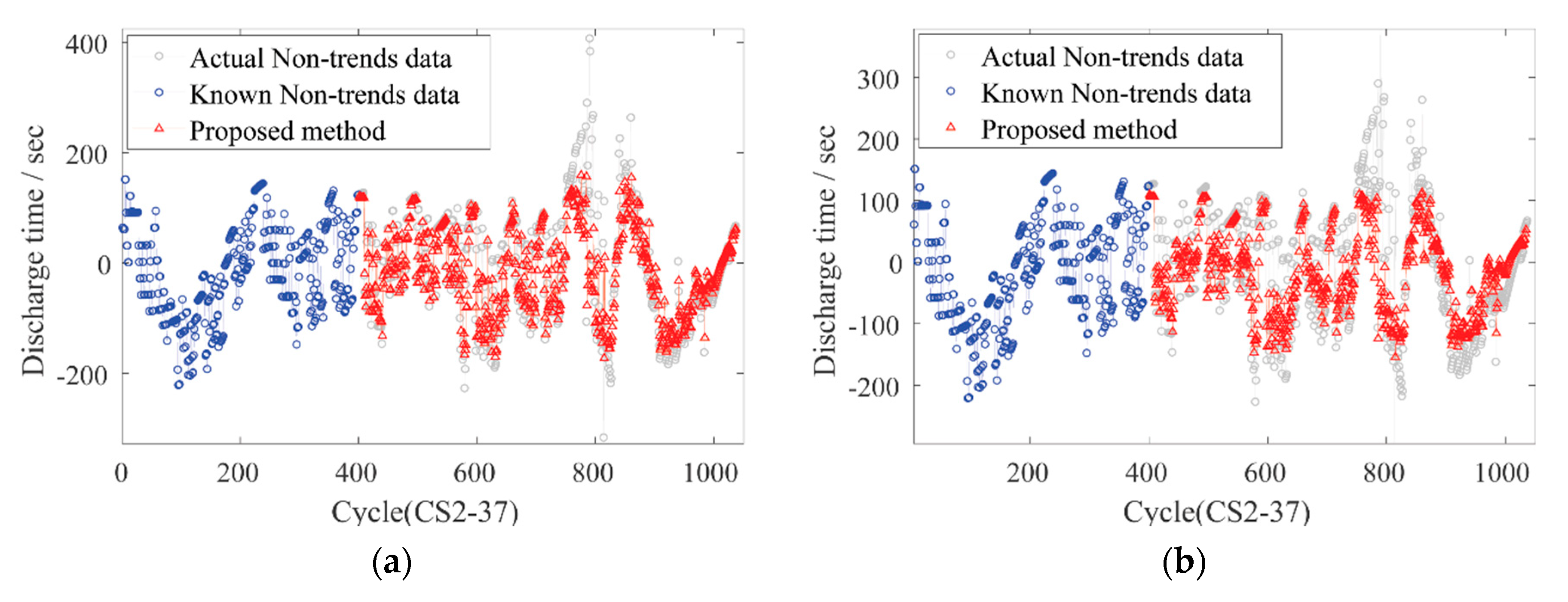

5.2. Prediction Experiment of Non-Trend Data Sequence of Lithium Battery Health Indicator

6. Comprehensive Evaluation of the SOH and Discussion

6.1. Experimental Results

6.2. Discuss

6.3. Error Analysis

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saha, B.; Goebel, K.; Poll, S.; Christophersen, J. Prognostics Methods for Battery Health Monitoring Using a Bayesian Framework. IEEE Trans. Instrum. Meas. 2009, 58, 291–296. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K.; Christophersen, J. Comparison of Prognostic Algorithms for Estimating Remaining Useful Life of Batteries. Trans. Inst. Meas. Control 2009, 31, 293–308. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Osterman, M.; Pecht, M. Prognostics of Lithium-Ion Batteries Based on Dempster-Shafer Theory and the Bayesian Monte Carlo Method. J. Power Sources 2011, 196, 10314–10321. [Google Scholar] [CrossRef]

- Wang, D.; Miao, Q.; Pecht, M. Prognostics of Lithium-Ion Batteries Based on Relevance Vectors and a Conditional Three-Parameter Capacity Degradation Model. J. Power Sources 2013, 239, 253–264. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.M.; Tsui, K.L.; Pecht, M. An Ensemble Model for Predicting the Remaining Useful Performance of Lithium-Ion Batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Liu, D.; Wang, H.; Peng, Y.; Xie, W.; Liao, H. Satellite Lithium-Ion Battery Remaining Cycle Life Prediction with Novel Indirect Health Indicator Extraction. Energies 2013, 6, 3654–3688. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Liao, H.; Peng, Y.; Peng, X. A Health Indicator Extraction and Optimization Framework for Lithium-Ion Battery Degradation Modeling and Prognostics. IEEE Trans. Syst. Man Cybern. Syst. 2015, 64, 660–670. [Google Scholar] [CrossRef]

- Liu, D.; Xie, W.; Liao, H.; Peng, Y. An Integrated Probabilistic Approach to Lithium-Ion Battery Remaining Useful Life Estimation. IEEE Trans. Instrum. Meas. 2015, 45, 915–928. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, M.; Chen, Y.; Tao, Y. A Novel Health Indicator for On-Line Lithium-Ion Batteries Remaining Useful Life Prediction. J. Power Sources 2016, 321, 1–10. [Google Scholar] [CrossRef]

- Huang, S.-C.; Tseng, K.-H.; Liang, J.-W.; Chang, C.-L.; Pecht, M.G. An Online SOC and SOH Estimation Model for Lithium-Ion Batteries. Energies 2017, 10, 512. [Google Scholar] [CrossRef]

- Su, X.; Wang, S.; Pecht, M.; Zhao, L.; Ye, Z. Interacting Multiple Model Particle Filter for Prognostics of Lithium-Ion Batteries. Microelectron. Reliab. 2017, 70, 59–69. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, L.; Hong, S.; Zhao, S.; Wang, H.; Zhang, L. Remaining Useful Life Prediction for Lithium-Ion Battery: A Deep Learning Approach. IEEE Access 2018, 6, 50587–50598. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, X.; Pecht, M.; Zhou, Y. Remaining Useful Life Prediction for Lithium-Ion Batteries Based on an Integrated Health Indicator. Microelectron. Reliab. 2018, 88–90, 1189–1194. [Google Scholar] [CrossRef]

- Wei, J.; Dong, G.; Chen, Z. Remaining Useful Life Prediction and State of Health Diagnosis for Lithium-Ion Batteries Using Particle Filter and Support Vector Regression. IEEE Trans. Ind. Electron. 2018, 65, 5634–5643. [Google Scholar] [CrossRef]

- Zhang, L.; Mu, Z.; Sun, C. Remaining Useful Life Prediction for Lithium-Ion Batteries Based on Exponential Model and Particle Filter. IEEE Access 2018, 6, 17729–17740. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Lithium-Ion Battery Remaining Useful Life Prediction with Box-Cox Transformation and Monte Carlo Simulation. IEEE Trans. Ind. Electron. 2019, 66, 1585–1597. [Google Scholar] [CrossRef]

- Jia, J.; Liang, J.; Shi, Y.; Wen, J.; Pang, X.; Zeng, J. SOH and RUL Prediction of Lithium-Ion Batteries Based on Gaussian Process Regression with Indirect Health Indicators. Energies 2020, 13, 375. [Google Scholar]

- Zhou, Y.; Huang, M. Lithium-Ion Batteries Remaining Useful Life Prediction Based on a Mixture of Empirical Mode Decomposition and ARIMA Model. Microelectron. Reliab. 2016, 65, 265–273. [Google Scholar] [CrossRef]

- Chen, L.; Xu, L.; Zhou, Y. Novel Approach for Lithium-Ion Battery On-Line Remaining Useful Life Prediction Based on Permutation Entropy. Energies 2018, 11, 820. [Google Scholar] [CrossRef]

- Mao, L.; Xu, J.; Chen, J.; Zhao, J.; Wu, Y.; Yao, F. A LSTM-STW and GS-LM Fusion Method for Lithium-Ion Battery Rul Prediction Based on EEMD. Energies 2020, 13, 2380. [Google Scholar] [CrossRef]

- Yun, Z.; Qin, W. Remaining Useful Life Estimation of Lithium-Ion Batteries Based on Optimal Time Series Health Indicator. IEEE Access 2020, 8, 55447–55461. [Google Scholar] [CrossRef]

- CALCE Battery Research Group of the University of Maryland. Battery Data Set. Available online: https://web.calce.umd.edu/batteries/data.htm (accessed on 12 September 2020).

- Gibbons, J.D.; Chakraborti, S. Nonparametric Statistical Inference, 5th ed.; CRC Press, Taylor & Francis Group: New York, NY, USA, 2011; pp. 389–416. [Google Scholar]

- Puth, M.; Neuh, M. Effective Use of Pearson’s Product-Moment Correlation Coefficient. Anim. Behav. 2014, 93, 183–189. [Google Scholar] [CrossRef]

- Cheng, J.; Yu, D.; Yang, Y. Application of Support Vector Regression Machines to the Processing of end Effects of Hilbert-Huang Transform. Mech. Syst. Signal Process. 2007, 21, 1197–1211. [Google Scholar] [CrossRef]

- El Bouny, L.; Khalil, M.; Adib, A. ECG Signal Filtering Based on CEEMDAN with Hybrid Interval Thresholding and Higher Order Statistics to Select Relevant Modes. Multimed. Tools Appl. 2019, 78, 13067–13089. [Google Scholar] [CrossRef]

- Rezaie-Balf, M.; Maleki, N.; Kim, S.; Ashrafian, A.; Babaie-Miri, F.; Kim, N.W.; Chung, I.-M.; Alaghmand, S. Forecasting Daily Solar Radiation Using CEEMDAN Decomposition-Based MARS Model Trained by Crow Search Algorithm. Energies 2019, 12, 1416. [Google Scholar] [CrossRef]

- Li, T.; Zhou, Y.; Li, X.; Wu, J.; He, T. Forecasting Daily Crude Oil Prices Using Improved CEEMDAN and Ridge Regression-Based Predictors. Energies 2019, 12, 3603. [Google Scholar] [CrossRef]

- Flandrin, P.; Torres, E.; Colominas, M.A. A Complete Ensemble Empirical Mode Decomposition with Adaptive Noise. In Proceeding of the 2011 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Prague, Czech Republic, 22–27 May 2011; pp. 4144–4147. [Google Scholar]

- Chaabi, L.; Lemzadmi, A.; Djebala, A.; Bouhalais, M.L.; Ouelaa, N. Fault Diagnosis of Rolling Bearings in Non-Stationary Running Conditions Using Improved CEEMDAN and Multivariate Denoising Based on Wavelet and Principal Component Analyses. J. Adv. Manuf. Technol. 2020, 107, 3859–3873. [Google Scholar] [CrossRef]

- Li, G.; Yang, Z.; Yang, H. A Denoising Method of Ship Radiated Noise Signal Based on Modified CEEMDAN, Dispersion Entropy, and Interval Thresholding. Electron. 2019, 8, 597. [Google Scholar] [CrossRef]

- Mousavi, A.A.; Zhang, C.; Masri, S.F.; Gholipour, G. Structural Damage Localization and Quantification Based on a CEEMDAN Hilbert Transform Neural Network Approach: A Model Steel Truss Bridge Case Study. Sensors 2020, 20, 1271. [Google Scholar] [CrossRef]

- Wang, J.; Hu, J. A Robust Combination Approach for Short-Term Wind Speed Forecasting and Analysis—Combination of the ARIMA (Autoregressive Integrated Moving Average), ELM (Extreme Learning Machine), SVM (Support Vector Machine) and LSSVM (Least Square SVM) Forecasts Using a GPR (Gaussian Process Regression) Model. Energy 2015, 93, 41–56. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, S.; Fang, Z. Comparison of China’s Primary Energy Consumption Forecasting by Using ARIMA (the Autoregressive Integrated Moving Average) Model and GM(1,1) Model. Energy 2016, 100, 384–390. [Google Scholar] [CrossRef]

- Singh, S.N.; Mohapatra, A. Repeated Wavelet Transform Based ARIMA Model for Very Short-Term Wind Speed Forecasting. Renew. Energy 2019, 136, 758–768. [Google Scholar] [CrossRef]

- Ordóñez, C.; Sánchez Lasheras, F.; Roca-Pardiñas, J.; de Cos Juez, F.J. A Hybrid ARIMA–SVM Model for the Study of the Remaining Useful Life of Aircraft Engines. J. Comput. Appl. Math. 2019, 346, 184–191. [Google Scholar] [CrossRef]

- Chen, Z.; Xue, Q.; Liu, Y.; Shen, J.; Xiao, R. State of Health Estimation for Lithium-Ion Batteries Based on Elman Neural Network. Renew. IEEE Access 2019, 7, 102662–102678. [Google Scholar] [CrossRef]

- Pan, Y.; Hong, R.; Chen, J.; Singh, J.; Jia, X. Performance Degradation Assessment of a Wind Turbine Gearbox Based on Multi-Sensor Data Fusion. Mech. Mach. Theory 2019, 137, 509–526. [Google Scholar] [CrossRef]

- Wang, Y.; Ni, Y.; Li, N.; Lu, S.; Zhang, S.; Feng, Z.; Wang, J. A Method Based on Improved Ant Lion Optimization and Support Vector Regression for Remaining Useful Life Estimation of Lithium-Ion Batteries. Energy Sci. Eng. 2019, 7, 2797–2813. [Google Scholar] [CrossRef]

- Cheng, Y.; Zerhouni, N.; Lu, C. A Hybrid Remaining Useful Life Prognostic Method for Proton Exchange Membrane Fuel Cell. Energy Sci. Eng. 2018, 43, 12314–12327. [Google Scholar] [CrossRef]

- Xue, X. Prediction of Slope Stability Based on Hybrid PSO and LSSVM. J. Comput. Civ. Eng. 2016, 31, 04016041. [Google Scholar] [CrossRef]

- Long, B.; Xian, W.; Li, M.; Wang, H. Improved Diagnostics for the Incipient Faults in Analog Circuits Using LSSVM Based on PSO Algorithm with Mahalanobis Distance. Neurocomputing 2014, 133, 237–248. [Google Scholar] [CrossRef]

| Correlation Coefficient | Dataset | Capa and Char | Capa and Dischar |

|---|---|---|---|

| Kendall’s tau | CALCE CS2-37 | 0.9484 | 0.9407 |

| Pearson’s r | 0.9825 | 0.9896 | |

| Spearman’s rho | 0.9954 | 0.9942 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, Z.; Qin, W.; Shi, W.; Ping, P. State-of-Health Prediction for Lithium-Ion Batteries Based on a Novel Hybrid Approach. Energies 2020, 13, 4858. https://doi.org/10.3390/en13184858

Yun Z, Qin W, Shi W, Ping P. State-of-Health Prediction for Lithium-Ion Batteries Based on a Novel Hybrid Approach. Energies. 2020; 13(18):4858. https://doi.org/10.3390/en13184858

Chicago/Turabian StyleYun, Zhonghua, Wenhu Qin, Weipeng Shi, and Peng Ping. 2020. "State-of-Health Prediction for Lithium-Ion Batteries Based on a Novel Hybrid Approach" Energies 13, no. 18: 4858. https://doi.org/10.3390/en13184858

APA StyleYun, Z., Qin, W., Shi, W., & Ping, P. (2020). State-of-Health Prediction for Lithium-Ion Batteries Based on a Novel Hybrid Approach. Energies, 13(18), 4858. https://doi.org/10.3390/en13184858